Patents

Literature

269results about How to "Increase the tilt angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

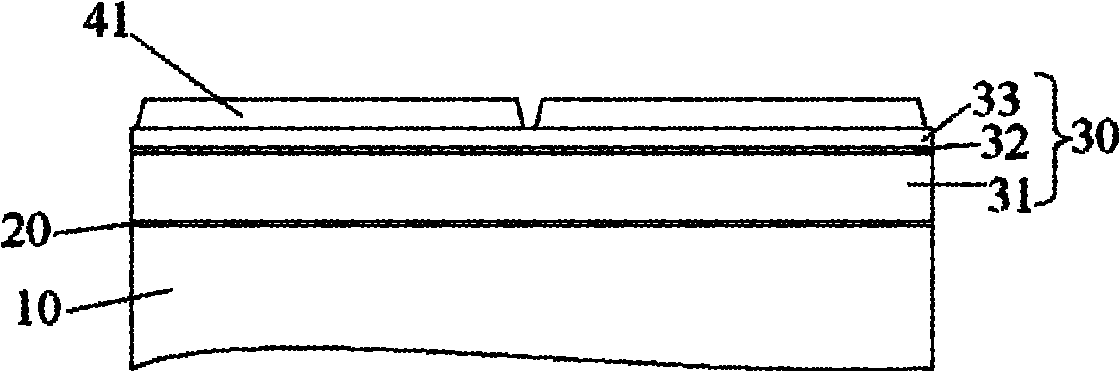

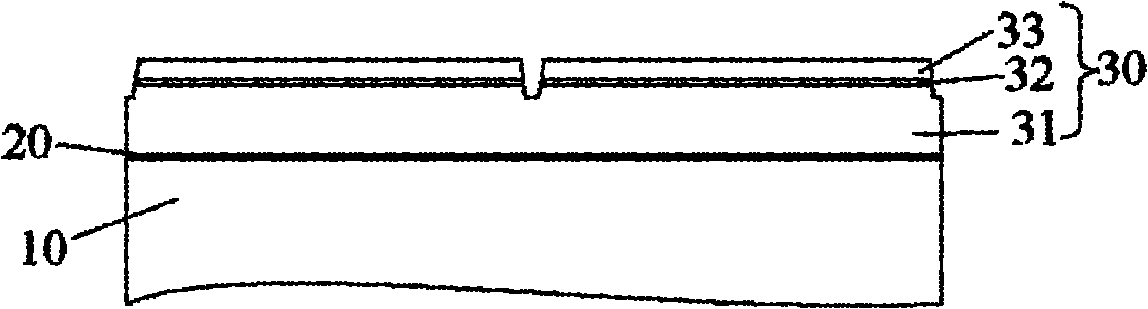

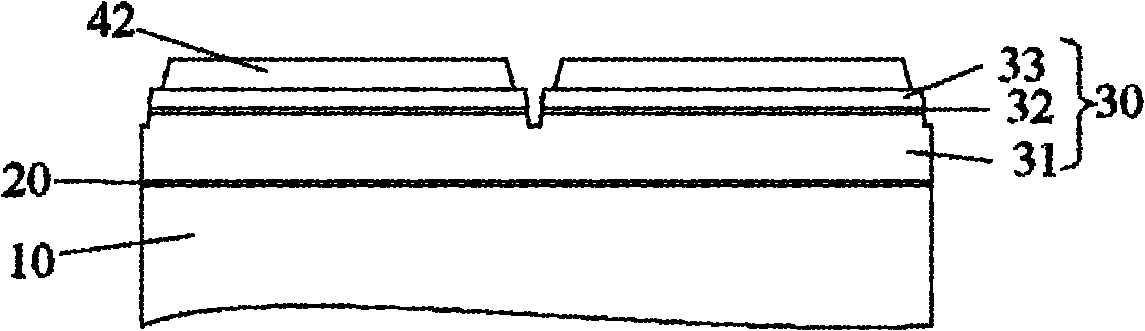

Manufacturing method of LED chip

The invention discloses a manufacturing method of an LED chip, wherein a procedure of removing one part of an epitaxial layer comprises the following steps of: forming a first mask film layer on the epitaxial layer, wherein the first mask film layer comprises a plurality of mask film layer units isolated from one another, and a first clearance with a predetermined size is arranged among the maskfilm layer units; removing a second semiconductor layer, a lighting layer and one part of a first semiconductor layer from a region where the first clearance is located to form a groove; eliminating the first mask film layer; repeating the steps for N times to remove parts of the epitaxial layer and a buffer layer until reaching a substrate, reserving an Nth clearance with predetermined size among the mask film layer units, wherein the width of the Nth clearance is greater than that of a (N-1)th clearance; forming an isolating groove with N steps, wherein N is not smaller than 2. By applying the technical scheme of the invention, the isolating groove has smaller depth and greater width as well as a certain inclination degree, thereby being beneficial to the coverage of an insulating material and the adhesion of metal connection wires, and solving the problem of breakage probably caused when the metal connection wires cross a deeper groove.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

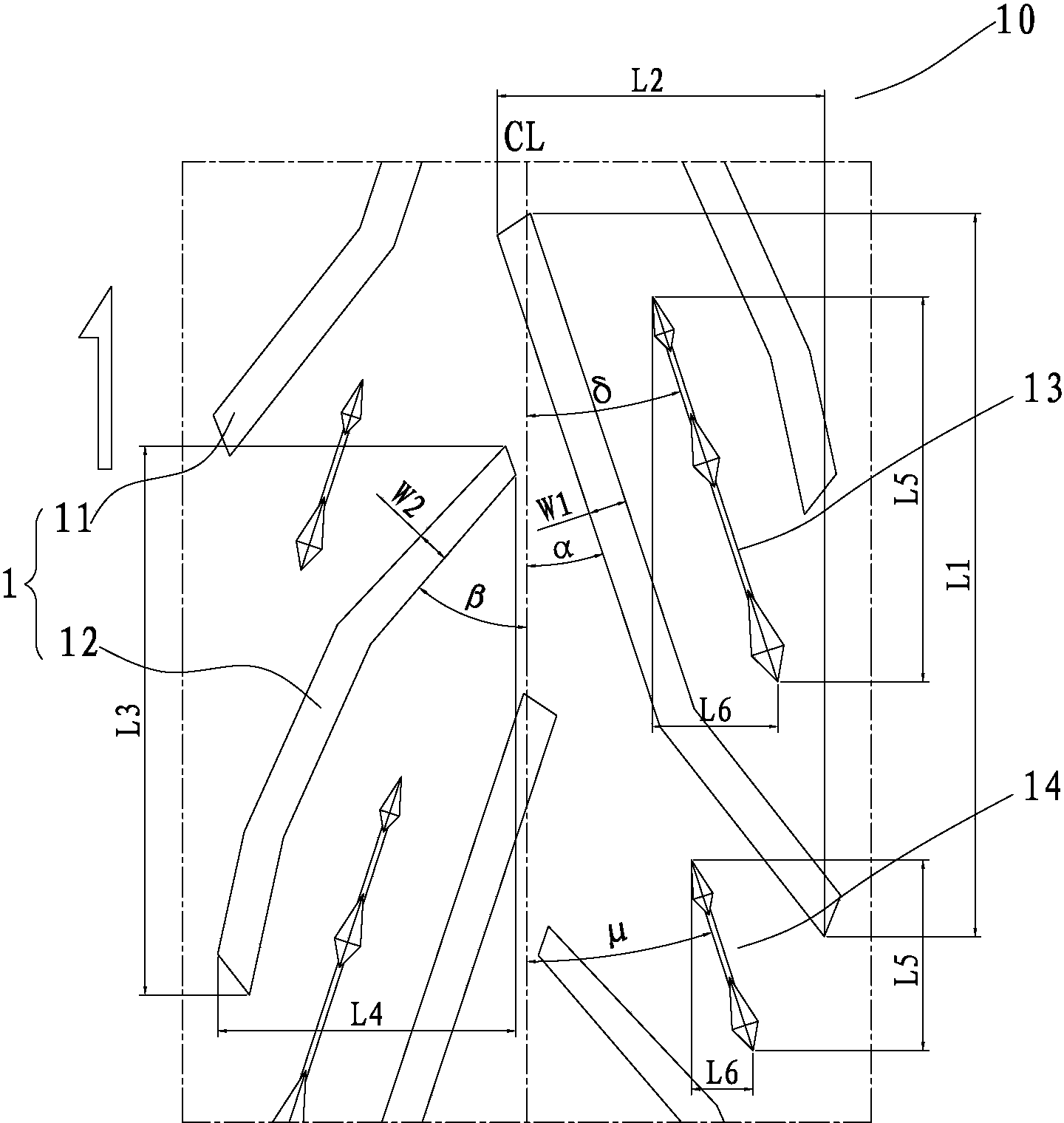

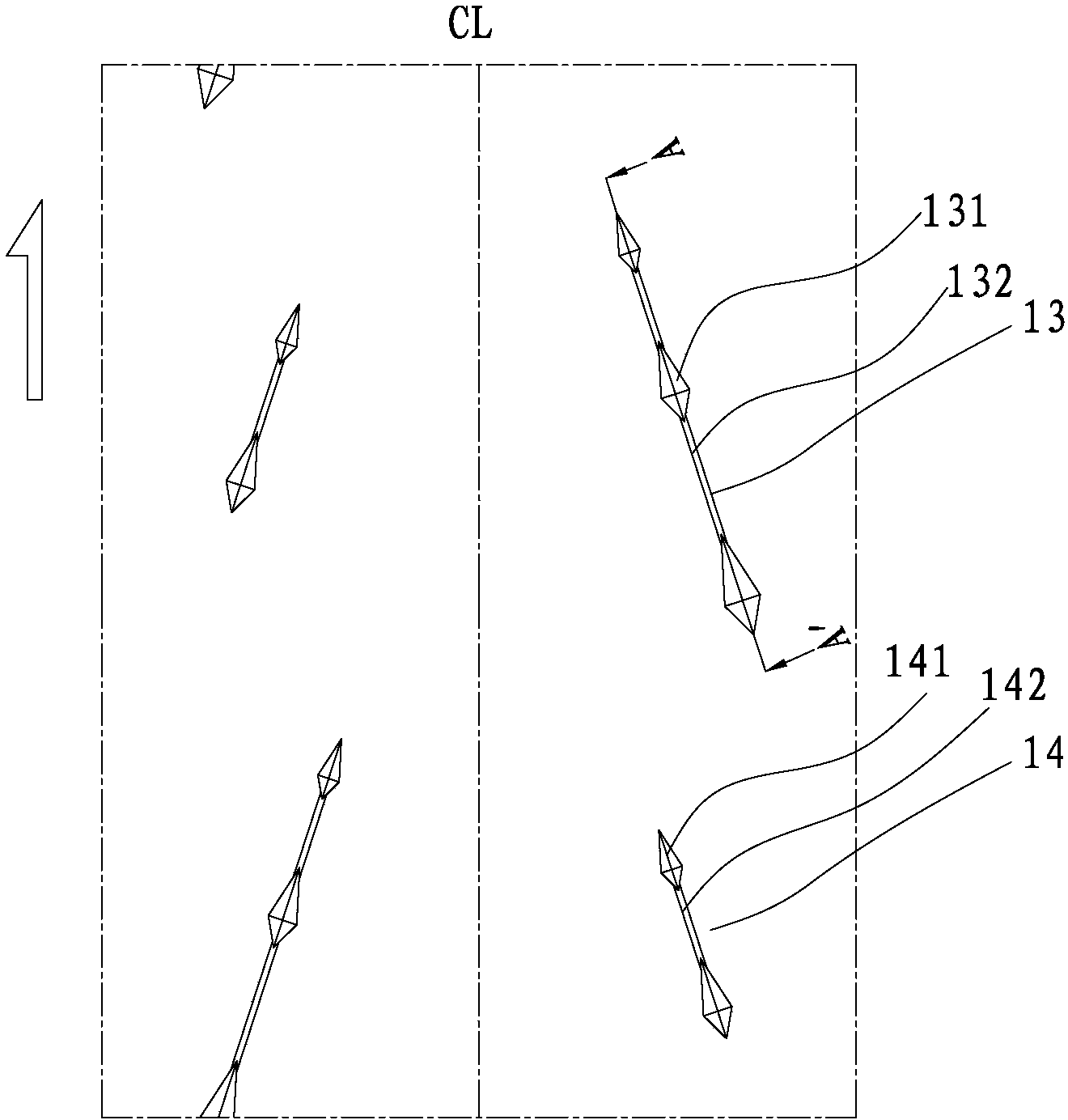

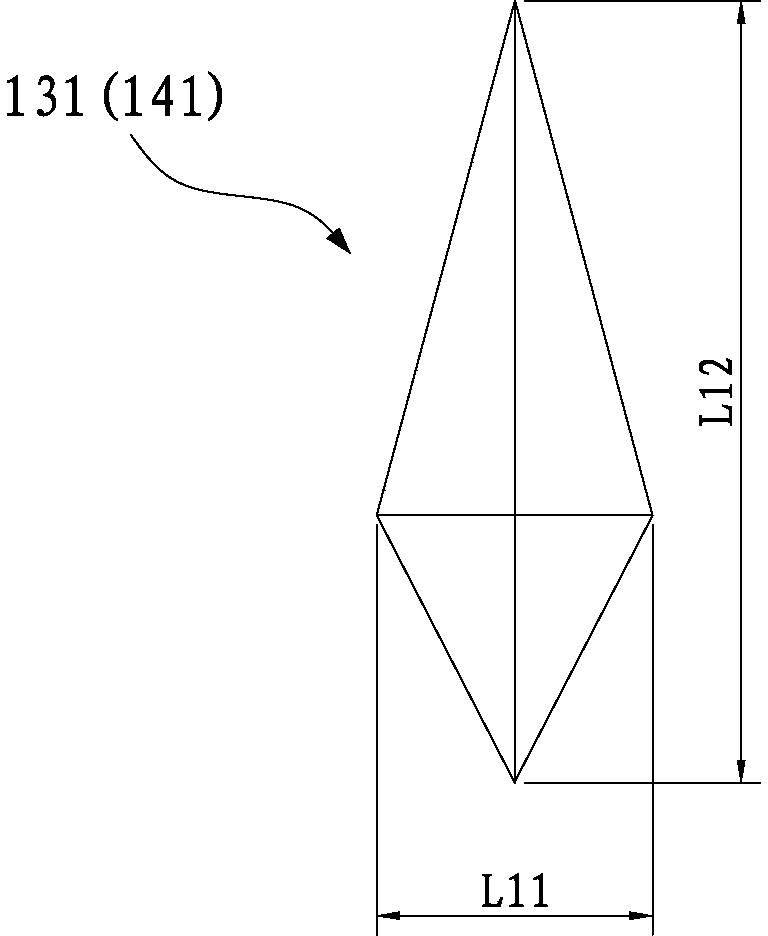

Tread structure of pneumatic tire for motorcycle

ActiveCN104029567AImprove tire drainage performanceImproves tire grip in wet conditionsTyre tread bands/patternsEngineeringTread

The invention discloses a tread structure of a pneumatic tire for a motorcycle. A tread comprises a plurality of main pattern groove groups which are formed in a staggered manner by using the center of the tread as a symmetry center, wherein first auxiliary fine diamond pattern grooves are formed among the main pattern groove groups, and each first auxiliary fine diamond pattern groove comprises a fine diamond part which is provided with a plurality of tangent planes and a fine groove which is connected with the fine diamond part. The fine diamond parts and the fine grooves of the auxiliary fine diamond pattern grooves are designed to be in mutual connection, so that water films can be effectively broken, the water drainage performance of the tire is effectively improved, and the wet land gripping performance of the tire is improved.

Owner:CHENG SHIN RUBBER XIAMEN IND

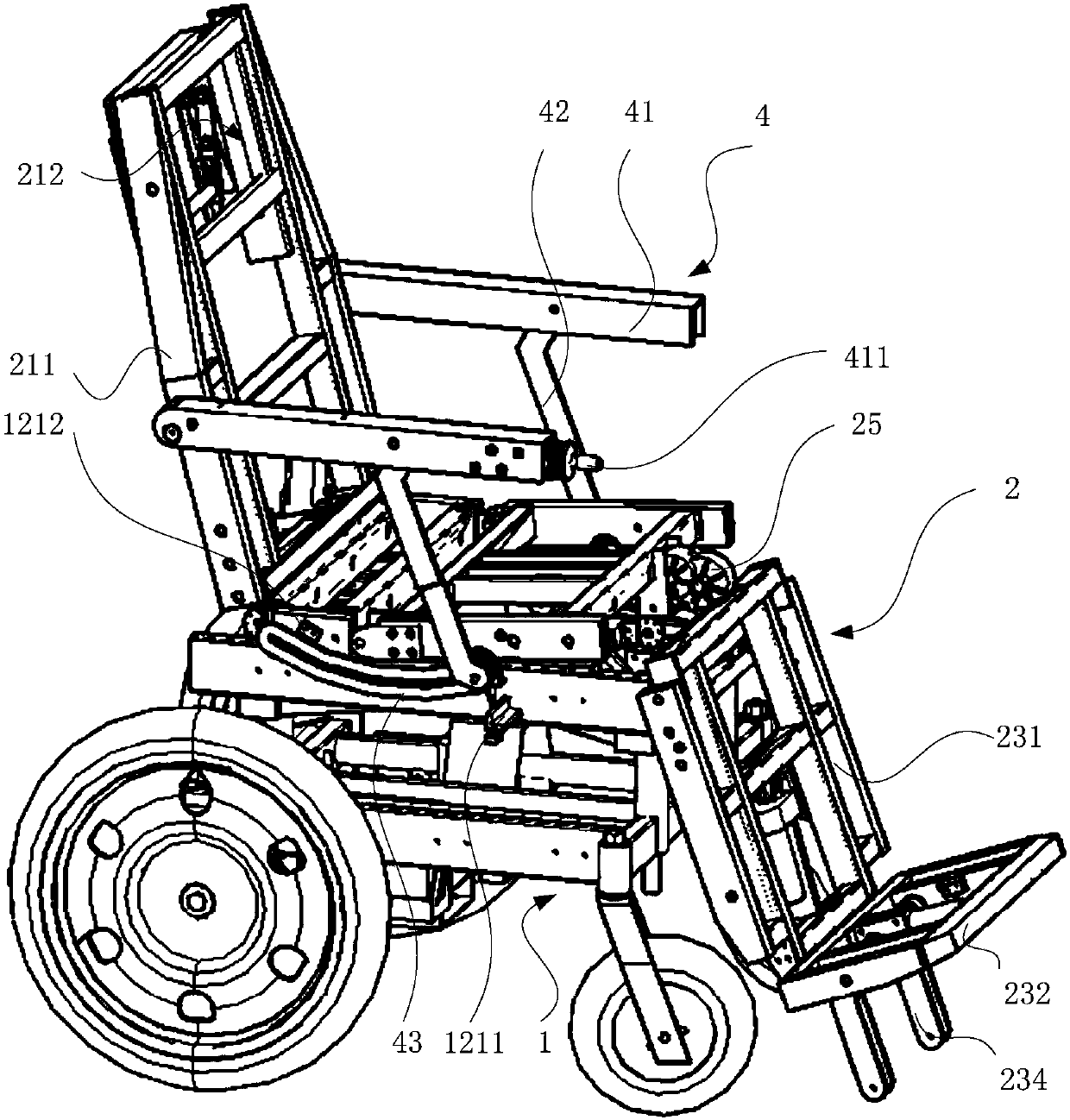

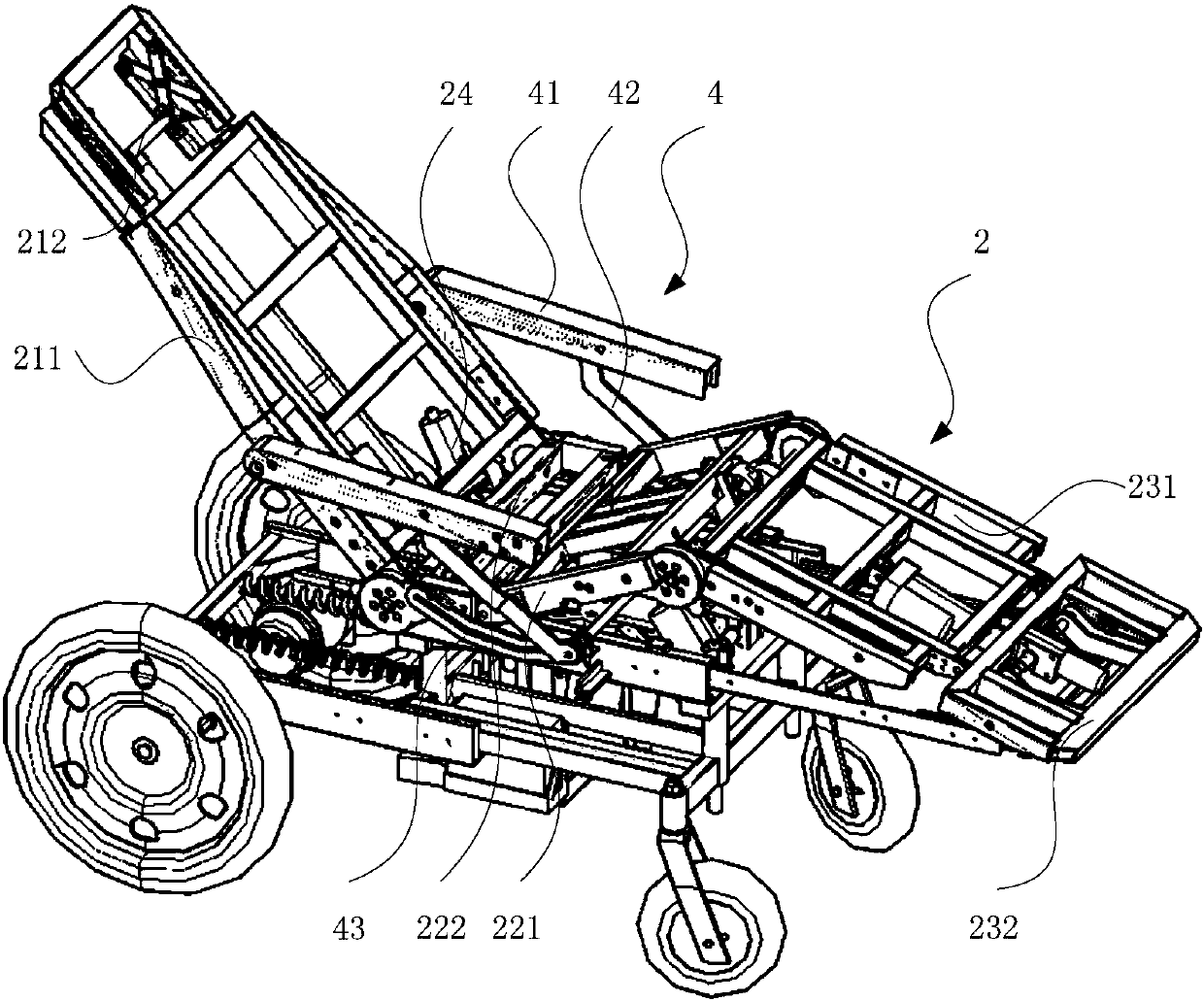

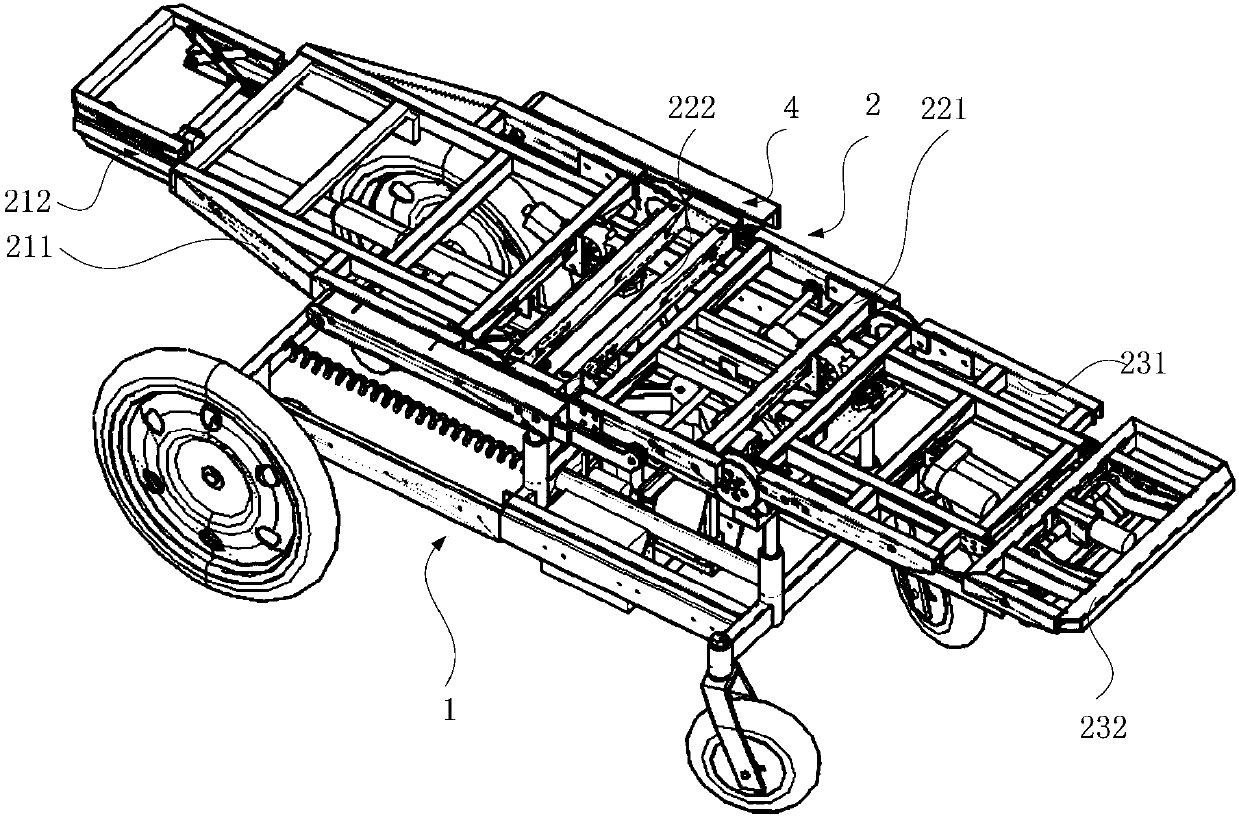

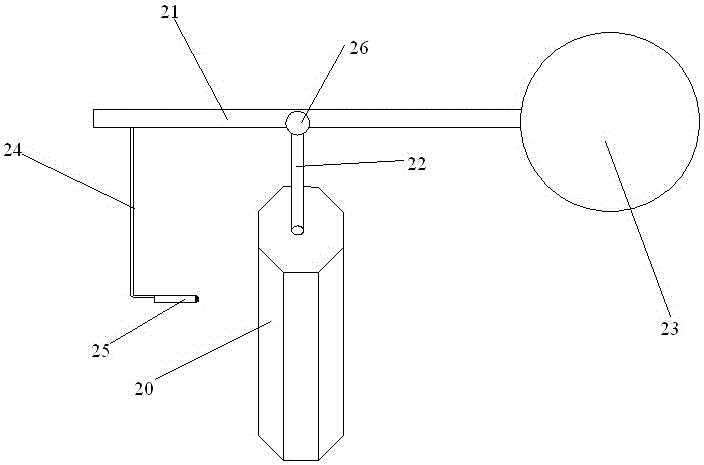

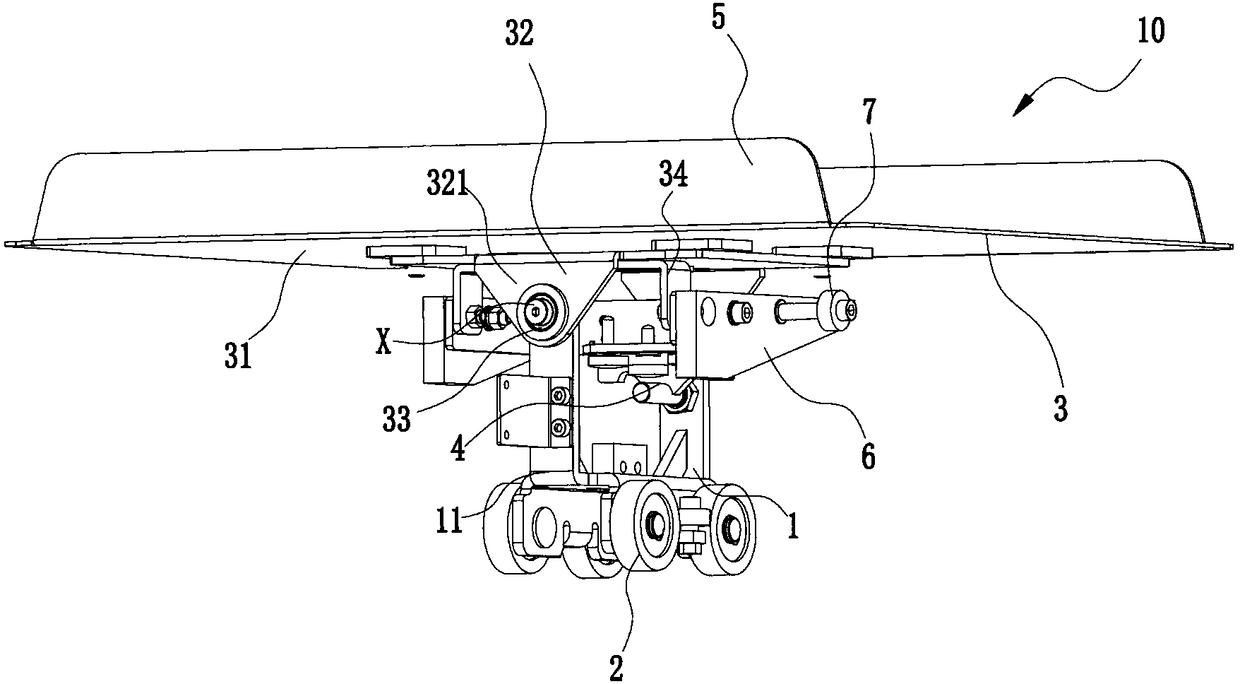

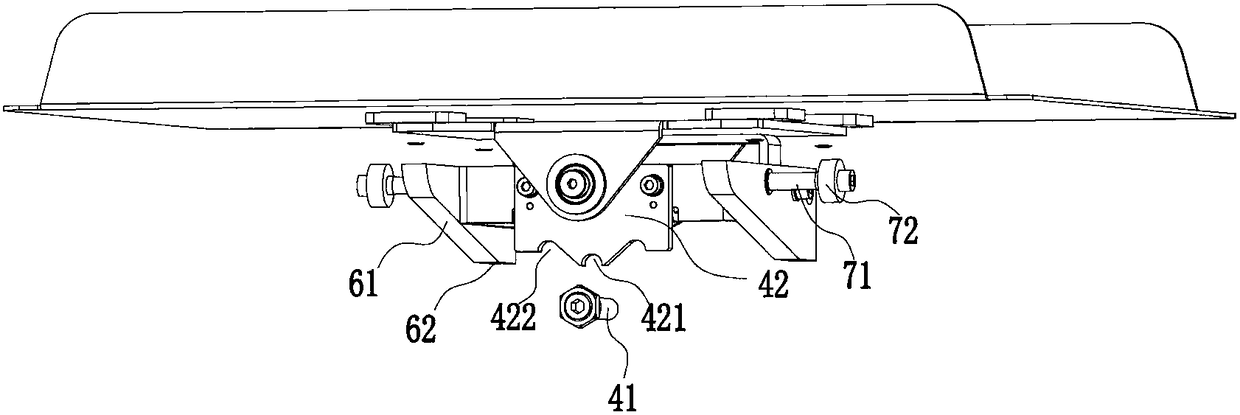

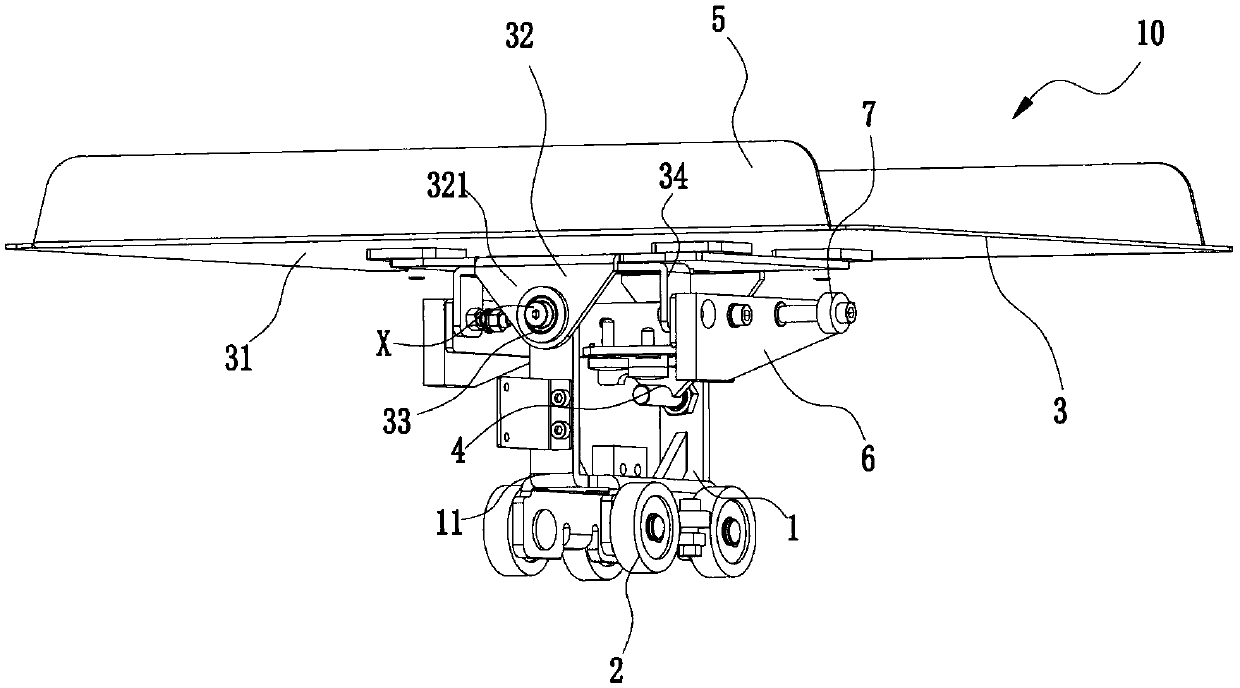

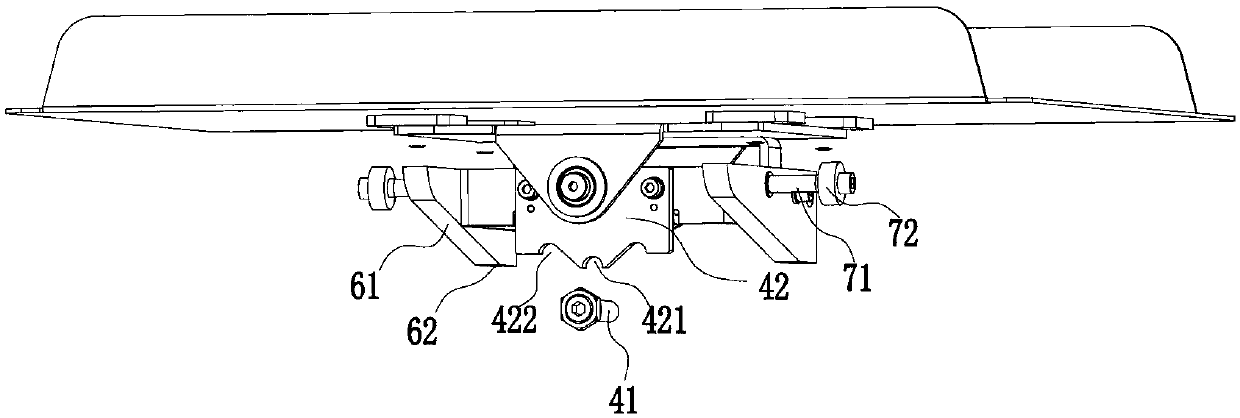

Wheelchair and wheelchair combined bed

PendingCN107928910ADecrease the tilt angleIncrease the tilt angleWheelchairs/patient conveyanceNursing bedsPhysical medicine and rehabilitationWheelchair

The invention provides a wheelchair and a wheelchair combined bed, and relates to the technical field of medical treatment equipment. The wheelchair comprises a walking driving device and a bearing body arranged above the walking driving device, the bearing body comprises a leaning assembly, a sitting cushion assembly and a supporting leg assembly, and the leaning assembly, the sitting cushion assembly and the supporting leg assembly are sequentially connected, wherein a backrest driving device is arranged between the leaning assembly and the sitting cushion assembly and used for driving the leaning assembly to rotate relative to the sitting cushion assembly; a supporting leg driving device is arranged between the supporting leg assembly and the sitting cushion assembly and used for driving the supporting leg assembly to rotate relative to the sitting cushion assembly. With the wheelchair, it is not needed to transfer a patient or old man with disabled action between a bed and the wheelchair, family members can conveniently take care of the patient or the old man, and troubles are avoided.

Owner:杨少辉

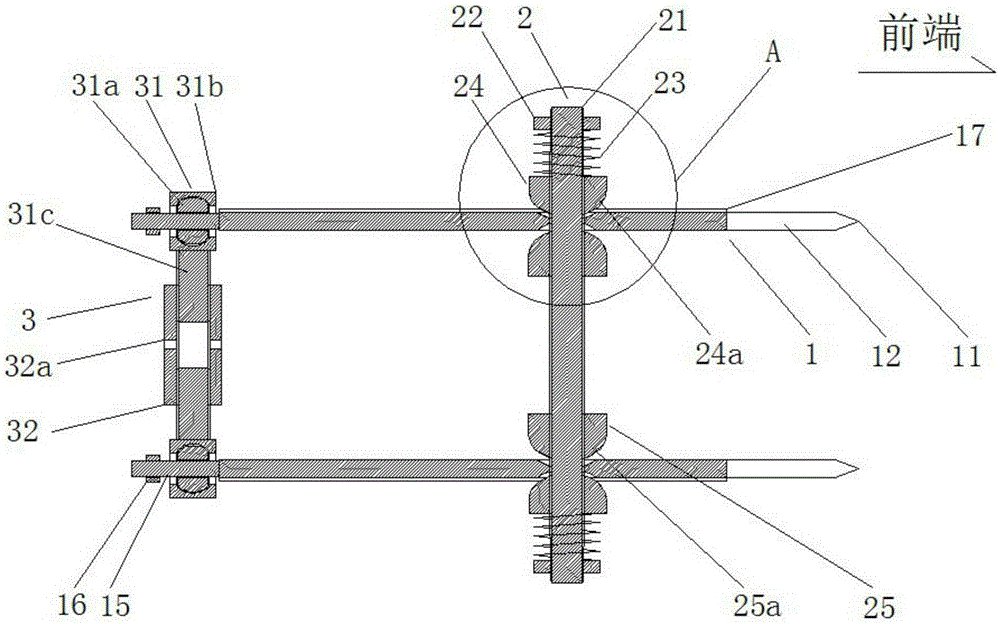

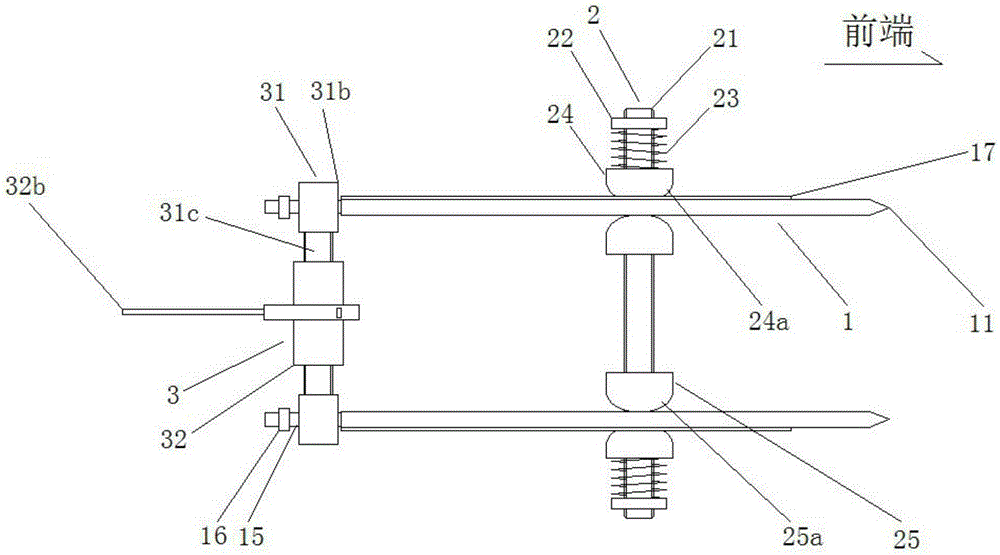

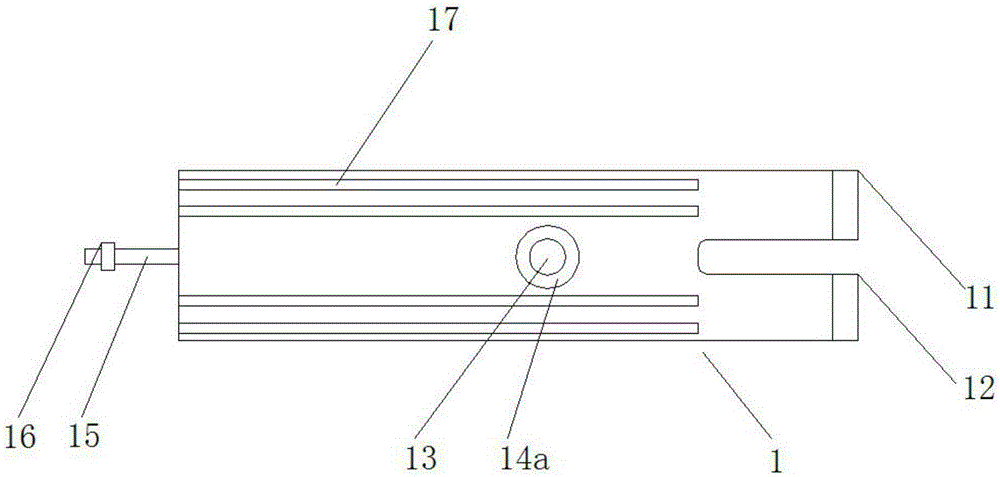

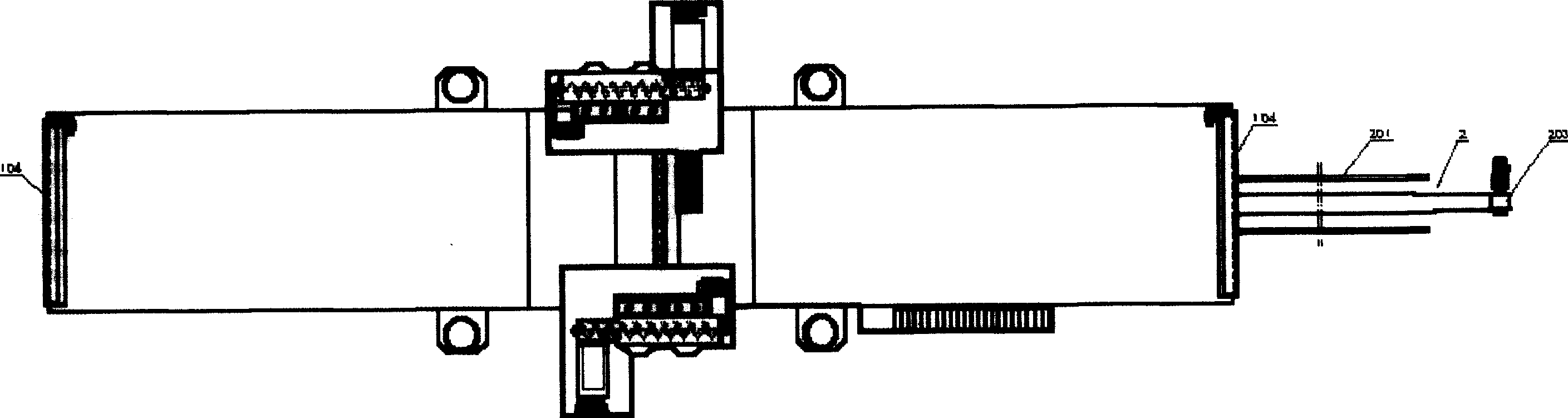

Electric breaker spring disassembly device

InactiveCN105291048AAvoid interferenceIncrease the tilt angleMetal-working hand toolsEngineeringScrew thread

The invention relates to an electric breaker spring disassembly device. The electric breaker spring disassembly device comprises turning plates, a support rod and an adjusting rod, wherein two turning plates are provided; sharp edges are arranged at the front ends of the turning plates; U-shaped grooves are formed in the middle parts of the front ends of the turning plates; first through holes are formed in the turning plates; shaft rods are arranged at the back ends of the turning plates; first external threads are arranged at the tail ends of the shaft rods; the support rod comprises a screw rod, a pretightening nut, a compression spring, a bulb slide block and a bulb nut; the adjusting rod comprises joint shaft heads arranged on the shaft rod, and a connecting rod movably connected between two joint shaft heads; the joint shaft heads comprise inner rings, outer rings and connecting rods; and the first external threads at the tail ends of the shaft rods are provided with limiting nuts for limiting the joint shaft heads. When the turning plates have larger inclined angles with the adjusting rod and the support rod, the adjusting rod and the support rod still can be continuously used, so that the adjusting range is largely widened.

Owner:国网山东莒南县供电公司 +1

Vortex air outlet device

InactiveCN1766452AImprove the effectIncrease the spreadLighting and heating apparatusSpace heating and ventilation detailsAirflowEngineering

The invention discloses a cyclone air outlet device, which is characterized by the following: placing multiple blades in the opening region of air outlet host to do free inclining movement around radiation shape axis; adjusting the inclined angle of each blade through the driving device movement; changing flow direction through blade; controlling the interflow of each blade as cyclone state; strengthening the vertical downward speed component of flow through increasing the inclined angle of blade; strengthening transverse speed component through decreasing the inclined angle of blade; selecting the discharging state ranged from vertical direction to transverse direction corresponding to each air adjustment condition.

Owner:KUKEN INDS +1

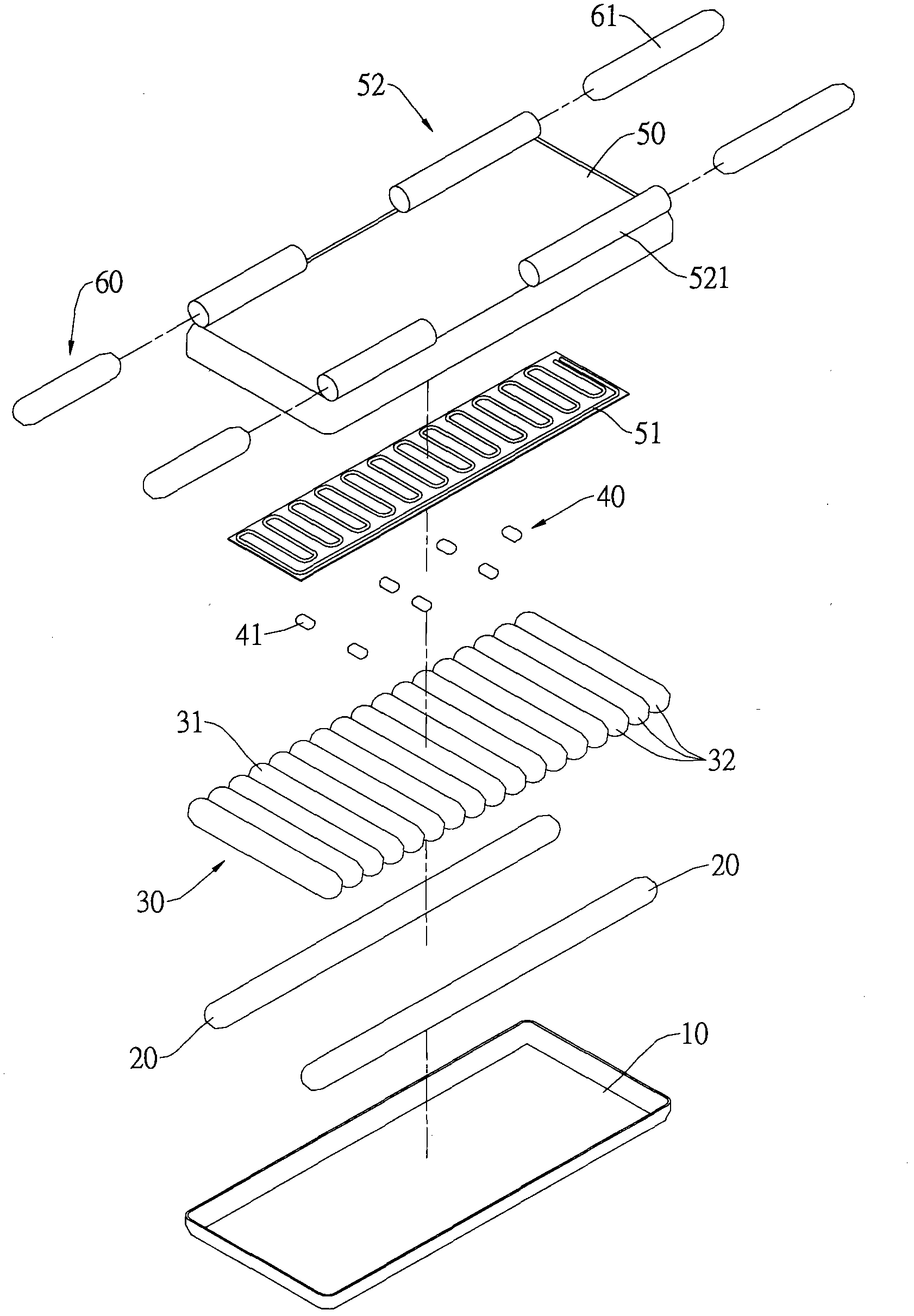

Medicinal inflatable mattress

The invention discloses a medicinal inflatable mattress, which comprises a body consists of a plurality of air bags which are arranged in parallel, wherein an upper cover is covered on the body, the two side edges of the upper cover are respectively extended to form guardrail sleeves on the top surface of the upper cover, guardrail components are arranged in the guardrail sleeves, and the guardrail sleeves are supported by the guardrail components to form protection for the two sides after the guardrail components are aerated. Because the two guardrail sleeves are fixedly arranged on the upper cover, the upper cover plays the role of traction to the two guardrail sleeves, when patients move immodestly to laterally press the guardrail sleeve on one side, the pressed guardrail sleeve stays the same by being drawn by the upper cover, and the guardrail sleeves can not dump laterally because of lateral pressing, thereby effectively maintaining the protection function of the sides of the guardrail sleeves.

Owner:PICARD HEALTHCARE TECH DONGGUAN

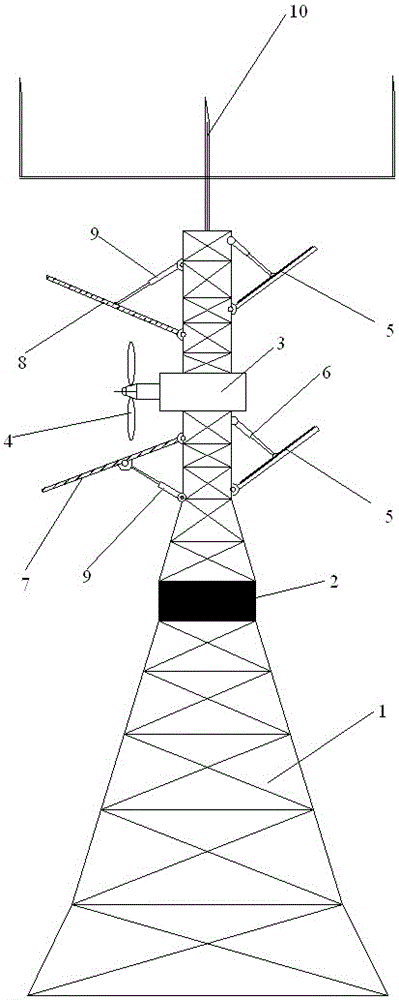

Wind-driven and solar combined power generation device

InactiveCN105715465AImprove power generation efficiencyBoost wind energyMachines/enginesWind energy generationEngineeringWind direction

The invention discloses a wind-driven and solar combined power generation device which is characterized by comprising towers, a support rotary base assembly, a wind driven generator, blades, a solar cell panel, wind-gathering components, a wind direction detection component, a lightning-protection component and a controller, wherein the support rotary base assembly is arranged between the upper tower and the lower tower; the upper and lower sides of the wind driven generator are provided with the wind-gathering components; the upper tower is obliquely and adjustably provided with the solar cell panel and also provided with the wind direction detection component and the lightning-protection component; the wind direction detection component is connected with the controller. The wind-driven and solar combined power generation device is capable of better realizing mutual complementation of wind energy and solar energy; meanwhile, the wind-gathering components are arranged and are capable of amplifying wind to a certain degree, so that the wind energy of the blades of the wind driven generator is improved, and the wind-driven power generation efficiency is enhanced; the wind driven generator can be rotated according to the detected wind direction, so that optimal direction and the optimal inclination angle of the solar cell panel are realized, and the power generation efficiency is improved.

Owner:XIHUA UNIV

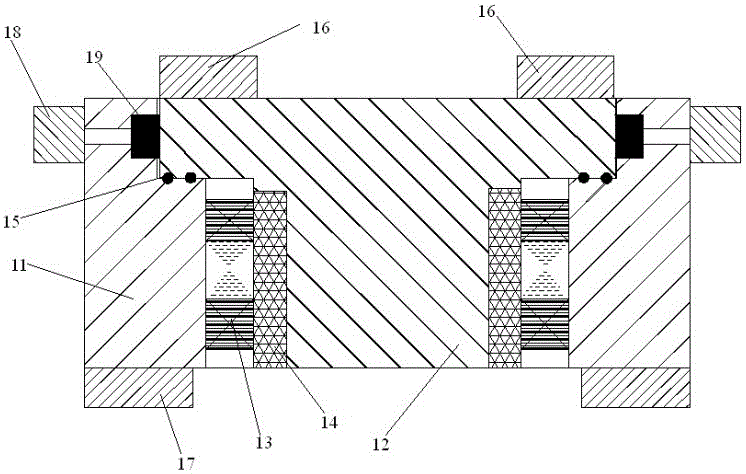

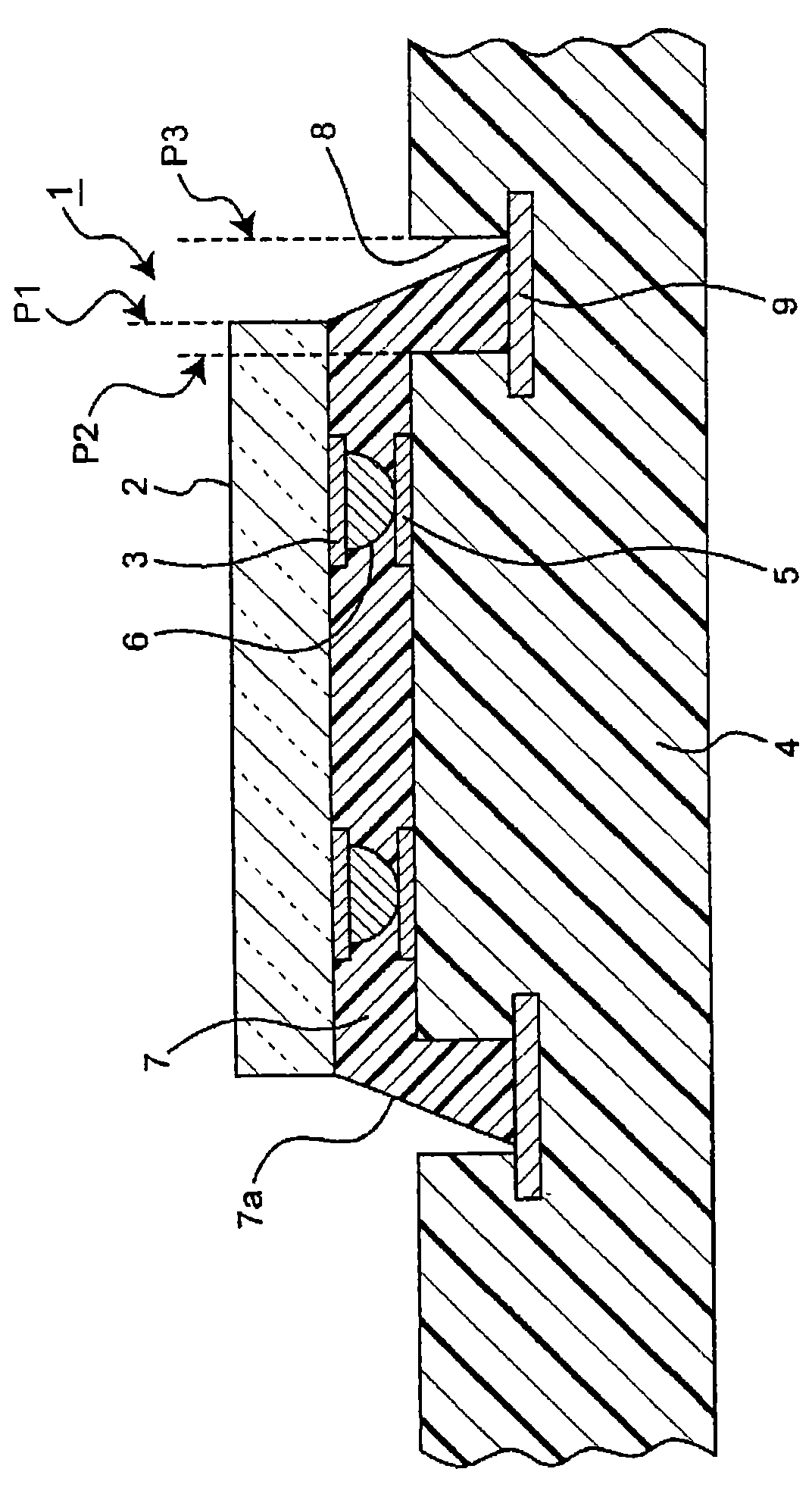

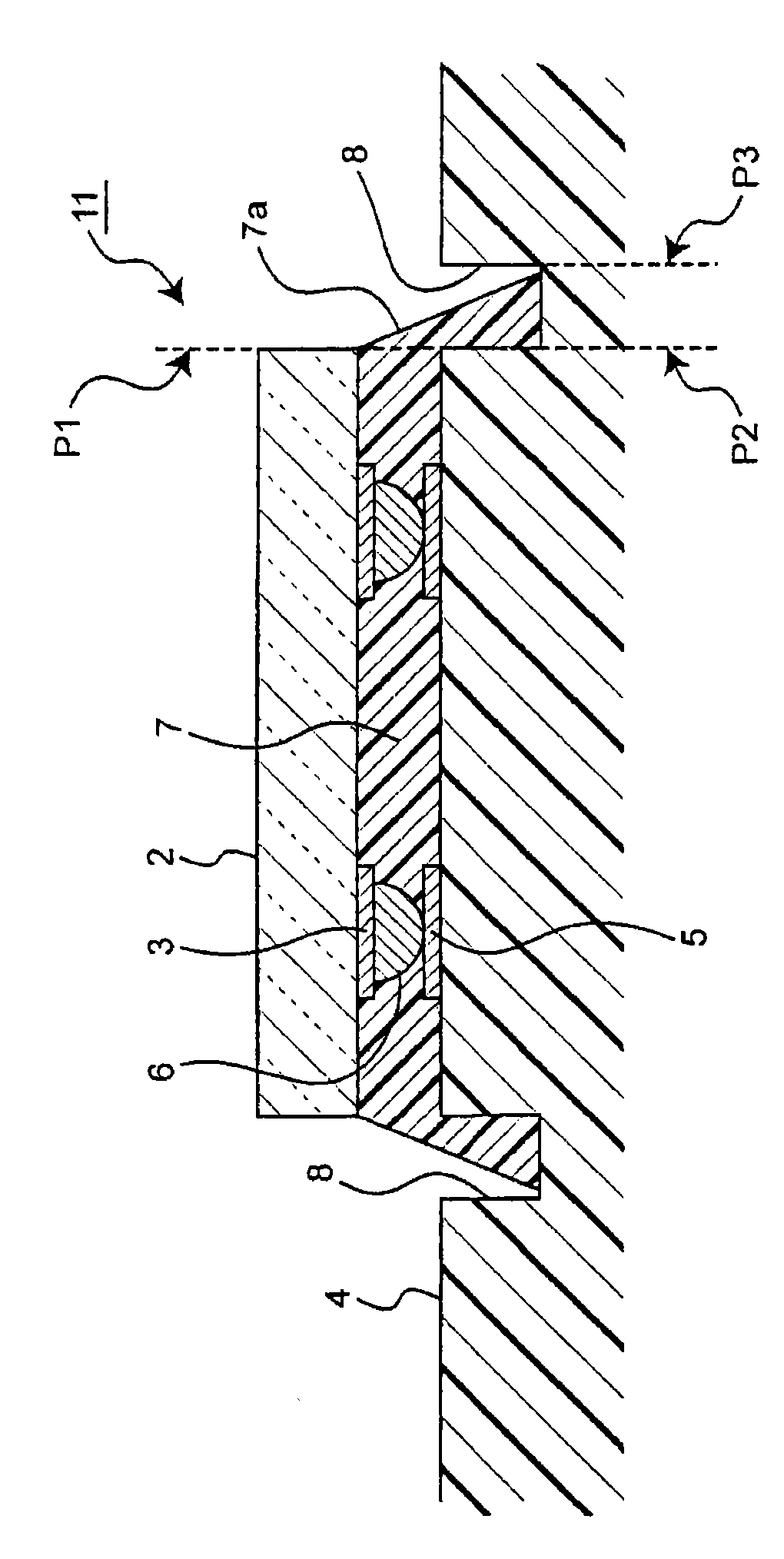

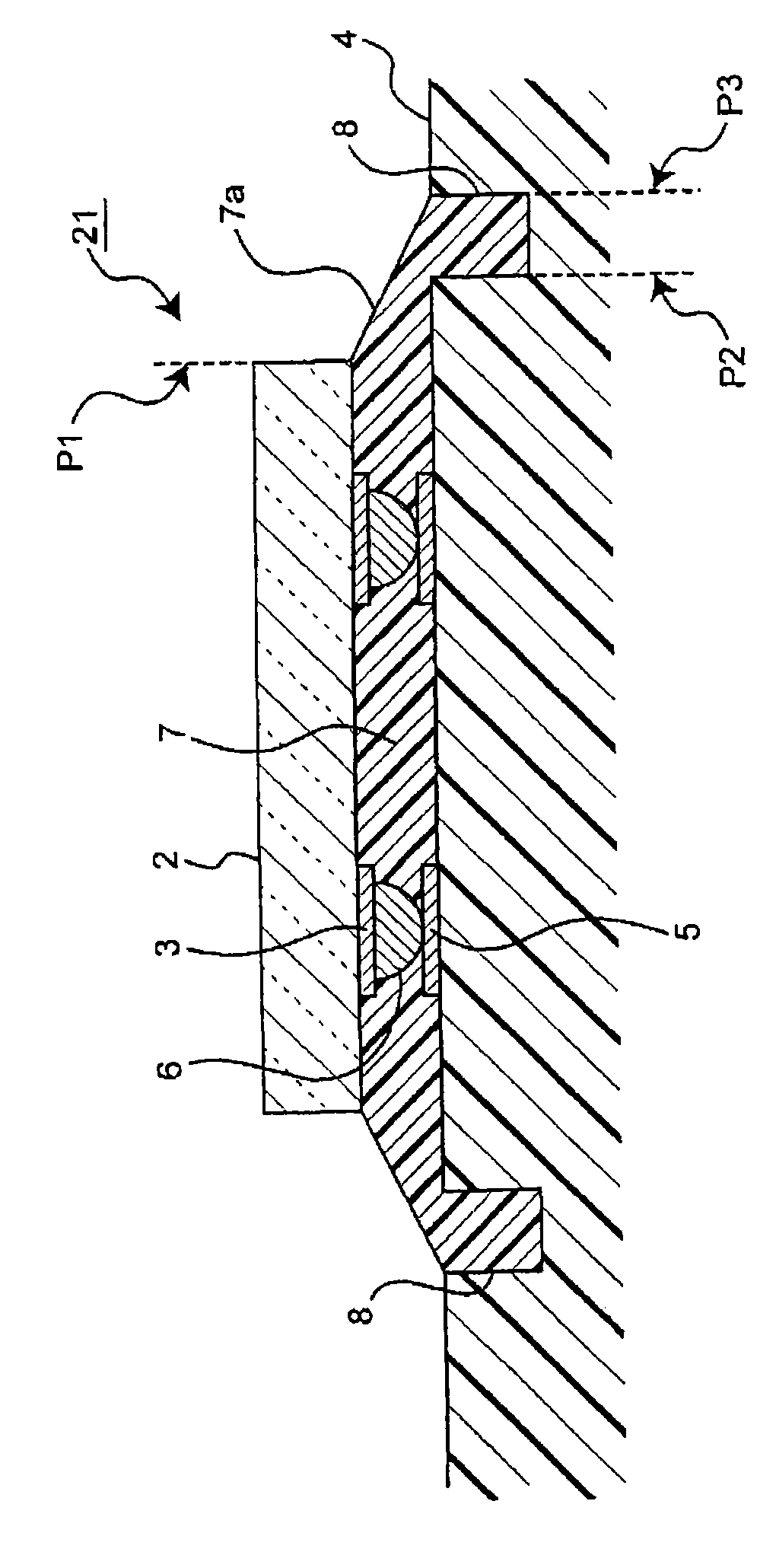

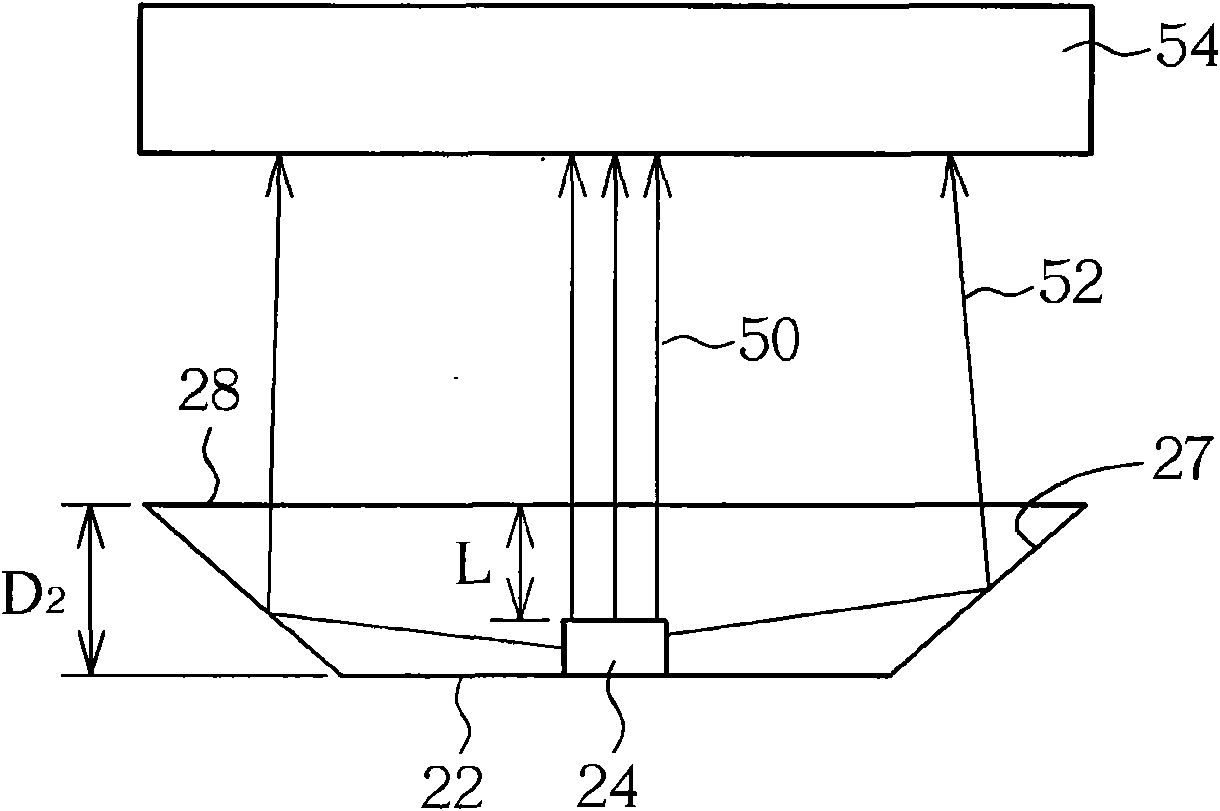

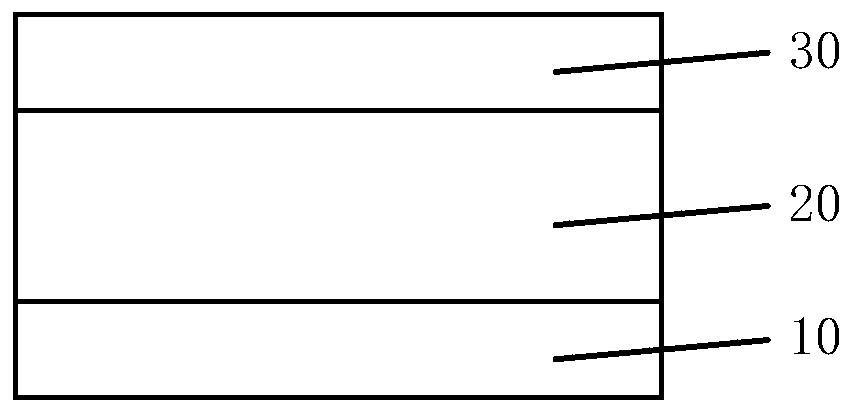

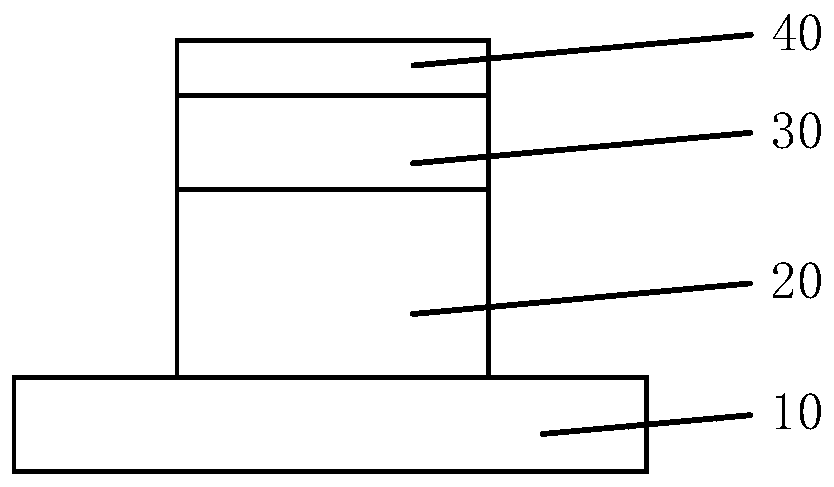

Semiconductor element mounting structure and semiconductor element mounting method

InactiveCN101578695AAvoid internal damageReduced extension areaSemiconductor/solid-state device detailsSolid-state devicesThermal expansionEngineering

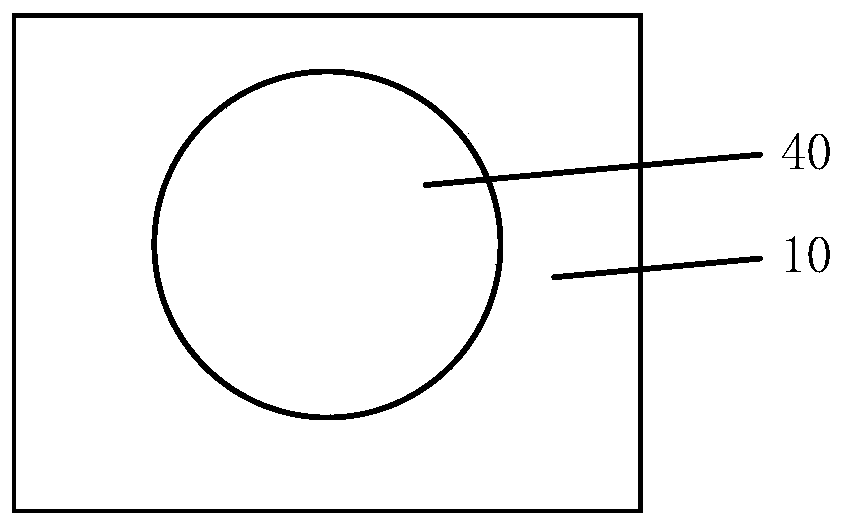

On a substrate surface at a position facing an outer circumference end portion of a semiconductor element, a recessed section wherein a sealing adhesive resin is partially arranged is formed. Thus, while suppressing expansion of an arrangement region of a fillet portion (a portion spreading toward bottom) of the sealing adhesive resin, the inclination angle is increased. A stress load generated at the periphery of the semiconductor element due to thermal expansion differences and thermal shrinkage differences between members due to heating process and cooling process for mounting is reduced, and internal breakage of a semiconductor element mounting structure is eliminated.

Owner:PANASONIC CORP

Postoperation nursing bed

InactiveCN107007409AReduce oppressionIncrease the tilt angleNursing bedsAmbulance serviceEngineeringMedical device

The invention discloses a postoperation nursing bed and relates to a medical device. The postoperation nursing bed comprises a bed frame, a bed board and an adjusting mechanism, wherein the bed board is formed by hinging a first bed board to a second bed board; the adjusting mechanism comprises driving motors, a control part, an adjusting part, a first supporting part and a second supporting part, and the first supporting part and the second supporting part are symmetrically arranged along the center of a door board; the adjusting part comprises an adjusting shell body, a first bevel gear which is rotatably connected with the adjusting shell body, a second bevel gear and a middle bevel gear, wherein the first bevel gear and the second bevel gear are meshed with the middle bevel gear. The first supporting part and the second supporting part control free ends of the first bed board and the second bed board to go up and down respectively, the first supporting part and the second supporting part are driven by the first bevel gear and the second bevel gear respectively, through the control over the running resistance of the second bevel gear, the speed ratio of the first bevel gear to the second bevel gear can be changed, and the bed board can be presented with different states.

Owner:AFFILIATED YONGCHUAN HOSPITAL OF CHONGQING MEDICAL UNIV

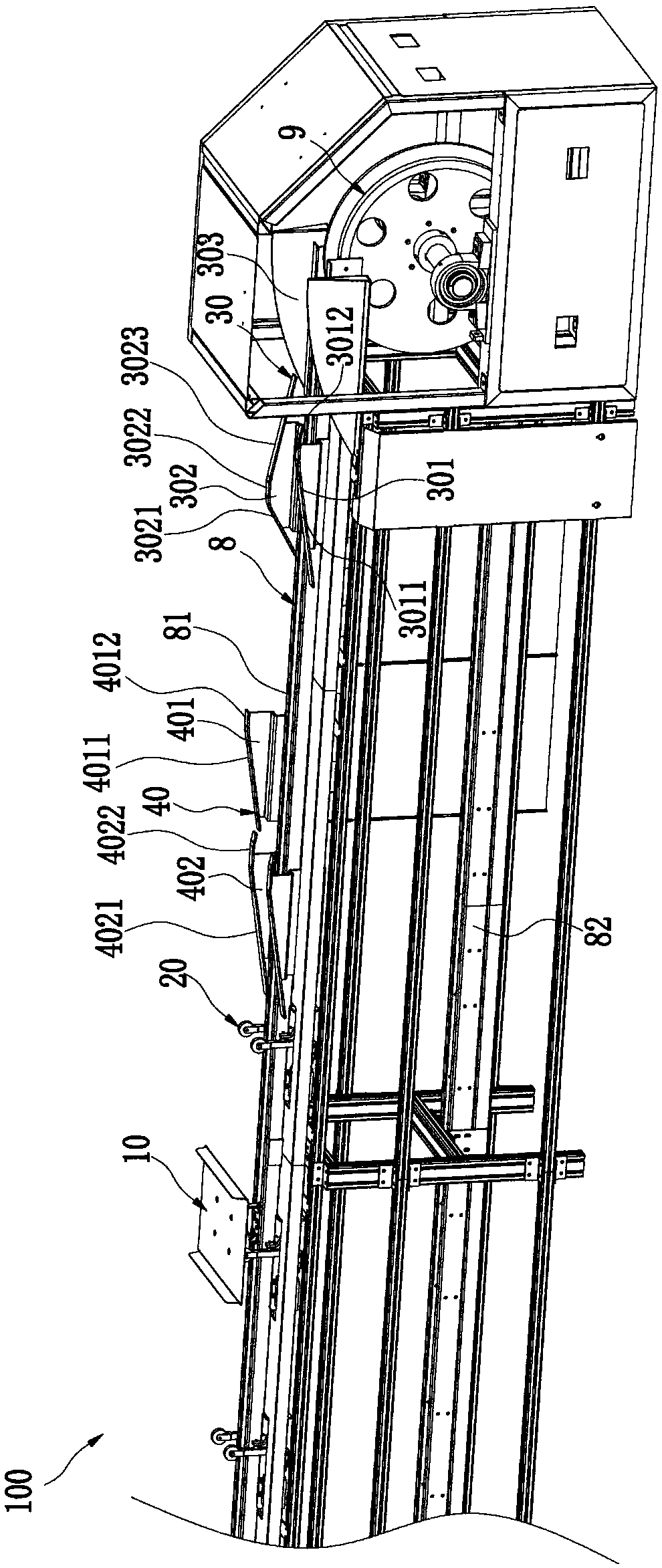

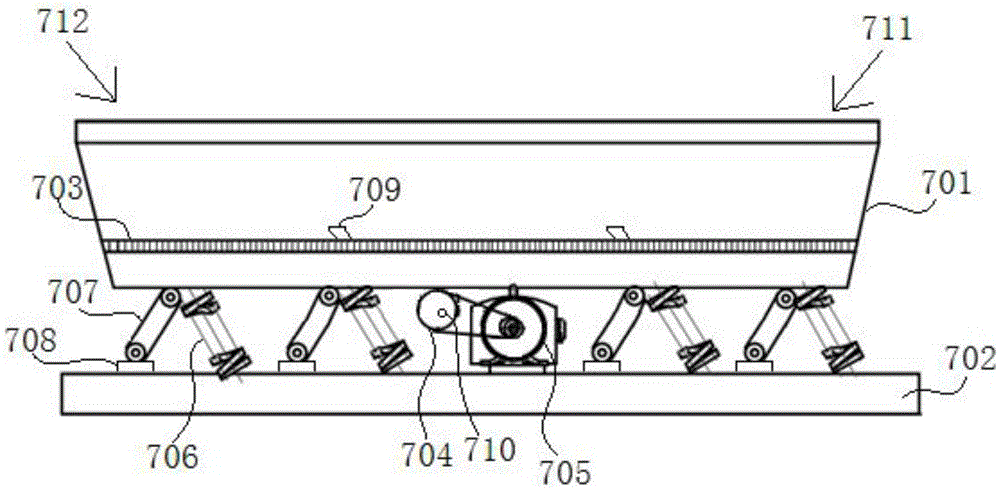

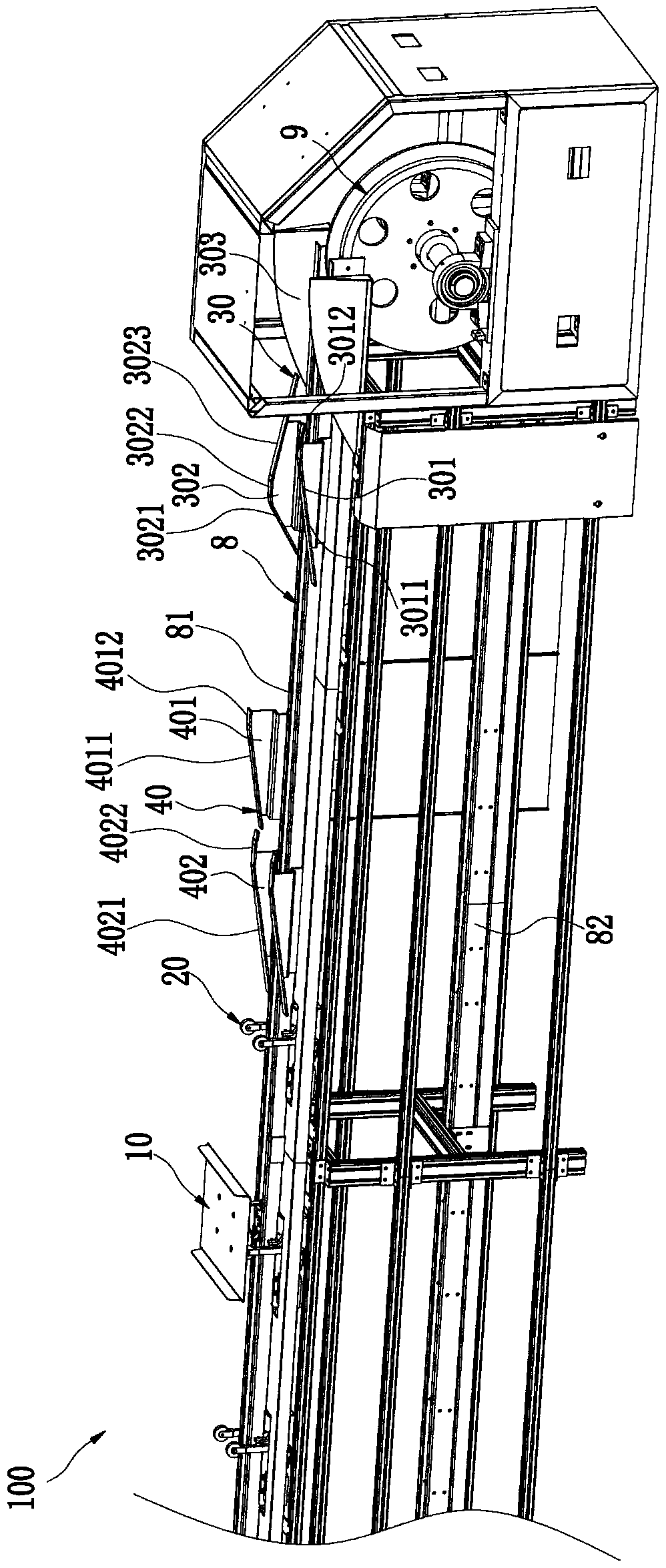

Turning-plate type sorting system

PendingCN108408314AResolve interferenceEffective combinationSortingStorage devicesEngineeringMulti path

The invention discloses a turning-plate type sorting system comprising a track and further comprising a feeding area located beside the track, detecting equipment located on the track and a grid opening area located beside the track. The track is slidably provided with at least one bidirectional turning-plate trolley with a turning plate capable of turning over towards two directions for unloading; and the bidirectional turning-plate trolleys are connected with driving devices driving the bidirectional turning-plate trolleys to slide along the track. In the turning-plate type sorting system, the bidirectional turning-plate trolleys can sort bidirectionally and can be combined with the track to realize synchronous work of multiple trolleys; by controlling the discharging position and discharging direction of each bidirectional sorting trolley, multi-path sorting can be effectively realized under the limited site condition, the problem of disturbance caused by travelling paths of a conventional trolley is avoided, and the requirement on the site is low; meanwhile, the multiple trolleys synchronously sort in multiple paths, and thus the sorting efficiency is greatly improved; and by combining feeding, detecting and sorting openings, automatic operation of the whole sorting process can further be achieved, and the turning-plate type sorting system is advantageously matched with other sorting equipment for being used through the design of discharging grid openings.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

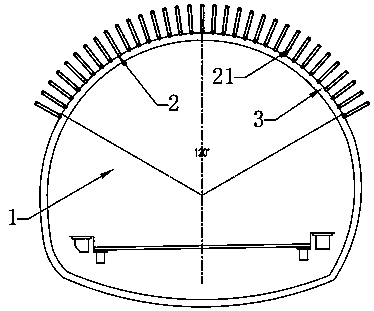

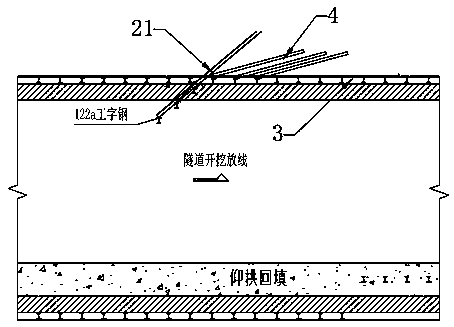

Shallow underground excavation unsymmetrial loading tunnel roof caving in-hole forepoling method

InactiveCN110318762AIncrease the tilt angleHigh strengthUnderground chambersTunnel liningRebarSteel tube

The invention discloses a shallow underground excavation unsymmetrial loading tunnel roof caving in-hole forepoling method. The method comprises the following steps that advanced geological predictionis carried out; in-hole back pressure backfill is carried out; guide frame erecting is carried out; advanced pipe shed supporting is carried out, and steel cages are sleeved with seamless steel pipesof all pipe sheds for grouting subsequently; earthwork is excavated from top to bottom; initial supports are applied under the pipe sheds, joist steel adopted by initial supporting after initial supporting is completed is used as supports to drive advanced small pipes, grouting is carried out after the advanced small pipes are driven, and supporting is completed. By means of the shallow underground excavation unsymmetrial loading tunnel roof caving in-hole forepoling method, a manner of supporting the advanced pipe sheds and then driving the advanced small pipes is used for supporting the tunnel roof caving position, the pipe shed supporting angle is large, strong supporting is formed at the tunnel collapse position at the maximum extent, later initial supporting and advanced small pipe arranging are further facilitated, meanwhile, a pipe shed working chamber does not need to be excavated during initial supporting.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

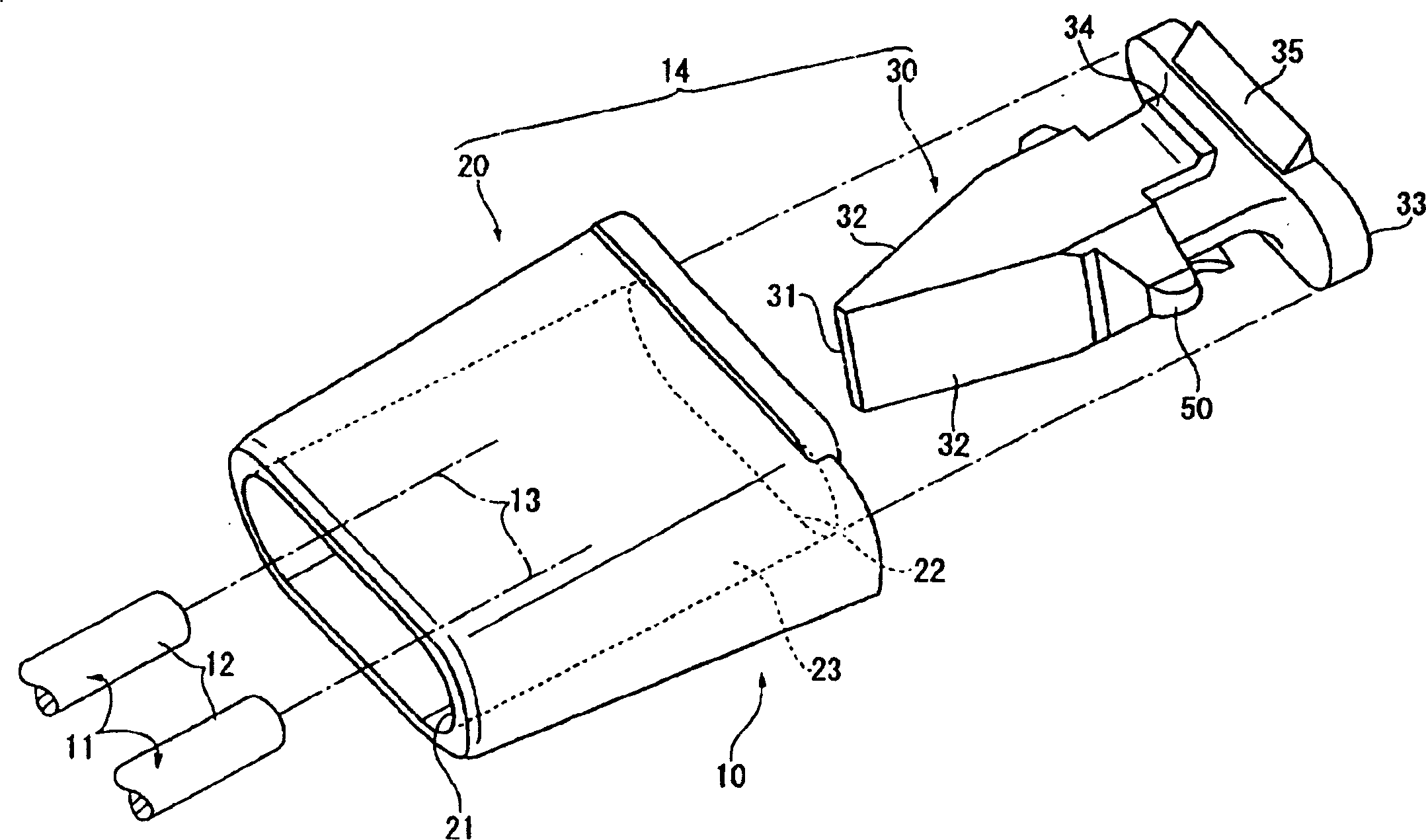

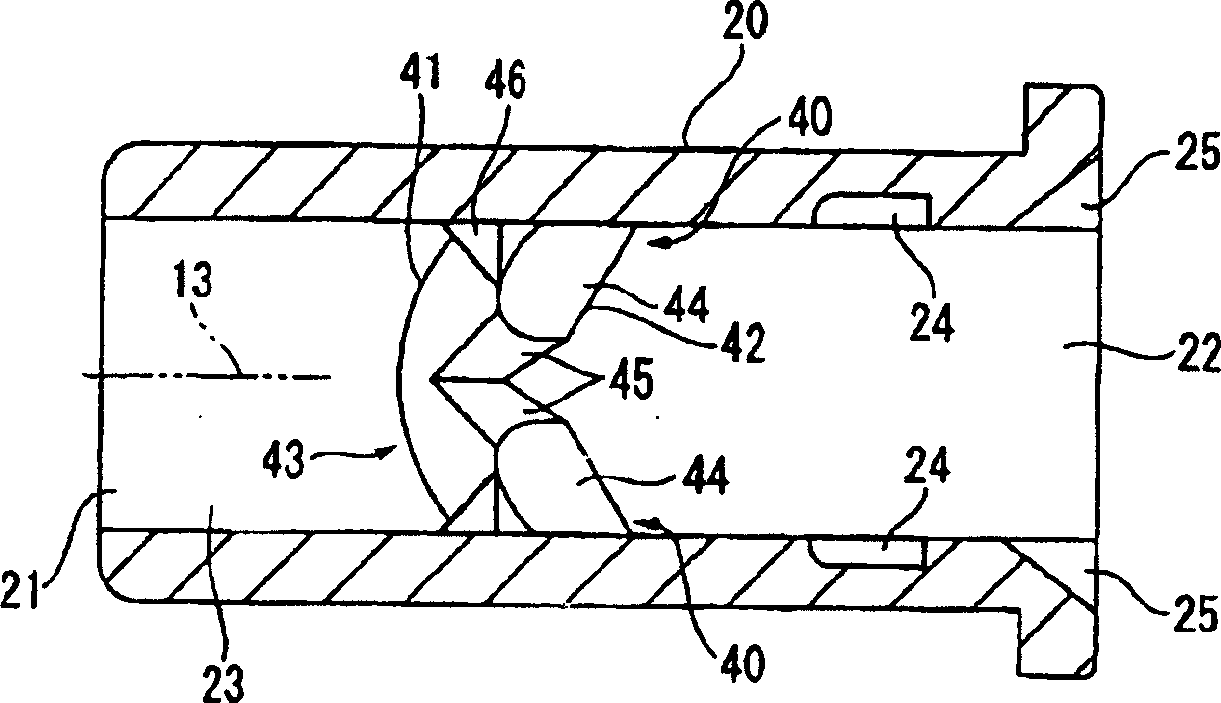

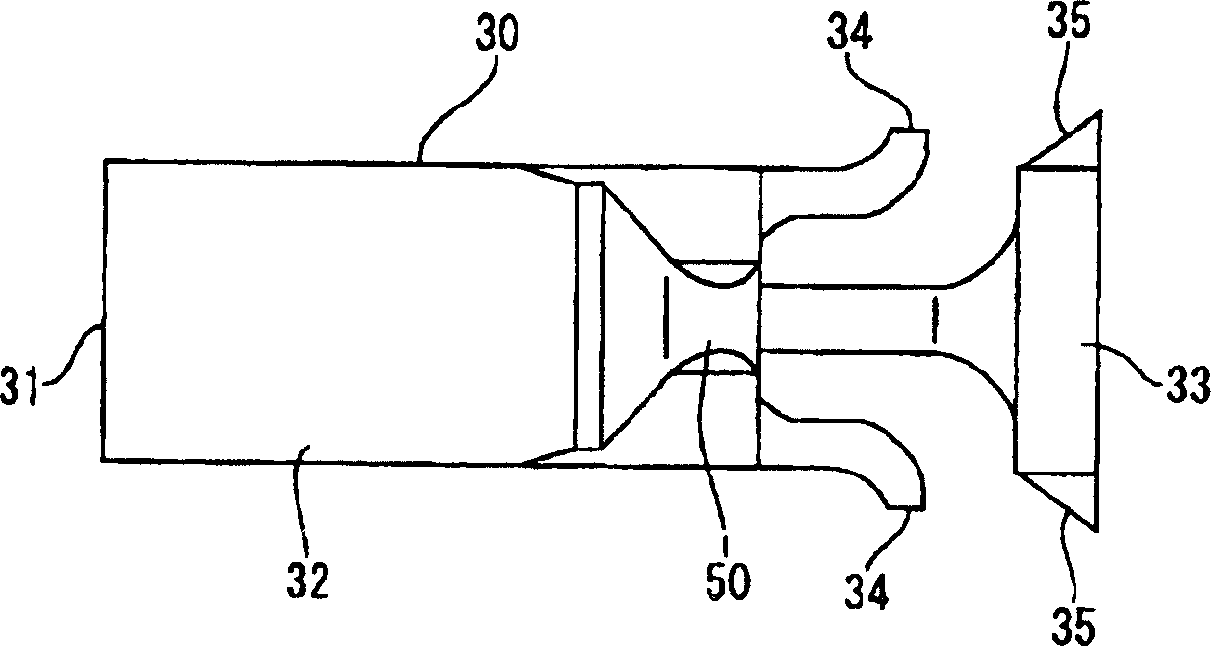

Buckle for fastening rope

ActiveCN1647711AIncrease the tilt angleDecrease the tilt angleRopes and cables for vehicles/pulleyShoe lace fasteningsMechanical engineering

Owner:YKK CORP

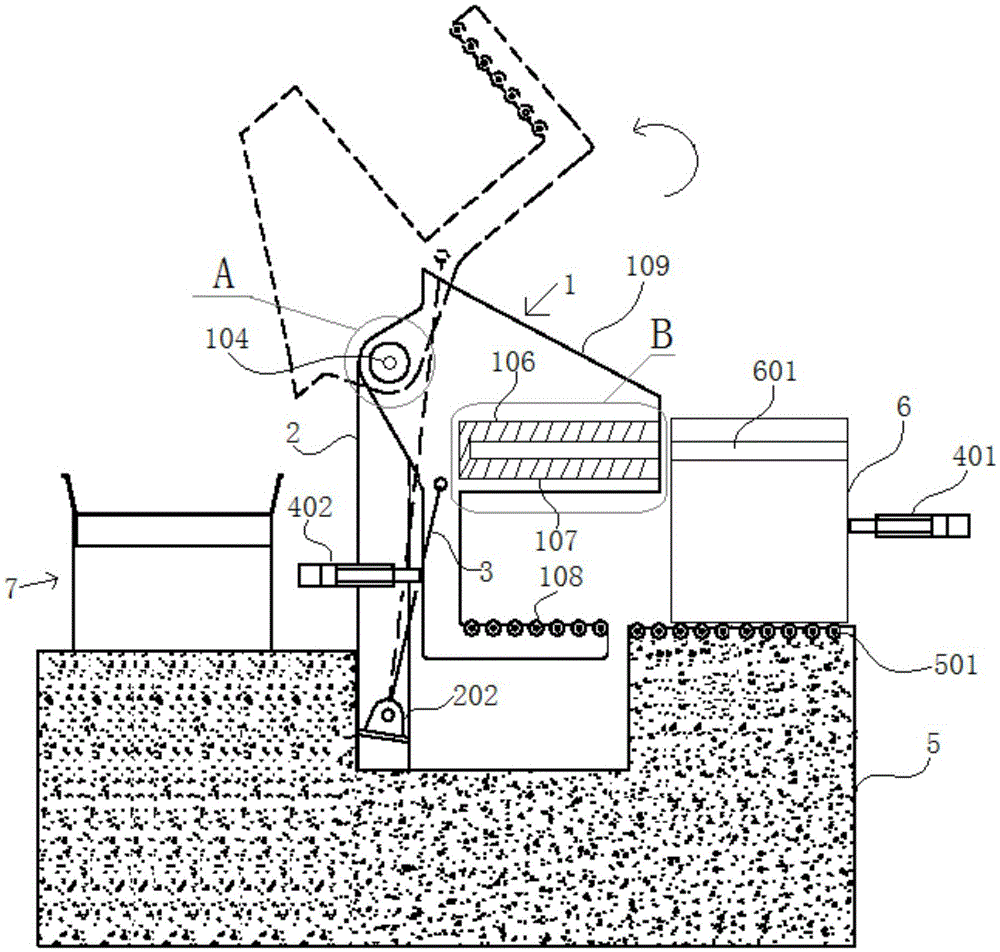

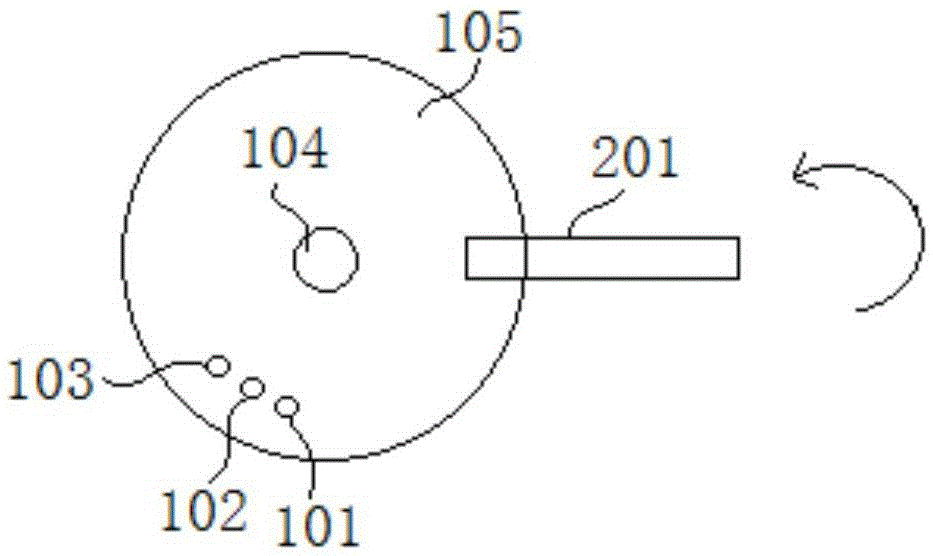

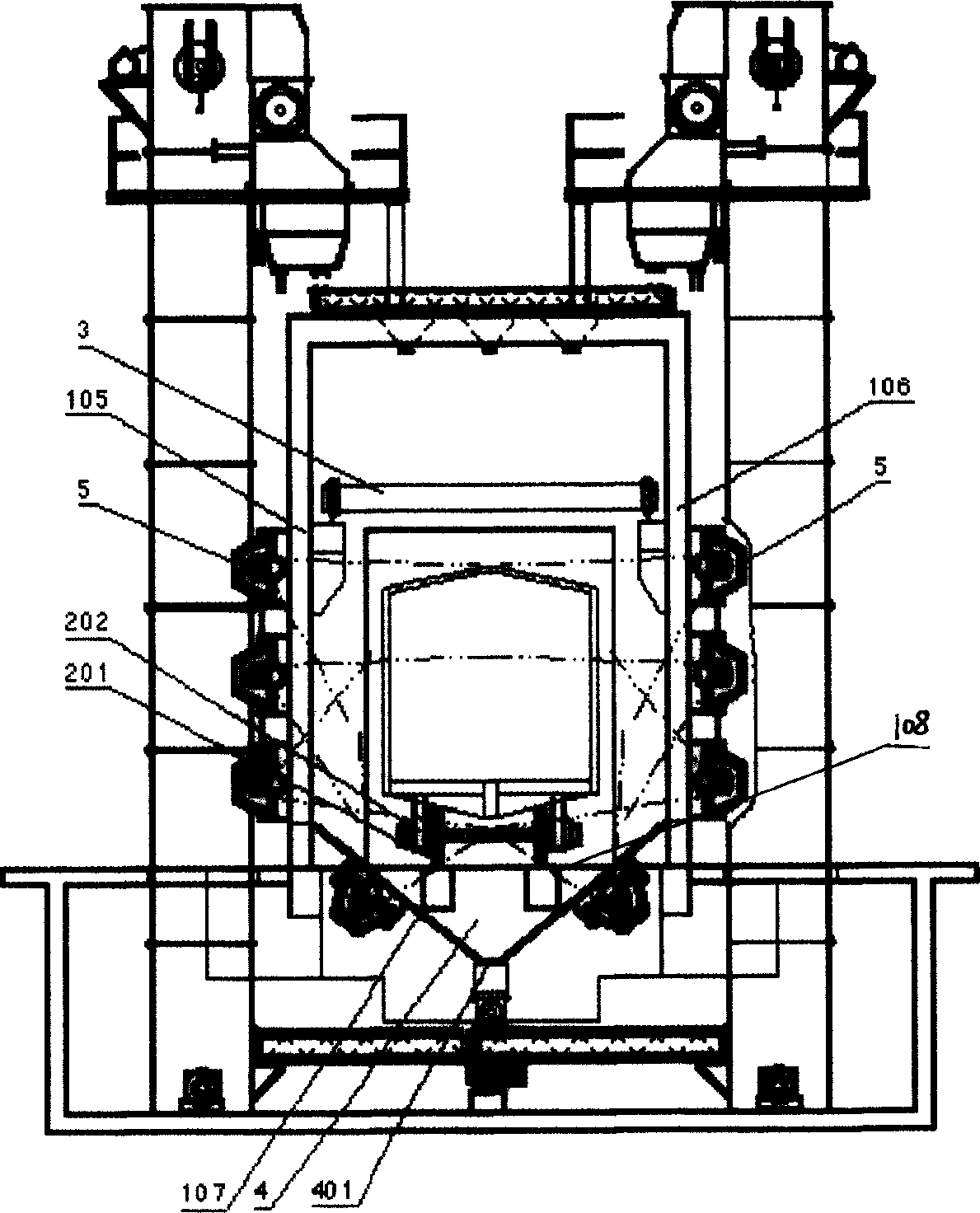

Box turnover and sand strip system for casting wear-resisting parts

ActiveCN105414493AAvoid instant sand pouringGuarantee safe and reliableMoulding machinesEngineeringHinge point

The invention discloses a box turnover and sand strip system for casting wear-resisting parts and belongs to the field of wear-resisting part casting equipment. The system comprises a sand box turnover device and a sand strip device. The sand box turnover device comprises a rotating arm, a rack, a telescopic arm, a base and a sand box. The rack is fixed to the base. The rotating arm is hinged to the rack. The telescopic arm is connected with the rotating arm. The telescopic arm is used for pushing the rotating arm and rotates with a hinge point of the rotating arm and the rack as the circle center. The rotating arm is used for installing the sand box. The sand strip device is located at one side of the sand box turnover device. The sand strip device comprises a conveying groove, a supporting mechanism, a vibrating mechanism and a conveying groove base. The conveying groove is installed in the conveying groove base through the supporting mechanism. The conveying groove is connected with the vibrating mechanism. The vibrating mechanism is used for conveying materials in the conveying groove from the material input end of the conveying groove to the material output end of the conveying groove in a vibrating mode. The system mainly has a function of carrying out sand box turnover operation safely and reliably, and is suitable for carrying out sand strip operation on a large scale.

Owner:马鞍山市海天重工科技发展有限公司

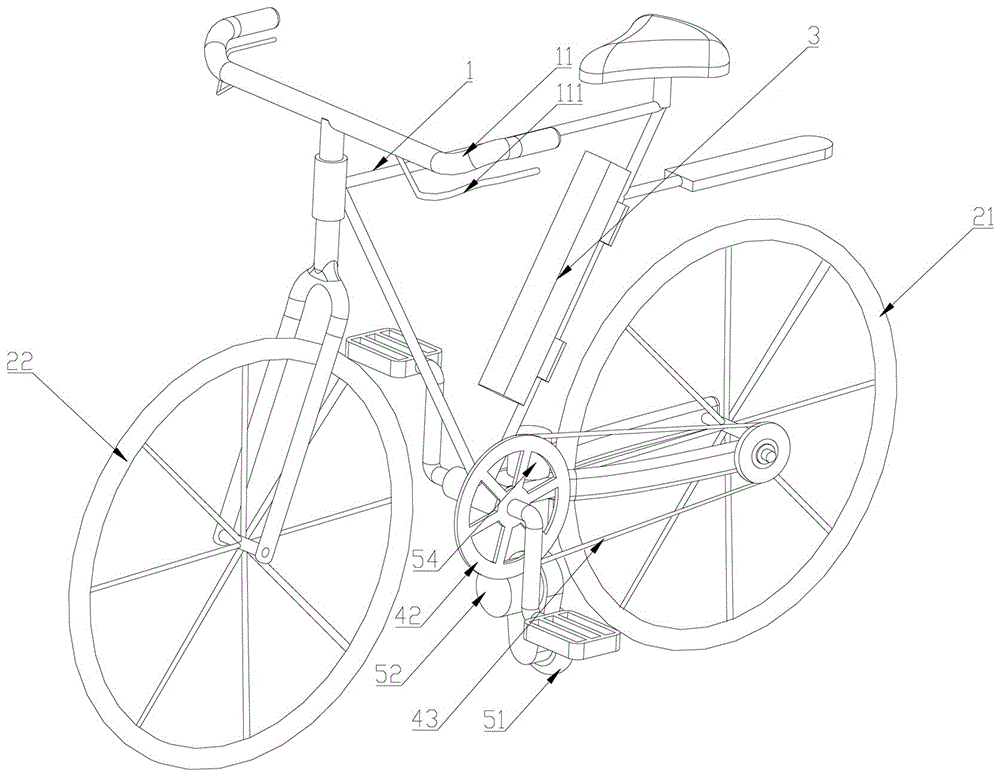

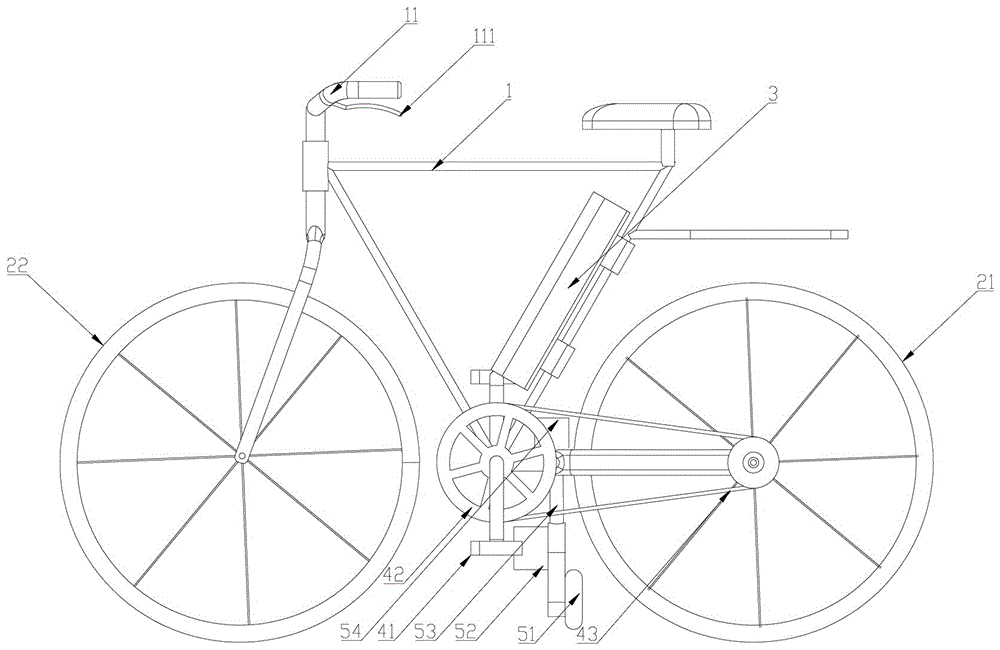

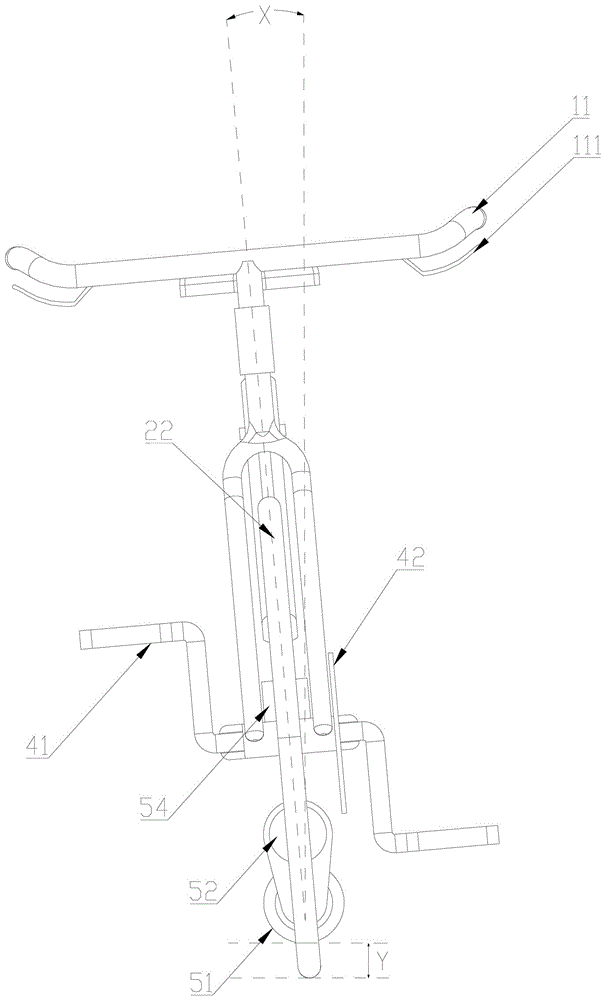

Bicycle provided with anti-toppling auxiliary wheel

ActiveCN106080852AIncrease the tilt angleAffect normal operationCycle standsVehicle frameRotational axis

The invention relates to the technical field of bicycles, in particular to a bicycle provided with an anti-toppling auxiliary balance wheel and an operating method of the bicycle. The auxiliary balance wheel which is driven by a motor to rotate, rise and fall is arranged on a bicycle frame. The auxiliary balance wheel is arranged transversely, a tyre of the auxiliary balance wheel does not make contact with the ground within a safe inclination range, the driving motor makes the auxiliary balance wheel fall to make contact with the ground beyond the safe inclination range, and the auxiliary balance wheel rotates towards the inclined side in the same direction around a rotary shaft, so that reverse torsion is provided to make a bicycle body rapidly restore to the safe inclination range, and a rider is prevented from falling. Since the auxiliary balance wheel does not automatically restore to the original position in a period of time, when the bicycle inclines leftwards and rightwards repeatedly, after it is guaranteed that the angle of the bicycle is adjusted to the safe inclination range by the auxiliary balance wheel, the auxiliary balance wheel rise again to not make contact with the ground, and the situation that normal traveling of the bicycle body is affected by the descending auxiliary balance wheel is avoided while the effect that the bicycle does not topple is guaranteed.

Owner:汕头市东讯信息科技有限公司

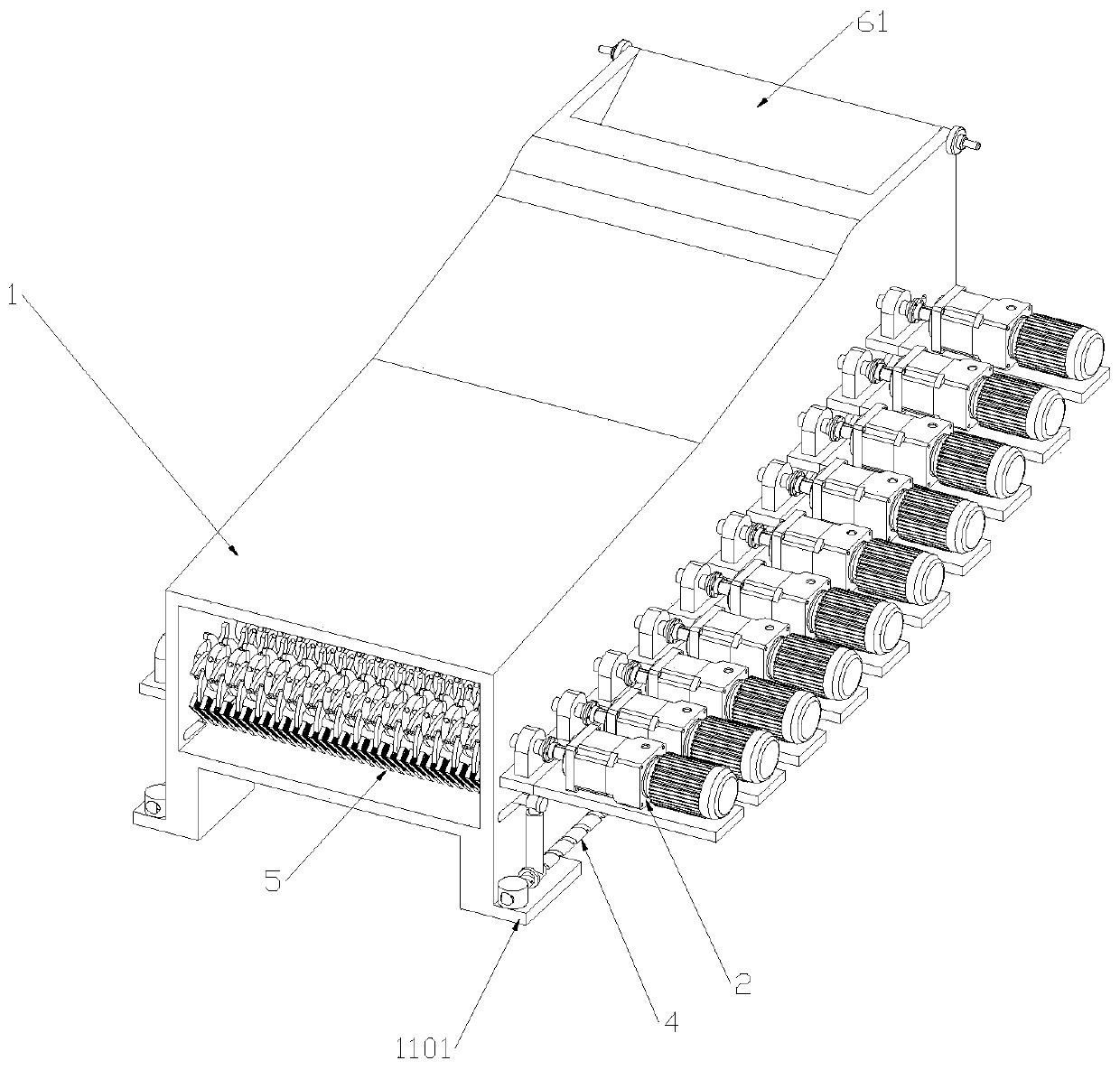

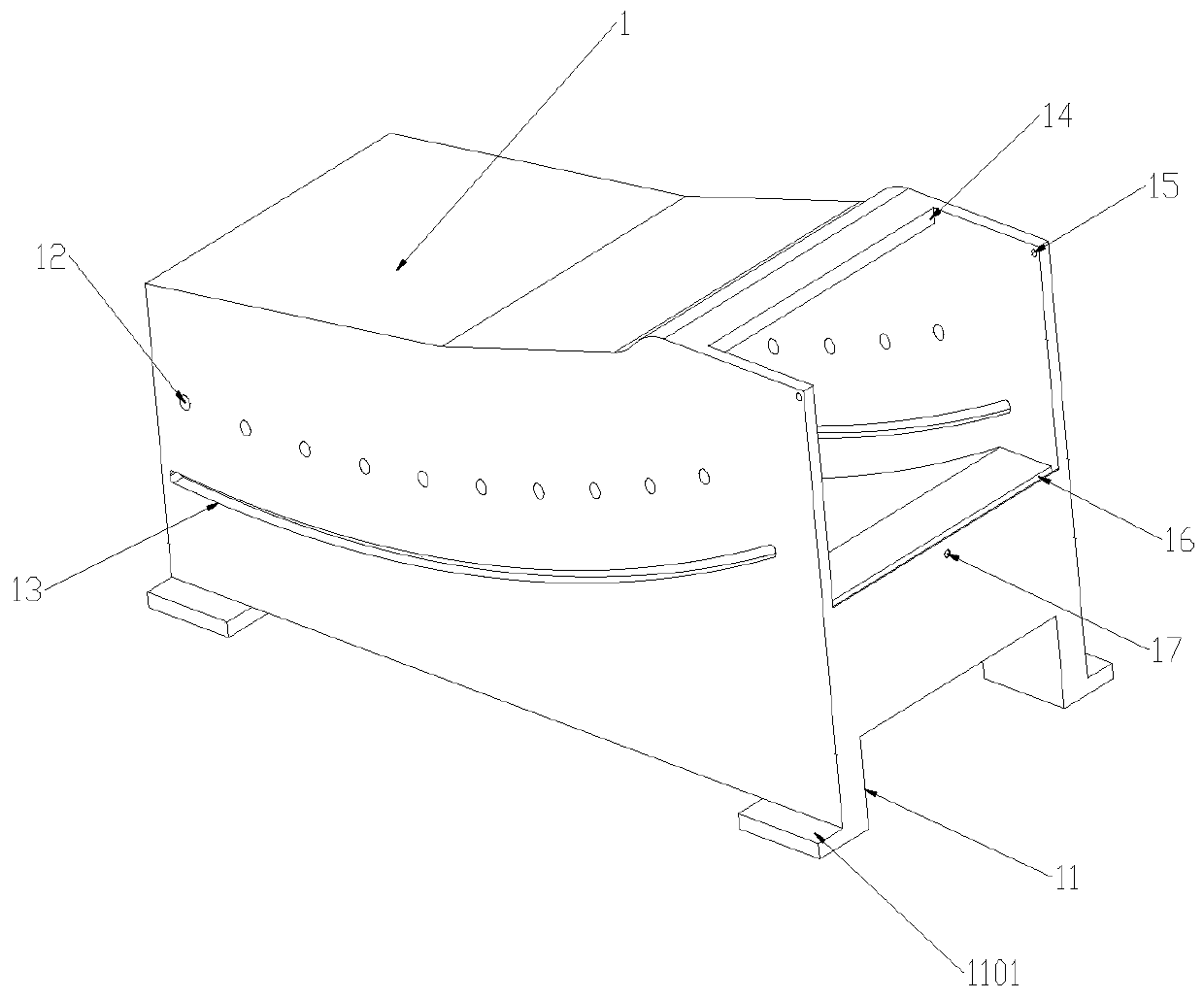

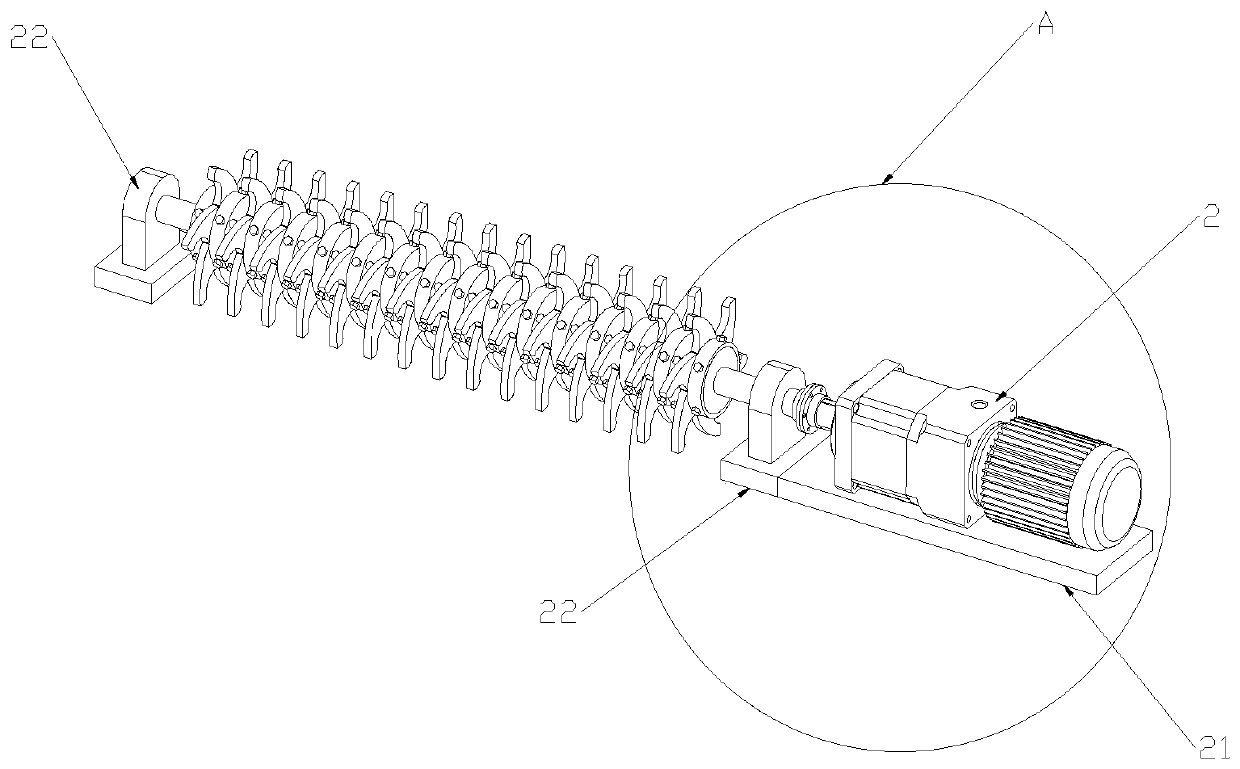

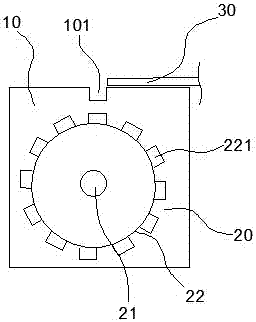

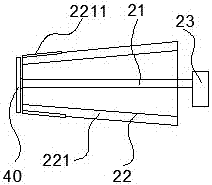

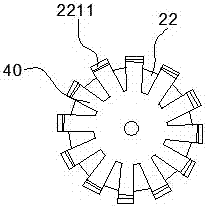

Sinusoidal roller screen structure assembly and intelligent anti-blocking monitoring system thereof

ActiveCN109894347ARealize intelligent detectionSolve the blockageSievingScreeningDrive shaftMonitoring system

The invention discloses a sinusoidal roller screen structure assembly and an intelligent anti-blocking monitoring system thereof. The sinusoidal roller screen structure assembly comprises a roller screen box, wherein the side end of the roller screen box is provided with a speed reducing motor, one end of a driving shaft arranged at an output end of the speed reducing motor is provided with a rotating shaft, a roller body is welded and fixed on the rotating shaft, and screen wheels are fixed on the roller body. First driving mechanisms are arranged on a supporting face board, and a sweeping mechanism is arranged between the first driving mechanisms. A second driving mechanism is arranged at the bottom end of a material blocking plate. The system involves a gravity sensor and a PLC, so thatthe purpose of intelligently detecting materials in a feeding port can be achieved, and the problem of material blockage is solved. According to the sinusoidal roller screen structure assembly, whenthe designed screen wheels are worn after working for a long time, the screen wheels can be quickly replaced, so that the production cost is reduced while the working efficiency is improved; and the sweeping mechanism is arranged, the sweeping mechanism comprises sweeping teeth, when the sweeping teeth rotate, ores adhered to the screen wheels can be swept, the screen wheels in the roller screen box can be cleaned, and the sweeping efficiency is improved.

Owner:HUAIBEI HUAXING GONGMAO

Two-way flipping plate trolley, flipping plate type sorting line and flipping plate type sorting system

The invention discloses a two-way flipping plate trolley, a flipping plate type sorting line and a flipping plate type sorting system. The two-way flipping plate trolley comprises a trolley frame, wherein the bottom portion of the trolley frame is provided with rollers, a flipping plate is pivotally connected above the trolley frame, the connection shaft of the flipping plate and the trolley frameis the symmetry axis of the flipping plate, the flipping plate is maintained horizontally by a position limiting mechanism in a material feeding state, and the flipping plate inclines a certain anglethrough the position limiting mechanism in a material discharge state. According to the present invention, the technical scheme has characteristics of sophisticated design and simple structure; the flipping plate can flip in two directions around the symmetry axis; by arranging the position limiting structure, the flipping plate can be stably maintained at the horizontal state and the inclined state, such that the two-way selective sorting can be effectively achieved; the two-way flipping plate trolley does not require the independent power structure for driving the flipping plate to rotate and the wheel driving structure, such that the whole structure is simplified, and the cost of the equipment is low; and by using the pure mechanical structure, the complicated electrical control structure is not required, such that the production and the maintenance are conveniently performed.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

Waste gas treatment device for municipal environmental protection

ActiveCN111514671AMeet processing needsIncrease the tilt angleDispersed particle filtrationTransportation and packagingEnvironmental engineeringMechanical engineering

The invention discloses a waste gas treatment device for municipal environmental protection, belongs to the technical field of municipal environments, and solves the problem that the waste gas absorption efficiency of the device is not high and the air purification effect is influenced due to the fact that the gas inlet angle of the existing device is inconvenient to adjust. The device is technically characterized in that the device comprises a machine body, a working cavity is formed in the machine body, a filtering cavity is formed in the middle of the working cavity, a filtering assembly used for filtering air is arranged in the filtering cavity, two negative pressure cavities used for pressurization are symmetrically formed in the two sides of the filtering cavity, the filtering cavityis communicated with the negative pressure cavities through flow guide pipes, a pressurization assembly is arranged in each negative pressure cavity, and two gas inlet assemblies are symmetrically arranged on the two sides of the machine body. According to the embodiment of the invention, the inclination angle of the gas inlet assembly can be adjusted, so that the requirement on waste gas treatment is met, the treatment efficiency and the inclination angle are increased, the contact area of a filter screen and gas is increased, and the purification efficiency is improved.

Owner:广东省第十一建设有限公司

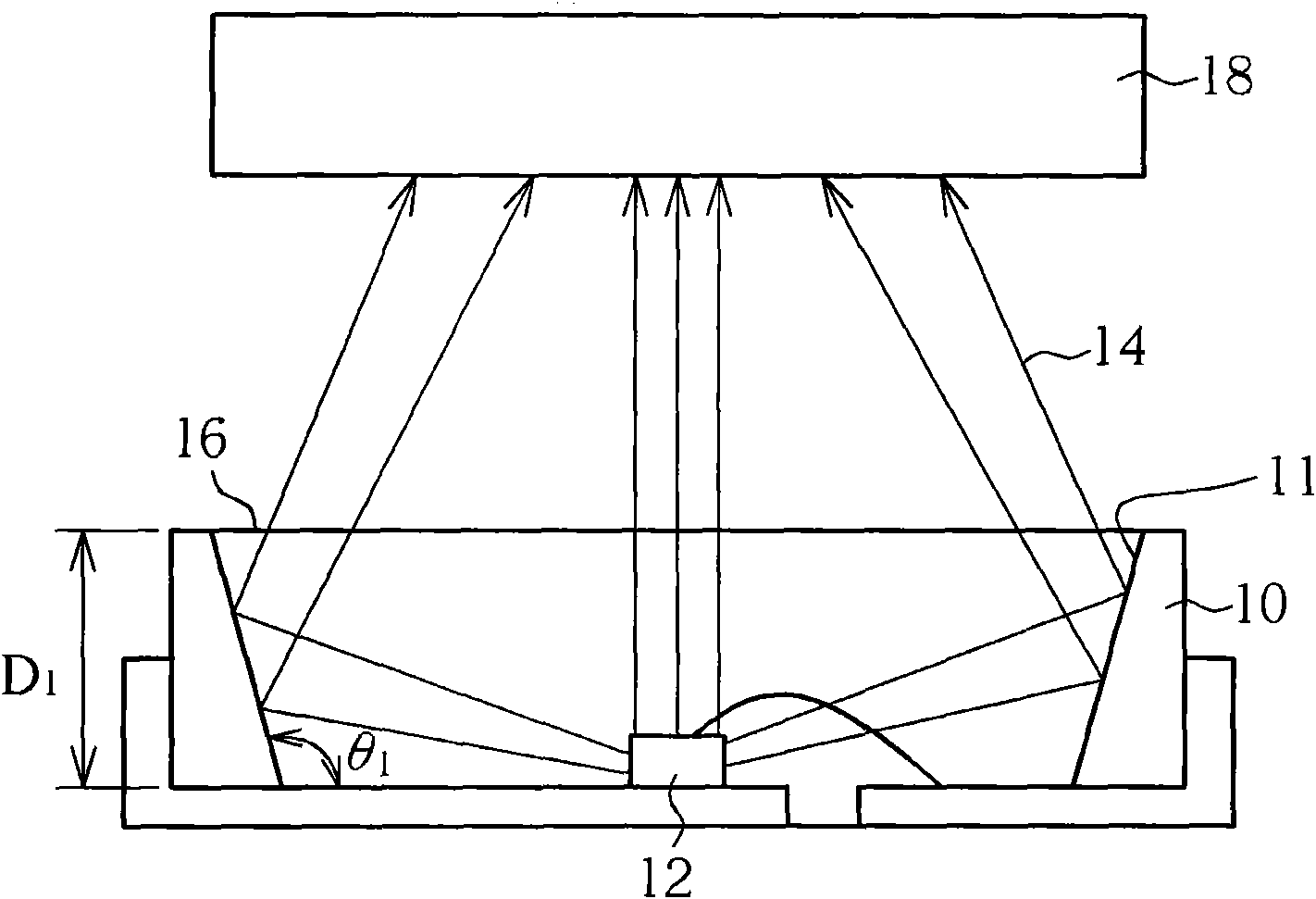

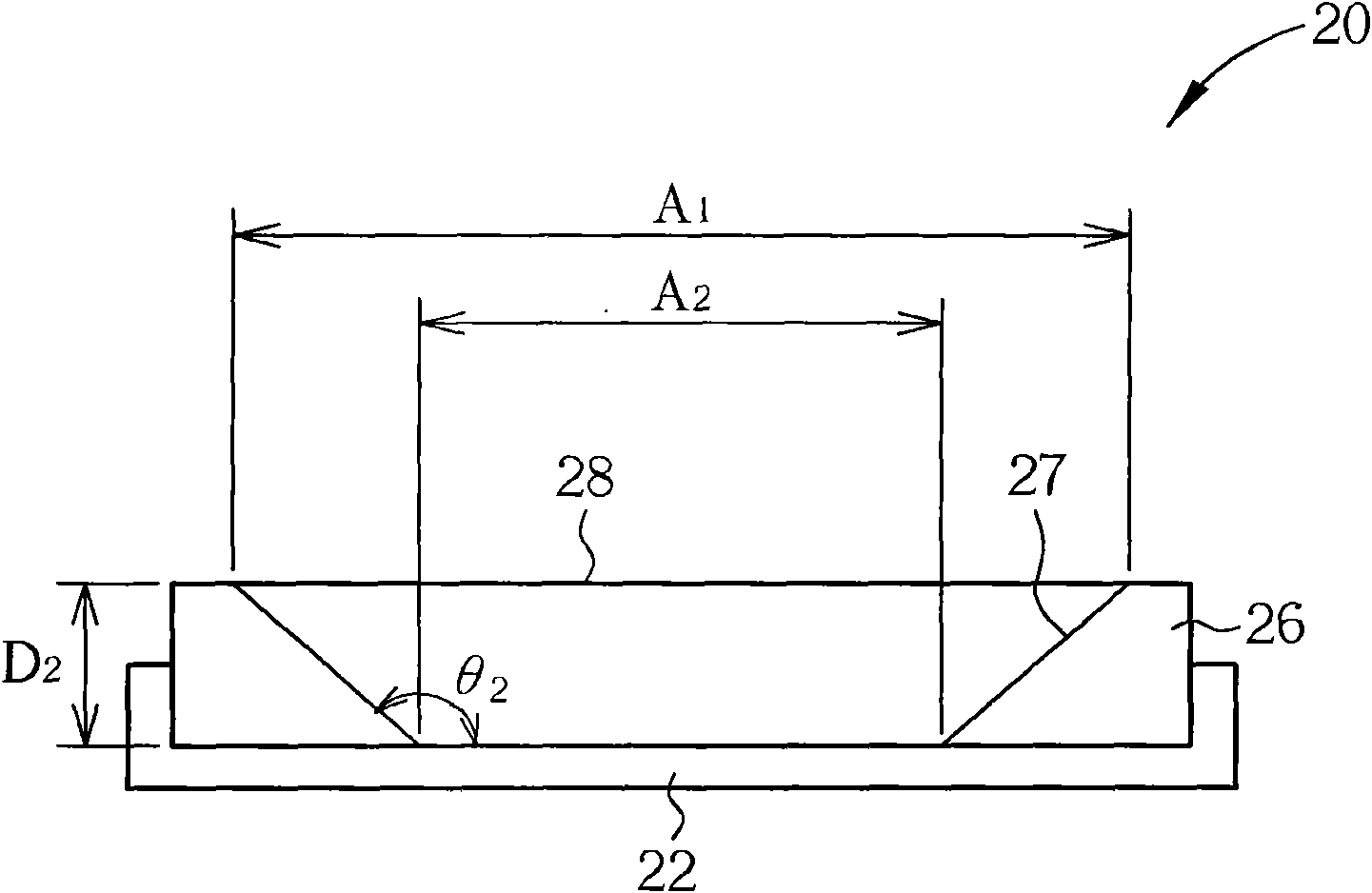

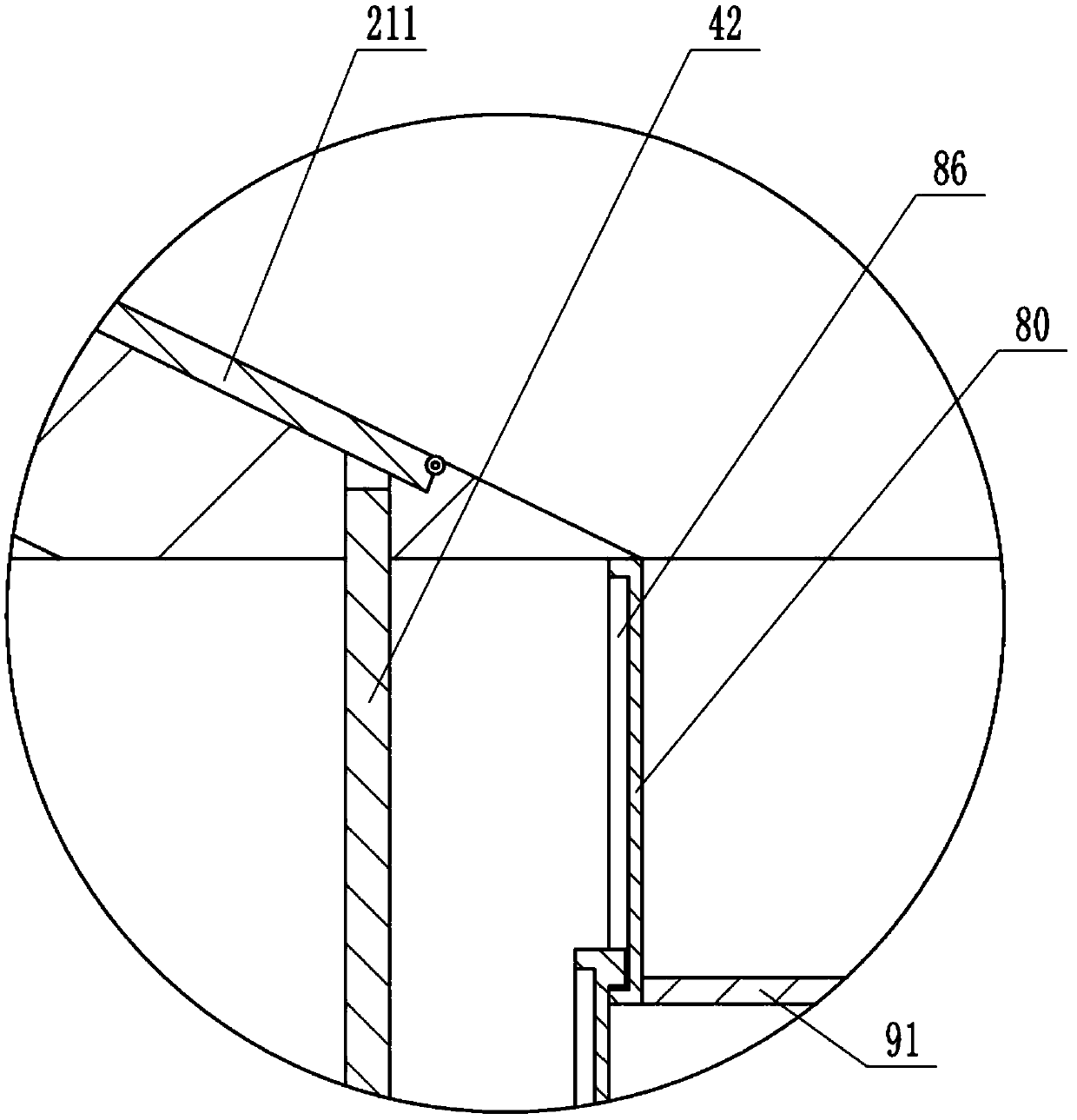

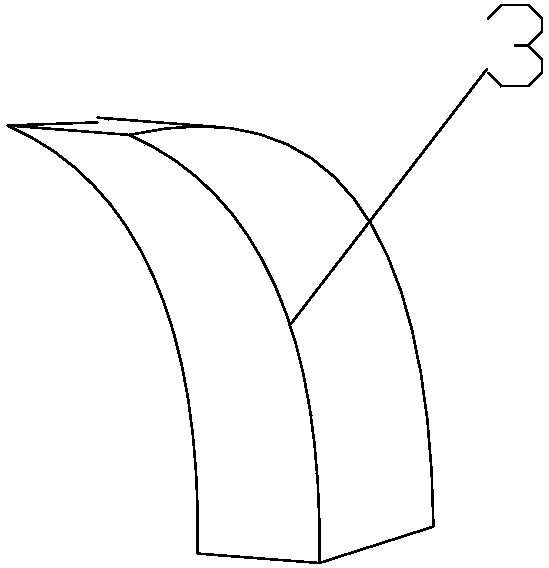

Packaging shell and packaging structure of edge type light emitting component

InactiveCN102054828AIncrease the tilt angleReduce refractionSemiconductor laser arrangementsSolid-state devicesEngineering

The invention discloses a packaging structure of an edge type light emitting component, comprising a shell and a light emitting component, wherein the cup shell of the shell is inclined outwards so that the side wall and a base form an included angle of 140-150 DEG; the cup shell is provided with a depth vertical to the base, and the depth ranges from 0.25mm to 0.3mm; and the cup rim of the cup shell is an emergent surface of which the area is 1.5-2 times that of the base.

Owner:ZHANJING TECH SHENZHEN +1

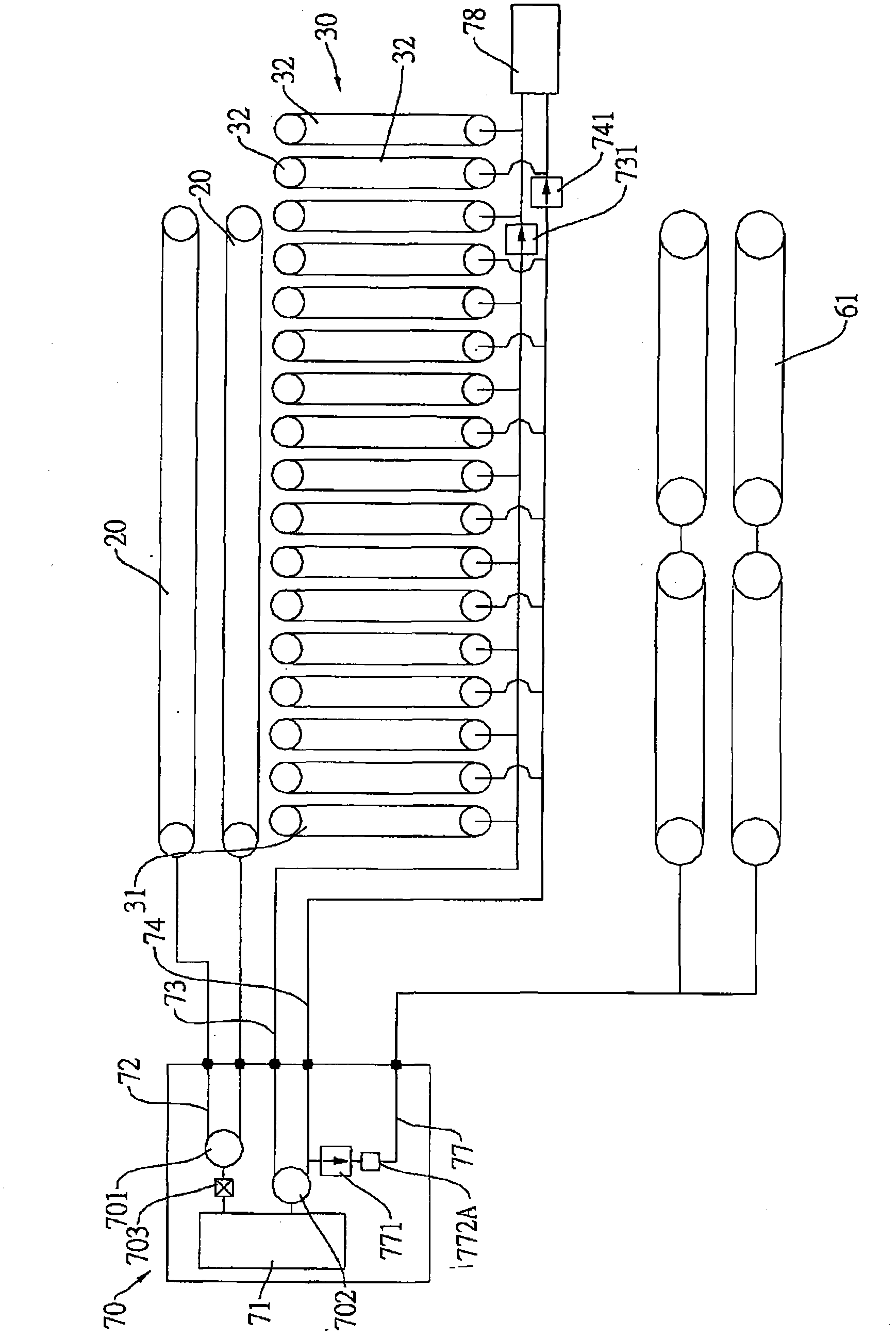

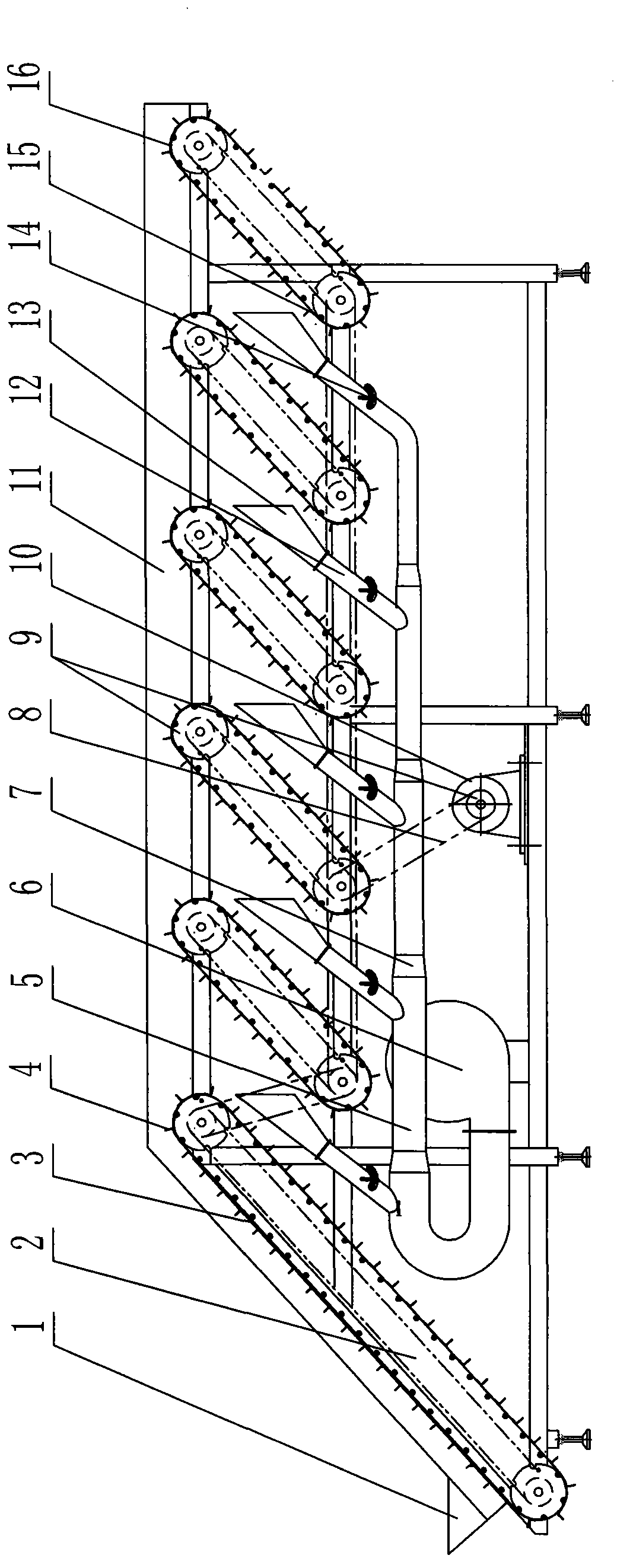

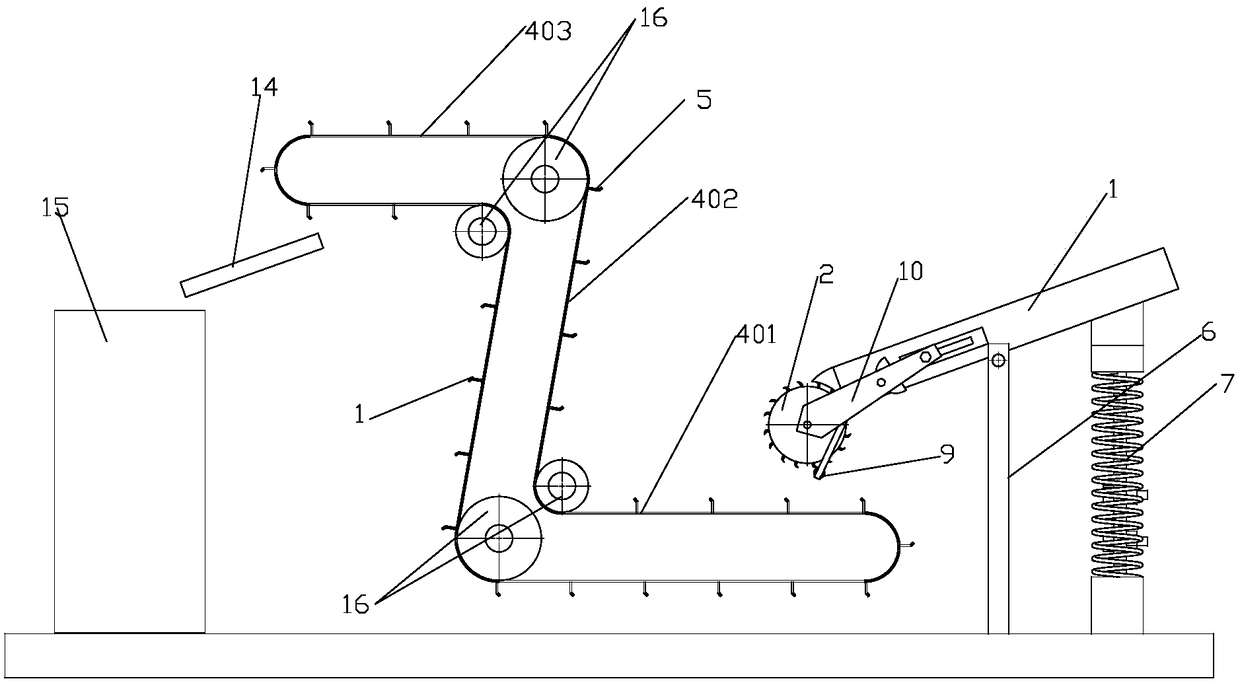

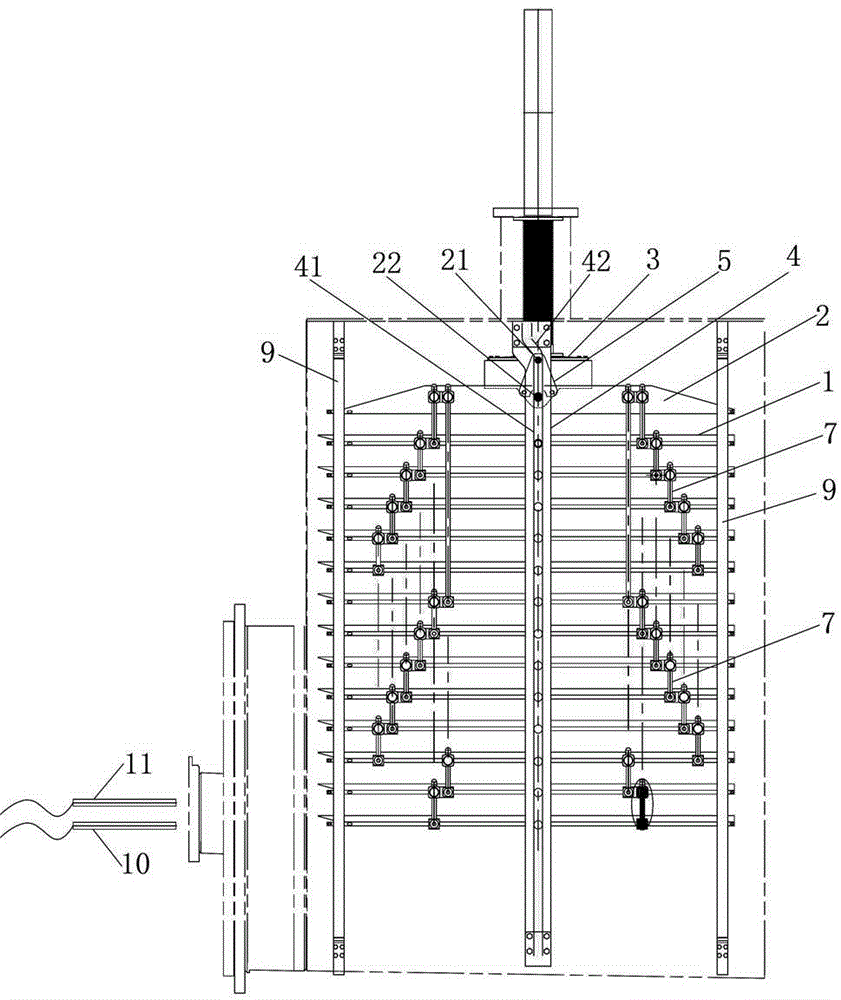

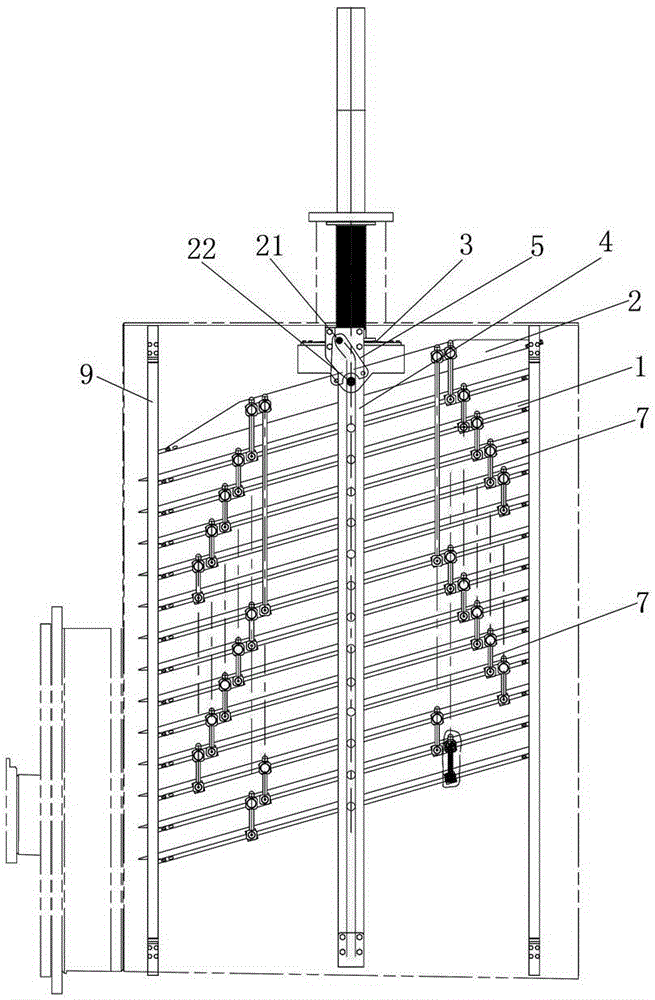

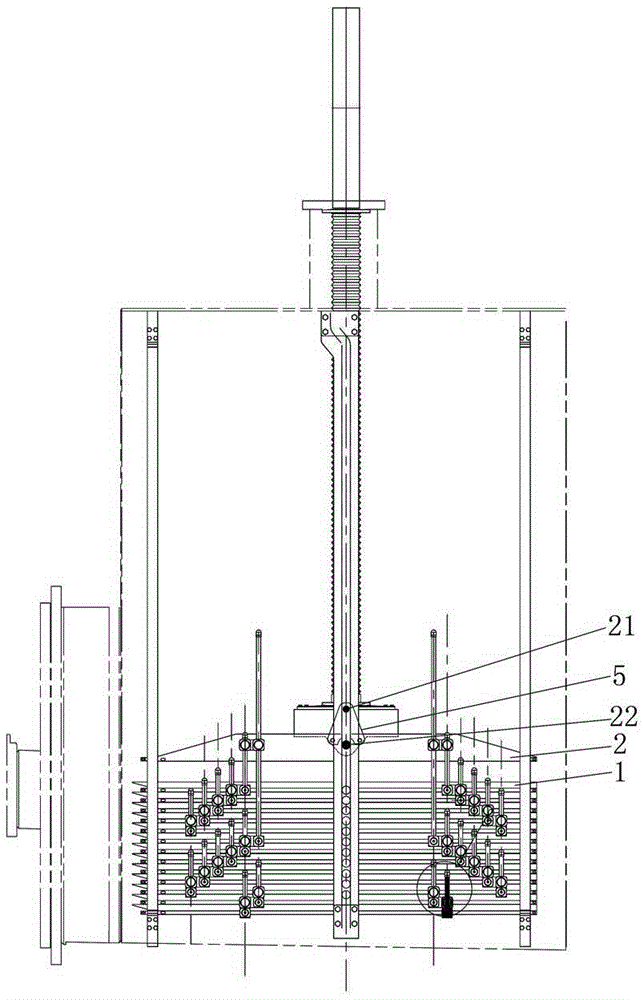

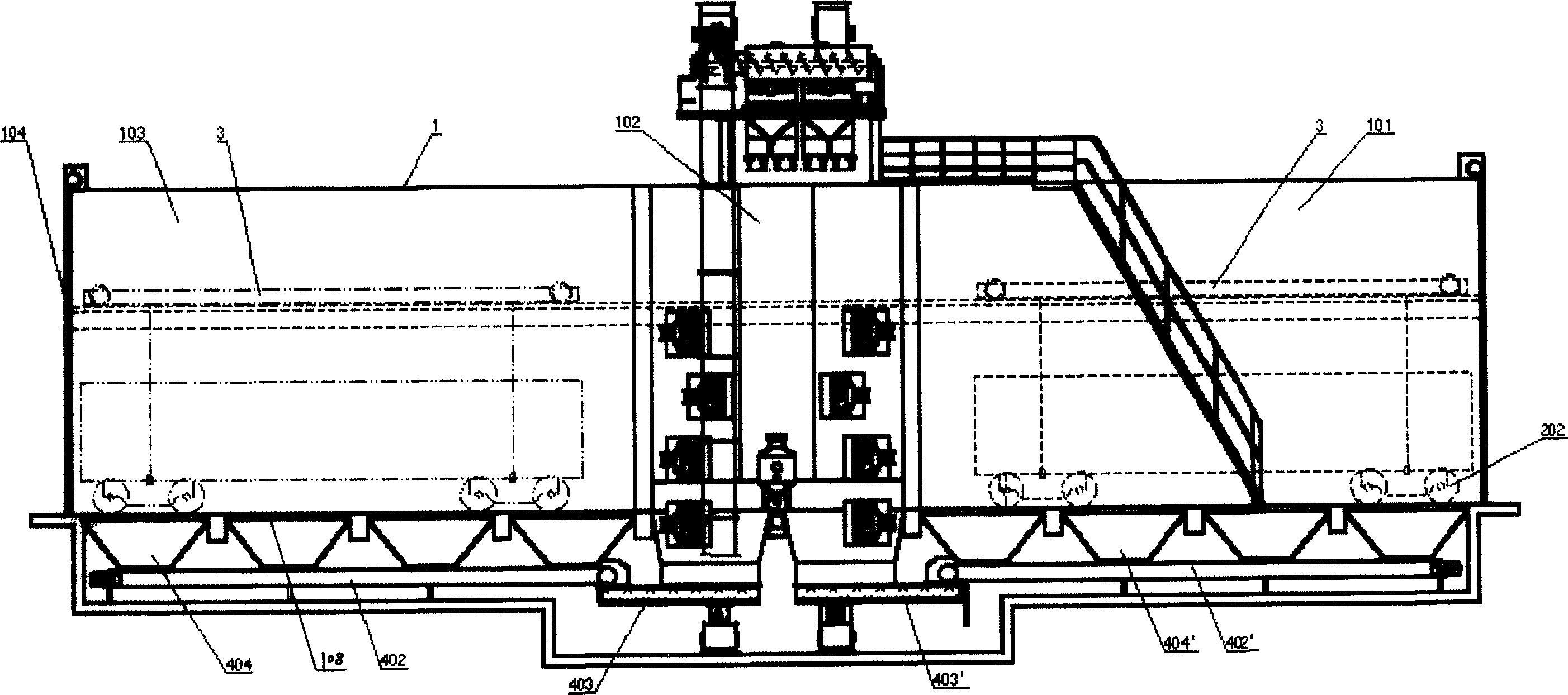

Automatic stillage air-drying machine

InactiveCN103255017AGood total power consumptionSmall total power consumptionAlcoholic beverage preparationSmall footprintSprocket

The invention relates to an automatic stillage air-drying machine, and aims to provide an automatic stillage air-drying machine which is low in energy consumption, high in cooling efficiency, small in occupied area and convenient to use, can promote fermentation and cannot be cleaned. The automatic stillage air-drying machine comprises a stander, inclined conveyers arranged on the stander, an air supply device and a driving motor, wherein the driving motor is connected with the inclined conveyers through chain wheels and chains. The structural key point is that a plurality of inclined conveyers are arranged; and the material feeding end of the back inclined conveyer is arranged below the material discharging end of the front inclined conveyer.

Owner:黄先全

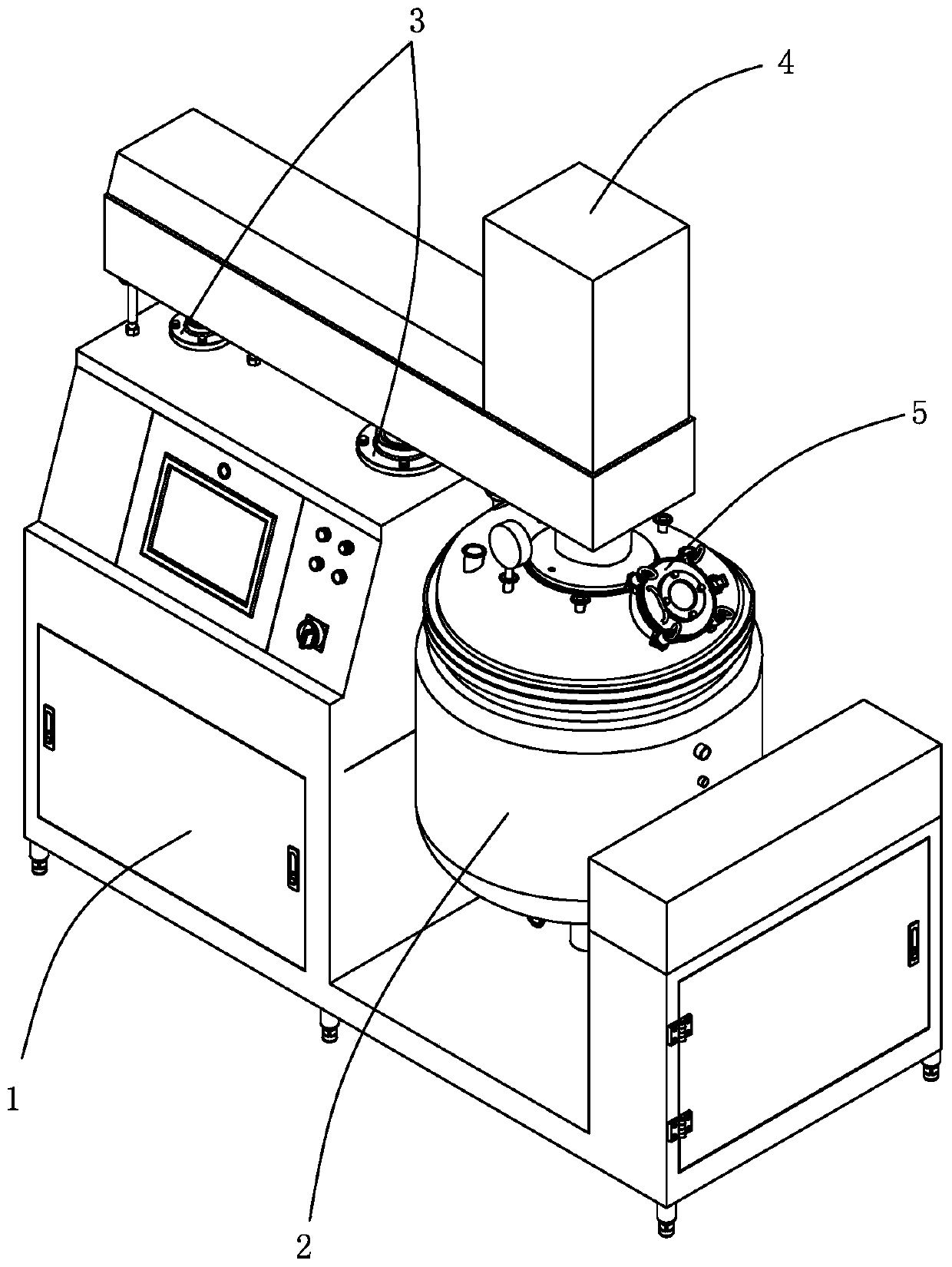

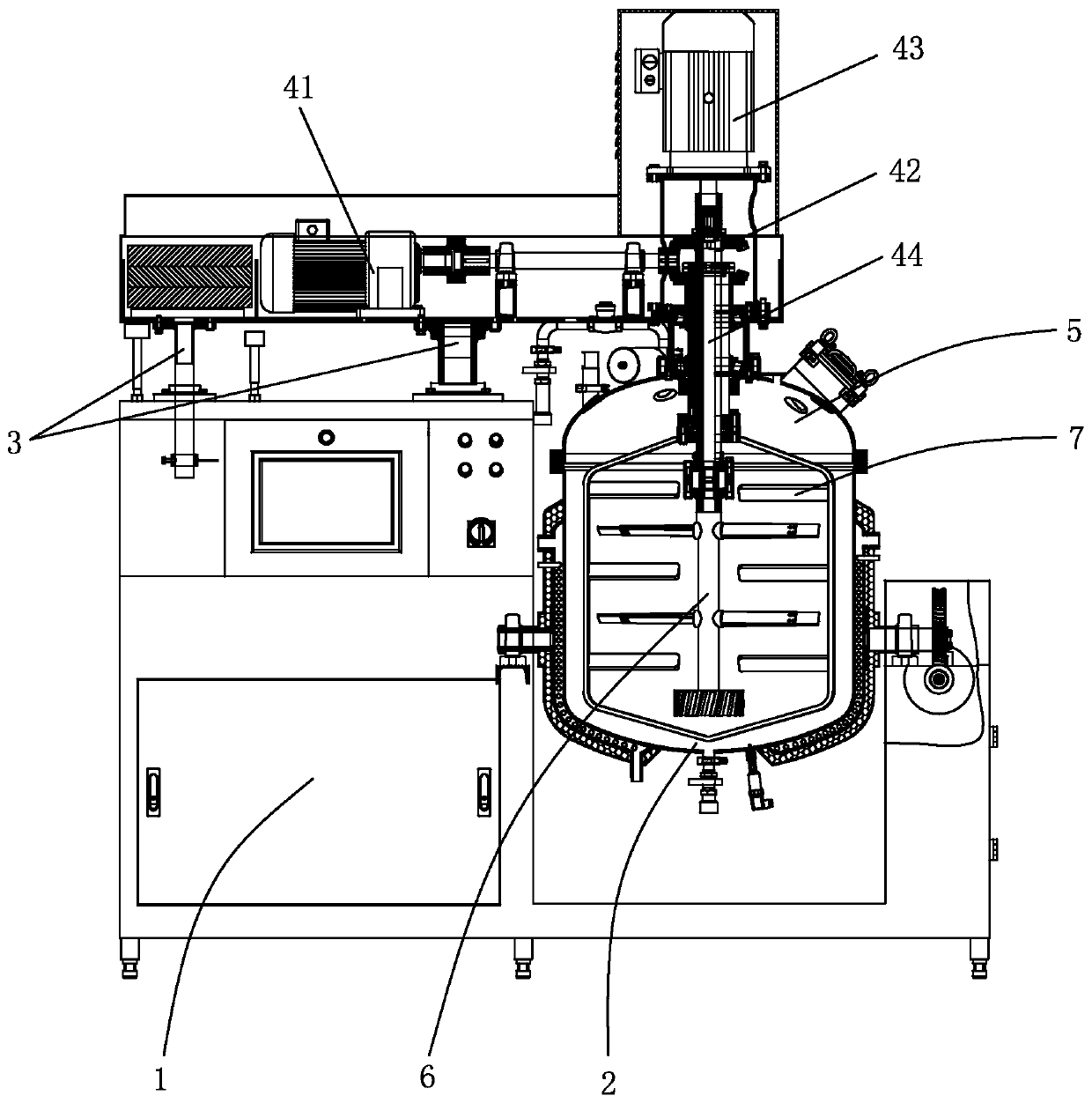

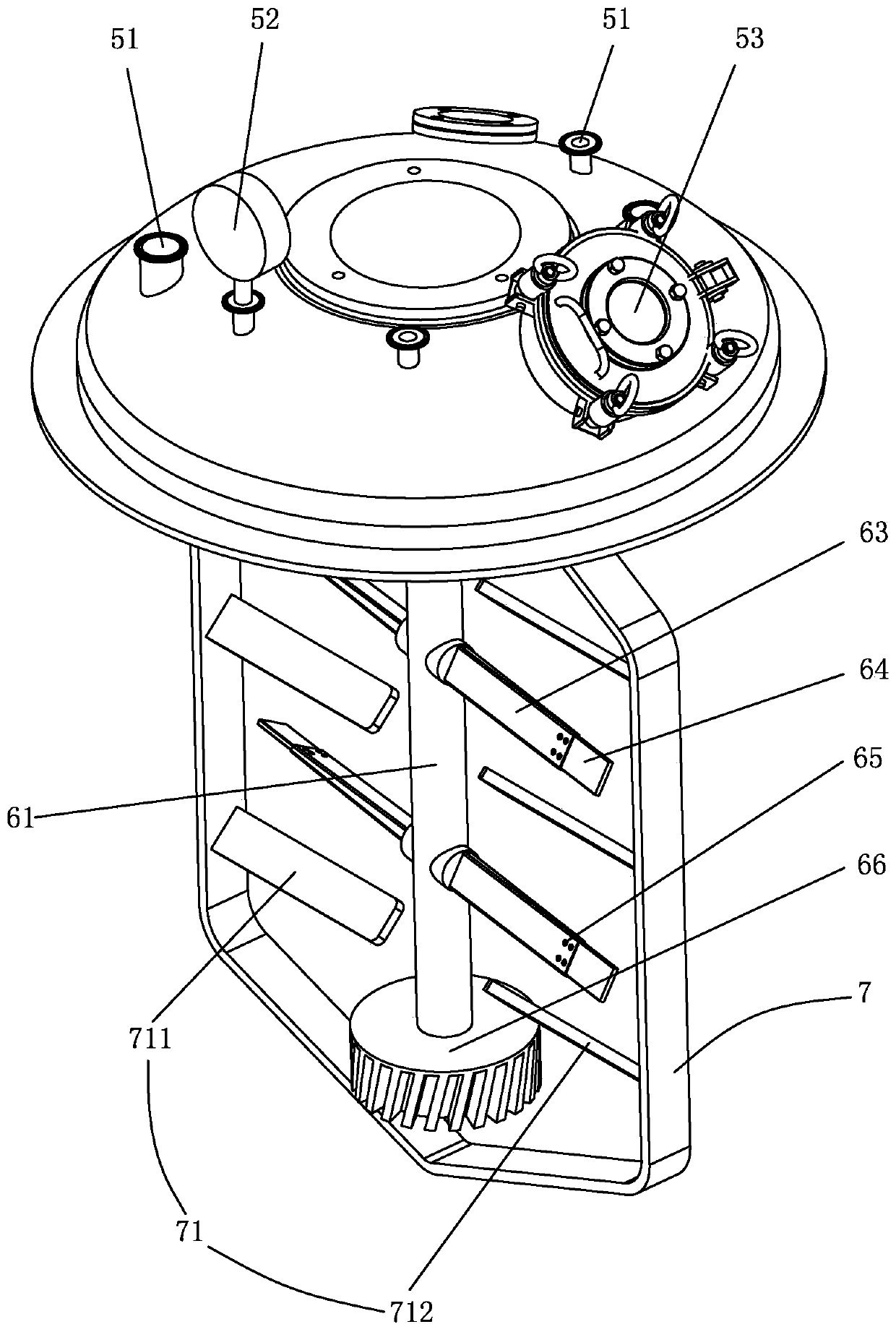

Emulsifying equipment with adjustable stirring blades

PendingCN109847605ALarge Stirring AngleReduce starting loadMixing methodsTransportation and packagingLocking mechanismHigh-speed grinding

The application discloses emulsifying equipment with adjustable stirring blades. The emulsifying equipment comprises a machine frame, an emulsifying tank, a lifting driving group, a rotating driving group, an emulsifying tank cover and an adjustable rotating group, wherein the adjustable rotating group comprises a connecting stirring shaft, an angle adjusting driving component, mother-stirring blades, sub-stirring blades, locking mechanisms and a high-speed grinding working head. According to the equipment, the emulsifying tank cover is driven to move downward to cover the emulsifying tank bythe rotating driving group driven by the lifting driving group, and then the adjustable rotating group is driven to rotate to perform the stirring and emulsifying work by the rotating driving group. Aiming at an emulsified material with the high viscosity, the mother-stirring blades are driven to rotate to increase the inclination angle by the angle adjusting driving component, so that the mother-stirring blades have relatively large stirring cutting-in angles to facilitate the initial stirring of the emulsified material, and the service life of the rotating driving group is improved. When different emulsifying tanks need to be replaced, the telescopic length of the sub-stirring blades can be adjusted to meet use needs of different sizes, so that the practicability, applicability and flexibility are improved.

Owner:中山翰华锡业有限公司

Slag discharge structure of secondary combustor

The invention belongs to the technical field of incinerator supporting equipment and particularly discloses a slag discharge structure of a secondary combustor. The slag discharge structure comprisesa melting unit arranged at the lower end of the secondary combustor; the melting unit includes an insulation base and a melting chamber arranged in the insulation base; a combustion mechanism to meltslag is arranged in the melting chamber; a slag discharge mechanism is connected to the lower end of the melting chamber. The the slag discharge structure herein helps effectively remove the slag generated during operating of the secondary combustor; slag discharging is convenient and reliable; the existing application needs can be effectively met.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

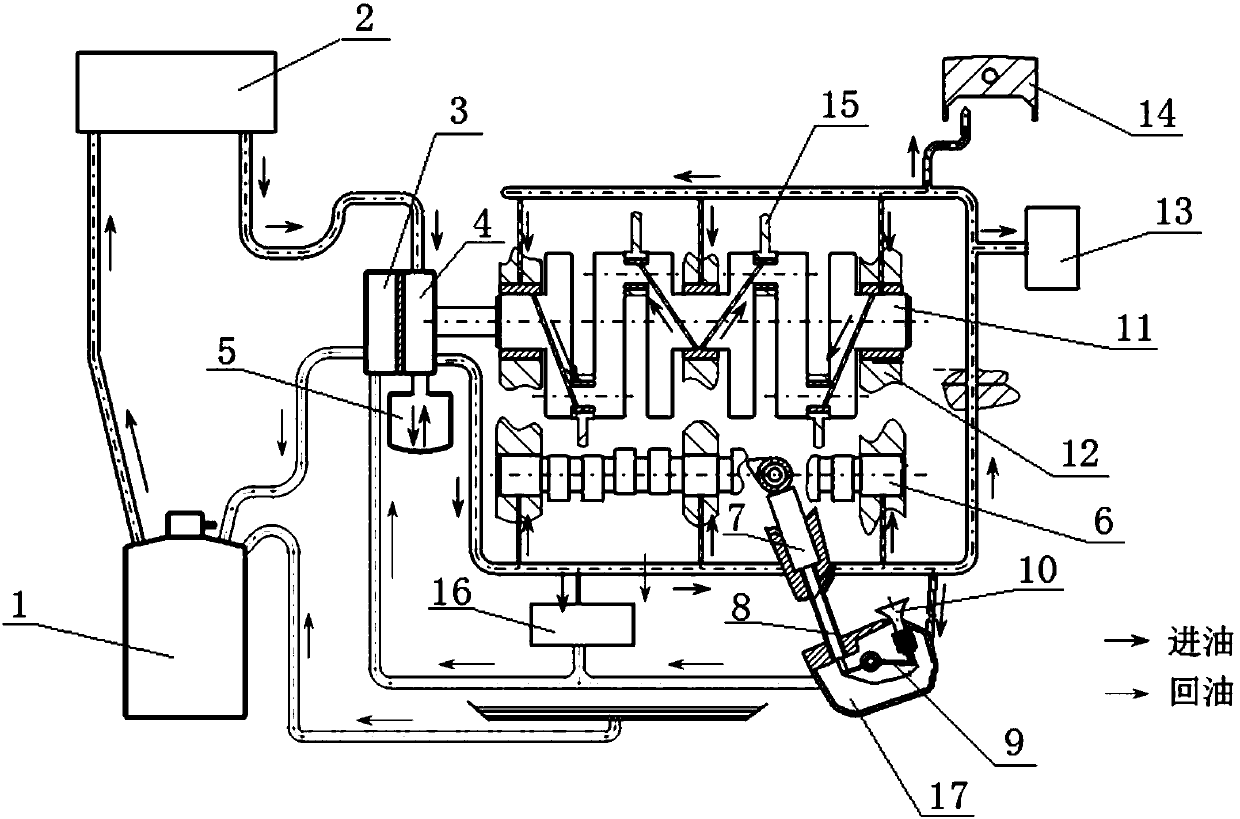

Engine lubricating system and engine

PendingCN107559063AReduce weightSimple structureMachines/enginesLubricant mounting/connectionFuel tankDry sump

The invention discloses an engine lubricating system and an engine. The engine lubricating system comprises two parts, namely oil suction part and oil return part; the oil suction part comprises a lubricating oil tank, an air cooling oil cooler and a main oil pump which are connected in sequence, the main oil pump sucks the lubricating oil in the lubricating oil tank into the air cooling oil cooler to be cooled under the driving of a crankshaft, and the cooled lubricating oil enters the main oil passage under the action of the main oil pump; the oil return part comprises two parts, the first part is as follow: the lubricating oil entering a piston cooling nozzle, a main bearing, a camshaft bearing and an accessory system flows back to a dry-type oil sump under the action of gravity, and the lubricating flowing back to the dry-type oil sump is pressed back to the lubricating oil tank under the action of the air pressure of a crankcase; and the second part is as follow: the lubricating oil entering a supercharger and a valve cover of the air valve is sucked back to the lubricating oil tank under the action of an oil return pump and through an external oil return pipe. According to the engine lubricating system and the engine, the oil can be directly taken out from the lubricating oil tank by a lubricating oil pump, the situation that the oil cannot be sucked is avoided, limitation on the flying angle of a aircraft is small, the aircraft can do more actions, and flight performance is improved.

Owner:芜湖钻石航空发动机有限公司

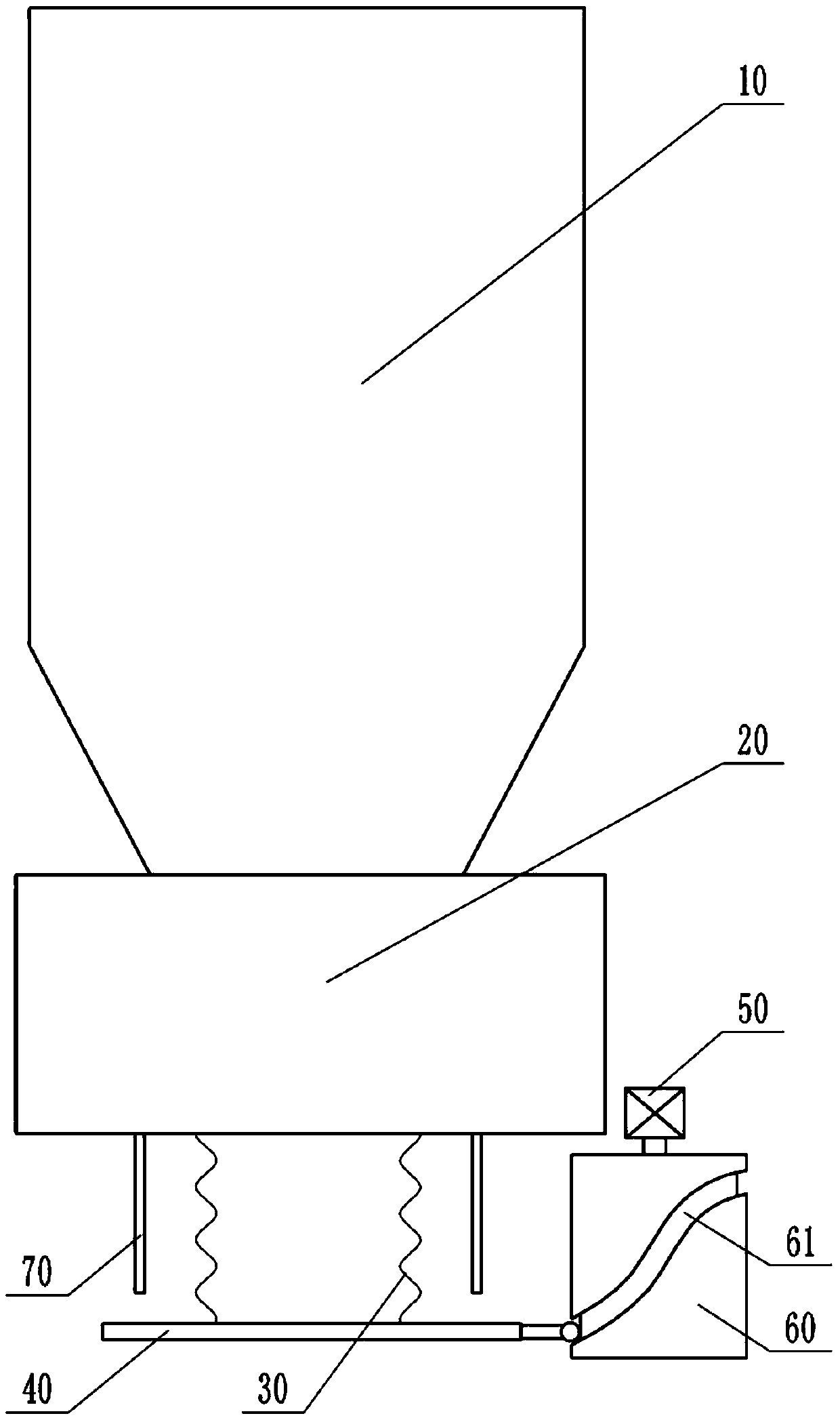

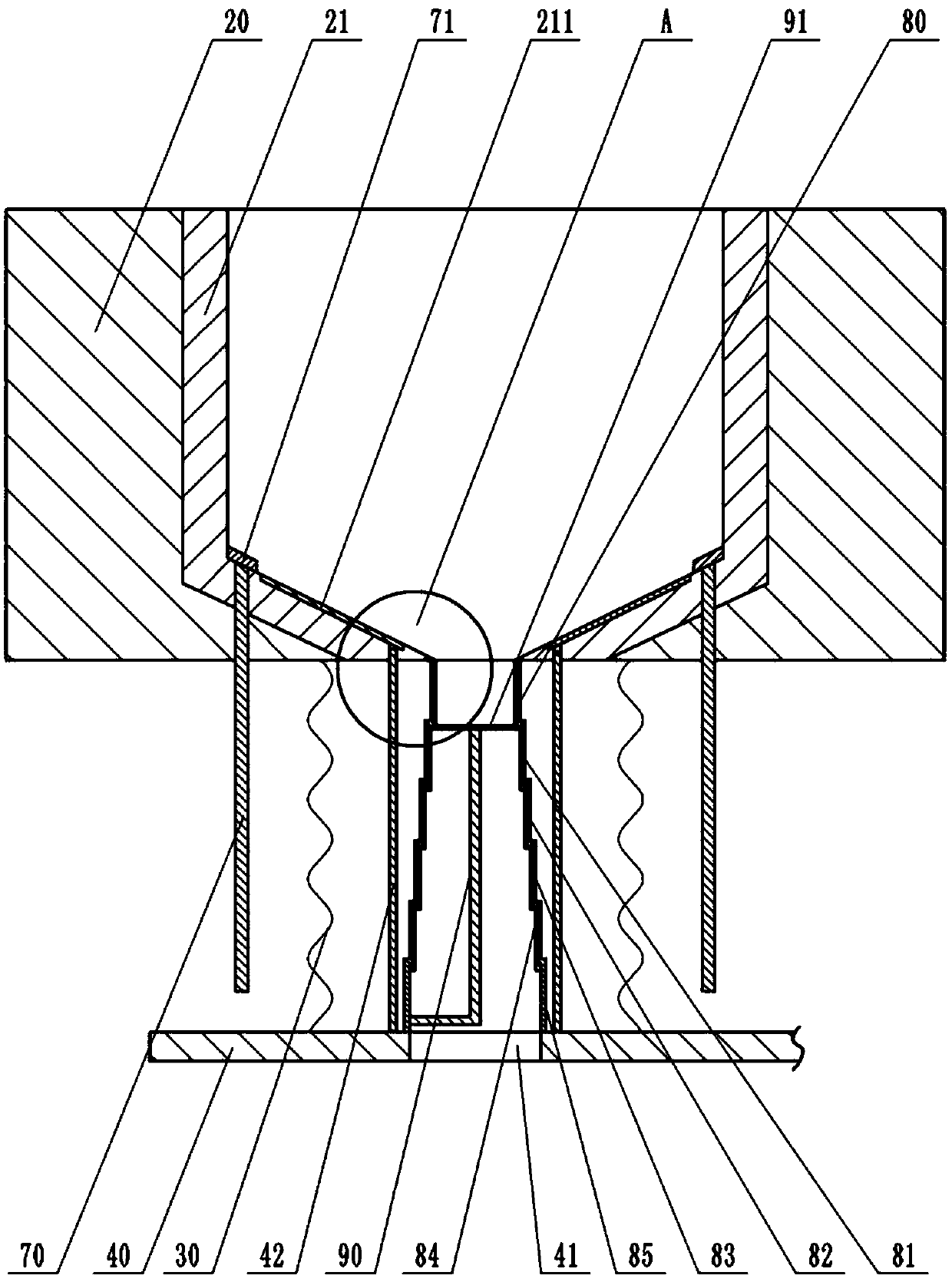

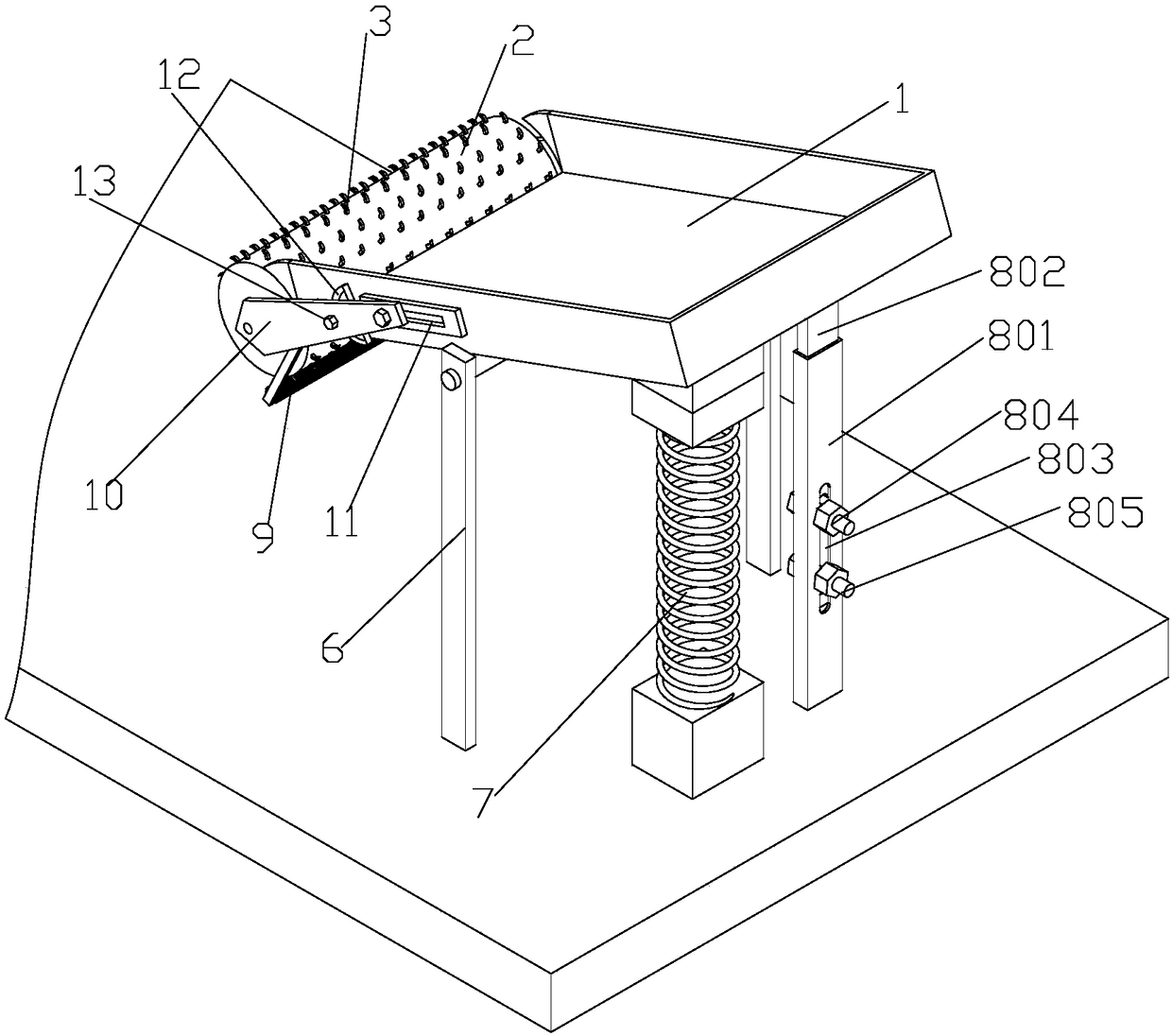

Refining and feeding device

ActiveCN108529266AUniform materialReduce distractions and injuriesConveyorsLoading/unloadingJoint actionMaterial distribution

The invention discloses a refining and feeding device. The refining and feeding device comprises a hopper and a conveying device, and a hopper rotating frame is arranged below the hopper. A roller isarranged on the front lower part of a discharge hole of the hopper, and a set of material combing teeth are arranged on the roller. An elastic support and a hopper overturn limiting structure are arranged at the end, away from the discharge hole, of the hopper. The conveying device at least includes a first horizontal conveying section located below the roller, a lifting section which is connectedwith the first horizontal conveying section in an engagement mode, and a second horizontal conveying section located after the lifting section, and the lifting section is inclined and arranged at anacute angle relative to the first horizontal conveying section. The refining and feeding device has a simple structure, skillfully utilizes the joint action of the hopper, the roller and various typesof comb teeth disposed on the roller for refining, and further refines materials by using the lifting section of the conveying device, so that the material distribution is more uniform, and the refining and feeding device can be widely used in the fields of tea processing and feeding and refining processing of agricultural and sideline products and other materials.

Owner:刘才林

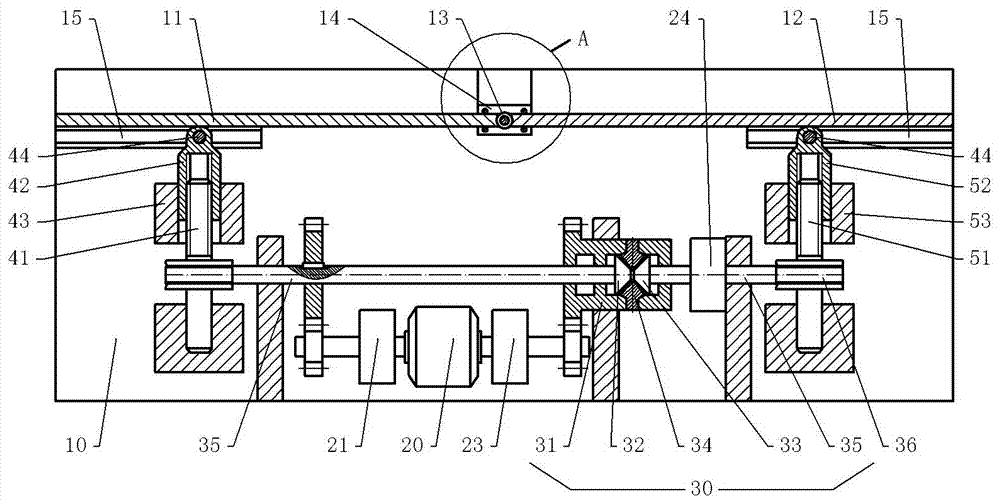

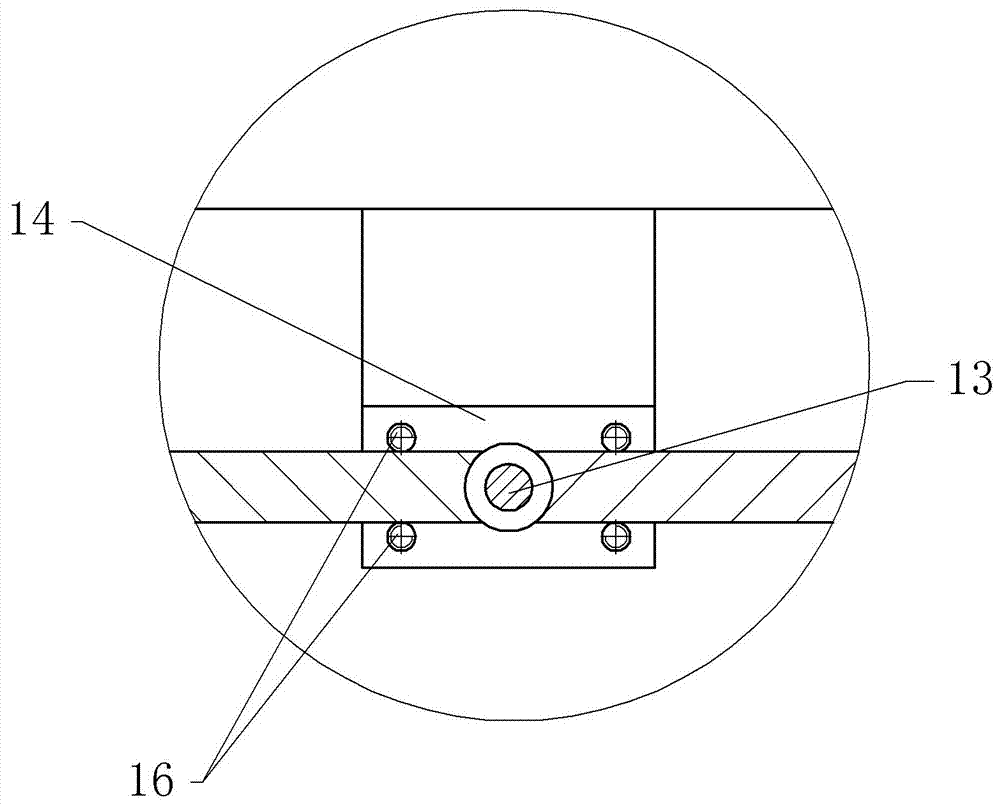

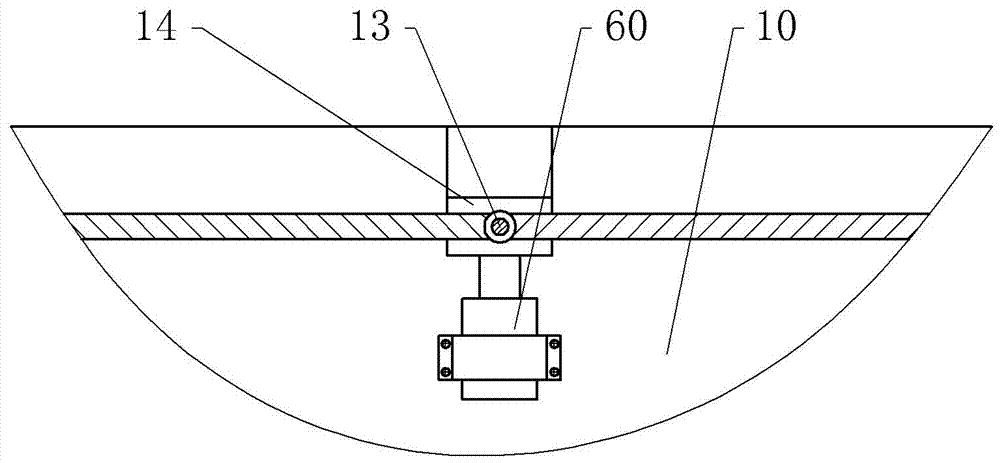

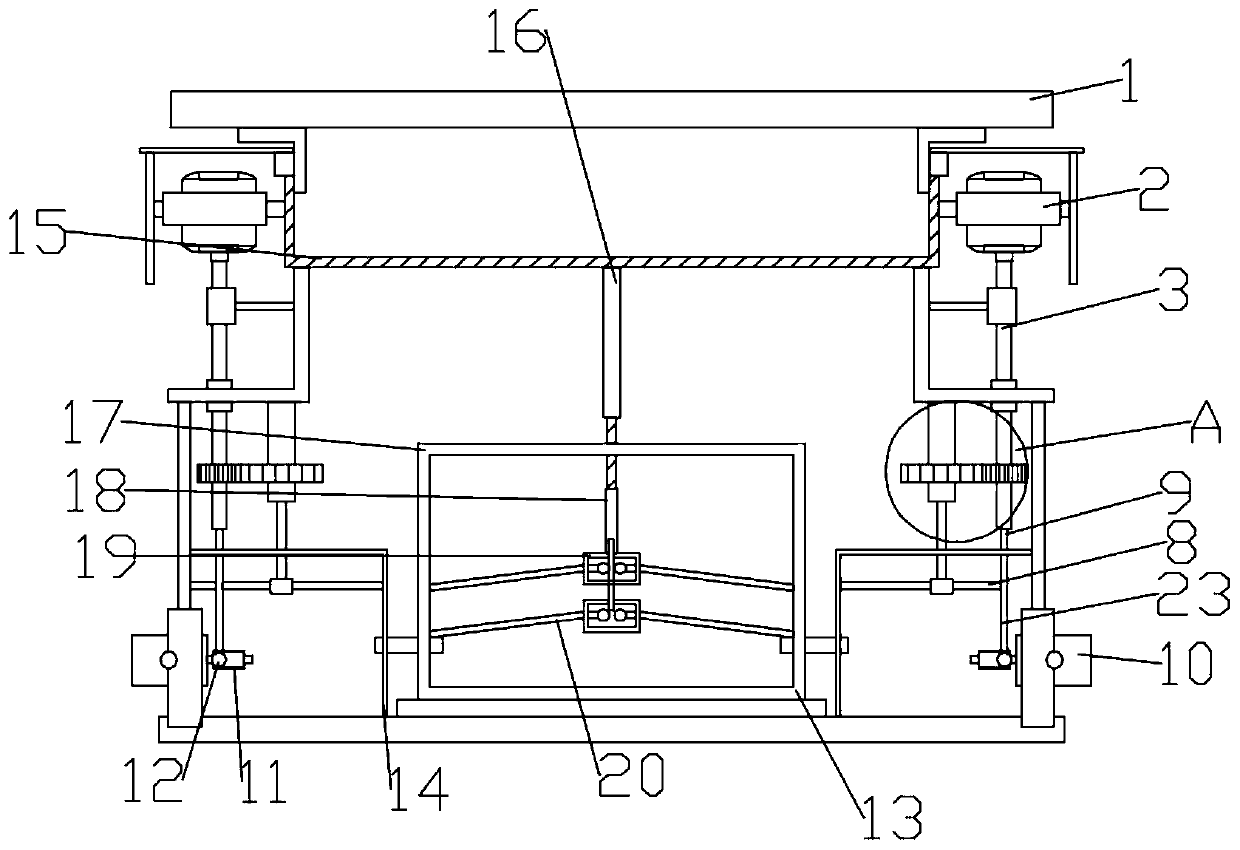

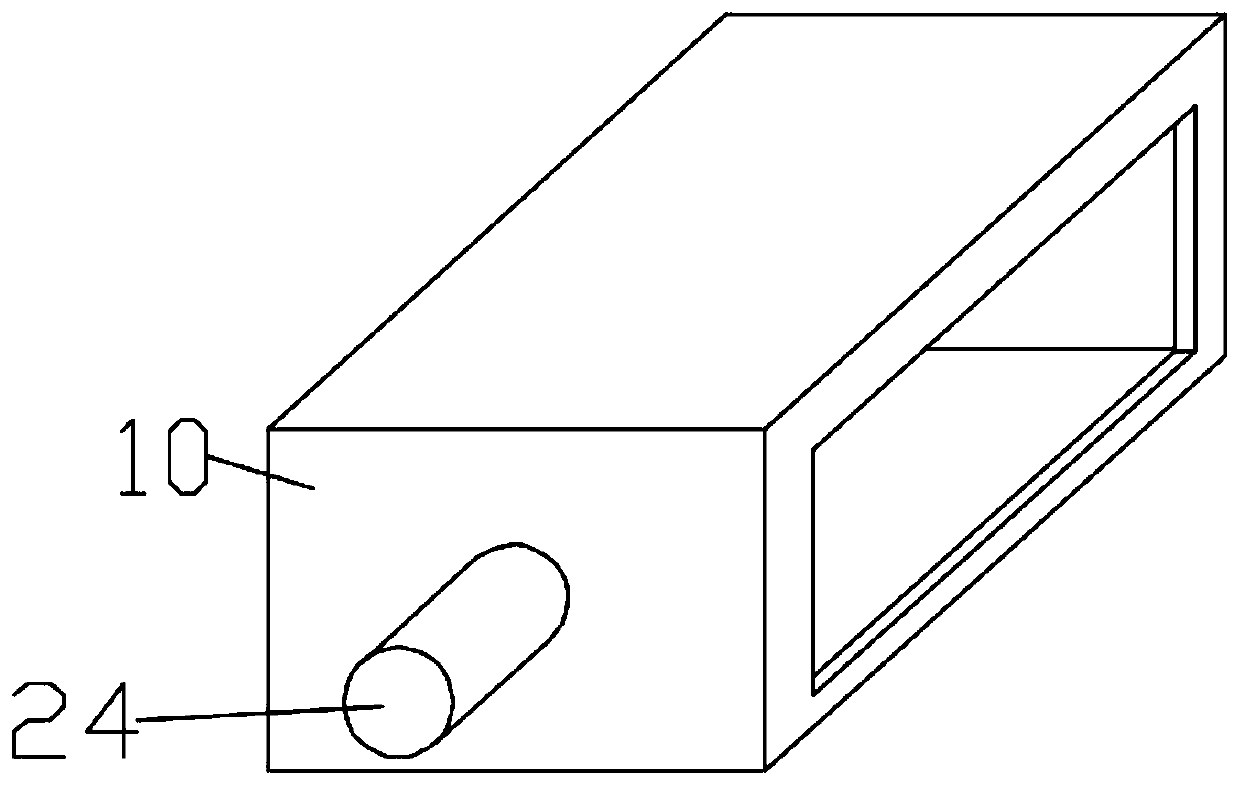

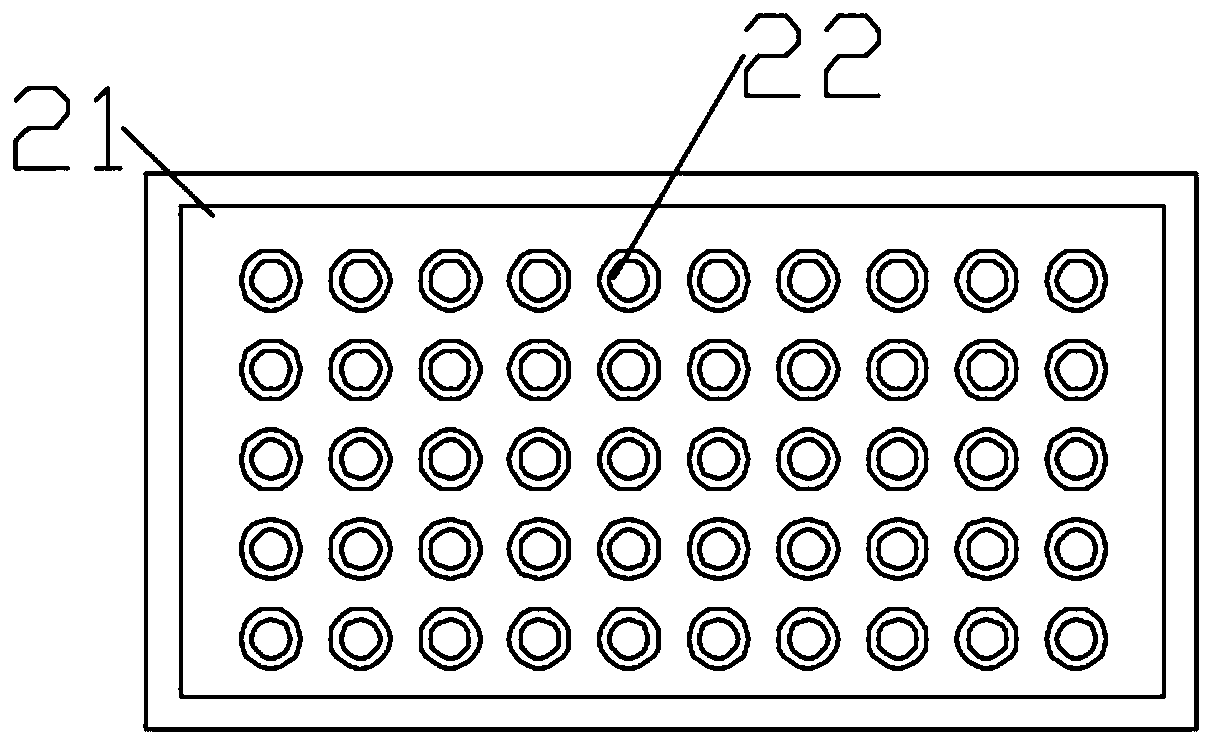

Freeze dryer with liftable and inclinable board layers

ActiveCN105258459AReduce friction pointsReduce the risk of contaminationDrying solid materials without heatFreeze-dryingEngineering

The invention discloses a freeze dryer with liftable and inclinable board layers. The freeze dryer comprises a driving piece, the additional board layer and the multiple freeze-drying board layers. The multiple freeze-drying board layers are connected to the lower portion of the additional board layer and keep synchronous linkage along with movement of the additional board layer. A guide piece and a connecting piece are arranged on the additional board layer, and the driving piece is hinged to the additional board layer through the connecting piece and drives the additional board layer to be lifted. A restraining piece is arranged on at least one side of the additional board layer, and the restraining piece is provided with vertical guide sections and a slant guide section, wherein the vertical guide sections are used for guiding the guide piece and the connecting piece to lift the additional board layer, and the slant guide section is used for guiding the guide piece to overturn the additional board layer. The freeze dryer with the liftable and inclinable board layers has the beneficial effects that the structure is simple, the water inclined pouring efficiency is high, and the pollution risk is greatly reduced.

Owner:TRUKING TECH LTD

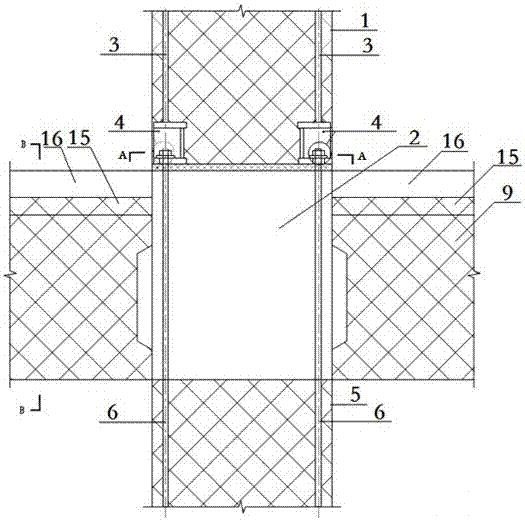

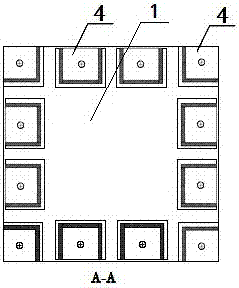

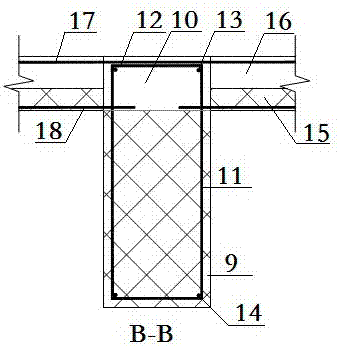

Prefabricated column connecting structure

PendingCN107288217AQuality control High production efficiencyIncrease the tilt angleBuilding constructionsAgricultural engineeringSteel bar

A prefabricated column connecting structure comprises an upper prefabricated column, a lower prefabricated column and a beam-column cast-in-situ connecting joint, wherein the upper end and the lower end of the beam-column cast-in-situ connecting joint are connected with the bottom face of the upper prefabricated column and the top face of the lower prefabricated column correspondingly. An upper prefabricated column connecting steel bar and a steel bar connecting box are pre-embedded in the upper prefabricated column. The bottom end of the upper prefabricated column connecting steel bar is connected and fixed to the steel bar connecting box. A lower prefabricated column connecting steel bar is pre-embedded in the lower prefabricated column. After the upper portion of the lower prefabricated column connecting steel bar stretches out from the top face of the lower prefabricated column to penetrate through the beam-column cast-in-situ connecting joint, the top end of the lower prefabricated column connecting steel bar is fixedly connected with the steel bar connecting box pre-embedded in the upper prefabricated column. The prefabricated columns are prefabricated in a factory, produced in a standardized mode, controllable in quality, free of environment pollution and high in production speed, the upper and lower prefabricated column connecting steel bars are connected easily in a butting mode, the construction efficiency is high, and structural strength is good.

Owner:CHANGSHA HOME BROAD HOMES IND JIANGSU CO LTD

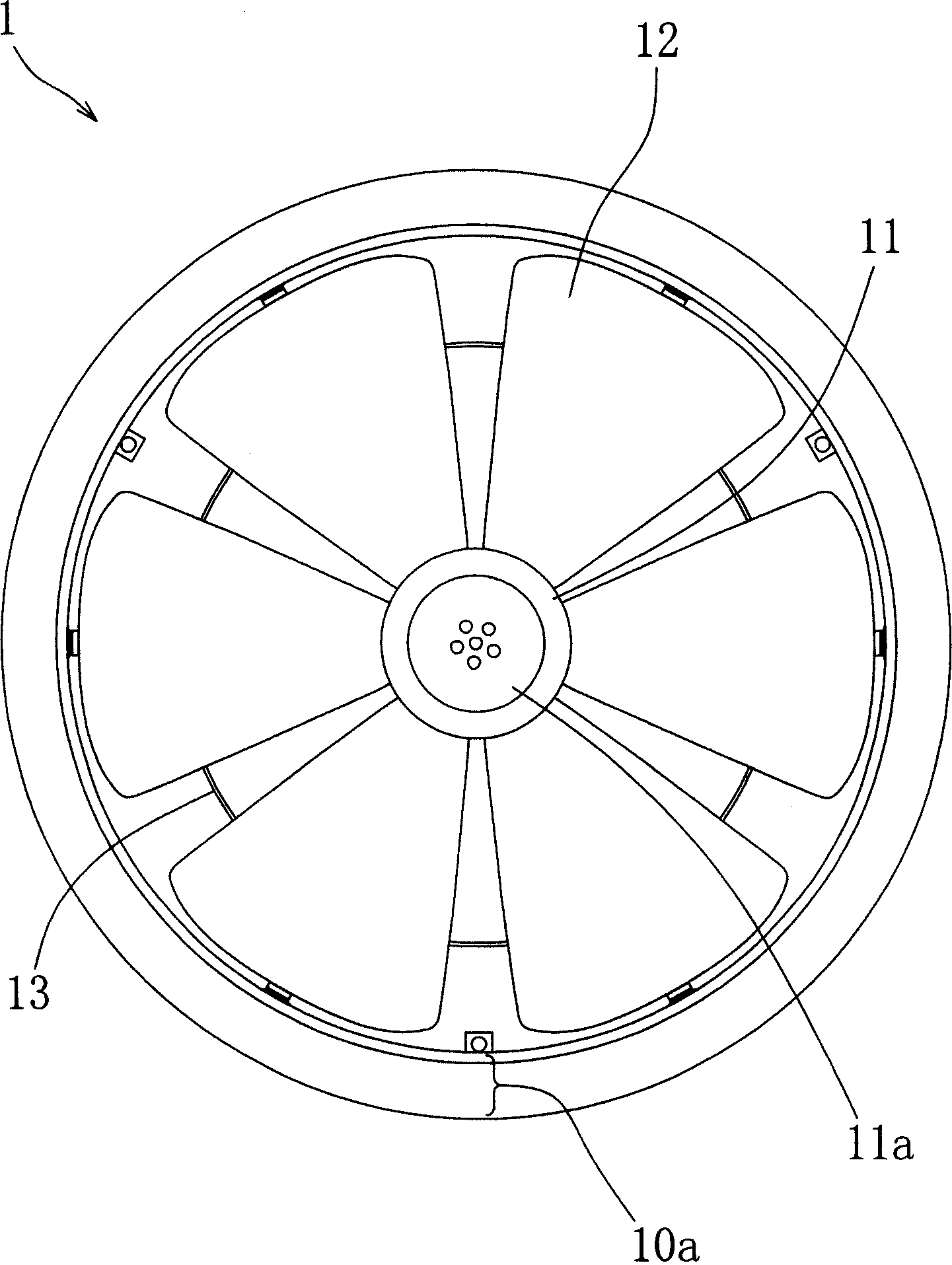

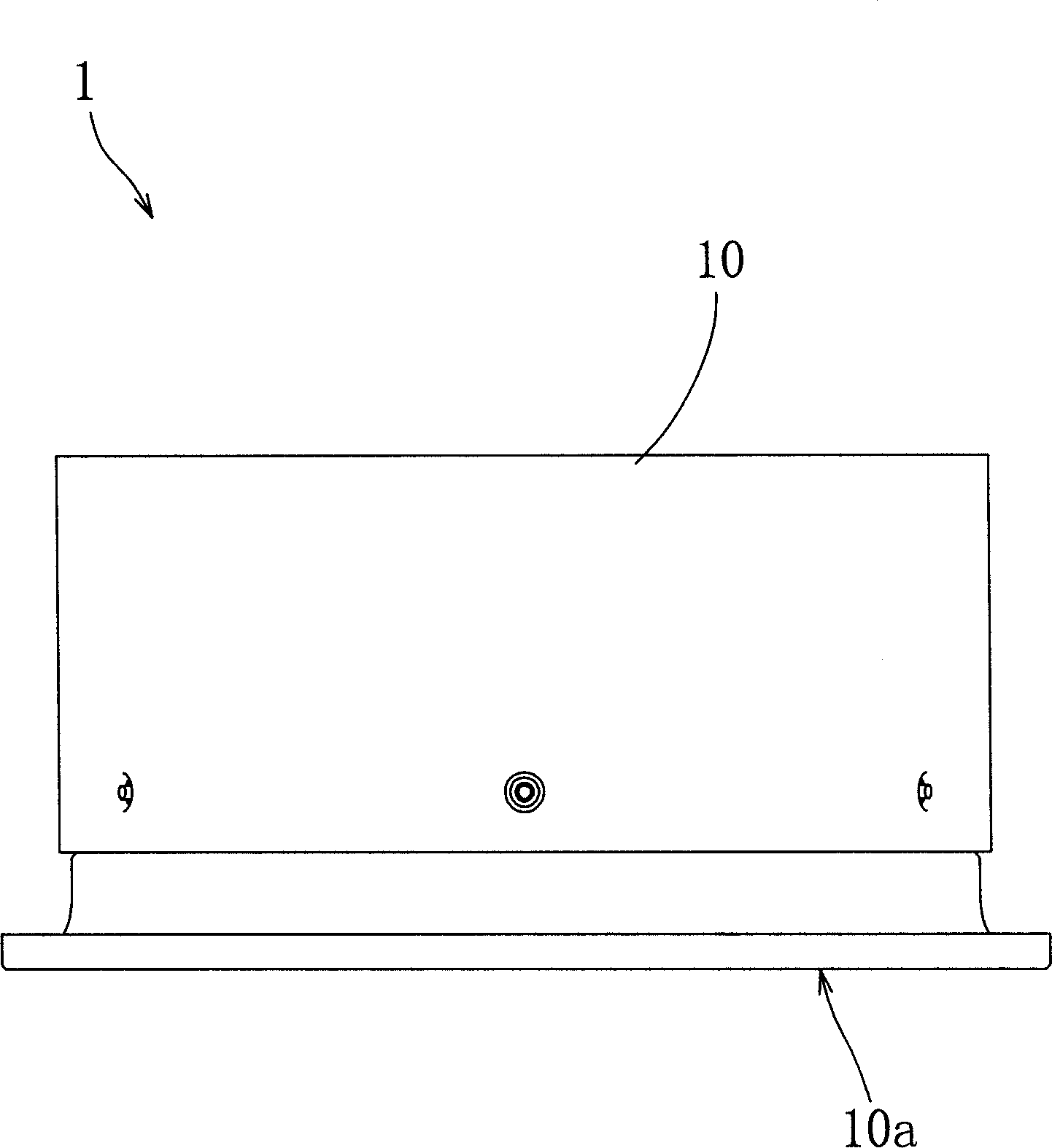

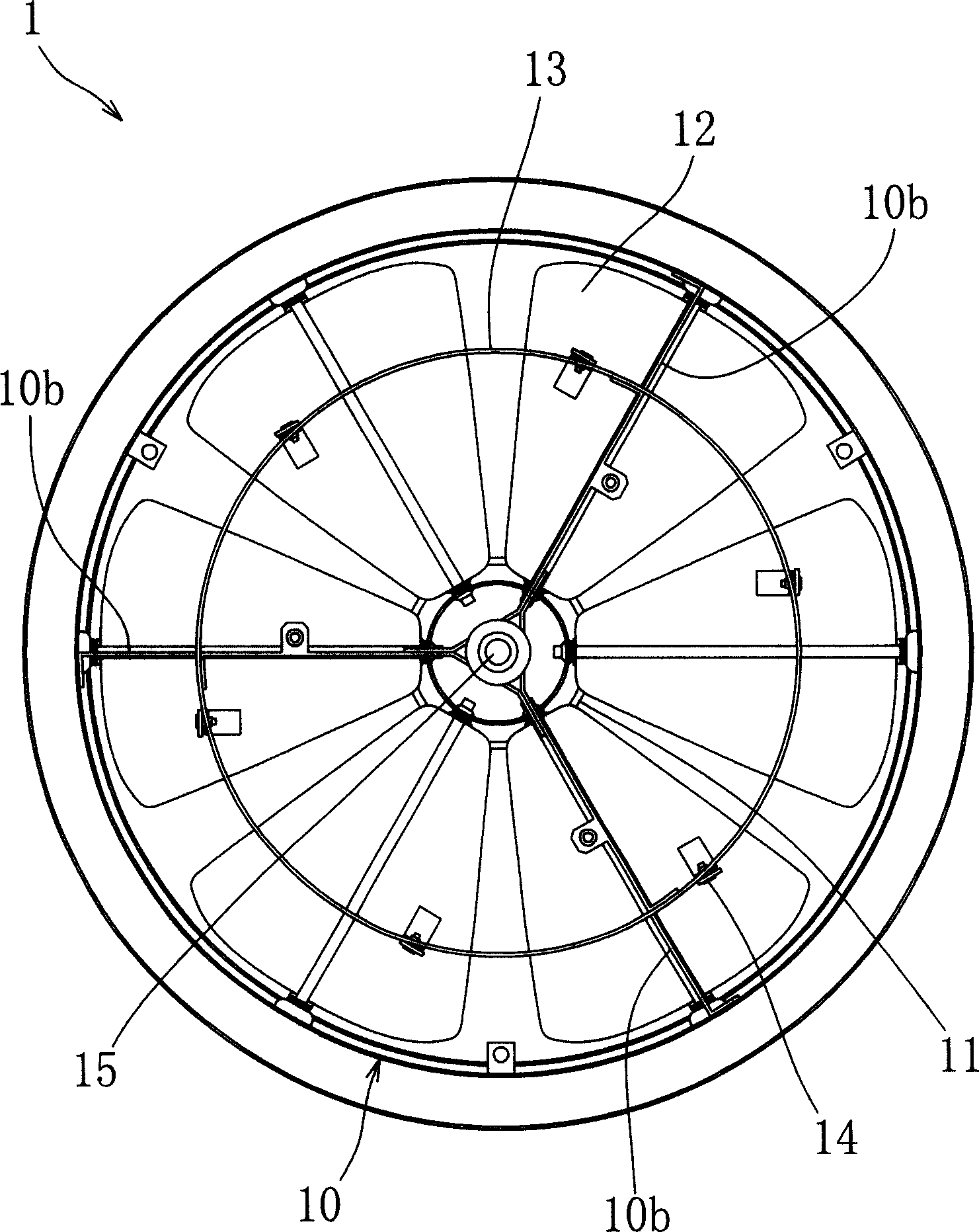

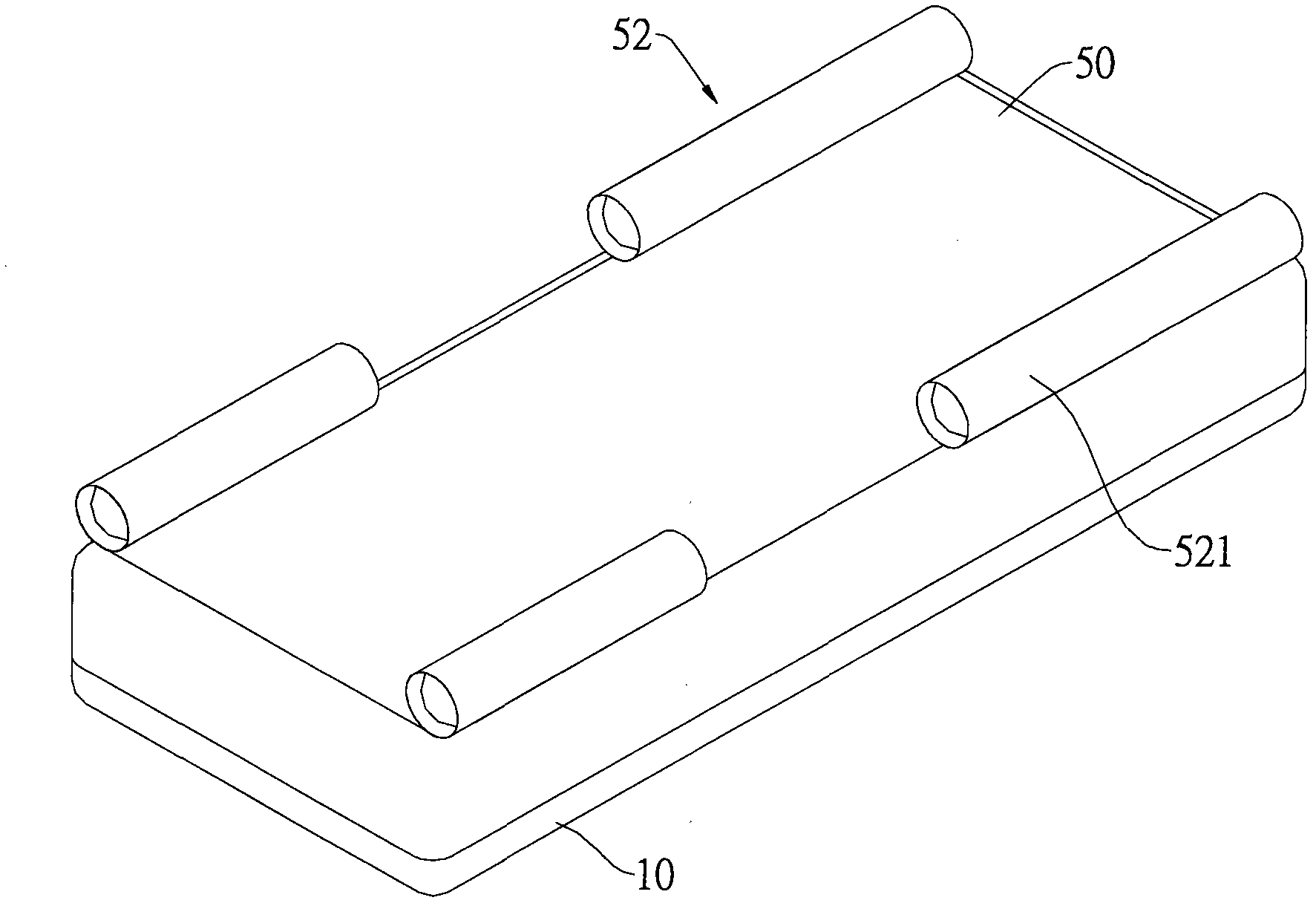

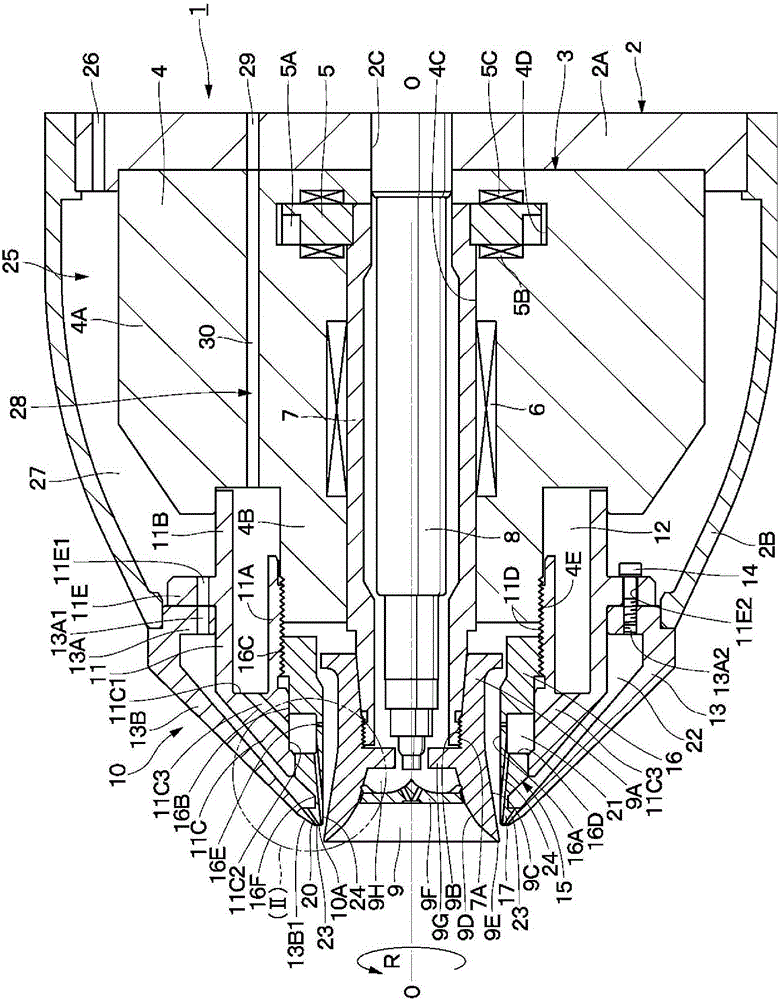

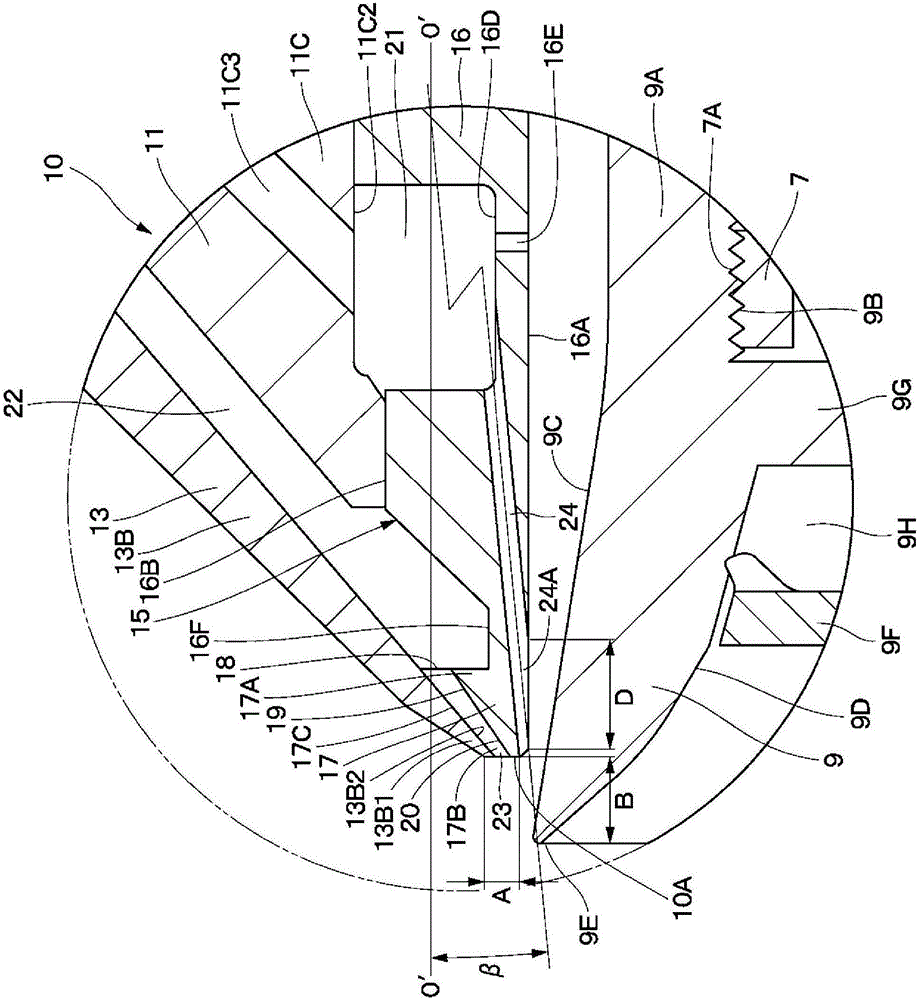

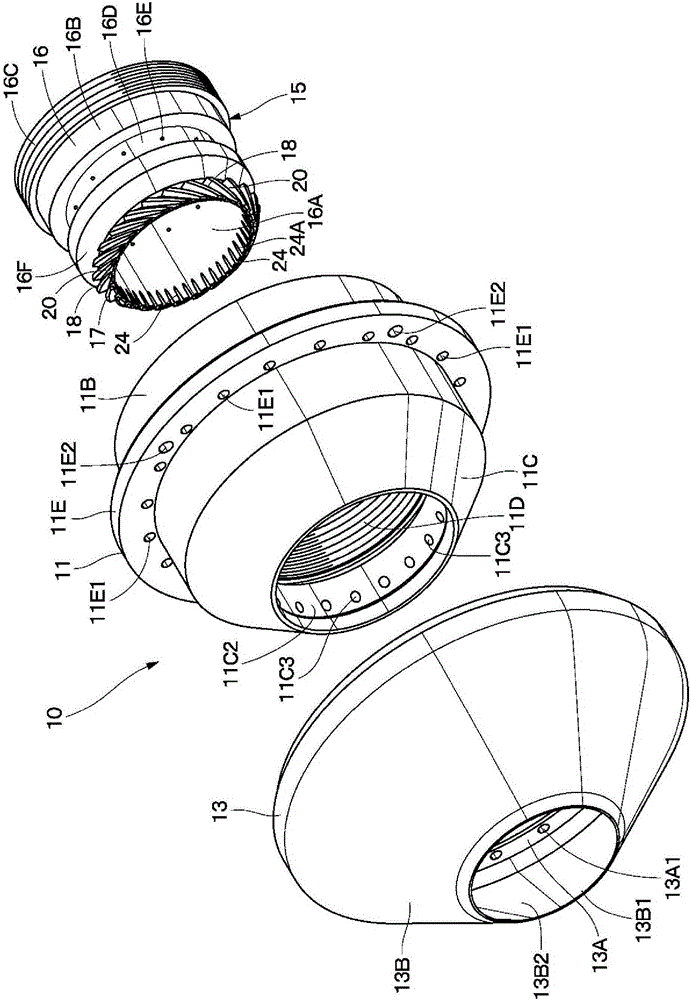

Coating machine having rotary atomizing head

InactiveCN105188950APromote micronizationImprove controllabilityMovable spraying apparatusInduction-charging sprayingEngineeringInjection air

In the present invention, a shaping air ring (10) is configured from a body (11), a cover (13), and a nozzle (15). The tip of the nozzle (15) is provided with a tapered conical protrusion (17) that is abutted against the cover (13) in a gapless contacted state. A plurality of inclination grooves (20) are provided along the entire circumference of a tapered taper surface (17C) of the conical protrusion (17). Furthermore, first shaping-air injection holes (23), which inject shaping air towards a discharge edge (9E) of a rotary atomizing head (9), are provided between each inclination groove (20) and the inner circumferential surface (13B2) of the cover (13). A second shaping-air injection hole (24), which injects shaping air along the outer circumferential surface (9C) of the rotary atomizing head (9), is provided to an inner circumferential surface (16A) of the nozzle (15).

Owner:ABB (SCHWEIZ) AG

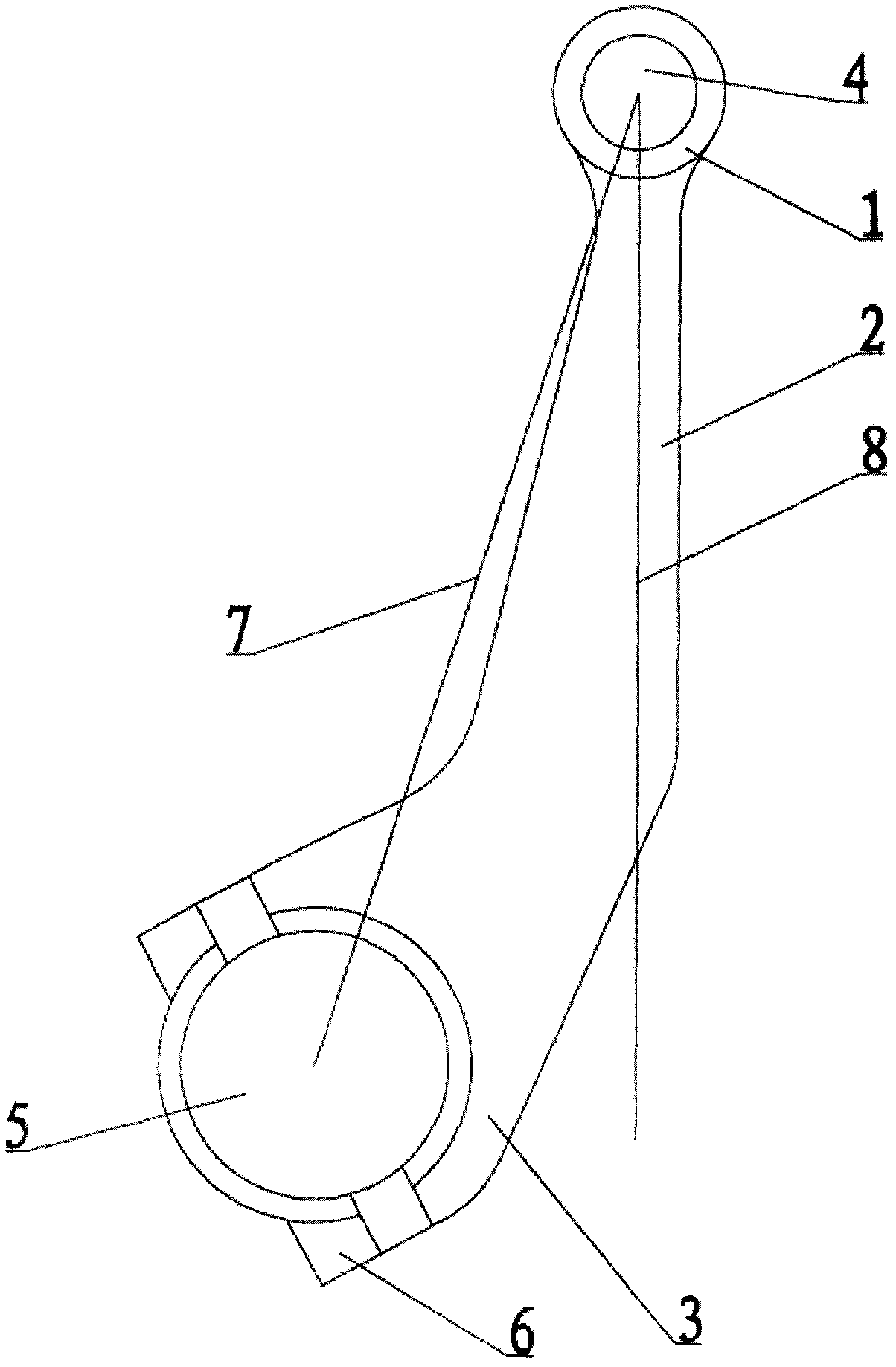

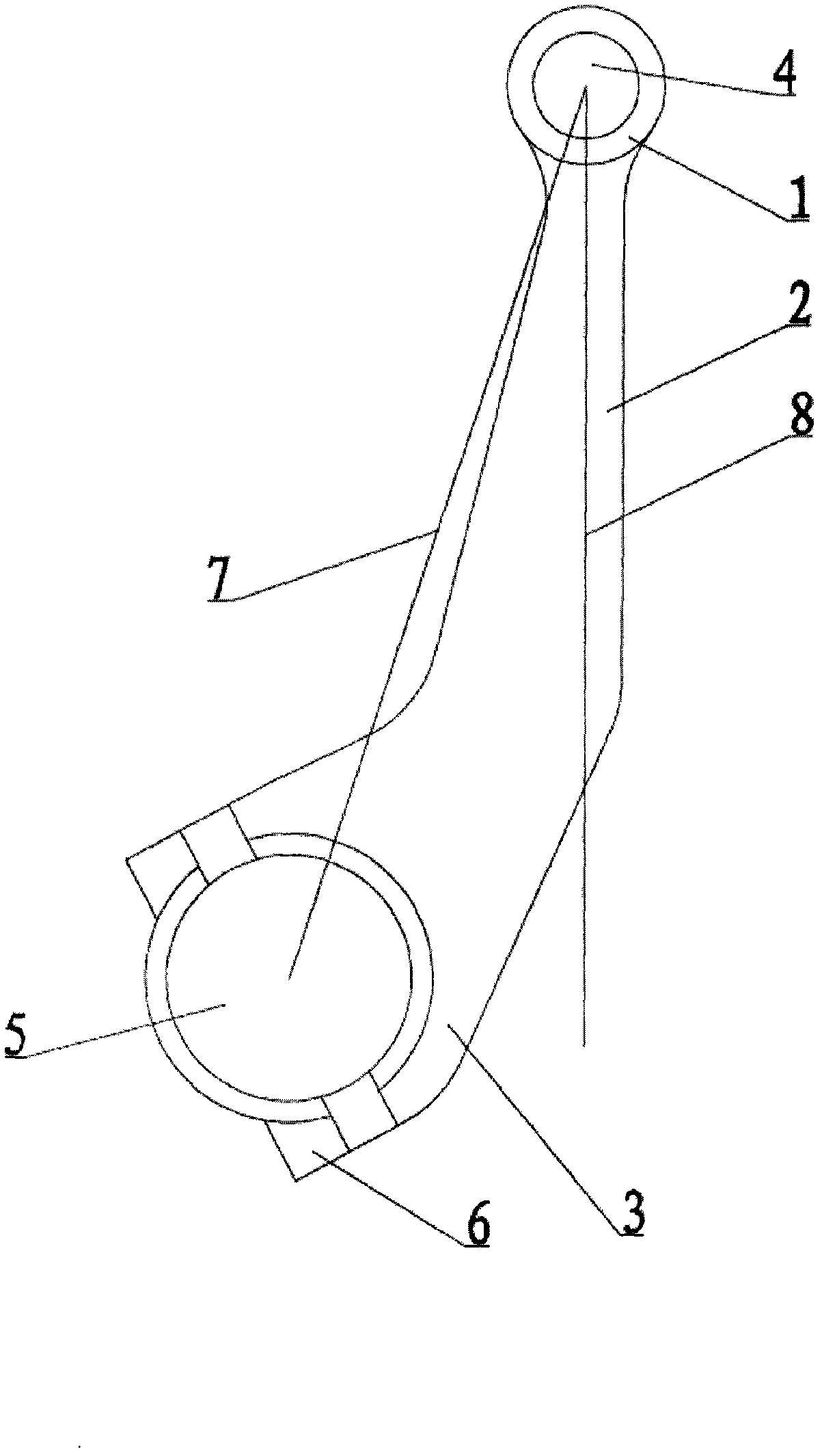

Connecting rod of engine

The invention discloses a connecting rod of an engine, which solves the problem of serious abrasion to a crankshaft, and is capable of improving the working efficiency of the engine. The connecting rod of the engine comprises a connecting rod small end provided with a mounting hole of a piston shaft, and a mounting seat of the crankshaft which is cast into a whole together with the connecting rod small end by a rod body; the mounting seat of the crankshaft is provided with a connecting rod cover; a mounting hole of the crankshaft is formed by the connecting rod cover and the mounting seat of the crankshaft; the end of the mounting seat of the crankshaft of the rod body is bended towards the side of the rod body and is in an L shape; and the included angle between the connecting line of the centre of a circle of the mounting hole of the piston shaft and the centre of a circle of mounting hole of the crankshaft and the vertical line passing through the centre of a circle of the mounting hole of the piston shaft is within the range 10-25 degrees. The connecting rod of the engine has the advantages of being simple in structure, strong in practicability and convenient to popularize, and being capable of improving the working efficiency of the engine by better utilizing the lever principle.

Owner:李合理

Bamboo fan framework and processing equipment thereof

InactiveCN107160516AMeet the intensityFulfil requirementsUmbrellasWood treatment detailsSoftware engineeringUltimate tensile strength

The invention relates to a bamboo fan framework and processing equipment thereof. The bamboo fan framework comprises a large fan framework body and a small fan framework body. The large fan framework body is obtained through the following treatment methods that (A) a large fan framework blank is treated for 1.5-2 H under the vacuum conditions that the humidity is 68-75%, the temperature is 85-90 DEG C, and the pressure is 0.8-1.2 MPa; (B) the large fan framework blank treated through the step (A) is cooled till the temperature is 45-50 DEG C and then put into a large fan framework treatment solution for treatment; and (C) the large fan framework blank treated through the step (B) is roasted in a drying device for 30-40 min and then placed for at least five days under the ventilating condition, and thus the large fan framework body is obtained. The processing equipment of the bamboo fan framework comprises the drying device for roasting the large fan framework blank, the drying device comprises a drying box, a rotary cylinder piece arranged in the drying box and a conveying track arranged outside the drying box, and the driving box is provided with a fan framework inlet aligning with the rotary cylinder piece. According to the bamboo fan framework and the processing equipment thereof, the large fan framework body and the small fan framework body are subjected to different treatment, the requirements that the strength of the large fan framework body is large, and the toughness of the small fan framework body is good are met, the obtained fan framework is good in anti-corrosive performance, long in service life and sanitary in use, and bacteria cannot be bred.

Owner:安吉县苏吉制扇有限公司

Complete abrator for locomotive

InactiveCN1654168AIncrease the tilt angleProjectile increaseAbrasive blasting machinesEngineeringOverhead crane

The shot blasting and cleaning machine for locomotive includes cleaning chamber, feedthrough traction apparatus, shot collecting and supplying system and shot blasting apparatus assembly. The cleaning chamber has front auxiliary work area, shot blasting area and back auxiliary work area successively, and the walking and turning overhead crane in the upper part of the cleaning chamber can lift, shift and turn the workpiece. The present invention makes it possible to shot blast all the surface of locomotive owing to the overhead crane.

Owner:青岛双星铸造机械有限公司

Selective etching method and preparation method of nano needle tip structure

InactiveCN110002393AHigh sharpnessIncrease the tilt angleSemi-permeable membranesVolume/mass flow by thermal effectsLinear relationshipNanometre

The invention provides a selective etching method and a preparation method of a nano needle tip structure. The selective etching method comprises the following steps that a first material layer and asecond material layer are sequentially formed on a substrate, the isotropic etching selection ratio of the first material layer to the second material layer is larger than 10, the first material layercontains doping elements, and the concentration of the doping elements is linearly increased in the thickness direction of the first material layer; and selective isotropic etching is performed on the first material layer, wherein the etching rate of the selective isotropic etching has a positive linear relationship with the concentration of the doping elements, so as to complete the etching of the outer wall of the first material layer. According to the invention, the positive linear relationship between the etching rate in the etching process and the concentration of the doping elements inthe to-be-etched material is utilized, so that sloped sidewalls opposite to the increasing direction of the concentration is obtained; by the adoption of the selective etching method, the nano needletip structure with high sharpness can be obtained, and the size, the shape and the angle of the needle tip structure can be flexibly adjusted.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com