Electric breaker spring disassembly device

A technology for dismantling devices and circuit breakers, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of time-consuming, uneven spring force, and long spring dismantling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

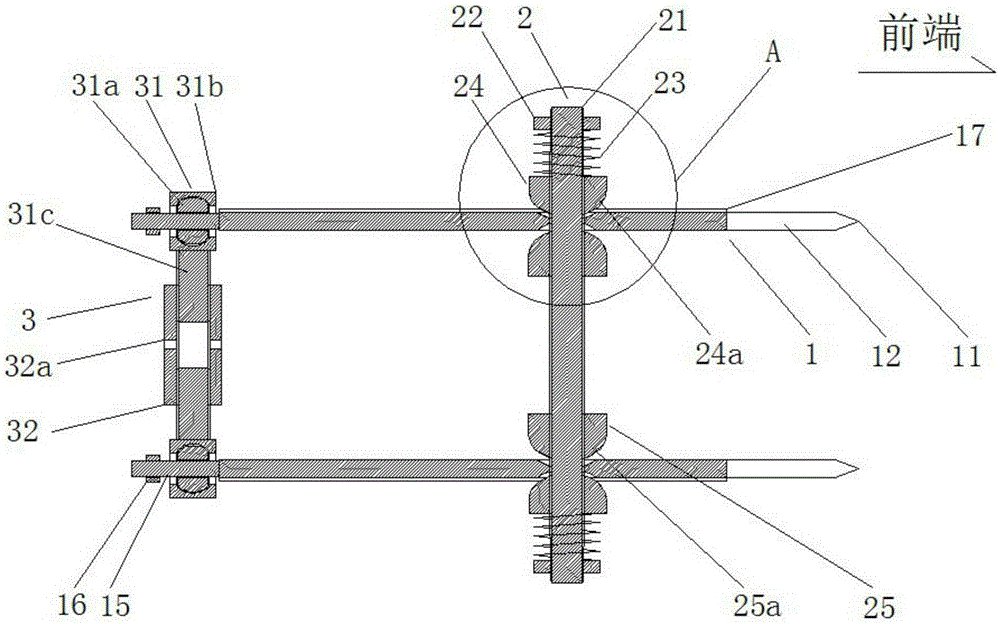

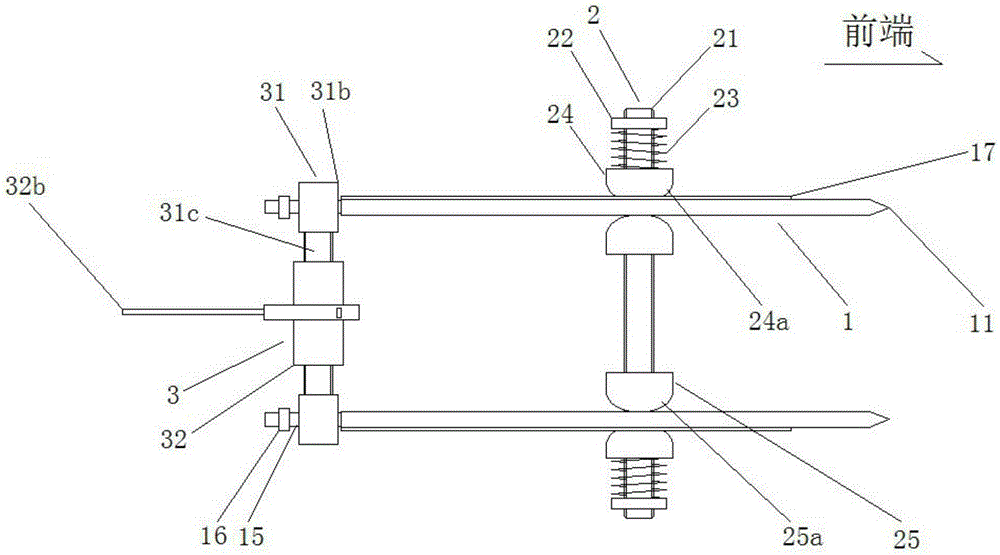

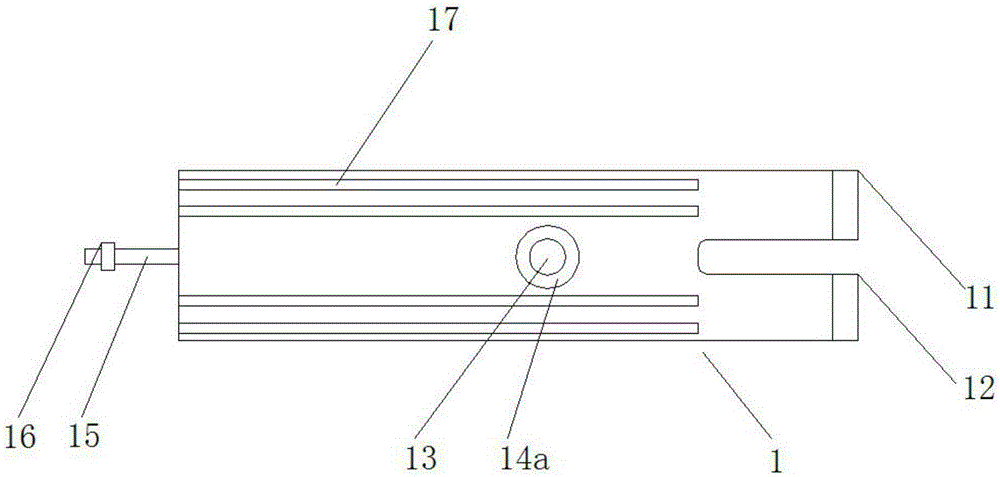

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the "front-end", "back-end" and Figure 1-Figure 2 Corresponds to the "front end" shown in .

[0023] A spring removal device for a power circuit breaker, comprising a seesaw 1, a support rod 2, and an adjustment rod 3; two seesaws 1 are provided, and a pointed blade 11 is provided at the front end of the seesaw 1, and the seesaw 1. A "U"-shaped groove 12 is provided in the middle part of the front end, and a first through hole 13 is provided on the seesaw 1, which is characterized in that:

[0024] The parts where the end faces of the two seesaws 1 are far away from each other are located on the outer edge of the first through hole 13 are formed with an outer arc-shaped depression 14a, and the end faces of the two seesaws 1 that are close to each other are located on the outer edge of the first through hole 13. An inner arc-shaped dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com