Selective etching method and preparation method of nano needle tip structure

A selective, needle-tip technology, applied in the semiconductor field, can solve problems such as the complexity of the nano-tip structure process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

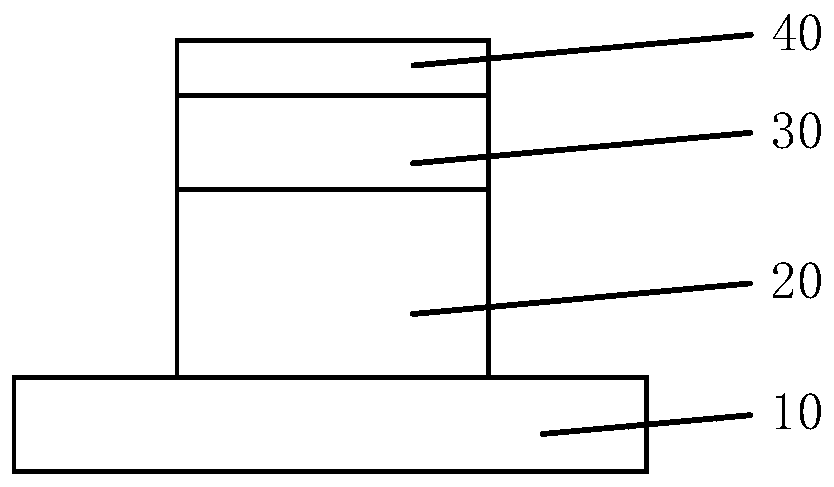

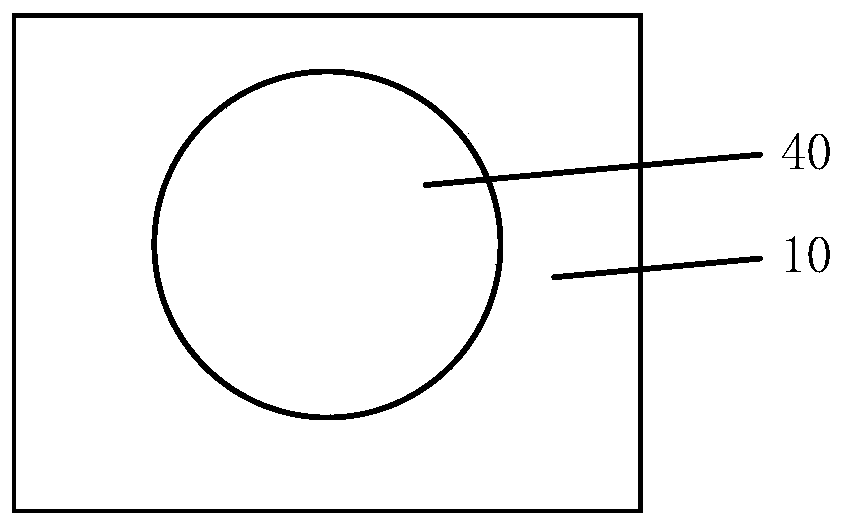

[0041] According to another aspect of the present invention, there is also provided a method for preparing a nano-needle structure, such as Figure 1 to Figure 6 As shown, it includes the following steps: using the above-mentioned selective etching method to form the first material layer 20 into the nano-tip structure 220; removing the second material layer 30 to expose the top of the nano-tip structure 220.

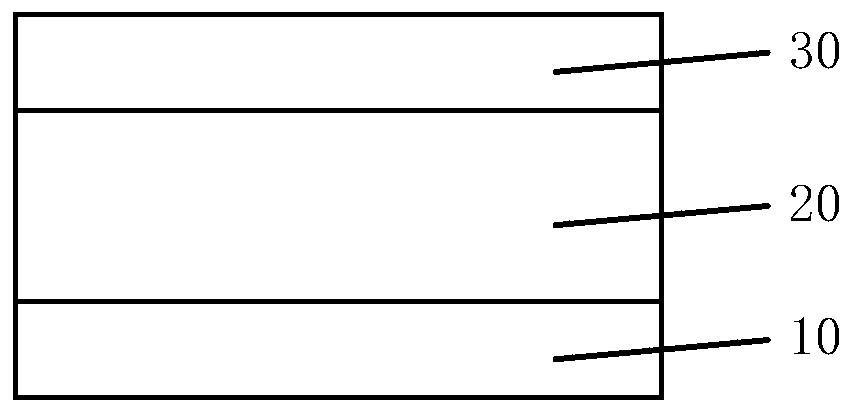

[0042] The above selective etching method includes: S1, sequentially forming the first material layer 20 and the second material layer 30 on the substrate 10, such as figure 1 As shown, wherein the isotropic etching selectivity ratio of the first material layer 20 to the second material layer 30 is greater than 1, the material of the first material layer 20 is a material containing doping elements, and the material containing doping elements includes doping element, and the concentration of the doped element increases linearly along the thickness direction of the first m...

Embodiment 1

[0055] The preparation method of the nano-needle tip structure provided by this embodiment is as follows: Figure 1 to Figure 6 As shown, the process flow is as follows Figure 9 shown, including the following steps:

[0056] SiGe and Si are sequentially deposited on the substrate 10 of single crystal silicon to form the first material layer 20 and the second material layer 30, and the concentration of Ge along the thickness direction of the first material layer 20 is linearly increasing, such as figure 1 shown;

[0057] Deposit SiO on the second material layer 30 2 To form a mask material layer, the mask material layer is formed into a mask layer 40 by using a photolithography process and an etching process. The mask layer 40 has the same size as the bottom of the nano needle tip structure to be formed. Through the mask layer 40 Etching the first material layer 20 and the second material layer 30 to form protrusions on the substrate surface, such as figure 2 with image...

Embodiment 2

[0061] The difference between the preparation method provided in this example and Example 1 is that after the nano-needle structure is formed, the preparation method further includes the following steps:

[0062] An evaporation or sputtering process is used to cover a conductive film on the surface of the nano needle tip structure to form a conductive needle tip structure, and the conductive film may be an Au layer or a Pt layer.

[0063] The above conductive tip structure can be applied to conductive probes or bio-electrodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com