Patents

Literature

101results about How to "High sharpness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

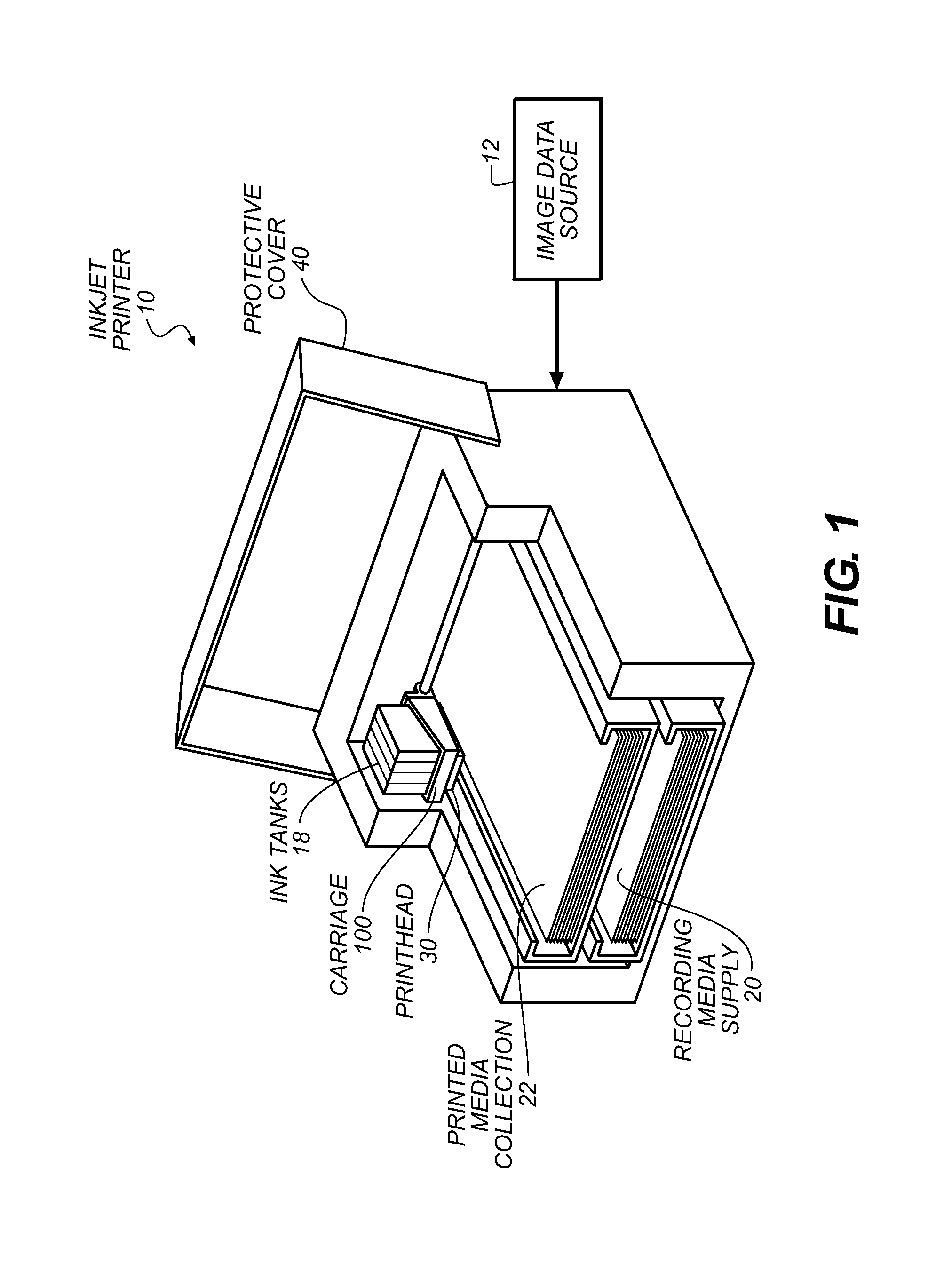

Ink set, ink cartridge, inkjet recording method, and inkjet recording apparatus

ActiveUS20100196602A1Poor ink absorbabilityLess show-throughMeasurement apparatus componentsDuplicating/marking methodsColor imageWater dispersible

An ink set includes at least two aqueous inks A and B with different colors, the inks A and B used in an inkjet recording method in which the inks A and B are superimposed for formation of a color image, wherein the ink A contains water-dispersible colorant A1 free of a surfactant-based dispersant, and anionic compound A2, and wherein the ink B contains water-dispersible colorant B1 containing a surfactant-based dispersant.

Owner:RICOH KK

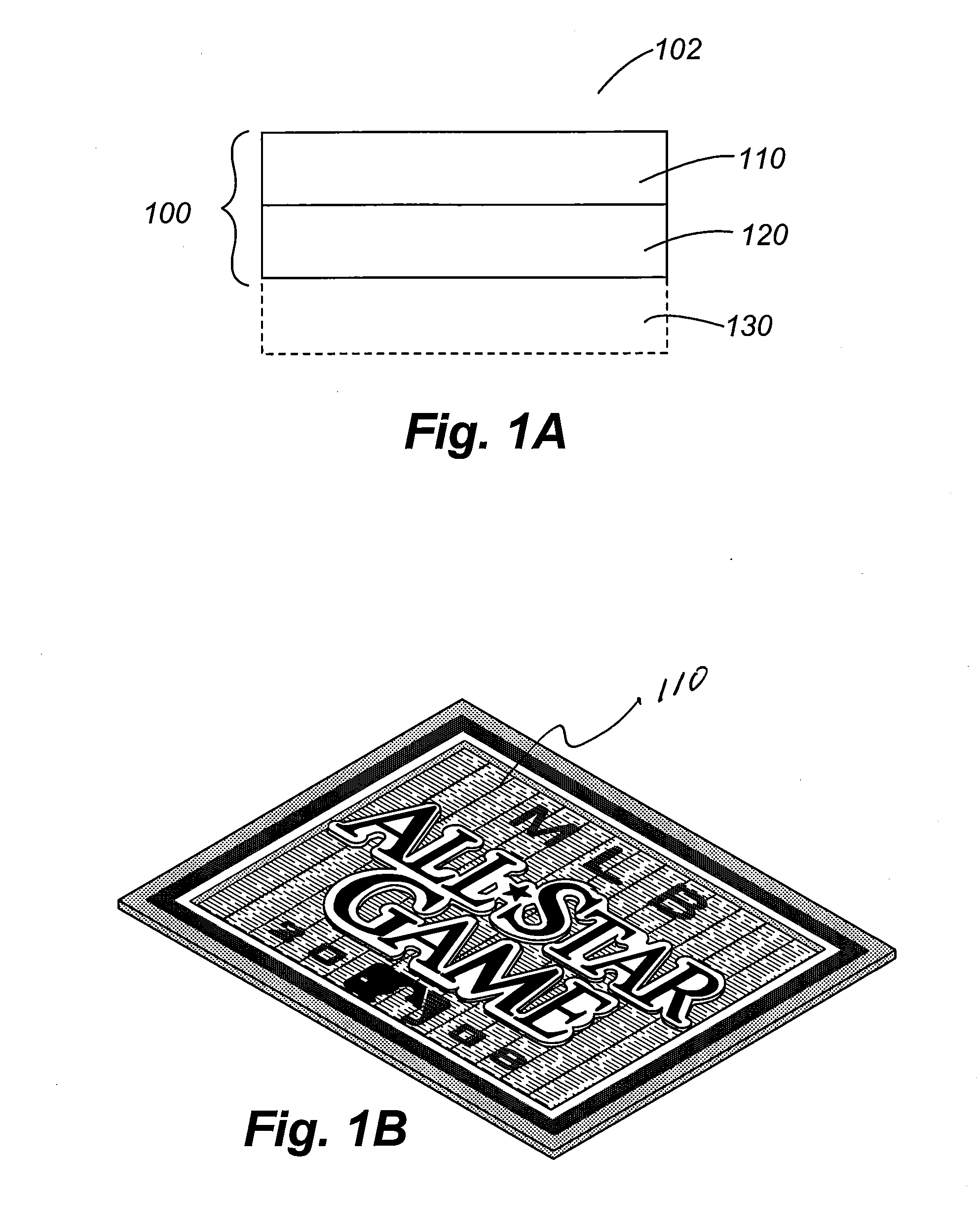

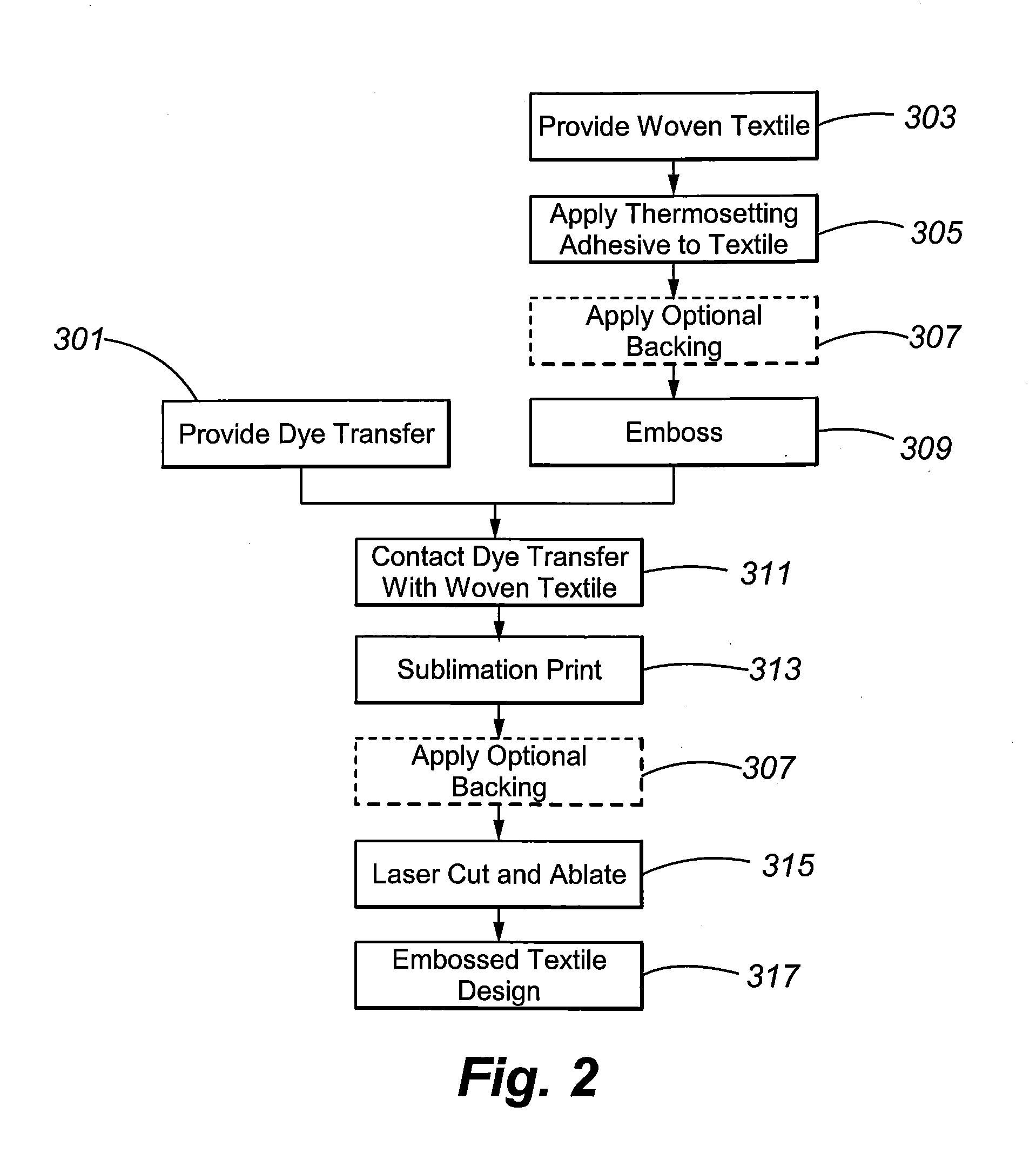

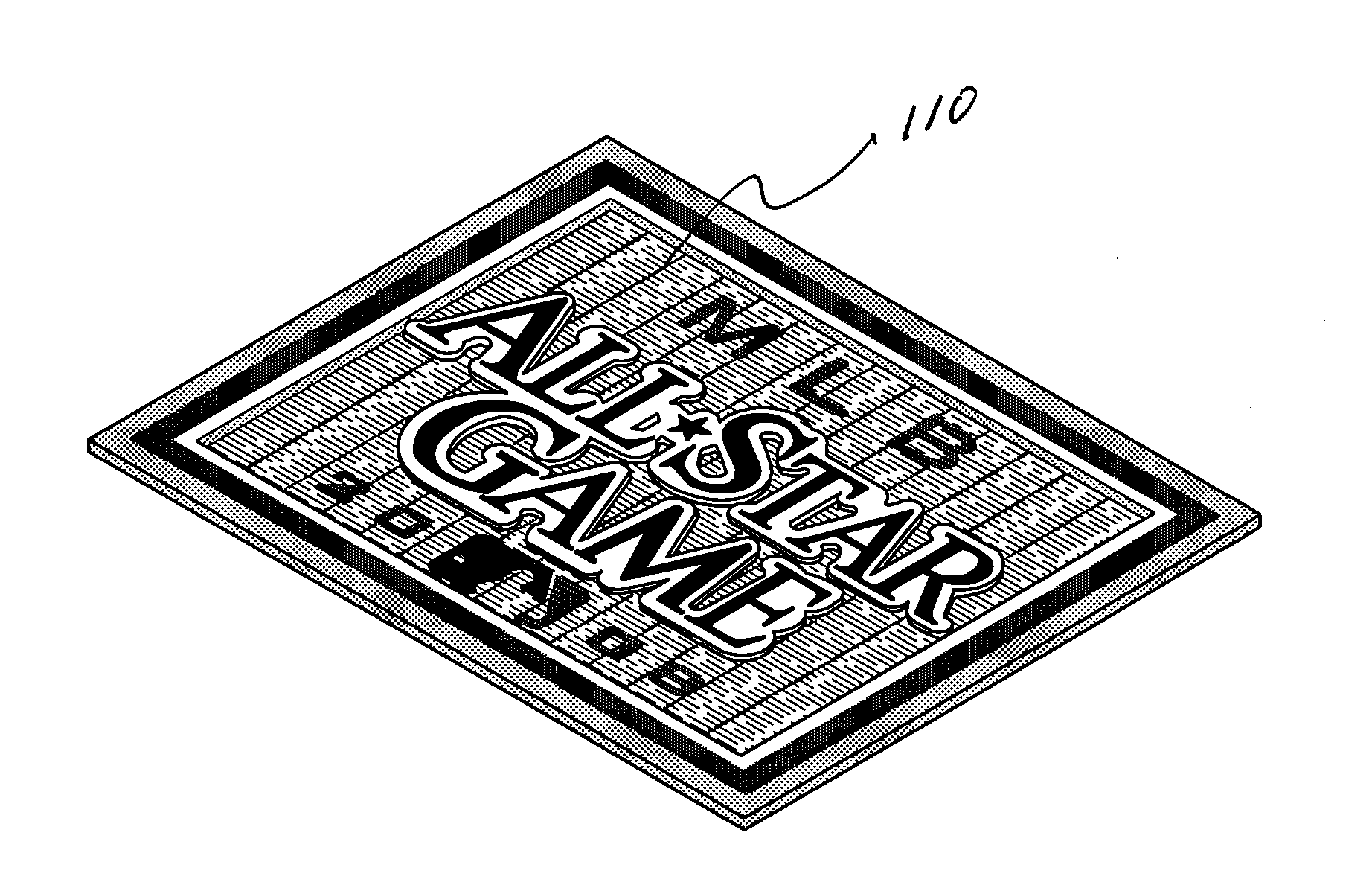

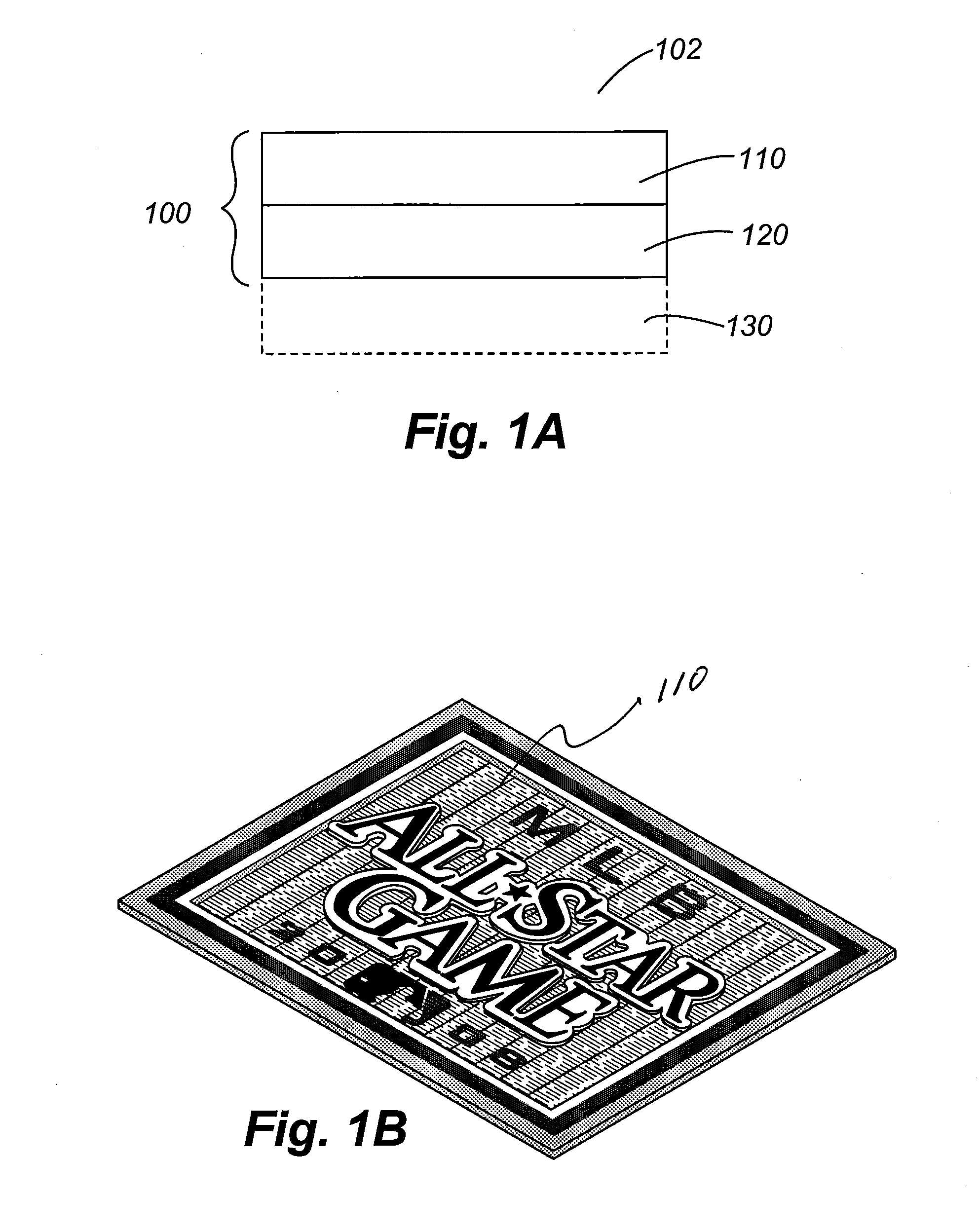

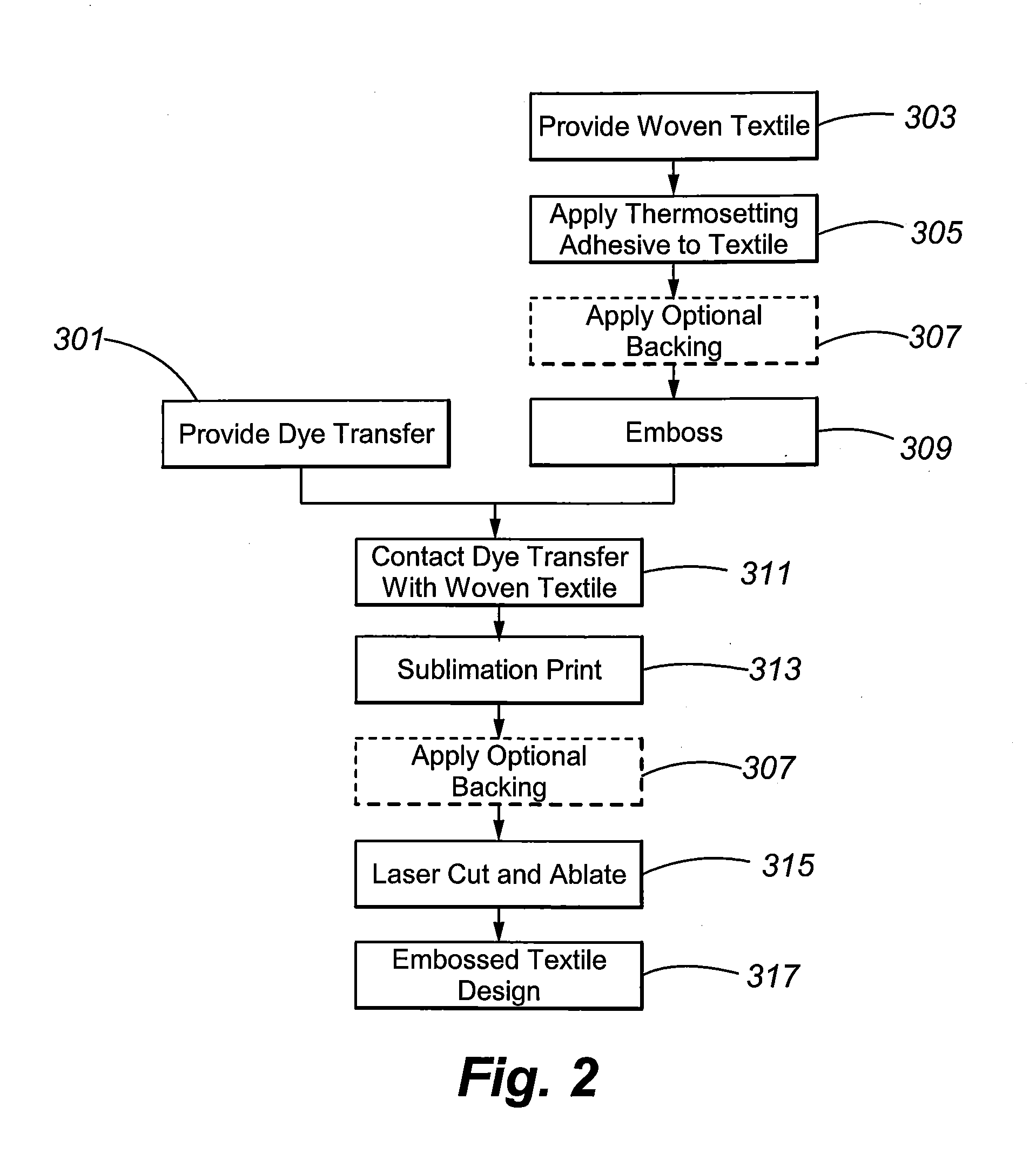

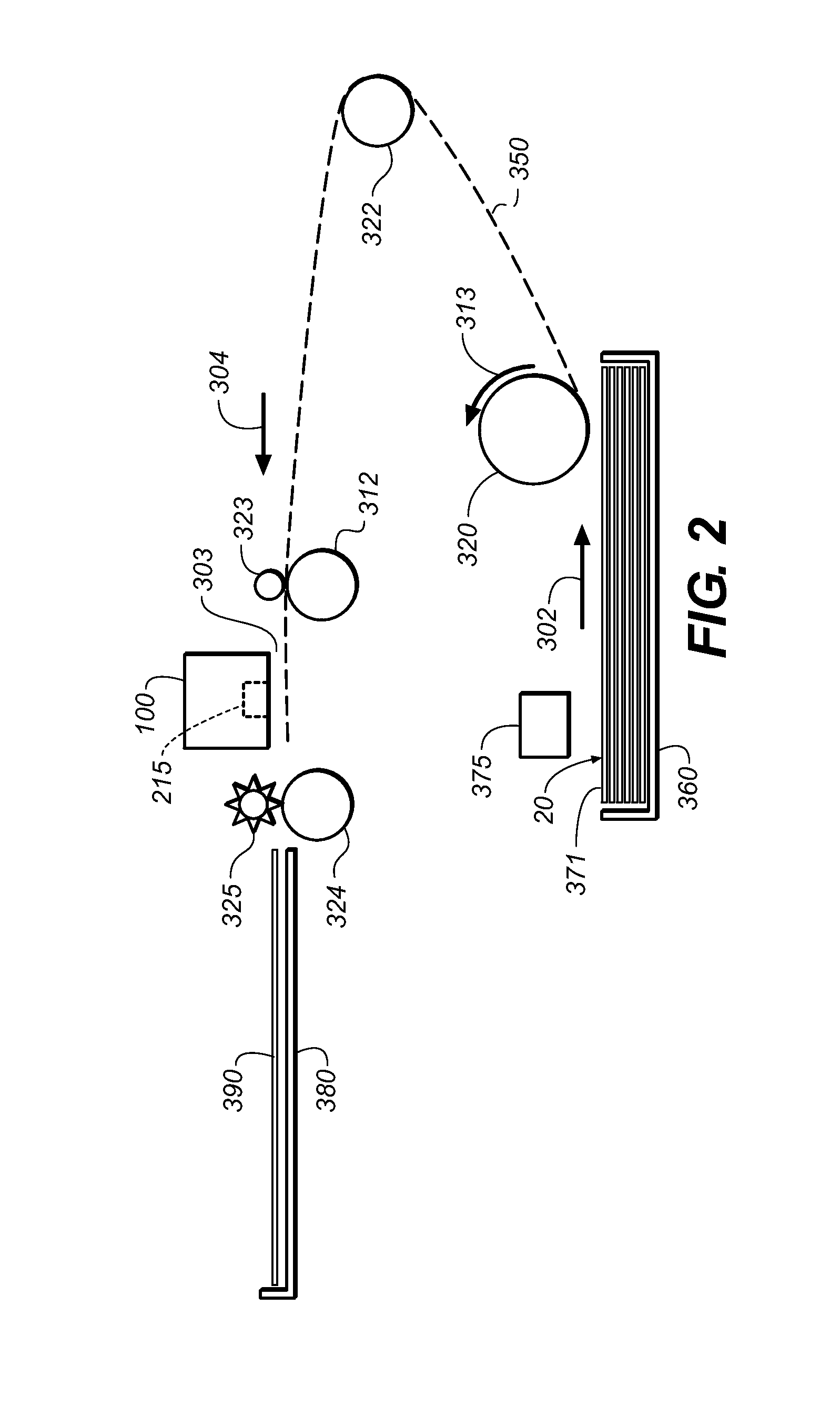

Sublimation dye printed textile

ActiveUS20090075075A1Quality improvementIncreased surface dimensionality and characterLiquid surface applicatorsDecorative surface effectsTextile printerDigital imaging

The present invention is directed to an unstitched design having the appearance of being stitched or embroidered. A stitched design is digitally imaged, and the digital image used to control dye sublimation printing of a representation of the image onto a desired surface. In one configuration, the surface is a woven textile.

Owner:HIGH VOLTAGE GRAPHICS

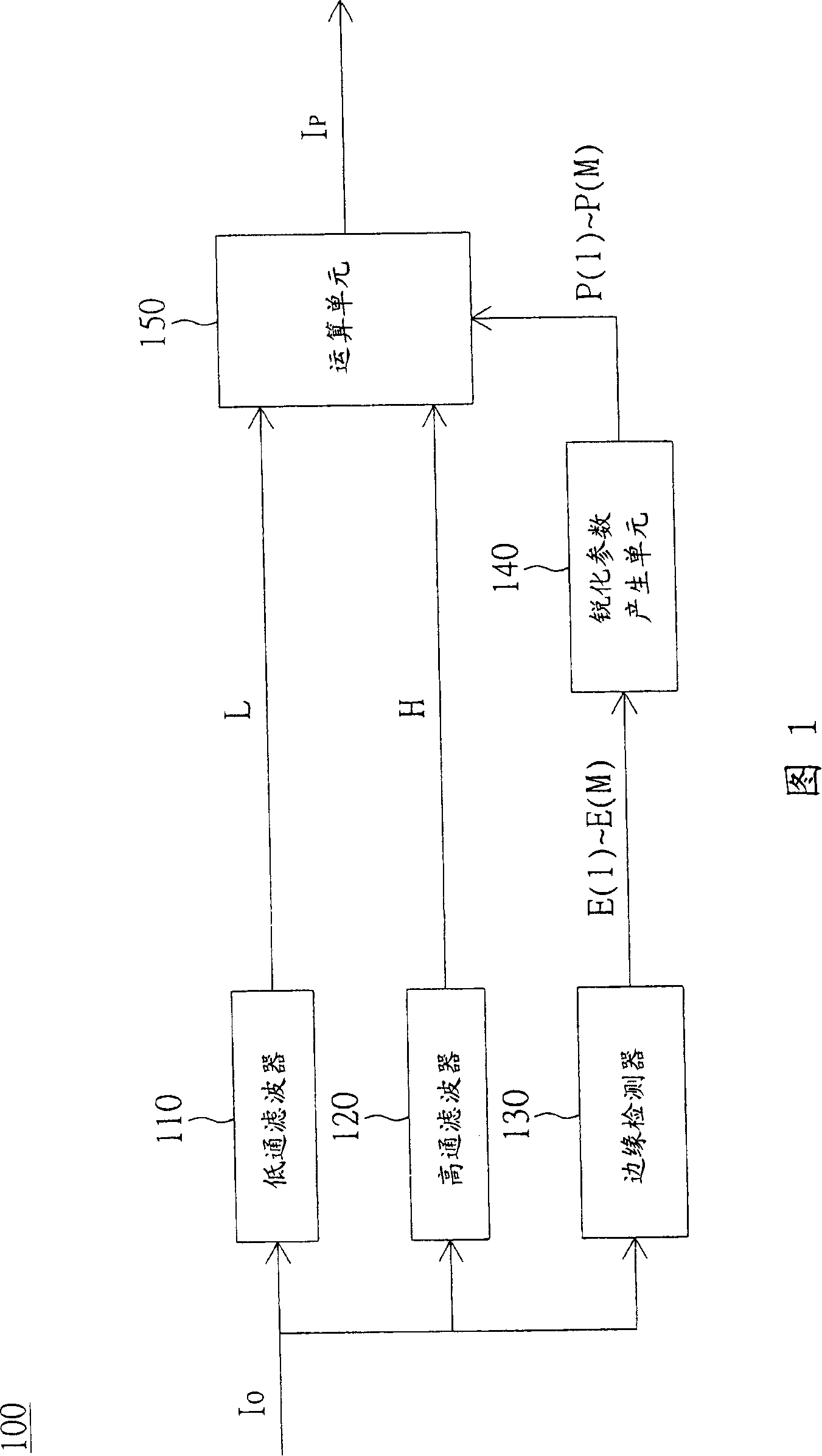

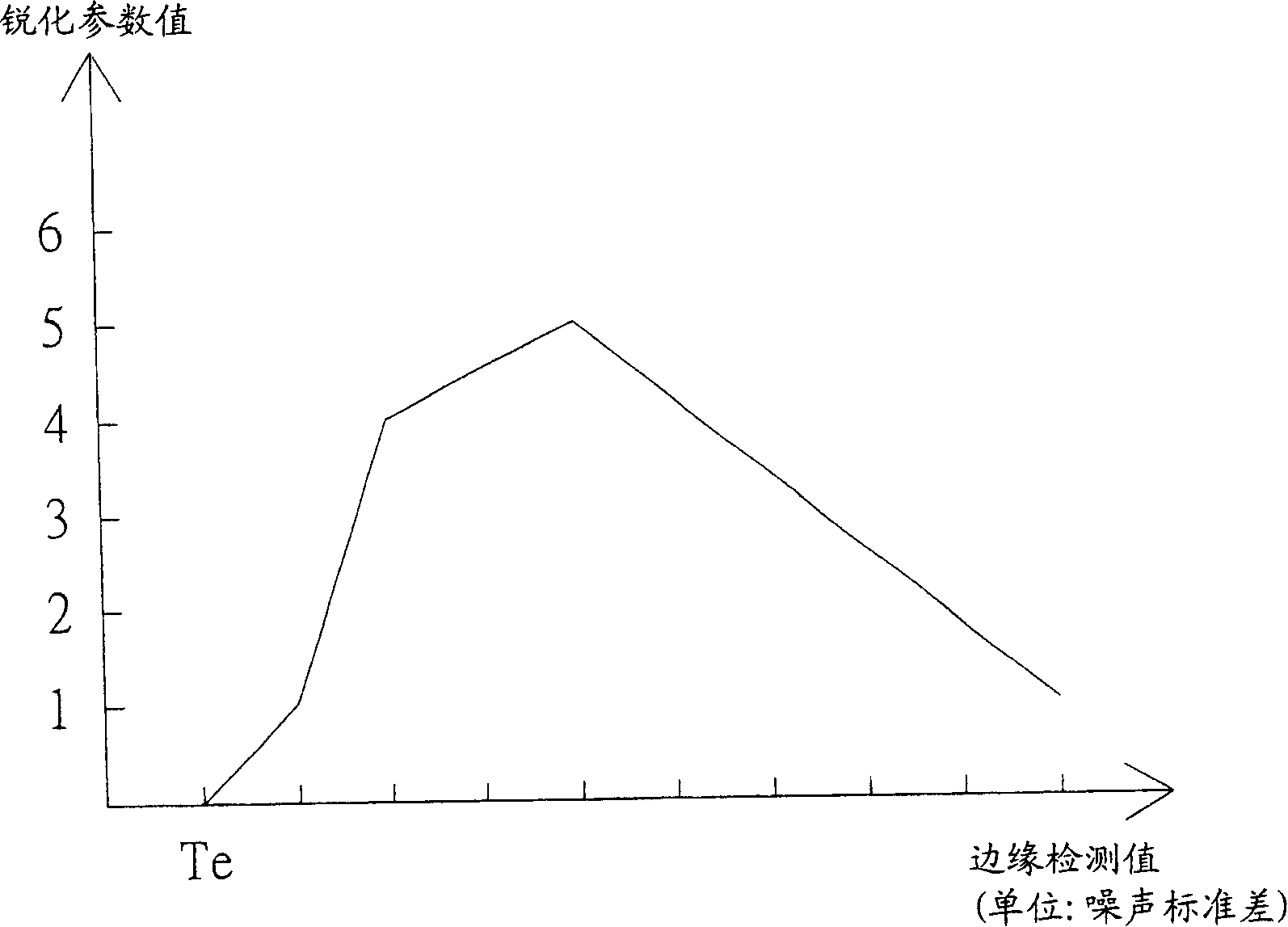

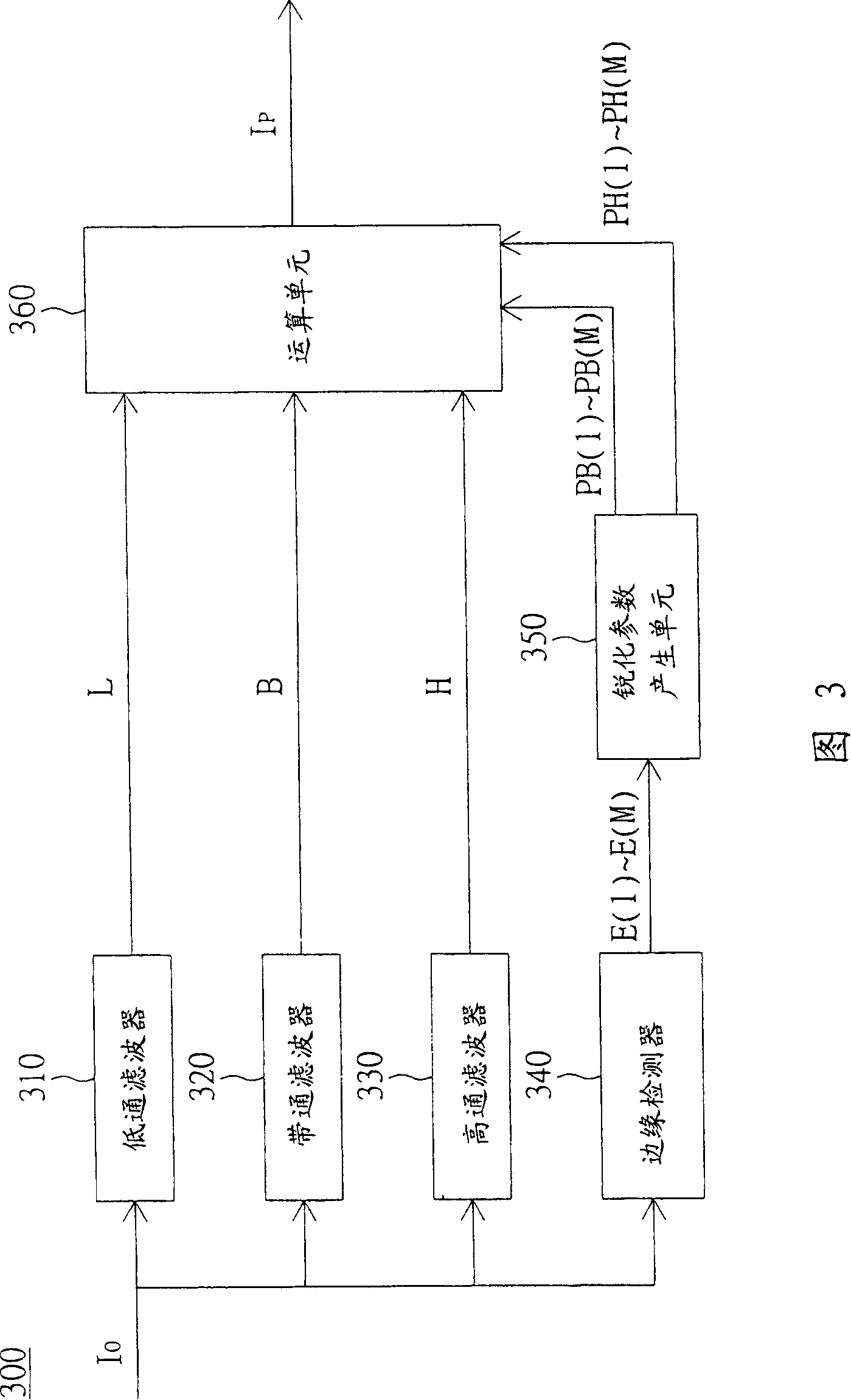

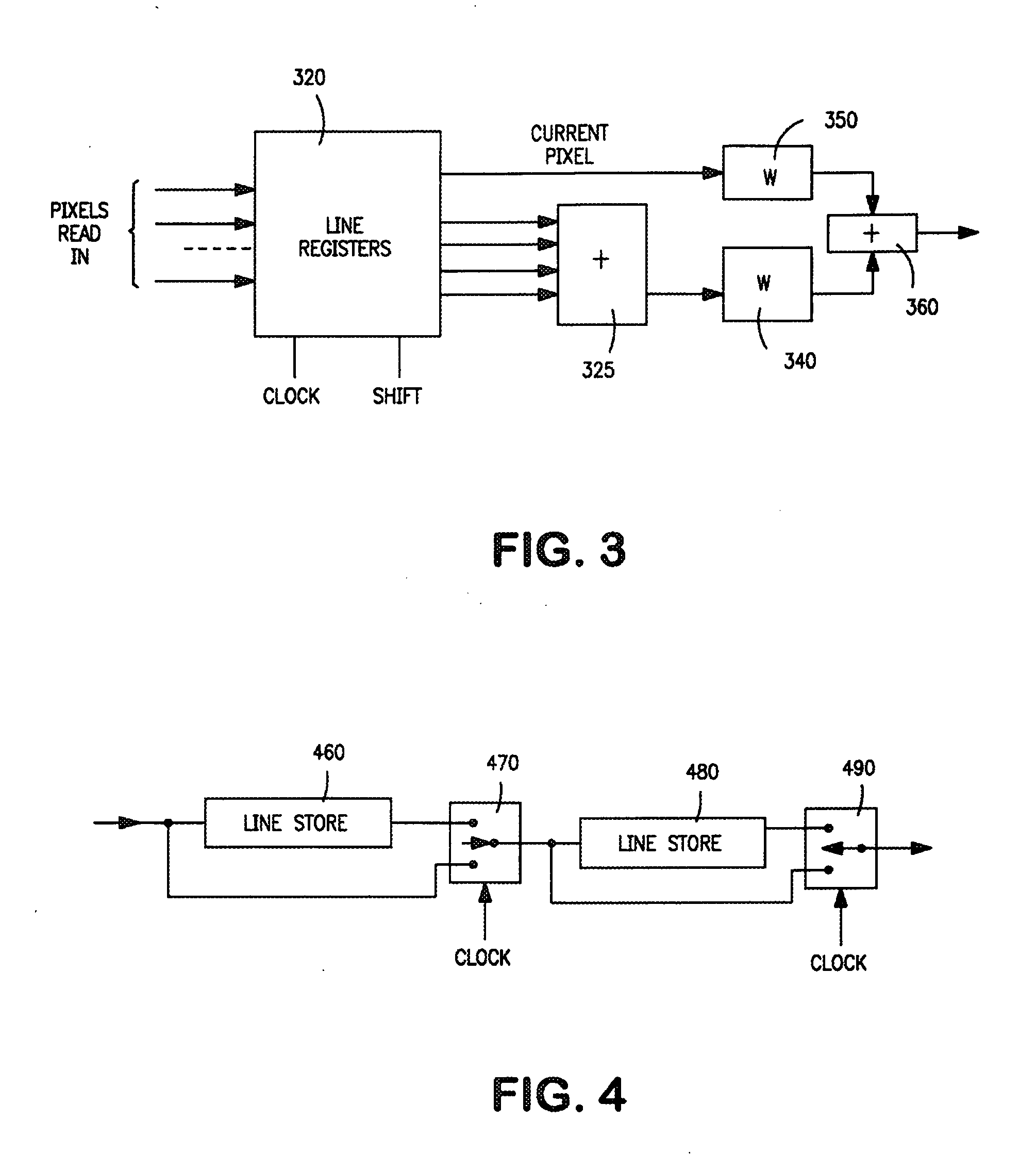

Image sharpening device and method

The invention discloses an image sharpening device used to sharpen original images. The image sharpening device comprises a low-pass filter, a high-pass filter, an edge detector, a sharpening parameter generating unit and an operation unit. The low-pass filter and the high-pass filter as well as the edge detector respectively receive the original image and respectively output a low-frequency image, a high-frequency image and a plurality of edge detection values correspondingly. The sharpening parameter generating unit receives the plurality of edge detection values and respectively outputs a plurality of corresponding sharpening parameters. The operation unit adjusts the high-frequency image according to the sharpening parameters, outputs the adjusted high-frequency image, and combines the adjusted high-frequency image with the low-frequency image to obtain the output image with a sharpened image.

Owner:QUANTA COMPUTER INC

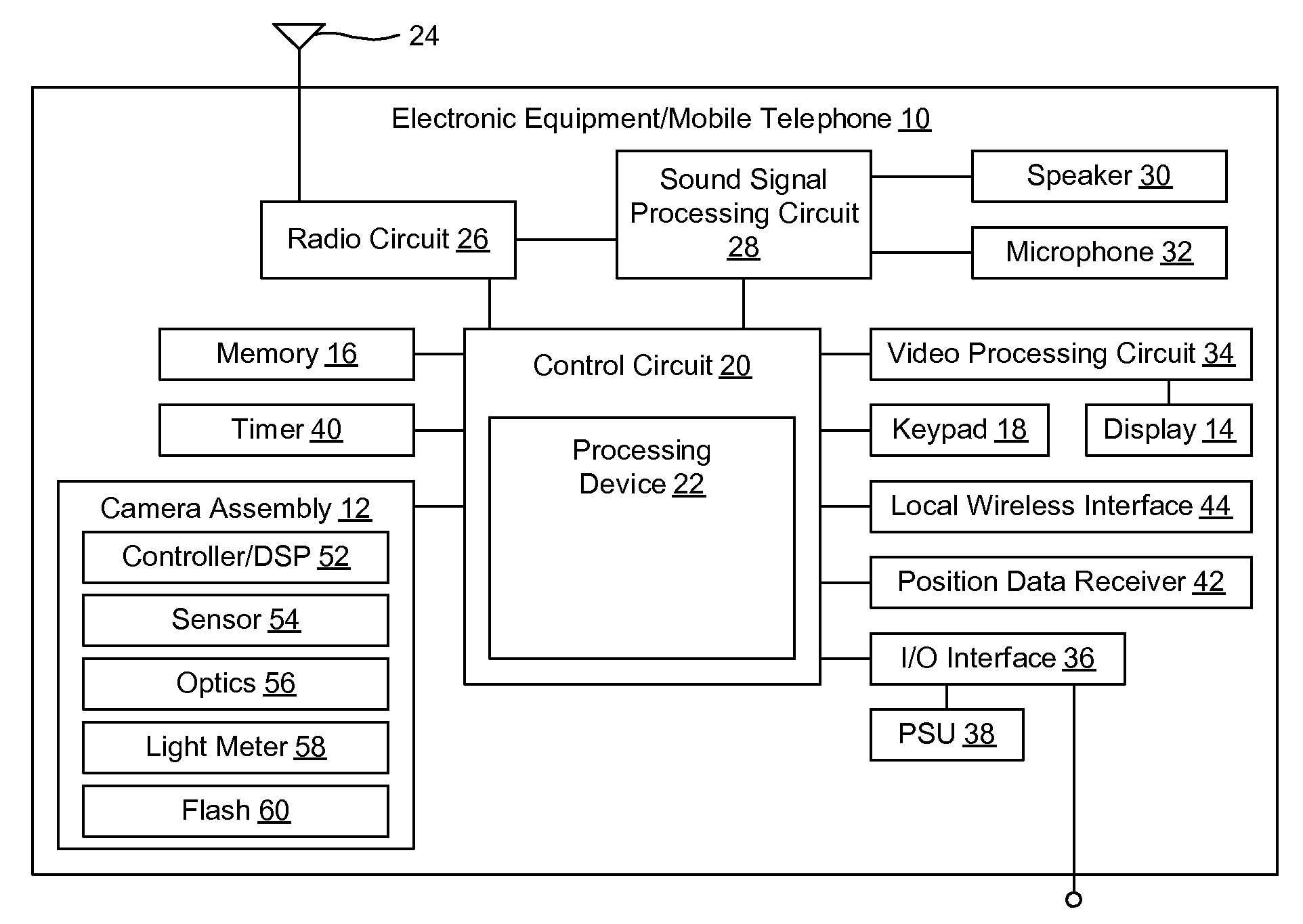

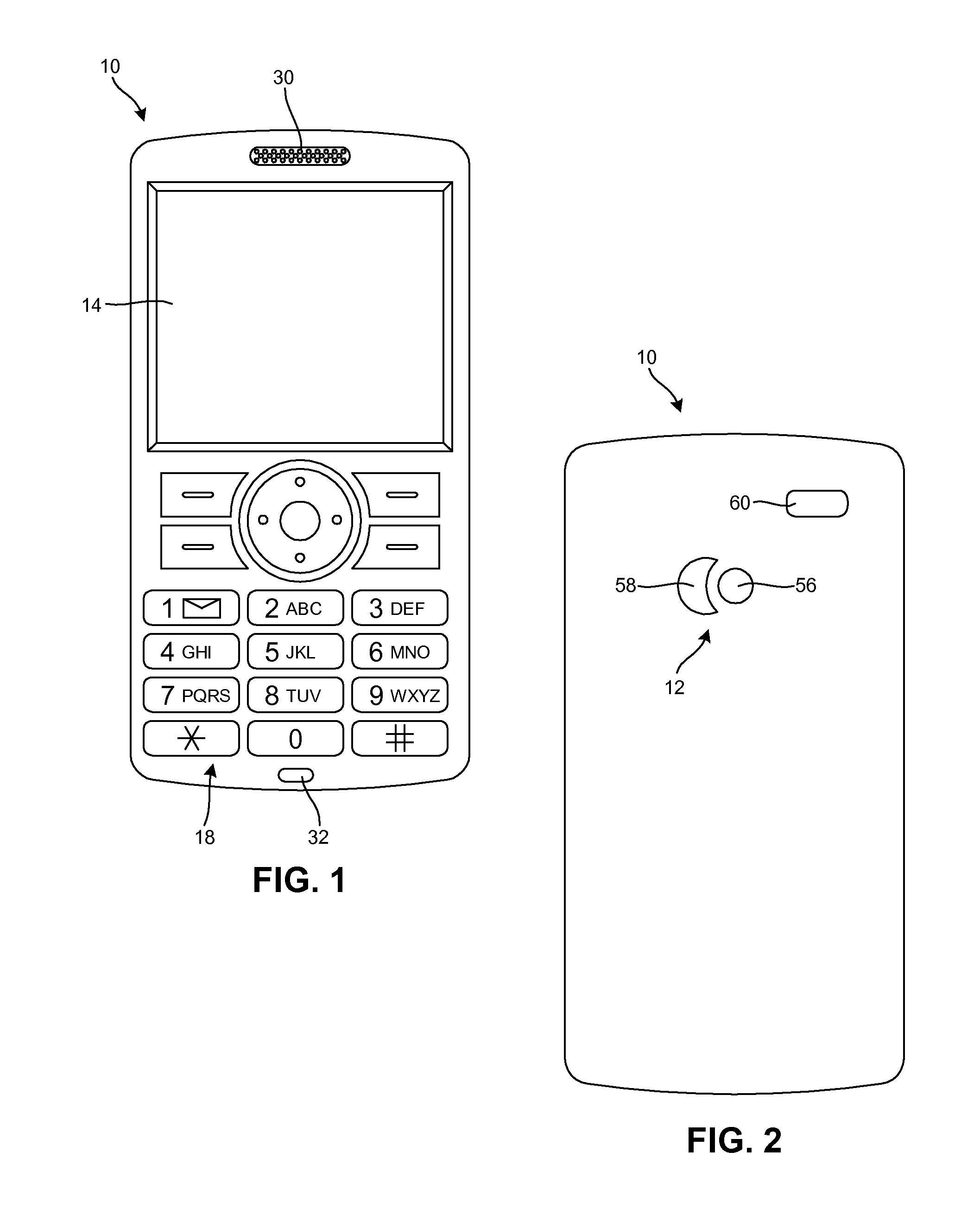

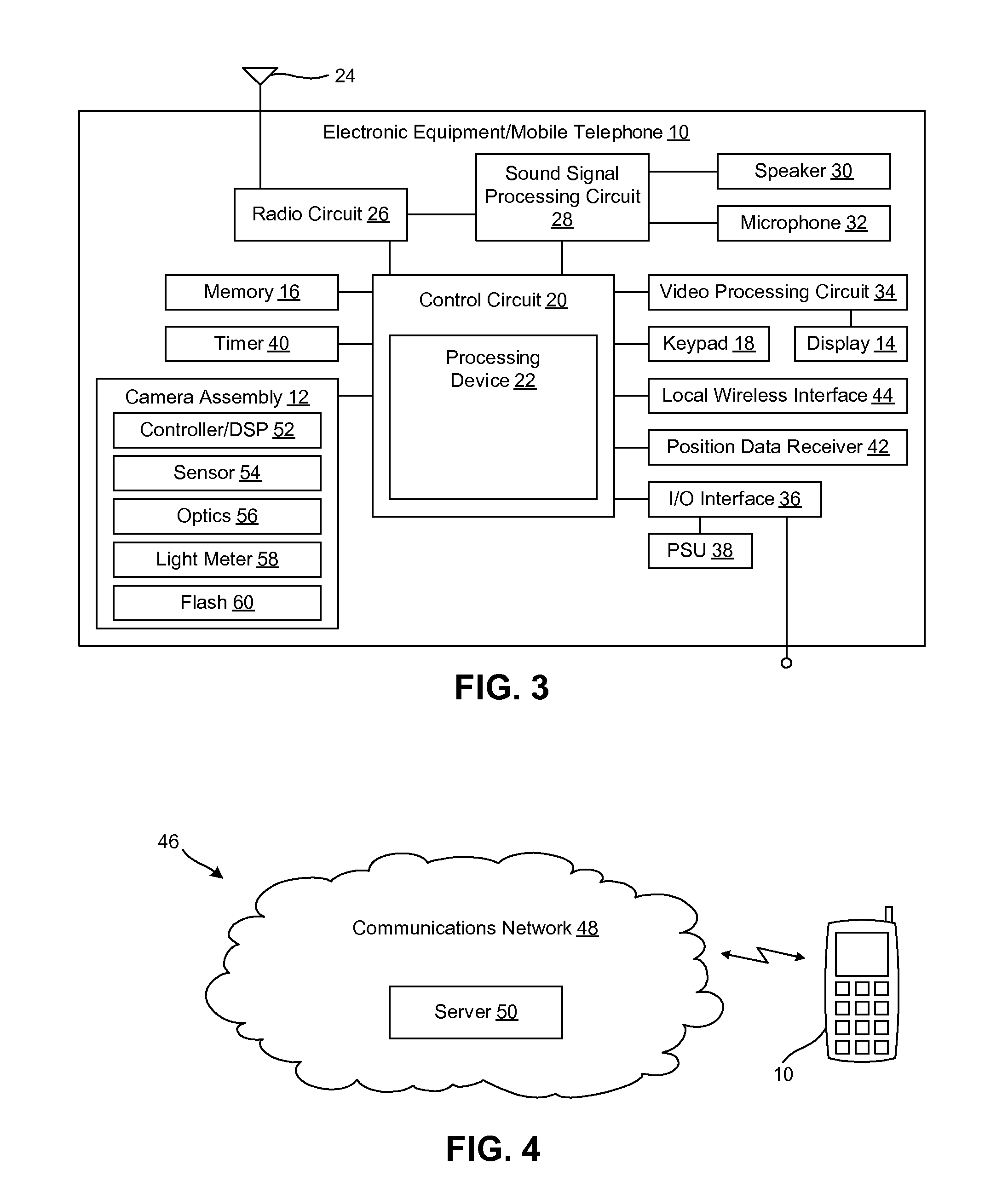

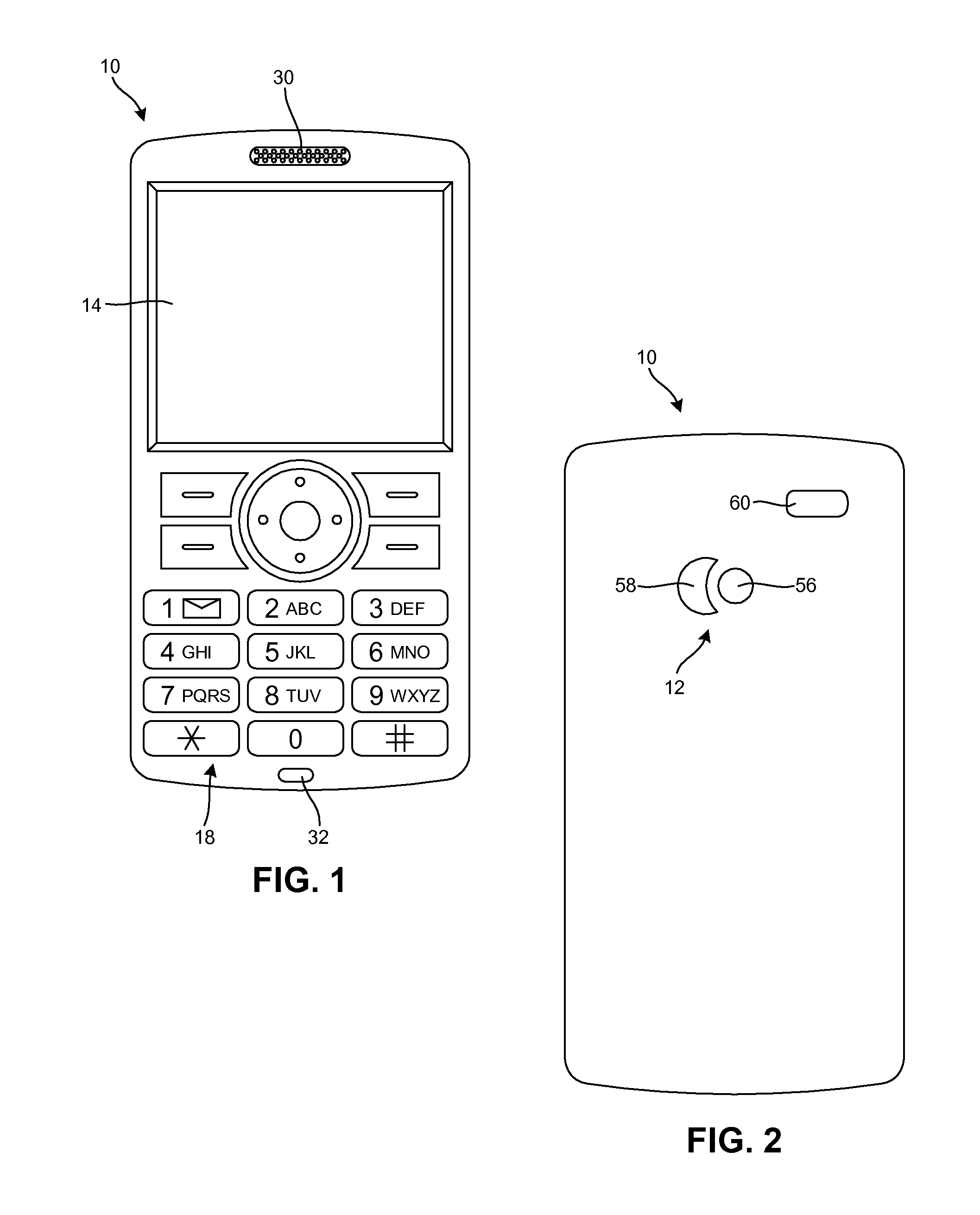

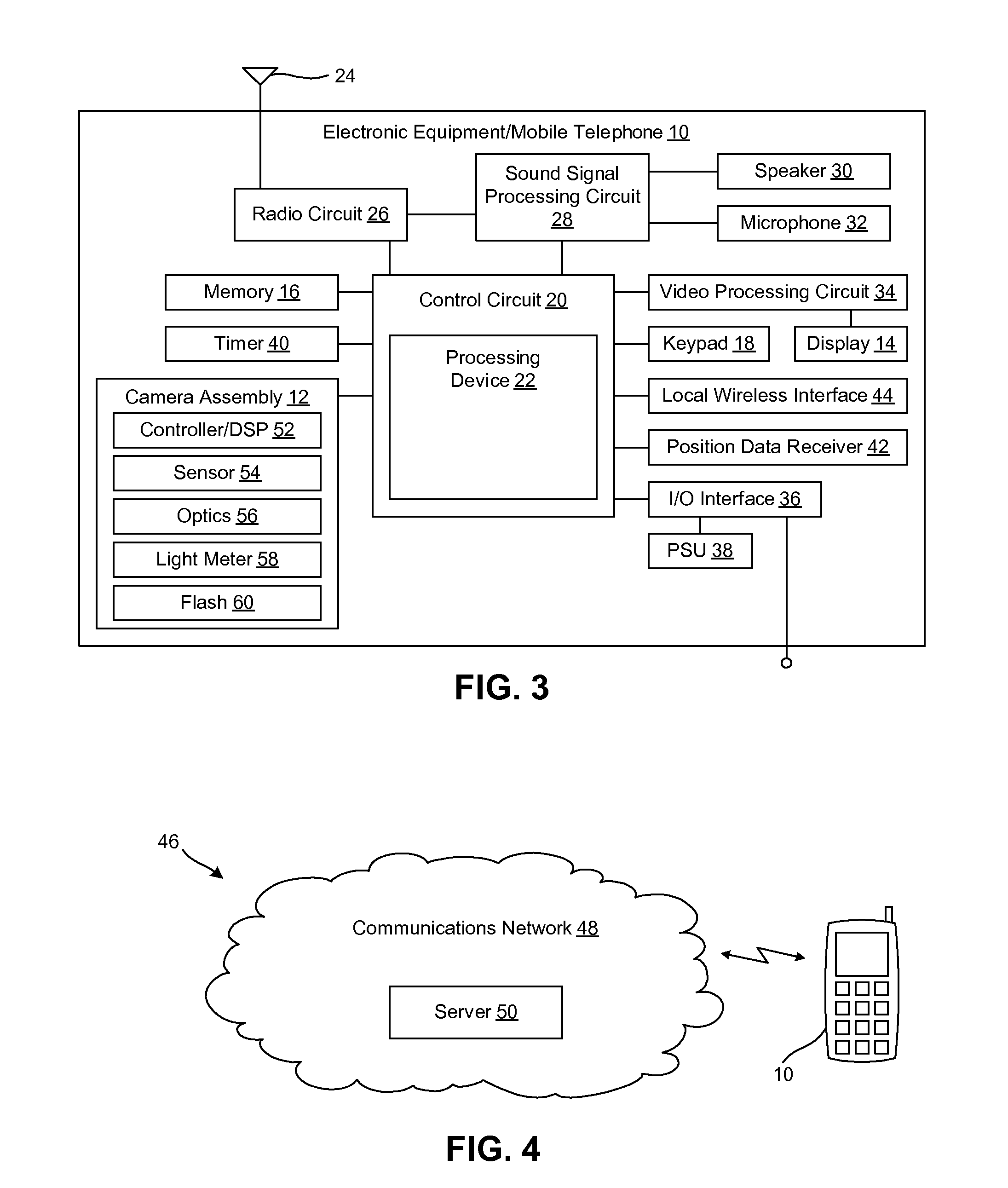

System and method for camera metering based on flesh tone detection

InactiveUS20080117305A1Improve qualityHigh degree of detailTelevision system detailsColor television detailsDigital cameraSkin color

A method of adjusting exposure settings for a digital camera includes searching at least a portion of the field of view of the camera for pixels having a flesh tone. The flesh tone pixels are analyzed to identify at least one flesh tone spot. Spot metering of the field of view of the camera is carried out such that at least one flesh tone spot is given greater weight than the rest of the field of view. Then, the exposure settings are adjusted based on the spot metering.

Owner:SONY ERICSSON MOBILE COMM AB

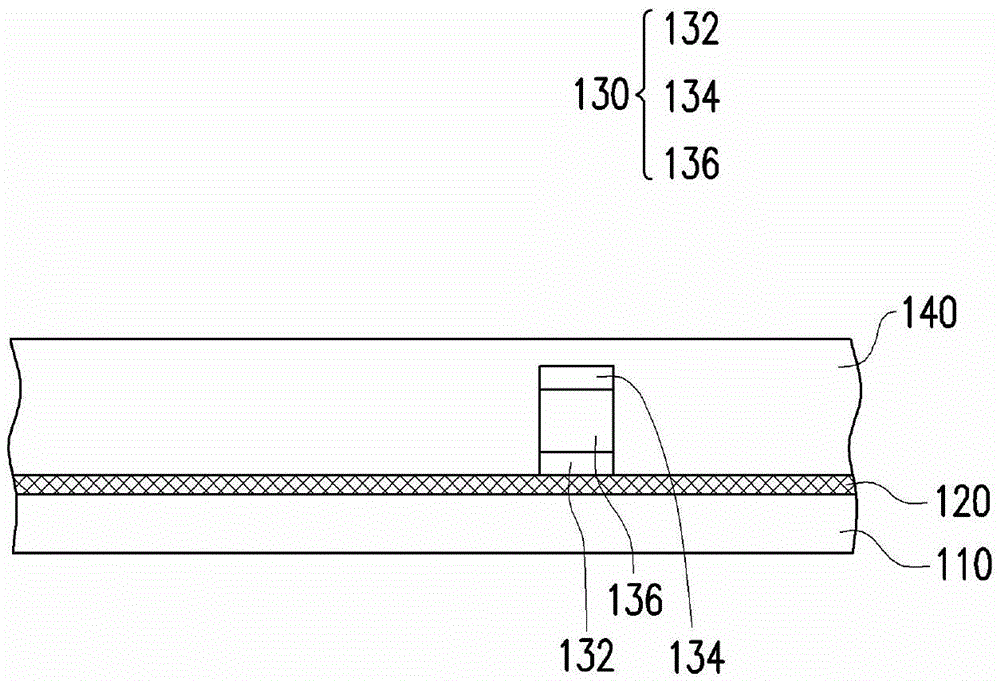

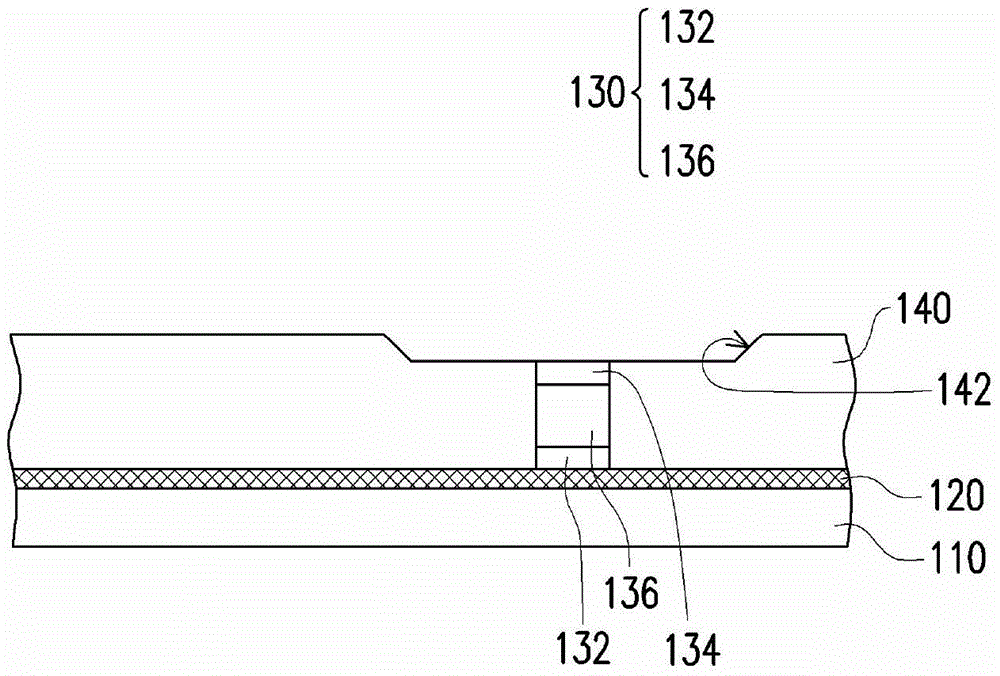

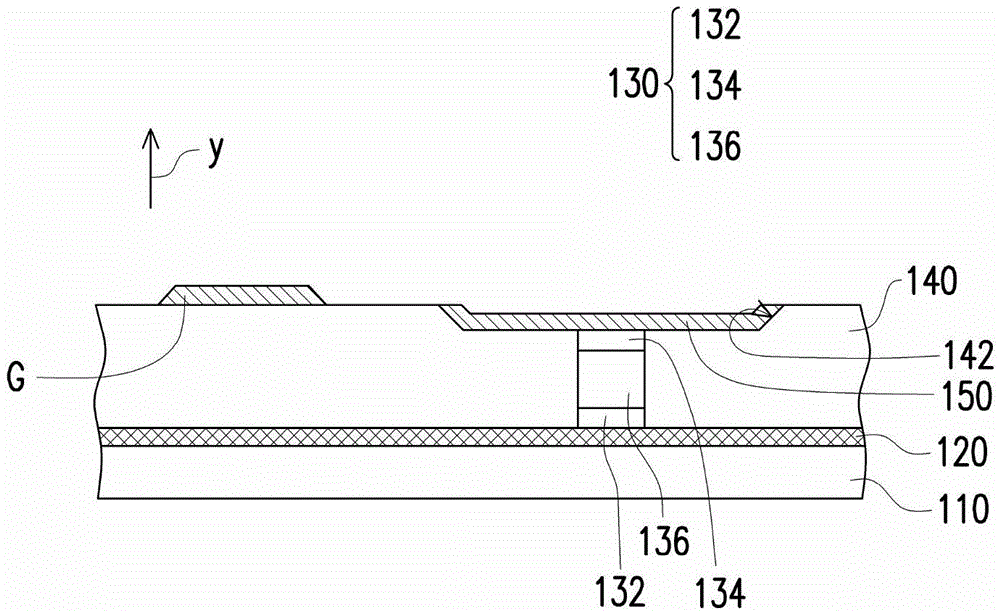

Light sensing apparatus

ActiveCN105552159AReduce thicknessNot easy to straySolid-state devicesSemiconductor devicesLight sensingLight-emitting diode

A light sensing apparatus comprises a first base plate, a light emitting diode, a light sensing unit and a driving element electrically connected with the light sensing unit. The invention relates an arraying relation between the light emitting diode and the light sensing unit on the first base plate.

Owner:AU OPTRONICS CORP

Method for producing a composite layer

InactiveUS20050196545A1Preventing oxidation and burningEasy to sprayLiquid surface applicatorsMolten spray coatingVitrificationInorganic particle

Disclosed is a method for forming a composite layer, in which a mixture of the inorganic particles and the thermoplastic resin are flame sprayed to a substrate at a temperature of not less than the glass transition point of the thermoplastic resin and not more than melting point of the inorganic particles, wherein the mixture comprises 85-99% by weight of the inorganic particles and 15-1% by weight of the thermoplastic resin, total weight of the mixture being 100% by weight.

Owner:KONICA MINOLTA INC

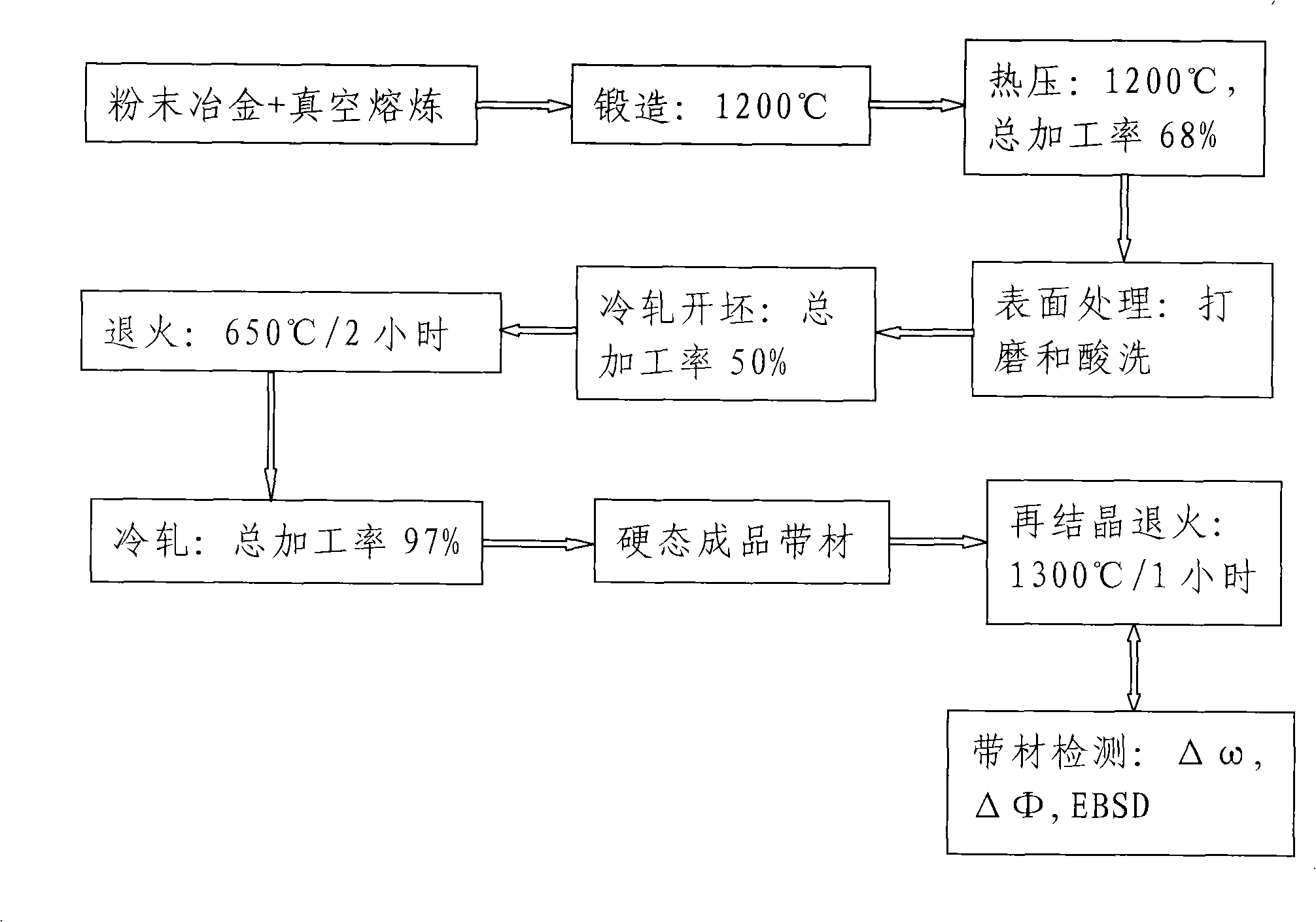

Preparing method of nickel tungsten base band used for coated conductor

InactiveCN101514413AImprove uniformityHigh sharpnessFurnace typesHeat treatment furnacesElectrical conductorElectric arc furnace

The invention discloses a preparing method of a nickel tungsten base band used for a coated conductor. A powder metallurgic method is adopted to prepare a Ni-5at%W pre alloy rod according to the atomic ratio of Ni to W which is equal to 95 to 5; the pre alloy rod is melted for two times in a vacuum electric arc furnace to obtain nickel tungsten cast ingot; after forging, hot rolling and cold rolling, Ni-5at%W alloy strip is obtained, and one time of destressing intermediate annealing is added into the cold rolling process; the continuous recrystallization annealing is carried out on the Ni-5at%W alloy strip to obtain the nickel tungsten base band with cubic texture. The powder metallurgic method and the vacuum electric arc furnace are adopted for the melting by the invention to prepare the nickel tungsten cast ingot. The evenness of the alloy distribution is improved. Processes of forging, hot rolling, cold rolling and continuous recrystallization annealing are adopted to obtain the nickel tungsten base band with the cubic texture with high sharpness. The alloy base band has high tensile strength and yield strength. The width and the length of the alloy base band can reach to the practical application requirement for the preparation of practical coated conductor long band.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

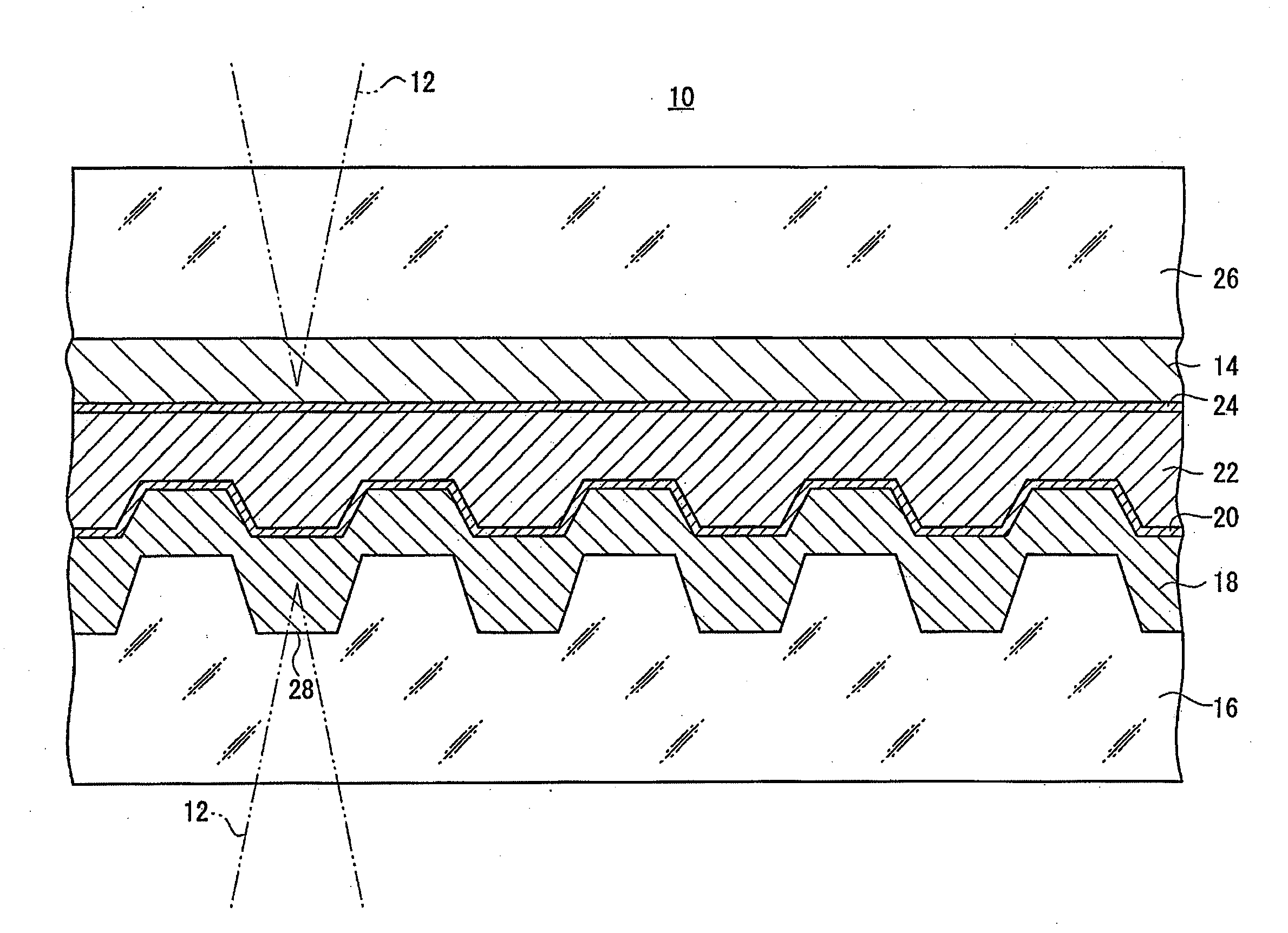

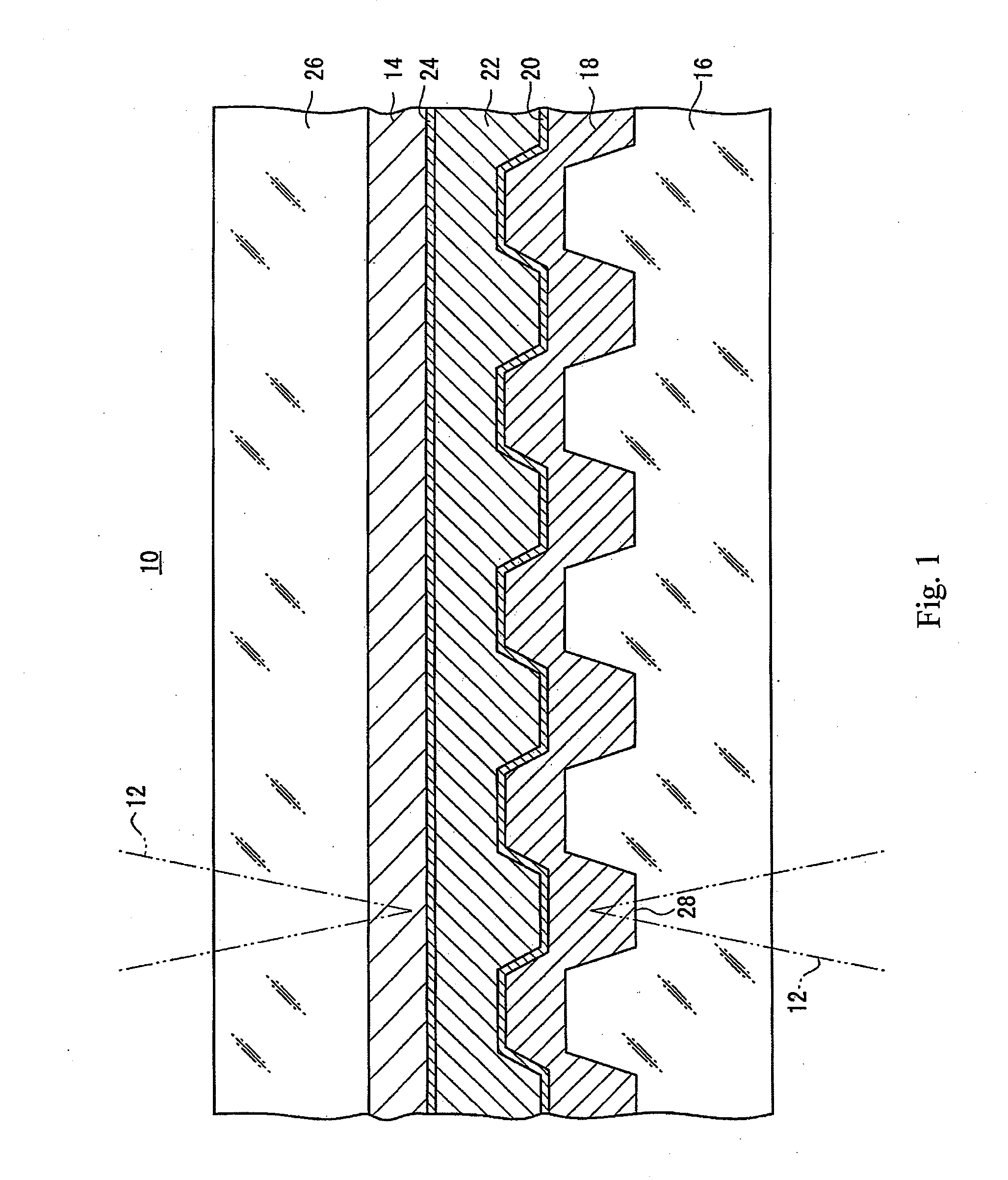

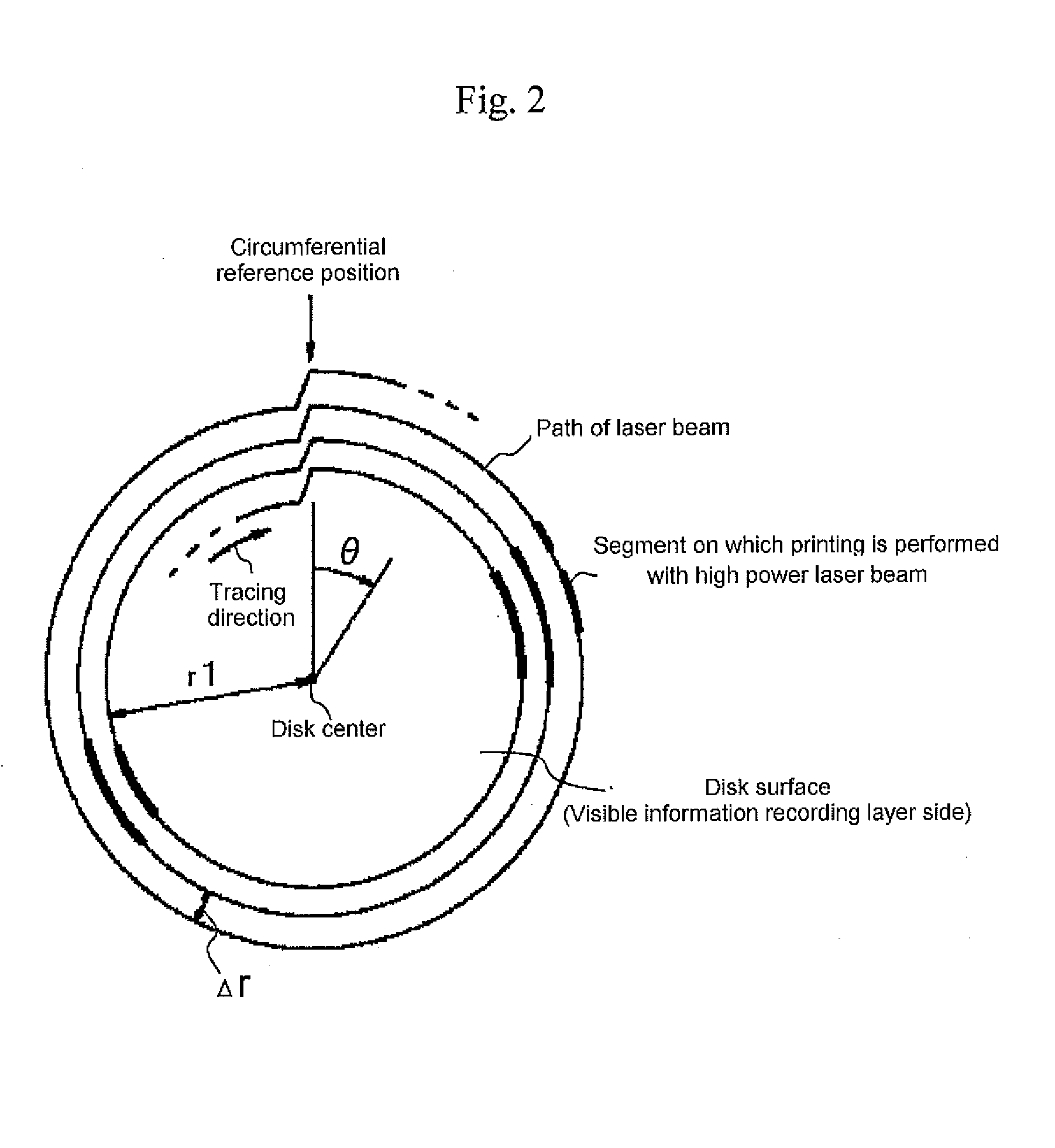

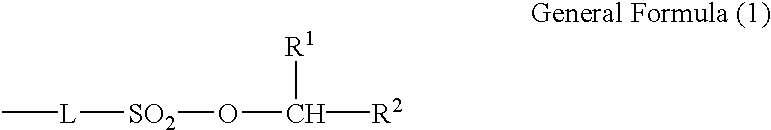

Optical recording medium and method of recording visible information

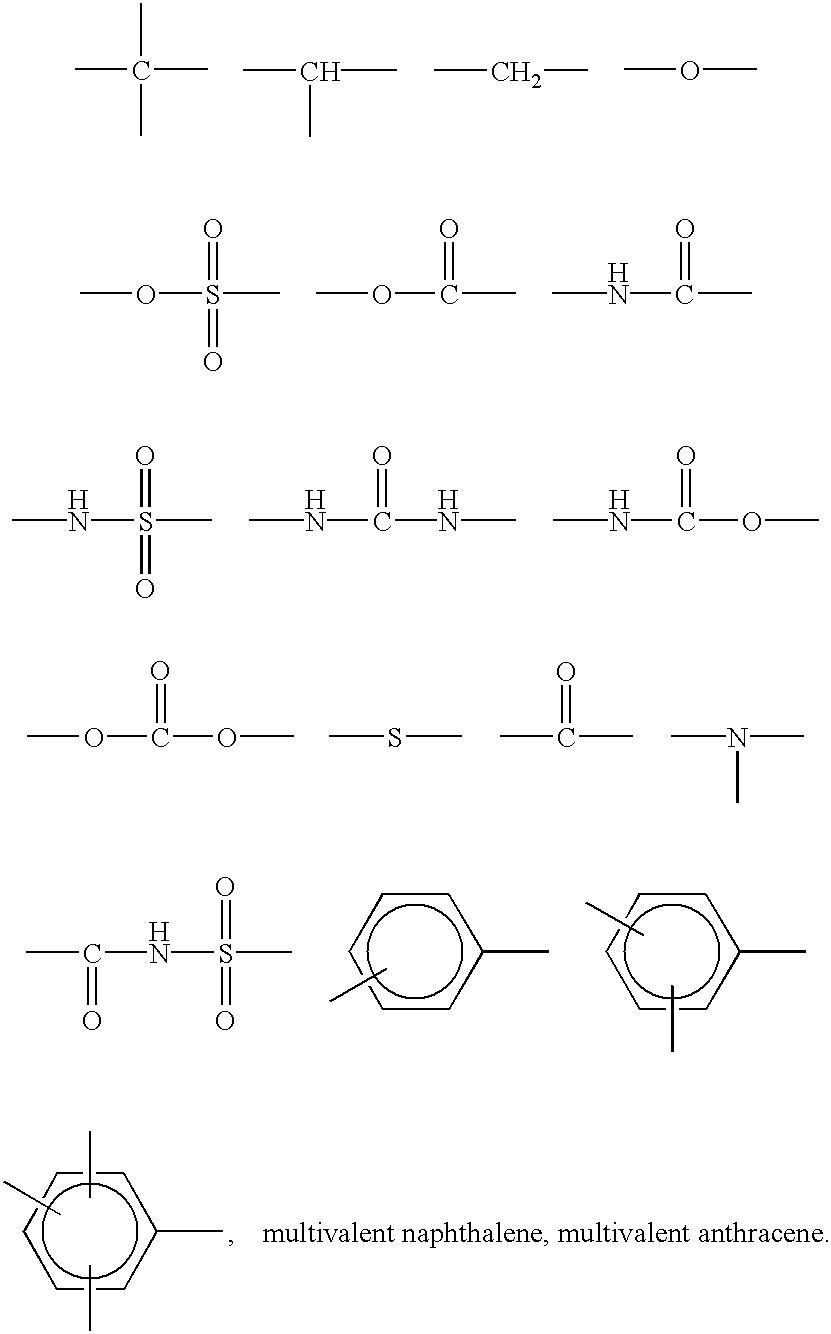

InactiveUS20090058982A1Increase contrastImprove visibilityLayered productsRecord information storageArylHydrogen atom

The optical recording medium comprises a visible information recording layer comprising at least two dyes of the following dyes.Ra1 to Rb3 each independently denote a hydrogen atom or a monovalent substituent, Ra2 and Ra3 may bond together to form a five to seven-membered heterocyclic ring, A denotes a substituted or unsubstituted aliphatic group, substituted or unsubstituted aryl group, or substituted or unsubstituted heterocyclic group, n denotes 0, 1, 2, or 3.In general formula (II), Rα1 to Rα8 and Rβ1 to Rβ8 each independently denote a hydrogen atom or a monovalent substituent, M denotes two hydrogen atoms, a metal, a metal oxide, or a metal having a ligand.A1═N—B1 General formula (III)A1 denotes a substituted or unsubstituted heterocyclic group, a substituted aliphatic group, or a substituted or unsubstituted carbocyclic group, and B1 denotes a substituted or unsubstituted heterocyclic group or a substituted or unsubstituted aryl group.

Owner:FUJIFILM CORP

Sublimation dye printed textile

ActiveUS8475905B2Quality improvementIncreased surface dimensionality and characterLiquid surface applicatorsDecorative surface effectsTextile printerPolymer science

The present invention is directed to an unstitched design having the appearance of being stitched or embroidered. A stitched design is digitally imaged, and the digital image used to control dye sublimation printing of a representation of the image onto a desired surface. In one configuration, the surface is a woven textile.

Owner:HIGH VOLTAGE GRAPHICS

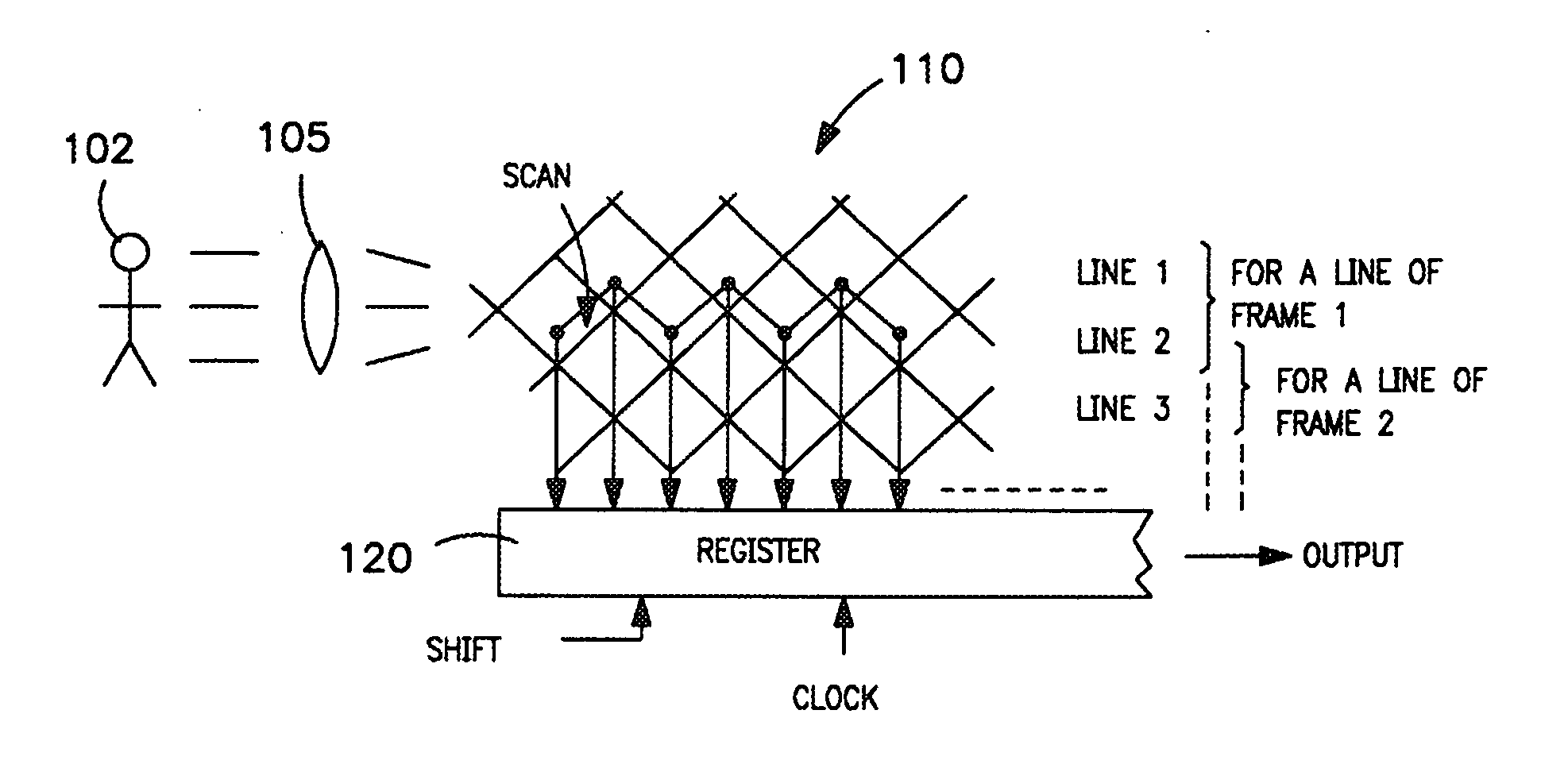

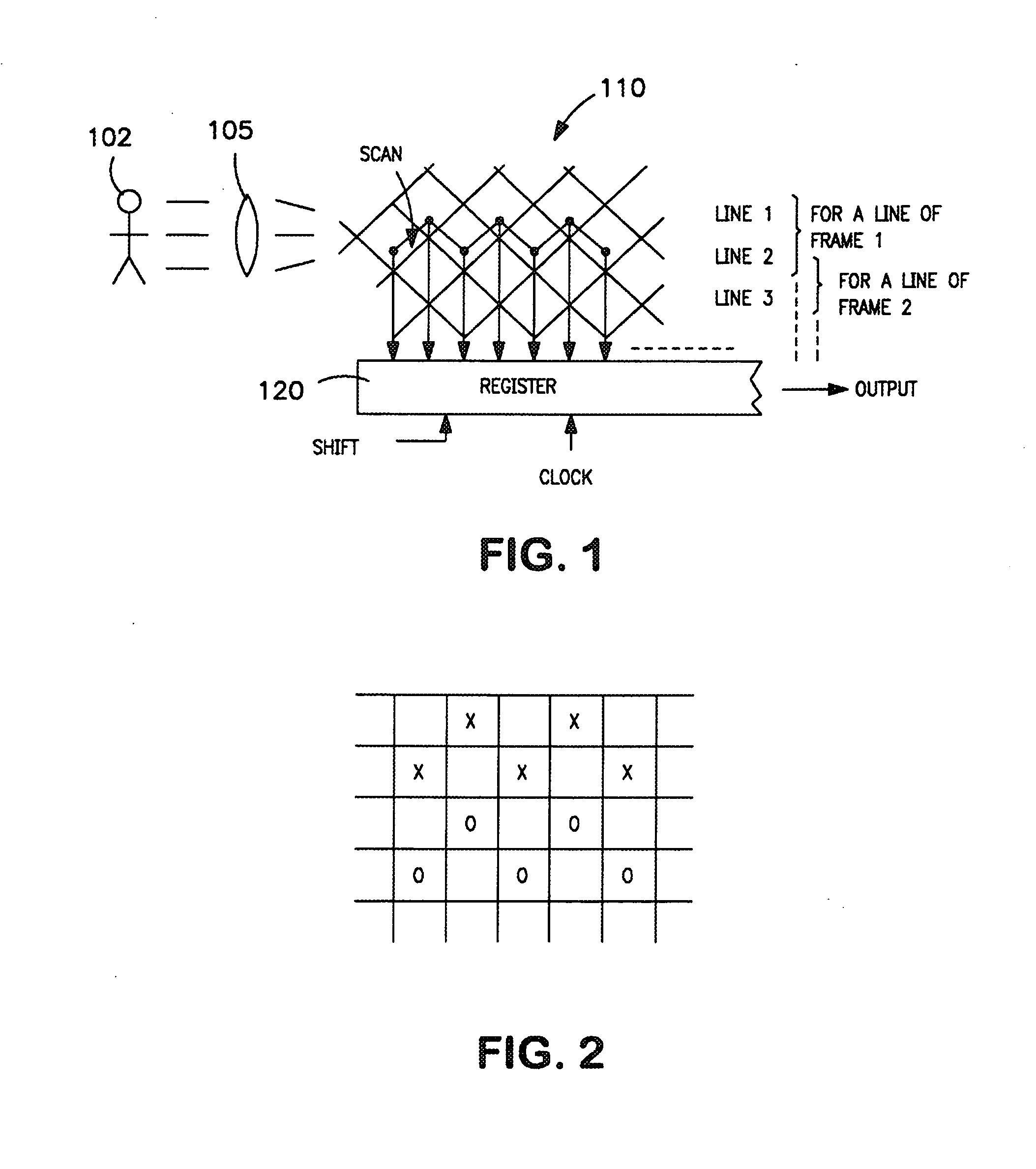

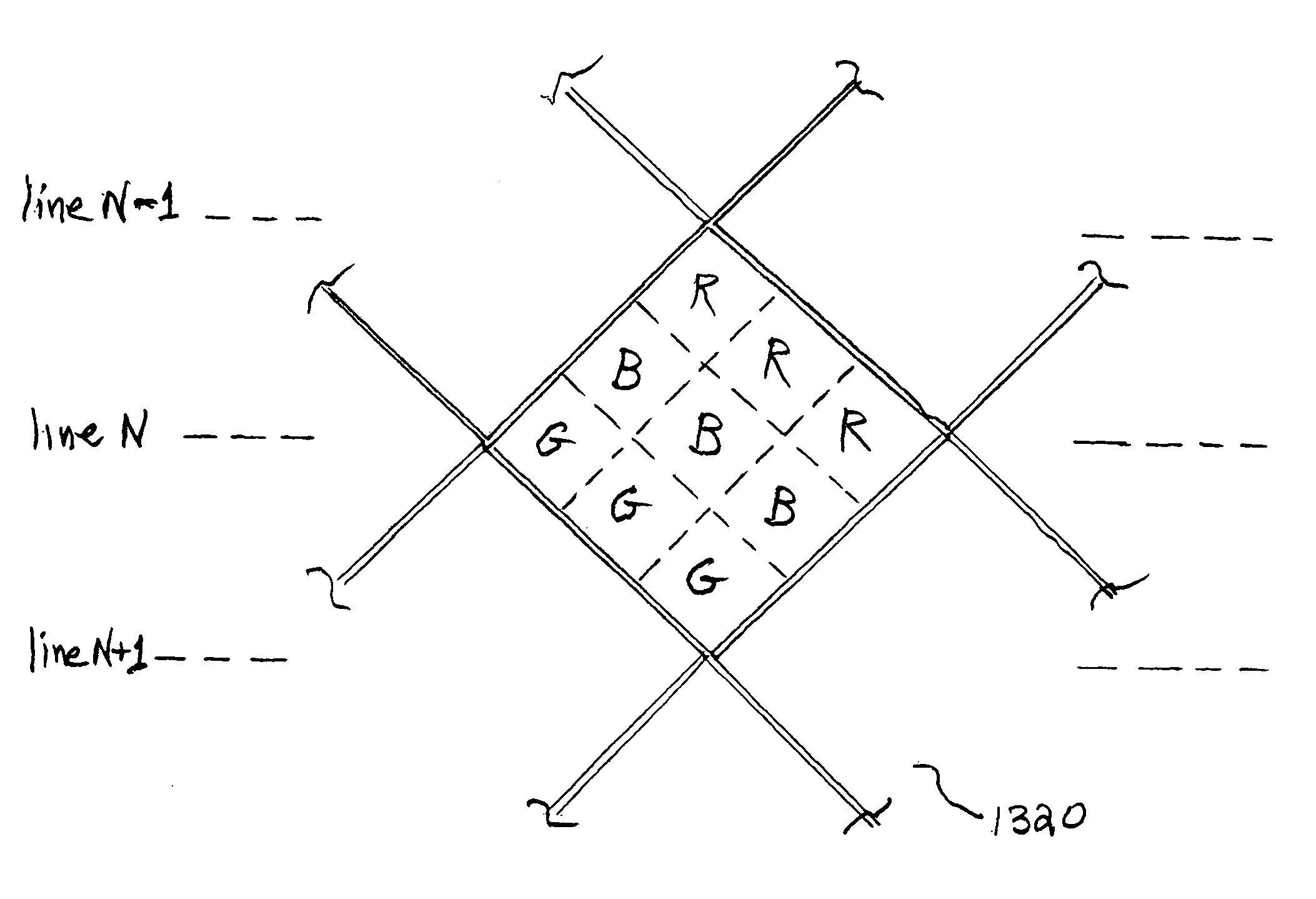

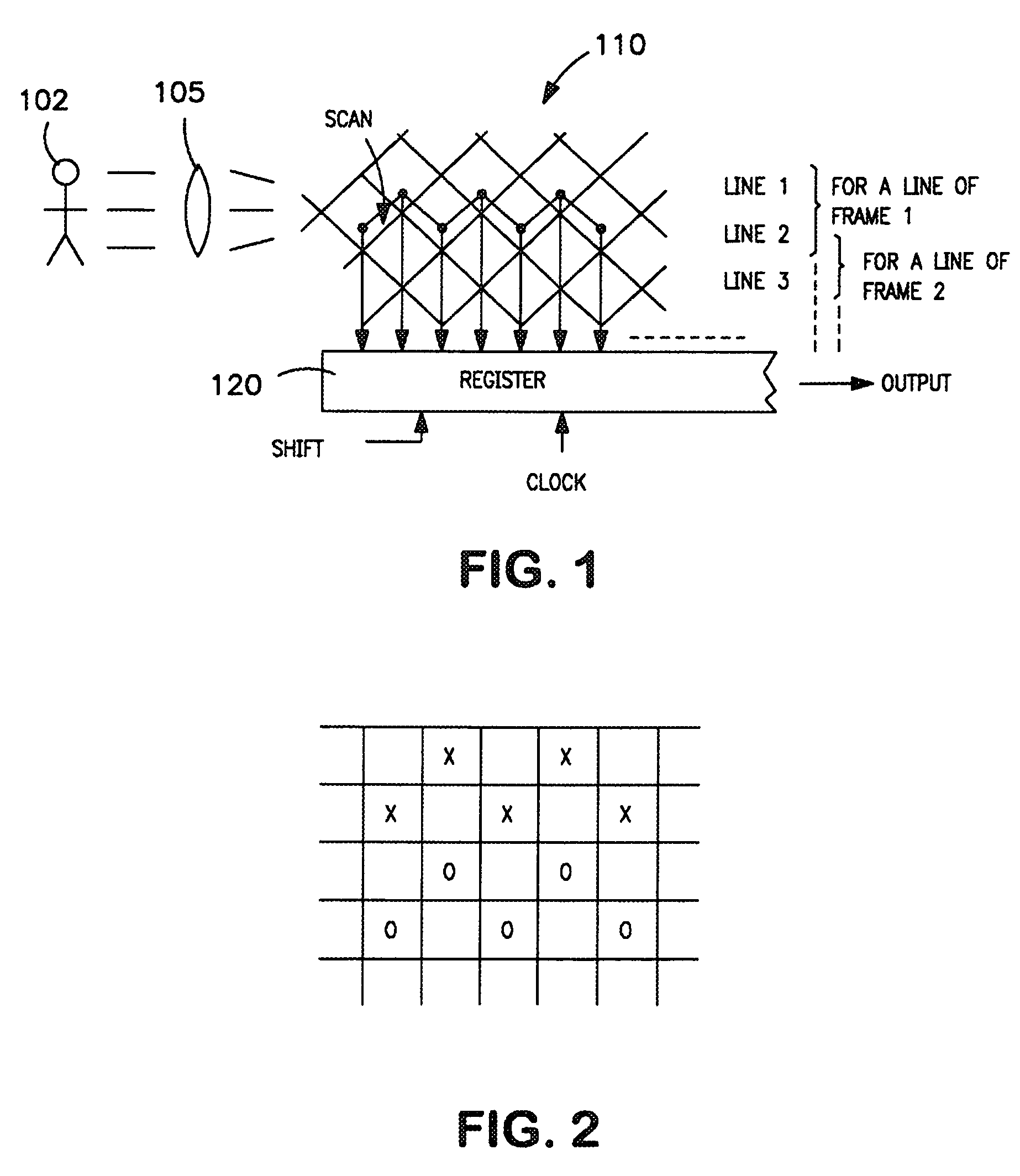

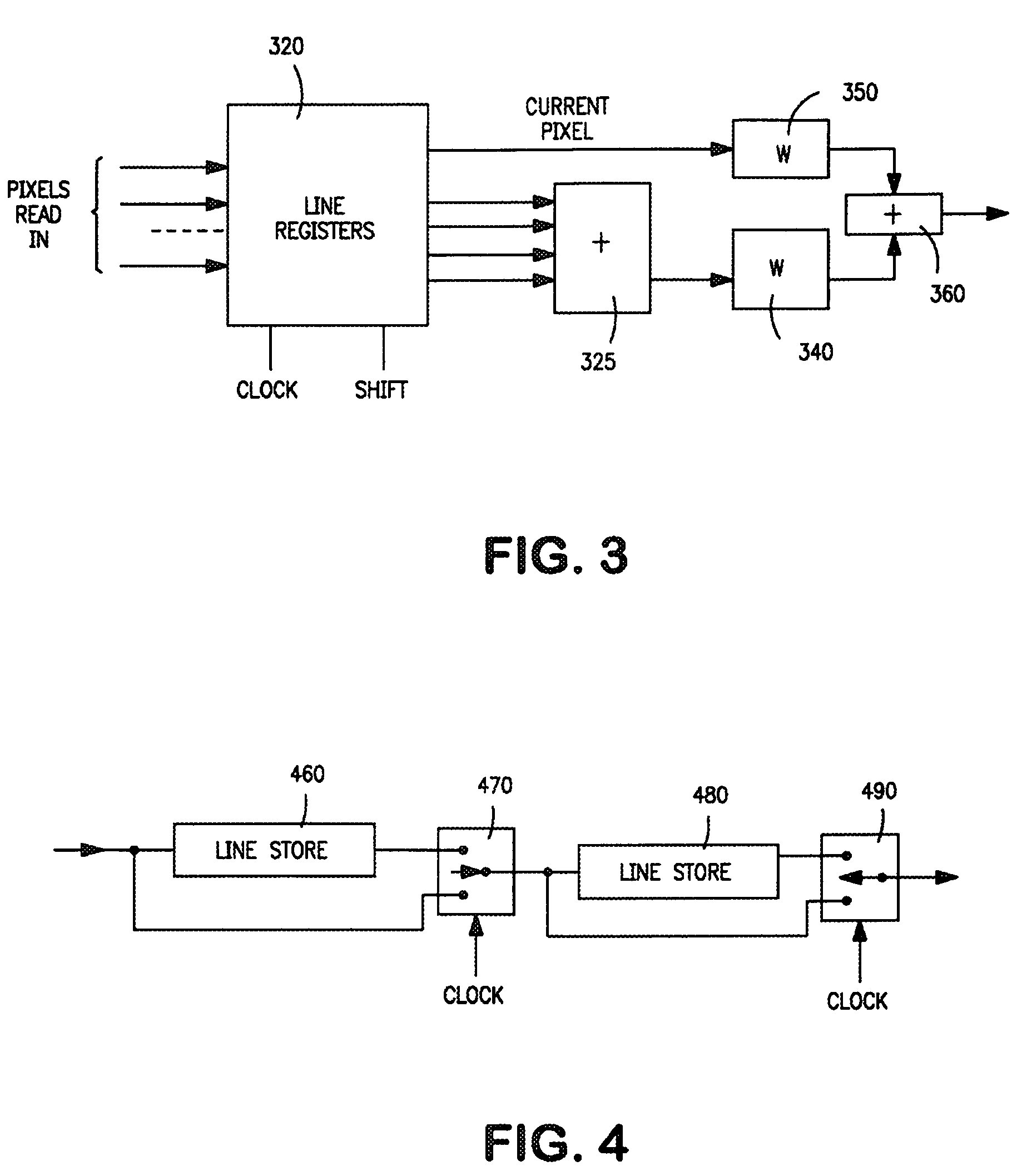

Apparatus and method for producing video signals

InactiveUS20090040362A1Reduce in quantityReduce resolutionTelevision system detailsTelevision system scanning detailsLenticular lensImage sensor

A method is disclosed for producing signals representative of an image of a scene including the following steps: providing an image sensor with a lenticular lens pattern thereon, and projecting the image onto the image sensor via the lenticular lens pattern, the image sensor having a pixel element pattern and the lenticular lens pattern having diamond shaped lenticles and being diagonally oriented with respect to the horizontal scanning direction of the pixel element pattern; and producing image-representative signals by reading out signals from the pixel elements of the image sensor.

Owner:FLORIDA ATLANTIC UNIVERSITY

Ink set, ink cartridge, inkjet recording method, and inkjet recording apparatus

ActiveUS8435339B2Improve permeabilityHigh densityMeasurement apparatus componentsDuplicating/marking methodsColor imageWater dispersible

An ink set includes at least two aqueous inks A and B with different colors, the inks A and B used in an inkjet recording method in which the inks A and B are superimposed for formation of a color image, wherein the ink A contains water-dispersible colorant A1 free of a surfactant-based dispersant, and anionic compound A2, and wherein the ink B contains water-dispersible colorant B1 containing a surfactant-based dispersant.

Owner:RICOH KK

Inkjet printing system, ink, and process

InactiveUS20100092669A1High printing densityHigh text sharpnessNon-fibrous pulp additionSpecial tyresOrganic baseWater soluble

An inkjet printing system comprises an inkjet printer and an inkjet ink comprising water, a self-dispersing carbon black pigment, and a water soluble polymer containing carboxylate groups, wherein:the carbon black pigment comprises greater than 11 weight % volatile surface functional groups; andthe ink also contains an organic base having a pKa>7.5 and an optional inorganic base in combined amounts sufficient to provide alkaline equivalents of at least 150% of the acid equivalents of the water soluble polymer;provided the equivalents of the organic base are greater than or equal to the equivalents of the inorganic base.

Owner:EASTMAN KODAK CO

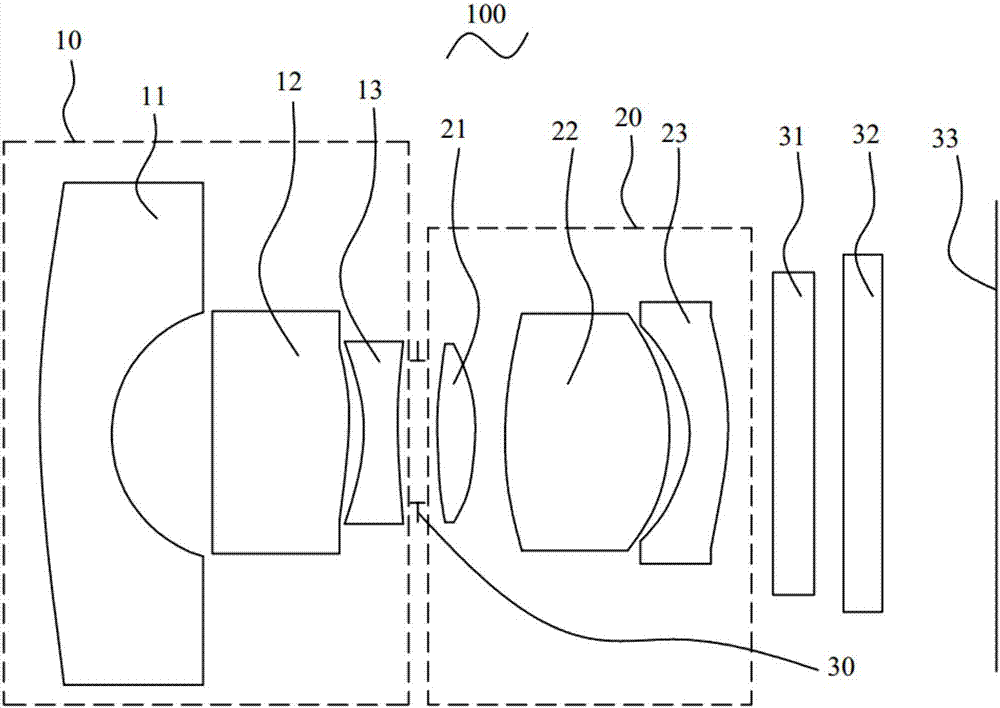

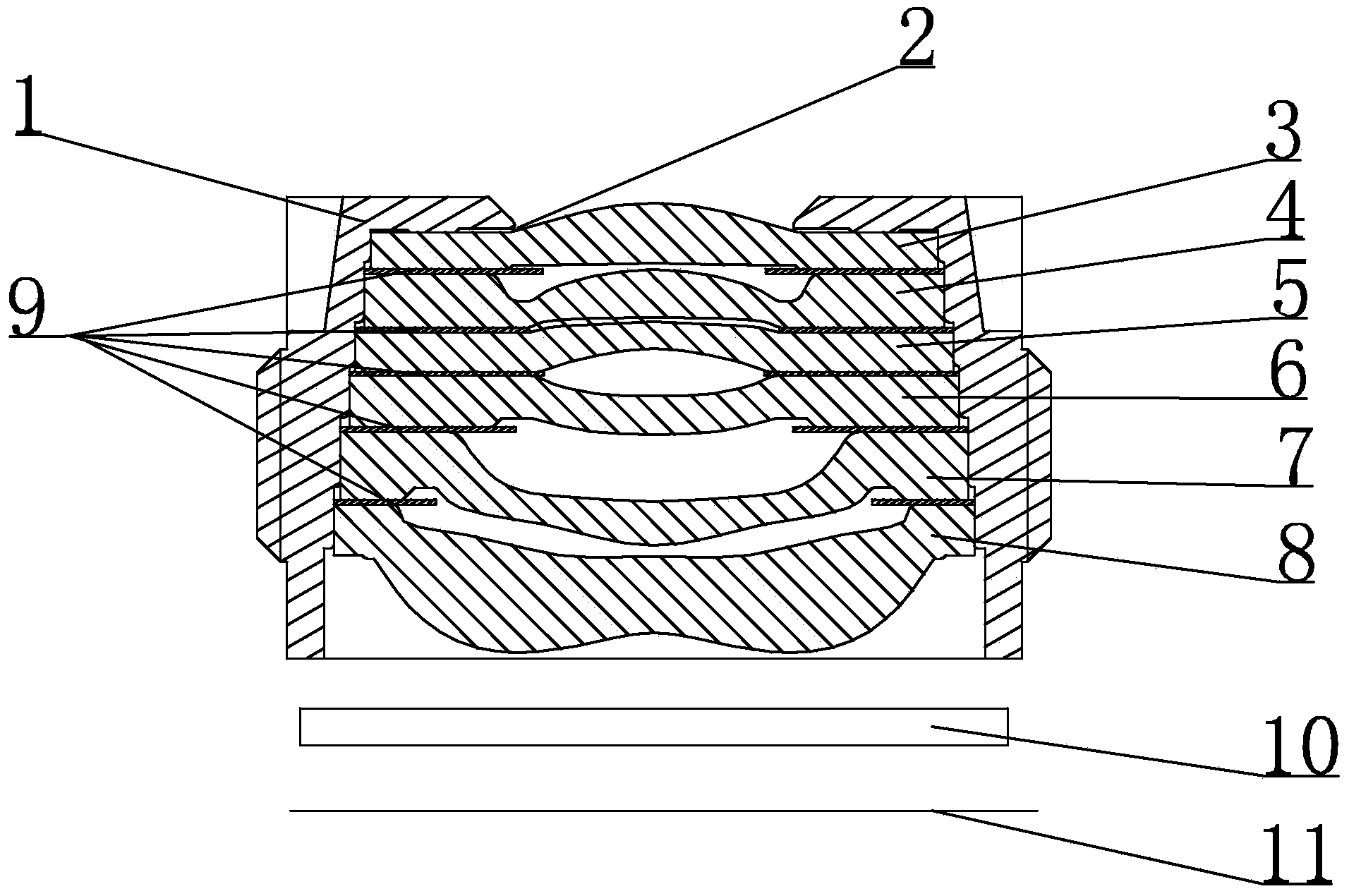

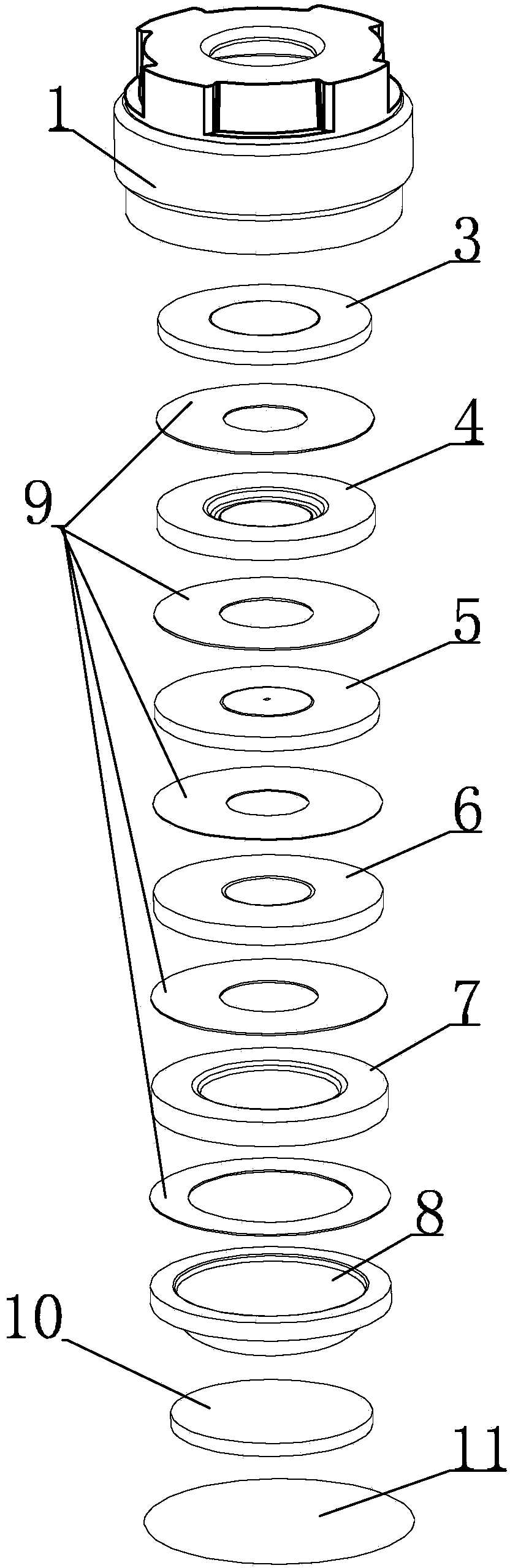

Monitoring lens

Owner:JIANGXI LIANCHUANG ELECTRONICS CO LTD

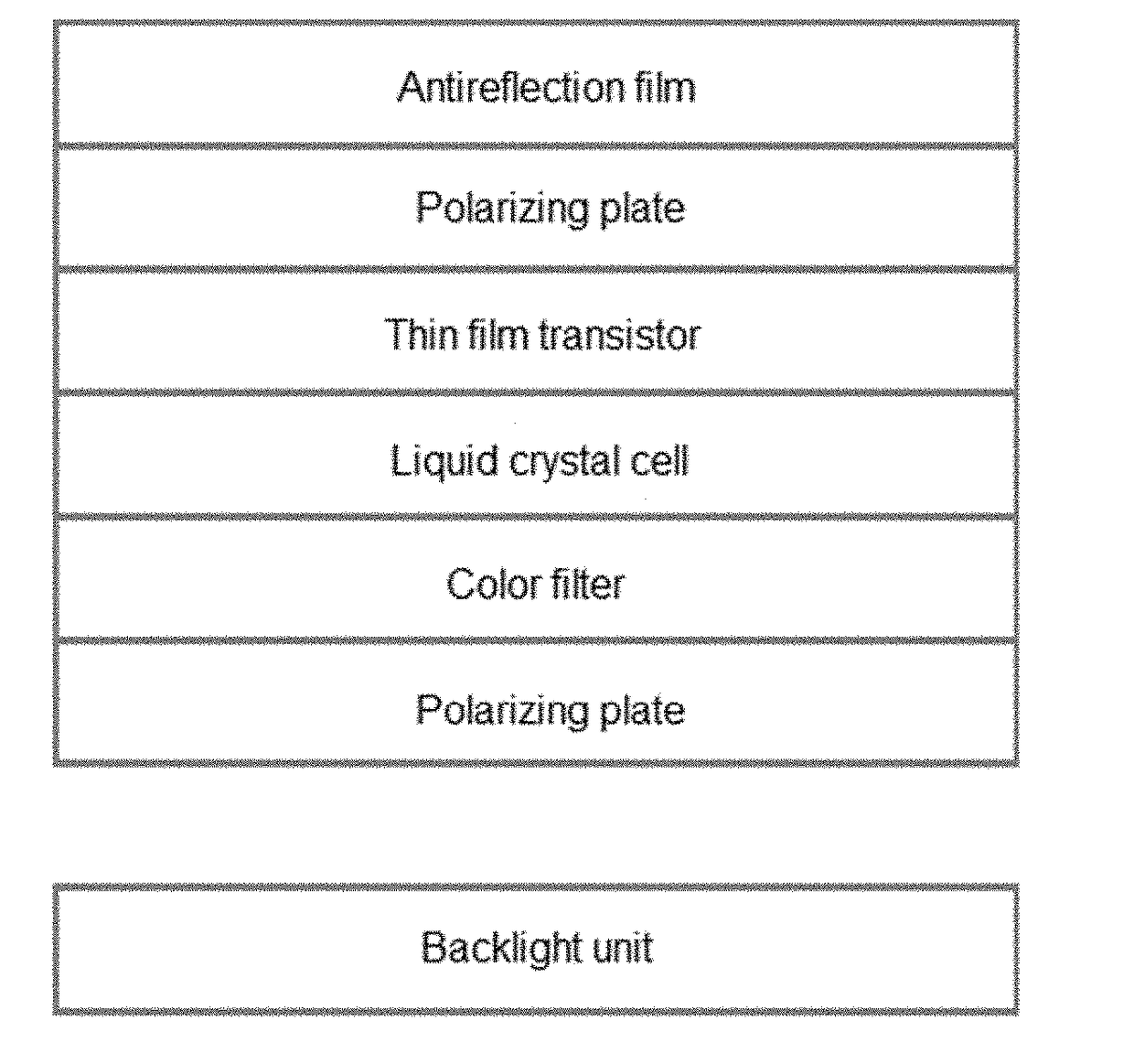

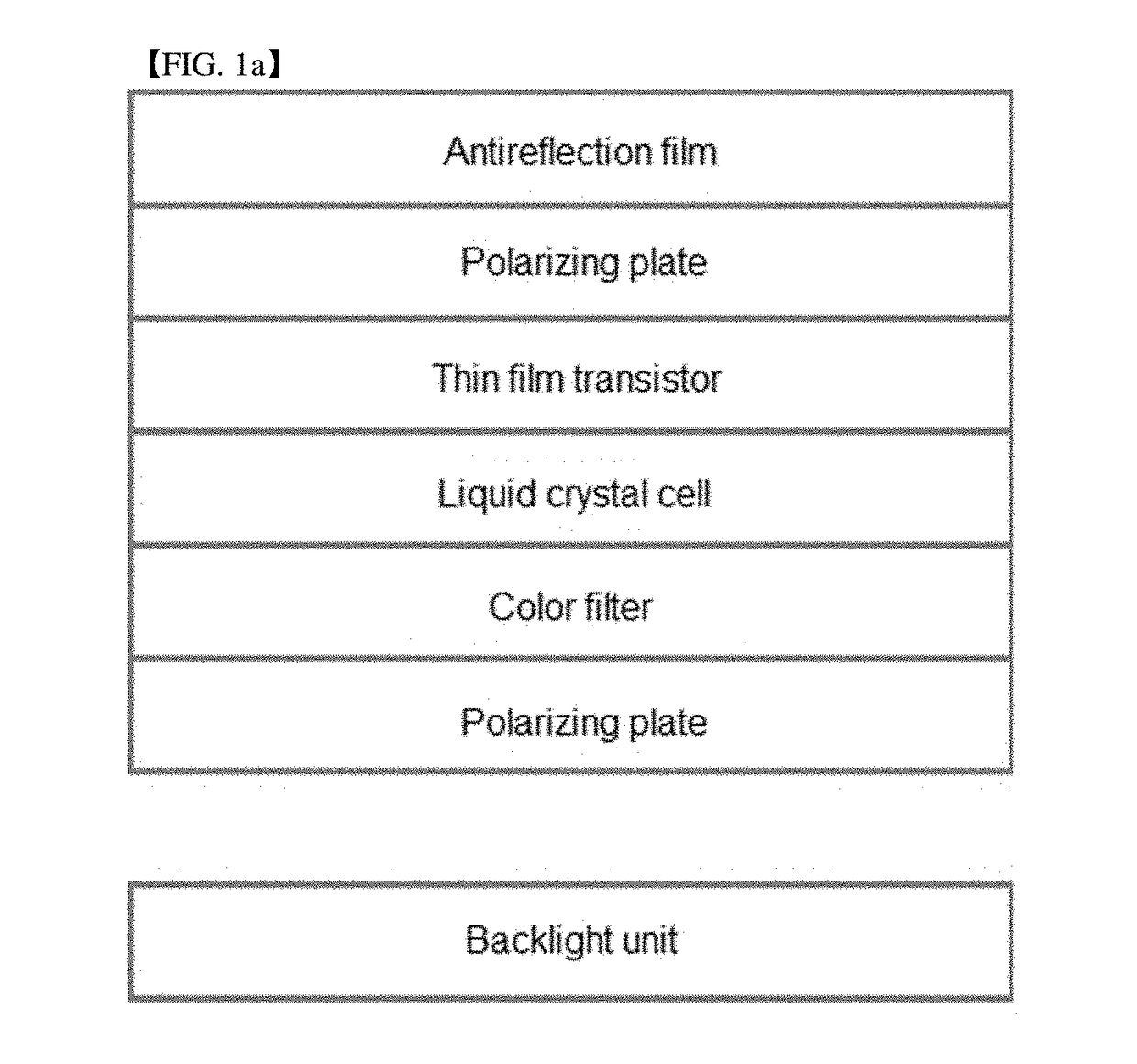

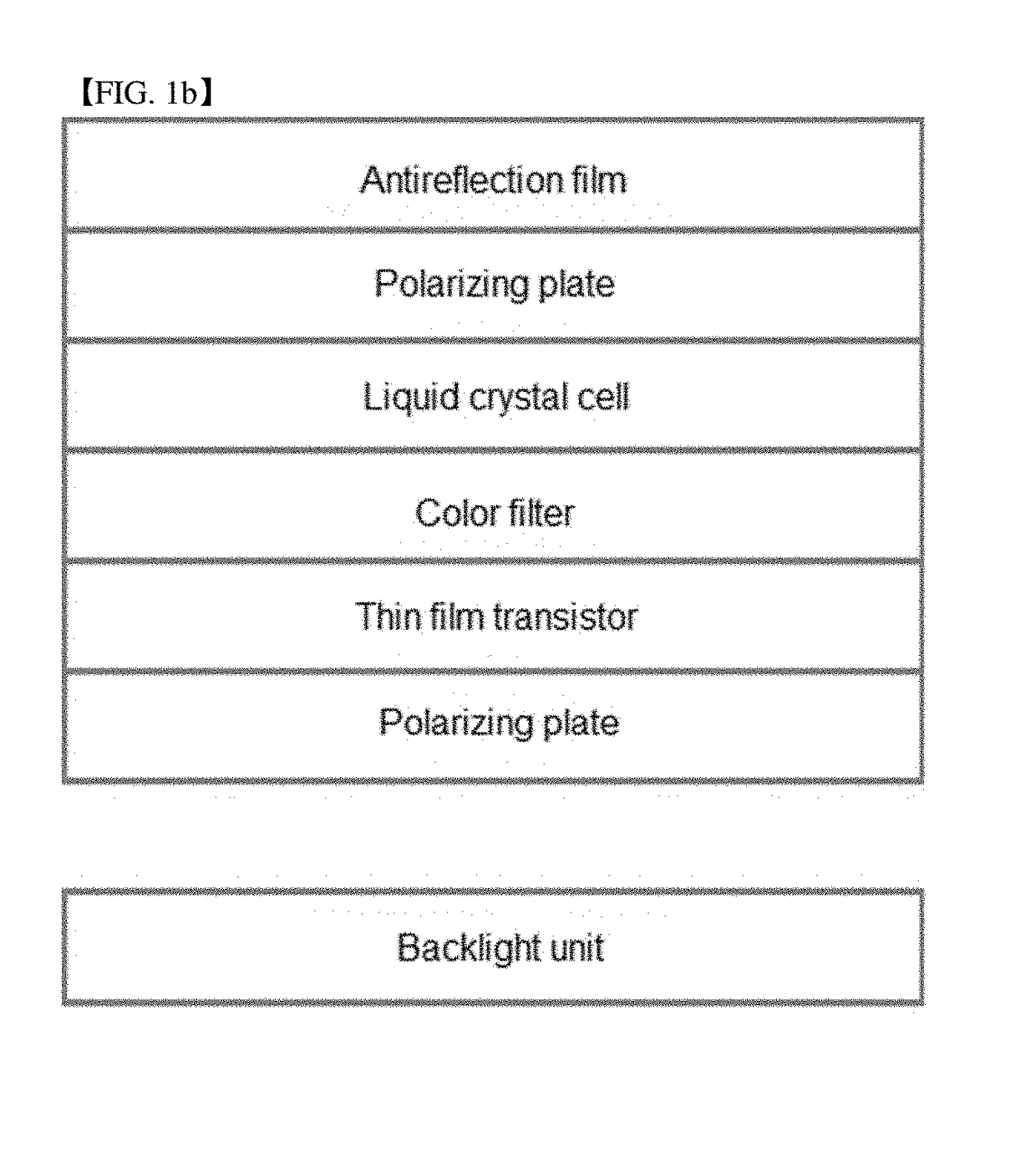

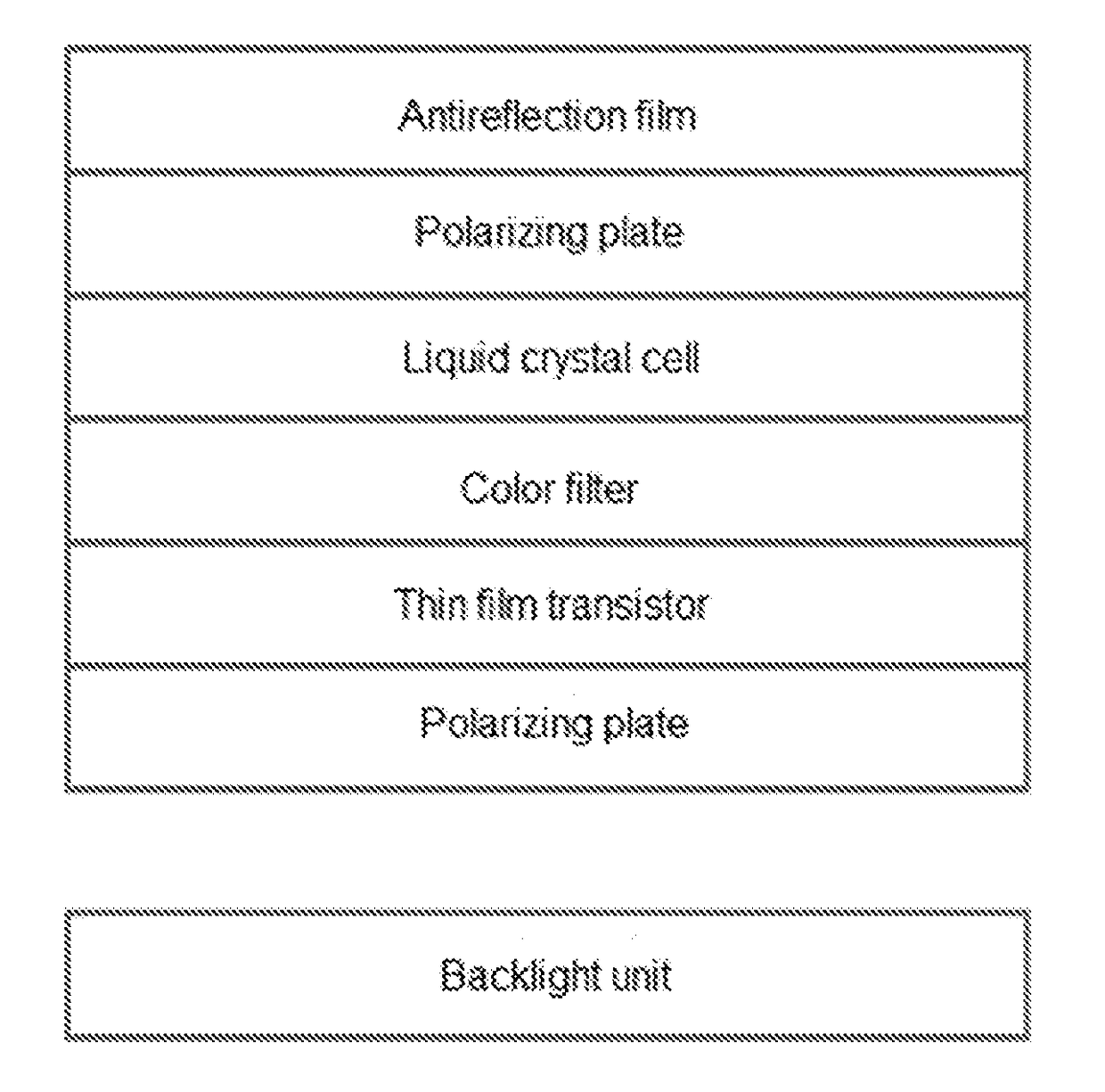

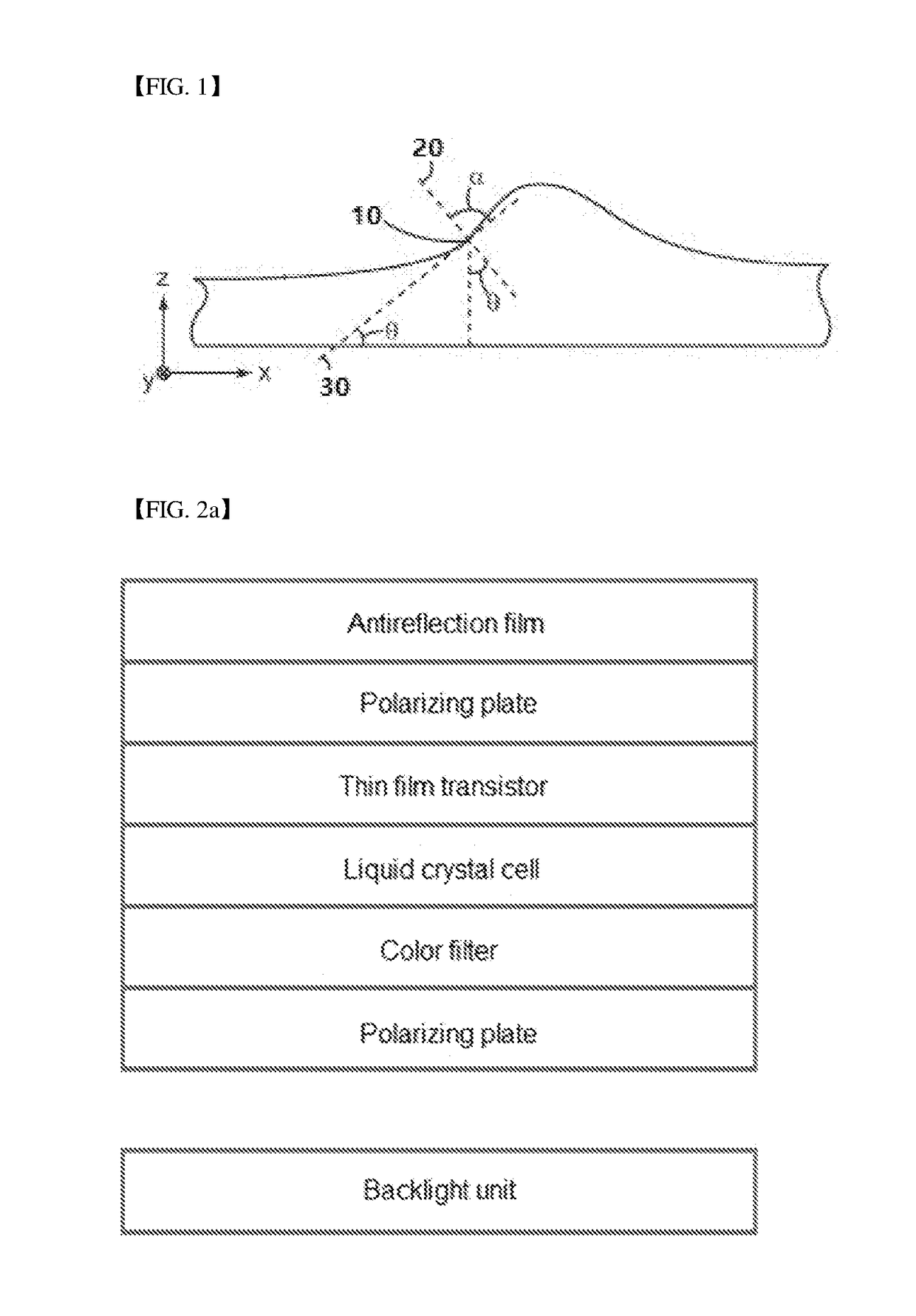

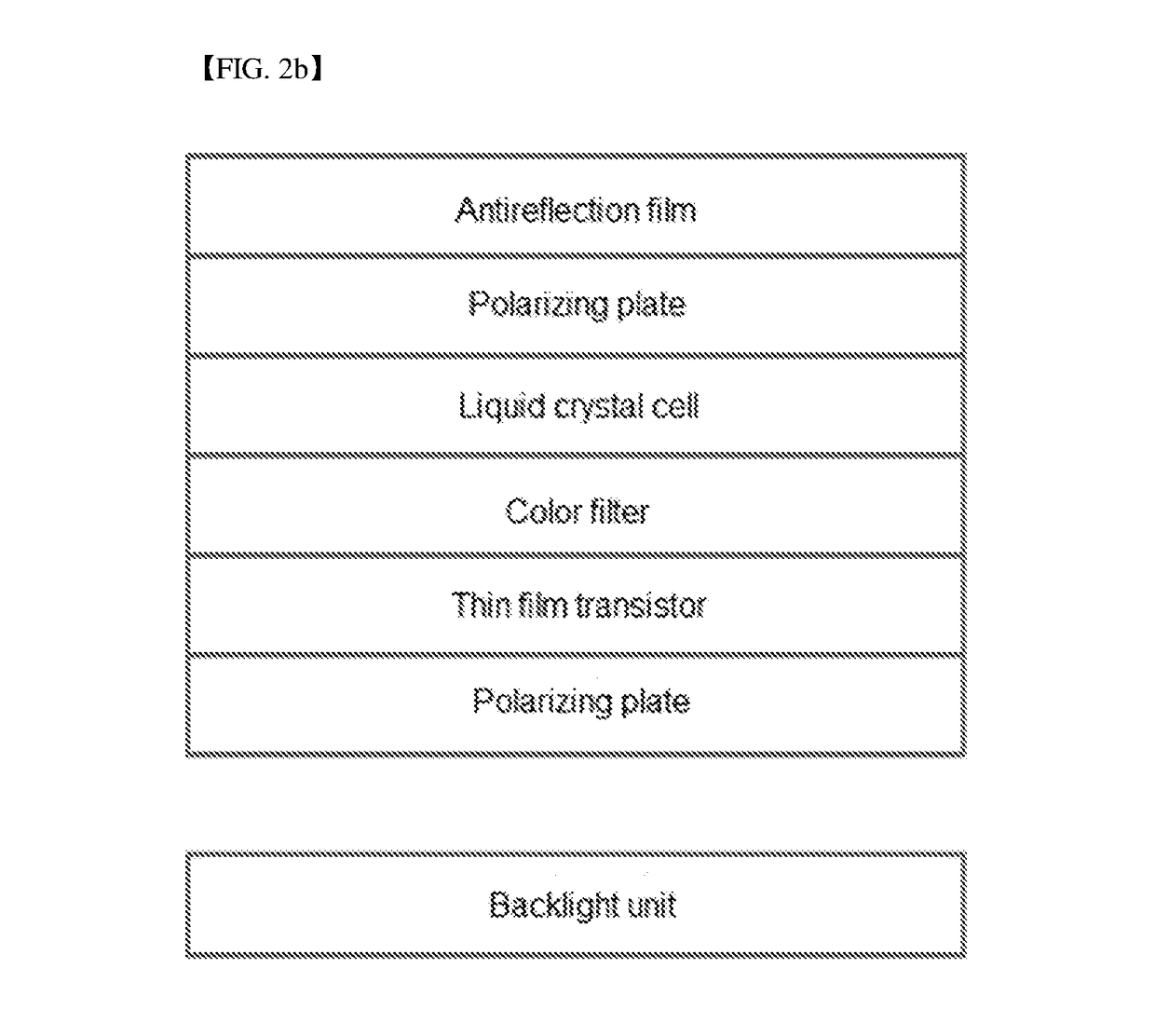

Antireflection film and display device

ActiveUS20180313978A1Reduced sparkling phenomenonImprove visibilityCoatingsNon-linear opticsRefractive indexDisplay device

The present invention relates to an antireflection film comprising a hard coating layer in which a ten-point average roughness (Rz) of the surface irregularities is 0.05 μm to 0.2 μm and an internal haze is 0.5% to 5%; and a low refractive index layer formed on the hard coating layer, and a display device comprising the antireflection film.

Owner:LG CHEM LTD

Apparatus and method for producing video signals

InactiveUS7834927B2Reduce in quantityHigh sharpnessTelevision system detailsTelevision system scanning detailsLenticular lensComputer science

A method is disclosed for producing signals representative of an image of a scene including the following steps: providing an image sensor with a lenticular lens pattern thereon, and projecting the image onto the image sensor via the lenticular lens pattern, the image sensor having a pixel element pattern and the lenticular lens pattern having diamond shaped lenticles and being diagonally oriented with respect to the horizontal scanning direction of the pixel element pattern; and producing image-representative signals by reading out signals from the pixel elements of the image sensor.

Owner:FLORIDA ATLANTIC UNIVERSITY

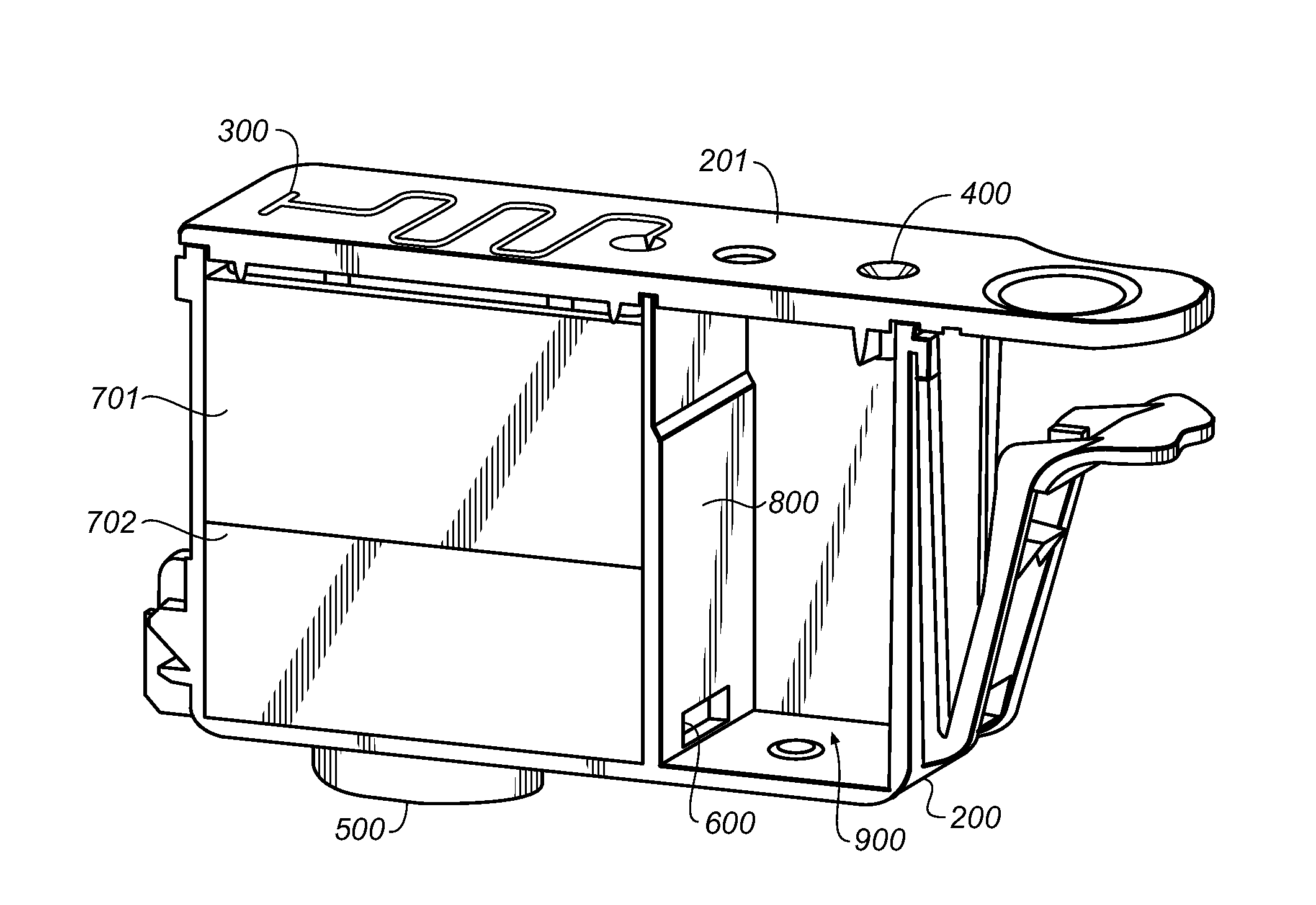

Inkjet printing system

An inkjet printing system including an inkjet printer having a printhead and an inkjet ink in an ink tank supplying the inkjet ink to the printhead, wherein the ink tank includes a free ink compartment and a capillary media compartment vented to the atmosphere and in fluid communication with ink in the free ink compartment, and wherein the inkjet ink includes water, a self-dispersing carbon black pigment having greater than 11 weight % volatile surface functional groups, and a surfactant at a concentration of 0.10 weight percent or less, and having a static surface tension of 37.5 dynes / cm or less at 25° C. The system provides high print density and text sharpness when printed onto an ink receiving medium, and provides good performance in a bubbler-type ink tank which reduces the amount of ink trapped in the ink tank.

Owner:EASTMAN KODAK CO

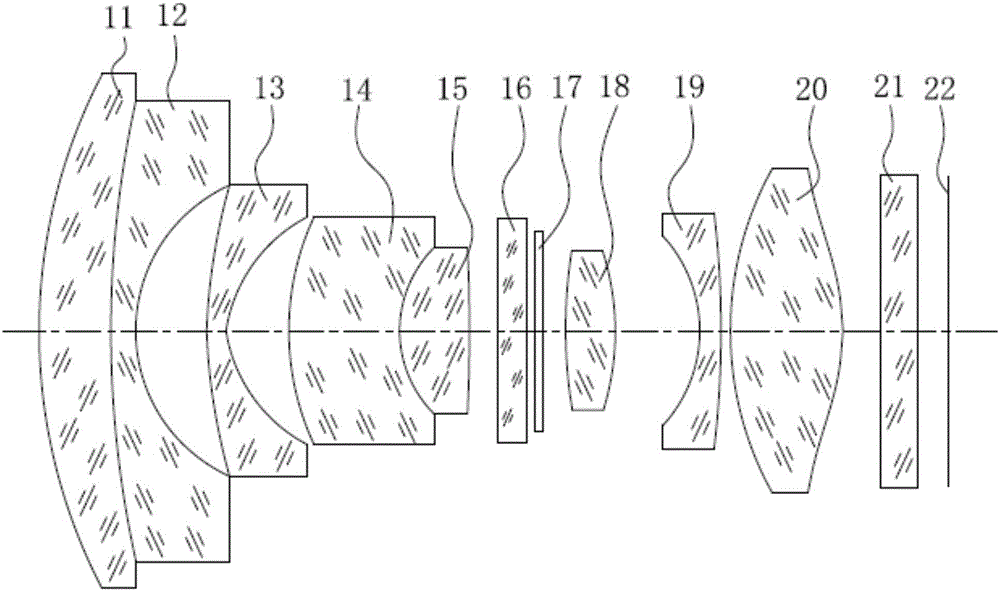

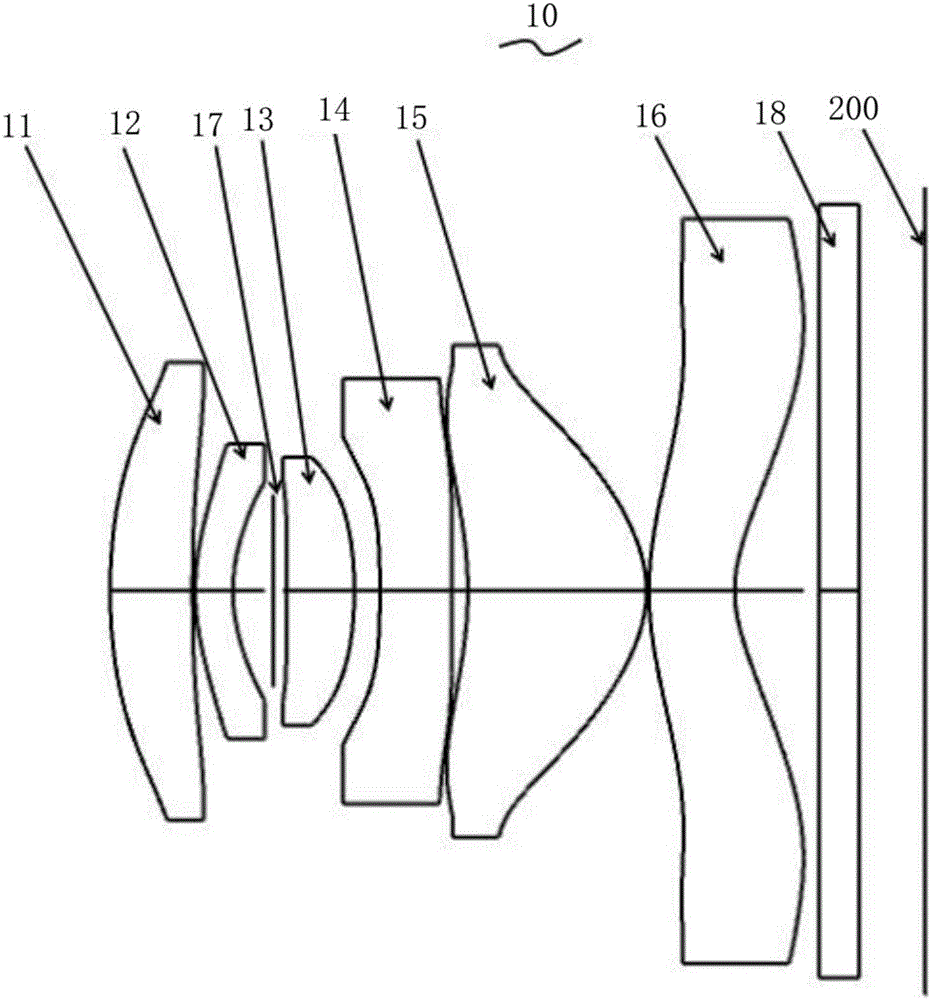

Unmanned aerial vehicle camera lens

ActiveCN106501921AEasy temperature controlExtended service lifeOptical elementsTemperature controlCamera lens

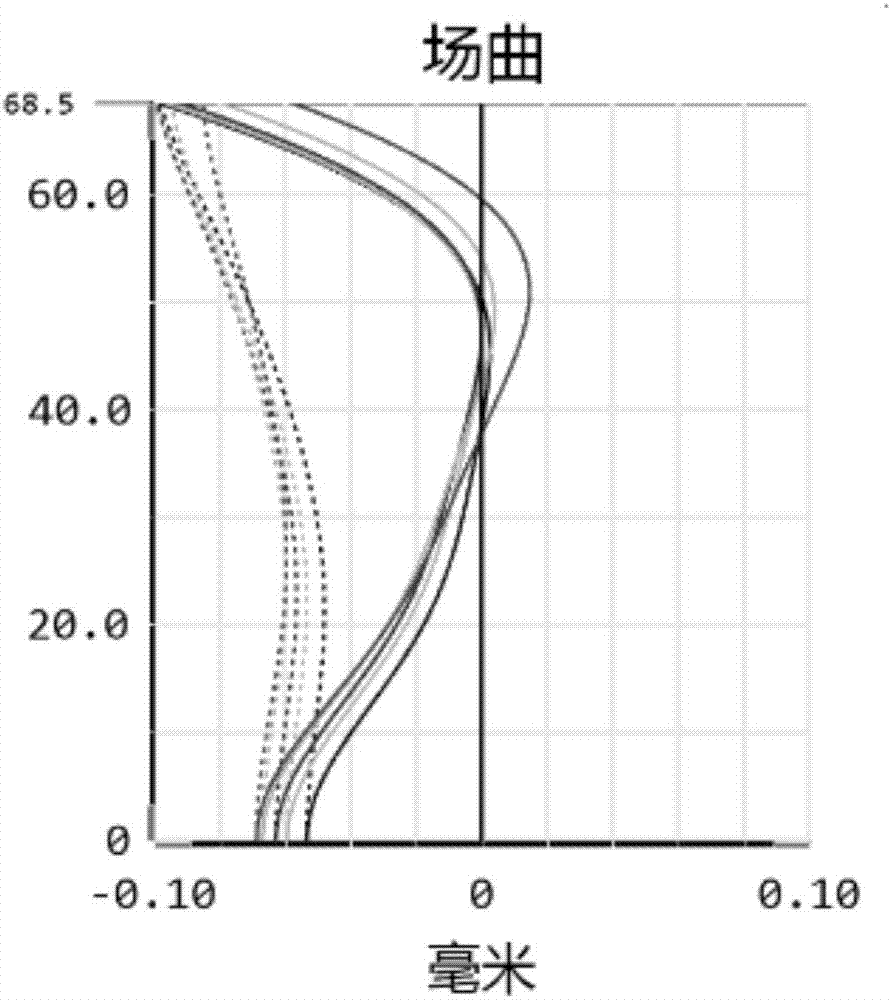

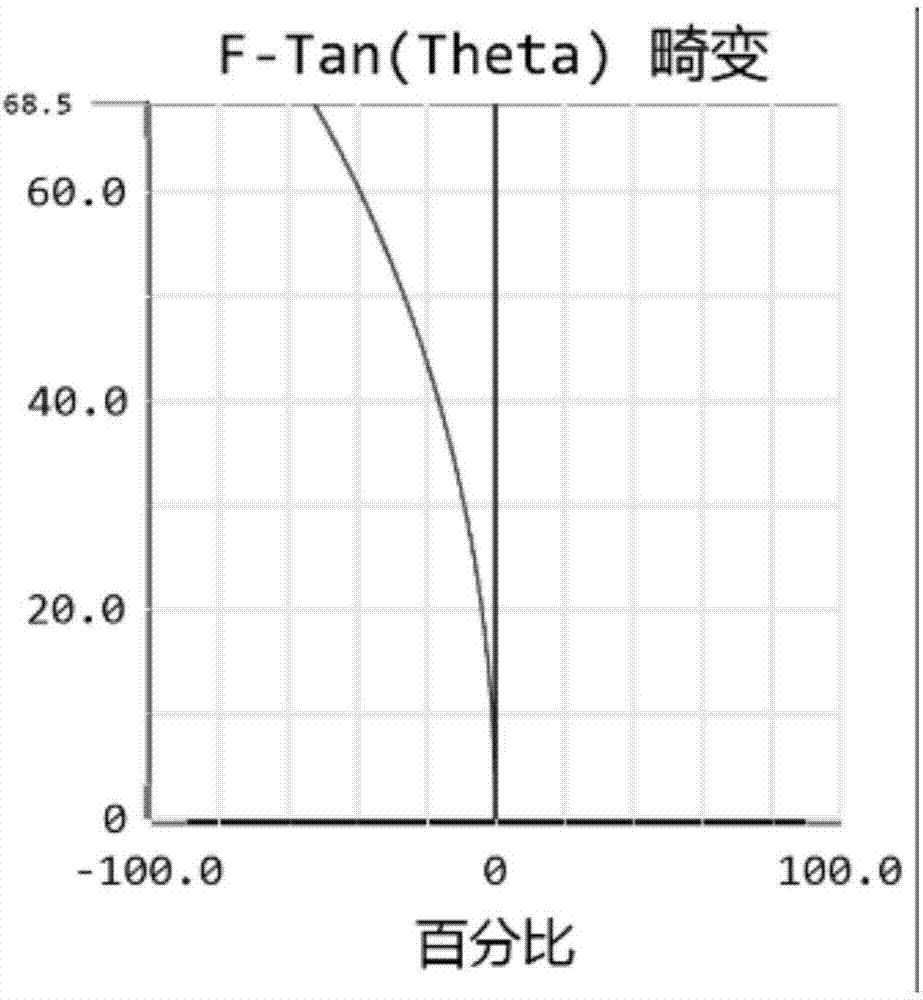

The invention provides an unmanned aerial vehicle (UAV) camera lens. The camera lens sequentially comprises, from the object side to the imaging plane, a first lens, a second lens, a third lens, a fourth lens, a fifth lens, a diaphragm, a sixth lens, a seventh lens, and an eighth lens. The first lens, the second lens and the fourth lens are glass spherical lenses which are meniscus-shaped and concaved toward the imaging plane. The third lens is a glass aspheric lens which is meniscus-shaped and concaved toward the imaging plane. The fifth lens and the sixth lens are biconvex glass spherical lenses. The fifth lens and the fourth lens form an agglutinated lens. The seventh lens is a glass spherical lens which is meniscus-shaped and concaved toward the object side. The eighth lens is a biconvex glass aspheric lens. All the lenses of the UAV camera lens are made of glass. The UAV camera lens can adapt to different temperature occasions. The UAV camera lens has the advantages of good temperature control effect, clear imaging, high sharpness, and high resolution quality. The number of pixels is at least above 12 millions.

Owner:JIANGXI LIANYI OPTICS CO LTD

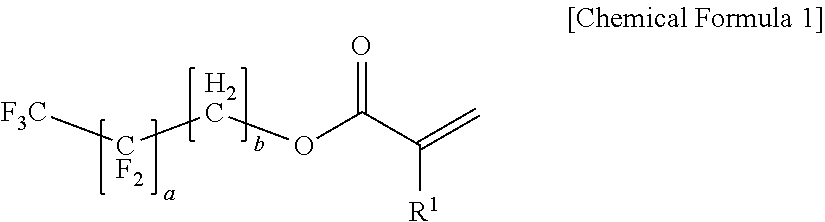

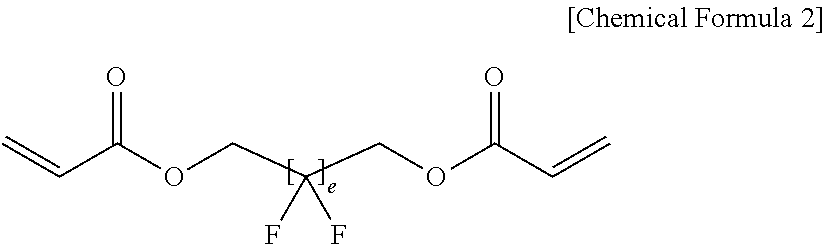

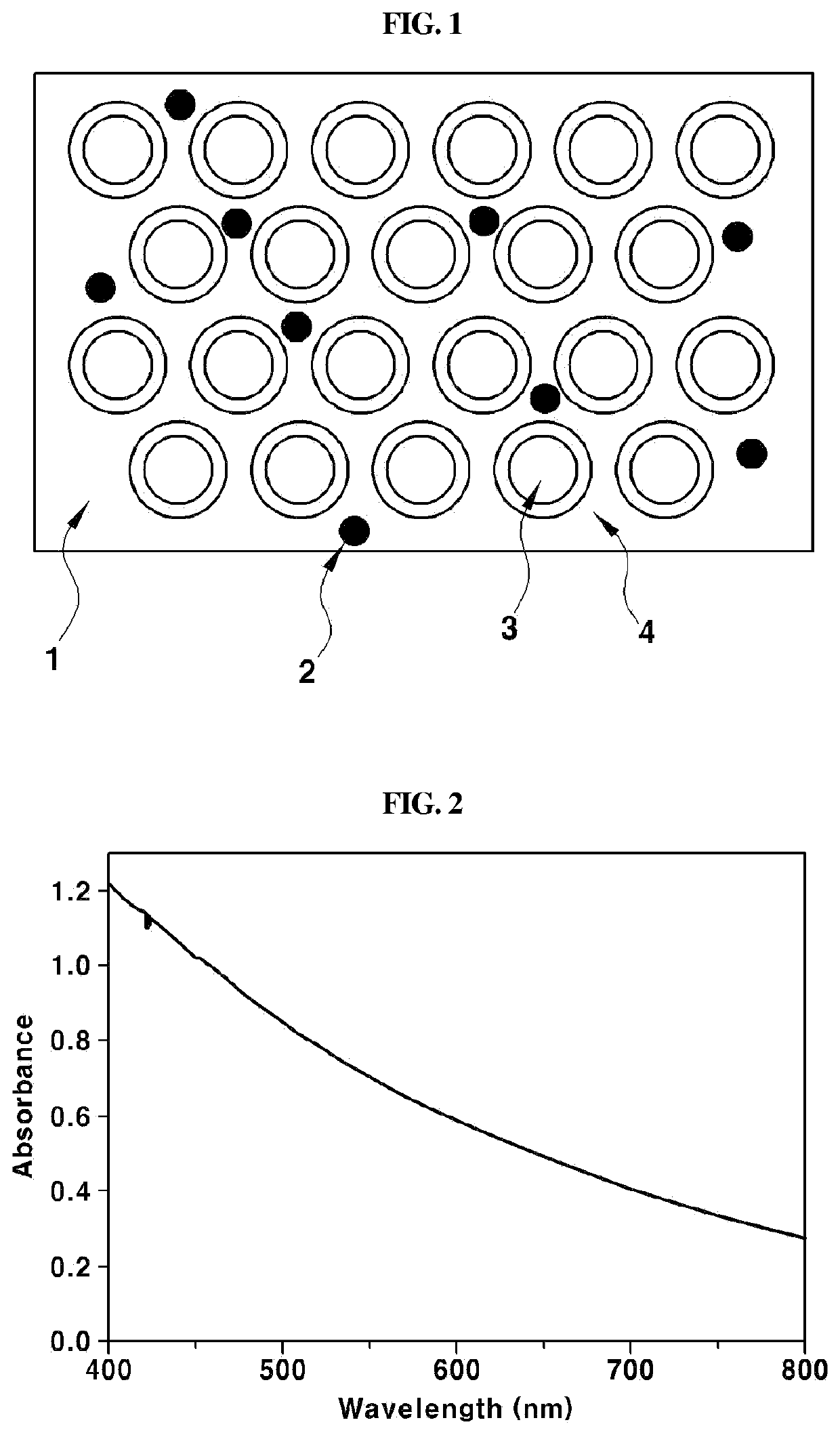

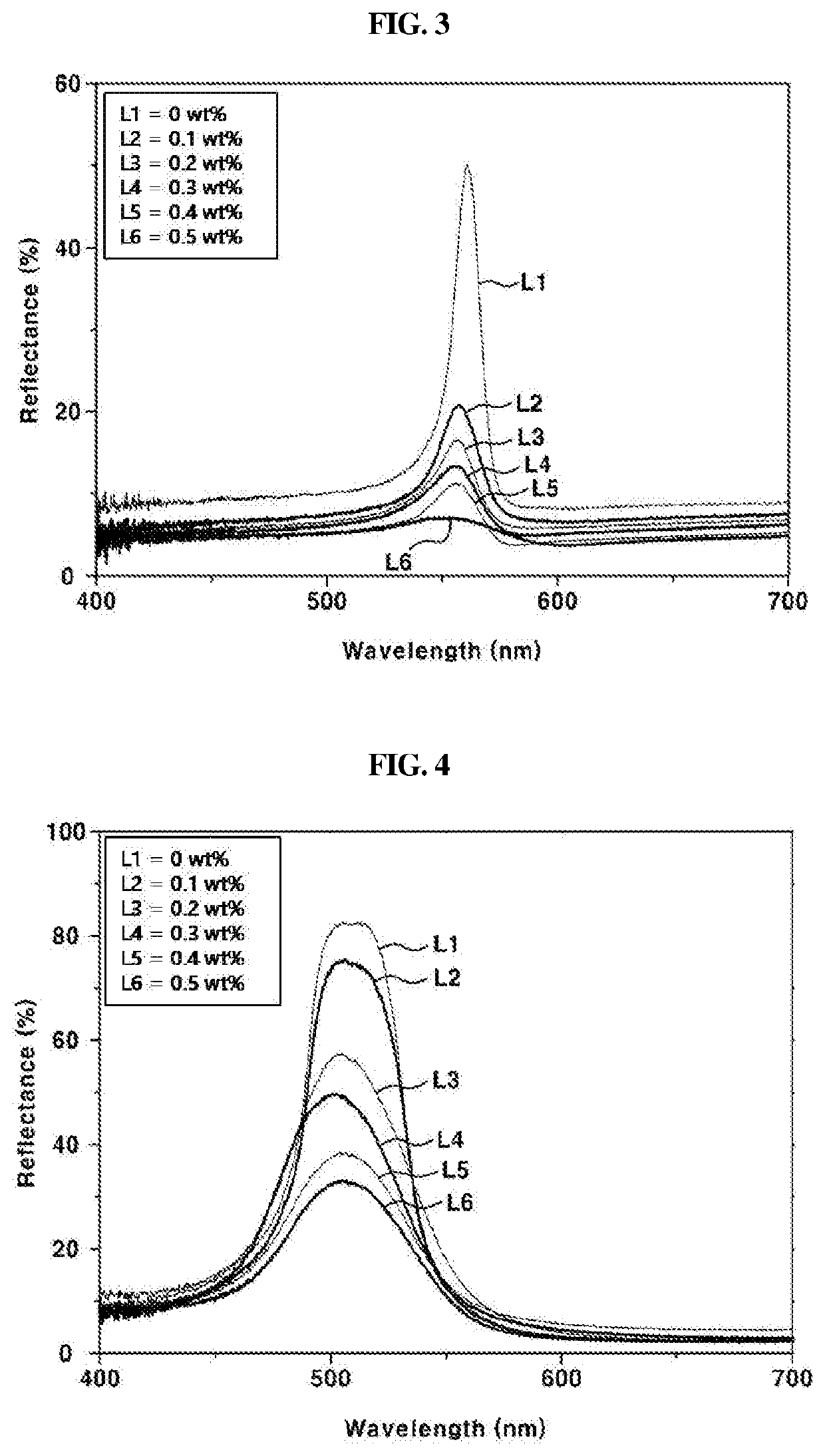

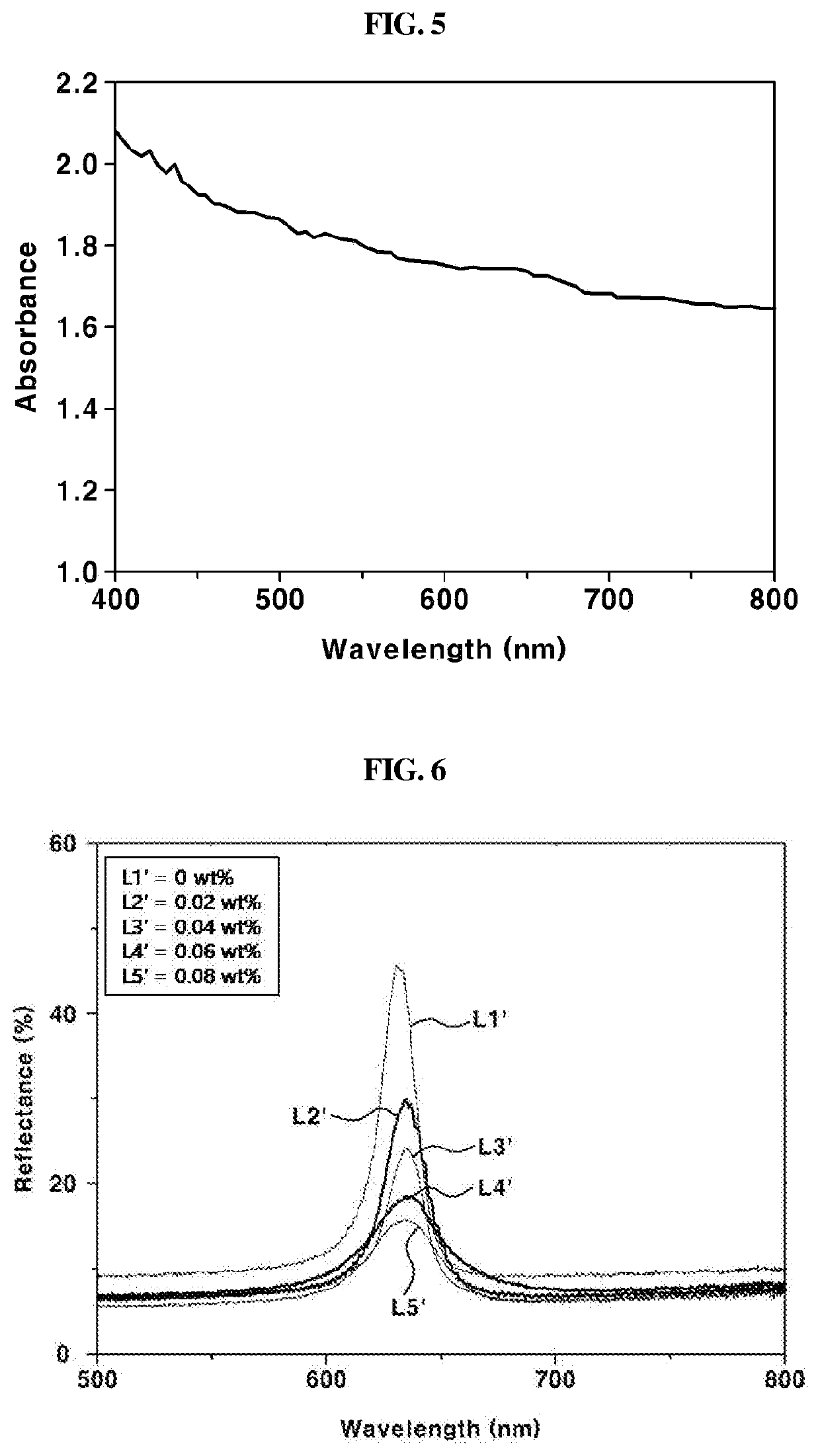

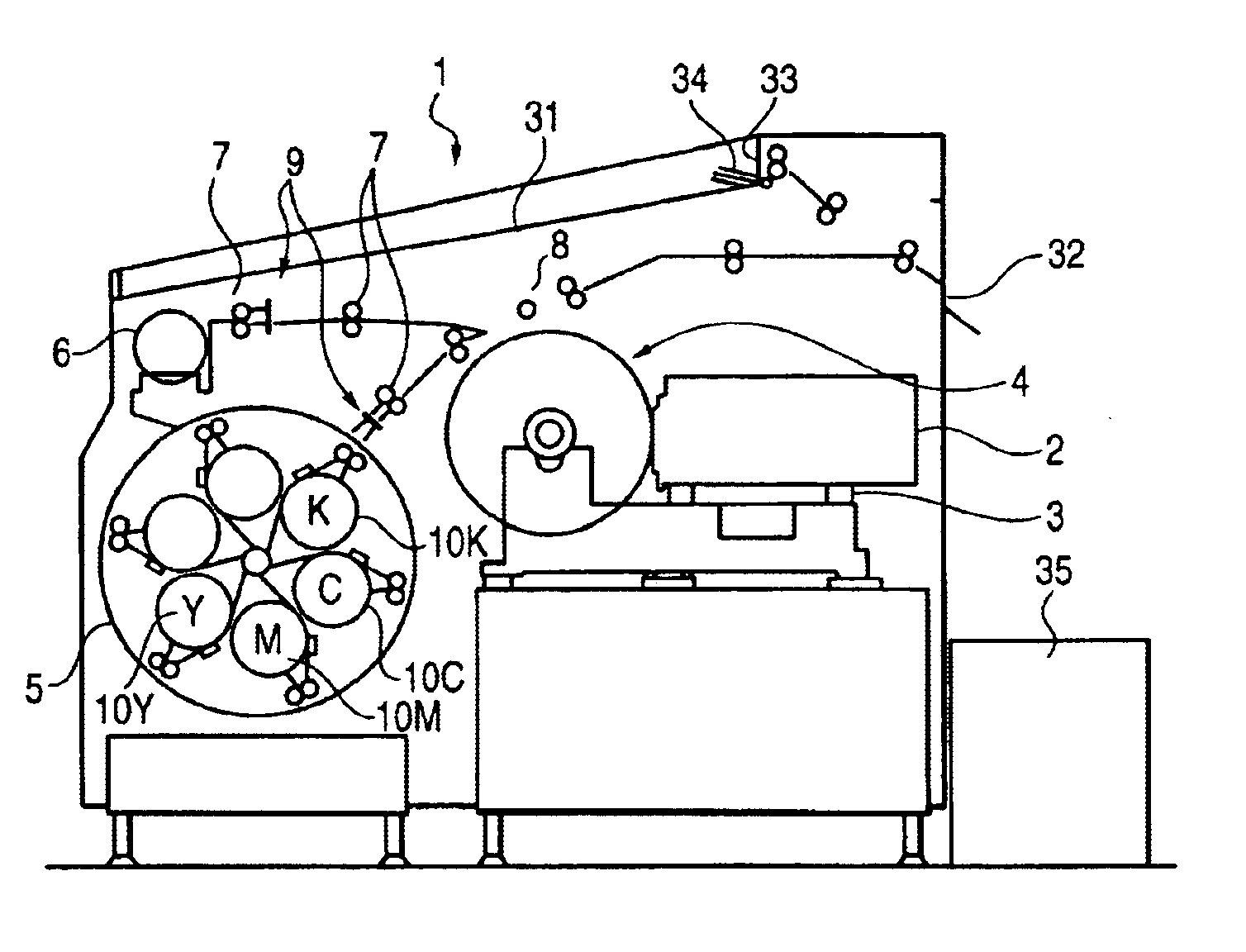

Photonic crystal ink composition comprising light-absorbing nanoparticles and photonic crystal structure formed using the same

ActiveUS20200017696A1High sharpnessSuppressing white scatteringInksArtificial dyesInorganic particlePhotonic crystal structure

Disclosed are an ink composition including light-absorbing nanoparticles and a photonic crystal structure formed using the same. The ink composition may include inorganic particles; monomer; photoinitiator; and nanoparticles light-absorbing nanoparticles to provide the photonic crystal structure. As consequence, problems such as low color sharpness, which makes photonic crystals visible, and attaining high productivity may be eliminated. Moreover, white scattering can be reduced, and thus a distinctive color can be exhibited even when there is a difference between a reflection angle and an observation angle of light, thereby improving visibility.

Owner:HYUNDAI MOTOR CO LTD +2

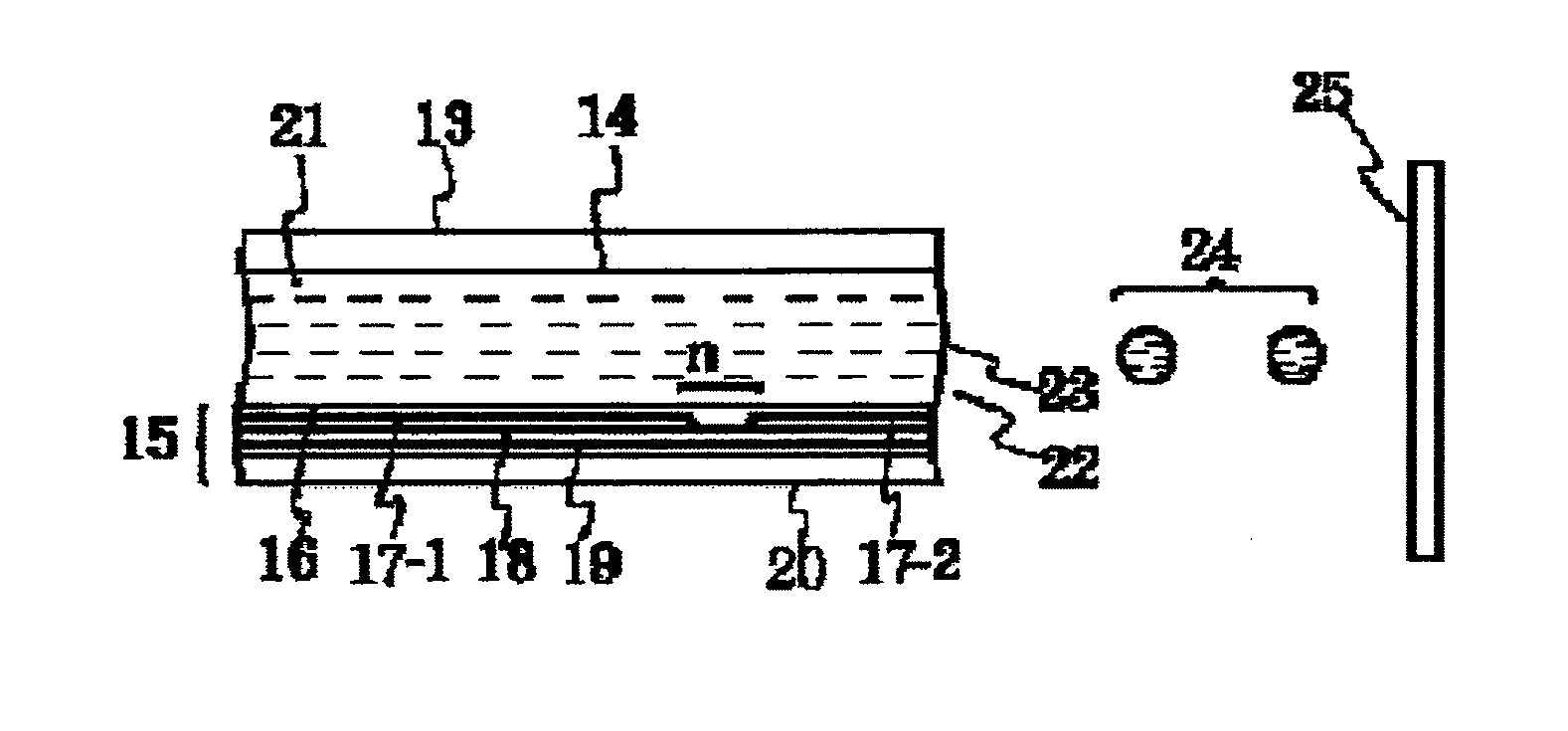

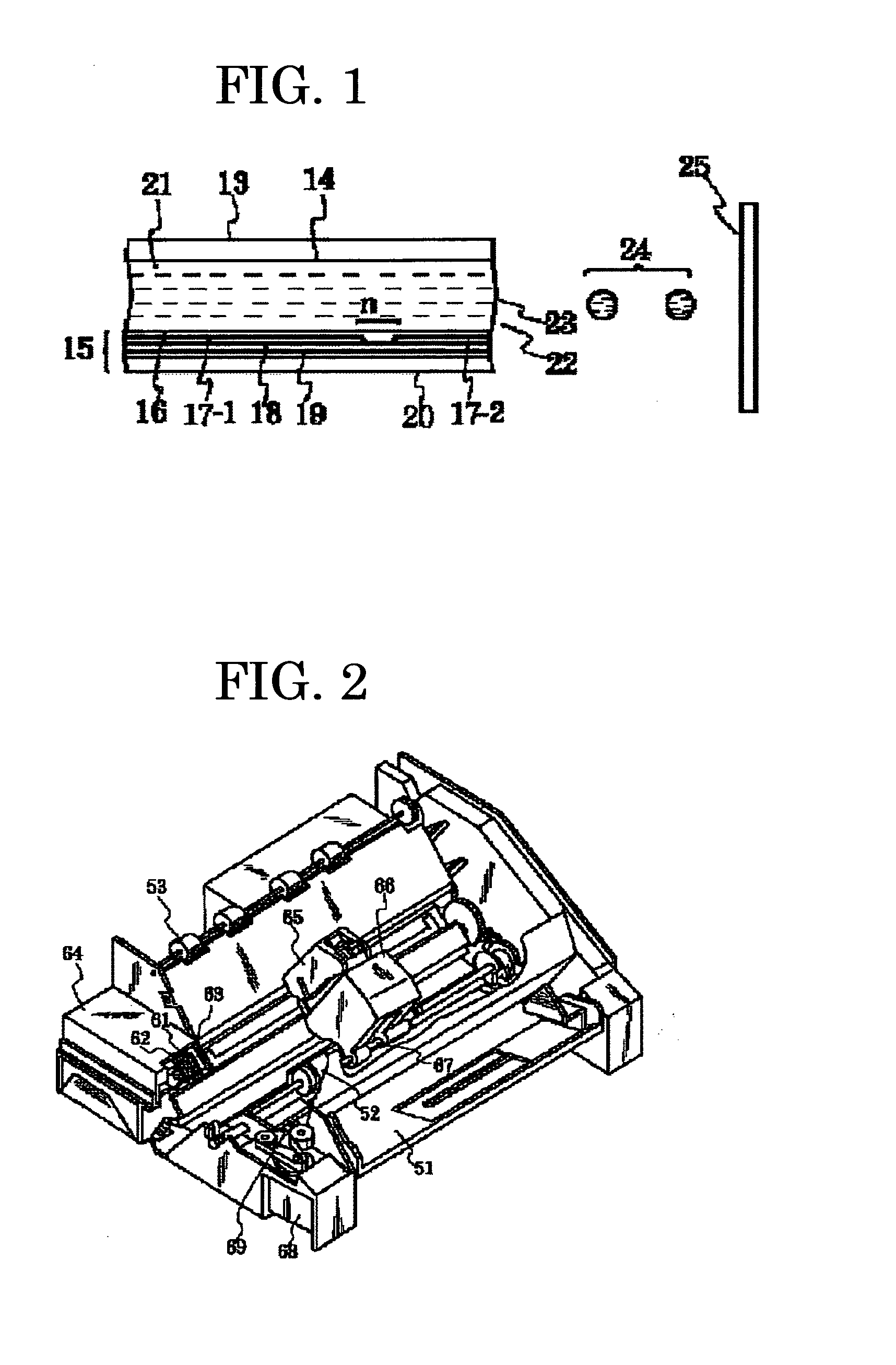

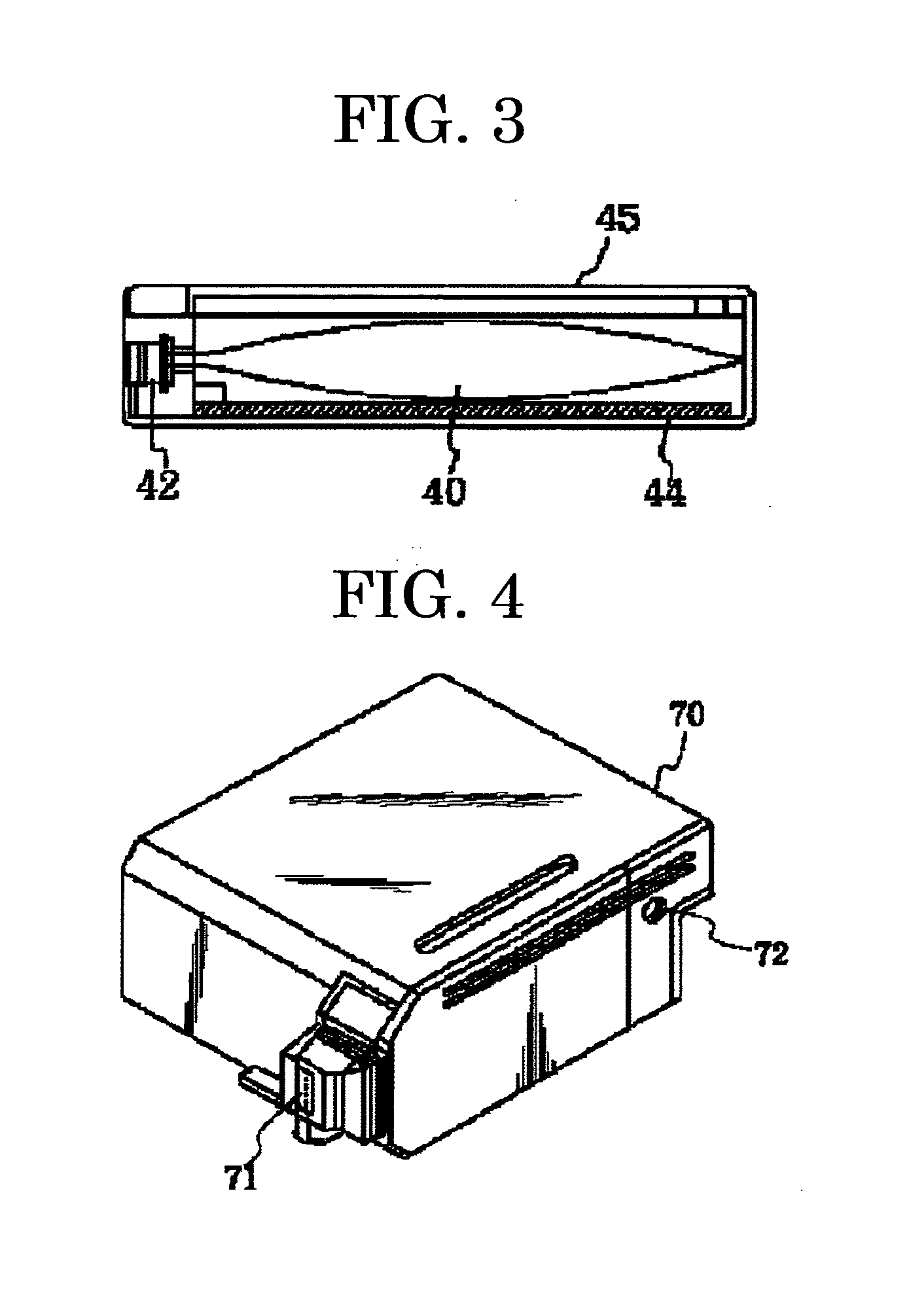

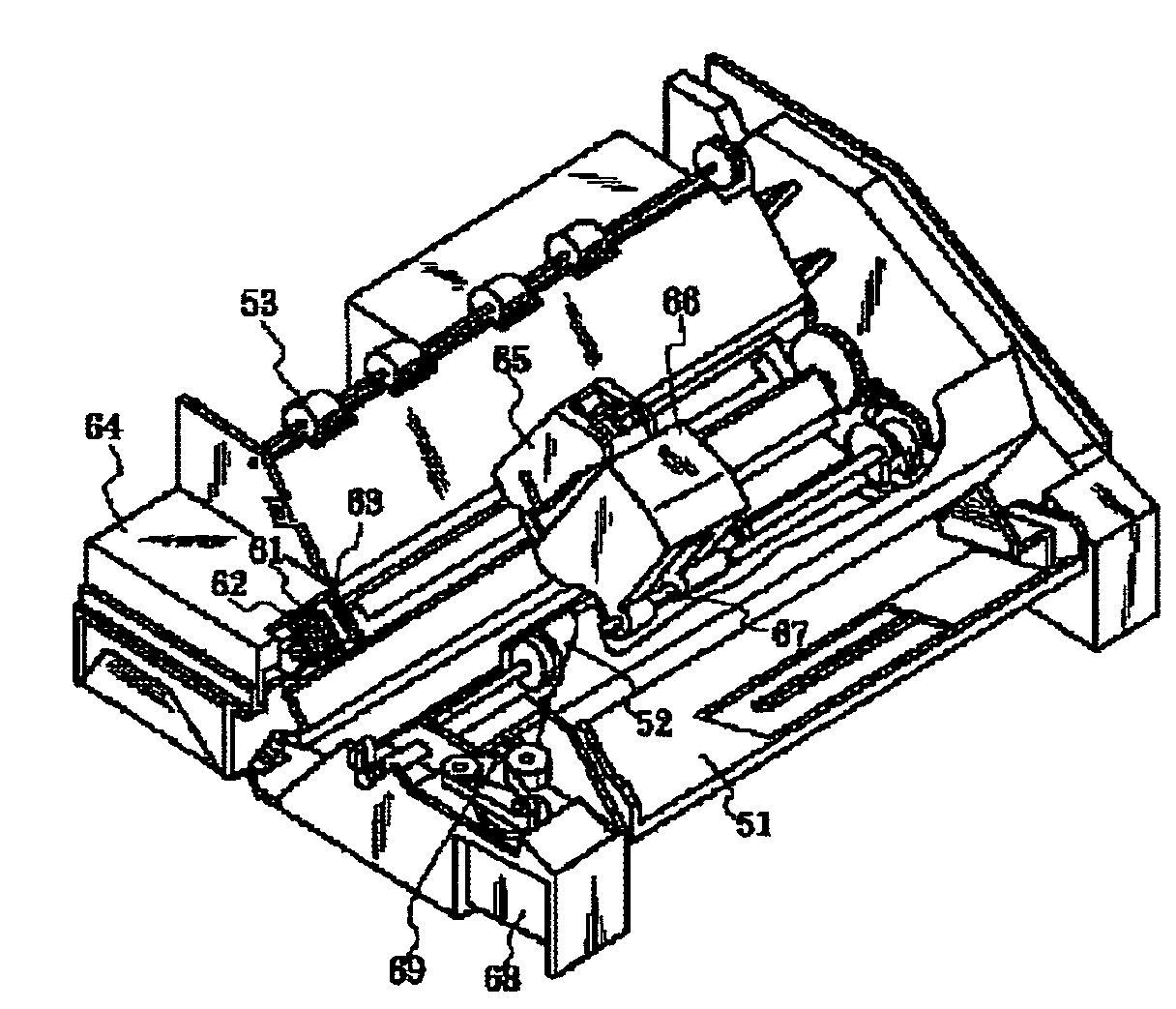

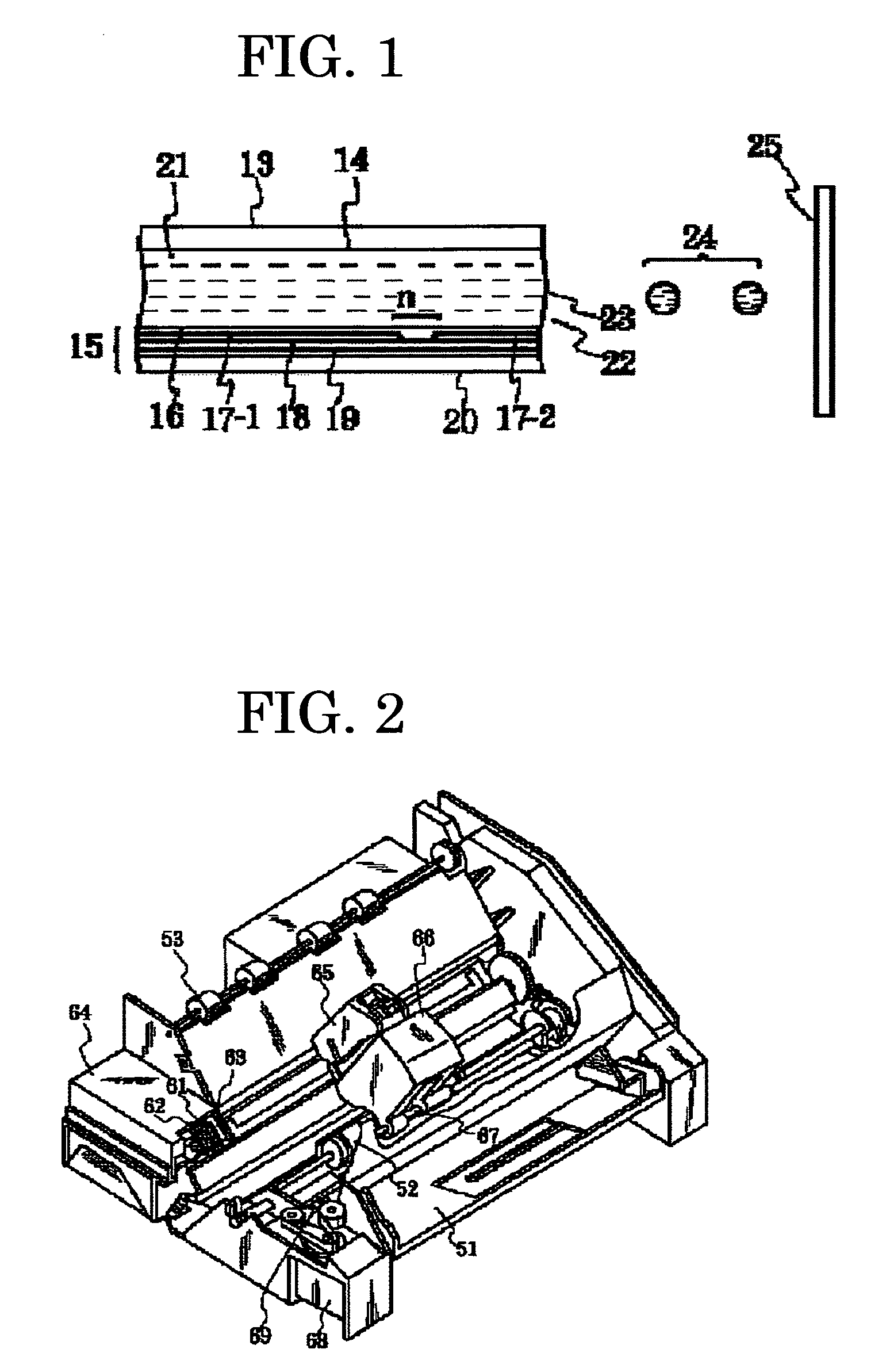

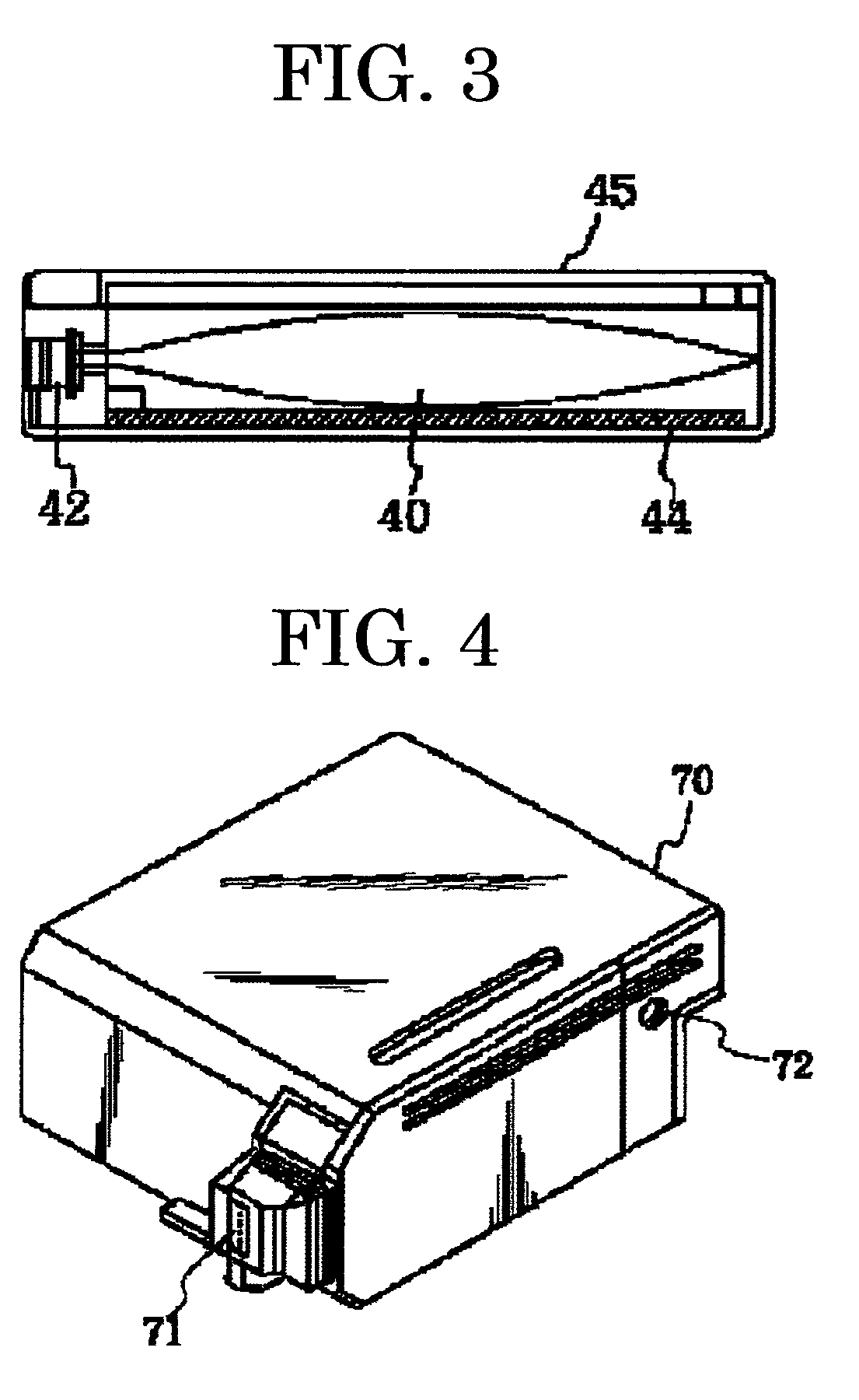

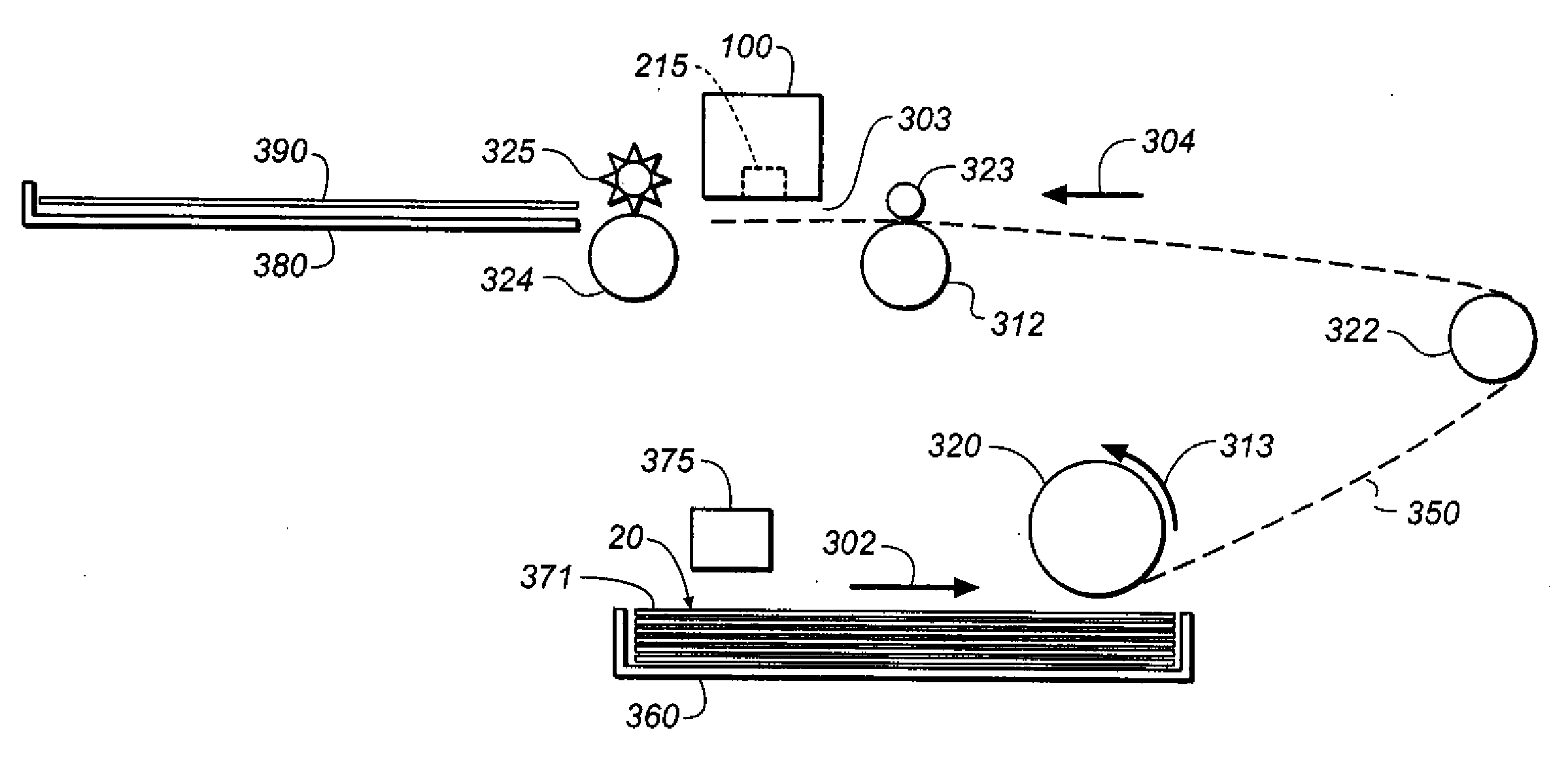

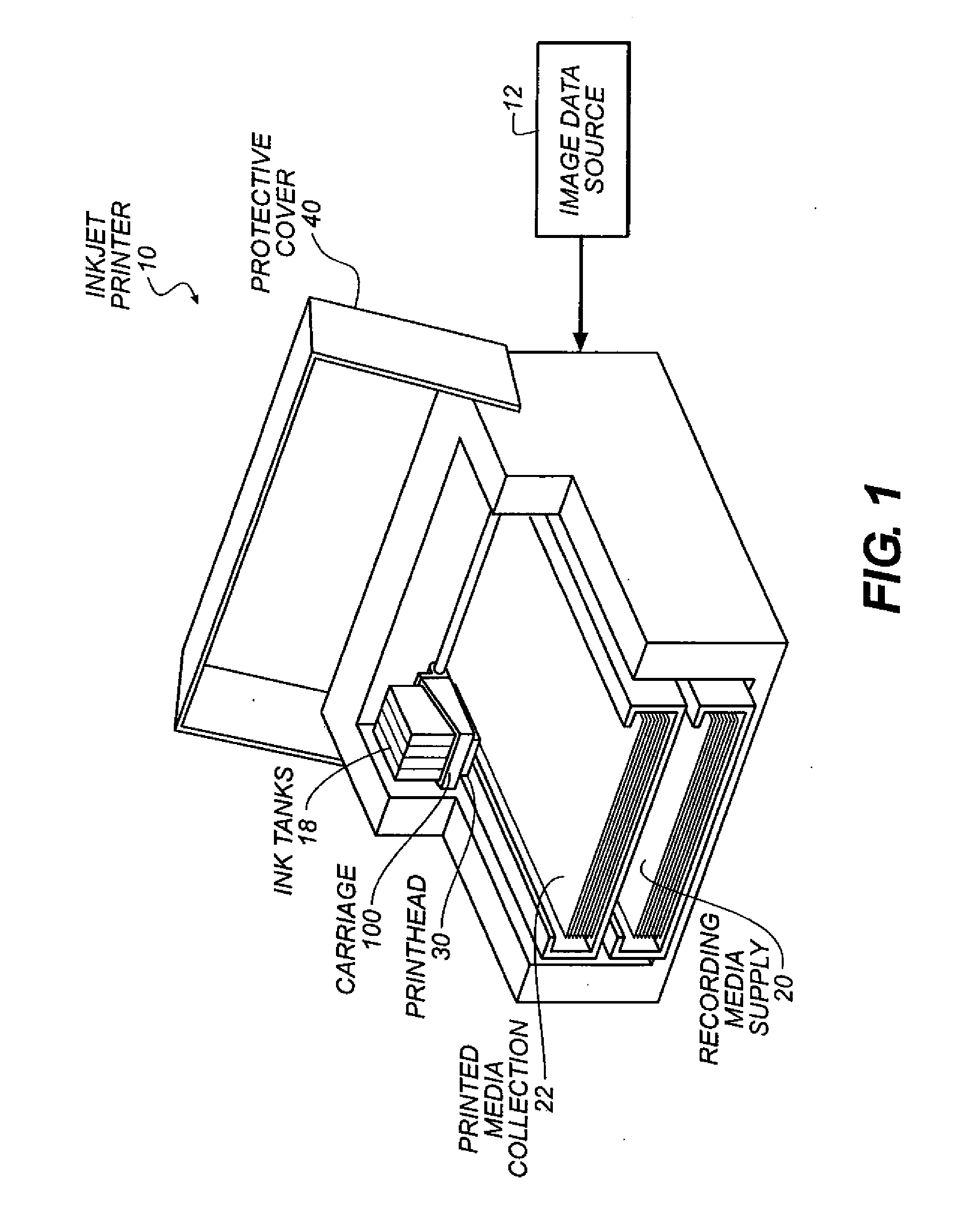

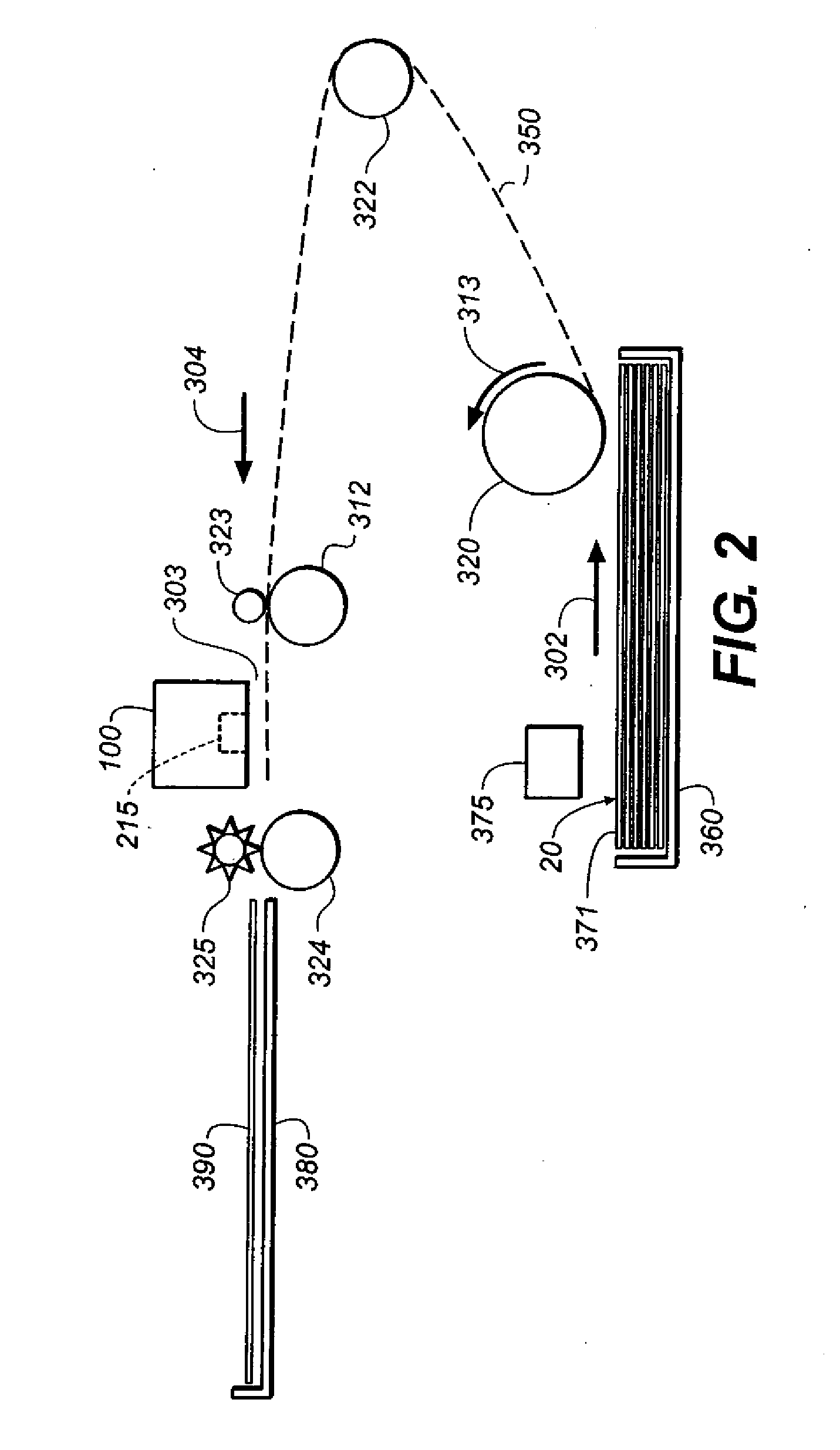

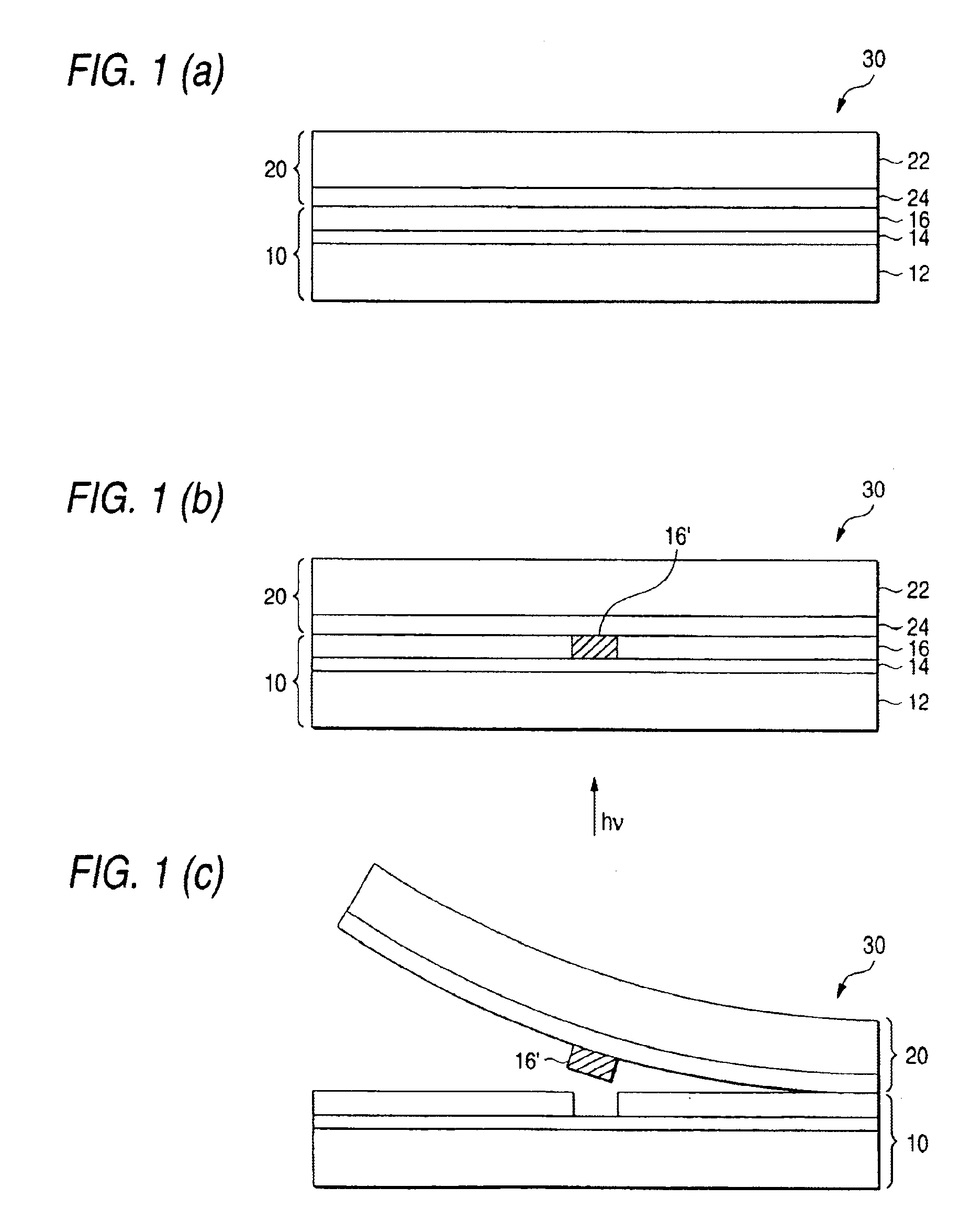

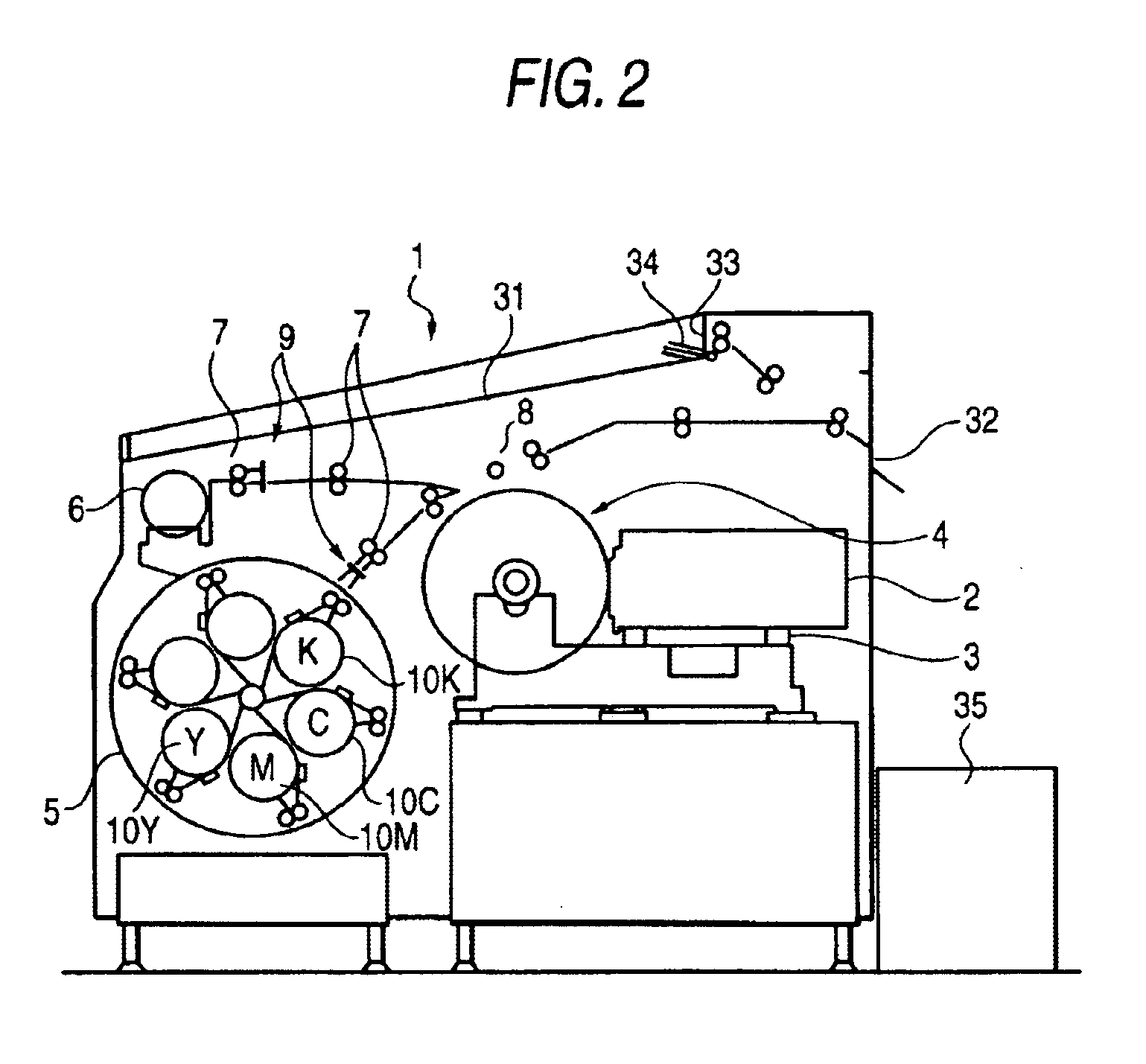

Laser thermal transfer recording method and apparatus therefor

InactiveUS6879336B2High definitionImprove stabilityRecording apparatusThermographyLaser beamsAdhesive materials

A laser thermal transfer recording method comprises: dispensing a thermal transfer sheet and an image-receiving sheet to an exposure recording device; cutting each of the sheets into pieces of a predetermined length; superposing each of the cut pieces of the image-receiving sheet on each of the cut pieces of the thermal transfer sheet; loading an exposure drum installed in the exposure recording device with the thus superposed pieces of sheets; and irradiating the sheets loaded on the exposure drum with a laser beam according to image information, in which the laser beam is absorbed in the thermal transfer sheet and converted into a heat, and an image is transferred onto the image-receiving sheet by the heat converted from the laser beam, wherein each surface of the thermal transfer sheet and the image-receiving sheet is cleaned by contacting with an adhesive roller that includes an adhesive material on its surface, in which the adhesive roller is disposed in any one of a feeding part and a conveying part of the thermal transfer sheet and the image-receiving sheet in the exposure recording device, and the image-receiving sheet has a thickness of 110 to 160 μm, and at least one of pieces of the thermal transfer sheet and pieces of the image-receiving sheet is stacked while be blown.

Owner:FUJIFILM HLDG CORP +1

Antireflection film and display device

ActiveUS20180230317A1Reduced sparkling phenomenonRaise the ratioAnti-reflective coatingsNon-linear opticsPhysical chemistryDisplay device

The present invention relates to an antireflection film which includes a hard coating layer and a low refractive index layer formed on the hard coating layer, wherein a roughness kurtosis (Rku) of the concavo-convex shape of the surface is greater than 3.5 and less than 6, a Swedish height (H) of the concavo-convex shape of the surface is greater than 20 nm and less than 200 nm, and the light transmittance in a wavelength region of 380 nm to 780 nm is 94% or more, and a display device comprising the antireflection film.

Owner:LG CHEM LTD

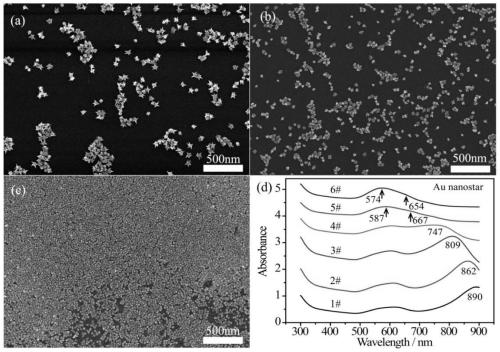

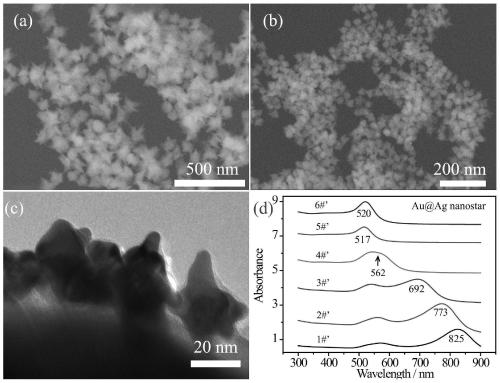

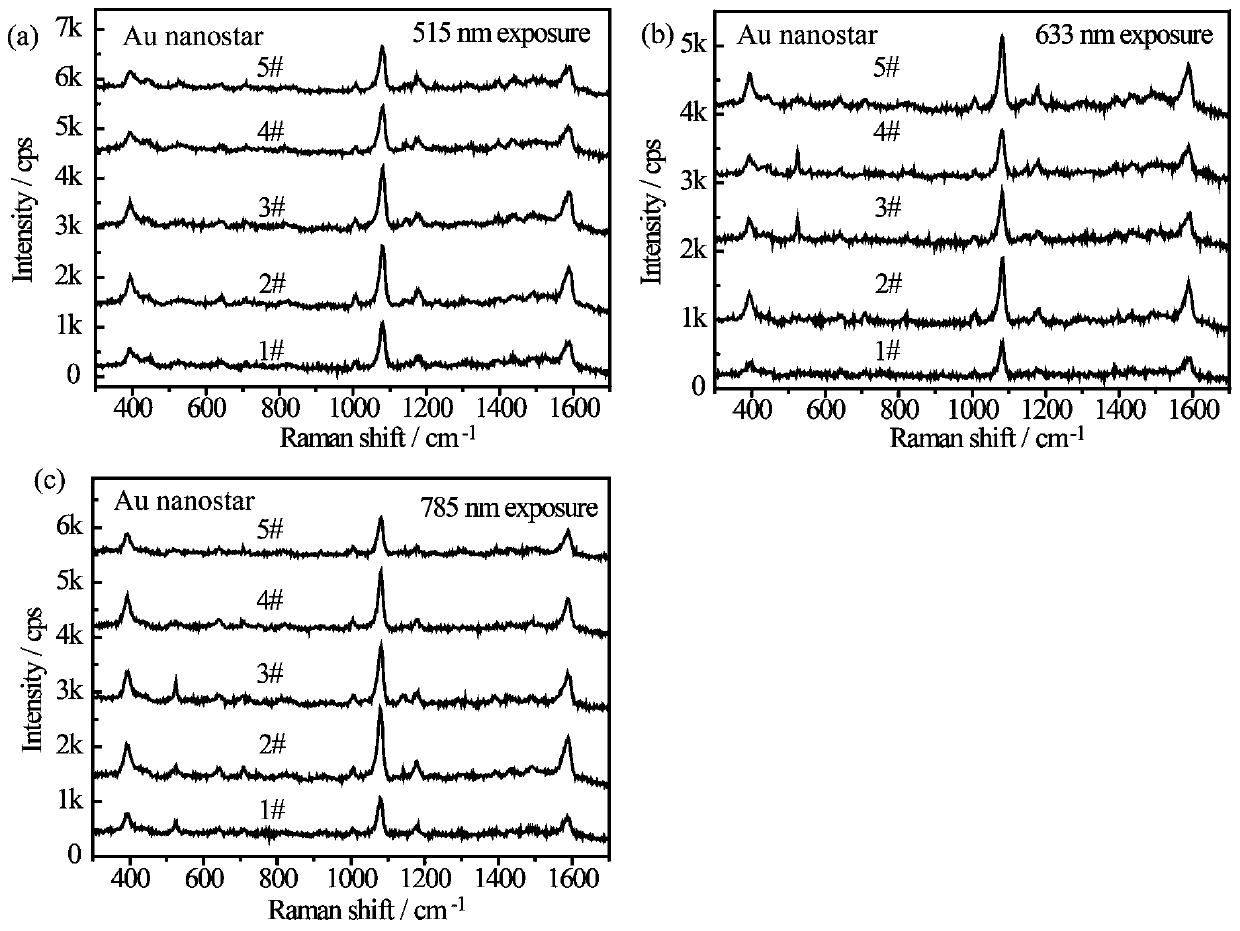

LSPR adjustable gold@silver core-shell nanostar and preparation method thereof

ActiveCN111299570AHigh activityLower conversion rateMaterial nanotechnologyTransportation and packagingPhotocatalytic reactionSolar chemical

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

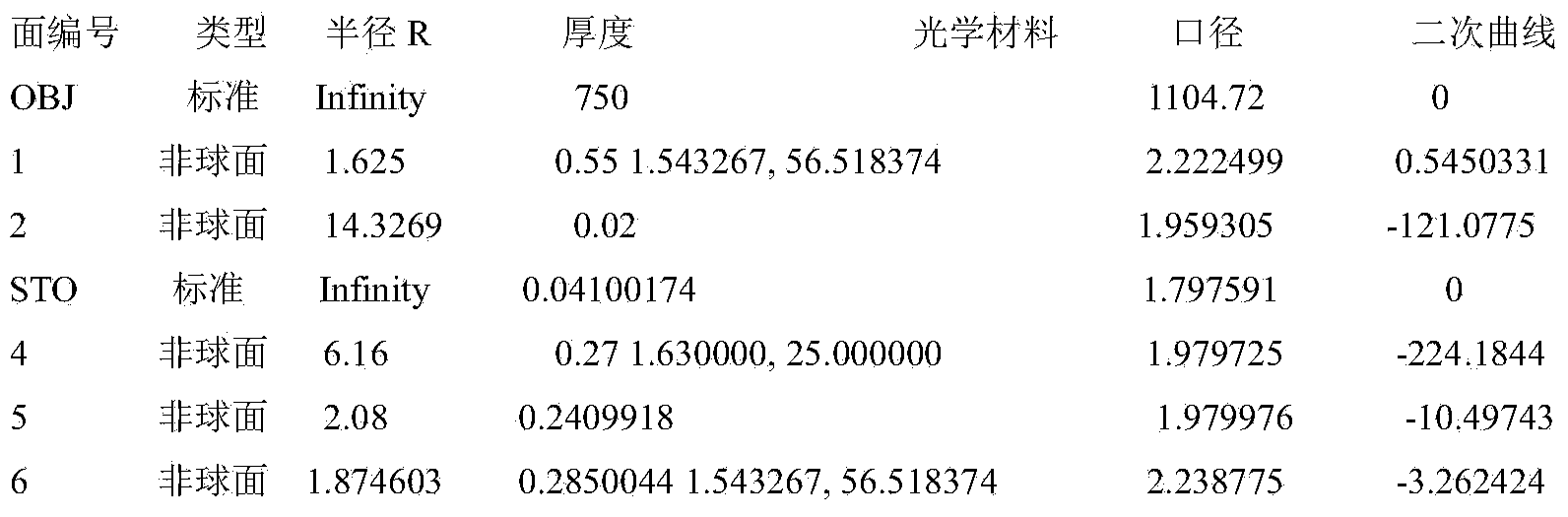

Micro camera lens

The present invention discloses a micro camera lens. The micro camera lens sequentially comprises a meniscus first lens, a meniscus second lens, a diaphragm, a meniscus third lens, a biconcave fourth lens, a fifth lens, a sixth lens and an infrared cut-off filter from the object side to the image side. The first lens has a positive focal power and the concave surface of the first lens is facing the image side. The second lens has a negative focal power and the concave surface of the second lens is facing the image side. The third lens has a positive focal power and the convex surface of the third lens is facing the image side. The fourth lens has a negative focal power. The fifth lens has a positive focal power, wherein the convex surface of the fifth lens is facing the image side and the concave surface of the fifth lens is facing the object side. The sixth lens has a negative focal power and the concave surface of the sixth lens is facing the image side. The optical centers of the above six lenses are positioned on the same straight line. The first lens is a glass aspheric lens. The second lens, the third lens, the fourth lens, the fifth lens and the sixth lens are plastic aspheric lenses. The micro camera lens provided by the present invention has the advantages of miniaturization, light weight, low cost and high image pixel.

Owner:JIANGXI LIANYI OPTICS CO LTD

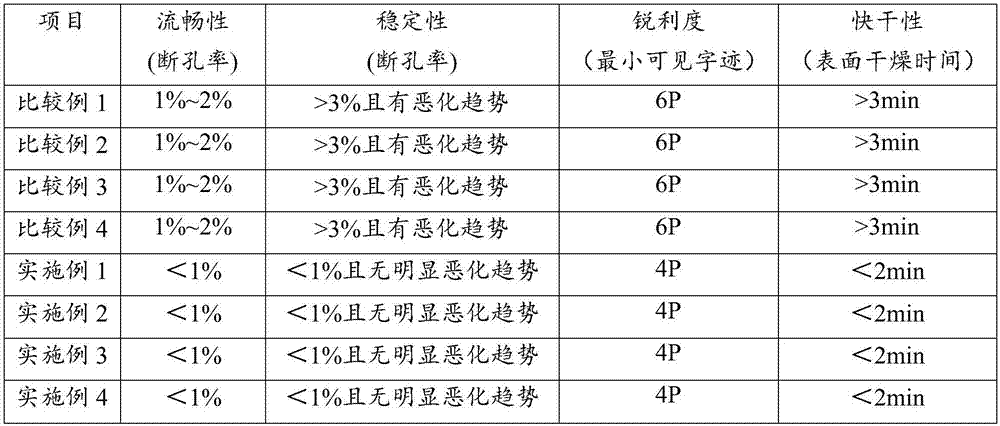

Water-based digital printing thermal dye sublimation jet ink

The invention discloses water-based digital printing thermal dye sublimation jet ink and belongs to the technical field of thermal dye sublimation ink. The thermal dye sublimation jet ink is preparedfrom components in percentage by mass as follows: 1%-10% of resin, 5%-50% of color paste, 10%-50% of a solvent, 0.1%-1% of an antibacterial preservative, 0.1%-1% of a pH regulator, 0.1%-3% of a wetting agent and 10%-50% of deionized water. The thermal dye sublimation jet ink has better printing smoothness and stability and high sharpness, the quick drying property is greatly improved, the printingeffect is good, and the applicability to an EPSON MT4114 nozzle is also improved.

Owner:ZHUHAI HUACAI PRINTING SUPPLIES LTD

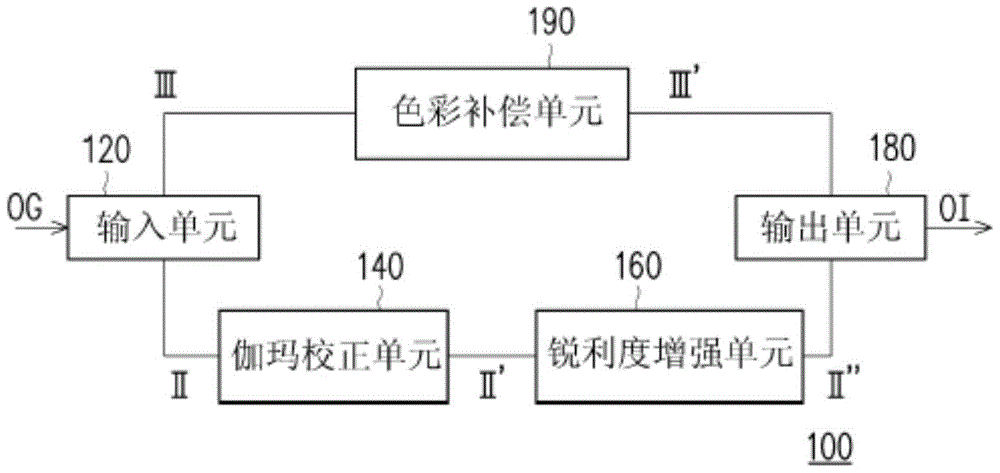

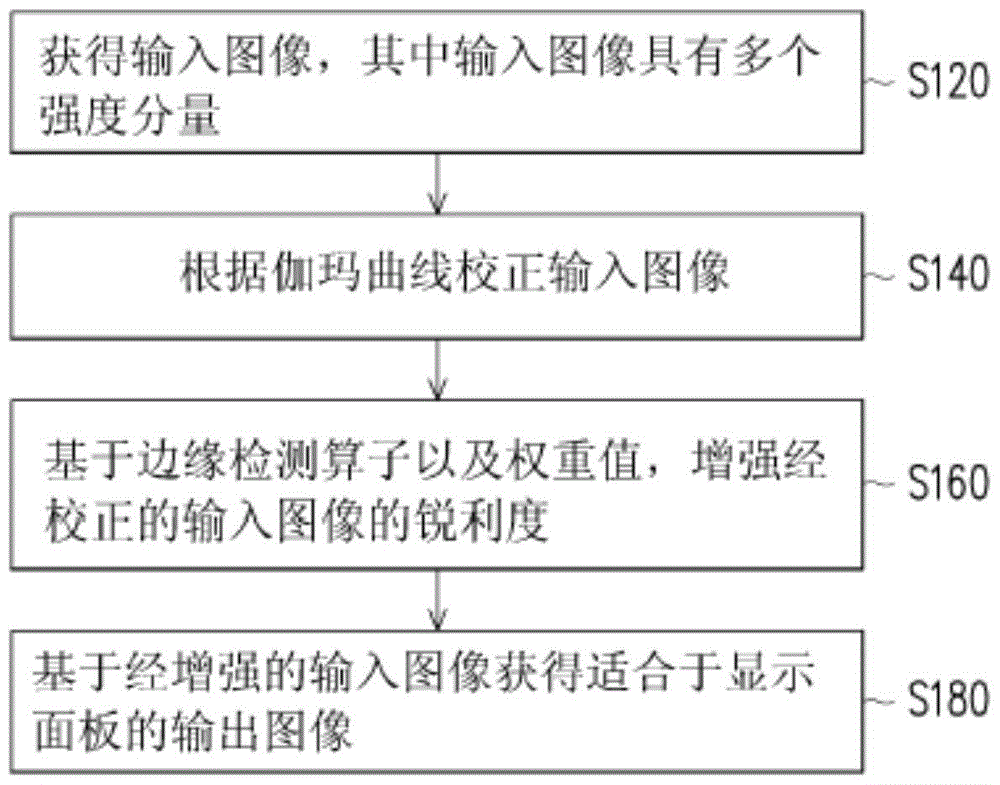

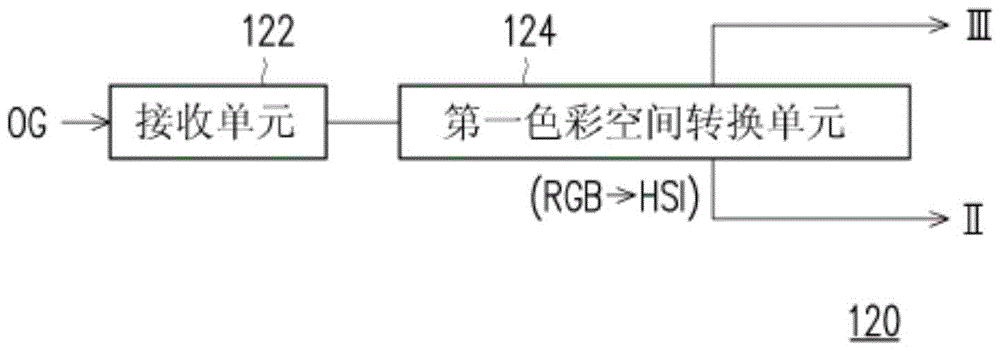

Image enhancement method and image processing apparatus thereof

InactiveCN106611407AHigh sharpnessImprove legibilityImage enhancementImage analysisImaging processingEdge based

An image enhancement method and an image processing apparatus thereof are provided. The image enhancement method is adapted to the image processing apparatus and includes the following steps. An input image is obtained, wherein the input image has a plurality of intensity components. The input image is corrected according to a gamma curve. The sharpness of the corrected input image is enhanced based on an edge detection operator and a weight value. An output image suitable for a display panel is obtained based on the enhanced input image. The image enhancement method provided by the invention can enahnce the sharpness of the image to realize a defogging effect, and thus can improve the display quality of the display panel.

Owner:CHUNGHWA PICTURE TUBES LTD

Anti-reflective film, polarizing plate, and display apparatus

PendingUS20200241173A1Improve screen clarityHigh light transmittanceOptical filtersSynthetic resin layered productsNanoparti clesOptical polarization

The present invention relates to anti-reflective films including: a light-transmitting substrate; a hard coating layer; and a low refractive layer, wherein the low refractive layer includes a first region including a binder resin and high refractive inorganic nanoparticles and a second region including a binder resin and low refractive inorganic nanoparticles, and when polarization ellipticity measured by ellipsometry is fitted to a Cauchy model for each of the first region and the second region, predetermined requirements are fulfilled.

Owner:LG CHEM LTD

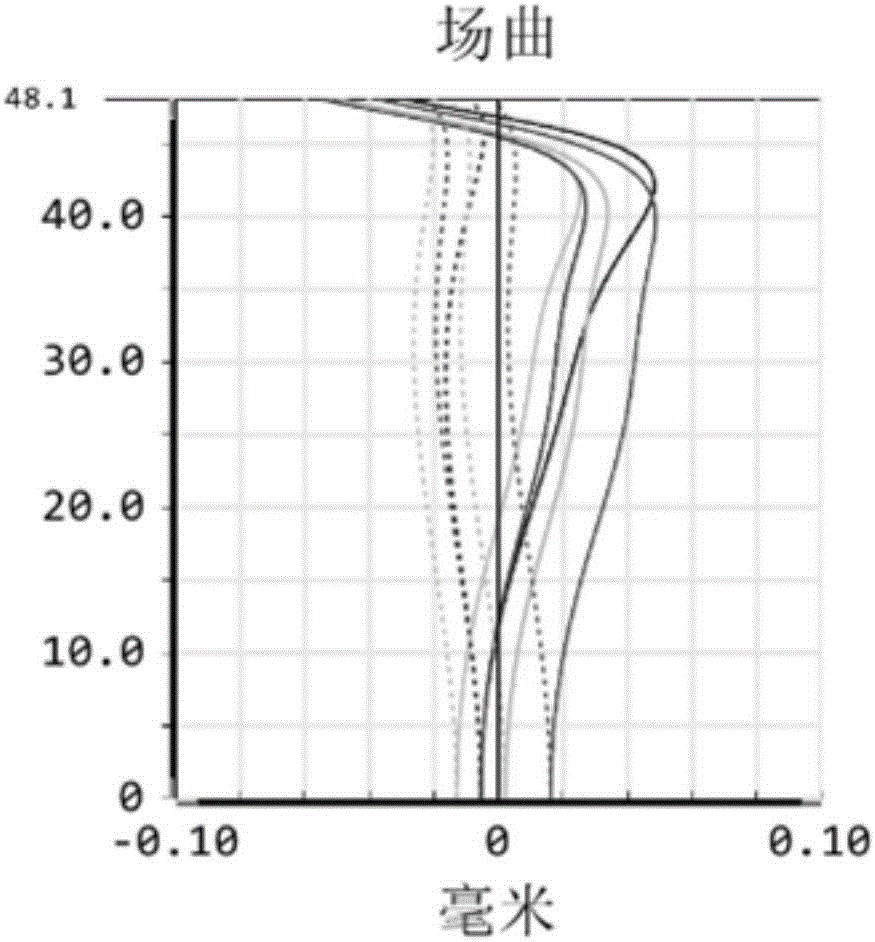

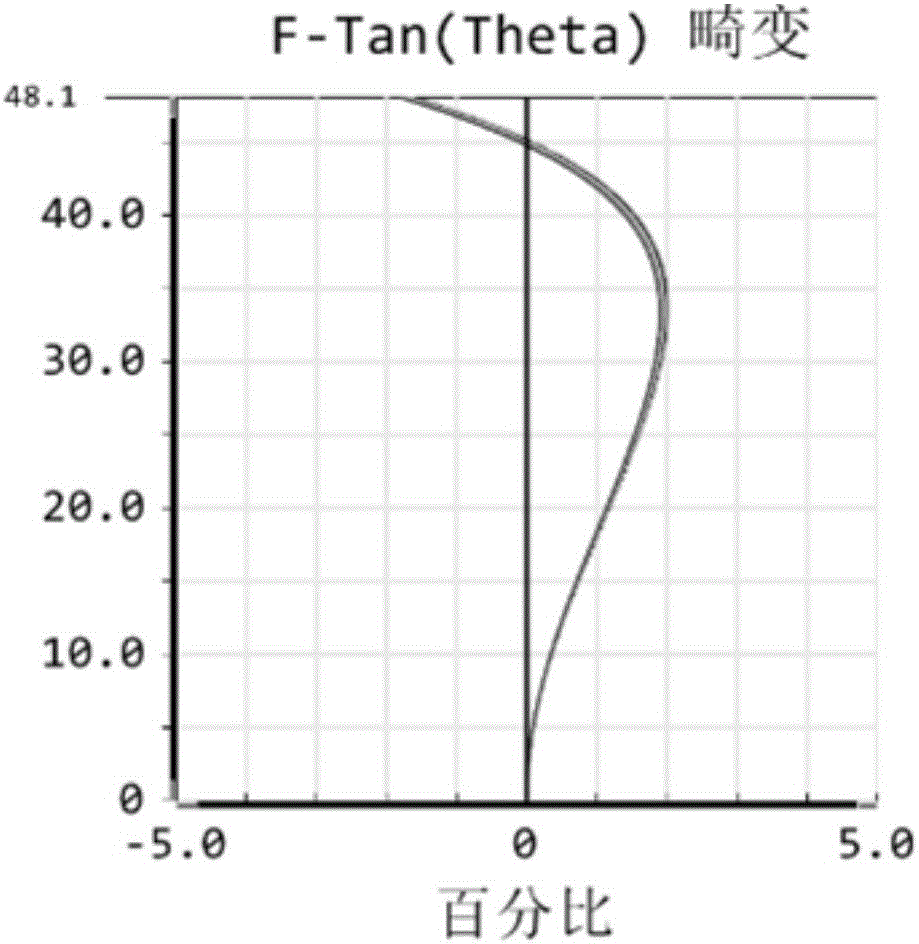

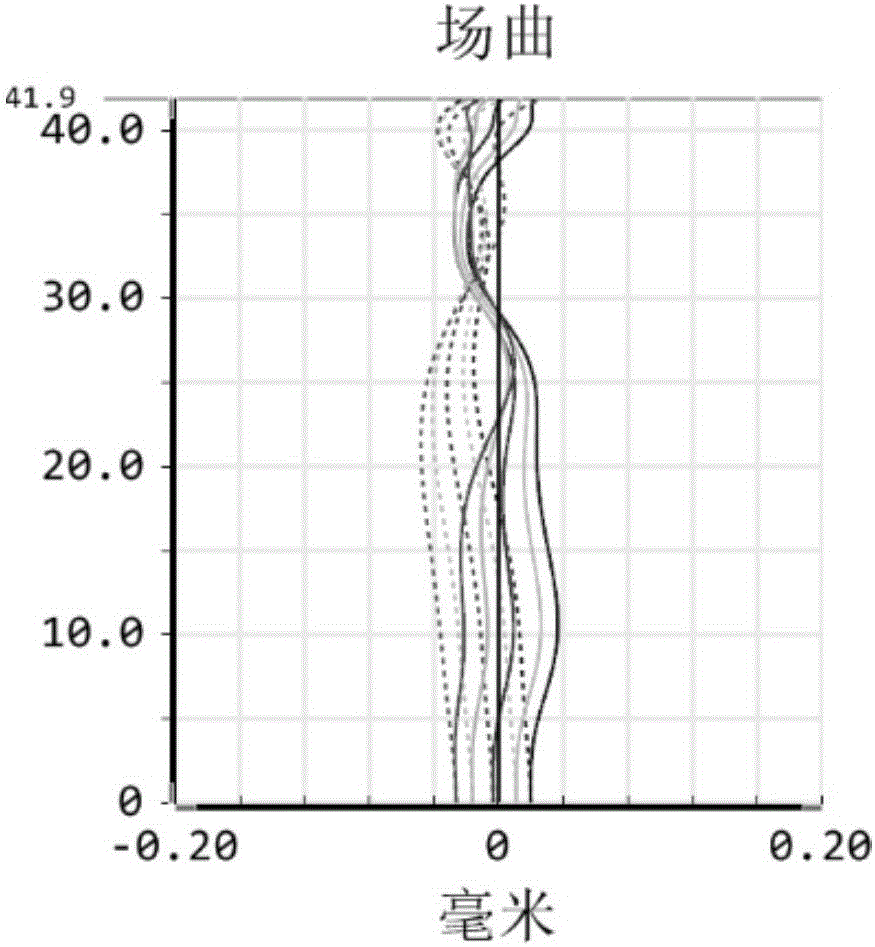

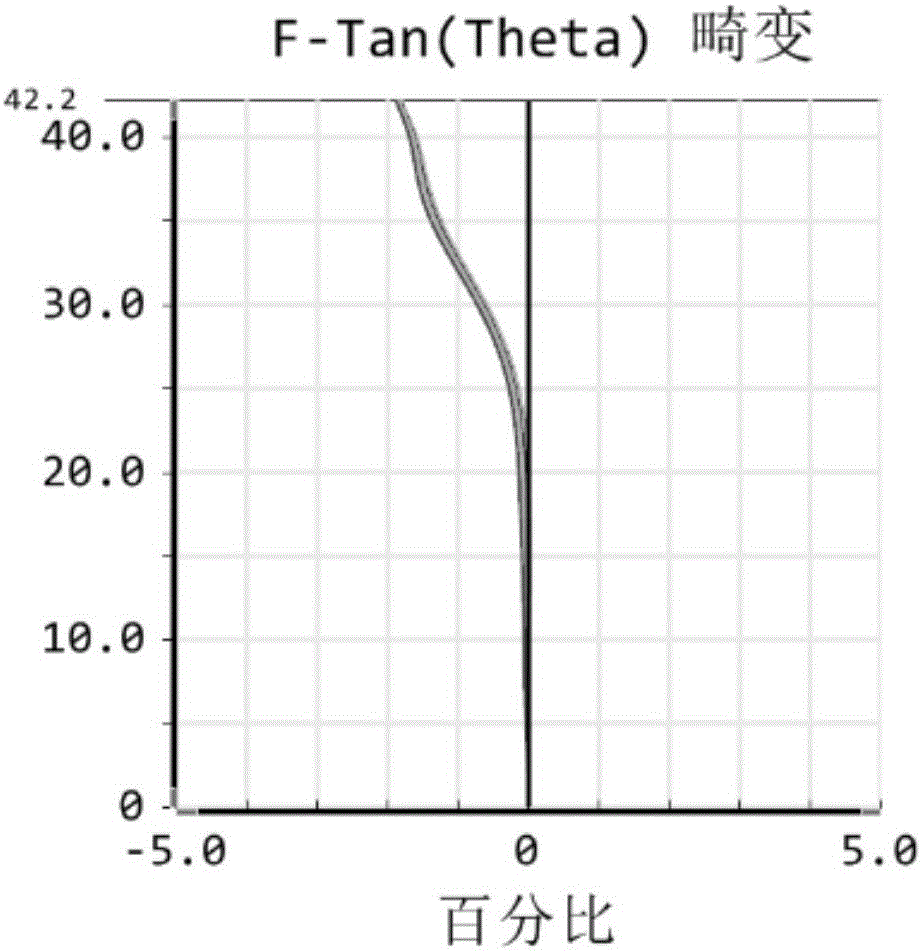

High-image-quality wide-angle optical camera lens

ActiveCN103454751AUniform illumination image surfaceIncrease brightnessOptical elementsCamera lensImaging quality

The invention relates to a high-image-quality wide-angle optical camera lens. The high-image-quality wide-angle optical camera lens comprises a lens cone. A diaphragm is arranged at the front end of the lens cone. In a cavity of the lens cone, a first lens, a second lens, a third lens, a fourth lens, a fifth lens and a sixth lens are sequentially arranged behind the diaphragm from outside to inside, and space rings are correspondingly arranged between the adjacent lens. The first lens is a forward focal length lens, the first surface towards the object surface is an oval aspheric surface, and the second surface towards the image surface is a hyperbola aspheric surface. Crescent backward focal length lenses are arranged on the two surfaces of the second lens, and both the surfaces are hyperbola aspheric surfaces. The third lens is a forward focal length lens, the first surface towards the object surface is a hyperbola aspheric surface, and the second surface towards the image surface is an oval aspheric surface. Forward focal length lenses are arranged on the two surfaces of the fourth lens, and both the surfaces of the fourth lens are hyperbola aspheric surfaces. The fifth lens is a backward focal length lens, and both the surfaces of the fifth lens are hyperbola aspheric surfaces. The sixth lens is a backward focal length lens, and both the surfaces of the sixth lens are hyperbola aspheric surfaces.

Owner:UNION OPTECH

Antireflection film and display device

ActiveUS20180223113A1Reduced sparkling phenomenonRaise the ratioDiffusing elementsPolyurea/polyurethane coatingsDisplay deviceRefractive index

The present invention relates to an antireflection film which includes a hard coating layer and a low refractive index layer formed on the hard coating layer, wherein a roughness skewness (Rsk) of the concavo-convex shape of the surface is greater than 0.5 and less than 5, and a slope angle of the concavo-convex shape of the surface is greater than 0.01 degree and less than 0.2 degree, and a display device comprising the antireflection film.

Owner:LG CHEM LTD

System and method for camera metering based on flesh tone detection

InactiveUS7847830B2Quality improvementHigh degreeTelevision system detailsColor television detailsSkin colorField of view

A method of adjusting exposure settings for a digital camera includes searching at least a portion of the field of view of the camera for pixels having a flesh tone. The flesh tone pixels are analyzed to identify at least one flesh tone spot. Spot metering of the field of view of the camera is carried out such that at least one flesh tone spot is given greater weight than the rest of the field of view. Then, the exposure settings are adjusted based on the spot metering.

Owner:SONY ERICSSON MOBILE COMM AB

Image forming material, color filter master plate, and color filter

InactiveUS7157193B2High sensitivityHigh resolutionPhotosensitive materialsOptical filtersImage recordingIrradiation

An image recording material provided with an image recording layer including a polymer compound which contains a functional group with a hydrophilic / hydrophobic character thereof being changeable by heat, acid, or irradiation and which is directly chemically bonded to the substrate, wherein the image recording layer is heated, treated with acid, or irradiated to change the hydrophilic / hydrophobic character of a surface of the image recording layer and organic or inorganic molecules for forming a visible image are adsorbed at regions thereof where the hydrophilic / hydrophobic character has been changed.

Owner:FUJIFILM CORP

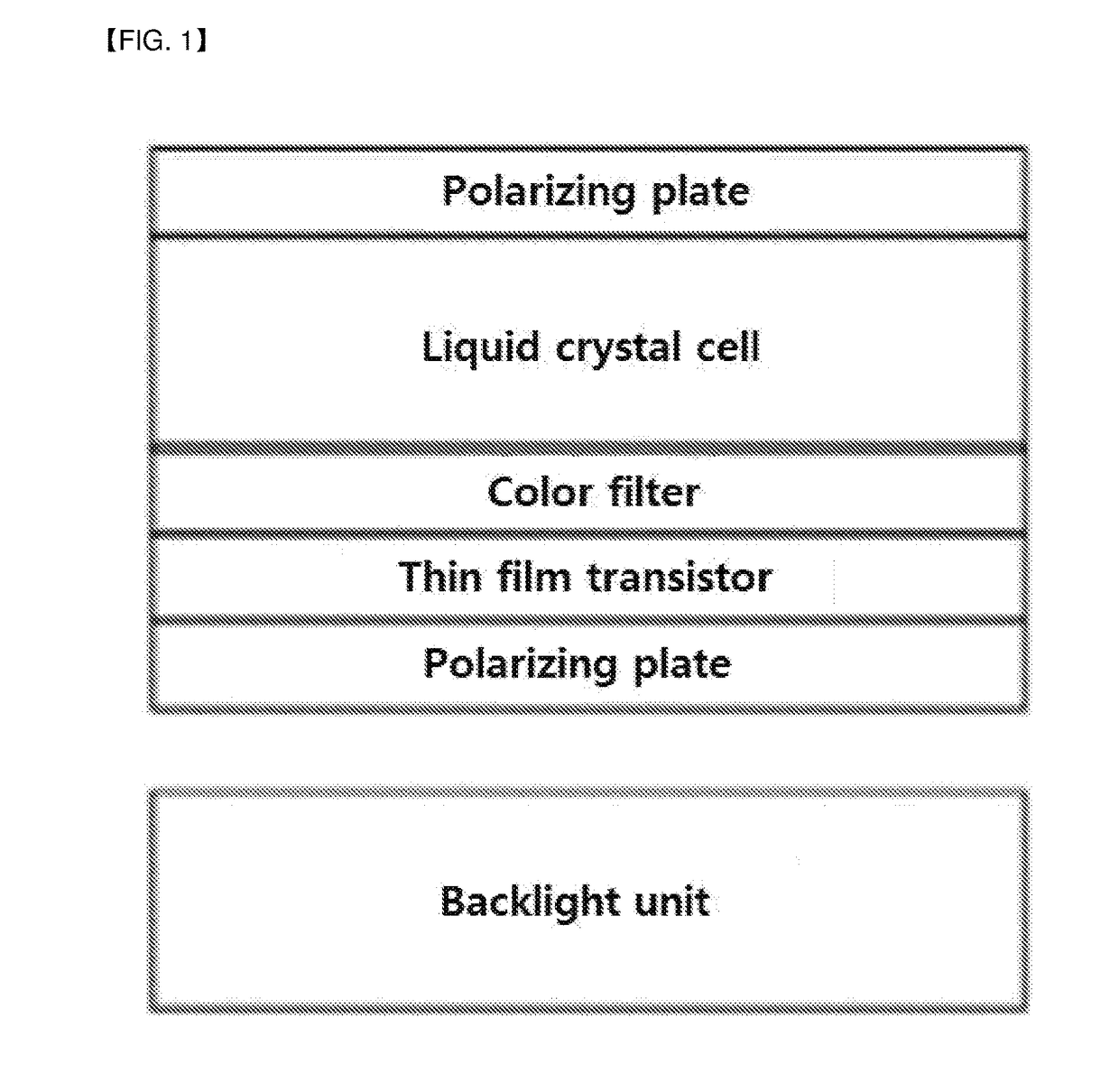

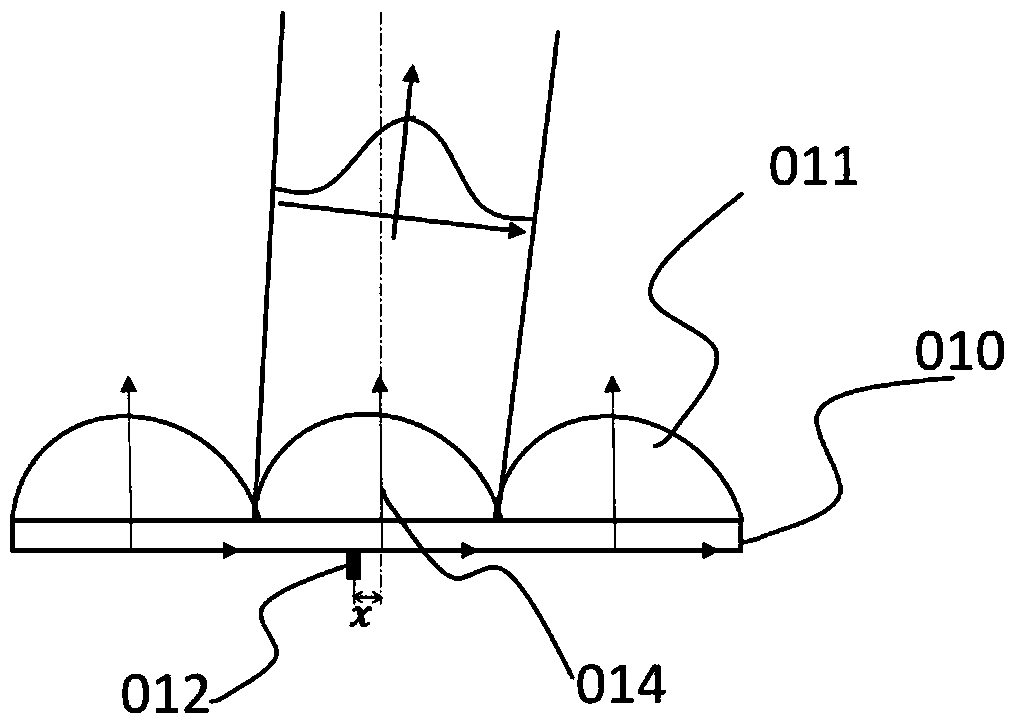

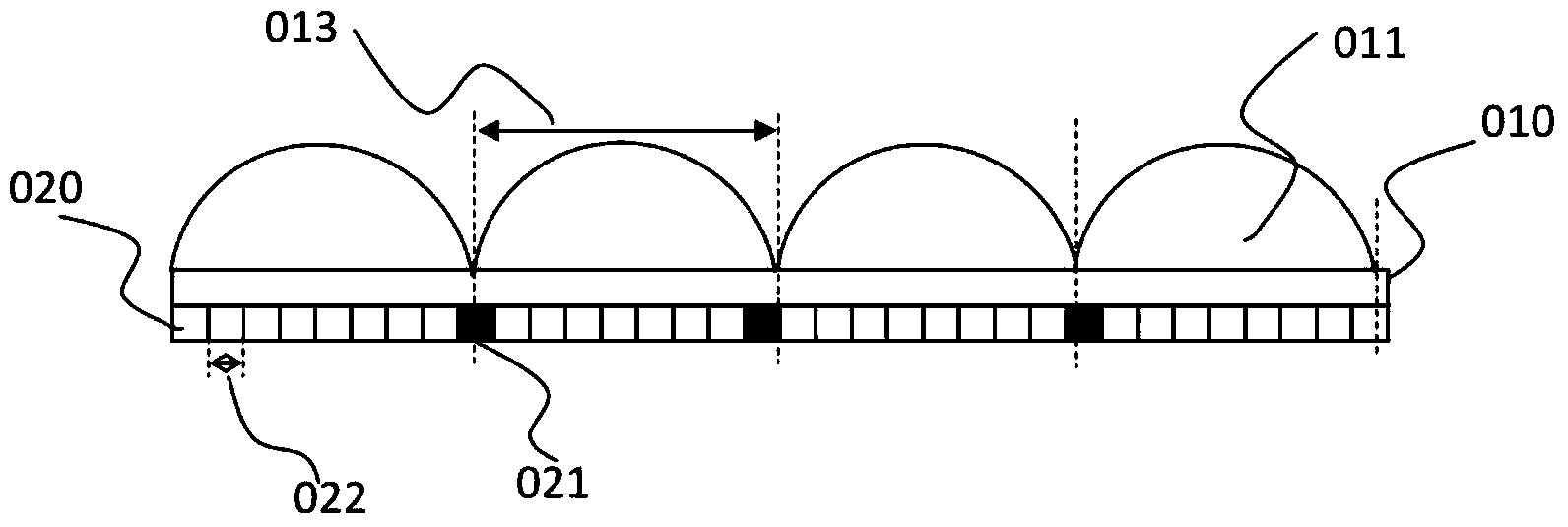

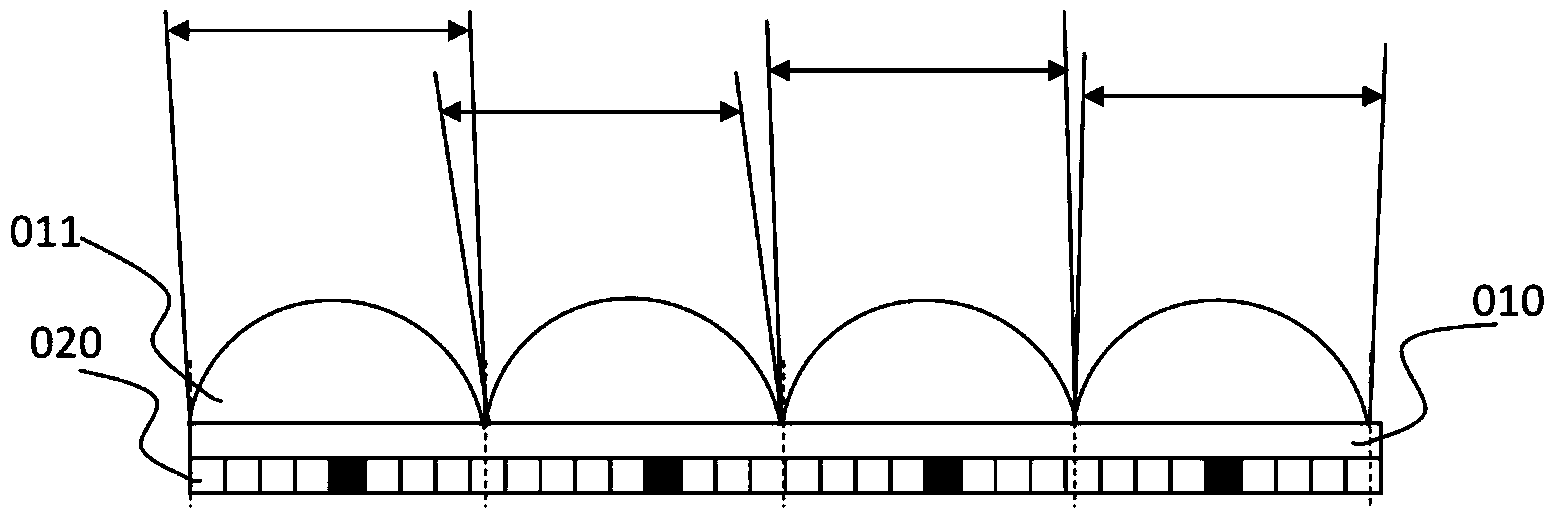

Directional backlight generation method and system

ActiveCN104076519AImprove directionalityHigh sharpnessOptical elementsLiquid-crystal displayDisplay device

The invention discloses a directional backlight generation method. The directional backlight generation method comprises the steps of measuring the cycle angle of a micro-column lens array; installing the micro-column lens array on the surface of a liquid crystal displayer panel and fixedly attaching the micro-column lens array to the surface of the liquid crystal displayer panel; dividing the liquid crystal displayer panel into a plurality of areas in the horizontal direction according to the width of each cylindrical surface prism and distributing all pixels to the corresponding areas according to the relative positions of the pixels and the cylindrical surface prisms; establishing an independent coordinate system for each area; constructing a brightness control curve with the interval width equal to the width of each cylindrical surface prism; carrying out integral on the brightness control curve in the width interval of each pixel and regarding the integral results as the brightness values of the corresponding pixels; determining the brightness values of all the pixels to obtain the liquid crystal displayer image of backlight in the current direction. The invention further discloses a directional backlight generation system. According to the directional backlight generation method and system, the micro-column lens array does not need to be inclined, Morie fringes are reduced, and the directionality, the sharpness and the control flexibility of the backlight are greatly improved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com