Preparing method of nickel tungsten base band used for coated conductor

A nickel-tungsten alloy, coated conductor technology, applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve problems such as affecting the sharpness of cubic texture, achieve high tensile strength and yield strength, and improve uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

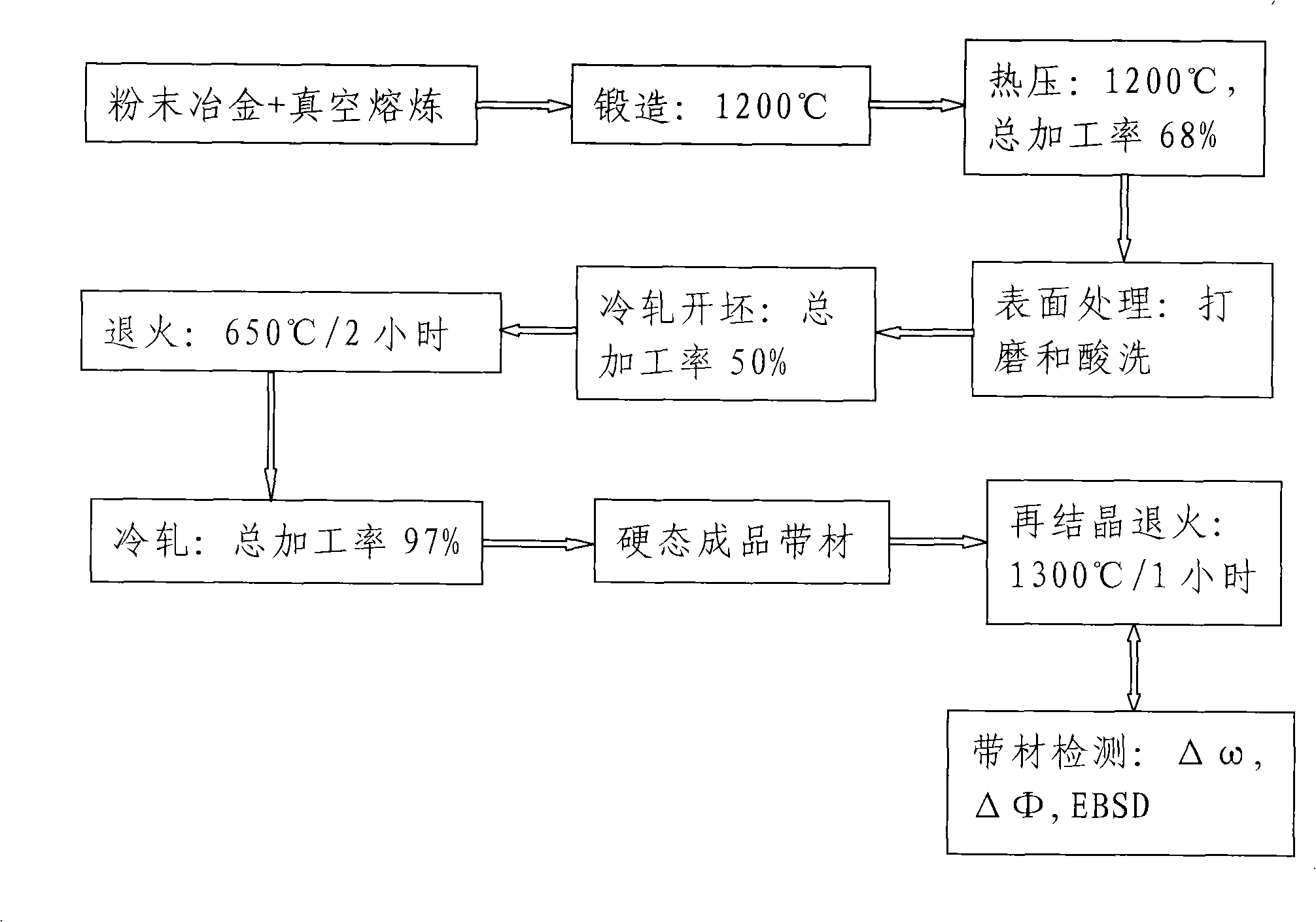

Image

Examples

Embodiment 1

[0019] A Ni-5at%W pre-alloyed rod was prepared by powder metallurgy, with a total amount of 30 kg. The gross weight of the alloy ingot obtained by smelting twice in a vacuum electric arc furnace is 26 kilograms. After removing the riser and peeling the surface through flaw detection, the net ingot obtained is 21.5 kg. A slab material with a thickness of 25 mm and a width of 120 mm was obtained by forging. After removing the scale on the surface of the forged slab, it was hot rolled at 1200° C. to obtain a plate with a thickness of 8 mm. The pass processing rate of the hot rolling was 25%, and the total processing rate was 68%. The surface of the hot-rolled piece is pickled and then cold-rolled, and the middle is subjected to stress-relief annealing. The annealing temperature is selected at 650°C and kept for 2 hours, and the vacuum degree is 10 -4 Pa. The total processing rate of continuous cold rolling is 97.77%, and the finished base strip has a thickness of 0.08 mm, a wi...

Embodiment 2

[0021] A Ni-5at%W pre-alloyed rod was prepared by powder metallurgy, with a total amount of 30 kg. The gross weight of the alloy ingot obtained by smelting twice in a vacuum electric arc furnace is 26.5 kilograms. After removing the riser and surface peeling through flaw detection, the net ingot obtained is 20 kg. A slab material with a thickness of 25 mm and a width of 120 mm was obtained by forging. After removing the scale on the surface of the forged slab, it was hot rolled at 1200° C. to obtain a plate with a thickness of 8 mm. The pass processing rate of the hot rolling was 25%, and the total processing rate was 68%. The surface of the hot-rolled piece is pickled and then cold-rolled, and the middle is subjected to stress relief annealing. The annealing temperature is 650 ° C for 2 hours, and the vacuum degree is 10 -4 Pa. The total processing rate of continuous cold rolling is 97.77%, and the finished base strip has a thickness of 0.08mm, a width of 100mm, and a leng...

Embodiment 3

[0023] A Ni-5at%W pre-alloyed rod was prepared by powder metallurgy, with a total amount of 30 kg. The gross weight of the alloy ingot obtained by smelting twice in a vacuum electric arc furnace is 27 kilograms. After removing the riser and surface peeling through flaw detection, the net ingot obtained is 21 kg. A slab material with a thickness of 25 mm and a width of 120 mm was obtained by forging. After removing the scale on the surface of the forged slab, it was hot rolled at 1200° C. to obtain a plate with a thickness of 8 mm. The pass processing rate of the hot rolling was 25%, and the total processing rate was 68%. The surface of the hot-rolled sheet is pickled and then cold-rolled, and the middle is subjected to stress-relief annealing. The annealing temperature is 650 ° C for 2 hours, and the vacuum degree is 10 -4 Pa. The total processing rate of continuous cold rolling is 97.77%, and the finished base strip has a thickness of 0.08 mm, a width of 100 mm, and a leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com