Water-based digital printing thermal dye sublimation jet ink

A digital printing and inkjet ink technology, applied in the field of ink, can solve the problems of user loss, poor nozzle fluency, plugging, etc., achieve the best printing fluency, improve quick-drying performance, and improve applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

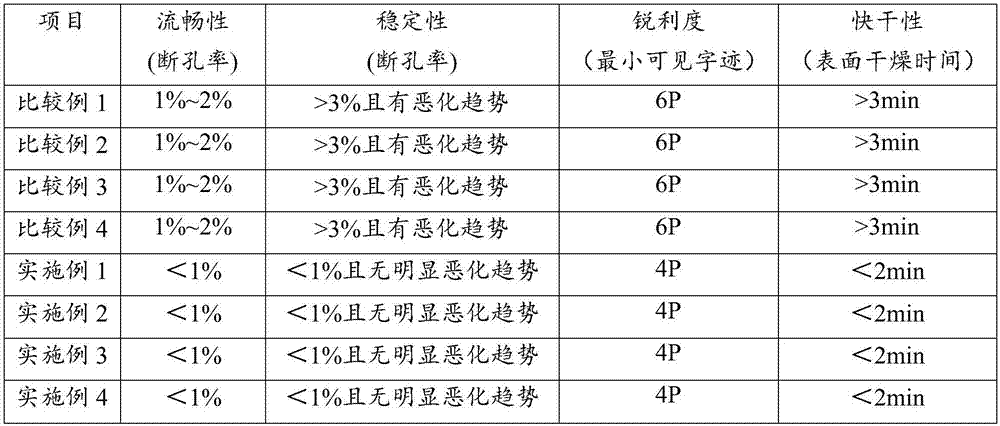

Examples

Embodiment 1

[0026] Example 1: Black Dye Sublimation Inkjet Ink

[0027] A water-based digital printing sublimation inkjet ink, which includes the following components by mass percentage: 10% resin, 30% color paste, 20% solvent, 0.5% bactericidal preservative, 0.5% pH regulator, wetting Agent 1.5%, deionized water 37.5%.

[0028] The above dye-sublimation inkjet ink is made according to the following steps:

[0029] 1) Put the formula amount of deionized water, solvent, bactericidal preservative, and pH regulator into the material bucket in order, and stir at a speed of 500r / min for 20 minutes; add the formula amount of wetting agent and continue stirring until the solution is clear as a whole Add the amount of resin in the recipe and continue to stir until the solution is clear as a whole;

[0030] 2) Add the formulated amount of color paste and stir for 20 minutes at a speed of 500 r / min; then filter with a combination of a 0.22 μm hydrophilic filter membrane and a 0.45 μm hydrophilic ...

Embodiment 2

[0031] Example 2: Blue Dye Sublimation Inkjet Ink

[0032] A water-based digital printing sublimation inkjet ink, which includes the following components by mass percentage: 8% resin, 40% color paste, 10% solvent, 0.1% bactericidal preservative, 0.8% pH regulator, wetting Agent 2.1%, deionized water 39%.

[0033] The preparation method is the same as in Example 1.

Embodiment 3

[0034] Example 3: Red dye sublimation inkjet ink

[0035] A water-based digital printing sublimation inkjet ink, which includes the following components by mass percentage: 5% resin, 45% color paste, 15% solvent, 1% bactericidal preservative, 1% pH regulator, wetting Agent 2%, deionized water 31%.

[0036] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com