Ultraviolet-curing water-based inkjet ink

An inkjet ink, water-based technology, applied in ink, household utensils, applications, etc., can solve the problems of not being able to adapt to printers and high viscosity of inkjet ink, achieve the effect of accelerating drying time and printing speed, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

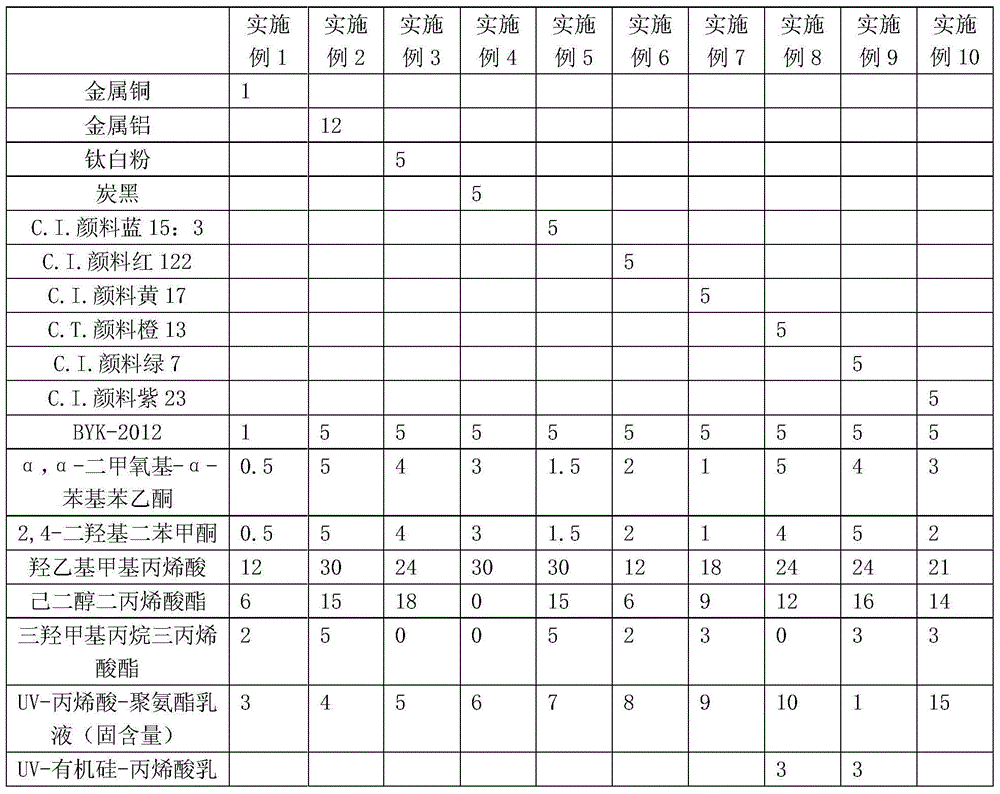

Examples

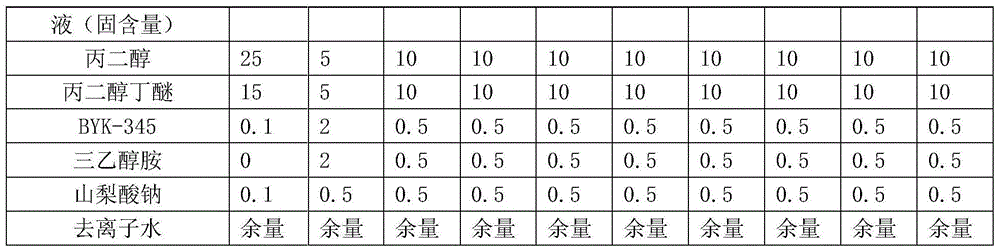

Embodiment 15- Embodiment 22

[0053] Example 15-Example 22: Examples and Comparative Examples Ink stability and intermittent printing effect, printing fluency detection:

[0054] Tested according to national QB / T2730.1-2005 and QB / T 2730.2-2005 standards

[0055] Load the prepared ink into the Epson me1+ printer cartridge and print on plain paper.

[0056] Table 3: Stability and intermittent printing effect, printing fluency of the inks of the examples and comparative examples

[0057]

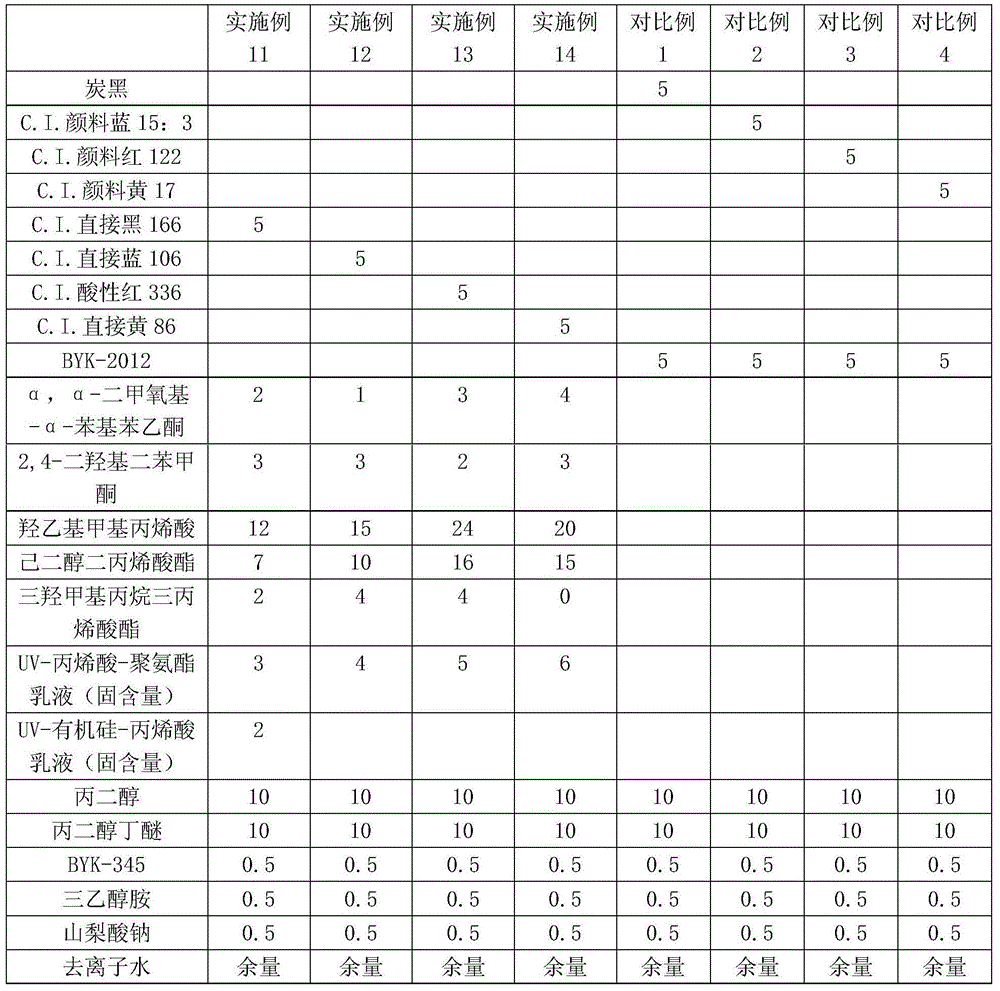

Embodiment 23- Embodiment 30

[0058] Example 23-Example 30: Comparison of the properties of the inks of the examples and the inks of the comparative examples:

[0059] Load the prepared ink into the Epson me1+ printer cartridge and print on plain paper.

[0060] Tested in accordance with national QB / T2730.1-2005, QB / T 2730.2-2005, QB / T2603-2007, GB / T13217.2-2009 standards

[0061] Water resistance test:

[0062] Detection method: Take a section of the diffusivity graded writing test paper, immerse it in deionized water, observe the fading and diffusion time of the ink, and record it. After immersion in deionized water for 24 hours, it was taken out to dry naturally, and visually compared with the contrast color standard.

[0063] Hydrochloric acid resistance test:

[0064] Detection method: Take a section of the diffusivity graded writing test paper, immerse it in 10% (volume ratio) hydrochloric acid aqueous solution for 24 hours, then immerse it in deionized water for 10 minutes, take it out and dry it...

Embodiment 31- Embodiment 38

[0081] Example 31-Example 38: Printing performance test of ink on various media

[0082] Detection method: The prepared example inks and comparative example inks were put into an Epson me1+ printer cartridge, printed on various media as described below, and the printing effect was observed.

[0083] In the table: A means the blot is clear and the effect is good. B: On behalf of the imprint is blurred, the effect is poor`. C: Represents severe blur, and the imprint cannot be seen clearly.

[0084] Table 5: Ink print results on various uncoated and unprinted coated media

[0085]

[0086] Example 33

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com