Patents

Literature

117results about How to "Good surface texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

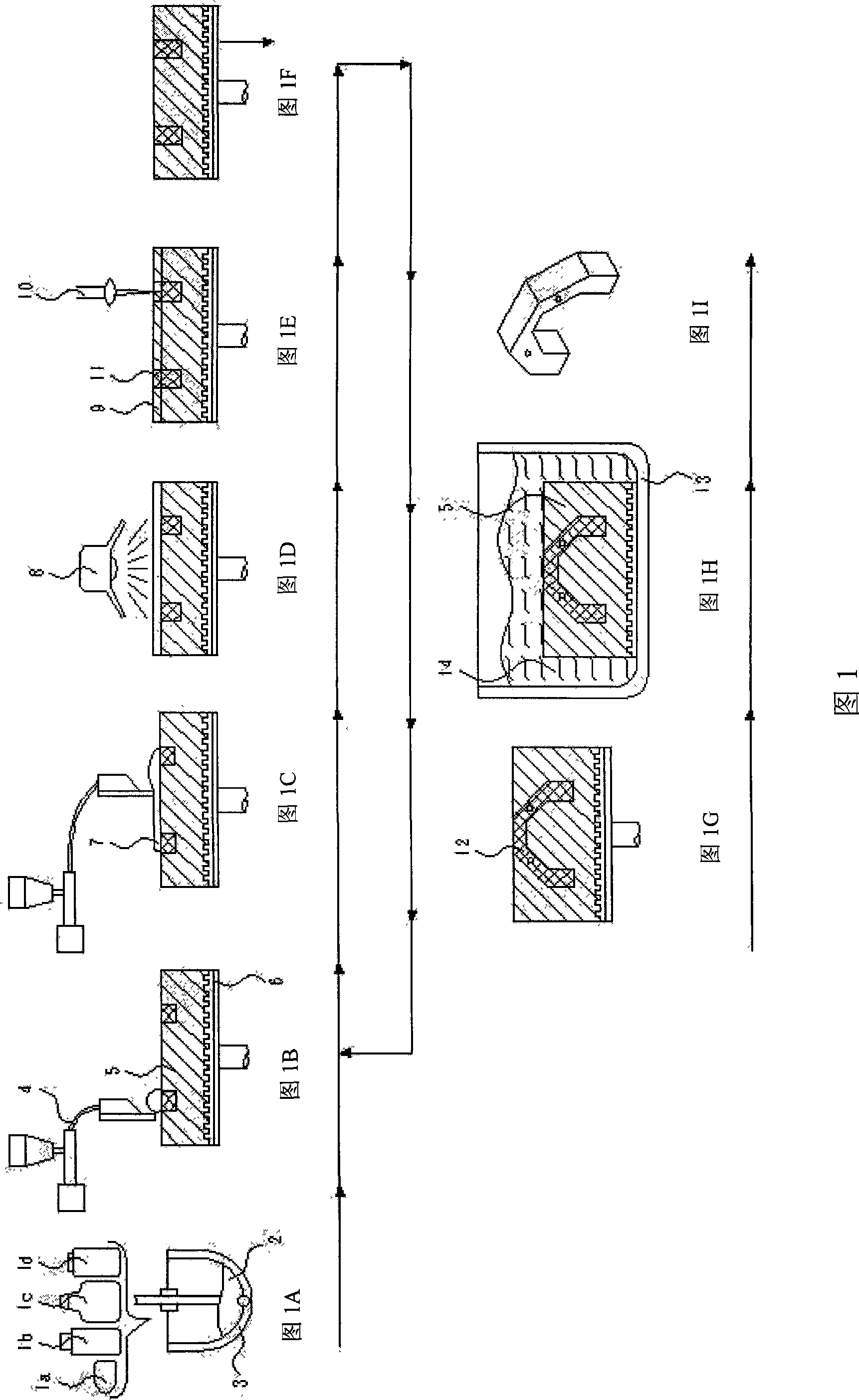

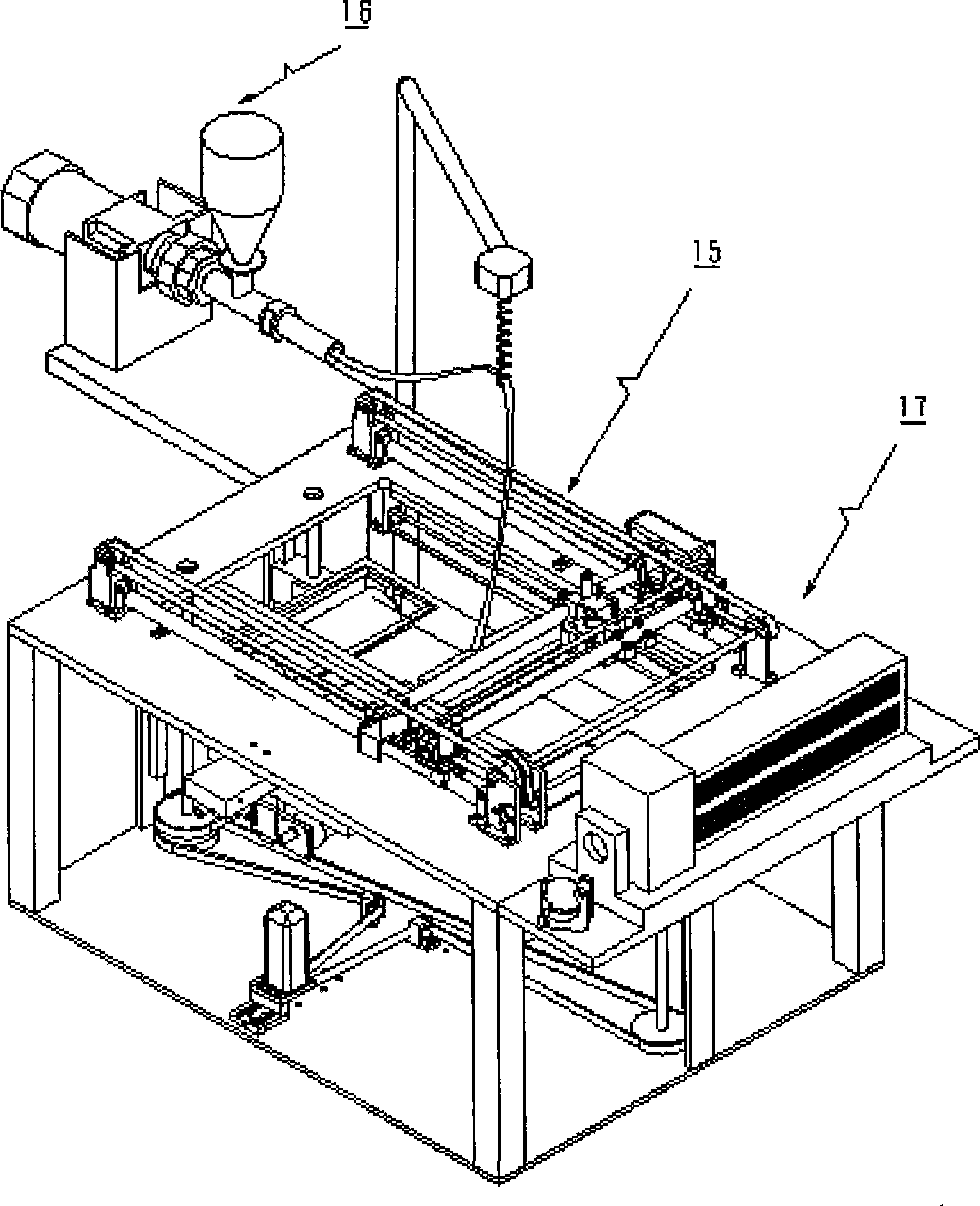

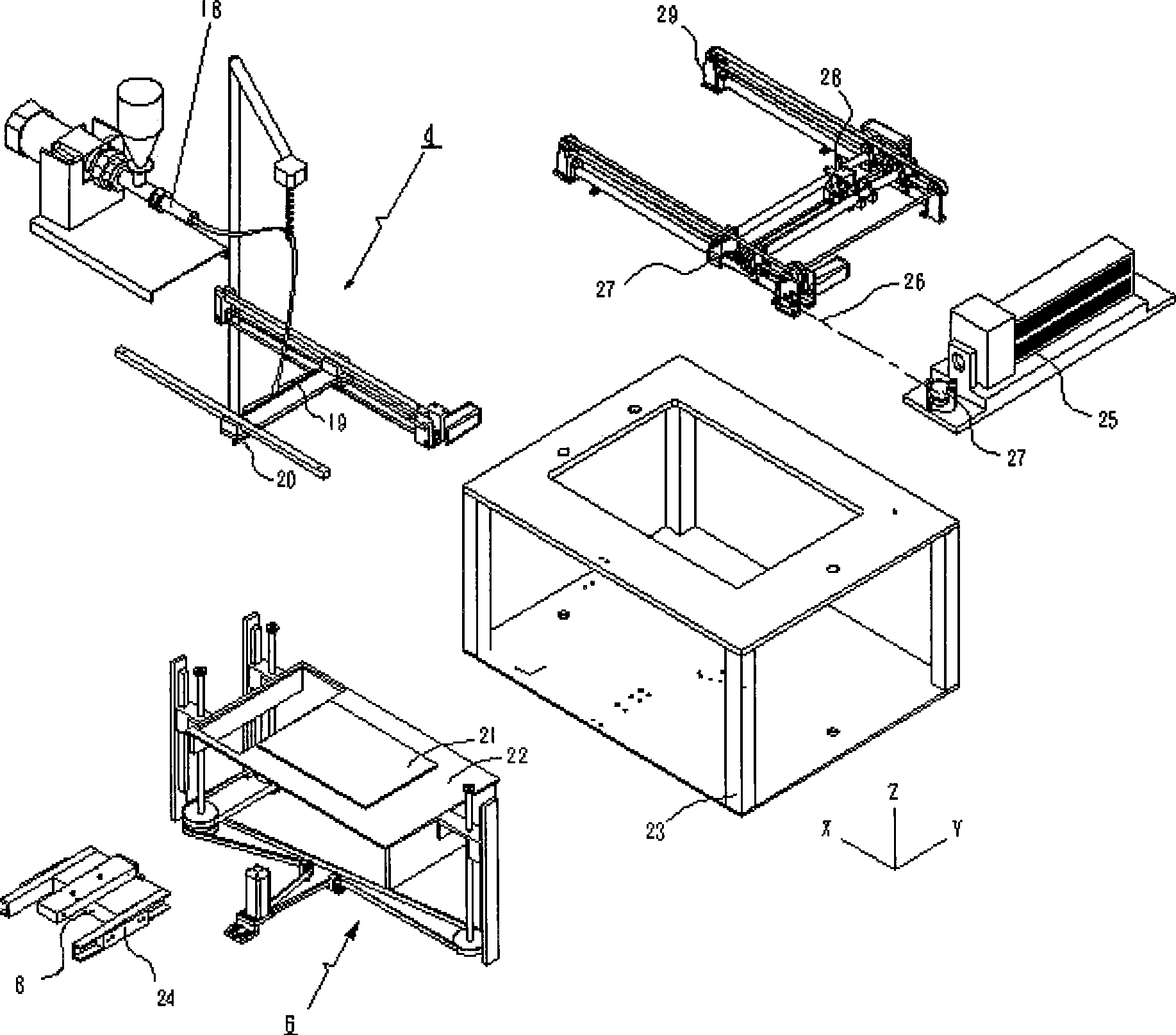

Manufacture method and device of three-dimensional workpiece

InactiveCN101422963AReduce the staircase effectHigh resolutionLiquid surface applicatorsIncreasing energy efficiencySelective laser sinteringAdhesive

The invention provides a method and equipment using organic adhesive mixed solvent and powder to manufacture three-dimensional workpieces. The work principle is as follows: the raw materials are stirred into slurry, which is laid as a green compact thin layer that can disintegrate in disintegrant; the green compact thin layer can form a workpiece thin layer that does not disintegrate in the disintegrant after scanned by an energy beam; in such a cycle, the steps of laying the thin layer and energy beam scanning are repeated, and then the three-dimensional workpiece can be formed; and the disintegant is used for separating the green compact not scanned by the energy beam from the workpiece, thus remaining the needed three-dimensional workpiece. The invention is widely applicable to manufacturing plastic, metallic, ceramic and compound workpieces, can avoid the defects of a selective laser sintering method, can use fine and very thin powder and therefore, can manufacture a finished product which is better than that made in the traditional selective laser sintering method in surface roughness and texture fineness, in addition, through subsequent densified sintering, the metallic and ceramic workpieces can have the strength superior to that in the traditional selective laser sintering method.

Owner:OUKESI INT

Manufacturing method for combined ceramic tile with complete pattern, spliced by plurality of ceramic tiles

InactiveCN103241049AStrong three-dimensional senseStrong sense of transparencyDecorative surface effectsClaywaresMetallurgyNatural stone

The invention relates to a manufacturing method for a combined ceramic tile with a complete pattern, which is spliced by a plurality of ceramic tiles. The method comprises the following steps of: mixing raw materials to prepare a powder material, pressing the powder material to obtain green tiles, carrying out printing and glaze spraying on the green tiles, sintering the obtained tiles to obtain the ceramic tiles, and performing seamless splicing on the plurality of ceramic tiles with different or identical figures to obtain the combined ceramic tile with the complete pattern. Compared with the prior art, the combined ceramic tile can fully display the real effect of natural stones by means of large format splicing, is strong in three-dimensional effect and rich in layering, can better adapt to current market trend, and is grand and very impressive after being paved.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD

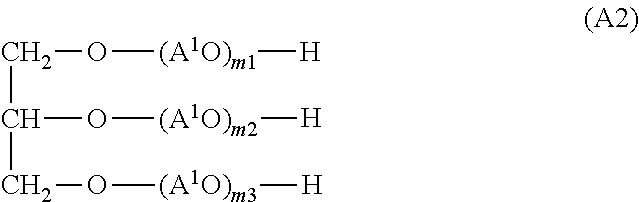

Additive composition for hydraulic composition

ActiveUS20110021668A1Good surface textureReduce retention timeInksGlycerol DerivativesPolymer science

Owner:KAO CORP

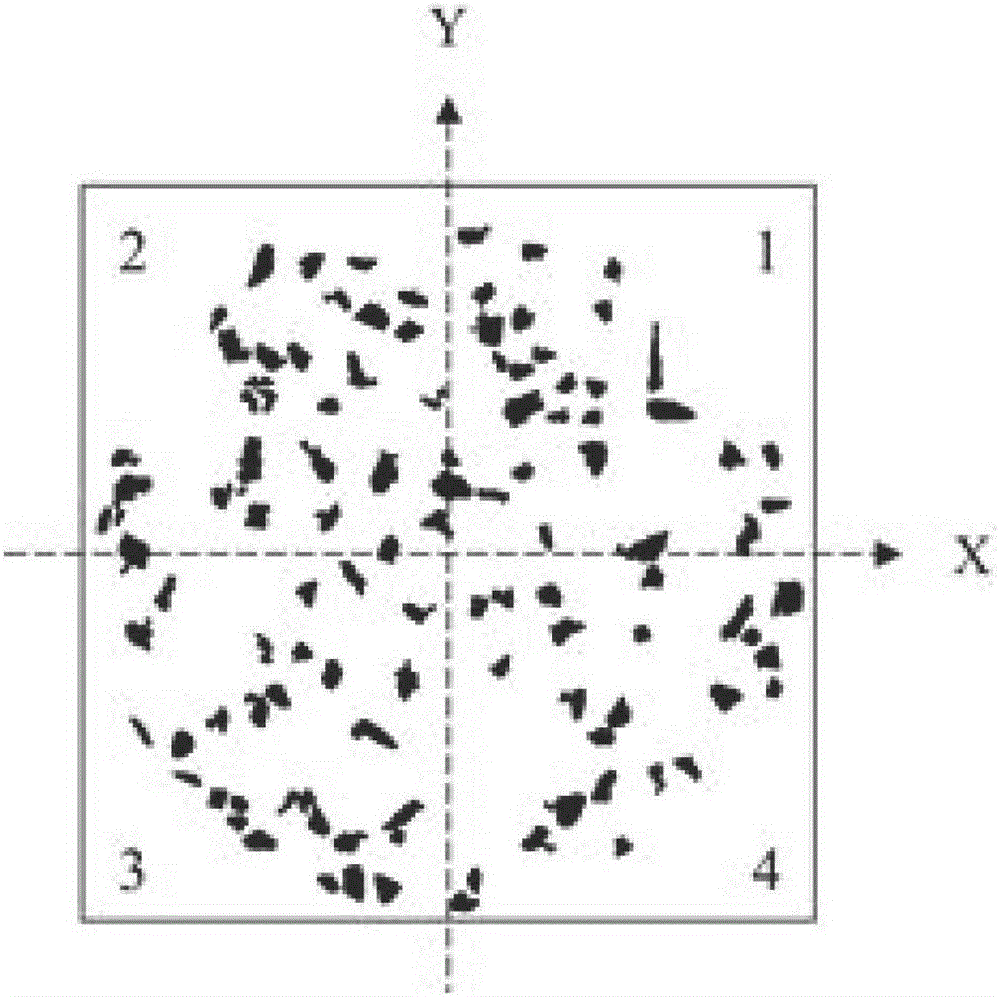

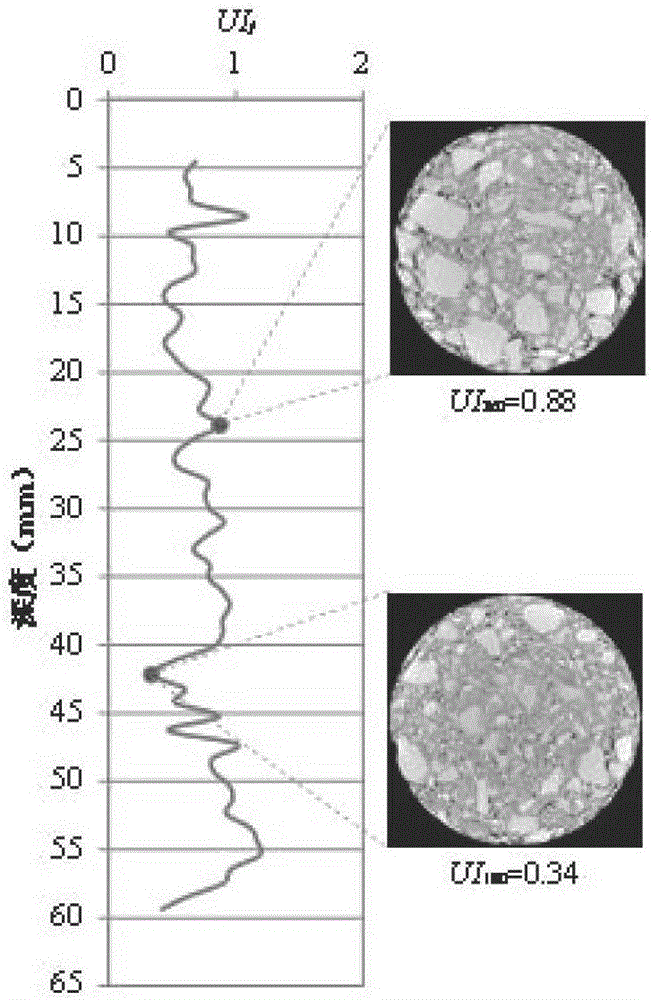

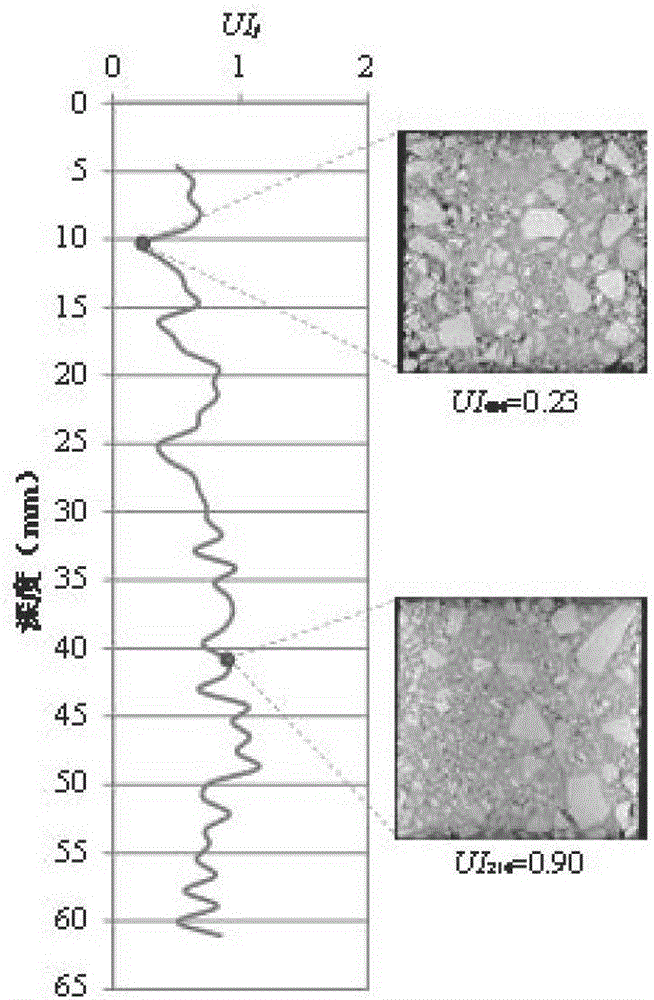

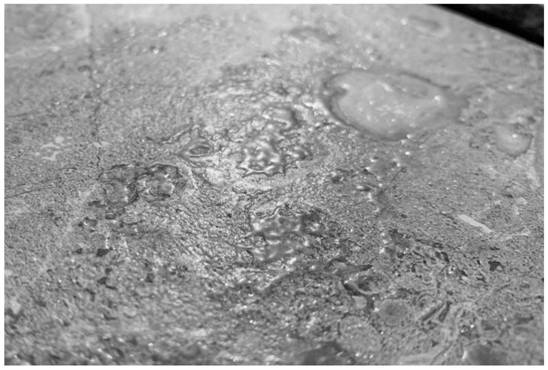

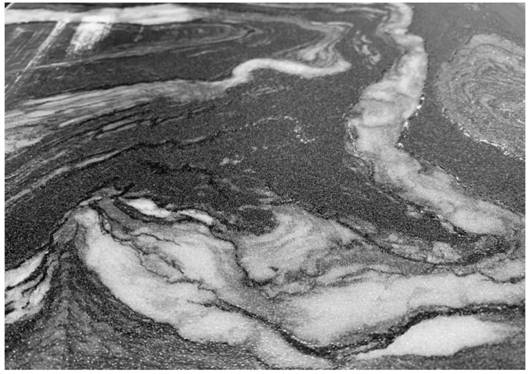

Coarse aggregation characteristic method for emulsified asphalt cold-recycled mixture

ActiveCN106447690AReduce uniformityEvenly distributedImage enhancementImage analysisAsphaltEnvironmental geology

The invention discloses a coarse aggregation characteristic method for an emulsified asphalt cold-recycled mixture. A series of indexes and algorithms are used to research spatial distribution condition, main-axis direction and particle shape features of coarsely aggregated particles in the emulsified asphalt cold-recycled mixture. The method comprises analysis on the spatial distribution condition of the coarsely aggregated particles, analysis on the main axis direction of the coarsely aggregated particles, and analysis on the shape feature of the coarsely aggregated particles. An image of the coarsely aggregated particles is obtained on the basis of CT scanning test, spatial distribution and main axis direction of the coarsely aggregated particles in the emulsified asphalt cold-recycled mixture are analyzed, the uniformity of cold-recycled test pieces in different molding manners and different grading as well as compacting effects in the different molding manners are evaluated, the indexes of the flatness ratio FER, the angularity index AI and the surface texture index STI of the roughly aggregated particles are calculated, and the shape feature of the roughly aggregated particles in a cold material is compared with that in a hot material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Digital glazed ceramic tile and production method thereof

PendingCN112830774AFine embossing effectGood surface textureCeramic materials productionPersonalizationBrick

The invention provides a production method of a digital glazed ceramic tile. The production method comprises the following steps of preparing a green brick and drying for later use, applying a layer of engobe on the green bricks and drying for later use, carrying out digital glaze texture pattern printing on the engobe applied and dried green brick, spraying cover glaze on the green brick printed with the digital glaze texture pattern, and drying for later use, carrying out color ink-jet printing on the green brick after the cover glaze is applied and the green brick is dried, carrying out digital protection glaze printing on the green brick with the printed pattern, and sintering the green brick in a roller kiln to obtain a finished product of the digital glaze ceramic tile. According to the production method of the digital glaze ceramic tile, the effect is finer, the surface texture is finer, the concave-convex details are rich, the concave-convex effect of the product is good, the concave-convex surface transition is natural, personalized customization production can be conveniently carried out, the requirements of consumers can be better met, and the market prospect is wide.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +1

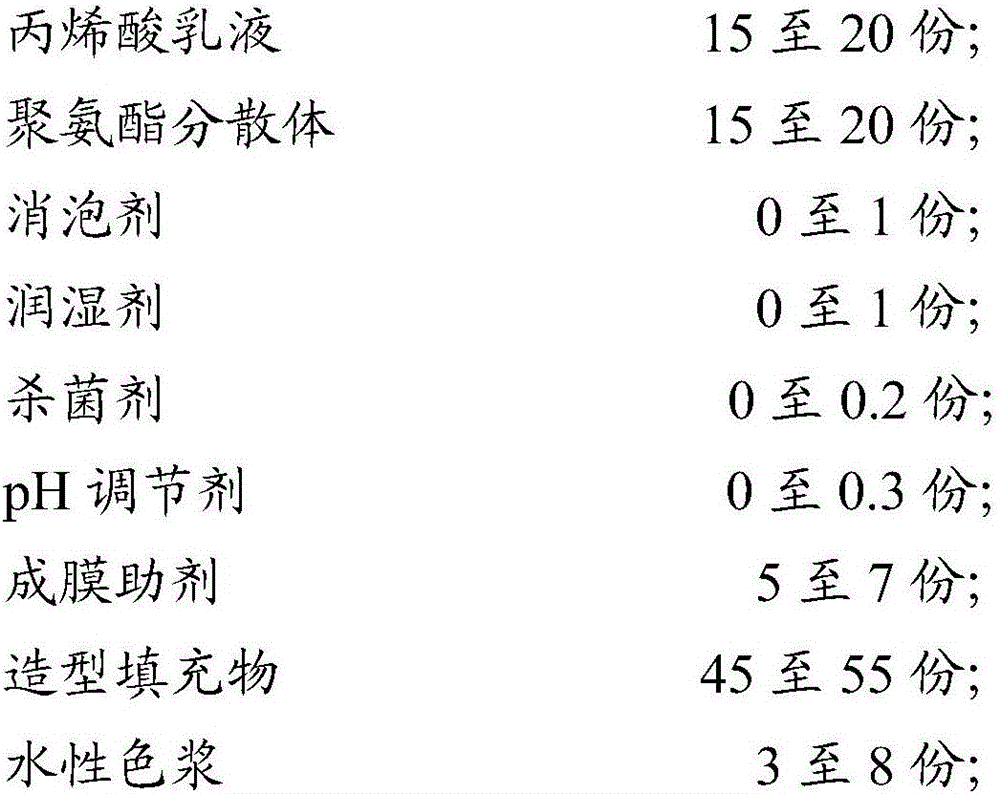

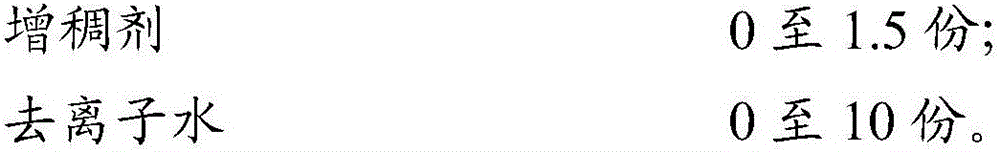

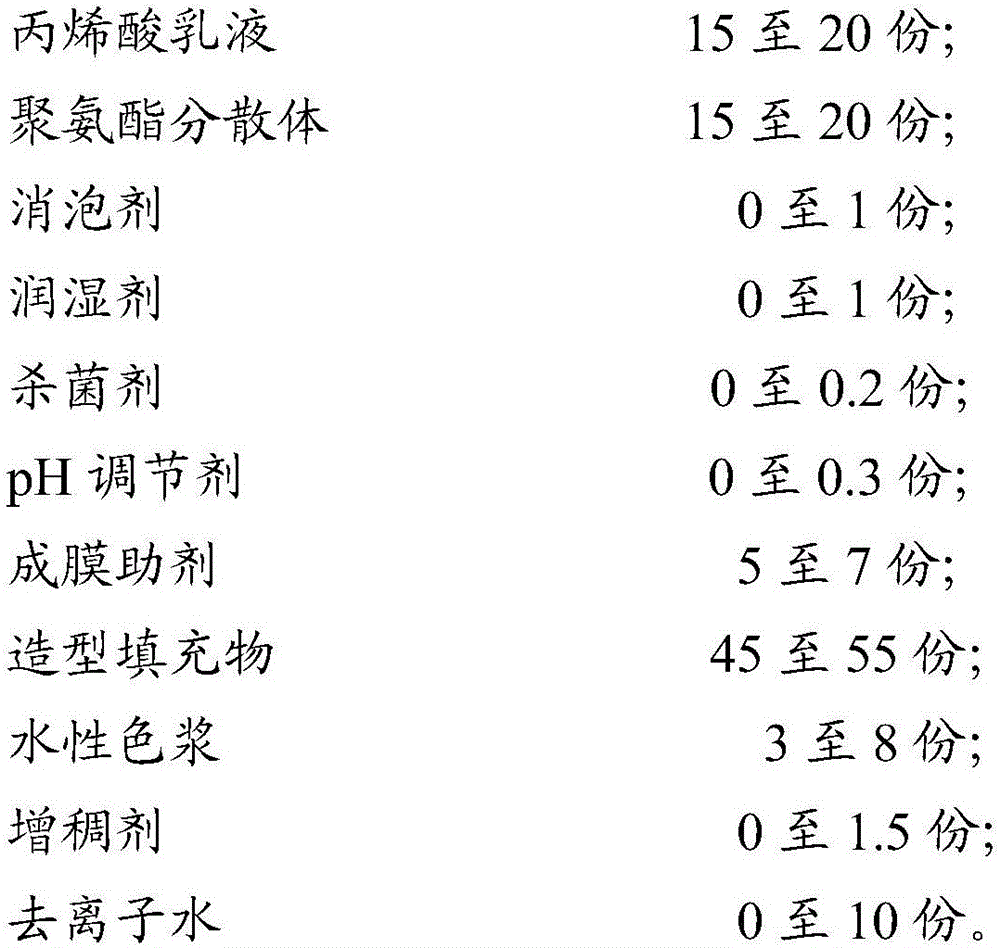

Water-borne wood coating

InactiveCN106634293AGood surface textureStain resistantAntifouling/underwater paintsPaints with biocidesFungicidePolyurethane dispersion

The embodiment of the invention discloses a water-borne wood coating which comprises, by weight parts, 15-20 parts of acrylic emulsion, 15-20 parts of polyurethane dispersion, 0-1 part of defoamer, 0-1 part of wetting agent, 0-0.2 part of fungicide, 0-0.3 part of pH modifier, 5-7 parts of coalescing agent, 45-55 parts of modelling filler, 3-8 parts of water-borne color paste, 0-1.5 parts of thickener and 0-10 parts of deionized water. The water-borne wood coating can be applied to woodwork furniture to achieve a coating effect of preparing the sand face, and the coating has the advantages of being high in three-dimensional effect and strength, excellent in adhesive force, good in water resistance and high in pollution resistance and art texture.

Owner:展辰新材料集团股份有限公司 +6

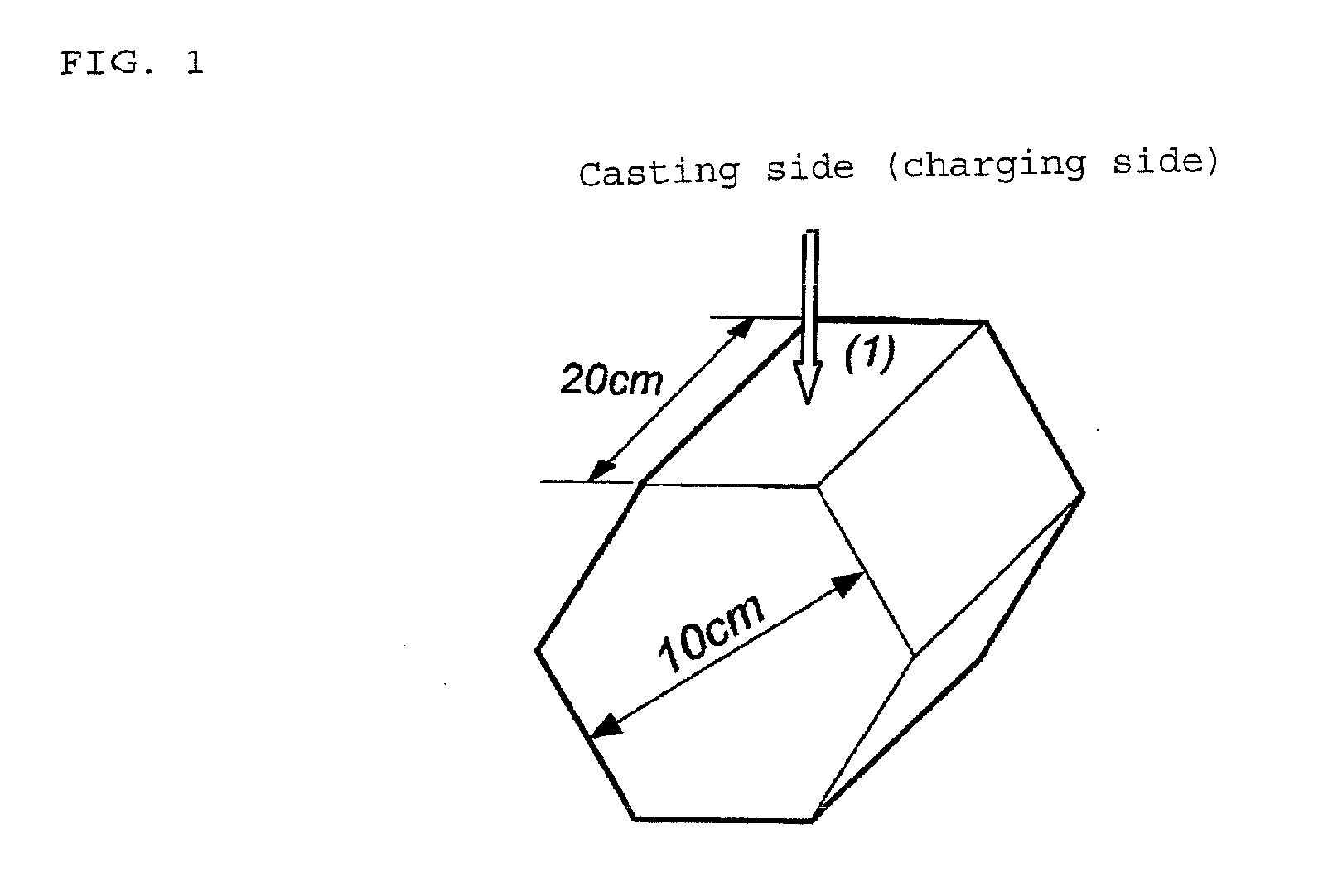

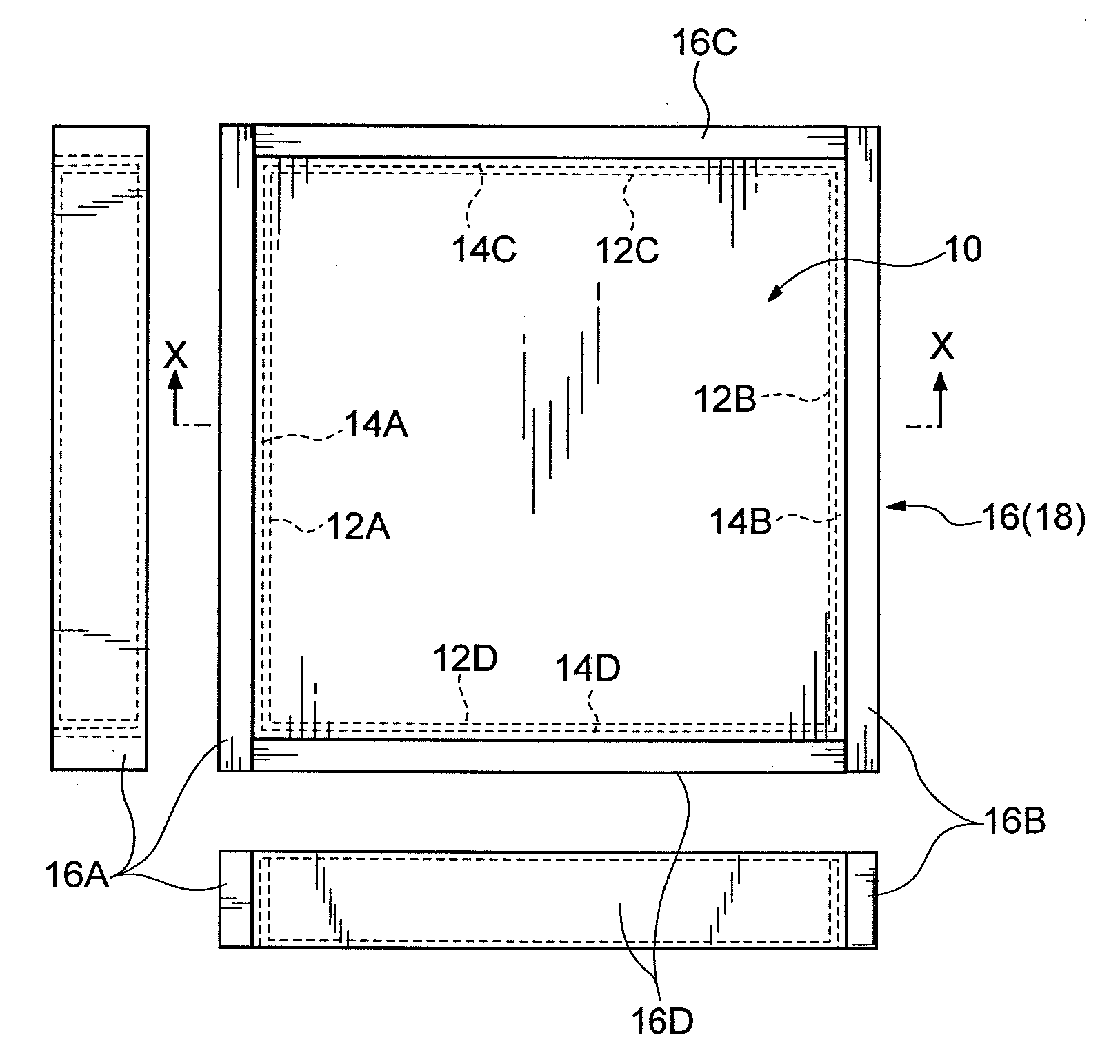

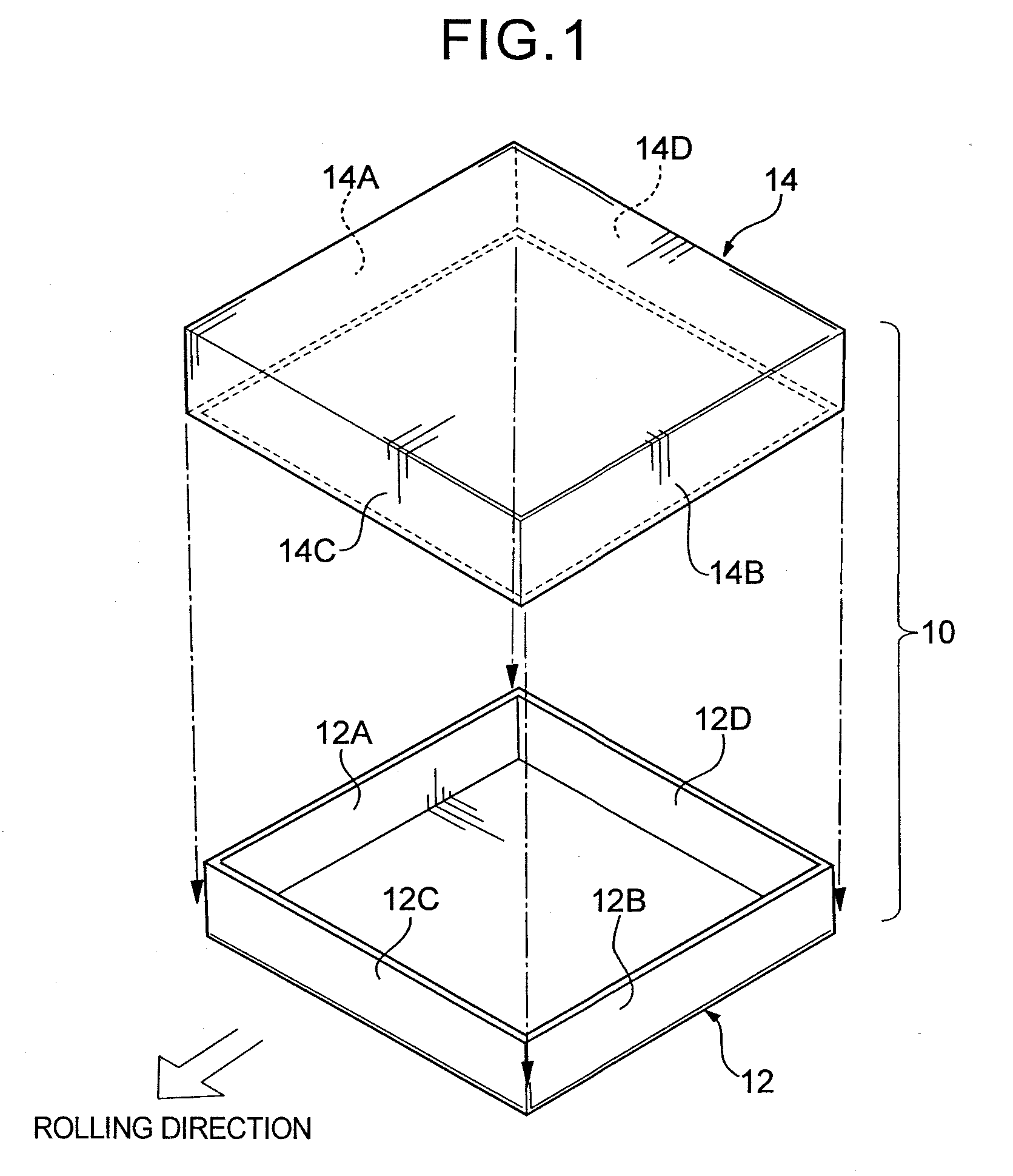

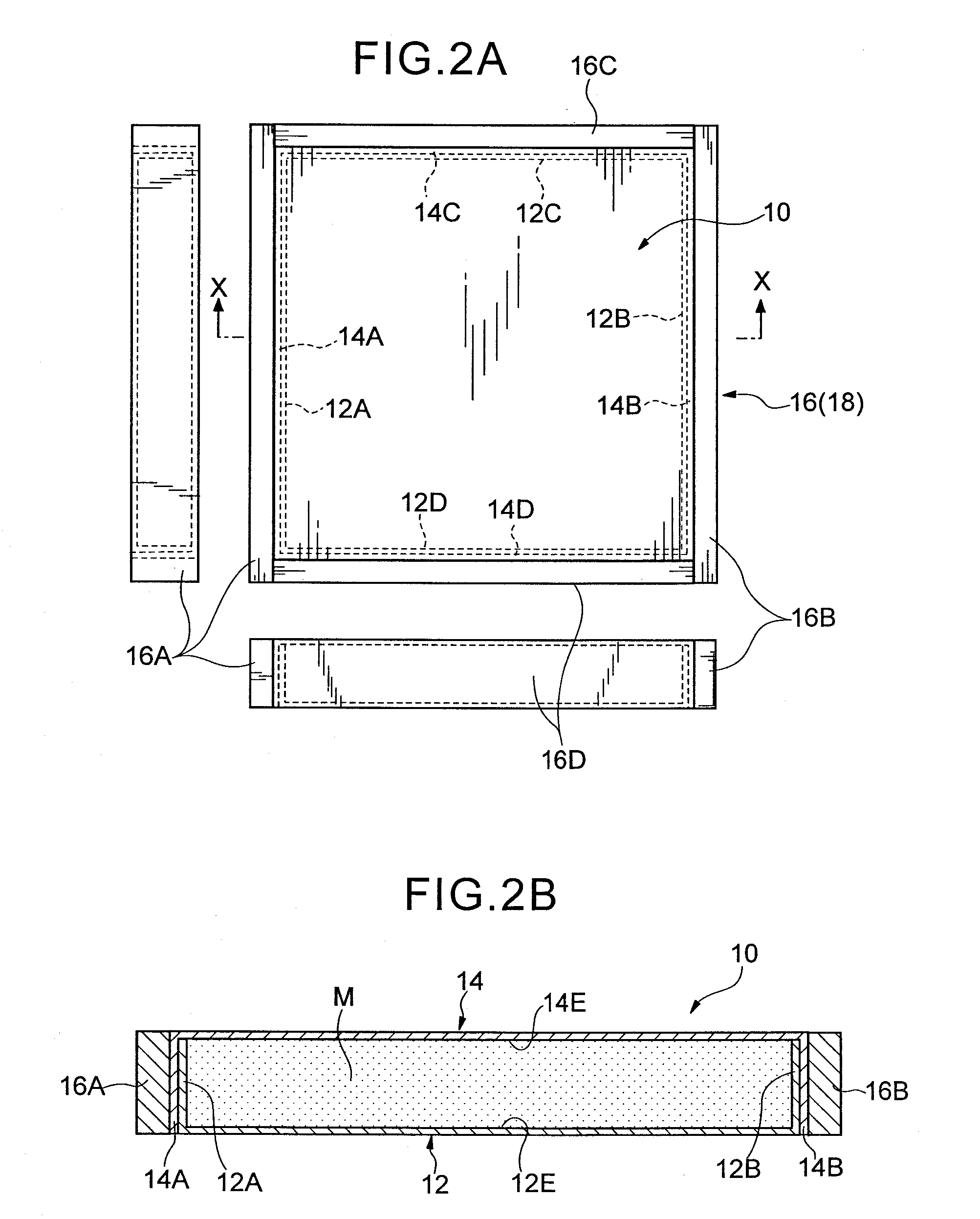

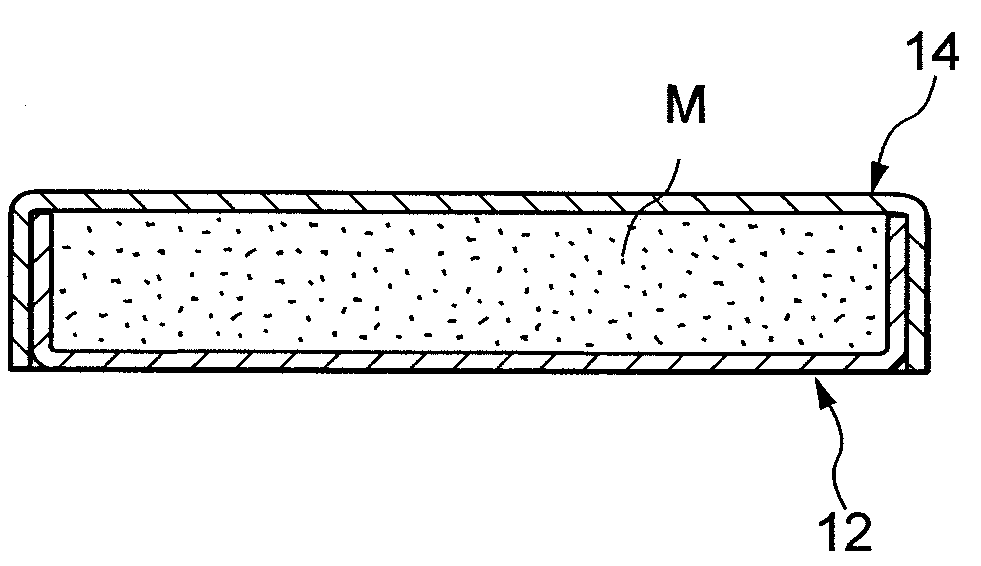

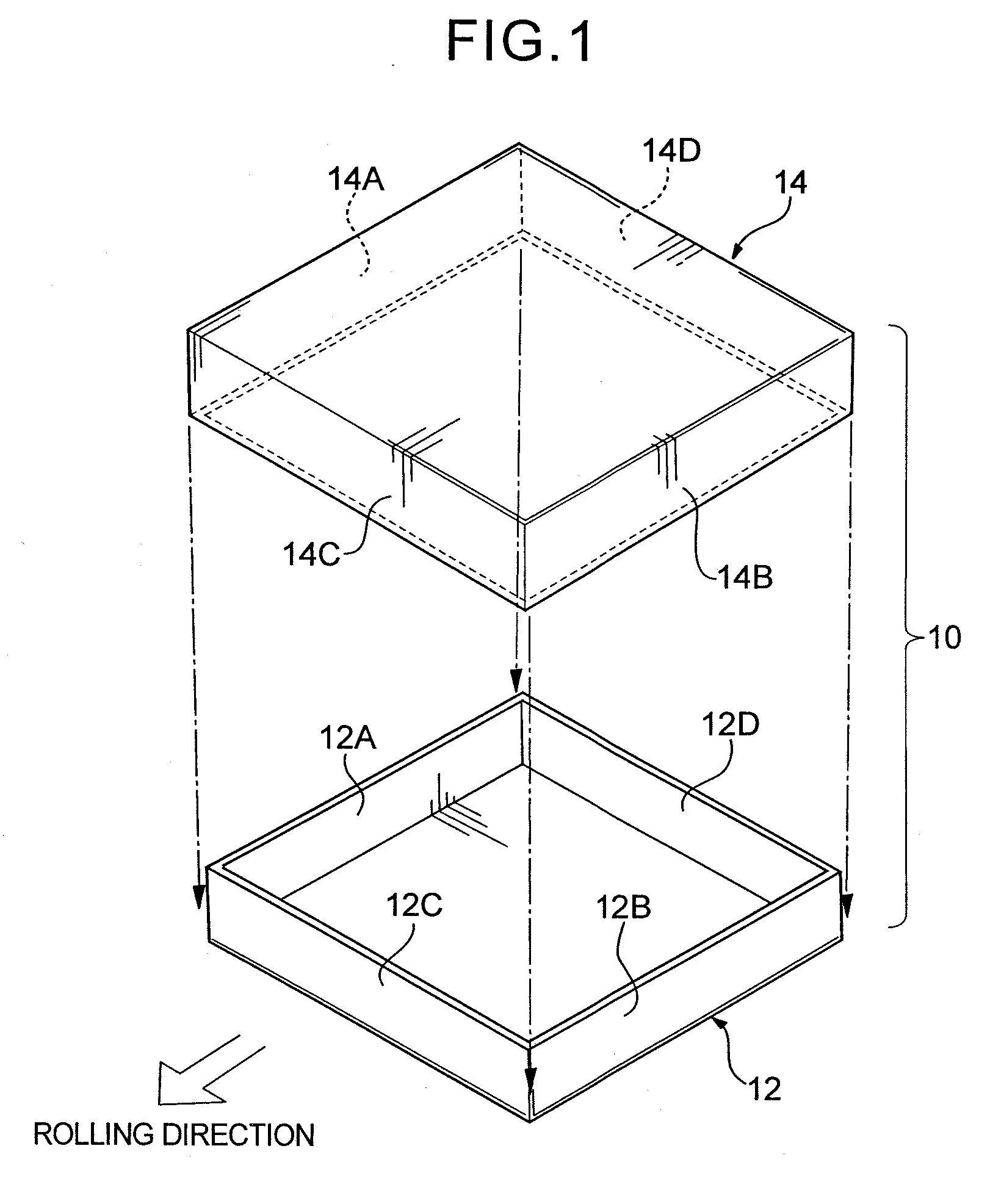

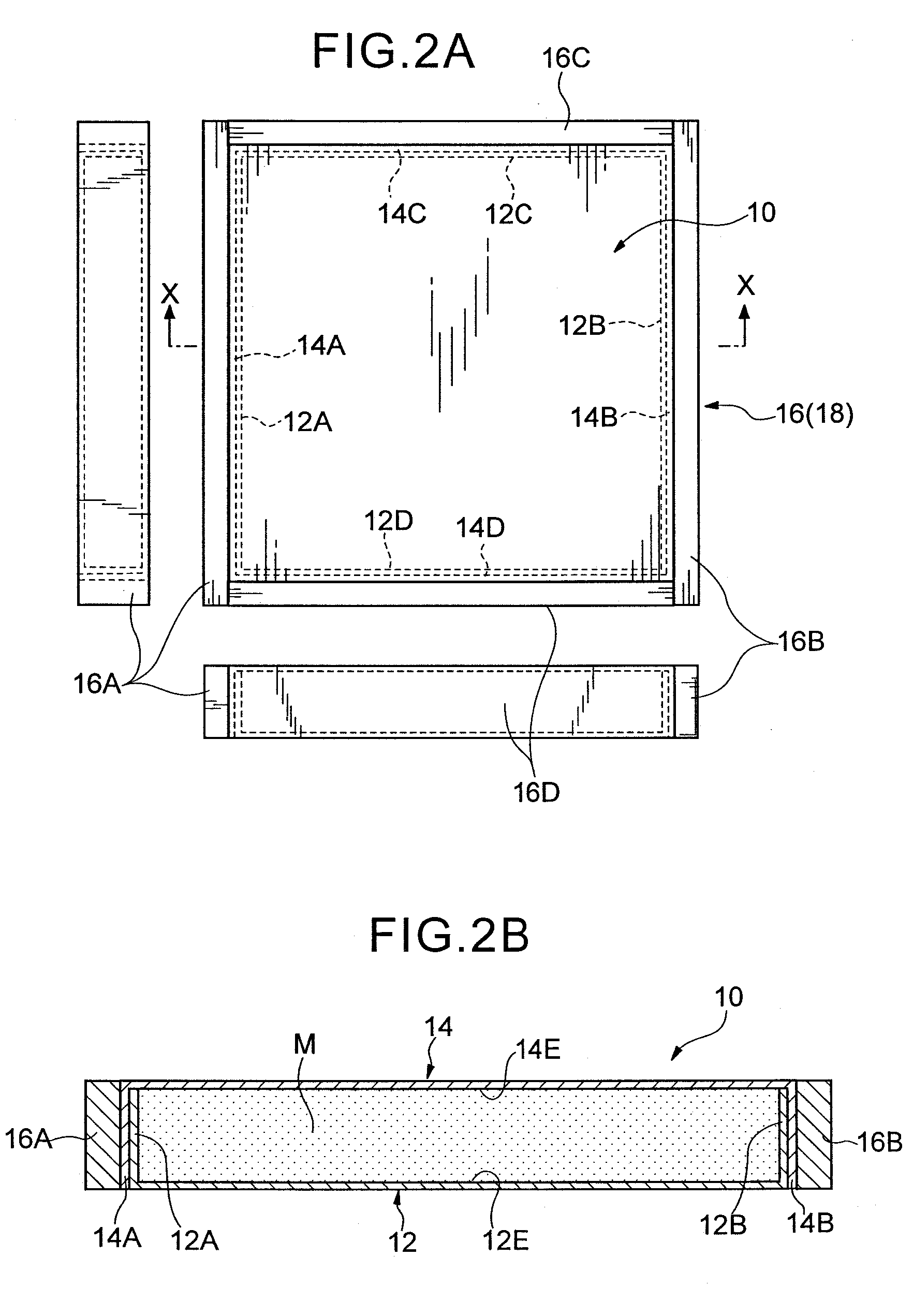

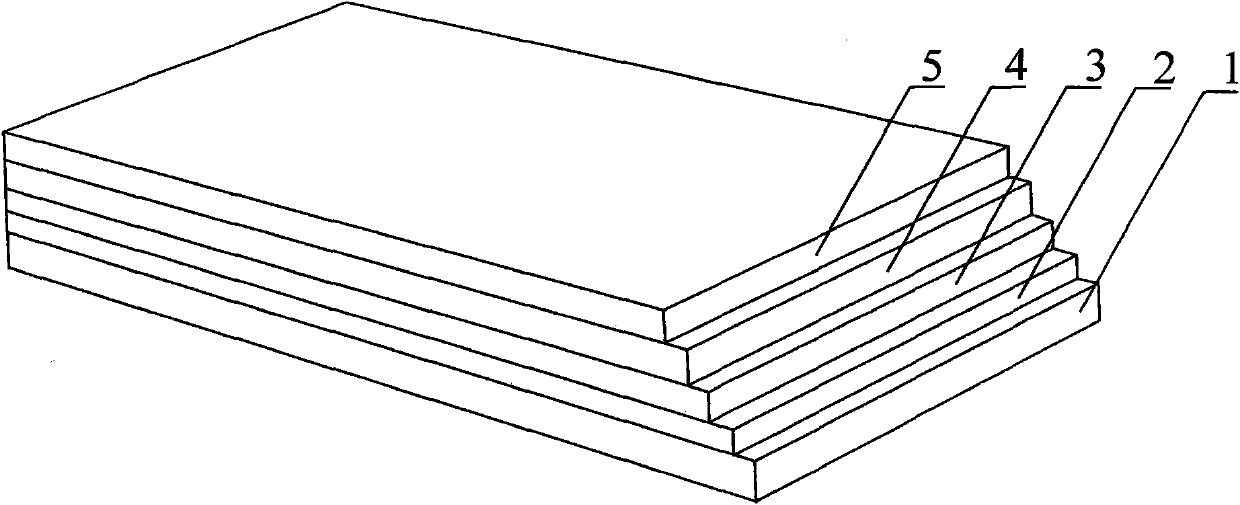

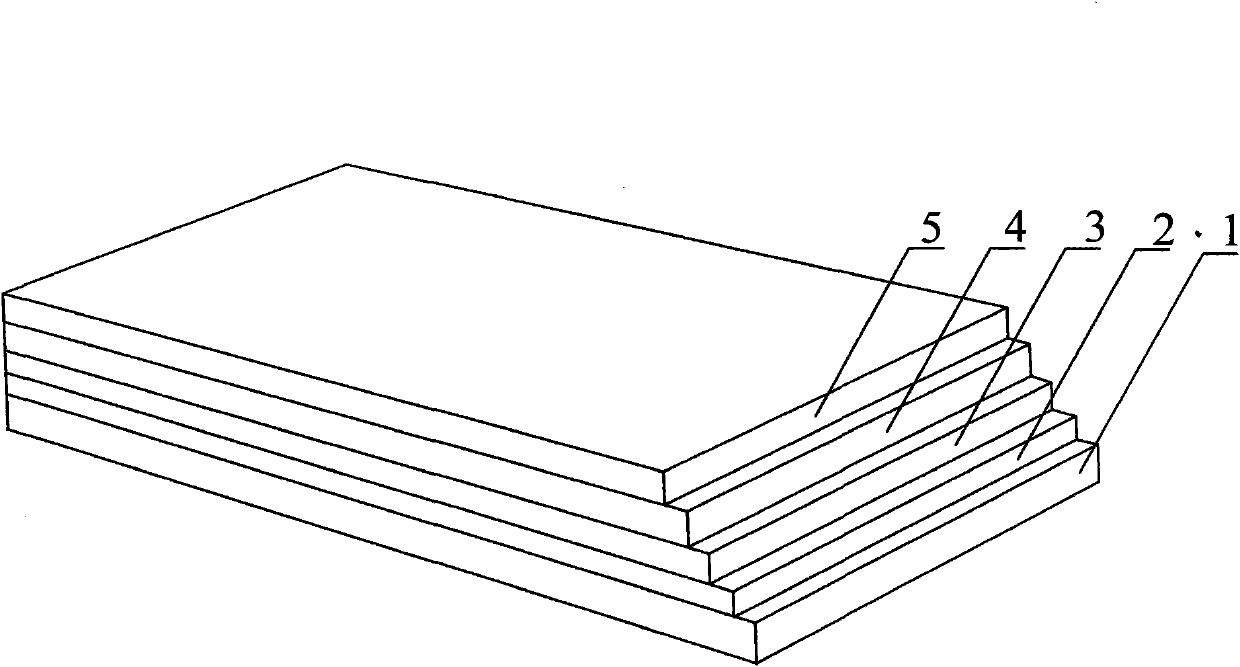

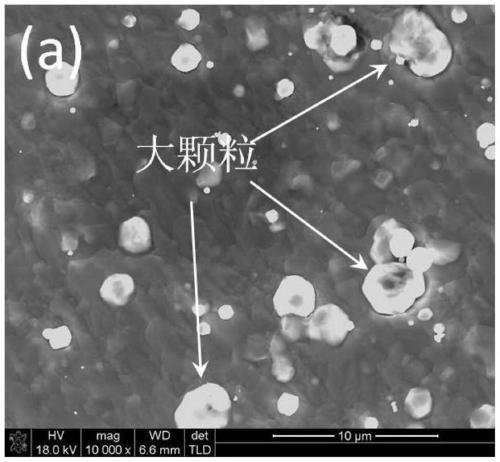

Metal matrix composite material

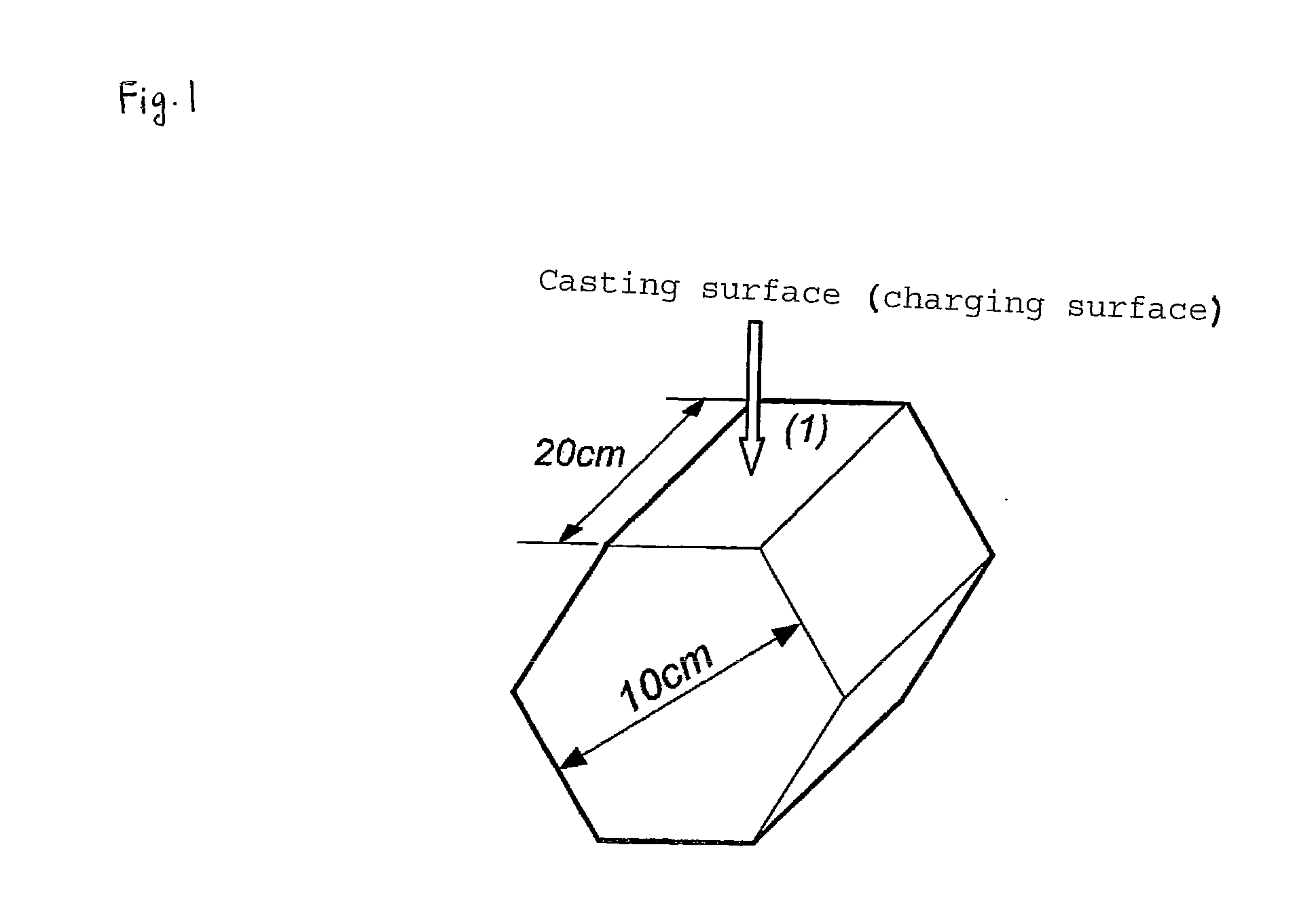

InactiveUS20090214886A1Improve fill rateFacilitate cold plastic workingThin material handlingCores/yokesDensity ratioPowder mixture

A metal matrix composite material comprising a pair of metal plates having a powder mixture disposed therebetween forming an intermediate layer is disclosed. Each of the metal plates having a main wall with opposed lateral walls on each end. The first of the metal plates having a main wall having a length greater than a length of the main wall of the second of the metal plates, so that the opposed lateral walls of the second metal plate are each disposed inside of a respective opposed lateral wall of the first metal plate. The powder mixture includes a metal powder and a ceramic powder. The ceramic powder has a neutron absorbing function, wherein the intermediate layer has a theoretical density ratio at least 98%, and a percentage of a total thickness of the metal plates to an overall thickness of the intermediate layer is in a range of 15 to 25%.

Owner:NIPPON LIGHT METAL CO LTD +1

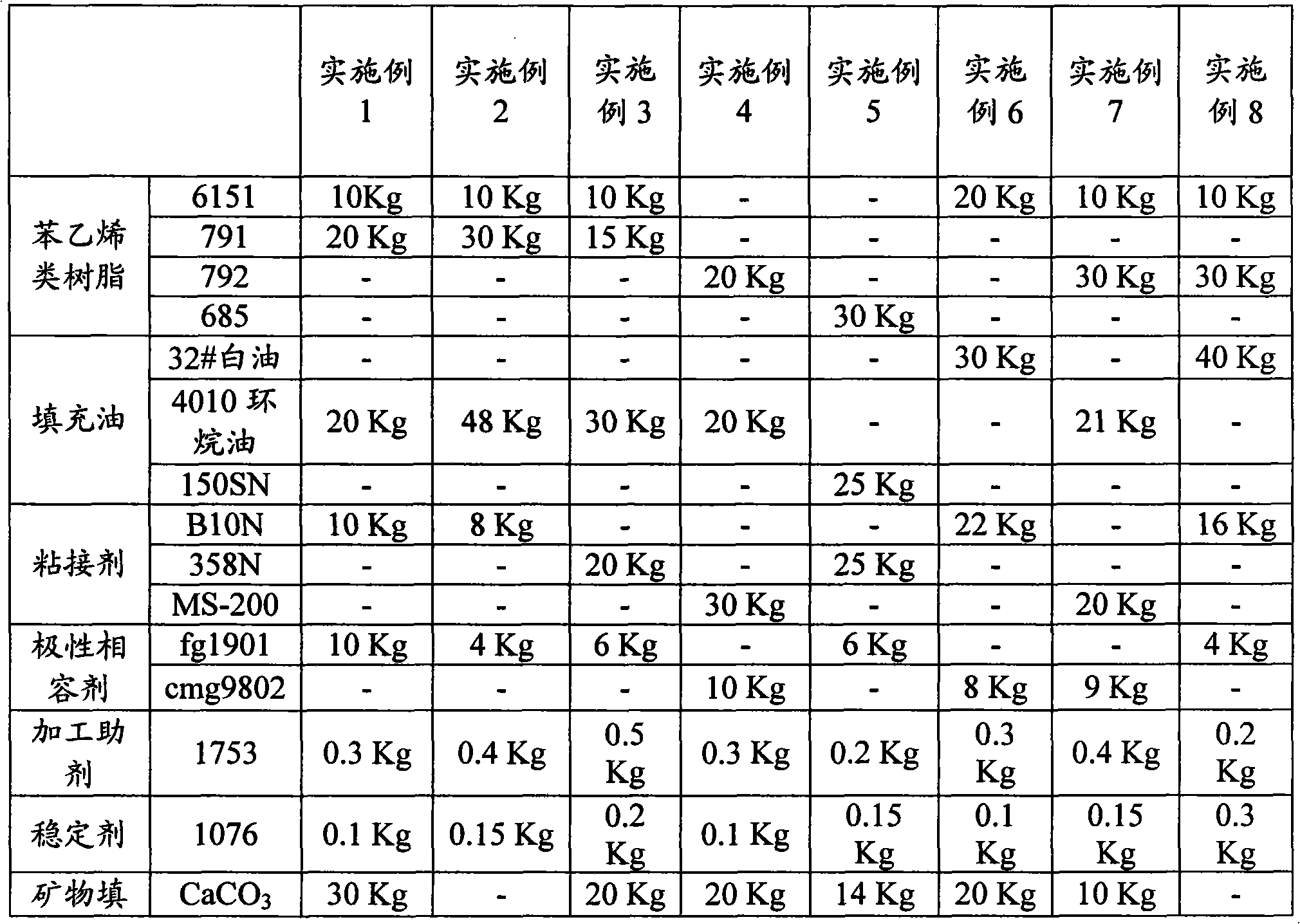

Thermoplastic elastomer for ABS jetting adhesion

The invention discloses a thermoplastic elastomer for ABS jetting adhesion, which comprises the following raw materials in percentage by weight: 10 to 80 percent of thermoplastic matrix resin, 0 to 60 percent of filling oil, 0 to 30 percent of adhesives, 0 to 30 percent of mineral filler, 0 to 10 percent of polar compatibilizer, 0.1 to 2 percent of processing aid and 0.08 to 2 percent of stabilizer. The problem of bonding non-polar base material and ABS is solved by improving a blending formulation and process. The hardness of the jetting adhesion ABS thermoplastic elastomer can be freely adjusted through the formulation so as to obtain the thermoplastic elastomer with high elasticity, high bonding strength to ABS material and good surface effect.

Owner:CGN JUNER NEW MATERIALS +1

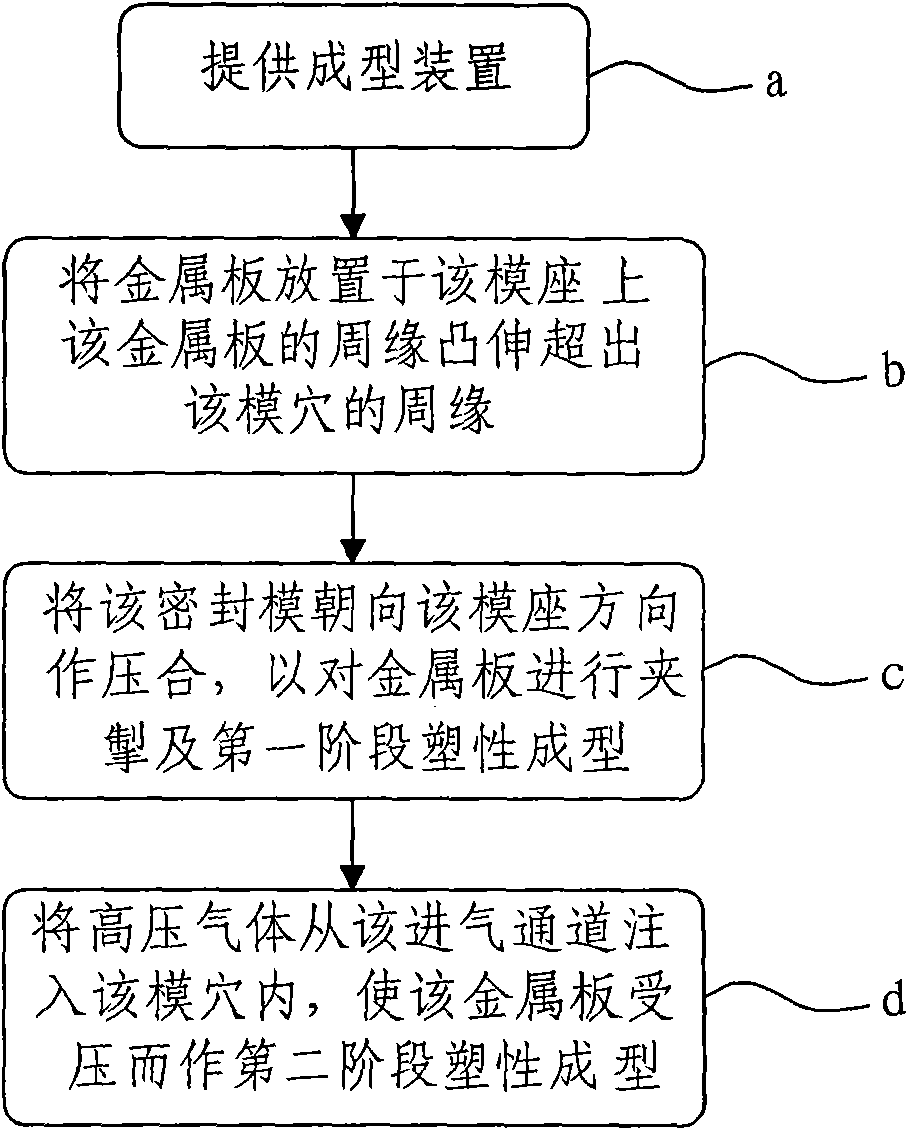

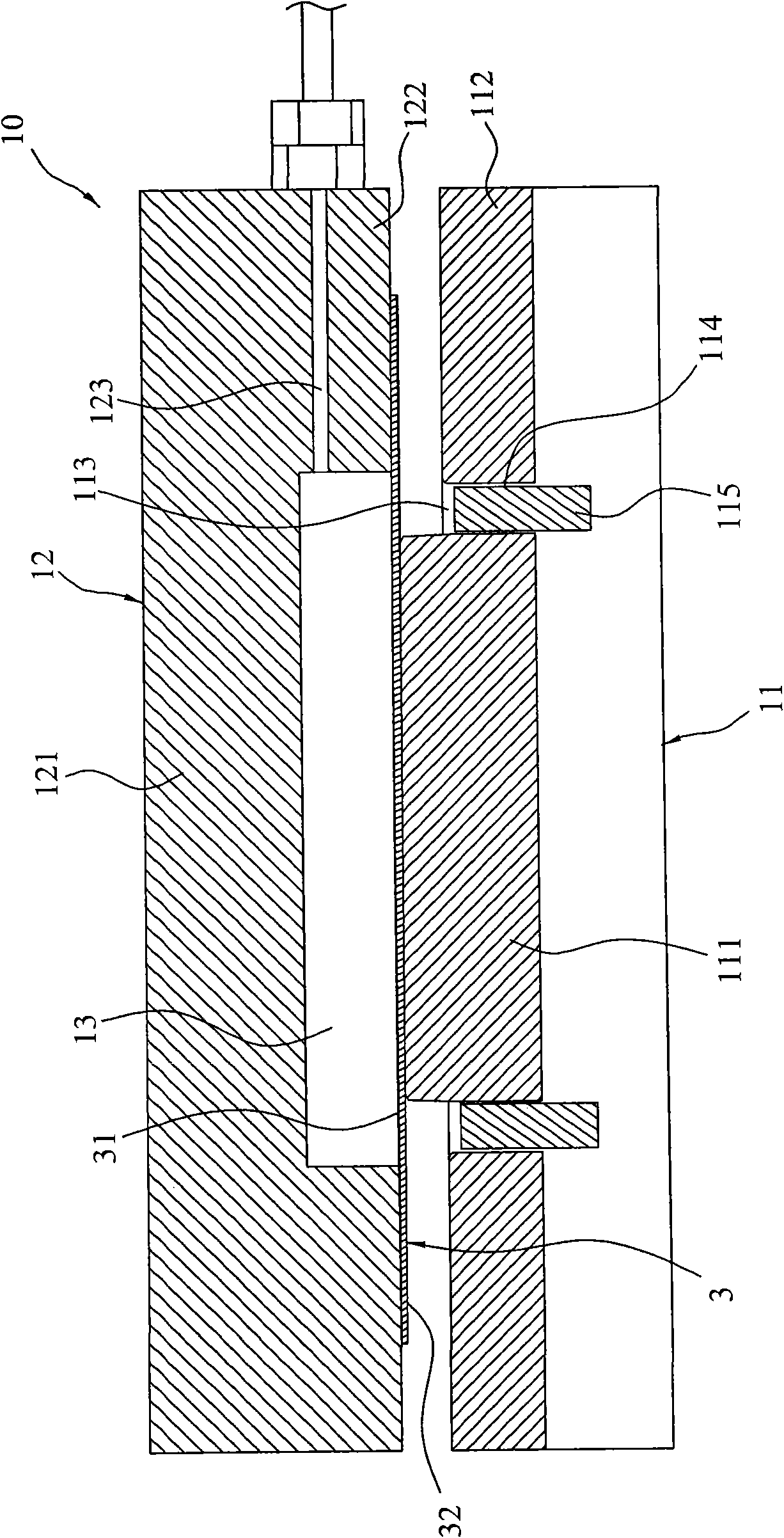

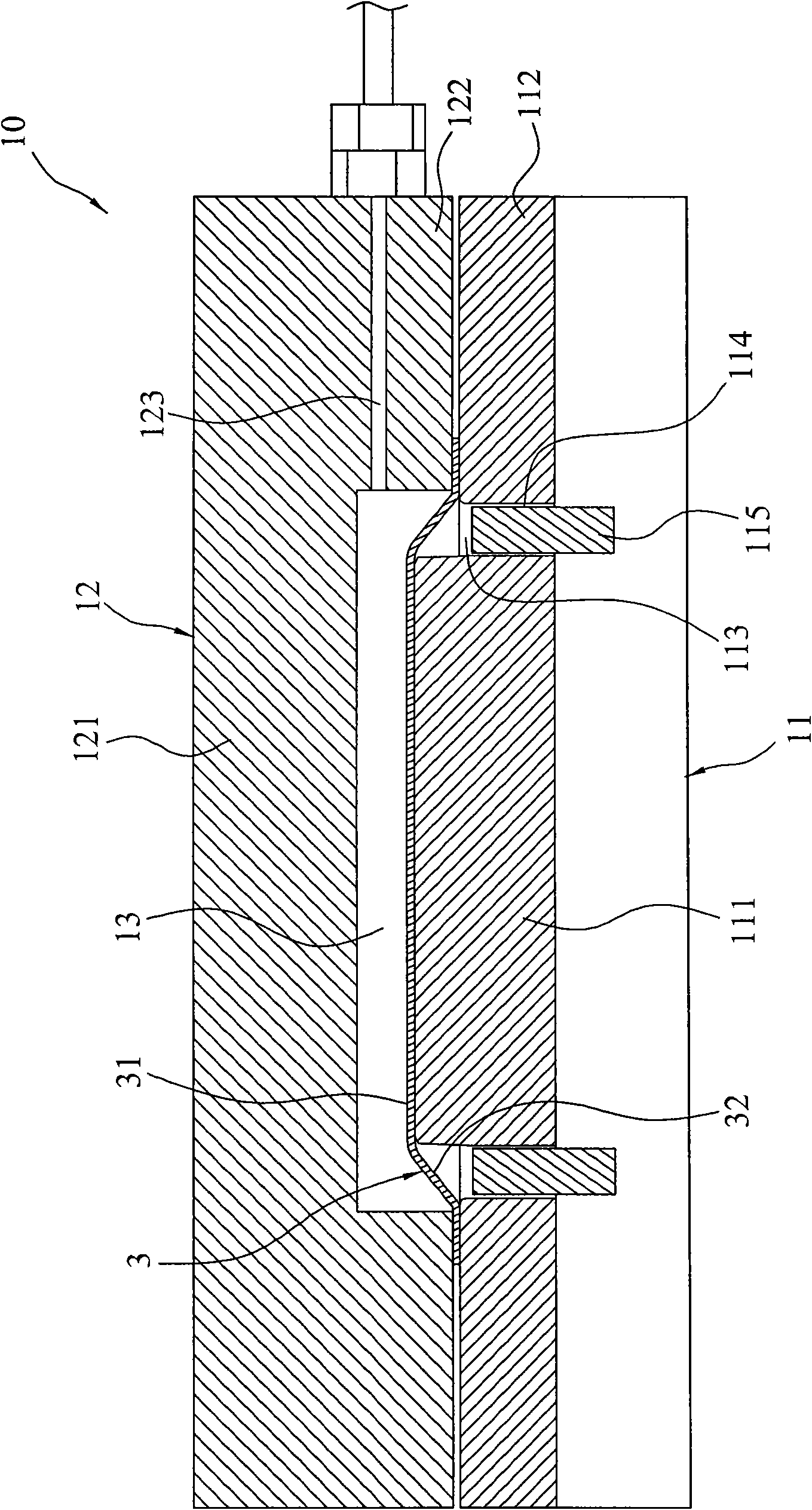

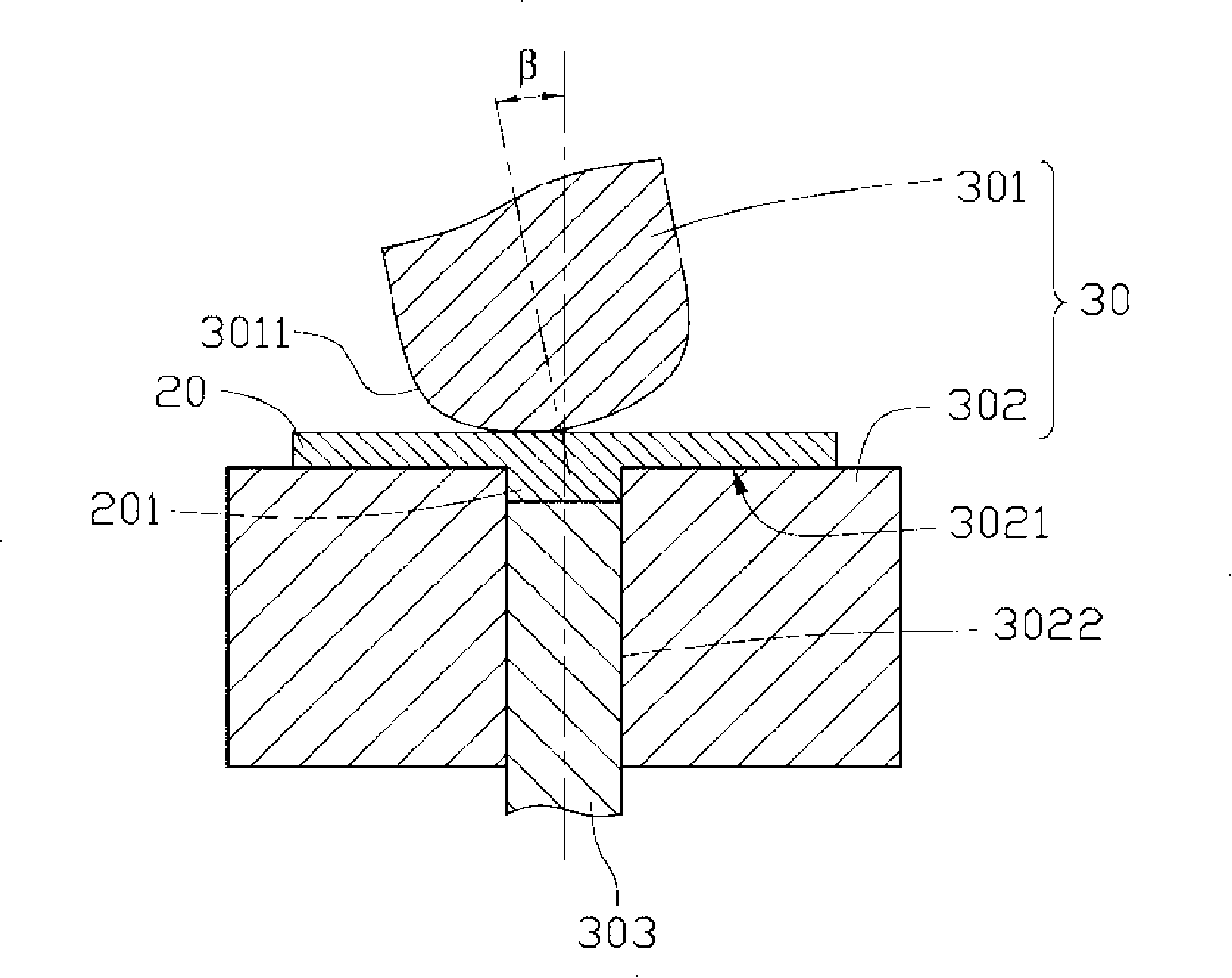

Two-section type molding method of metal plate

The invention relates to a two-section type molding method of a metal plate. The method comprise the following steps: providing a molding device comprising a die holder and a sealing die, wherein the sealing die is covered on the die holder to form a die cavity, and the sealing die is provided with a gas inlet channel communicated with the die cavity; placing the metal plate on the die holder to ensure that the circumference edge of the metal plate extends exceeding the circumference edge of the die cavity; pressing the sealing die towards the direction of the die holder and carrying out griping and a first stage of plastic molding on the metal plate; and injecting gas to the die cavity from the gas inlet channel, and pressing the metal plate for a second stage of plastic molding. . The two-section type molding method of the metal plate not only can enhance the production rate and the efficiency, but also can reduce the elastic recovery and residual stress of the metal plate.

Owner:ICHIA TECH

Metal matrix composite material

InactiveUS20090220814A1Improve fill rateFacilitate cold plastic workingThin material handlingCores/yokesDensity ratioPowder mixture

A metal matrix composite material comprising a pair of metal plates having a powder mixture disposed therebetween forming an intermediate layer is disclosed. The powder mixture includes a metal powder and a ceramic powder. The ceramic powder has a neutron absorbing function and includes a B4C powder. The intermediate layer has a theoretical density ratio at least 98%, and a percentage of a total thickness of the metal plates to an overall thickness of the intermediate layer is in a range of 15 to 25% and the ceramic powder has a neutron absorption rate of at least 90%.

Owner:NIPPON LIGHT METAL CO LTD +1

Imitation-rattan furniture and manufacturing method thereof

InactiveCN104287498AIncrease roughnessImprove sweat absorption and breathabilitySofasCouchesFiberWood flour

The invention discloses imitation-rattan furniture and a manufacturing method thereof. The imitation-rattan furniture is formed by weaving rattans, or is composed of a part made of rattans and a part made of other materials, wherein each rattan comprises one strand or multiple strands, and adopts imitation rattan made of fiber-containing bio-based composite material, the fiber-containing bio-based composite material is formed by compounding modified straw powder or modified wood flour and plastic at certain ratio. According to the invention, due to the adoption of the bio-based imitation rattan material, the use experience of the imitation-rattan furniture is improved, and the furniture is firm and durable, is convenient to manufacture, low in cost, and is environmentally friendly.

Owner:NANJING BIOFUNCTION CO LTD

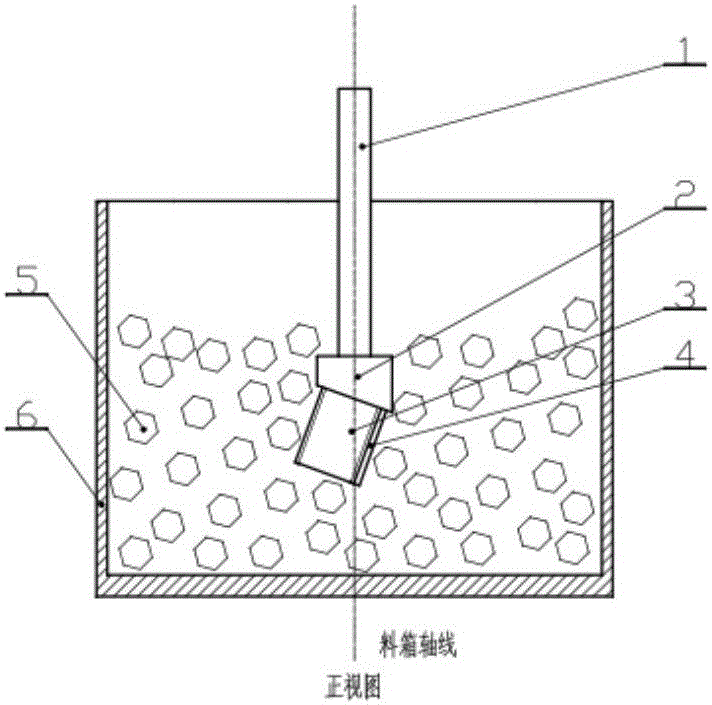

Blade surface roll-polishing finishing method adopting distributed protection measure

ActiveCN104985507AReduce surface roughness valueImprove surface integrityGrinding machinesSurface finishMechanical components

The invention discloses a blade surface roll-polishing finishing method adopting a distributed protection measure, and belongs to the technical field of machine part surface finishing. The method is characterized in that a blade and a blade basin protection device or blade back protection device are fixed to a fixture at a certain space angle, and the fixture is connected to a spindle; in the machining process, the spindle swings around the axis of the spindle, and the blade is machined in a work bin which contains machining media such as roll-polishing blocks and polishing liquid and rotates around the axis of the work bin. By means of the method, the blade finishing efficiency and uniformity can be effectively improved, the blade root machining effect can be improved, intake and exhaust sides can be prevented from being excessively polished, deformation of the blade in the machining process can be effectively reduced, and the blade can be protected.

Owner:TAIYUAN UNIV OF TECH

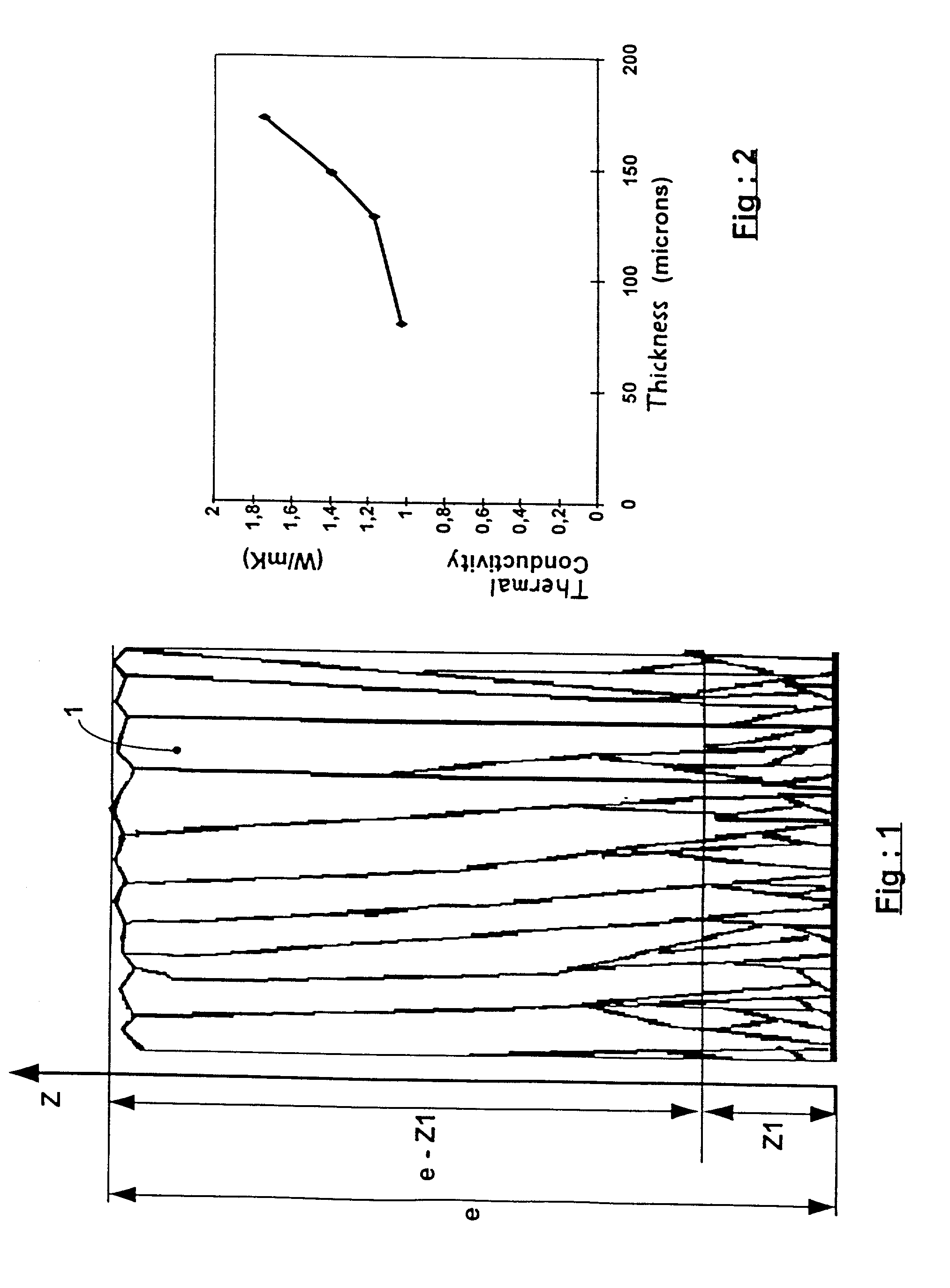

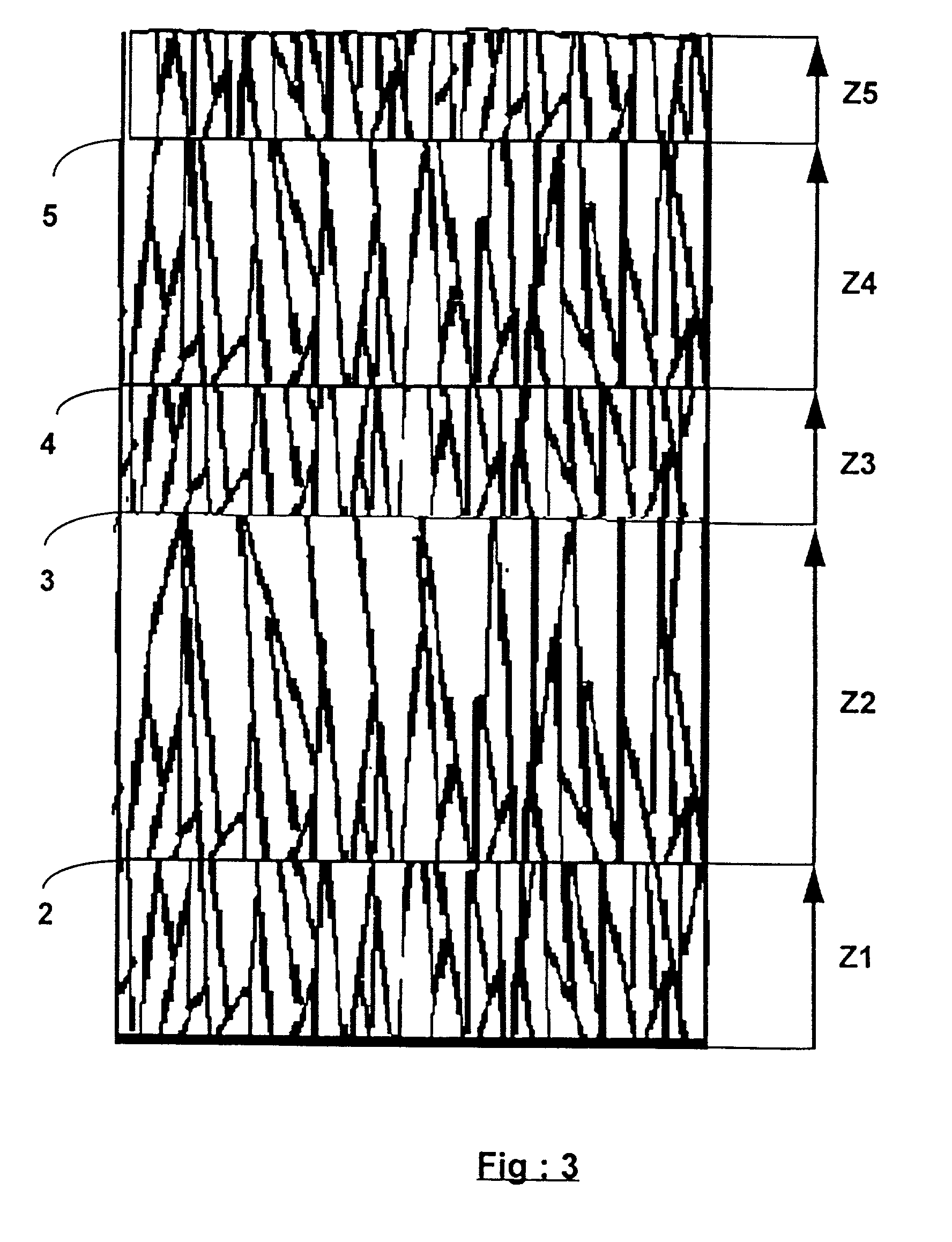

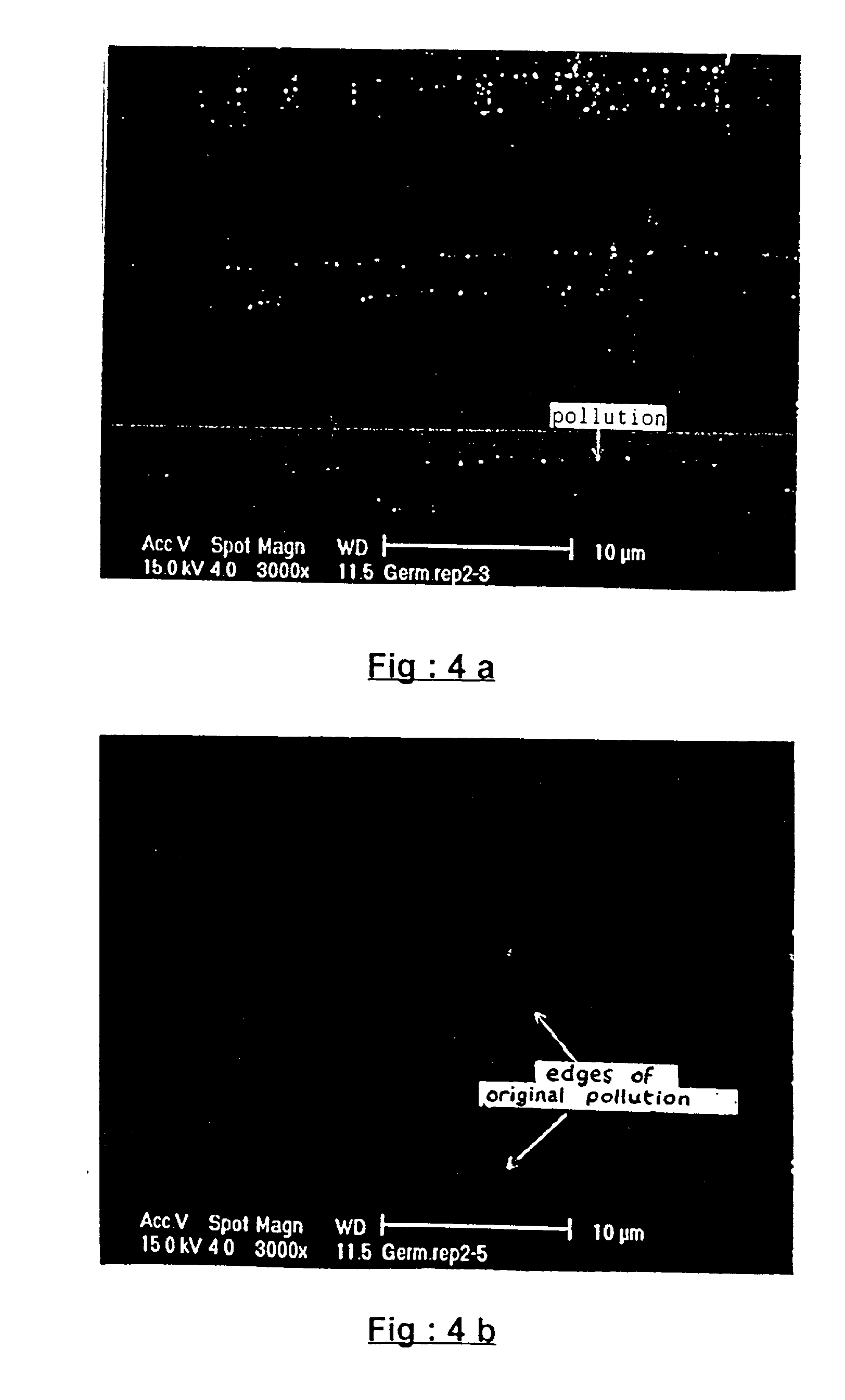

Ceramic heat barrier coating having low thermal conductivity, and process for the deposition of said coating

InactiveUS6432478B1Improve adhesionLow thermal conductivityAnodisationMolten spray coatingCeramic coatingGas phase

A ceramic heat barrier coating is deposited on a substrate so that the coating has a columnar growth pattern which is interrupted and repeated a number of times throughout its thickness by successive regermination of the ceramic deposit. The regermination is obtained by a vapor phase deposition process wherein a polluting gas is introduced intermittently during the deposition of the ceramic. The resulting ceramic coating has a lower thermal conductivity than conventional columnar ceramic coatings.

Owner:SAFRAN AIRCRAFT ENGINES SAS

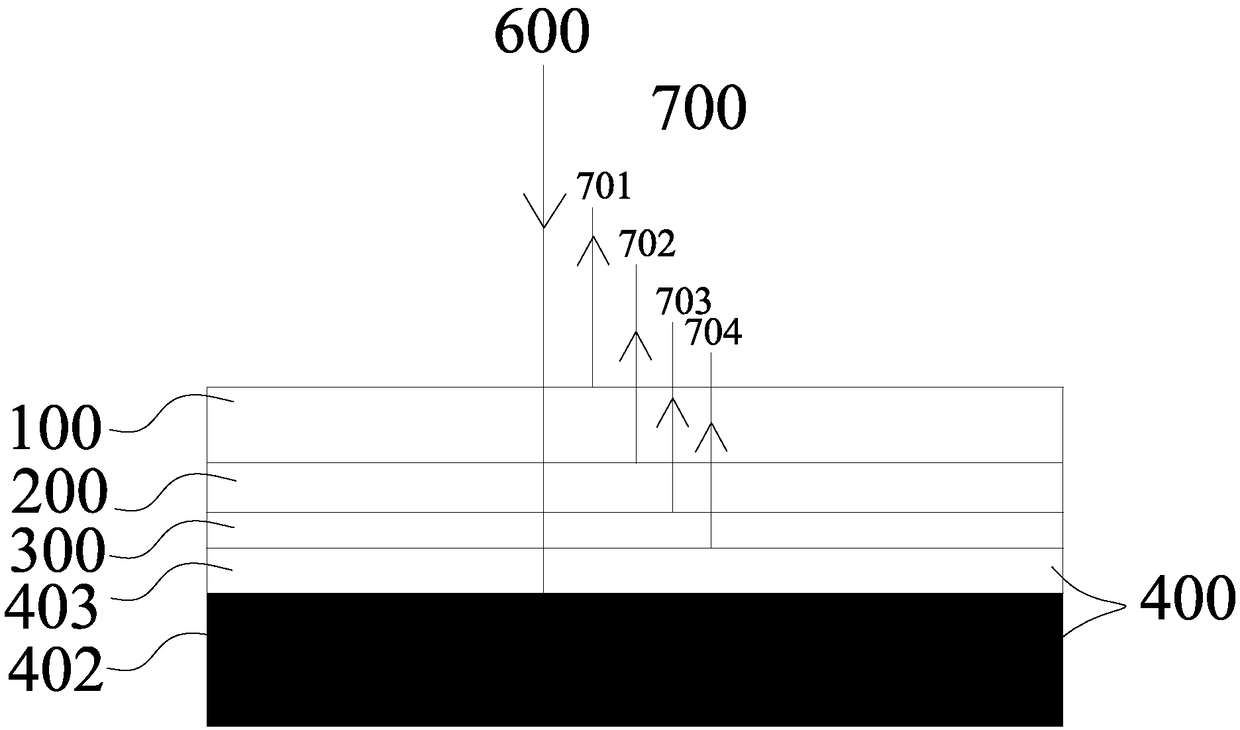

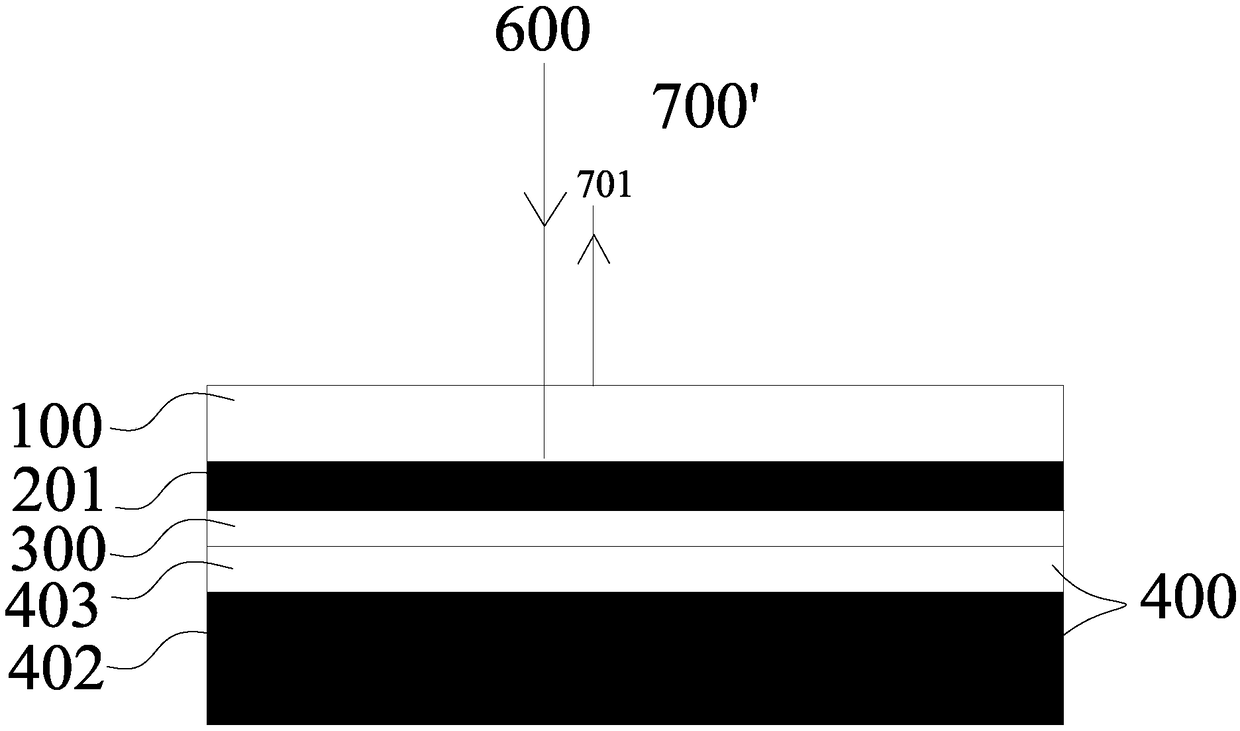

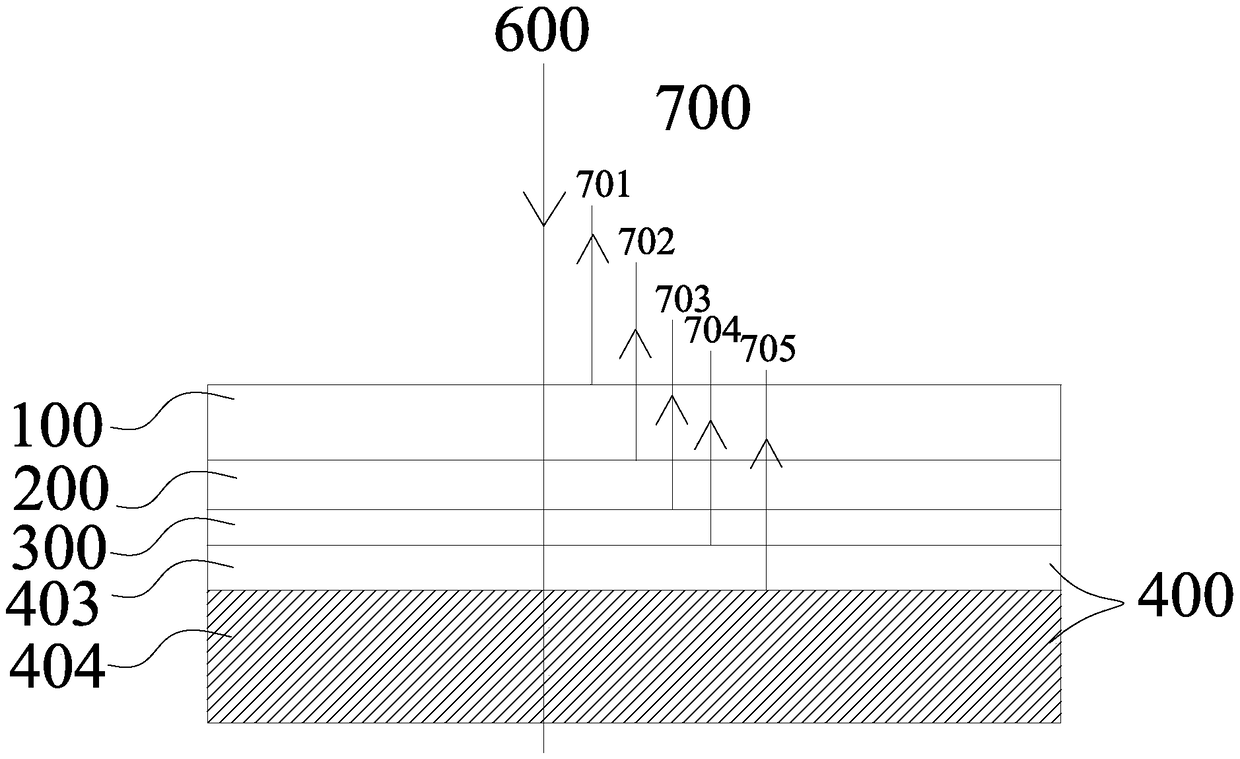

Electrochromic device in freely customizable color and application

PendingCN108845469AThe color is no longer singleAny custom reflection effectNon-linear opticsWater vaporOptoelectronics

The invention provides an electrochromic device in a freely customizable color and belongs to the technical field of electrochromic devices. The electrochromic device includes a transparent substratelayer, an EC stack, an optical membrane layer and / or a glue bottom layer; the transparent substrate layer is covered with the glue bottom layer, and the optical membrane layer and the EC stack are arranged in the glue bottom layer in sequence; otherwise, the transparent substrate layer is covered with the optical membrane layer, the optical membrane layer is covered with the glue bottom layer, andthe portion between the optical membrane layer and the transparent substrate layer or between the optical membrane layer and the glue bottom layer is covered with the EC stack, or the EC stack is arranged in the glue bottom layer. The electrochromic device is applied to mobile terminals, building doors and windows and household electrical appliances. A freely customized reflection effect is achieved on the surface of the electrochromic device through optical adjustment, and a product has better surface texture like metal. The optical membrane layer can protect the EC stack, the situation thatthe EC stack of the dense optical membrane layer is easily influenced by water vapor and correspondingly the service life of the EC stack is shortened is avoided, and the reliability of the product is improved greatly.

Owner:ZHEJIANG SHANGFANG ELECTRONICS EQUIP

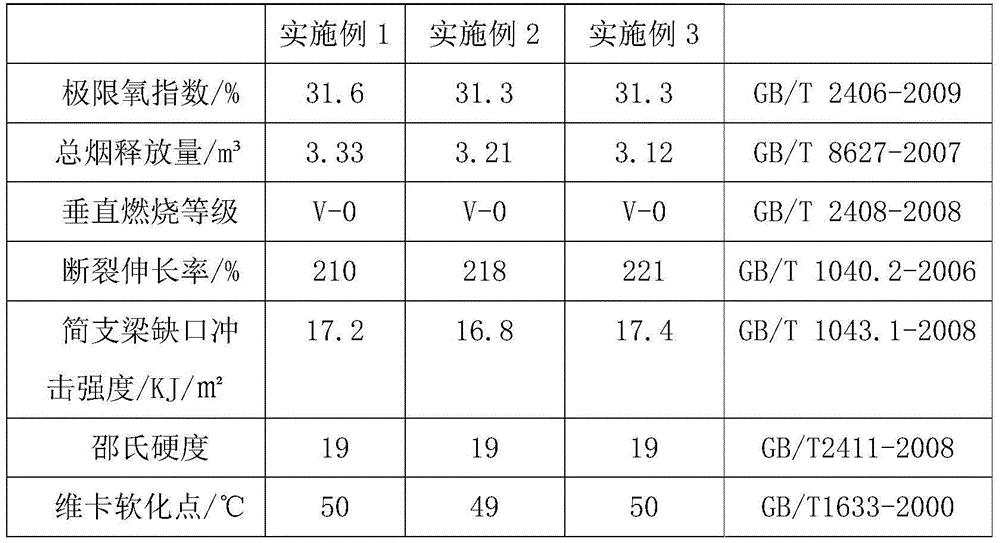

Antimony oxide compound flame-retardant PVC soft composite material and preparation method thereof

The present invention discloses an antimony oxide compound flame-retardant PVC soft composite material and a preparation method thereof. The composite material includes the following materials: PVC (SG-3), a plasticizer, antimony trioxide, ammonium molybdate, montmorillonite, a calcium zinc stabilizer, EVA, epoxy soybean oil, a coupling agent and a dispersing agent. The preparation process of the product is as below: modifying antimony trioxide; mixing the modified antimony trioxide with ammonium molybdate, montmorillonite and EVA; screening the mixture by a vibrating centrifugal screening machine; and drying the screened powder and conducting waterproof packaging. The product of the invention has efficient flame retardant and smoke suppression performance, limiting oxygen index up to 31.6%, elongation at break of 210% and Shore hardness as low as 17, can be used as a direct added raw material for PVC product, or be added as a modification additive, and can also be used as soft fireproof materials, such as PVC leather and protective decoration materials.

Owner:广西华锑科技有限公司

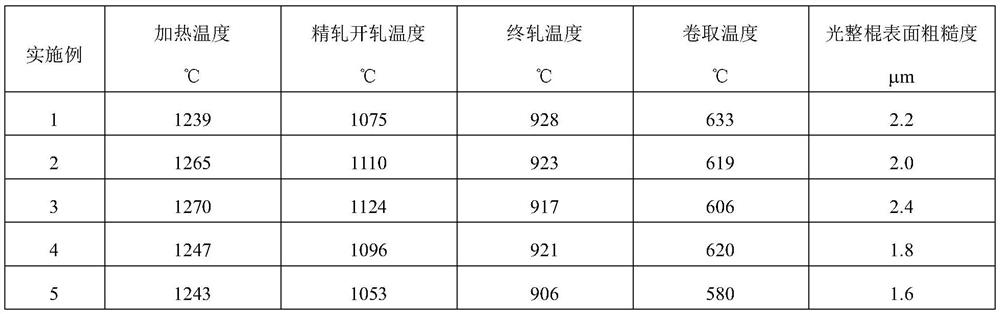

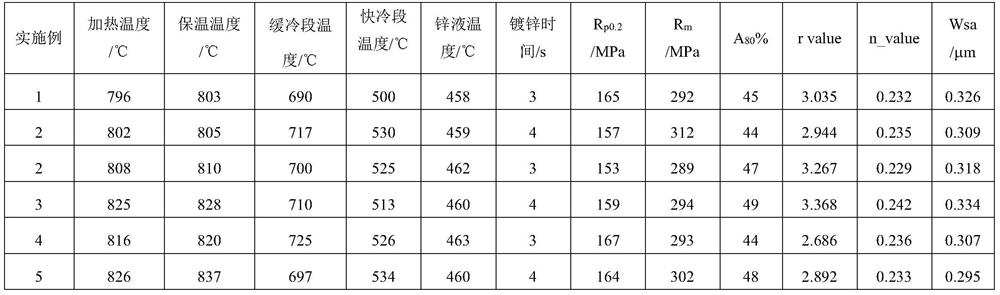

Hot-dip galvanized IF steel plate production method capable of controlling surface waviness

ActiveCN112538593AImprove uniformityImprove Wsa valueHot-dipping/immersion processesFurnace typesSteel platesChemical composition

The invention relates to a hot-dip galvanized IF steel plate production method capable of controlling surface waviness. The hot-dip galvanized IF steel plate is prepared from the following chemical components in percentage by weight: larger than 0 and less than or equal to 0.0030% of C, larger than 0 and less than or equal to 0.020% of Si, 0.04-0.15% of Mn, larger than 0 and less than or equal to0.010% of P, larger than 0 and less than or equal to 0.012% of S, 0.02-0.045% of Al, larger than 0 and less than or equal to 0.06% of Cr, larger than 0 and less than or equal to 0.005% of Nb, 0.05-0.09% of Ti, larger than 0 and less than or equal to 0.004% of N, larger than 0 and less than or equal to 0.06% of Ni and the balance of Fe and inevitable impurities. The production process of the hot-dip galvanized IF steel plate comprises the steps of smelting, external refining, continuous casting, hot continuous rolling, cold acid continuous rolling, annealing and hot dipping. Through the comprehensive measures of reasonably designing the chemical components of the steel plate, adjusting the process parameters of the hot continuous rolling and annealing process, controlling the surface roughness of a finishing roller and the like, the surface texture of the stamped hot galvanized IF steel plate is finally improved, and the requirements of a 2C1B painting process are met.

Owner:鞍钢蒂森克虏伯汽车钢有限公司

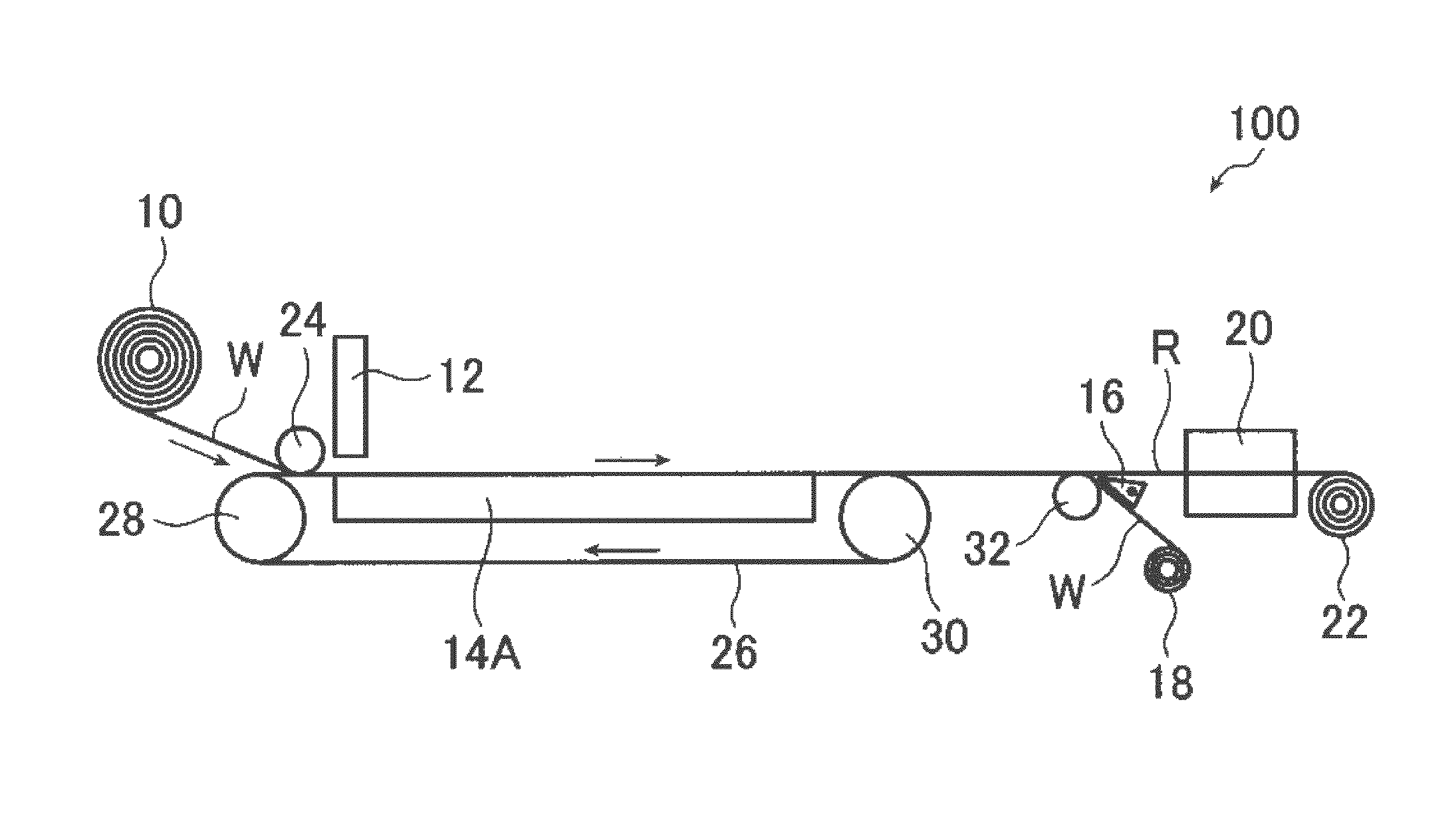

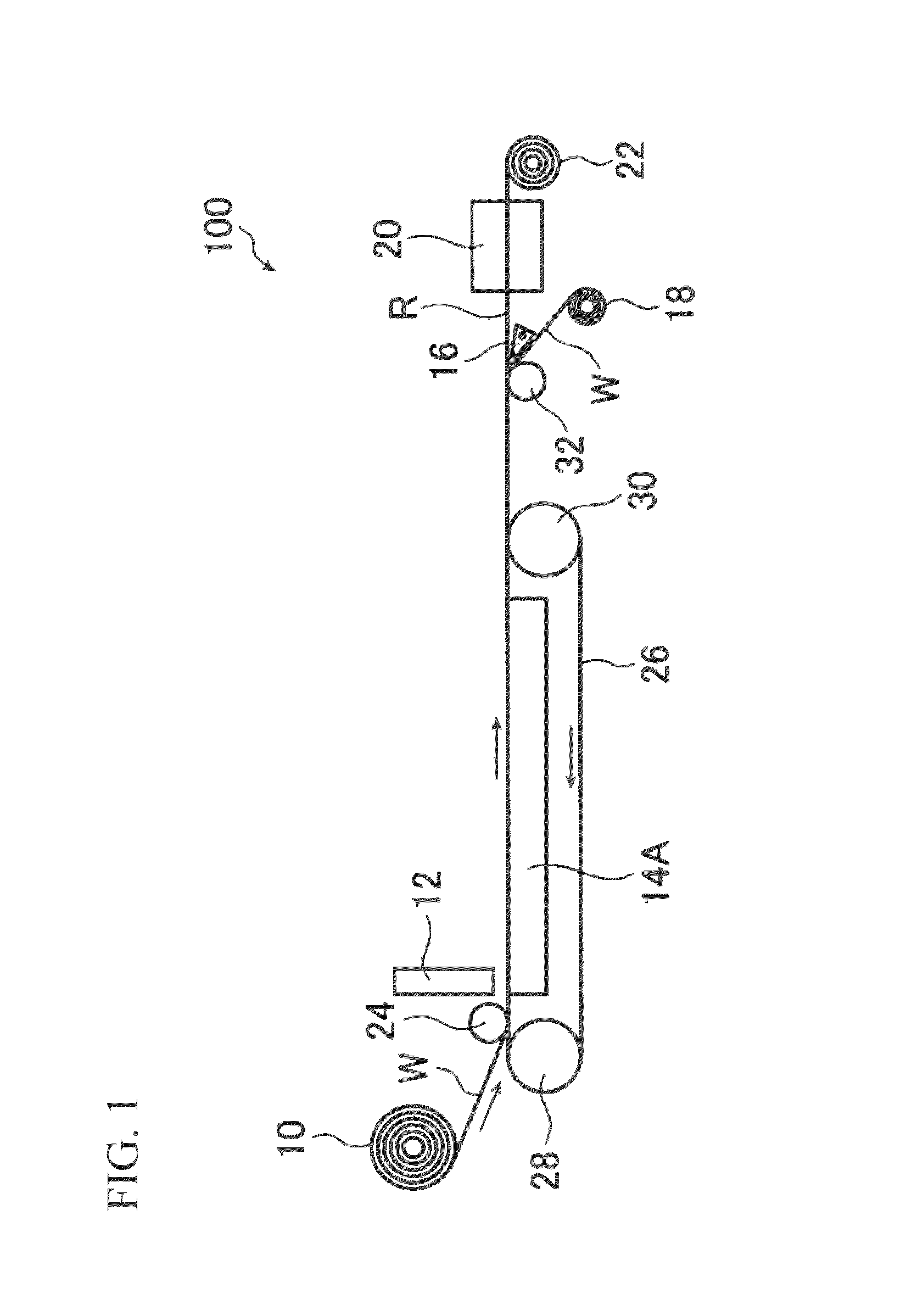

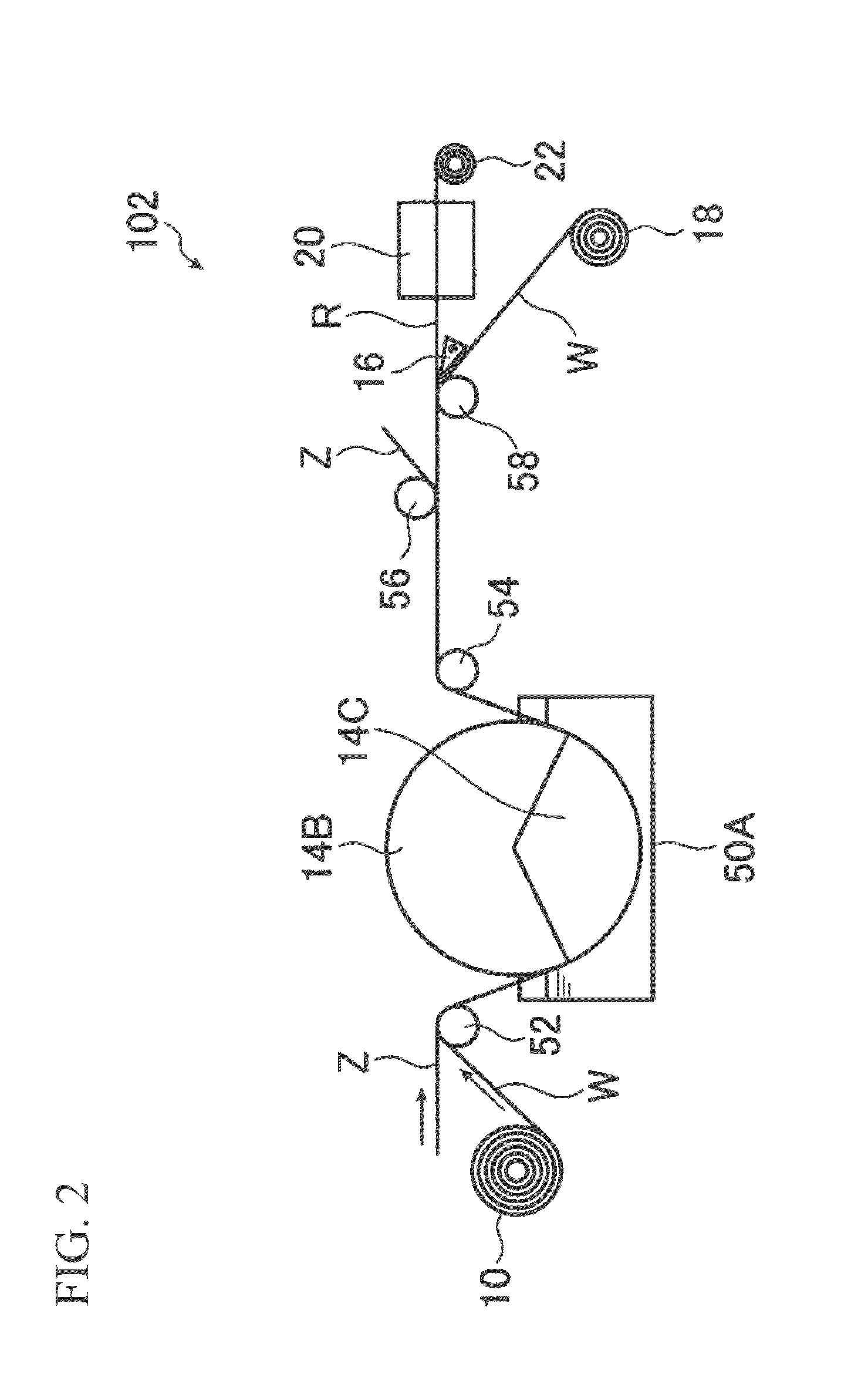

Method for producing cellulose-fiber flat structure

ActiveUS8663426B2Good surface textureEffective recoveryNon-fibrous pulp additionPaper after-treatmentPolymer scienceCellulose fiber

The present invention relates to a method of producing a cellulose-fiber flat structure, the method including obtaining a cellulose-fiber flat structure by filtering a fine cellulose-fiber dispersion containing fine cellulose fibers having an average fiber diameter of 4 to 100 nm, using a filter material having a water permeability of not more than 100 ml / m2·s and an initial tensile modulus of 20 MPa or greater. The present invention is able to produce a cellulose-fiber flat structure by efficiently recovering fine cellulose fibers from a dispersion containing fine cellulose fibers having an average fiber diameter at the nano level. The method of producing a cellulose-fiber flat structure can also be applied to a continuous process.

Owner:OJI HLDG CORP

Early strengthening agent for hydraulic composition

InactiveUS20110021667A1High early-strengthGood surface textureOrganic chemistryOrganic compound preparationGlycerol DerivativesPhosphate

This invention relates to an early strengthening agent for a hydraulic composition, which contains a compound (A) selected from a specific glycol ether-based compound and a specific glycerin derivate-based compound, as well as an additive composition for a hydraulic composition, which contains the early strengthening agent and a specific phosphate polymer (B).

Owner:KAO CORP

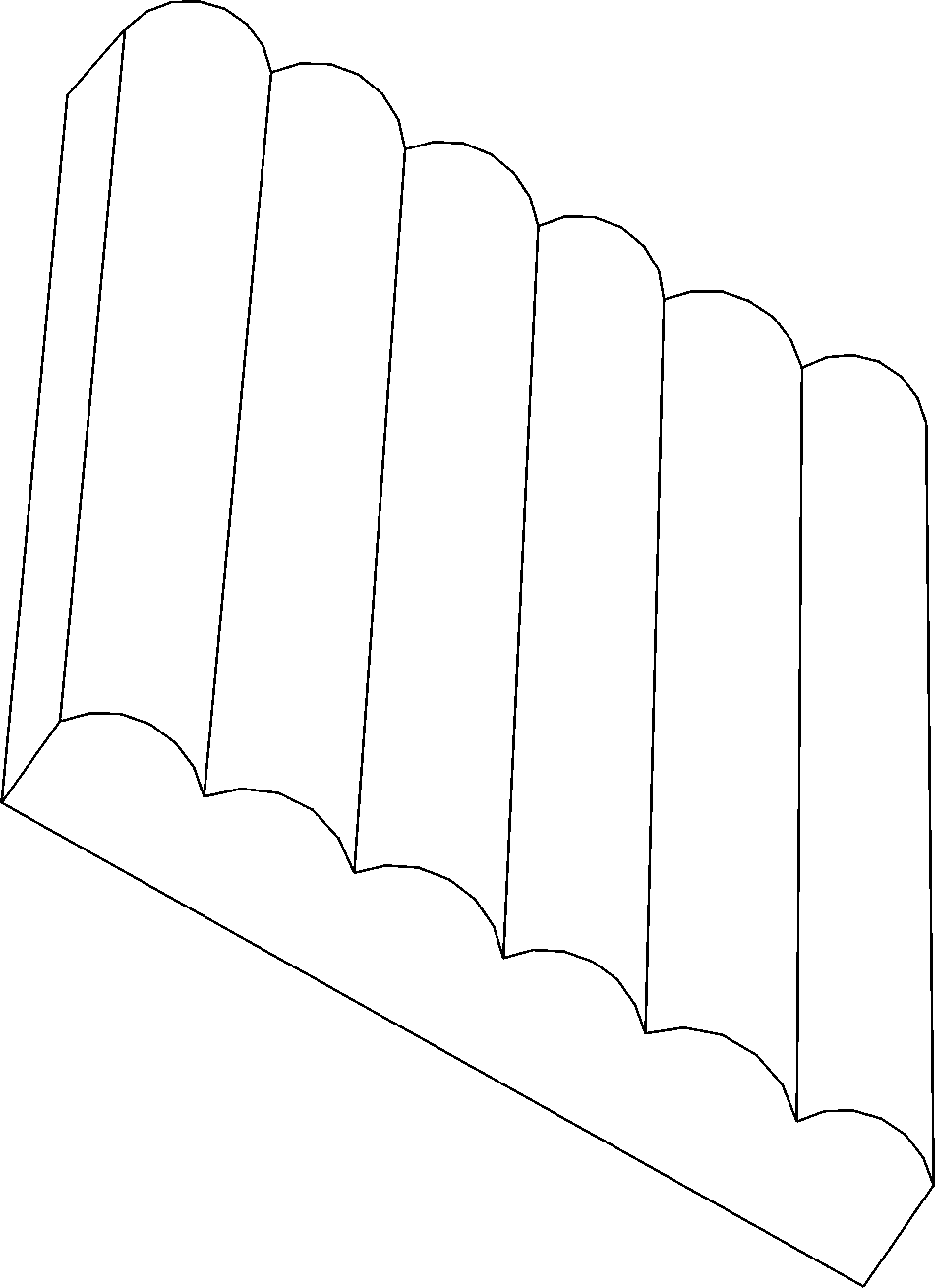

Manufacture method for forming local three-dimensional grating image and text on surface of printed matter and product thereof

ActiveCN103057337ASimple processEasy to controlSpecial ornamental structuresLight effect designsPhysicsEngineering

The present invention provides a manufacture method for forming local three-dimensional grating images and texts on a certain area of the surface of a printed matter according to the design requirements. The manufacture method comprises: firstly, forming an image-text layer which has a background layer and can display a three-dimensional effect on a selected area of a transparent plastic film; and then coating or printing a transparent resin layer which is easy to deform when subjected to heat and pressure on the corresponding area capable of displaying three-dimensional effect of the other side of the plastic film; and finally using the lenticular grating plate to emboss the surface of the transparent resin layer, so the surface of the transparent resin layer is enabled to have a semi-cylindrical surface symmetrical to the lenticular grating plate structure. The manufacture method of the invention is characterized by being simple in process, easy to control the operation, accuracy in overprinting and low in cost. In the printed matters having local three-dimensional grating images and texts produced by the method of the present invention, images and texts which need to be highlighted is three-dimensional, while the rest parts are planar; thereby improving the surface layering of a packaging material, highlighting key texts and images in three-dimensional form, and simultaneously allowing small descriptive text clearly manifested to better improve the concern degree of a product.

Owner:SHANTOU DONGFENG PRINTING CO LTD +1

Method for preparing soft powder capable of making skin feel smooth

InactiveCN108066175AImprove surface textureEffectively fills fine linesCosmetic preparationsMake-upTocopheryl acetatePhenoxyethanol

The invention discloses soft powder capable of making skin feel smooth. The soft powder comprises, by weight, 0.4-0.6% of hydrogenated polyisobutene, 2-4% of polydimethylsiloxane, 0.2-0.4% of bis-bisdiglyceryl polyacyladipate-2, 2.6-2.8% of polydimethylsiloxane / vinyldimethicone cross-linked polymers, 0.3-0.5% of phenoxyethanol, 0.1-0.3% of tocopheryl acetate and 0.01-0.03% of phenoxyethanol aromatic cosmetic essence. The soft powder has the advantages that the polydimethylsiloxane / vinyldimethicone cross-linked polymers are added into the soft powder and can be adsorbed on the surface of the soft powder on the basis of special gel elasticity, accordingly, the surface texture of the soft powder can be improved, and finished products made of the soft powder by means of compression have soft feel and smearing smooth feel.

Owner:广州慈康生物科技有限公司

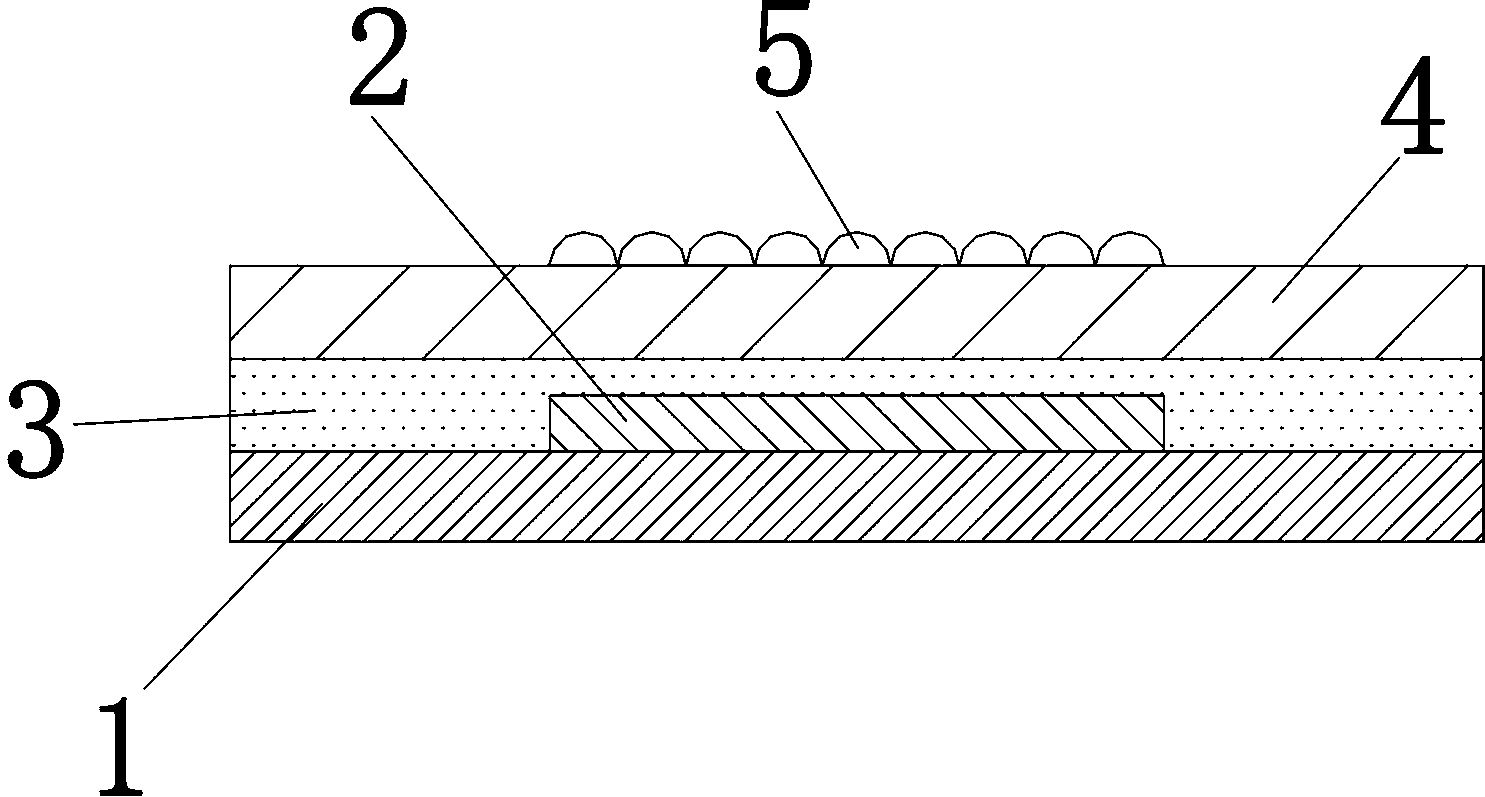

UV ink printed metal gusset plate for ceiling decoration

InactiveCN101906862APromote environmental protectionImprove the three-dimensional effectCovering/liningsGusset plateHardness

The invention discloses a UV ink printed metal gusset plate for ceiling decoration. The UV ink printed metal gusset plate comprises a metal base layer, wherein a varnish coating is coated on the upper surface of the metal base layer; a colored ink layer is printed on the upper surface of the varnish coating; and a transparent UV ink layer is printed on the upper surface of the colored ink layer. A polypropylene or polyethylene protective film is attached to the upper surface of the UV ink layer. The UV ink printed metal gusset plate has the advantages of high plate strength, high environmental protection property, rich colorful patterns, strong third dimension, strong surface texture feel, high surface hardness, scratch prevention, easy cleaning and nonflammability; besides, compared with the currently widely used UV ink metal gusset plate, the UV ink printed metal gusset plate has better decoration effect and protection effect and longer service life.

Owner:SHANGHAI XILV ELECTRICAL APPLIANCES

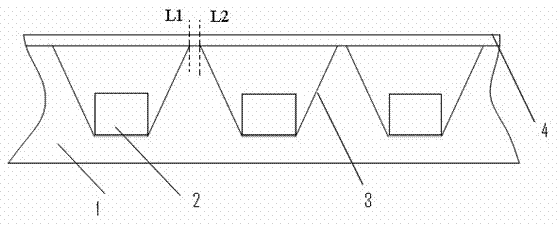

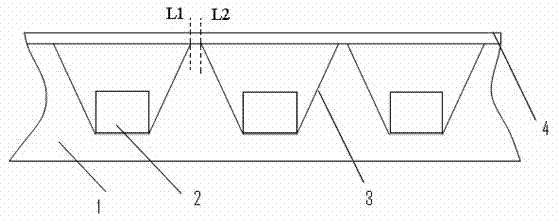

Full-color surface-mounted LED display screen and LED surface-mounted lamp module thereof

ActiveCN102411881AGood surface textureInhibition appearsIdentification meansLED displaySurface mounting

The invention provides an LED surface-mounted lamp display screen, which comprises a screen body and an LED surface-mounted lamp module, wherein the LED surface-mounted lamp module comprises LED surface-mounted lamps and a sleeve member for installation of the LED surface-mounted lamps; a reflection cover is arranged in the sleeve member; a semitransparent reflection cover plate is arranged at the upper end of the sleeve member in a covering way; the LED surface-mounted lamps are clamped between the reflection cover and the transparent reflection cover plate; the reflection cover is in a shape of a groove with a certain slope; and a certain distance is reserved between the semitransparent cover plate and an LED wafer. Due to the existence of the semitransparent reflection cover plate, surface texture can be remarkably improved, in particular when a plane is closed. In addition, due to arrangement of the reflection cover behind the LED surface-mounted lamps and the semitransparent reflection cover plate in front of the LED surface-mounted lamps, a light source of each independent LED surface-mounted lamp can be amplified, so that lights of all the LED surface-mounted lamps are connected to a whole, therefore moire fringes can be prevented from occurring, and visual effect during shooting and / or video recording is improved.

Owner:LIGHTKING TECH GRP CO LTD

Ceramic heat barrier coating having low thermal conductivity, and process for the deposition of said coating

InactiveUS20010008708A1Improve adhesionLow thermal conductivityAnodisationMolten spray coatingCeramic coatingGas phase

A ceramic heat barrier coating is deposited on a substrate so that the coating has a columnar growth pattern which is interrupted and repeated a number of times throughout its thickness by successive regermination of the ceramic deposit. The regermination is obtained by a vapour phase deposition process wherein a polluting gas is introduced intermittently during the deposition of the ceramic. The resulting ceramic coating has a lower thermal conductivity than conventional columnar ceramic coatings.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Method of preparing metal casing

InactiveCN101209522AImprove mechanical propertiesImprove wear resistanceMetal casingsForging/hammering/pressing machinesHardnessRoughcast

The invention discloses a manufacture method of a metal shell, comprising the steps of blanking, providing roughcast, rolling the roughcast by a rolling die, thus obtaining a pre-forming body and precise-milling the pre-forming body, thus obtaining the metal shell with unequal thickness. By adopting the manufacturing method, the metal shell produced has high hardness, good wearability and good surface quality sensing.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Highlighted glazed ceramic tile with water absorption rate of 8% and preparation method thereof

The invention belongs to the technical field of architectural ceramics, and particularly relates to a highlighted glazed ceramic tile with an water absorption rate of 8% and a preparation method thereof. The ceramic tile sequentially includes a rough body layer, a glazing layer and a surface pattern printing layer from the bottom to the top; the technological process comprises the steps of material preparation of rough bodies, ball-milling, pulp discharging, spray drying, material storage, corrosion prevention, molding, drying, glazing, printing, storage in trolleys, firing, classification, firing at low temperature, classification, packaging and warehousing. The highlight glaze ceramic tile with the water absorption rate of 8% completely solves the problem that after being used for a long time, the glazed surfaces of wall tiles are likely to crack, and meanwhile, the transparent texture of the highlighted glazed surface is maintained at the same time; moreover, the ceramic tile has the advantages of being abundant in grazed surface texture, great in surface texture, excellent in stereoscopic impression and the like; by additionally adopting other decoration methods including gold plating, silver plating and the like to process the surfaces, the added value of the ceramic tile is increased, the decoration effect of the product is greatly enriched, and the ceramic tile is significantly upgraded, so that during use of the ceramic stiles, an extravagant and luxurious effect can be achieved.

Owner:海鸥冠军有限公司

Uht treated 100% non-dairy whipping cream

InactiveUS20070071864A1Improved shape stabilityImprove textureEdible oils/fats ingredientsEdible oils/fats with fatty acid estersNon dairyFatty acid

The present invention relates to a UHT treated 100 non-dairy whipping cream with high shape stability and / or a very good surface texture and / or an overrun of at least 3.5. Said whipping cream preferably contains less than 2% of trans fatty acids, is free from any dairy product and free from any protein source. The whipping cream according to the present invention can be stored at temperatures up to 20° C. and thereby avoids frozen or cooled transport and / or storage.

Owner:PURATOS NV

SEBS composite material used for 3D printing and preparation method thereof

The invention relates to a SEBS composite material used for 3D printing and a preparation method thereof. The SEBS composite material comprises the following raw materials by mass percentage: 20-30 parts of polypropylene, 10-30 parts of a thermoplastic elastomer SEBS, 10-20 parts of polystyrene, 10-40 parts of mineral oil, 0-3 parts of an anti-oxidant, and 0-3 parts of a fire retardant. The above raw materials are mixed through a high-speed kneader, a double screw extruder is used for extrusion and wire drawing. Compared with the prior, the material has the characteristic of low hardness, the weatherability and hear resistance of the material are improved, and the material is excellent on fluency and bonding property between material layers.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

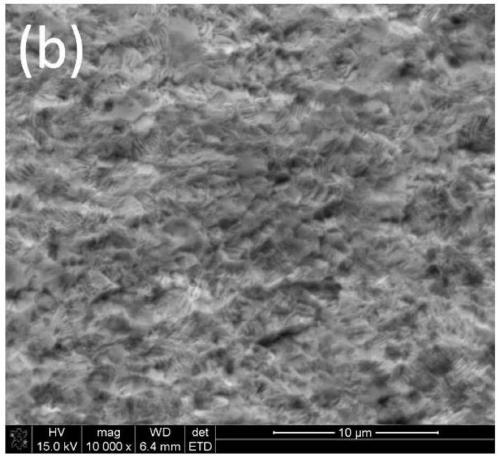

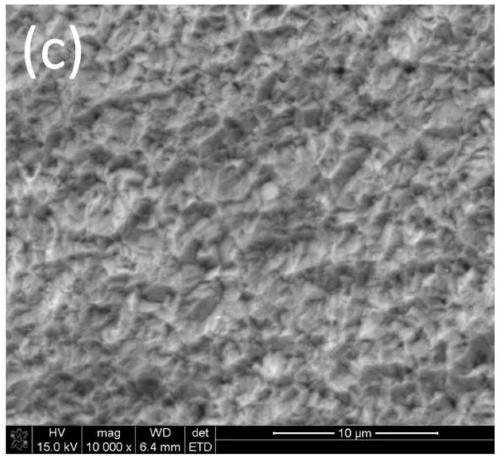

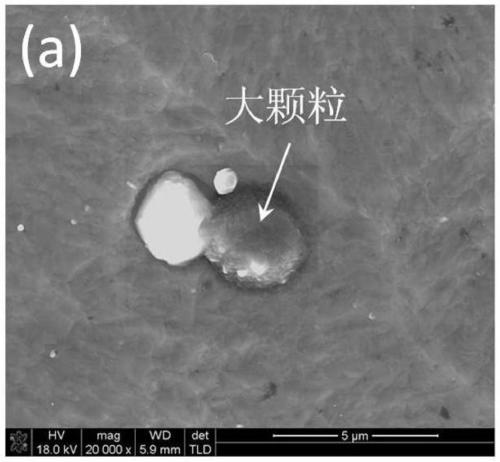

Preparation method of coating on zircomium alloy coverage shell

ActiveCN109943811AImprove bindingImprove compactnessVacuum evaporation coatingSputtering coatingSputteringCoated surface

The invention discloses a preparation method of a coating on a zircomium alloy coverage shell. The method solves the problem of defects existing in an existing coating preparation method. According tothe coating preparation technology, the method of combining vacuum arc ion plating with magnetron sputtering ion plating is adopted. According to the method, at first, the vacuum arc ion plating method is adopted for depositing the coating on the zircomium alloy coverage shell, and thus the film plating rate and the film base combination force are increased; vacuum arc ion plating depositing andmagnetron sputtering ion plating depositing are carried out at the same time, the compact middle layer is generated, and the surface evenness is improved; and finally, magnetron sputtering ion platingis adopted individually to continue depositing the coating, thus the compact and elaborate surface texture is obtained, and the effects of reducing the surface roughness of the coating and reducing the friction coefficient are achieved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

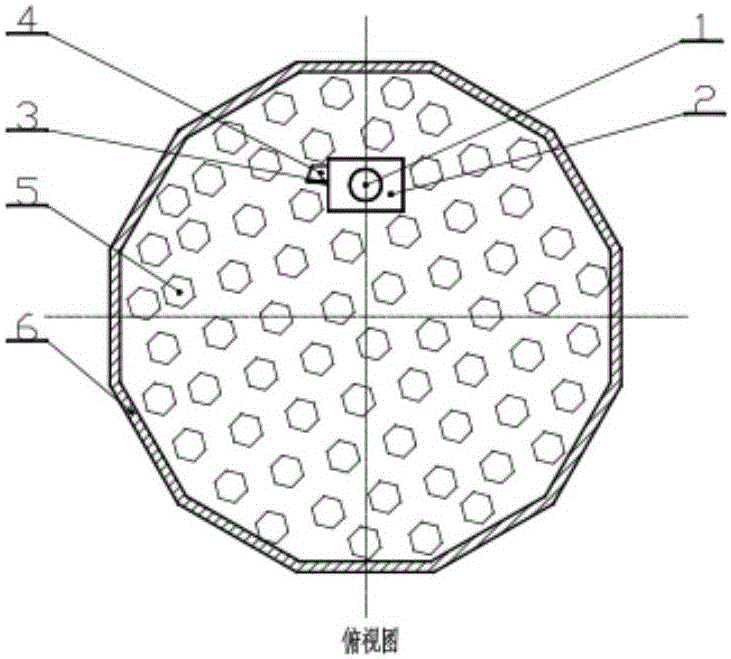

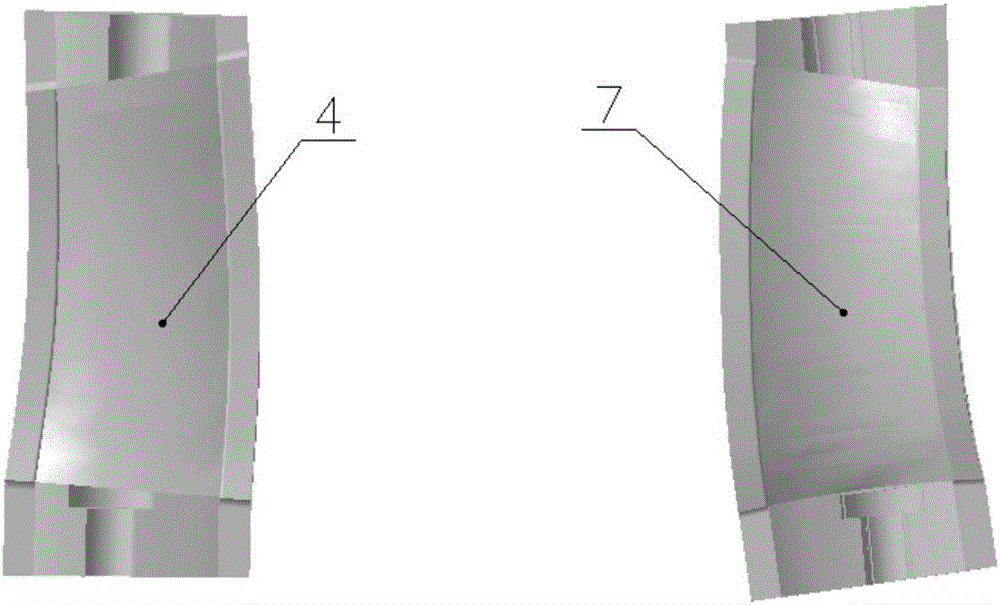

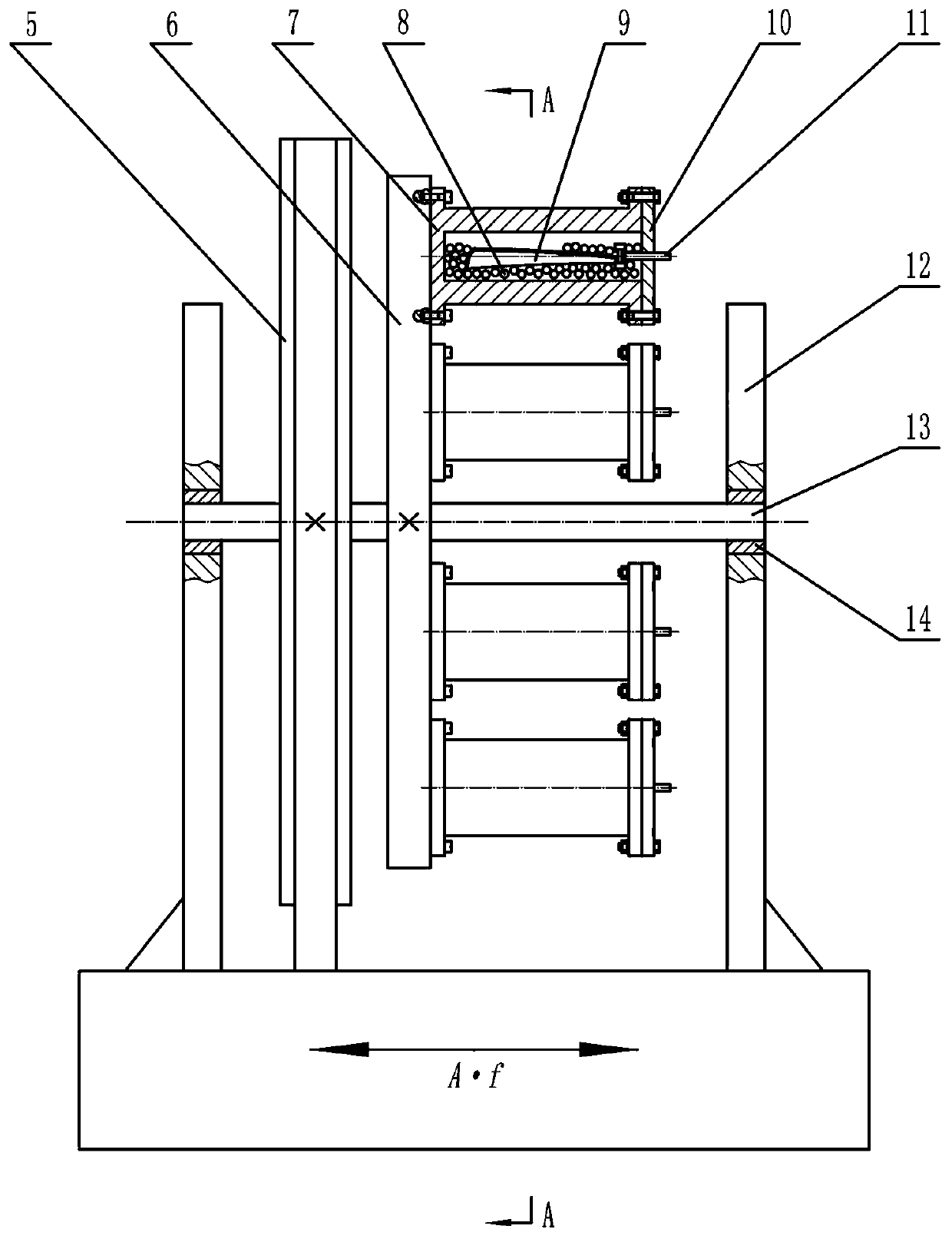

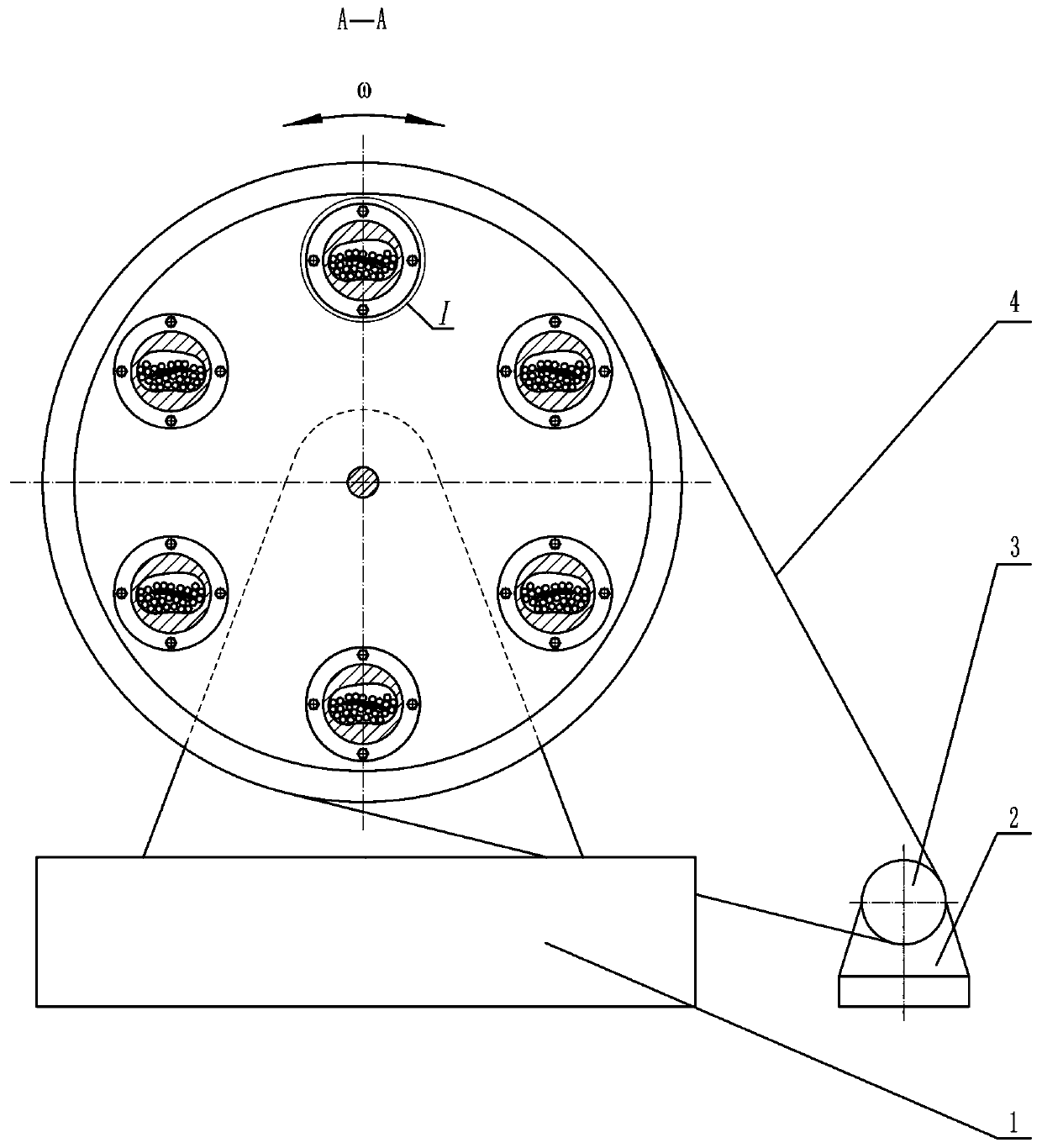

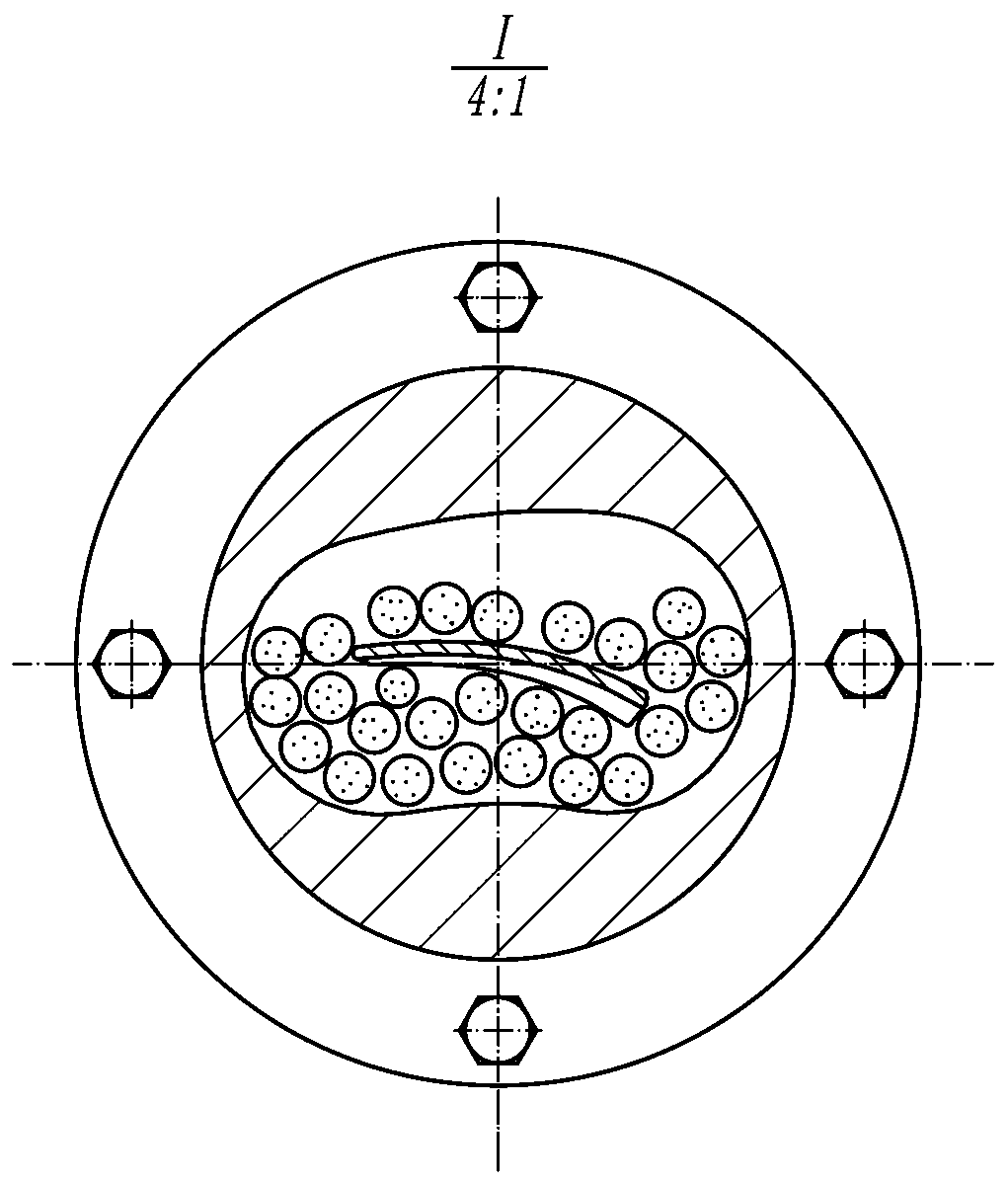

Combined closed cavity vibration type barrel finishing device for blade surface machining and method thereof

ActiveCN110842749AShape does not breakImprove surface integrityEdge grinding machinesPolishing machinesLiquid mediumMachined surface

The invention provides a combined closed cavity vibration type barrel finishing device for blade surface machining and a method thereof, and belongs to the technical field of blade surface finishing machining. A machined blade is fixed to the interior of a container of a special closed cavity matched with the blade shape to form a combined closed cavity; a certain amount of tumbling chip abrasivesand liquid mediums prefill the closed cavity; the tumbling chip abrasives and the machined blade which are sealed in the container rotate at a low speed along with the container, and simultaneously vibrate at the amplitude A and the frequency f, and the tumbling chip abrasives prefilling the container and each position of the machined surface of the blade generate certain relative motion and acting force, so that high-efficiency and consistent finishing machining of the high-performance blade is achieved through reasonable regulation and control of technological parameters, and the forming, and repairing and batch production requirements of the high-performance blade are met.

Owner:TAIYUAN UNIV OF TECH

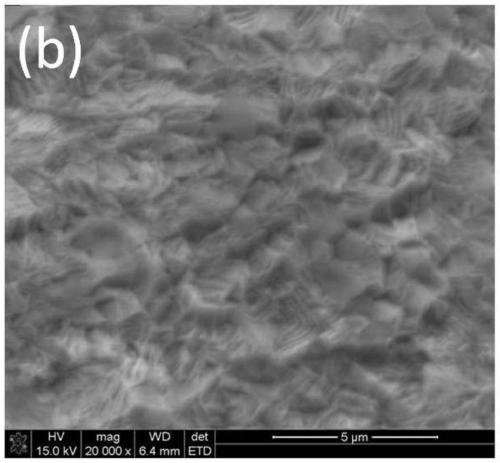

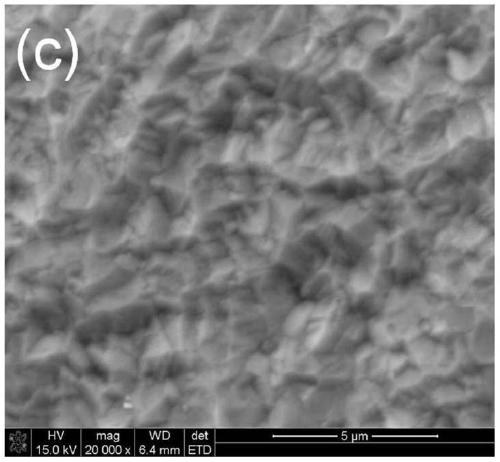

Zirconium alloy coating with high burnup and long service life and preparation method of zirconium alloy coating

ActiveCN109811316AImprove compactnessHigh fuel consumptionVacuum evaporation coatingSputtering coatingZirconium alloyBinding force

The invention relates to a zirconium alloy coating with high burnup and long service life and a preparation method of the zirconium alloy coating. Zirconium alloy is a fuel element cladding material,the coating is a metal Cr coating, the purity of metal Cr is 99.95%, and the thickness of the coating is 1-10 microns. The zirconium alloy coating is mainly used for improving the corrosion resistanceand high temperature oxidation resistance of a zirconium alloy cladding so as to improve the inherent safety of a fuel element and prolong the refuelling cycle. The invention also provides the preparation method of the zirconium alloy coating. By optimizing the method, better coating binding force and a fine coating surface structure are obtained.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com