Combined closed cavity vibration type barrel finishing device for blade surface machining and method thereof

A surface processing and processing device technology, which is applied in the field of combined closed-cavity vibration-type barreling and finishing processing devices, can solve the problems of difficult to meet surface accuracy, inconsistent surface roughness, low processing efficiency, etc., and achieve improved performance and Effect of life, reduction of surface roughness value, improvement of surface integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

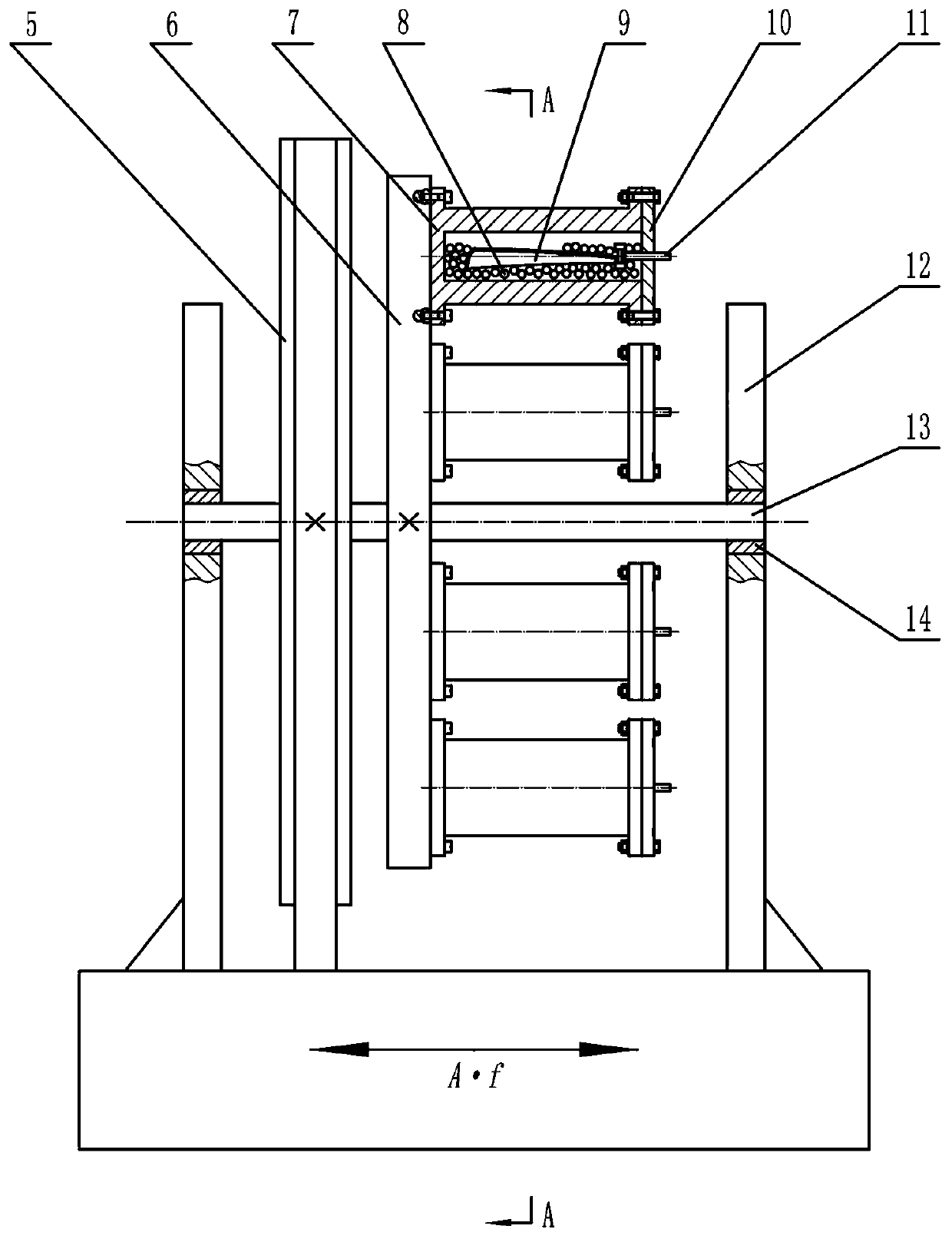

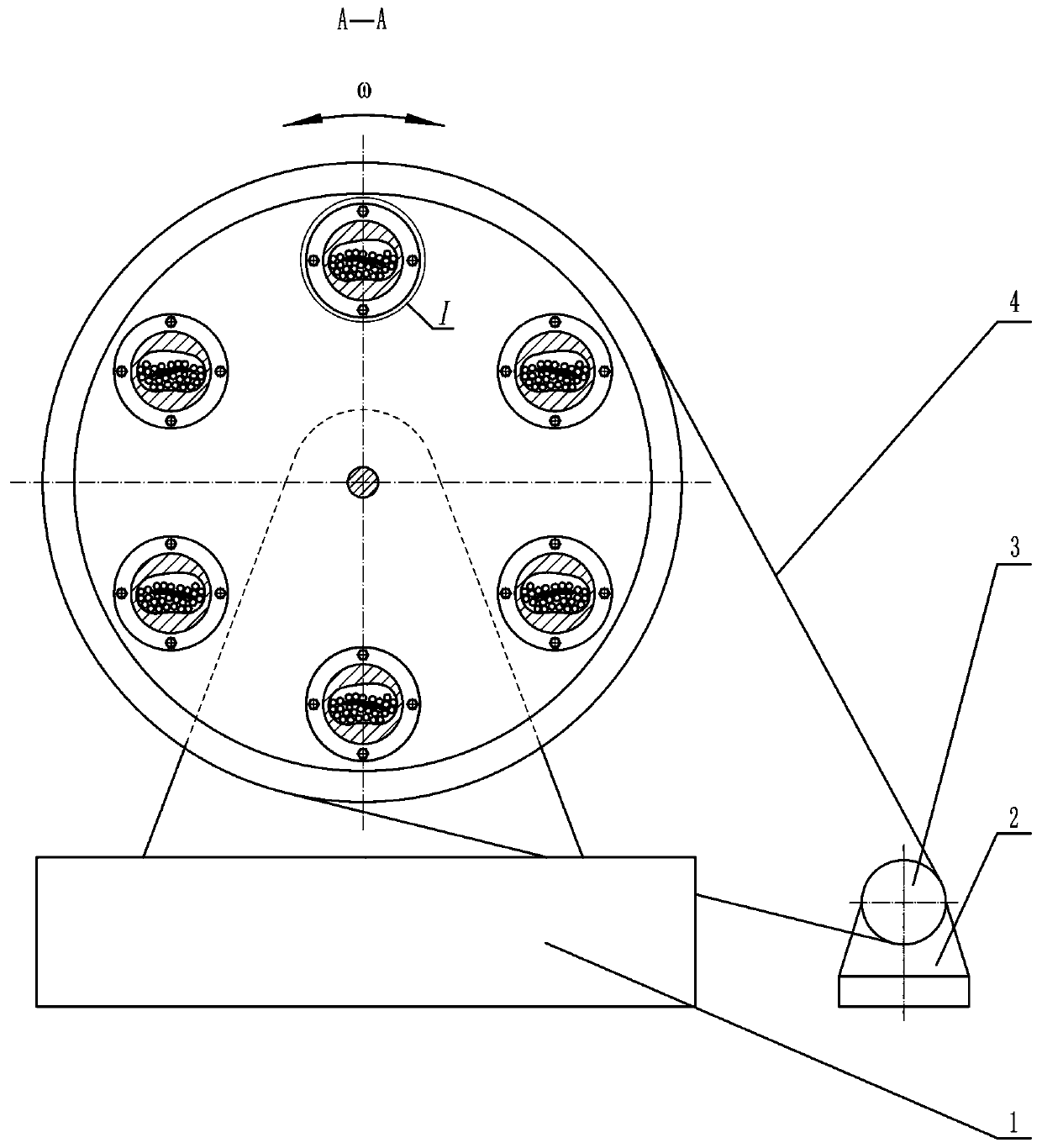

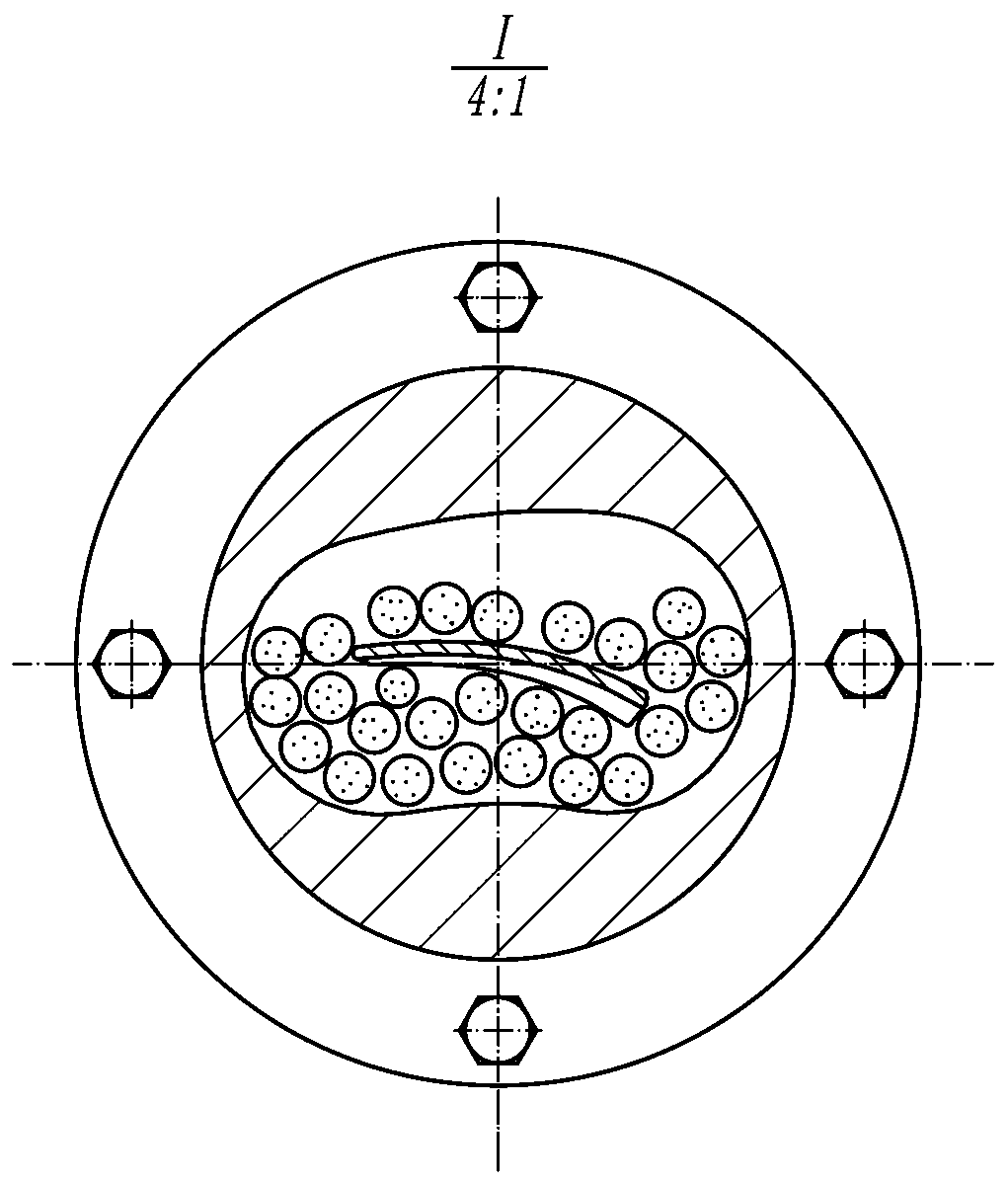

[0033] This embodiment provides a combined closed-cavity vibration-type barreling and finishing device for blade surface processing, including a vibration platform 1 (manufactured by Suzhou Sushi Test Instrument Co., Ltd. DC-5000-50), a bracket 12, and a support shaft 13. Bearing 14, speed regulating motor 2, small pulley 3, flat belt 4, large pulley 5, rotary platform 6 and processing components; vibration platform 1 is provided with bracket 12, and support shaft 13 is installed on bracket 12 through bearing 14 On the support shaft 13, the large pulley 5 and the rotary platform 6 are fixedly connected; the small pulley 3 is connected with the speed regulating motor 2, and rotates with the speed regulating motor 2; the small pulley 3 and the large pulley 5 are connected by a flat The belt 4 is connected; multiple processing components are fixed on the rotary platform 6 along the circumferential direction; the processing components include a container, a processing medium 8 and ...

Embodiment 2

[0045]This embodiment provides a processing method using the device described in Embodiment 1, the processed blade 9 is a rolled blade, comprising the following steps,

[0046] S1, fixing the processed blade 9 on the fixture 11;

[0047] S2, adding into the container body 7 the processing medium 8 containing 80% tumbling grinding blocks and a small amount of liquid medium, and closing the container;

[0048] S3, fixing the above-mentioned installed processing components on the rotary platform 6;

[0049] S4, repeat the above steps S1-S3 until all the components to be processed are fixed on the rotary platform 6 .

[0050] S5, adjust the speed of the speed regulating motor 2, so that the speed of the rotary platform 6 is 30r / min;

[0051] S6, adjusting the amplitude and frequency of the vibration platform 1; the amplitude is 3 mm, and the frequency is 100 Hz;

[0052] S7, start the speed regulating motor 2 and the vibration platform 1, the container rotates with the speed re...

Embodiment 3

[0059] This embodiment provides a processing method using the device described in Embodiment 1, the processed blade 9 is a superalloy blade, comprising the following steps,

[0060] S1, fixing the processed blade 9 on the fixture 11;

[0061] S2, adding into the container body 7 the processing medium 8 containing 60% tumbling grinding block and a small amount of liquid medium, and closing the container;

[0062] S3, fixing the above-mentioned installed processing components on the rotary platform 6;

[0063] S4, repeating the above S1-S3 steps, until all the components to be processed are fixed on the rotary platform 6;

[0064] S5, adjust the speed of the speed regulating motor 2, so that the speed of the rotary platform 6 is 15r / min;

[0065] S6, adjusting the amplitude and frequency of the vibration platform 1; the amplitude is 5 mm, and the frequency is 30 Hz;

[0066] S7, start the speed regulating motor 2 and the vibration platform 1, the container rotates with the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com