Forced sealing ball valve

A technology of forced sealing and ball valves, applied in valve details, valve devices, valve operation/release devices, etc., can solve the problems of difficult micro-leakage control, affecting the service life of valves, and many leakage control points, so as to save resources, Simple structure and low opening and closing torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

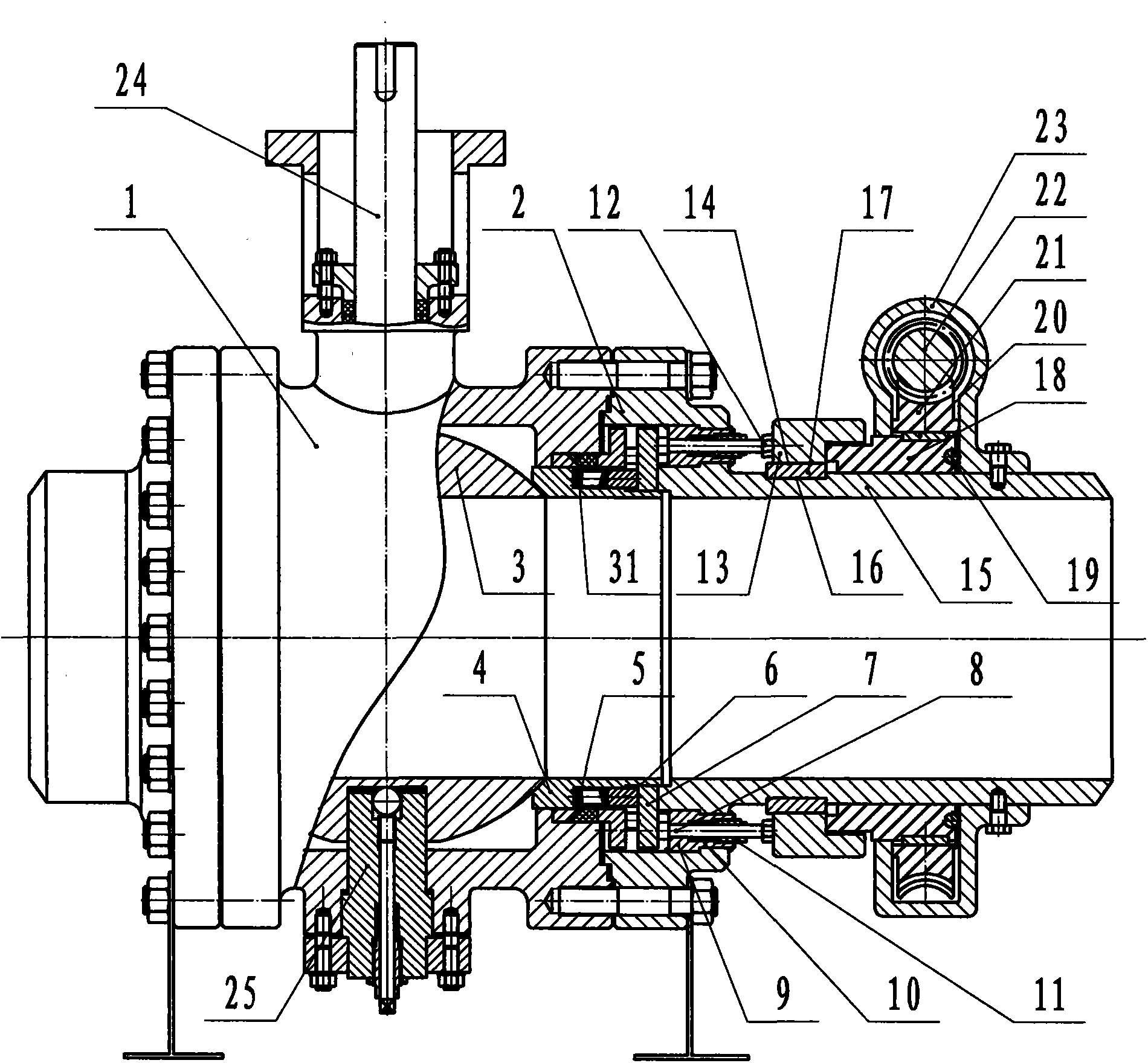

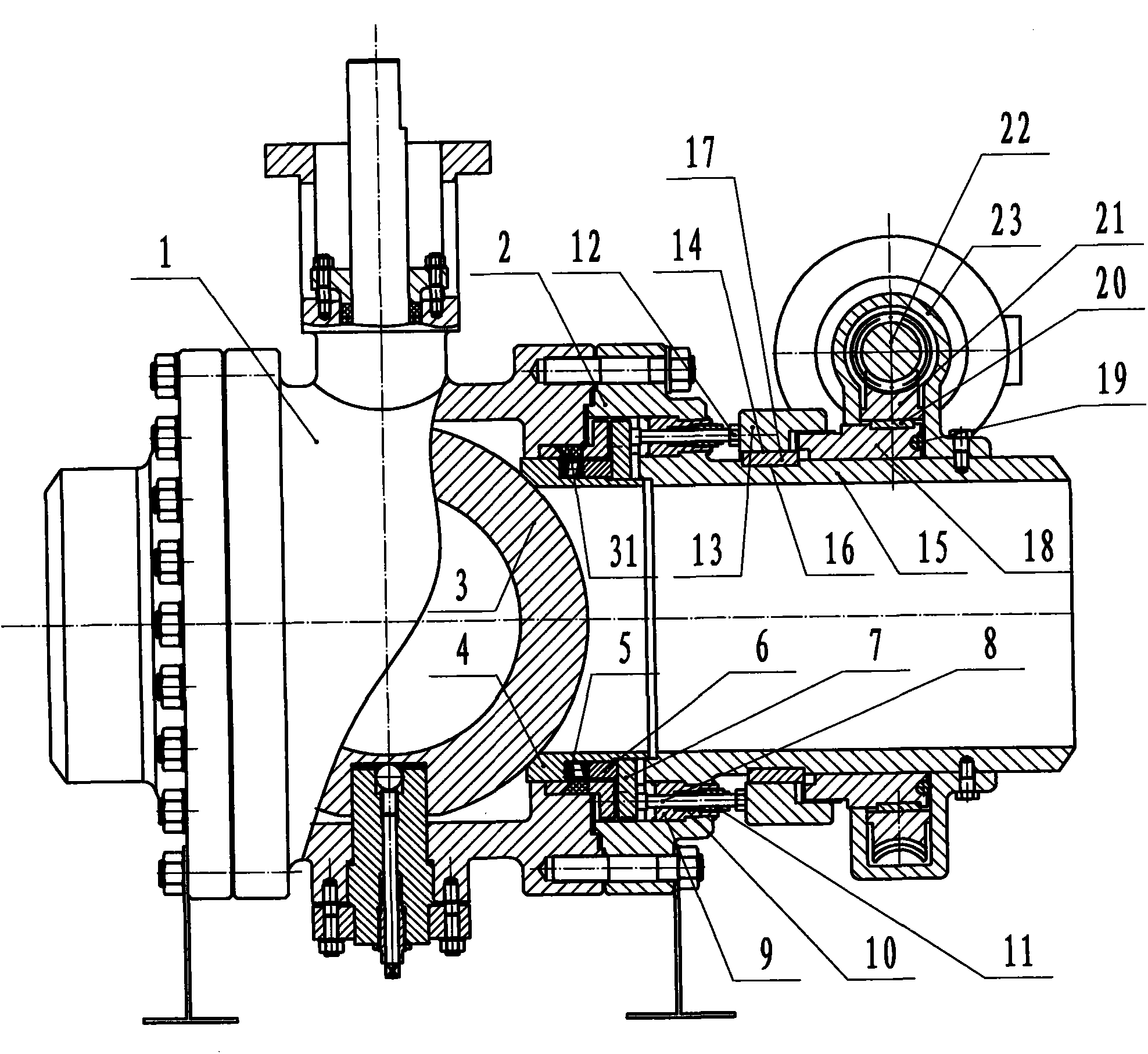

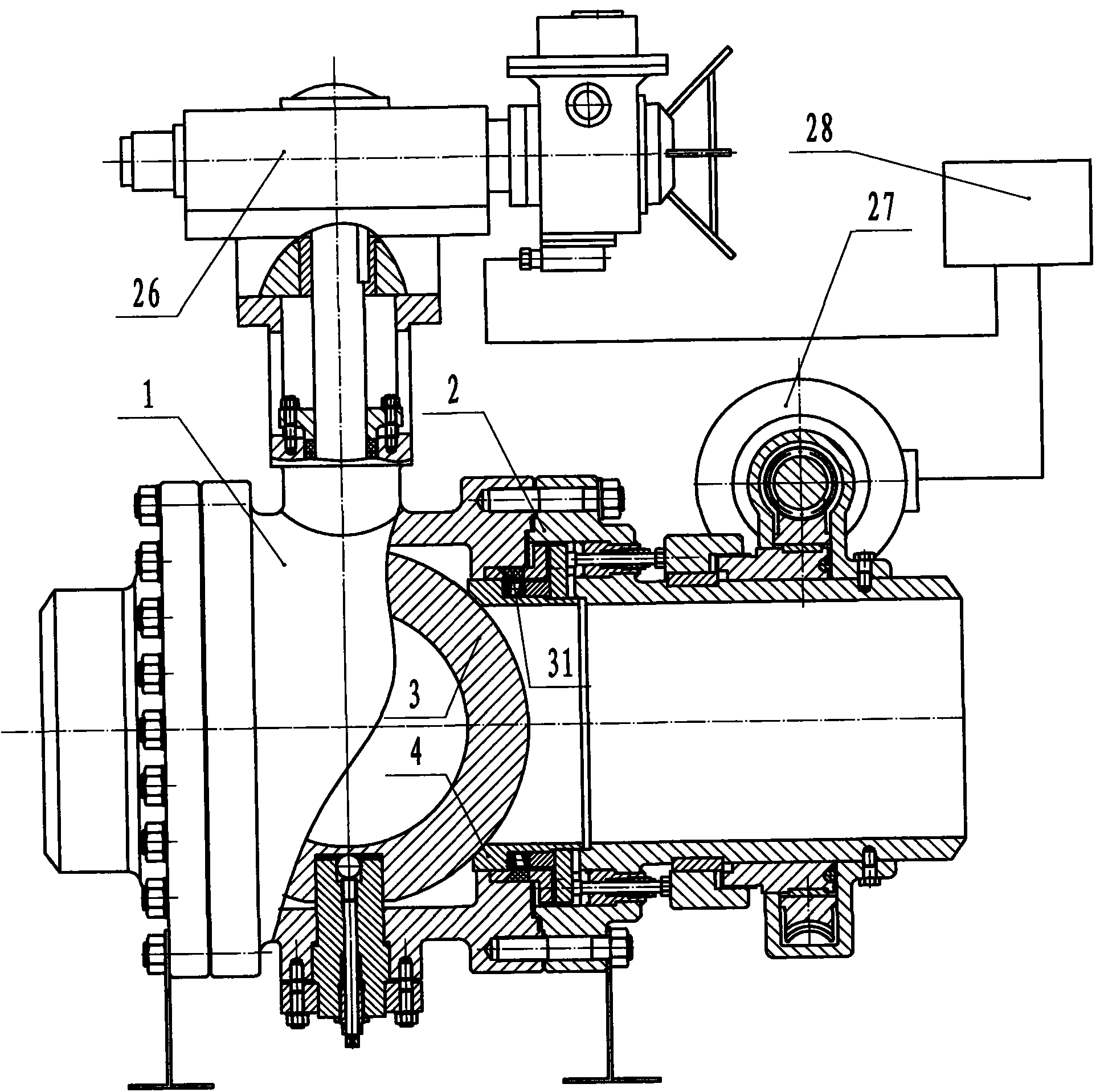

[0033] Such as figure 1 Shown is a schematic structural diagram of the open state of the first embodiment of the present invention, which includes a valve body 1, an auxiliary valve body 2, an upper valve stem 24, a lower valve stem 25, an electric actuator 26, a ball 3 with a flow channel, and a valve seat 4. Valve seat packing 31, the outer side of the valve seat 4 has a pressure transmission system connected to the stud nut driven forced sealing device 27 installed on the outer circle of the auxiliary valve body fluid pipeline 15, the pressure transmission system is: The back of the valve seat has several closed holes arranged in a circle, and springs 5 are placed in the closed holes, and a plunger 6 matched with the closed hole is placed on the outside of the spring 5, and the outer end of the plunger 6 and the force transmission plate 7 Conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com