A wear-resistant solid-liquid separation cyclone

A solid-liquid separation and cyclone technology, which is applied to cyclone devices, devices whose axial directions of cyclones can be reversed, etc., can solve problems such as affecting the service life of cyclones, difficulty in equipment maintenance and processing, and eliminate short circuits. The effect of reducing flow impact, improving service life and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

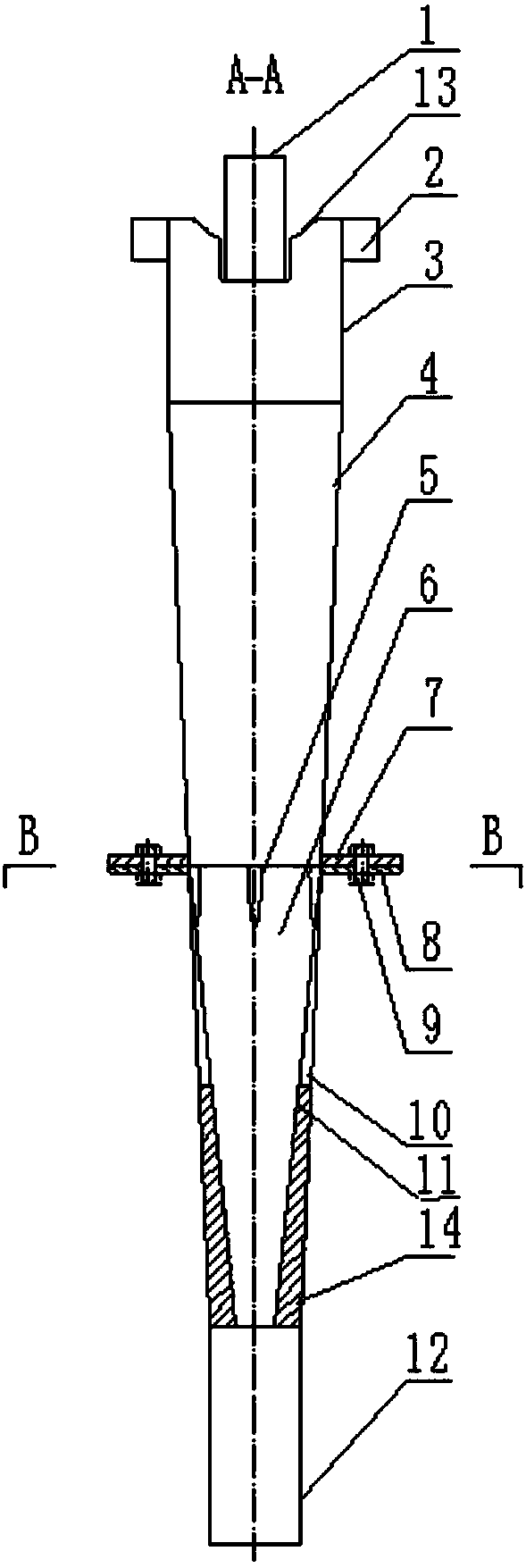

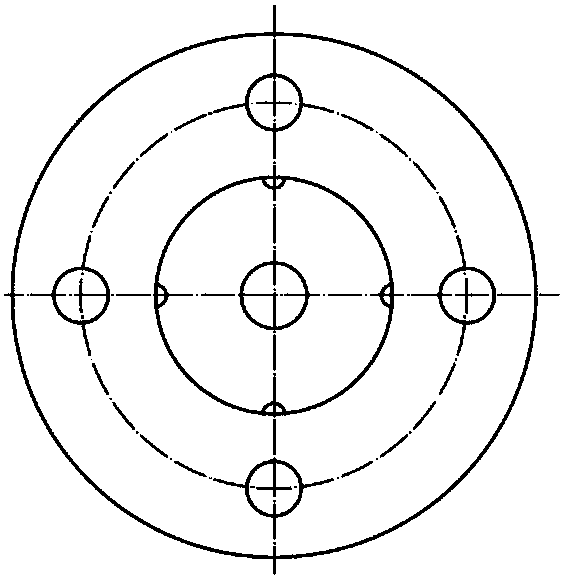

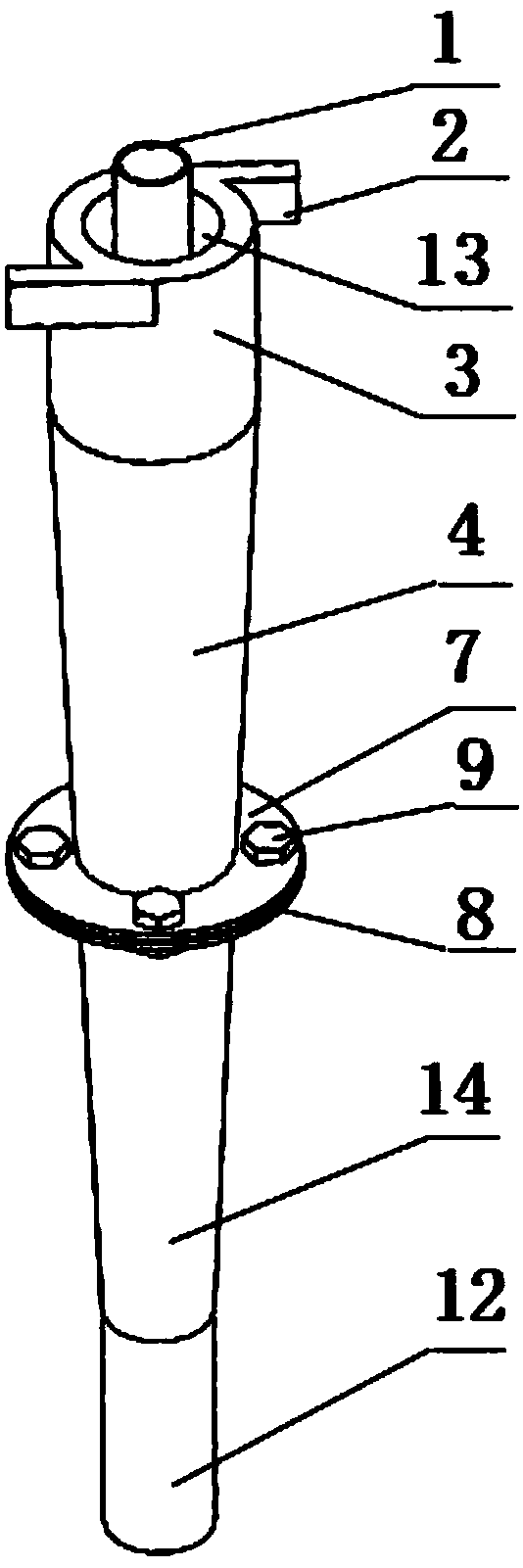

[0023] The present invention will be further described below in conjunction with accompanying drawing:

[0024] Depend on Figure 1 to Figure 10 As shown, this kind of wear-resistant solid-liquid separation cyclone includes a cylindrical swirl chamber 3, and two liquid inlets 2 are connected tangentially to the upper side wall of the swirl chamber 3. Its unique feature in:

[0025] The upper closed end of the swirl chamber 3 is an arc-shaped top surface 13, and the overflow port 1 is fixed on it after penetrating the arc-shaped top surface, and the overflow port is a straight pipe;

[0026] The wear-resistant solid-liquid separation cyclone also includes an upper section 4 of the outer cone, a lower section 14 of the outer cone, a bottom flow port 12 and a small inner cone 6;

[0027] Among them, the bottom flow port 12 is a straight tube, connected to the lower end of the lower section 14 of the outer cone; the upper section 4 of the outer cone and the lower section 14 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com