Patents

Literature

359results about How to "Good processing consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

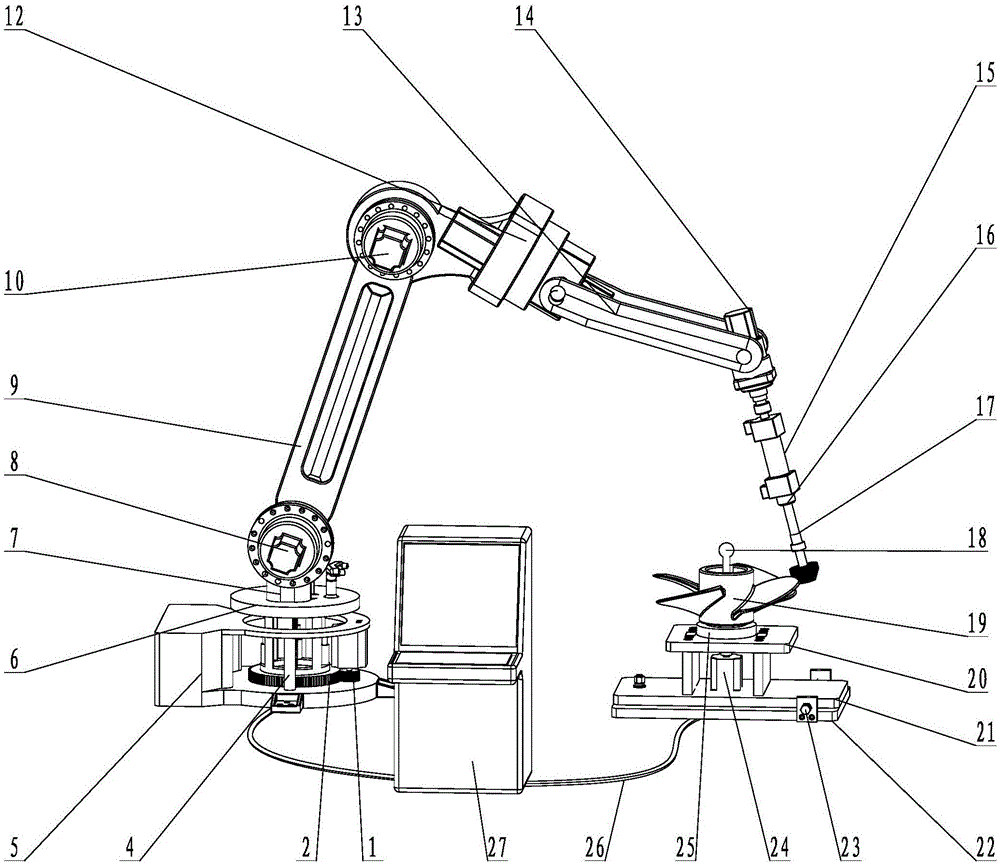

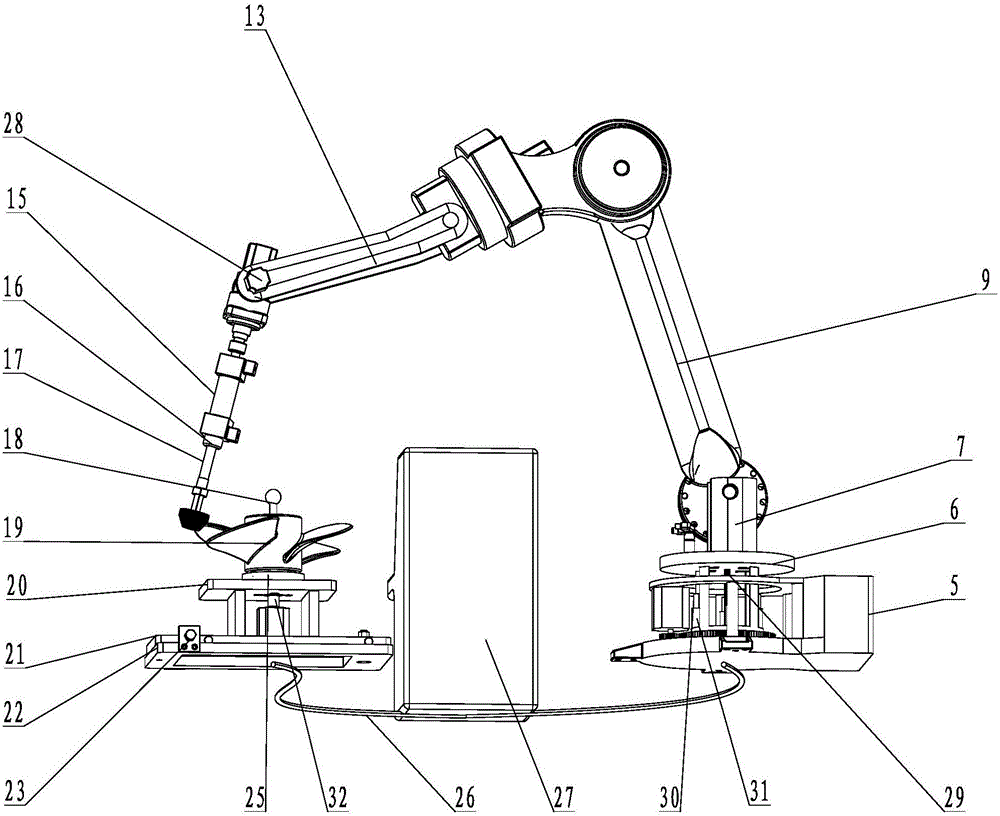

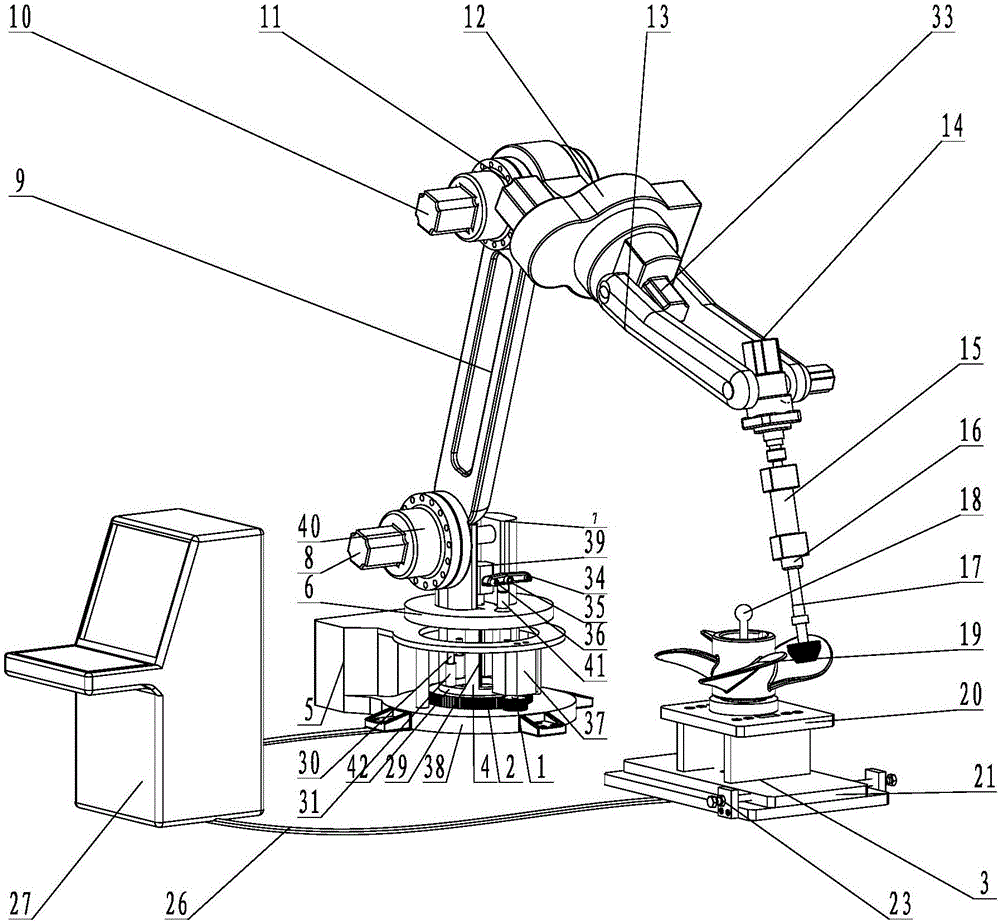

Industrial robot for grinding and polishing propeller and grinding and polishing method

ActiveCN106312754AImprove machining accuracyGood processing consistencyProgramme-controlled manipulatorGrinding machinesPropellerEngineering

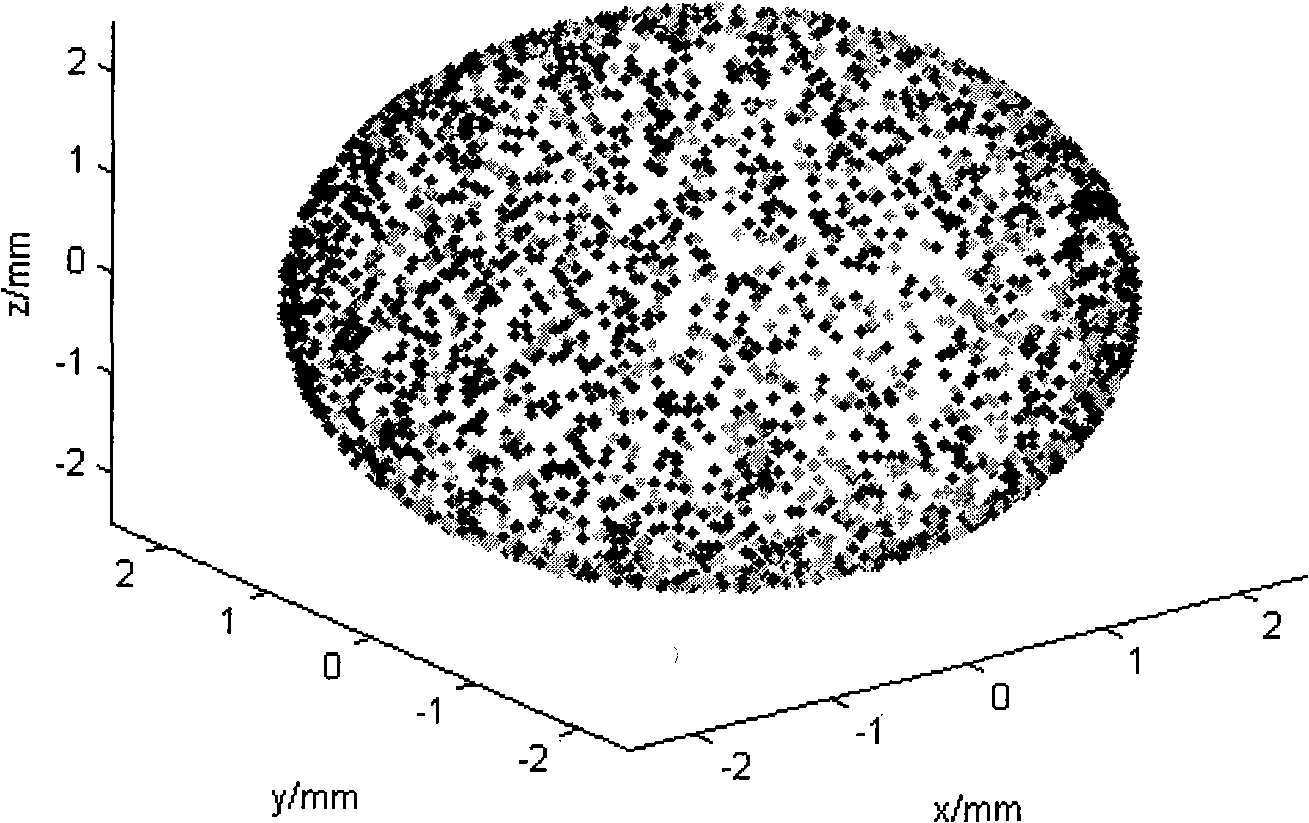

The invention relates to an industrial robot for grinding and polishing a propeller. The industrial robot for grinding and polishing the propeller is characterized by comprising a main robot body, a propeller locating and clamping drive mechanism and a 3D laser coordinate locating device, wherein the propeller locating and clamping drive mechanism comprises a rotary working table which can be used for adjusting the horizontal position, a propeller fixture is arranged on the rotary working table, and a zero point coordinate locating ball is connected with a rotating center of the propeller fixture; the main robot body comprises a rotating part, a lower bearing plate and an upper bearing plate which are capable of lifting and dropping are arranged on the rotating part, and a robot arm and the 3D laser coordinate locating device are mounted on the upper bearing plate; the robot arm comprises a large arm capable of rotating vertically and a small arm which is mounted at the upper end of the large arm and capable of rotating vertically and revolving, a grinding head capable of rotating vertically and revolving is mounted at the end part of the small arm, and an electromagnetic valve and a pressure sensor are arranged at the upper end of the grinding head. According to the industrial robot for grinding and polishing the propeller, processing and locating accuracy can be improved, and precision and consistency of grinding and polishing of the surface of the propeller are remarkably improved.

Owner:鹰普航空科技有限公司

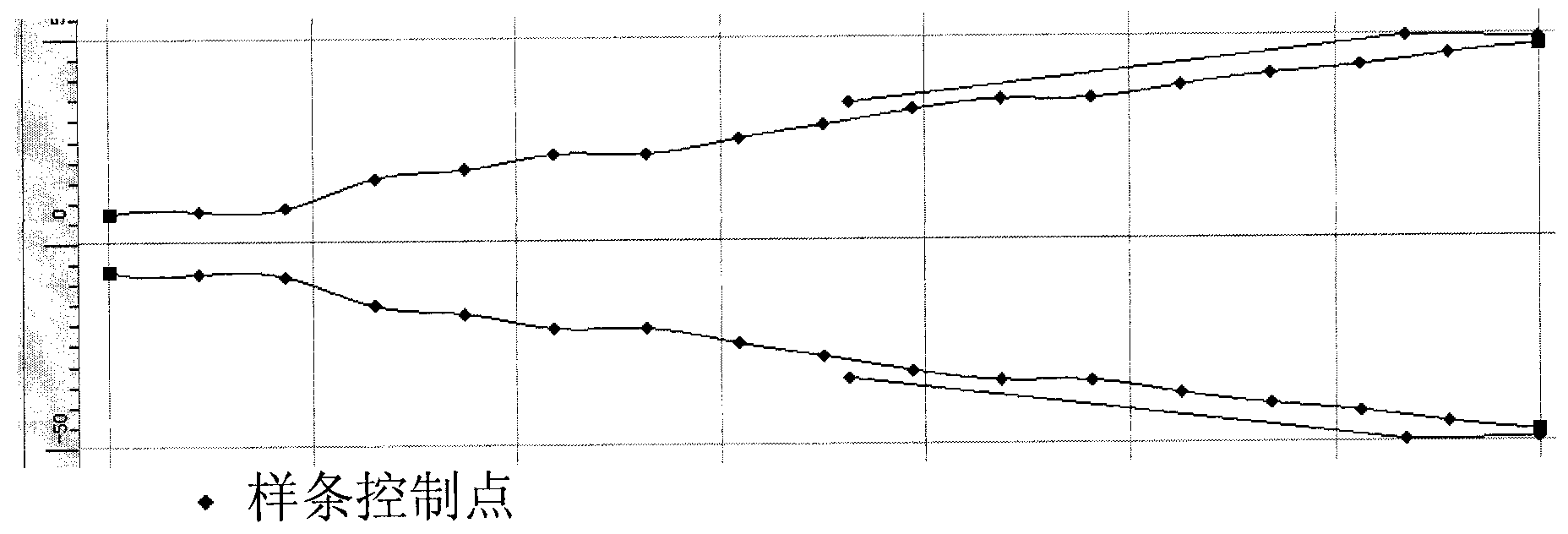

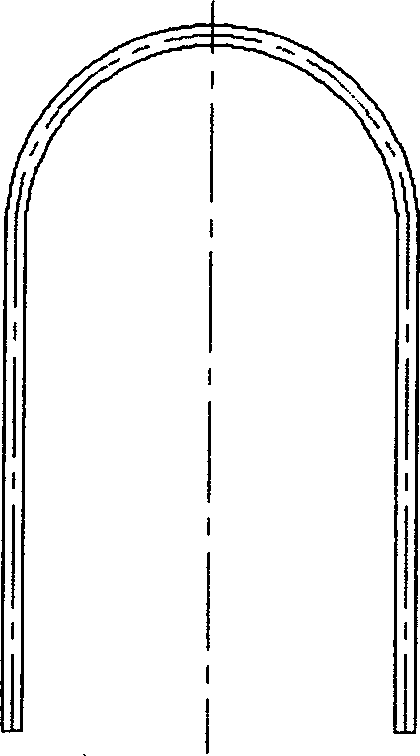

Vertical type method for processing nozzle cooling channel of liquid-propel land rocket engine

InactiveCN101412122AImprove smoothnessHigh-precision digital processingAutomatic control devicesMeasurement/indication equipmentsData setLaser sensor

The invention relates to a method for vertically processing a cooling passage of a liquid rocket engine thrust jet, which belongs to the processing method field of liquid rocket engine thrust jet. In the invention, the thrust jet adopts a vertical clamp; a single-point laser sensor scans bus bars strip by strip to acquire the actual profile of the thrust jet and a sampled data set to reconstruct the bus bars of the thrust jet strip by strip; the buses of the sampled data set are smoothed strip by strip to acquire a thrust jet smoothed data set; the data set of all the bus bars are compressed to acquire a compressed data set; and a cubic spline is used for performing interpolation to approximate the actual bus bars of the thrust jet. The milling tool position is calculated by dual milling head for symmetrical milling and high speed back chipping. The method realizes the integration of measurement and processing, finishes the treatments of profile measurement, milling groove and back chipping by one clamping, can satisfy the processing requirements on different physical dimensions and different bus bar linetypes, has high processing efficiency and good consistency, and realizes the digital processing with high efficiency and high precision of the cooling passage of the liquid rocket engine thrust jet.

Owner:DALIAN UNIV OF TECH

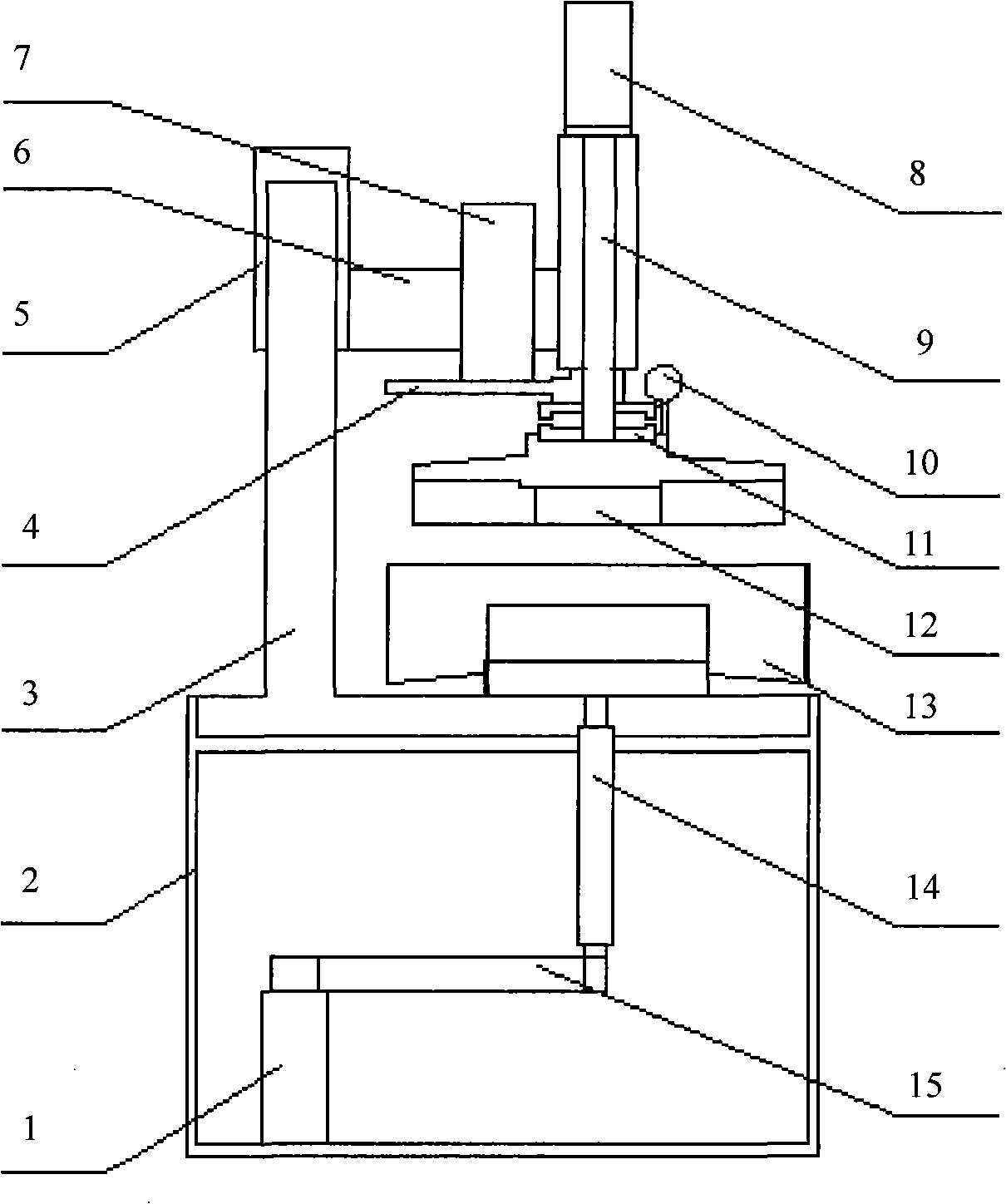

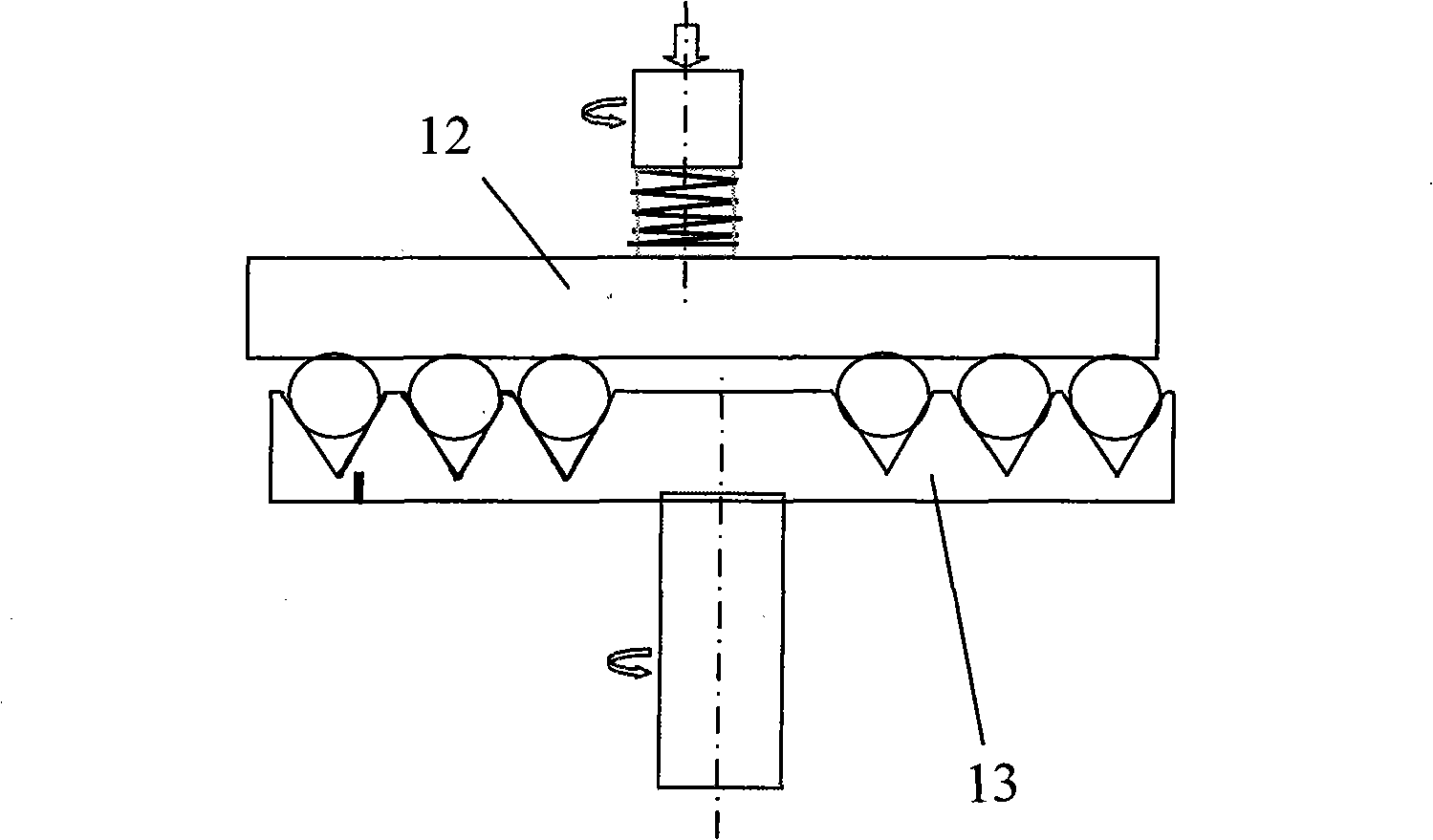

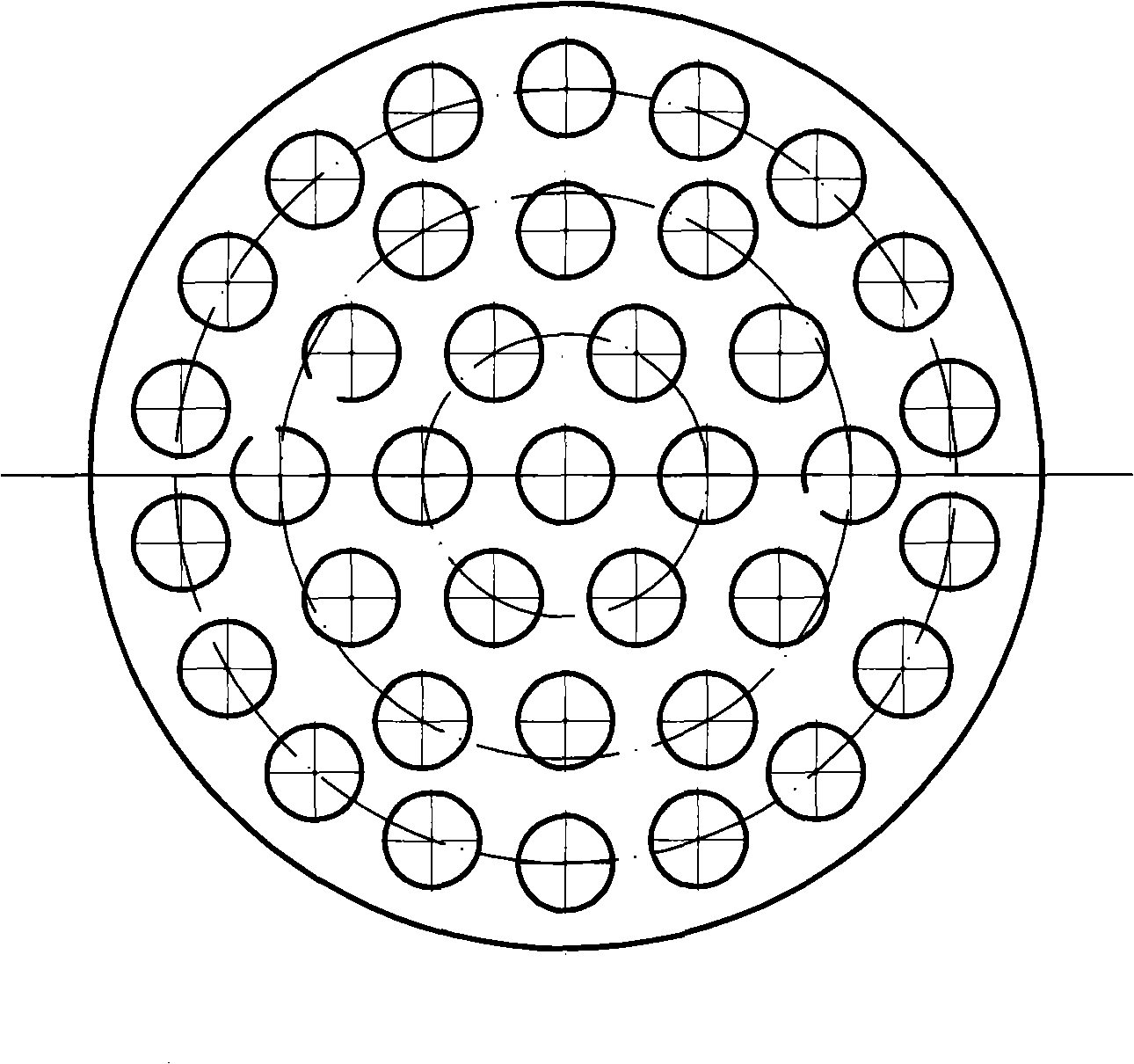

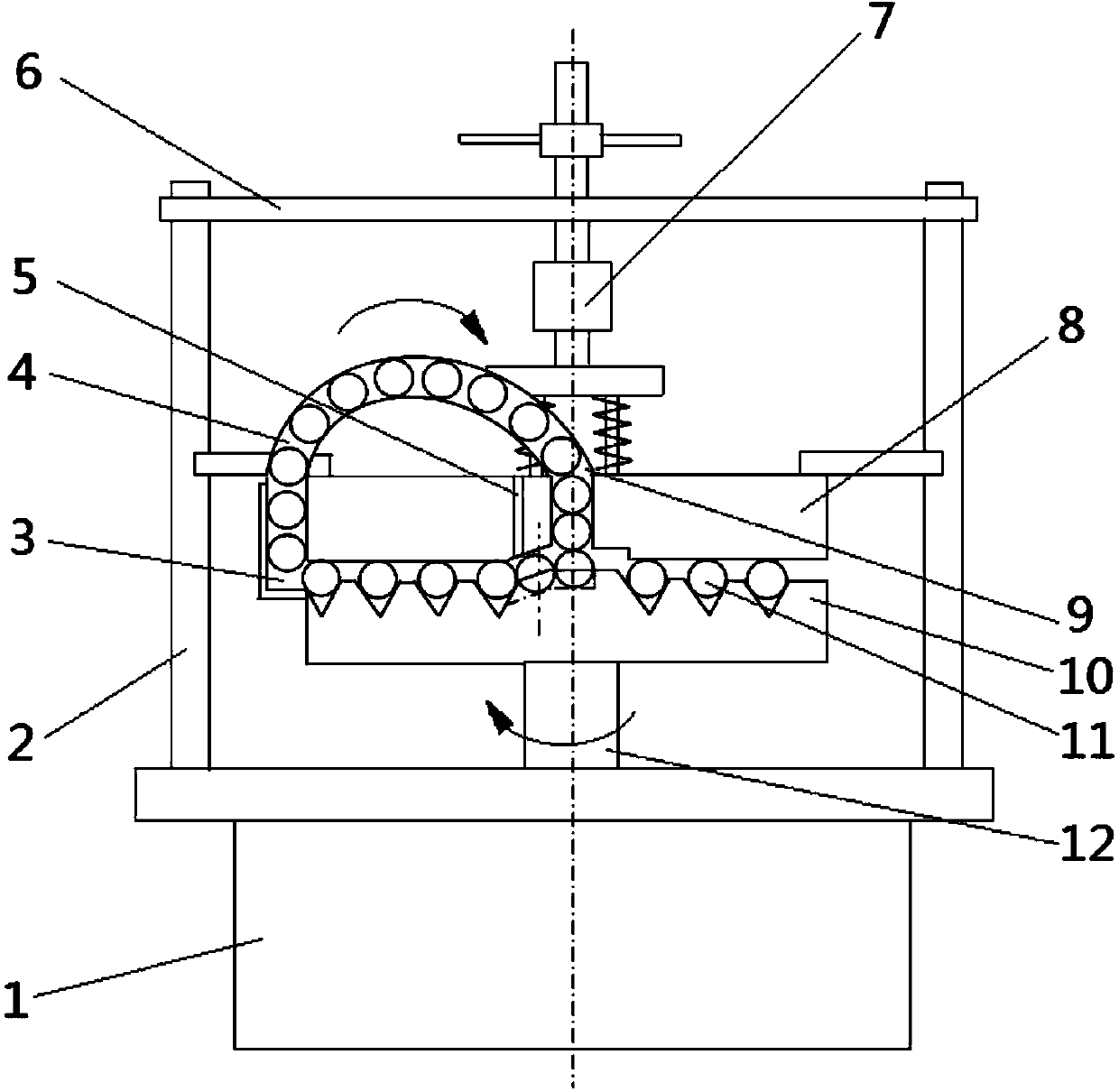

Double-disk rotation eccentric V shaped groove grinding miller

InactiveCN101279434AAdjustable speedSuitable for mass productionSpherical surface grinding machinesInsertion stentDrive motor

The invention discloses a double-disk autorotation eccentric V-shaped groove grinder, which comprises a frame, and an upper abrasive disk and a lower abrasive disk arranged on the frame; wherein, the upper abrasive disk is arranged on the spindle of the upper abrasive disk and the spindle of the upper abrasive disk is connected with the driving motor of the upper abrasive disk; the lower abrasive disk is connected with the driving motor of the lower abrasive disk, and the upper abrasive disk and the lower abrasive disk are arranged at the top and bottom. The frame comprises a frame body and an upper stent; wherein, the upper stent can be rotatablely arranged on the upper end of the frame body, and the upper abrasive disk is arranged on the upper stent while the lower abrasive disk is arranged on the frame body; at least three V-shaped grooves used for placing ball-billets are cut on the upper surface of the lower abrasive disk; each V-shaped groove is a concentric circle, the circle center of the concentric circle coincides with that of the lower abrasive disk, and the upper abrasive disk and the lower abrasive disk are eccentric with each other. The double-disk autorotation eccentric V-shaped groove grinder provided by the invention has simple structure and low manufacturing cost, and simultaneously has higher machining accuracy and machining efficiency.

Owner:ZHEJIANG UNIV OF TECH +1

Completely-integrated impact piece ignitor and preparation method thereof

InactiveCN101619954AImprove use reliabilityImprove assembly accuracySemi-permeable membranesPrecision positioning equipmentManufacturing cost reductionHigh volume manufacturing

The invention discloses a completely-integrated impact piece ignitor and a preparation method thereof, which belong to the technical filed of initiators and pyrotechnics. On the basis of a micro electronic mechanical system (MEMS) processing technology, the assembly can be finished in the process of processing a bridge foil, a flying plate, an accelerating chamber and a reflection plate, thus thepreparation method is beneficial to improving the assembly precision of devices. In addition, the completely-integrated impact piece ignitor has the characteristic of parallel processing of an integrated circuit, is convenient to produce in large batch and reduces the manufacturing cost, and is beneficial to improving the consistency and the reliability of the process; and meanwhile, by using themetal bridge foil, the completely-integrated impact piece ignitor has short igniting time and can be widely applied to ignition of a plurality of novel high and safe initiators and pyrotechnics.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

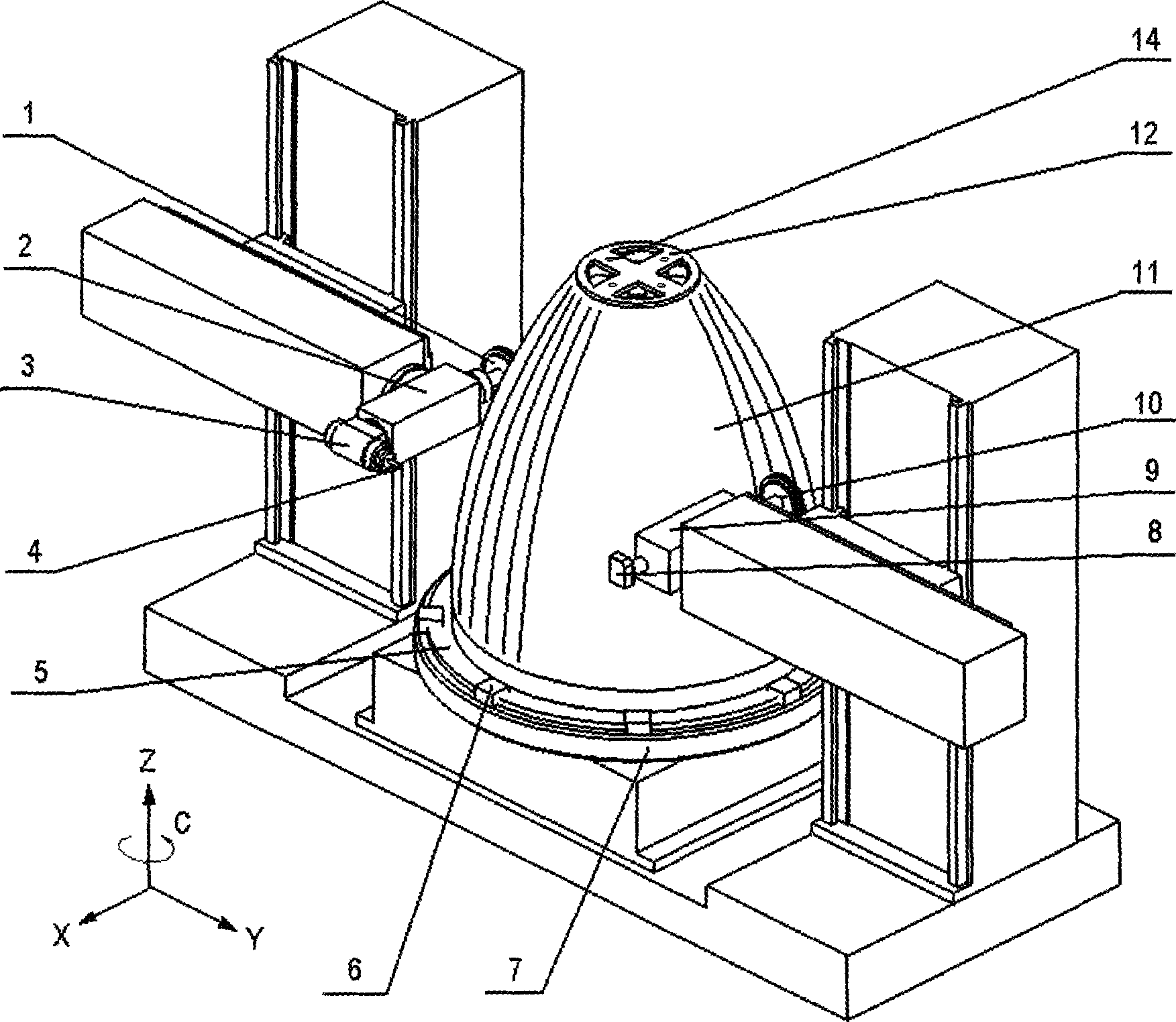

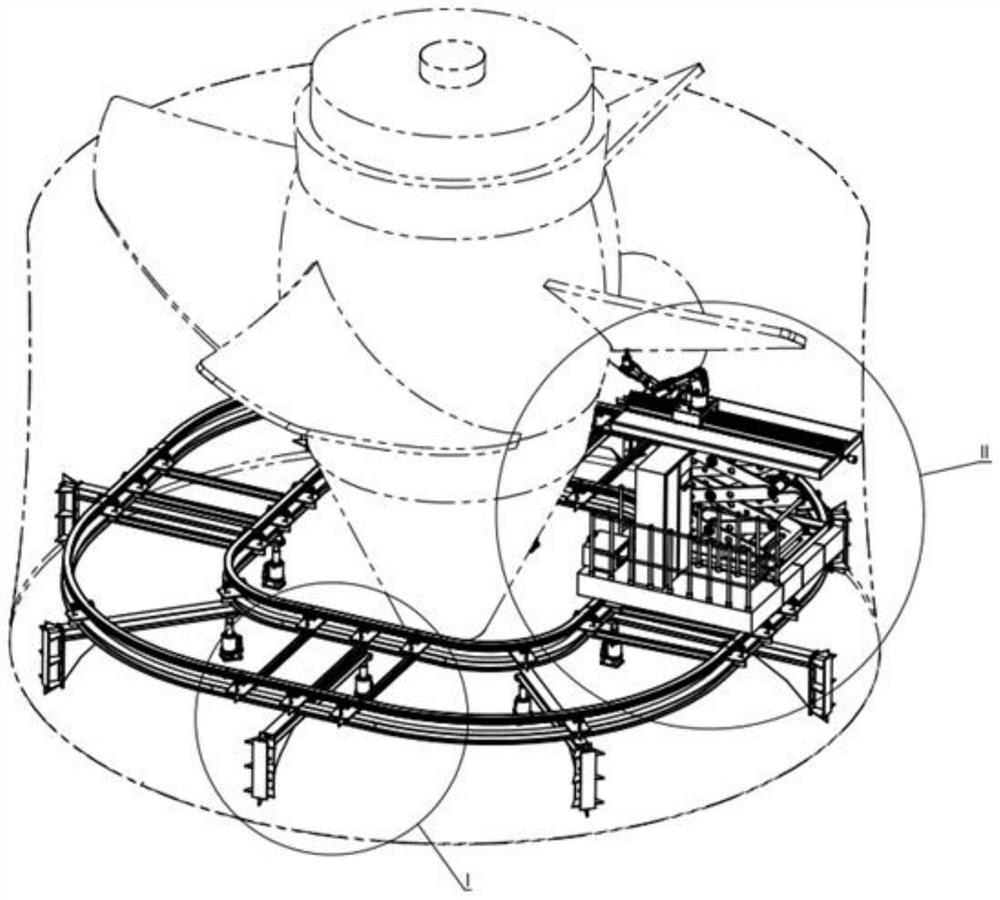

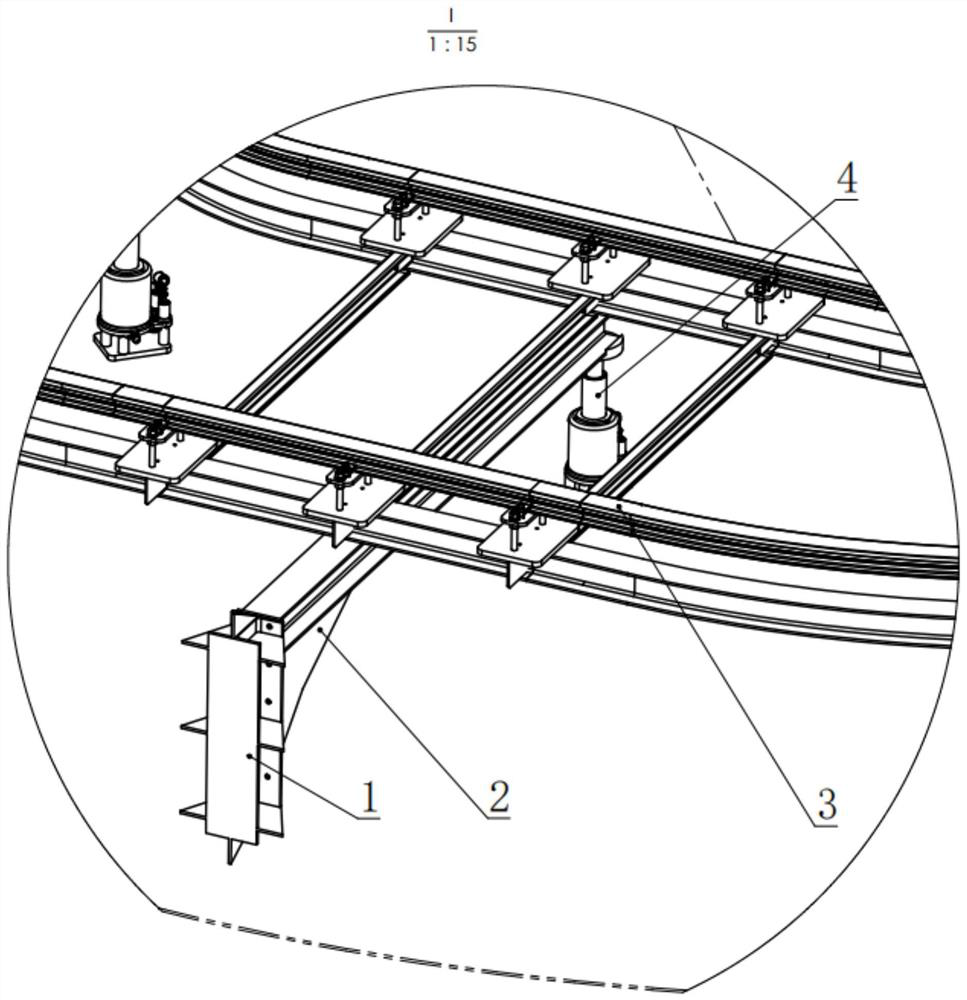

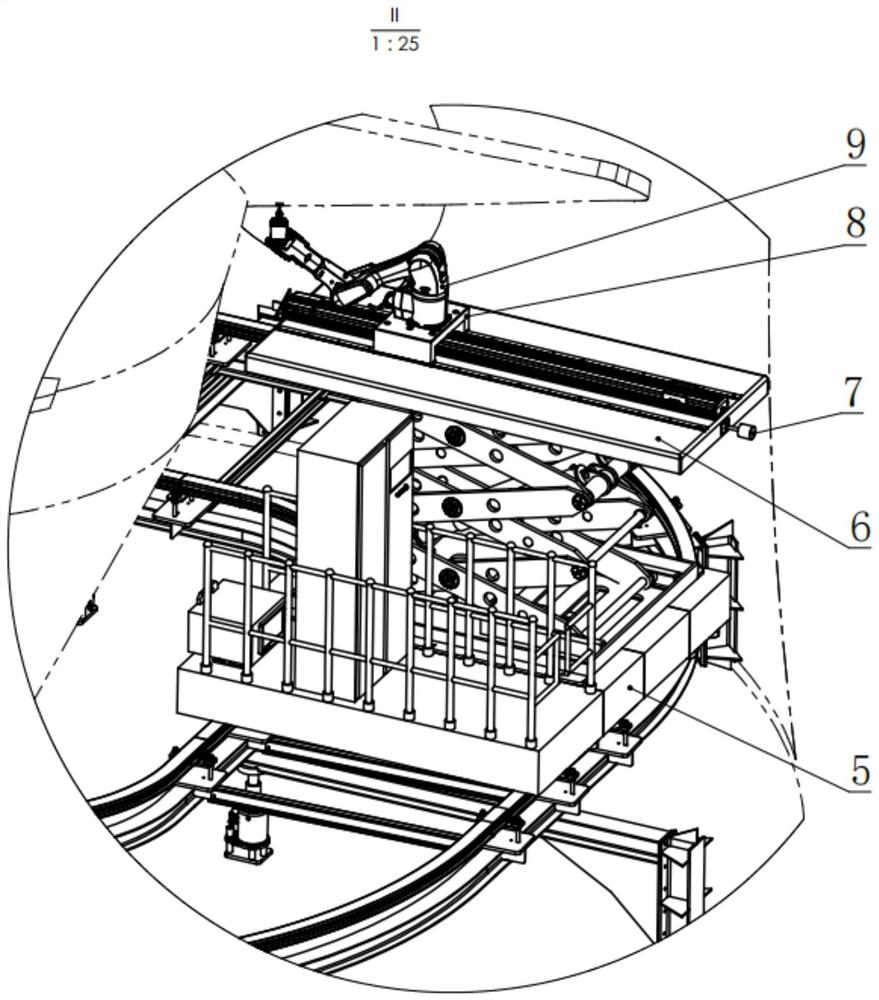

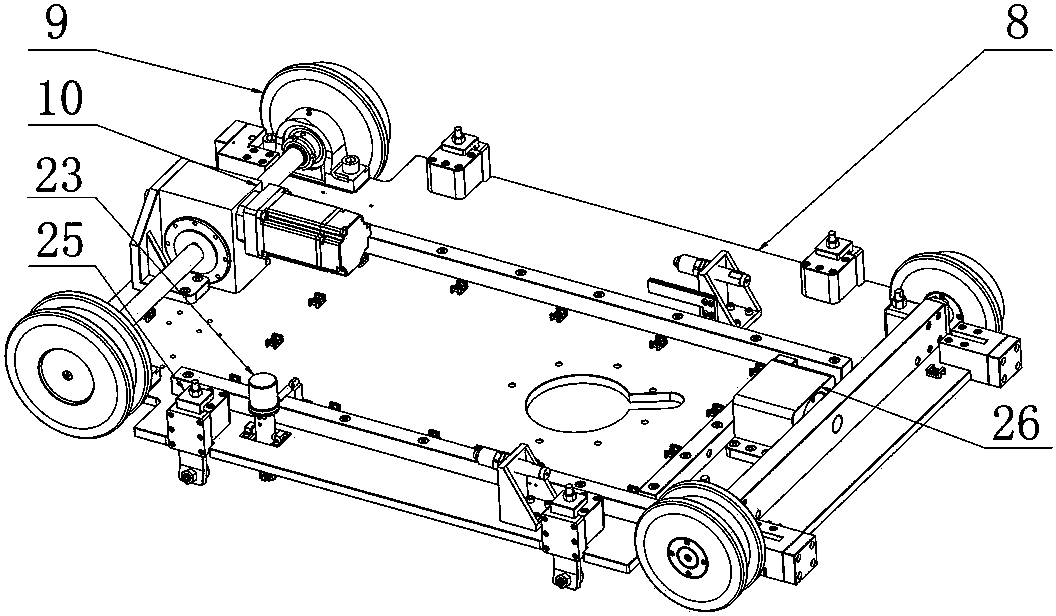

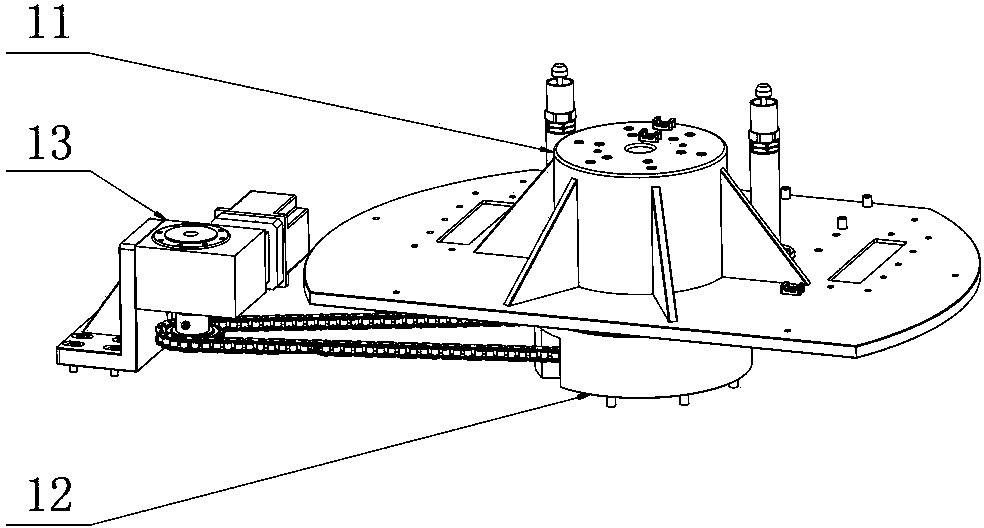

On-site robot in-situ measurement and milling repair integrated process and system

ActiveCN111843505ASpace availableSolve the entry problemProgramme-controlled manipulatorMeasurement/indication equipmentsMotion systemVisual perception

The invention discloses an on-site robot in-situ measurement and milling repair integrated system. The system comprises a mechanical motion system, an electrical control system, a robot milling machining system, a three-dimensional vision measurement and machining track generation system, and a machining process online monitoring and self-adaptive regulation and control system. By means of modulardesign and lightweight design, equipment move-in is achieved, and the space of a to-be-machined area of a large curved surface closed structure can be reached by virtue of an annular guide rail, a moving trolley, a lifting platform and a robot. Automatic measurement and trajectory planning of the robot are achieved through the three-dimensional vision measurement and machining trajectory generation system. The machining process real-time three-dimensional visual motion simulation, and real-time monitoring and self-adaptive regulation of signals such as force / vibration / spindle current are achieved through the machining process online monitoring and self-adaptive regulation and control system, and the automatic and intelligent machining of the large curved surface closed structure by the robot is achieved.

Owner:武汉数字化设计与制造创新中心有限公司

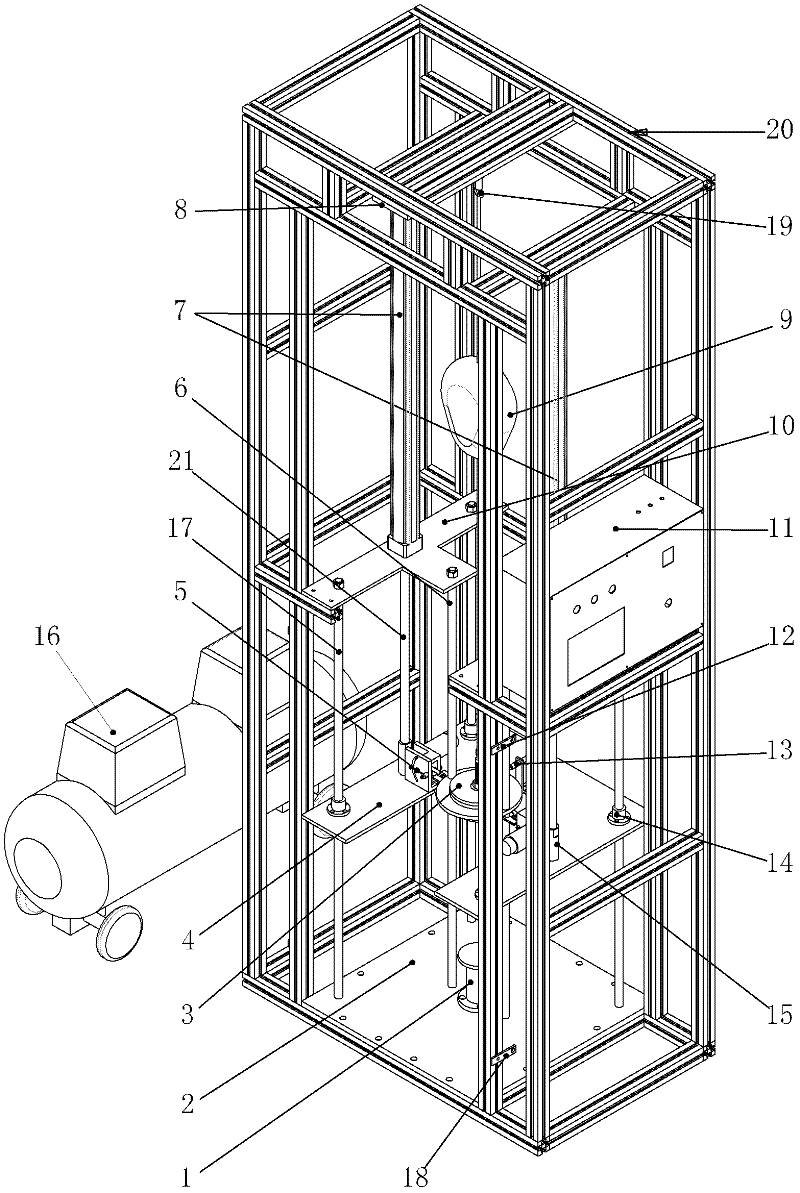

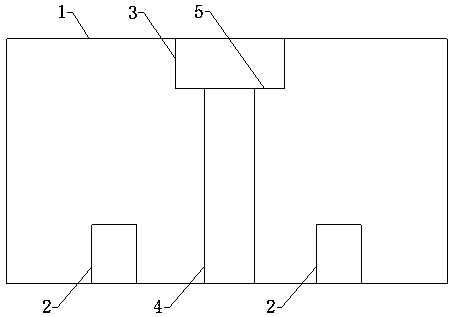

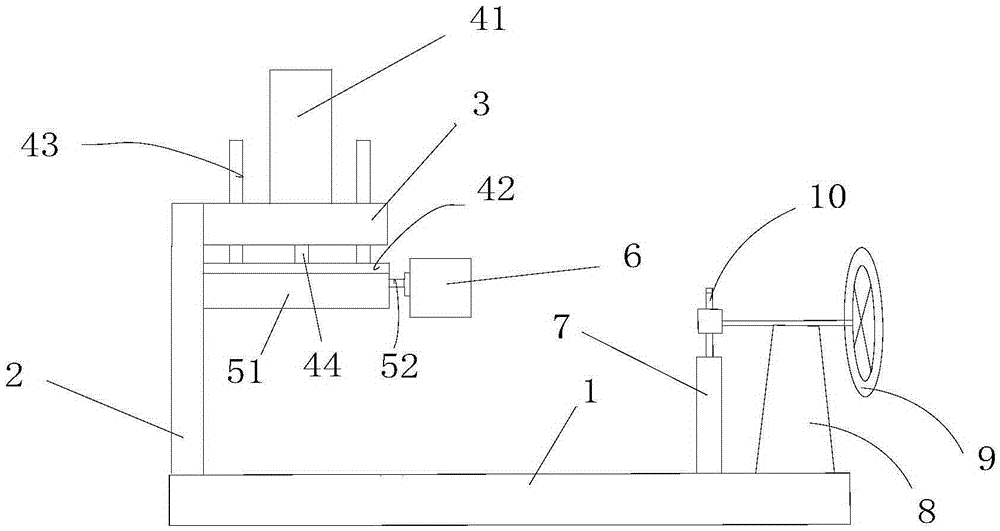

Self-locking reliability performance testing machine for speed differential fall arrester

ActiveCN102297762AReach releaseReach holdMachine part testingBuilding rescueHigh volume manufacturingEngineering

The invention discloses a speed-different type safety catcher self-locking reliability performance test machine which comprises a framework, a base plate 2 and an air pump. The framework is provided with two fixed plates, releasing mechanisms, one or two upper stop blocks, an impact pedestal, a control cabinet, a suspension ring, a weight block set, cylinders, movable plates, a sensor, movable plate gag lever posts, and a weight block gag lever post. Each releasing mechanism 5 comprises an electromagnet, a releasing pawl and a lever mechanism. The releasing pawl extends horizontally and inwardly to form a mobile platform capable of supporting the weight block set. The electromagnet and one end of the lever mechanism form a machinery linkage capable of tripping. The impact pedestal is arranged at a central position of the base plate. Center lines of the impact pedestal, the weight block set and the speed-different type safety catcher are superposed. The impact pedestal is provided witha counting sensor. The speed-different type safety catcher self-locking reliability performance test machine has the advantages of simple structure, low manufacture cost, good processing consistency,suitability of mass production and the like.

Owner:ZHEJIANG HUADIAN EQUIP TESTING INST

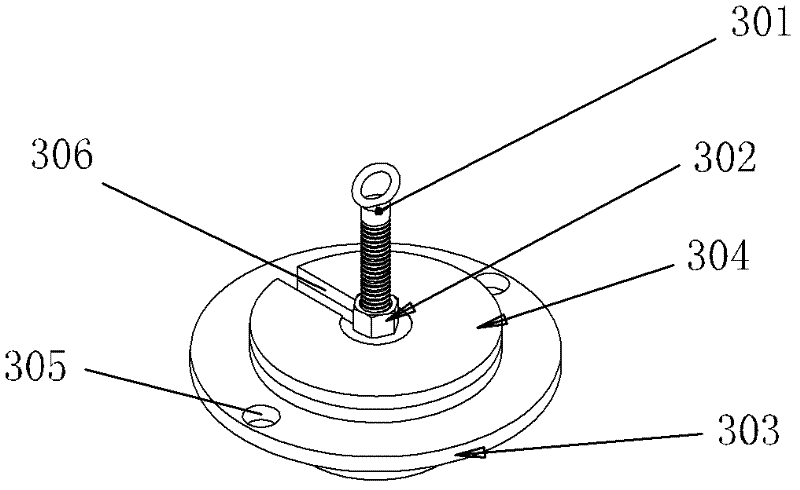

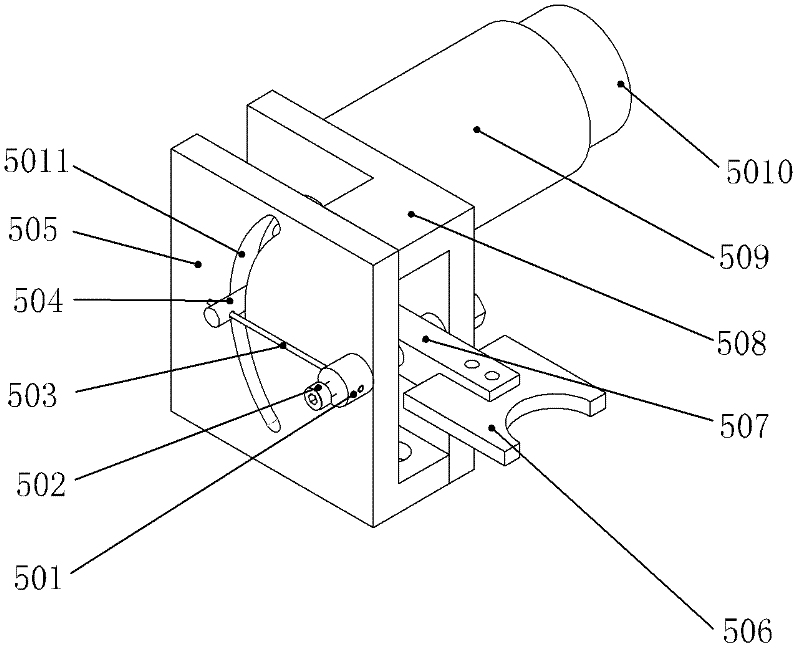

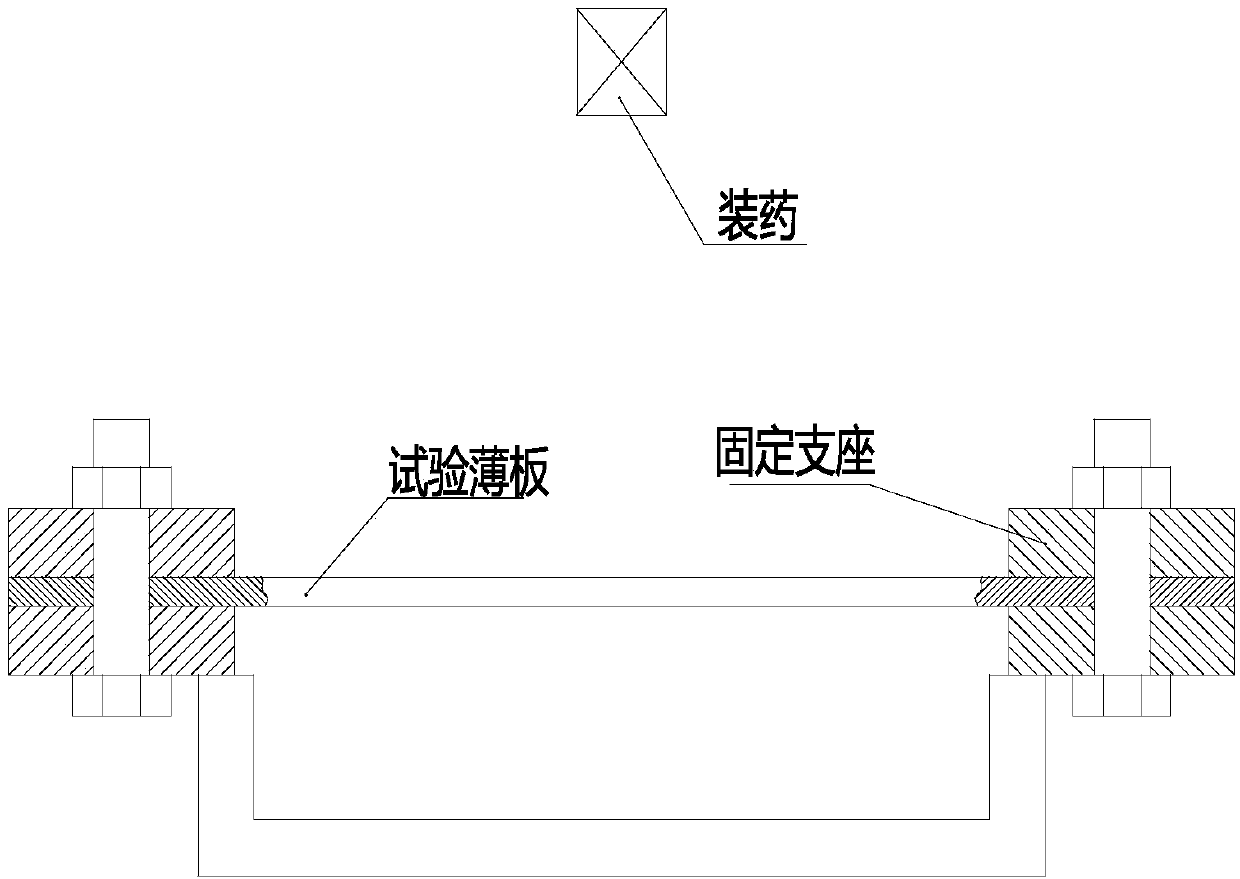

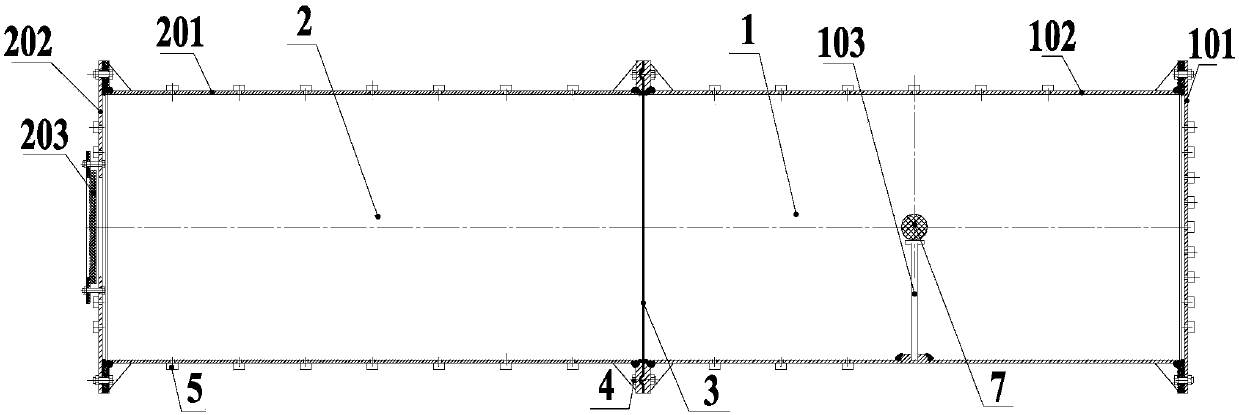

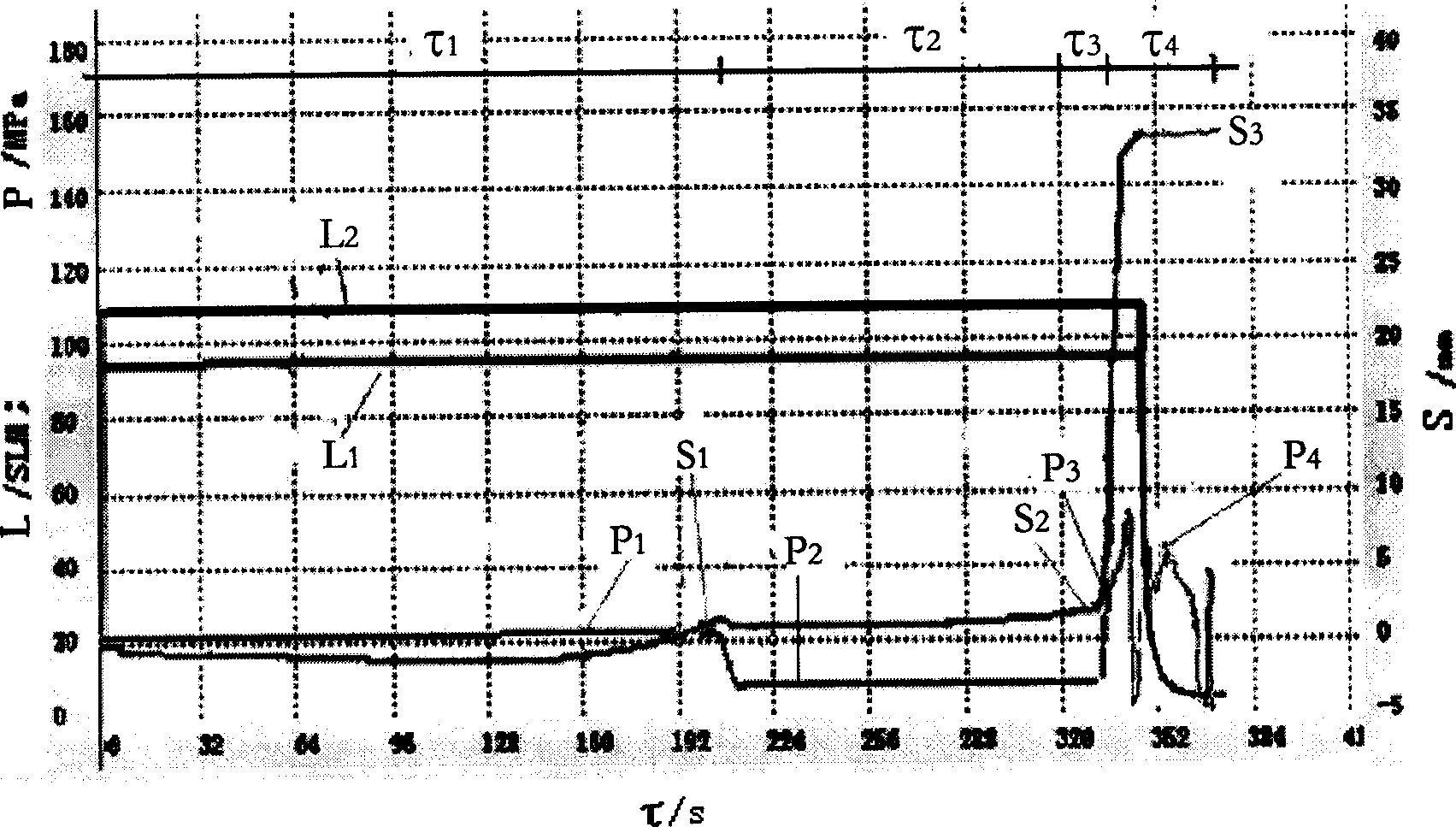

Internal explosion experimental device for cylindrical double-chamber structure

ActiveCN107655649ASolve the problem of poor data repeatabilityAvoid missingShock testingMeasurement of explosion forceEngineeringRepeatability

The invention discloses an internal explosion experimental device for a cylindrical double-chamber structure. The experimental device is composed of a front end cover 101, an explosion chamber side wall 102, an observation chamber side wall 201, a rear end cover 202, a bullet-proof glass observation window 203, a test sheet 3, a charging support rod 103, and a sensor mounting component 5. The front end cover 101 is installed at the head end of the explosion chamber side wall 102. The rear end cover 202 is installed at the tail end of the observation chamber side wall 201. The tail end of the explosion chamber side wall 102 and the head end of the observation chamber side wall 201 are in sealing connection through a flange structure. The test sheet 3 is clamped in the middle of the flange to form a closed double-chamber structure, namely, a closed explosion chamber 1 and a closed observation chamber 2. By using the internal explosion experimental device of the invention, the explosion load propagation law of the ship cabin and the damage characteristic of the cabin grillage structure can be researched and experimented under the condition of internal explosion, and the problem that the existing experimental device has poor test data repeatability and consistency is solved.

Owner:XIAN MODERN CHEM RES INST

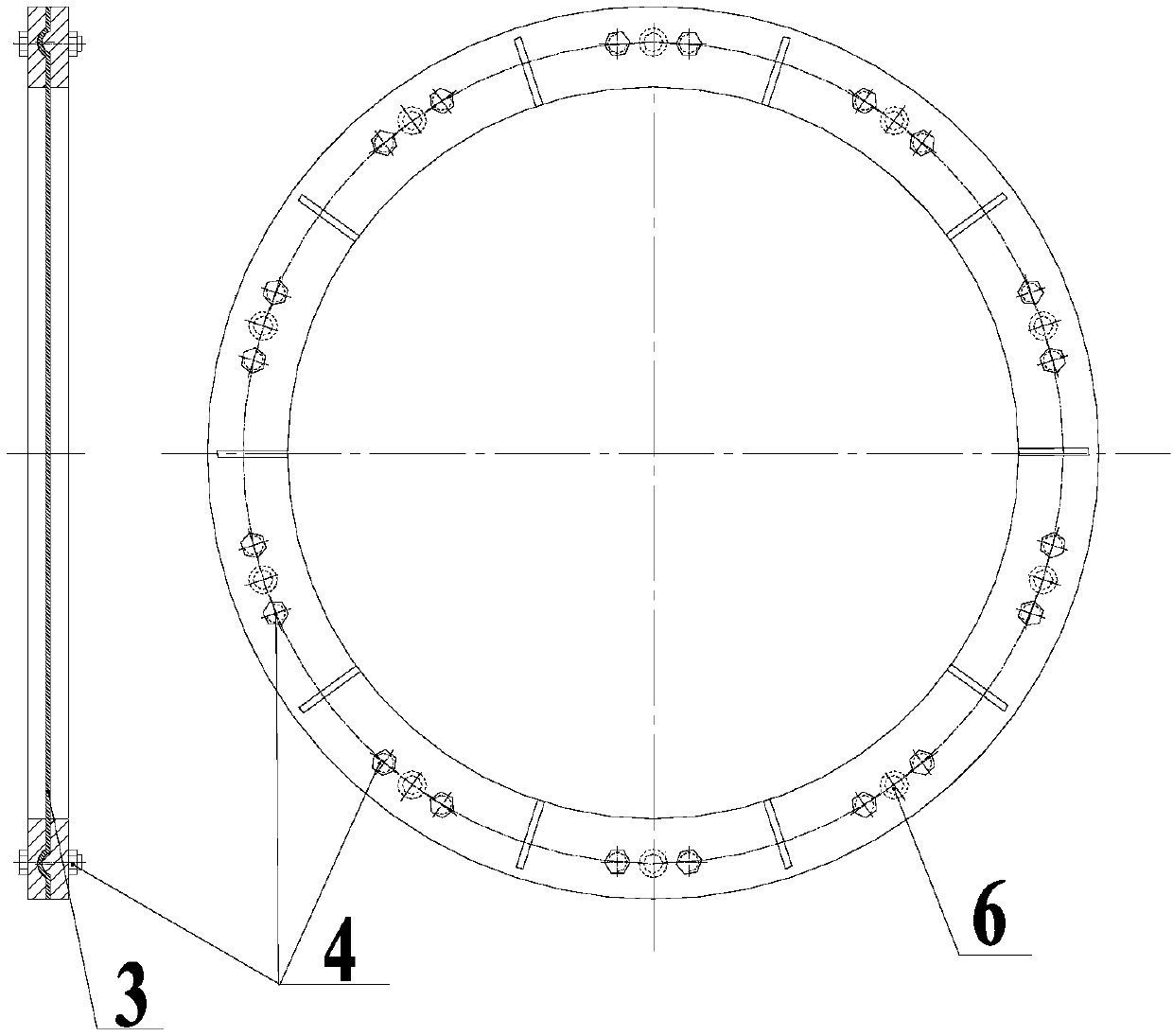

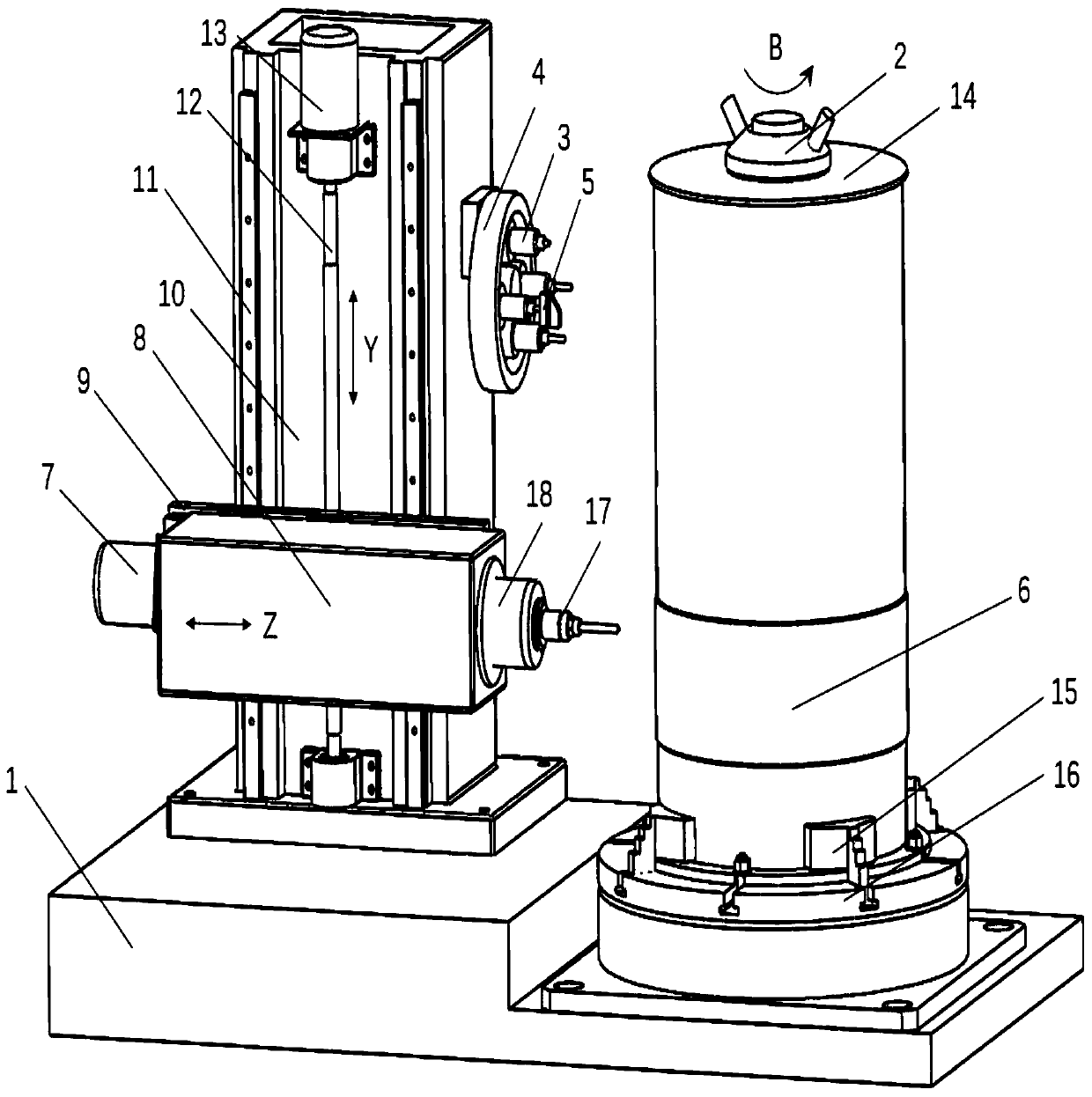

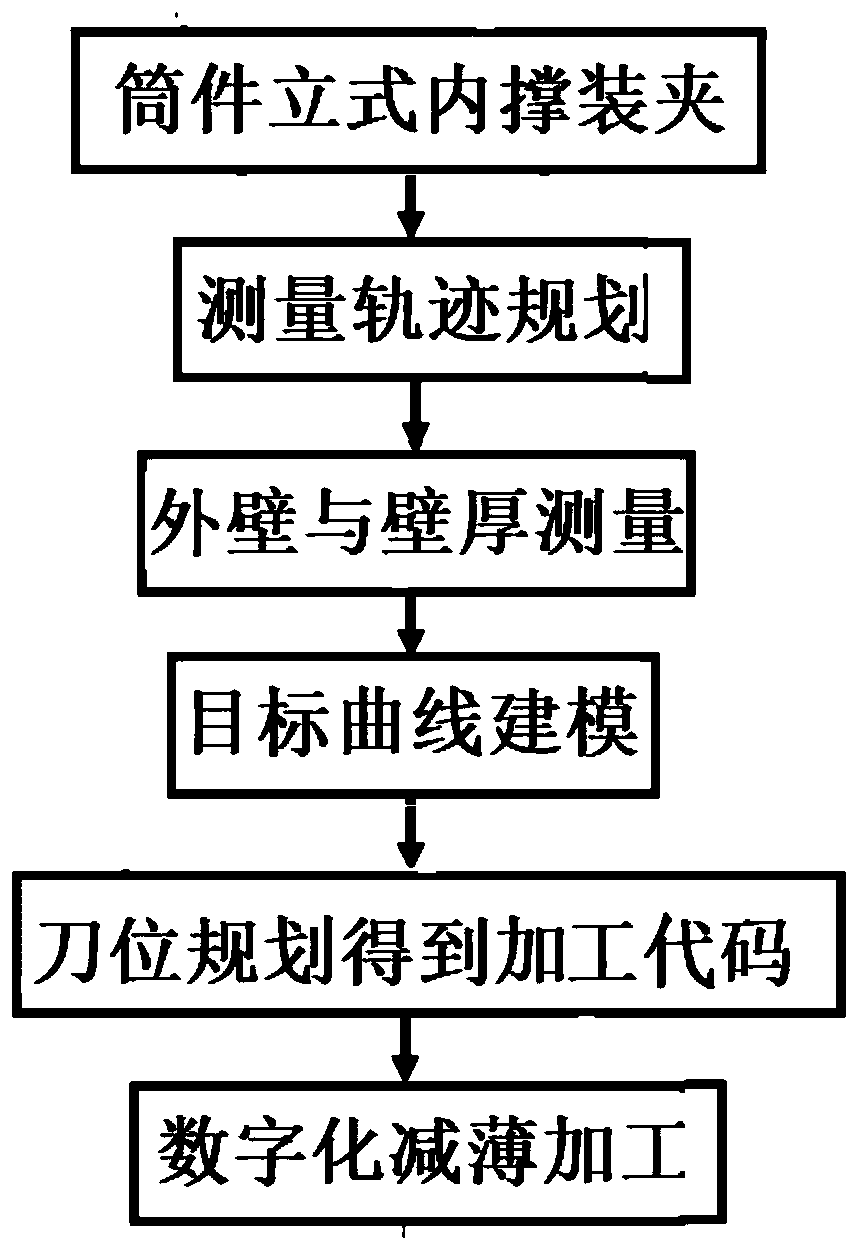

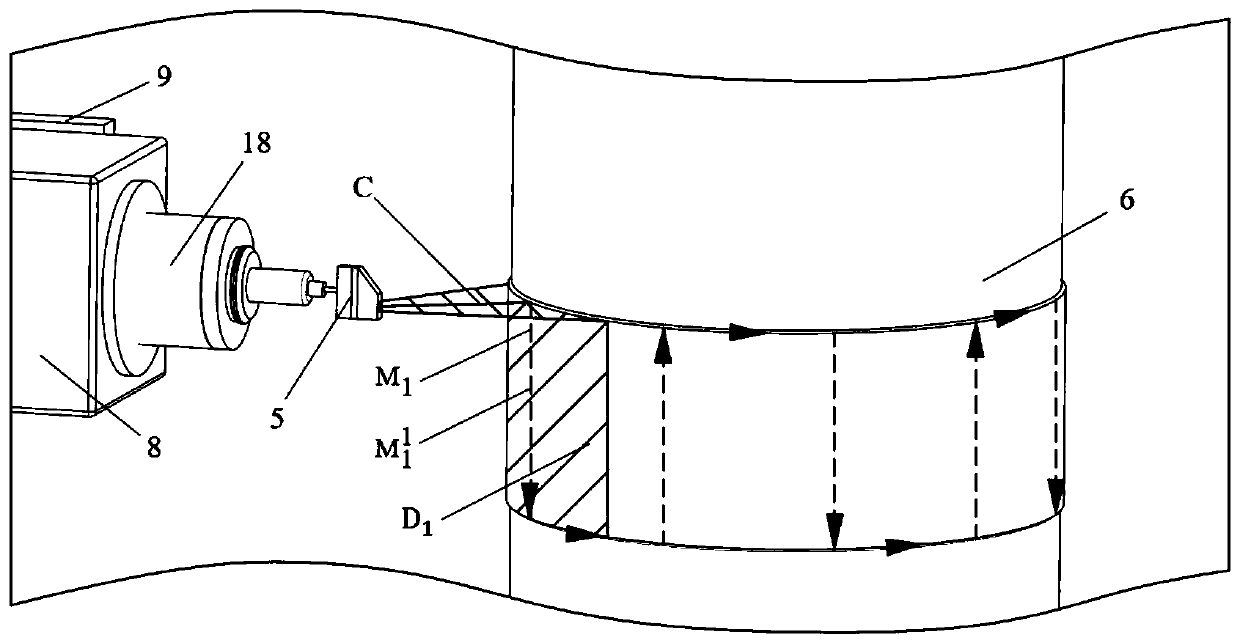

Digitalized thinning machining method for large thin-walled cylinder part

ActiveCN111195830AGuaranteed processing reliabilityEfficient digital thinning processingAutomatic control devicesMeasurement/indication equipmentsNumerical controlEngineering

The invention discloses a digitalized thinning machining method for a large thin-walled cylinder part, and belongs to the technical field of machining. The method comprises the following steps that firstly, a vertical inner support of the large thin-walled cylinder part is clamped, and the external contour and the wall thickness of a thinning section of the cylinder part are scanned and measured on a machine tool by using a line laser measurement device and an ultrasonic measurement device; then by utilizing the actual measurement data of the external contour and the wall thickness of the thin-walled cylinder part and considering the requirement for machining the residual wall thickness, a machining target curved surface of the thinning section is re-established, and a thinning machining code is automatically generated; and finally, the numerical control machine tool finishes thinning machining of the large thin-walled cylinder part through inspection. According to the method, the thinning machining target curved surface associated with the residual wall thickness is re-established by using the part external contour and wall thickness data measured on the machine tool, and the thinning machining code is generated, so that the function integration of CAD, CAM and CNC in the thinning machining of the large thin-walled cylinder part is effectively realized, the manual interventionis reduced, and partitioned thinning machining and equal-wall-thickness or variable-wall-thickness controllable machining of the large thin-wall cylinder part are achieved.

Owner:DALIAN UNIV OF TECH

Dual-band wave beam equalization side-fed offset cassegrain antenna and realization method thereof

ActiveCN102800993AEqual beam widthSimple structureWaveguide hornsAntenna arraysPolarizerStandard form

The invention relates to a dual-band wave beam equalization side-fed offset cassegrain antenna and a realization method thereof. The antenna comprises four pairs of standard side-fed offset cassegrain antennas and each pair of antenna comprises a primary reflector, a secondary reflector and a feed source assembly, wherein the four pairs of the standard side-fed offset cassegrain antennas are in a standard form and are used for receiving and transmitting; each feed source assembly is formed by a plurality of sample strip forming light wall loudspeaker feed sources; each sample strip forming light wall loudspeaker feed source is formed by sequentially connecting a sample strip forming light wall loudspeaker, a square and circle transition, a circular polarizer, a square and square transition and an orthogonal mould coupler; a main lobe of a low-frequency emission directional diagram and a first lateral lobe of a high-frequency receiving directional diagram irradiate the reflectors; and a phase center of each feed source assembly is located on focus planes of the reflectors and points at the center of an equivalent reflection face. According to the dual-band wave beam equalization side-fed offset cassegrain antenna and the realization method thereof disclosed by the invention, an antenna receiving-transmitting directional diagram has the equal beam width; and the dual-band wave beam equalization side-fed offset cassegrain antenna has the advantages of simple structure, portability, easiness for designing, good performance, strong practical applicability and the like, and has the good same frequency interference resistance.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

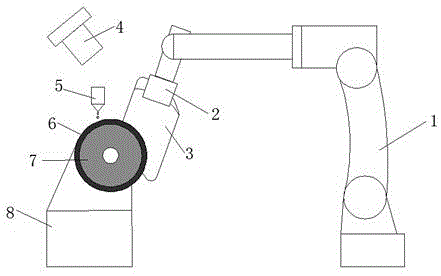

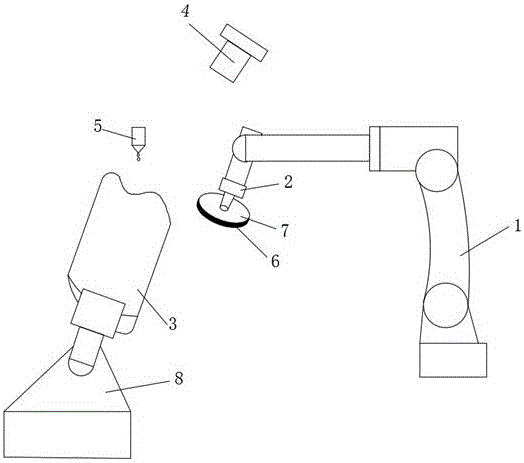

Robot grinding and polishing system based on CMP

ActiveCN105666287AImprove grinding efficiencyImprove efficiencyPolishing machinesGrinding machinesEngineeringMaster controller

The invention discloses a robot grinding and polishing system based on CMP. The robot grinding and polishing system comprises a six-axis robot, a workpiece clamp used for placing workpieces, a contour detection unit used for detecting the workpieces needing to be polished and conducting three-dimensional reconstruction, a grinding wheel with a polishing pad, a base provided with the grinding wheel and a master controller. The free end of the six-axis robot is provided with an electric spindle provided with servo motors. A polishing liquid jetting device capable of jetting CMP polishing liquid to the workpieces is arranged above the workpiece clamp. The workpiece clamp is installed on the electric spindle. The master controller controls the contour detection unit, the six-axis robot, the electric spindle and all the servo motors. The workpiece clamp and the grinding wheel with the polishing pad can also be exchanged in position so as to adapt to polishing of different sizes of workpieces. The robot grinding and polishing system is high in efficiency and good in machining consistency, harmful effects such as mechanical damage and burns which may be caused by common grinding cannot be caused on the workpieces, damage to surfaces or sub surfaces cannot occur, and perfect surfaces can be machined.

Owner:WUHAN UNIV

Prepn process of heat isolating C/C screen for monocrystal silicon drawing furnace and polycrystal silicon smelting furnace

The present invention relates to preparation process of heat isolating C / C screen for monocrystal silicon drawing furnace and polycrystal silicon smelting furnace. The preparation process includes preparing 3D heat isolating screen prefab with carbon fiber; dipping the prefab in mid-temperature pitch or furfural acetone resin and charring repeatedly to reach the compactness of 1.30 g / cu cm; high temperature purifying the heat isolating screen through introducing chlorine and Freon; and final machining to obtain the heat isolating C / C screen for monocrystal silicon drawing furnace and polycrystal silicon smelting furnace. The heat isolating C / C screen for monocrystal silicon drawing furnace and polycrystal silicon smelting furnace has effectively lowered thermal conductivity coefficient, low cost and long service life.

Owner:XIAN CHAOMA SCI TECH

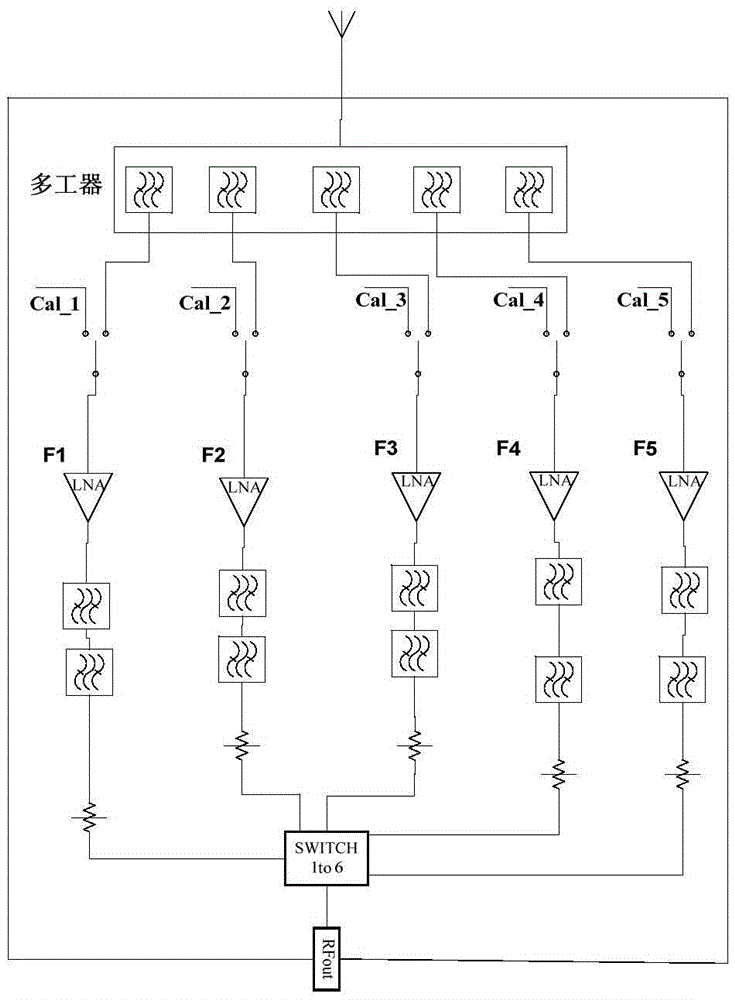

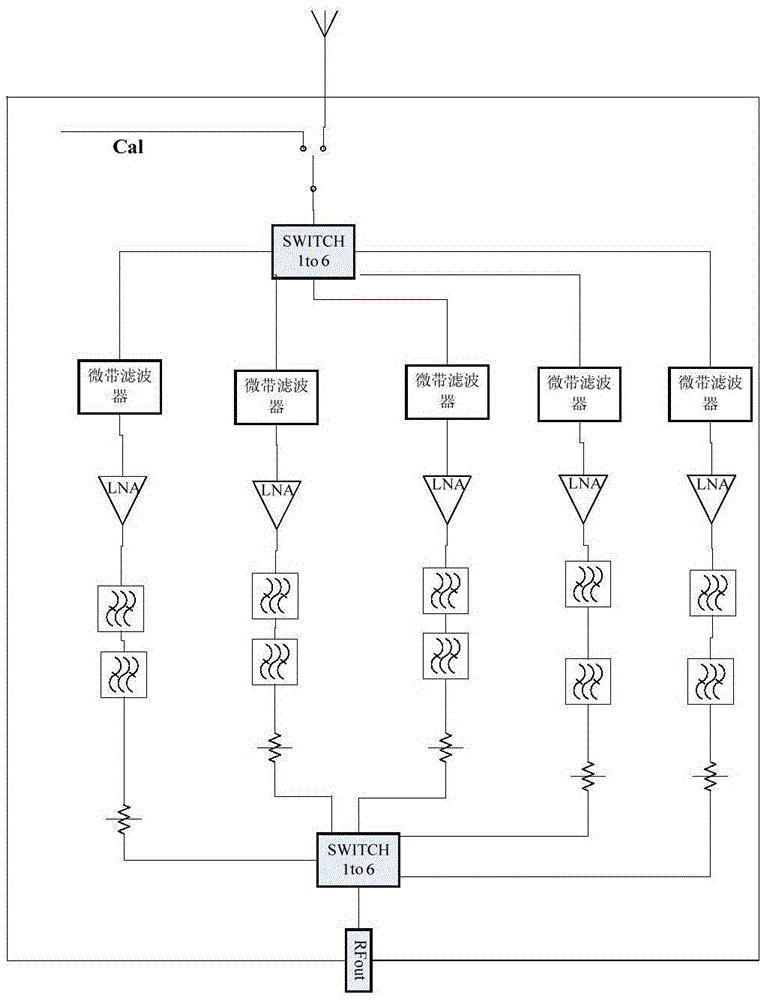

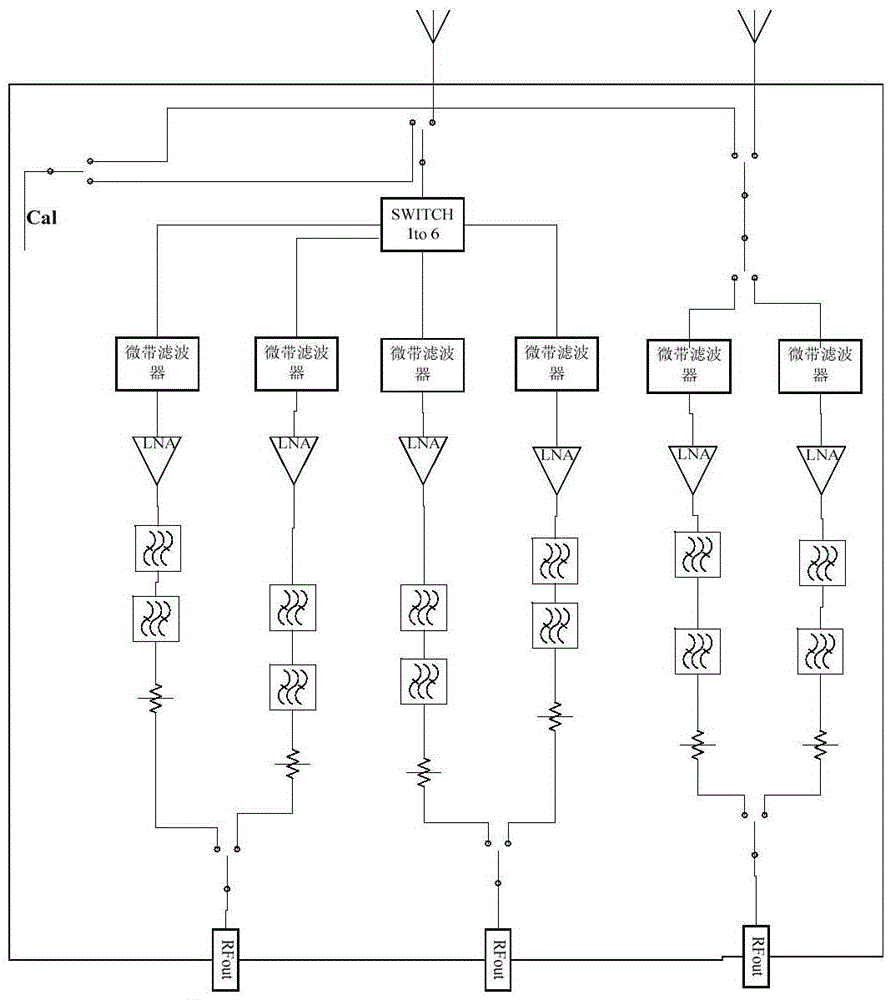

Radio frequency front-end frequency selection circuit and signal receiving method thereof

The invention discloses a radio frequency front-end frequency selection circuit and a signal receiving method thereof. The circuit comprises: an antenna used for coupling and receiving a radio frequency signal; a first multipath switch used for selecting the radio frequency signal to a microstrip filter of a corresponding frequency band; the microstrip filter used for filtering an out-of-band interference signal; a low noise amplifier used for amplifying the useful radio frequency signal; and a filter group used for filtering the amplified signal; a second multipath switch used for switching the radio frequency signal obtained by the filter group to a subsequent link of a receiver to be processed. The method comprises the steps that: the radio frequency signal is coupled to a radio frequency link by the antenna, the first multipath switch switches the radio frequency signal to the microstrip filter of the corresponding frequency band, the microstrip filter filters the out-of-band interference signal and amplifies and filters the useful signal for the second time, and finally the signal is switched to the subsequent link of the receiver to be processed. The radio frequency front-end frequency selection circuit disclosed by the invention has the advantages of miniaturization, integration and strong expansibility.

Owner:GUANGZHOU HUIRUI SITONG INFORMATION SCI & TECH CO LTD

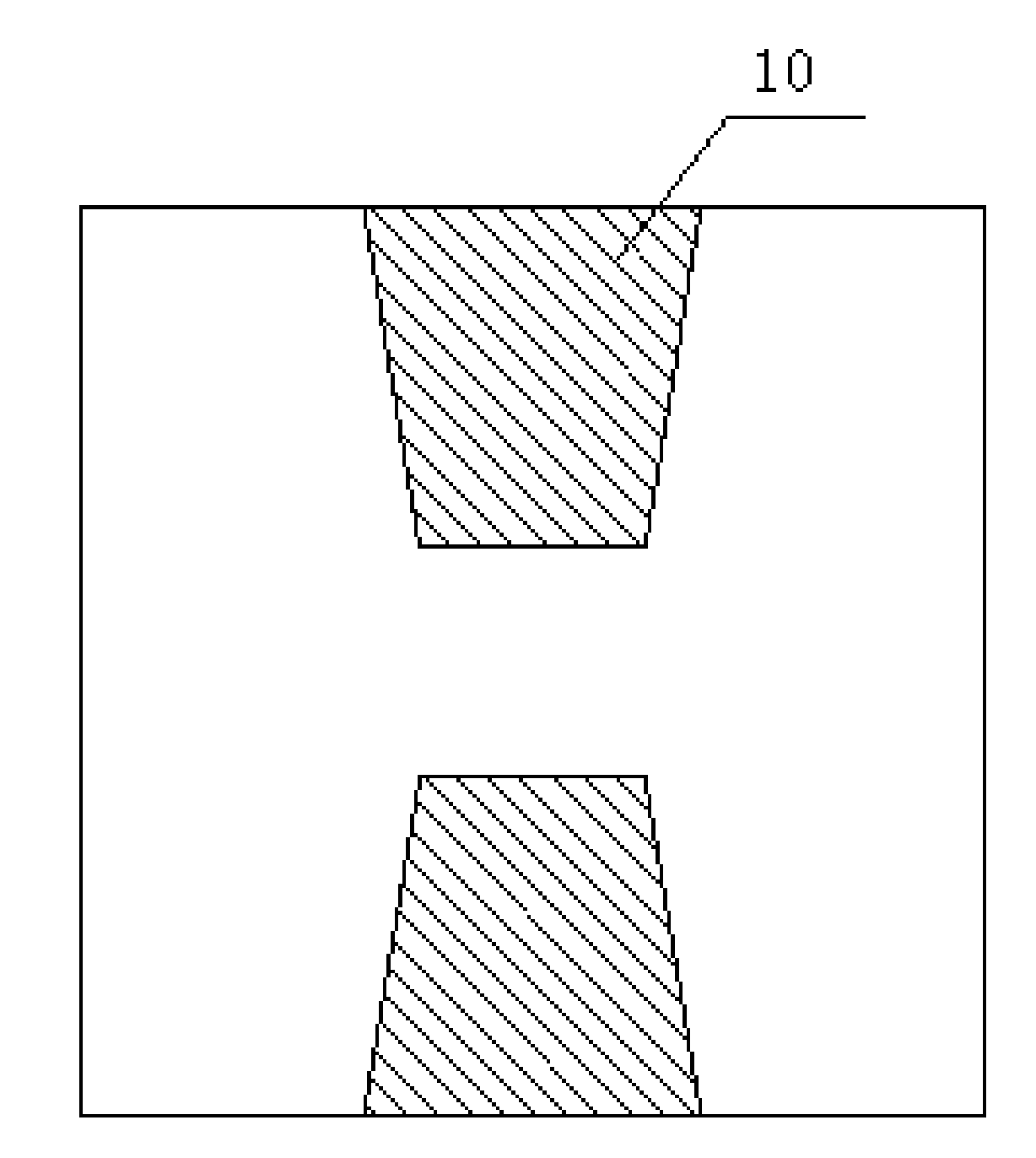

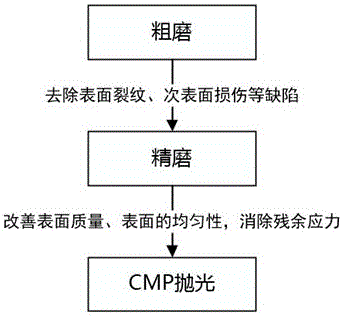

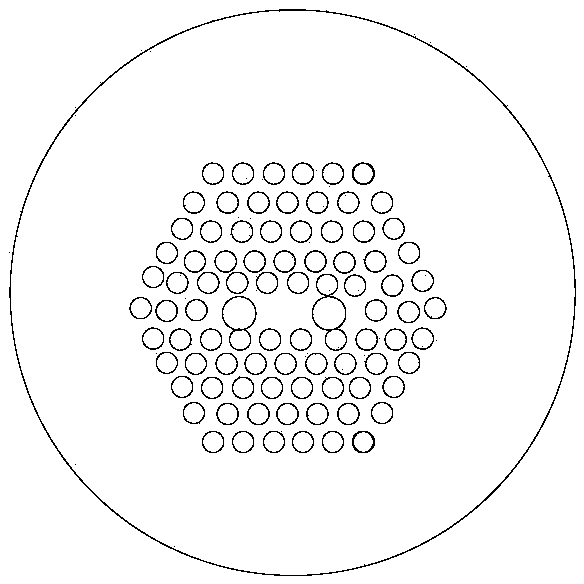

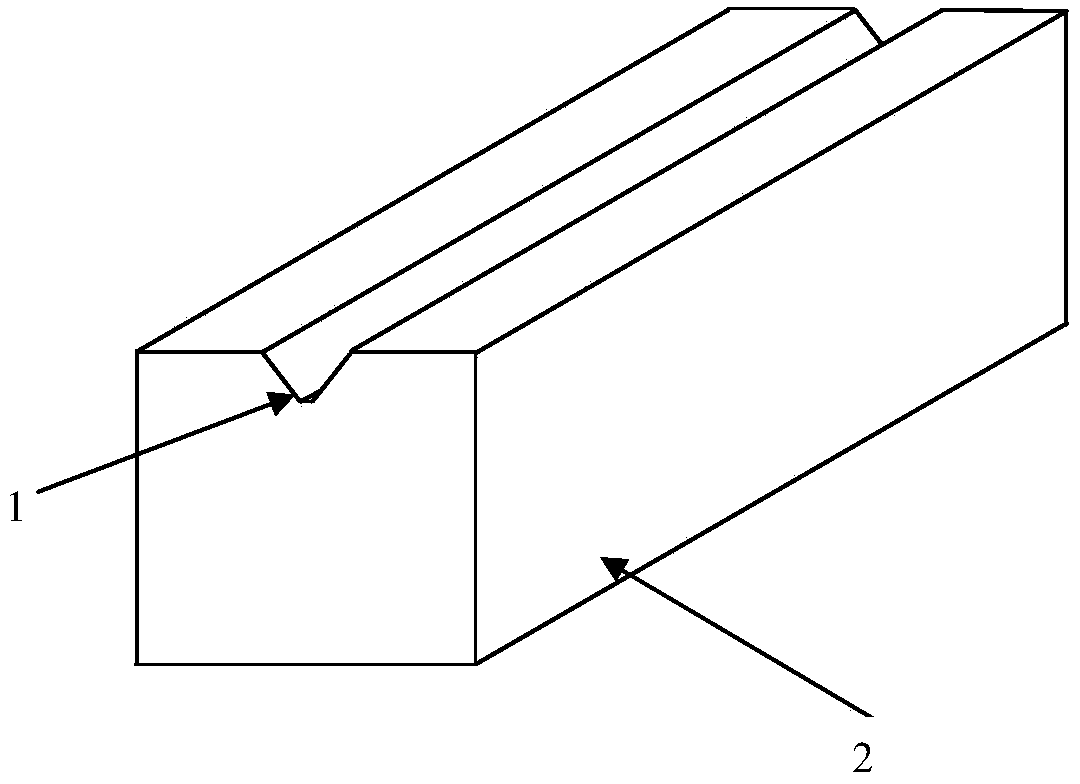

Photonic crystal fiber grinding and polishing technology method

ActiveCN103792619AAchieve regulationImprove machining accuracyCoupling light guidesPhotonic crystalTotal internal reflection

The invention discloses a photonic crystal fiber grinding and polishing technology method. The method comprises the steps that preparation before photonic crystal tail fiber grinding and polishing is conducted; clamping of a photonic crystal tail fiber is conducted; rough grinding is conducted on the end face of the photonic crystal optical fiber; fine grinding is conducted on the end face of the photonic crystal optical fiber; accurate grinding is conducted on the end face of the photonic crystal optical fiber; polishing is conducted on the end face of the photonic crystal optical fiber; examination is conducted on the end face of the optical fiber. According to the grinding and polishing technology method, the wet corrosion photo-etching technology or the cutting technology is adopted, a V-shaped groove is formed in an optical fiber fixing block, the CMP technology where a certain angle is formed between a polishing plane of the end face of the photonic crystal optical fiber and the cross section of the optical fiber is introduced on the basis of common photonic crystal end face grinding and polishing, the photonic crystal optical fiber prepared through the technology method can guarantee that loss of tail fibers is small and the method can be used for grinding and polishing for the angle between the end face of a whole-inner-reflection type photonic crystal optical fiber and the end face of a photonic band gap type photonic crystal optical fiber.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

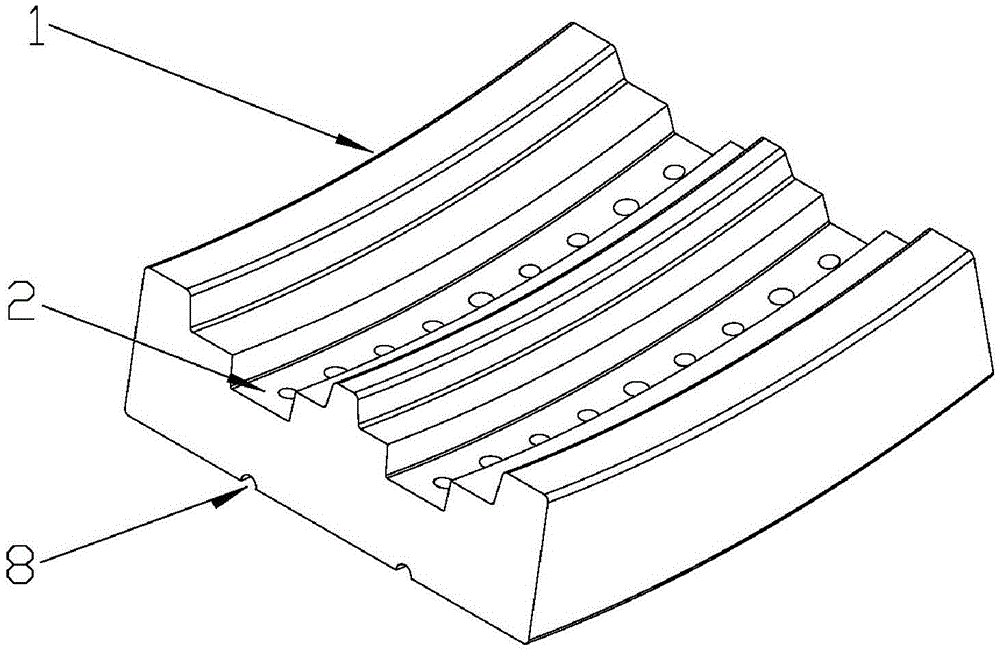

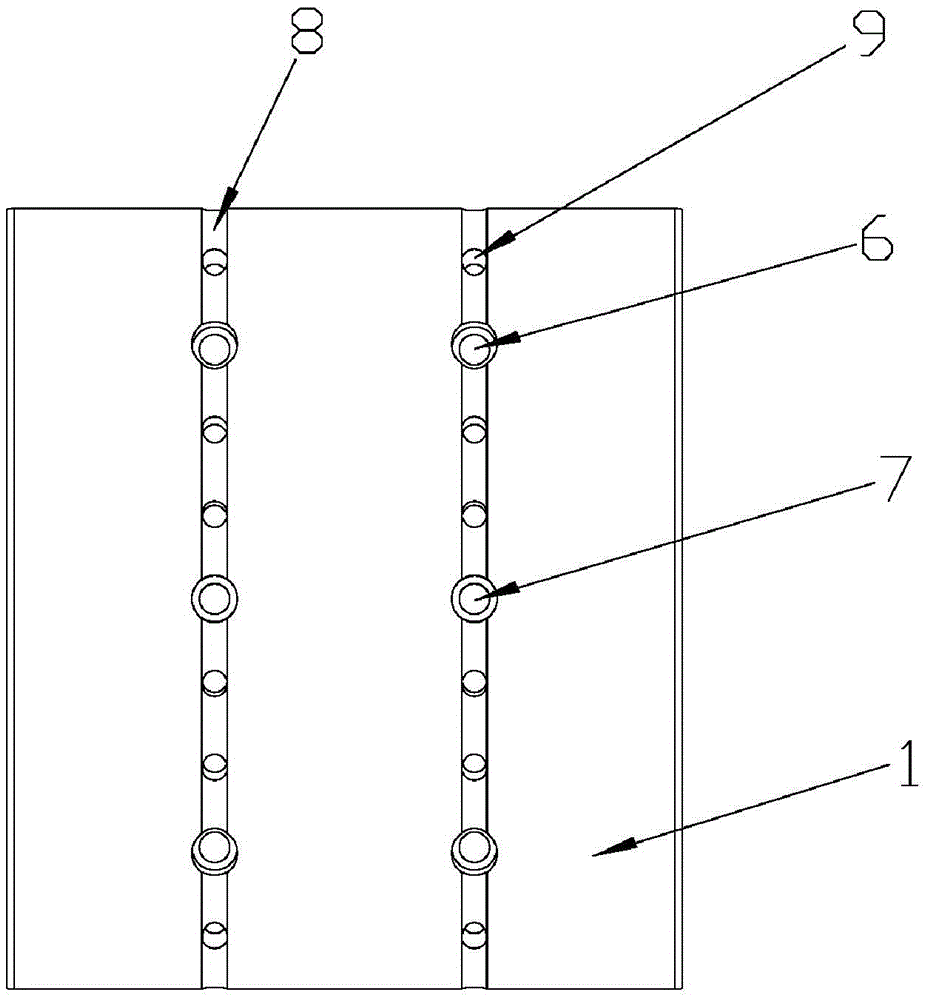

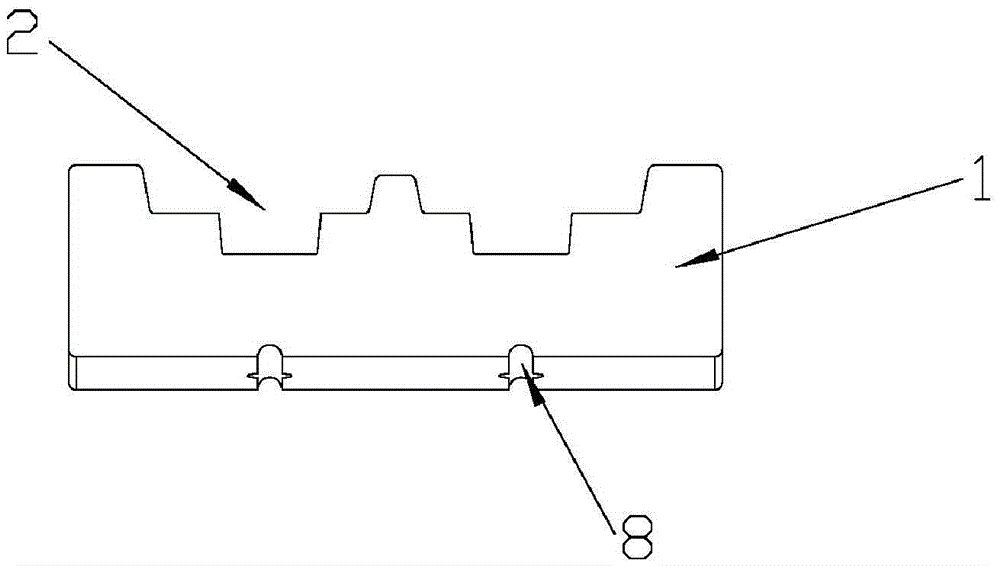

Pattern rib inlaid-type pore-free tire mold and pattern block thereof

ActiveCN105459300ASolve the problem that can only be processed by handImprove processing efficiencyTyresEngineeringPattern processing

The invention provides a pattern block of a pattern rib inlaid-type pore-free tire mold. The pattern block comprises a pattern block body and pattern rib main bodies, wherein the inner wall surface of the pattern block body is concavely provided with pattern rib inlaying grooves; the pattern block body is provided with exhaust passages for enabling the inner wall surface of the pattern block to communicate with the outer wall surface of the pattern block; each pattern rib main body comprises a pattern rib substrate and a pattern rib; each pattern rib substrate is inlaid into the corresponding pattern rib inlaying groove; each pattern rib is arranged at the inner side of the corresponding pattern rib substrate; circumferential exhaust lines are respectively arranged at included angles formed by each pattern rib and the corresponding pattern rib substrate; the circumferential exhaust lines communicate with the corresponding exhaust passage. The invention also provides the pattern rib inlaid-type pore-free tire mold, which is formed by splicing a plurality of pattern blocks side by side; the inner wall surfaces of the pattern blocks define an inner cavity of the pattern rib inlaid-type pore-free tire mold; the circumferential exhaust lines and the exhaust passages of the pattern blocks enable the inner cavity to communicate with the exterior of the pattern rib inlaid-type pore-free tire mold. According to the pattern block of the pattern rib inlaid-type pore-free tire mold and the pattern rib inlaid-type pore-free tire mold provided by the invention, only exhaust can be performed without material running, therefore an effect without pores is achieved, the efficiency and the consistency of pattern processing can be improved, and the quality of the tire mold is ensured.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

Process for producing carbon/carbon heat insulation bottom board for high temperature furnace

ActiveCN101269981AAppropriate densityLow thermal conductivitySpecial form destructive distillationPlain weaveThermal conductivity

The present invention relates to a preparation method of C / C insulating bottom plate that is used for a high-temperature furnace. In the method, carbon fiber plain weaves or twill is laid alternately with fetus of thin carbon fiber network; axial needle prick is used for preparing the prefabricated body of the low-density insulating bottom plate; furfural acetone resin or phenolic resin is used for vacuum impregnation, curing, carbonizing and densifing the prefabricated body of the insulating bottom plate; the prefabricated body is repeatedly densified 2 to 4 times until the density reaches more than or equal to 0.50g / cm<3>; after the densification, the prefabricated body is processed through high-temperature purification under the conditions with chlorine or Freon; and the C / C insulating bottom plate, which is used for a high-temperature furnace, can be prepared after mechanical processing. The preparation method has the significant characteristics that: first, the conditions for densification are simplified, the costs are reduced, and the preparation method is suitable for producing large-size products; secondly, the resin carbon-based matrix reduces the thermal conductivity of the C / C insulating bottom plate, improves the effects of heat preservation in the hot field and saves energy; and thirdly, the C / C insulating bottom plate has high mechanical properties, and the service life is prolonged.

Owner:XIAN CHAOMA SCI TECH

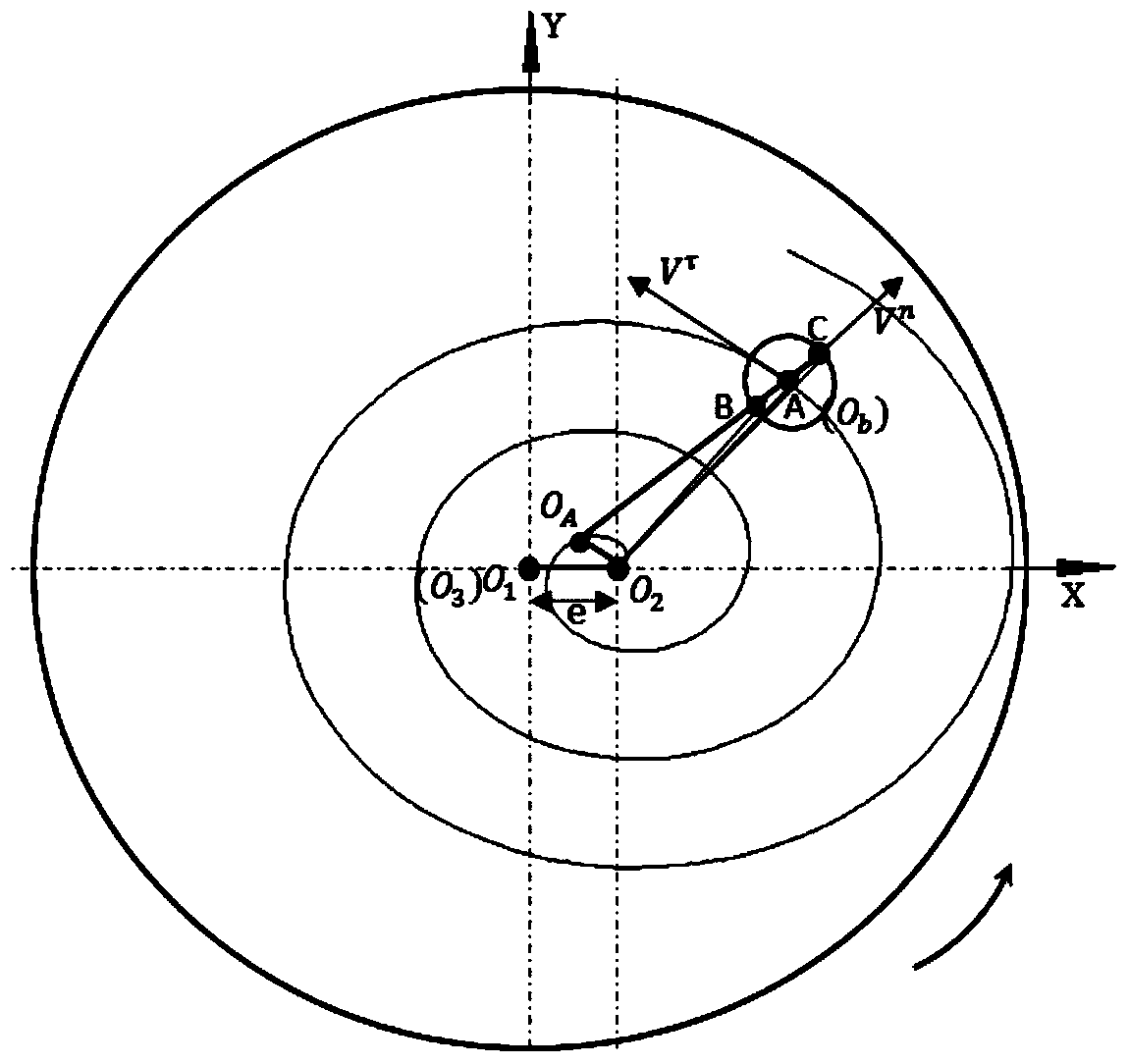

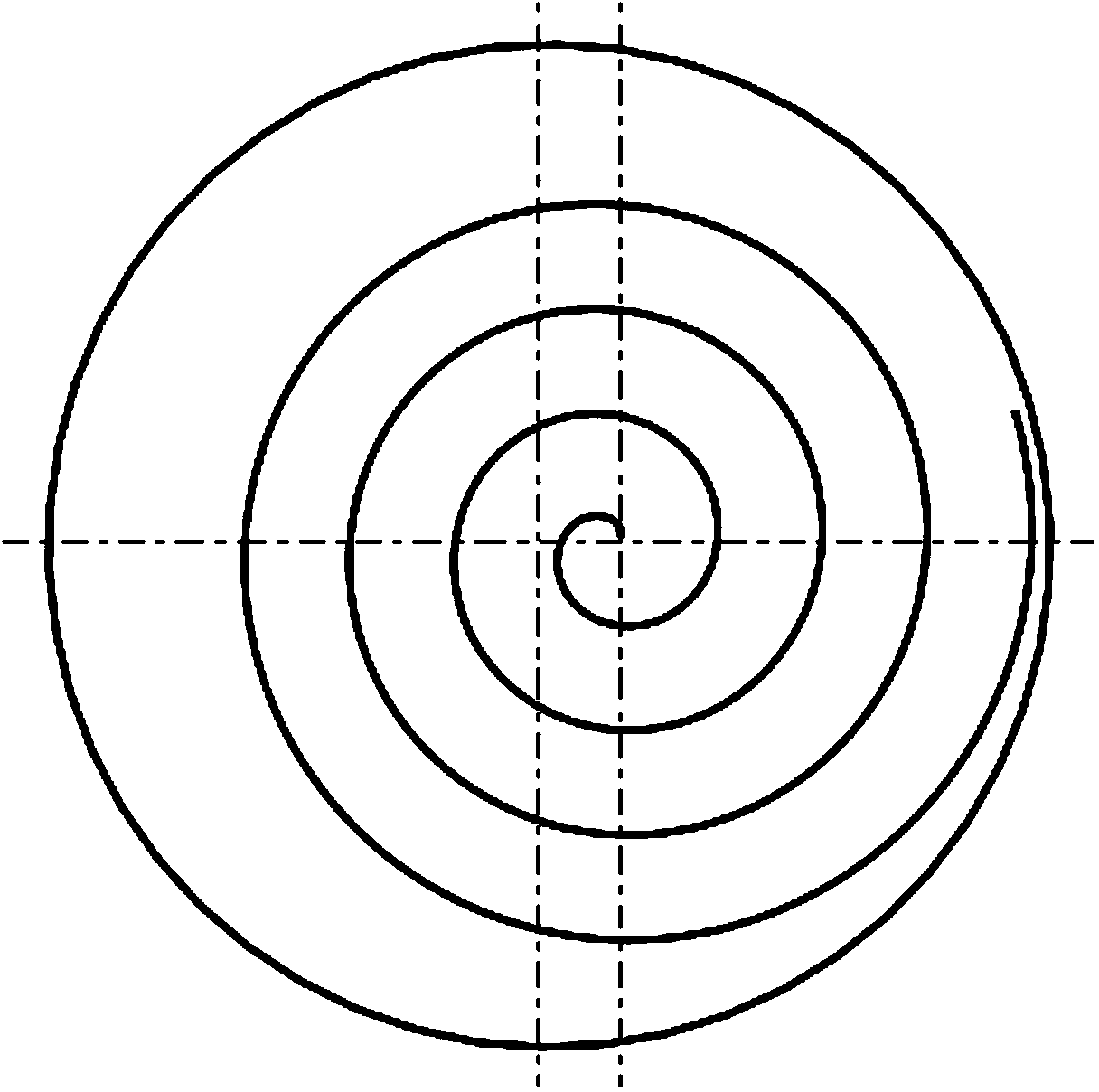

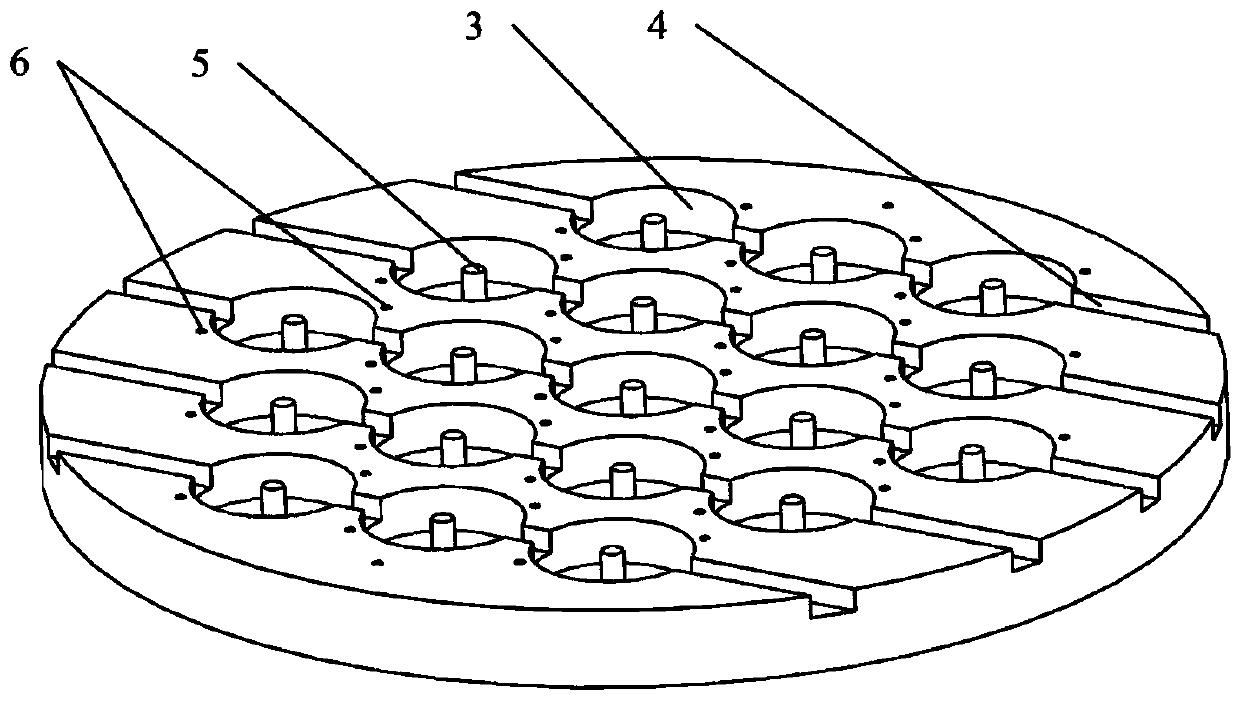

High-accuracy sphere machining device based on eccentric variable-curvature V-shaped grooved disc

InactiveCN103991018AHigh precisionImprove consistencyGrinding carriagesSpherical surface grinding machinesEngineeringMachining

A high-accuracy sphere machining device based on an eccentric variable-curvature V-shaped grooved disc comprises a rack, an upper grinding disc, a lower grinding disc and a loading system, wherein the upper grinding disc is peripherally and fixedly installed on the rack, the lower grinding disc is connected with a lower grinding disc spindle, the lower grinding disc spindle is rotatably installed on the rack, the lower grinding disc spindle is connected with a driving mechanism, the upper grinding disc is located right above the lower grinding disc, the loading system is located on the upper grinding disc, a sphere inlet is formed in the center of the upper grinding disc, a machining liquid inlet is arranged nearby the sphere inlet, the top face of the lower grinding disc is provided with a variable-curvature V-shaped groove, an eccentric distance exists between a starting point of the variable-curvature V-shaped groove and the center of the lower grinding disc, the lower end of the sphere inlet is communicated with an inlet of the variable-curvature V-shaped groove, an inlet of a sphere blank circulating system is connected with an outlet of the variable-curvature V-shaped groove, and an outlet of the sphere blank circulating system is connected with the upper end of the sphere inlet. The high-accuracy sphere machining device can achieve high machining accuracy and machining efficiency and have low device requirement.

Owner:ZHEJIANG UNIV OF TECH

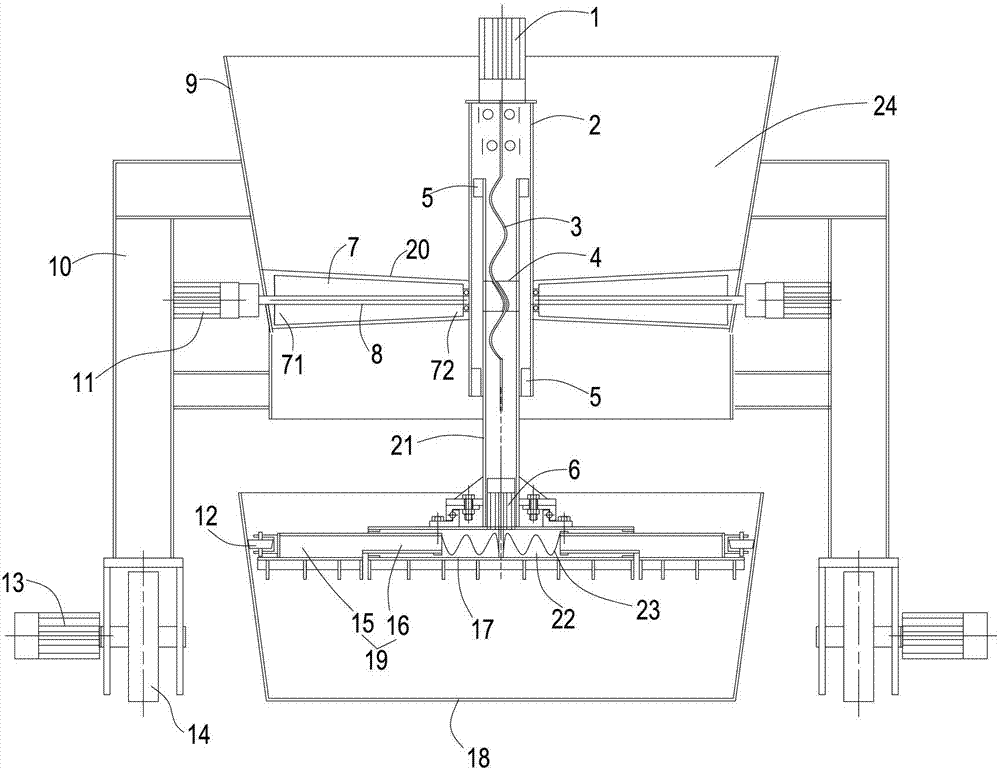

Automatic distillation device

ActiveCN103045422AImprove labor intensityImprove process consistency and specificationAlcoholic beverage preparationEngineeringDistillation

The invention discloses an automatic distillation device, which is favorable to the guarantee of the uniformity for spreading vinasse and has high distillation efficiency. The automatic distillation device comprises a hopper, wherein a material loading cavity is formed inside the hopper, a material conveying port is formed at the bottom of the material loading cavity, a material conveying mechanism which is connected with the hopper is arranged inside the hopper below the material conveying port, a lifting mechanism which is connected with the hopper is also arranged inside the hopper, and a feeding mechanism which is connected with the bottom of the lifting mechanism is arranged below the hopper. The automatic distillation device further comprises a hopper driving device which drives the hopper to move in a horizontal direction. The device can guarantee the uniformity for spreading vinasse, has high distillation efficiency, achieves mechanical distillation operation, improves the labor intensity of workers, the consistency and the standardization of the process, and is favorable to the stability of the liquor quality and the increase of the liquor yield.

Owner:WULIANGYE

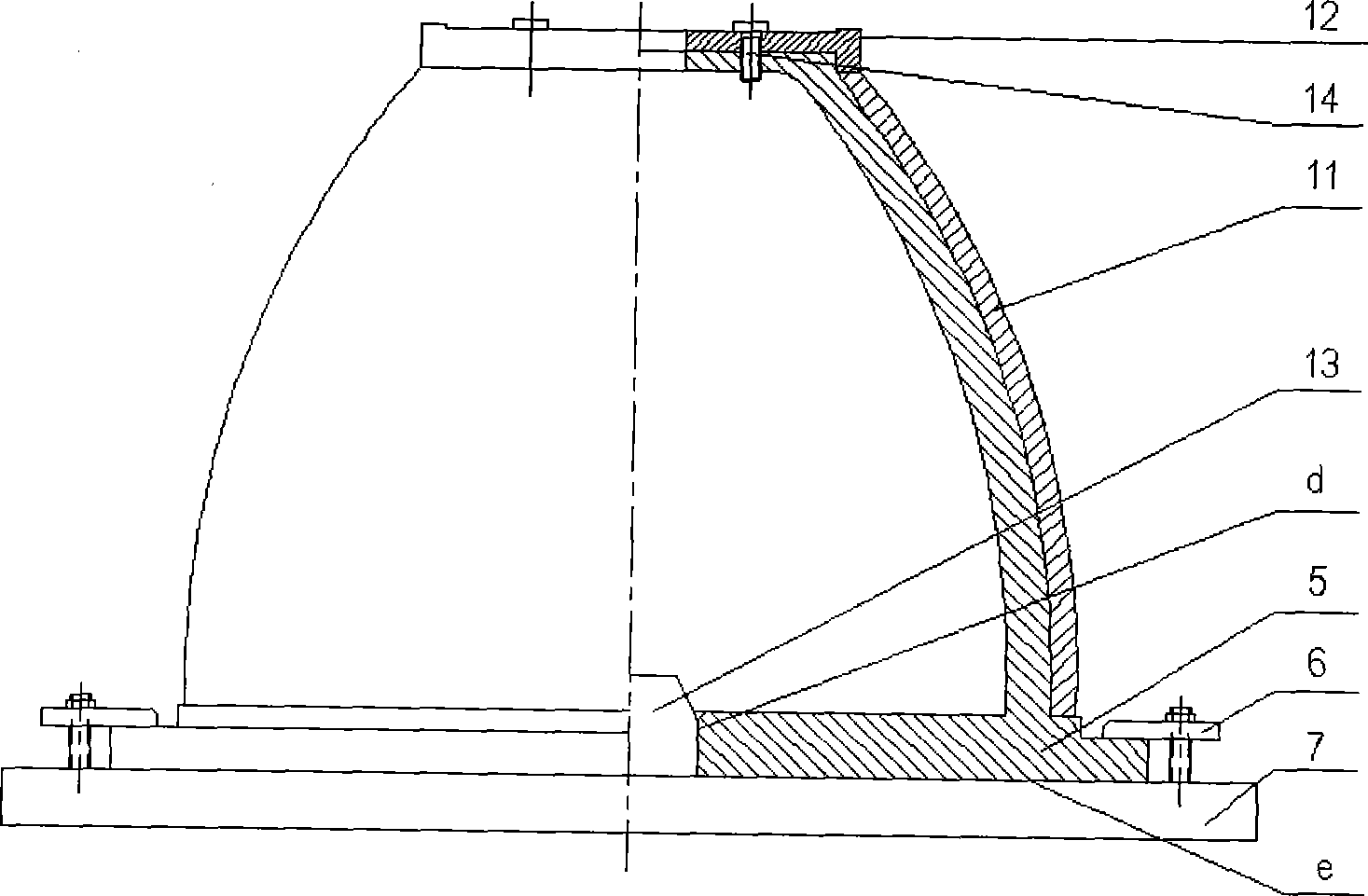

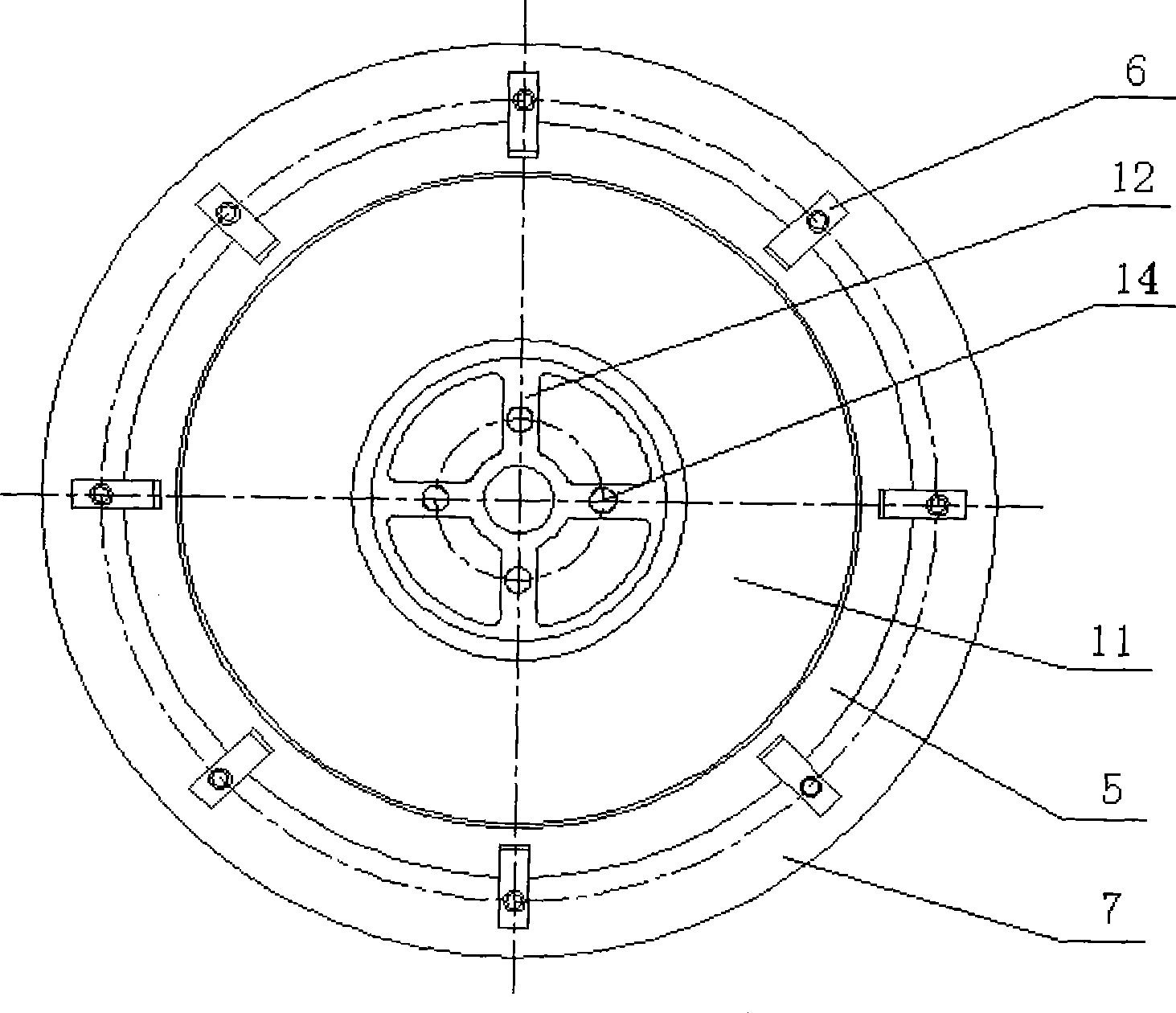

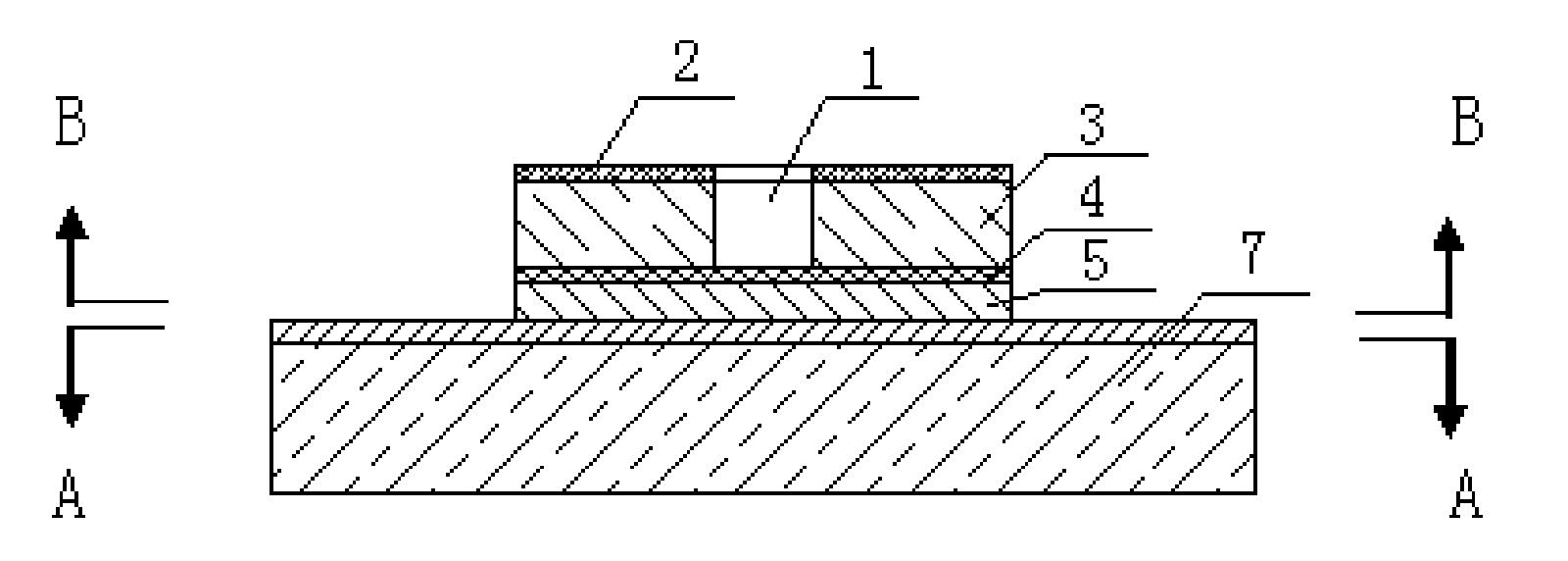

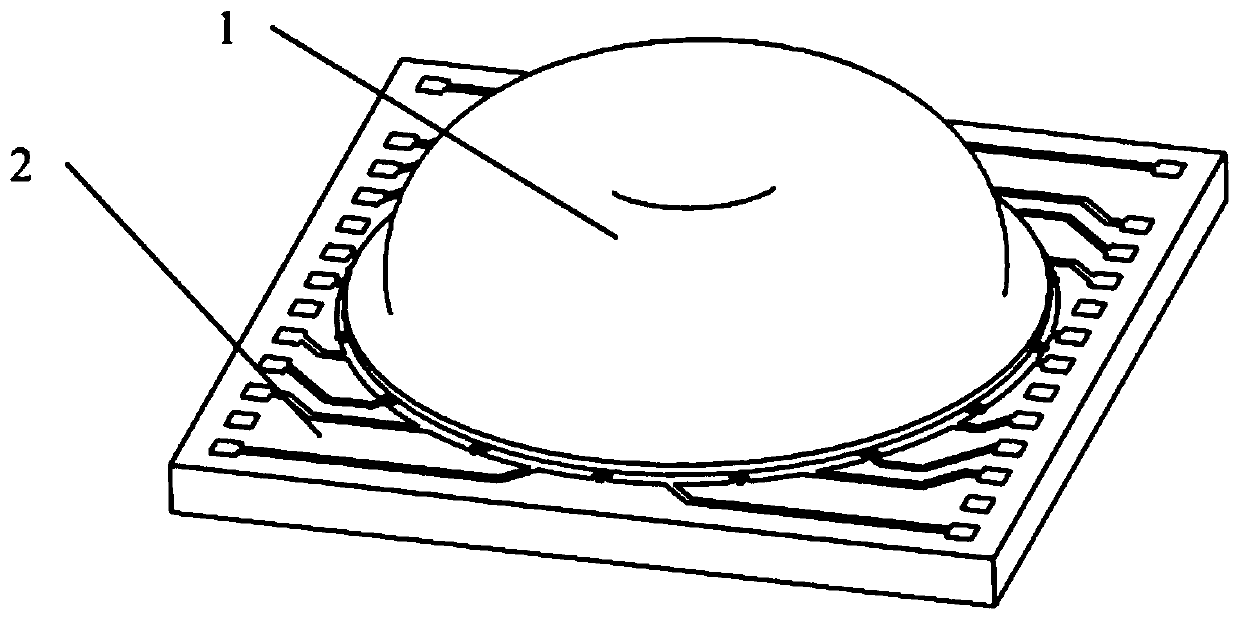

Micro-hemispherical resonator gyro structure, assembly method and wafer fixture

InactiveCN110749315AReduce assembly errorsImprove stabilitySpeed measurement using gyroscopic effectsMicrostructural device assemblyPhysicsResonator

The invention relates to a micro-hemispherical resonator gyro structure, an assembly method and a wafer fixture. The invention discloses a micro-hemispherical resonator gyro structure wafer level assembly method, comprising the following steps: performing high temperature softening deformation machining and forming on independently manufactured glass sheets, then forming a micro-hemispherical resonant structures in the middle of each glass sheet, cutting glass sheet locating holes at the two ends of each glass sheet by adopting laser cutting, and by taking the locating holes as a benchmark, aligning multiple micro-hemispherical resonant structures which are the same and fixing the same micro-hemispherical resonant structures on the wafer fixture; and then performing operations by taking the wafer fixture as a unit, and completing subsequent processes, namely micro-hemispherical resonant structure releasing, surface metallization, fixation with a planar electrode, separation from the wafer fixture as well as cleaning, thus the micro-hemispherical resonator gyro structure driven by the planar electrode at the bottom is obtained. The micro-hemispherical resonator gyro structure waferlevel assembly method disclosed by the invention fixes and mounts multiple independently manufactured micro-hemispherical resonant structures on the same wafer fixture, a wafer level mounting operation is realized, an assembly error of the micro-hemispherical resonator gyro structure can be obviously reduced, stability and consistency of the processes as well as assembly efficiency are improved.

Owner:NAT UNIV OF DEFENSE TECH

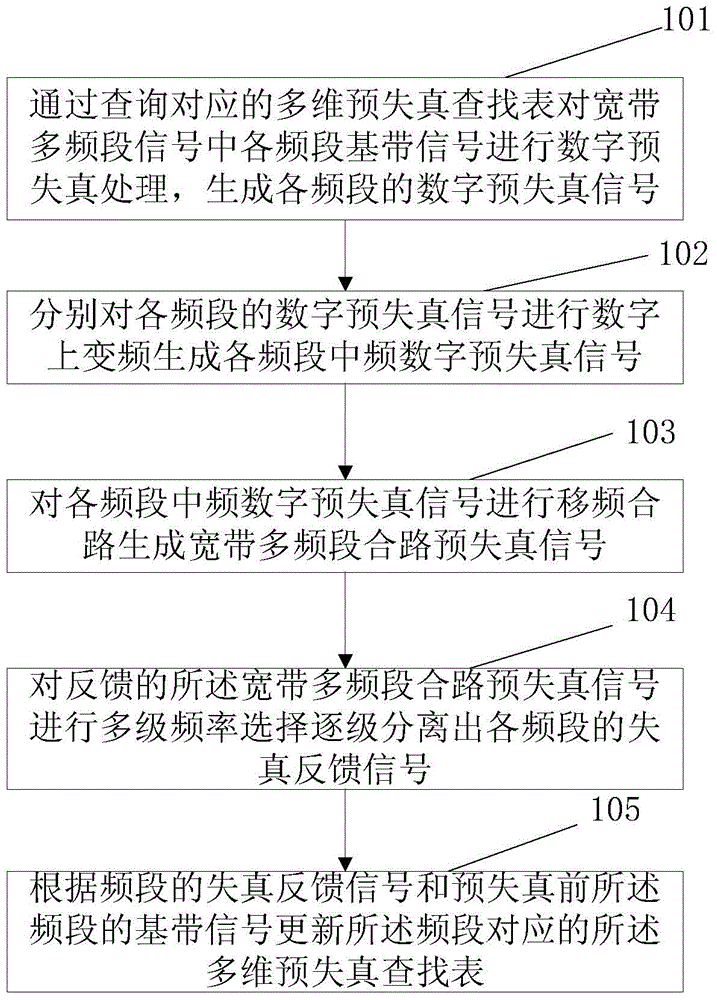

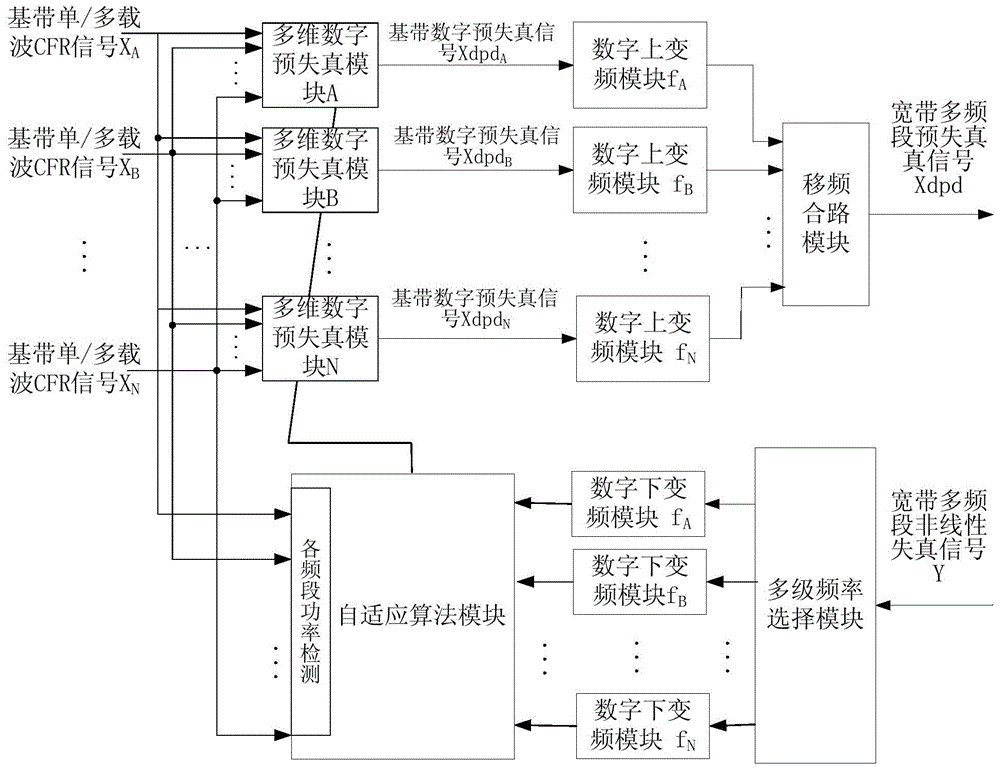

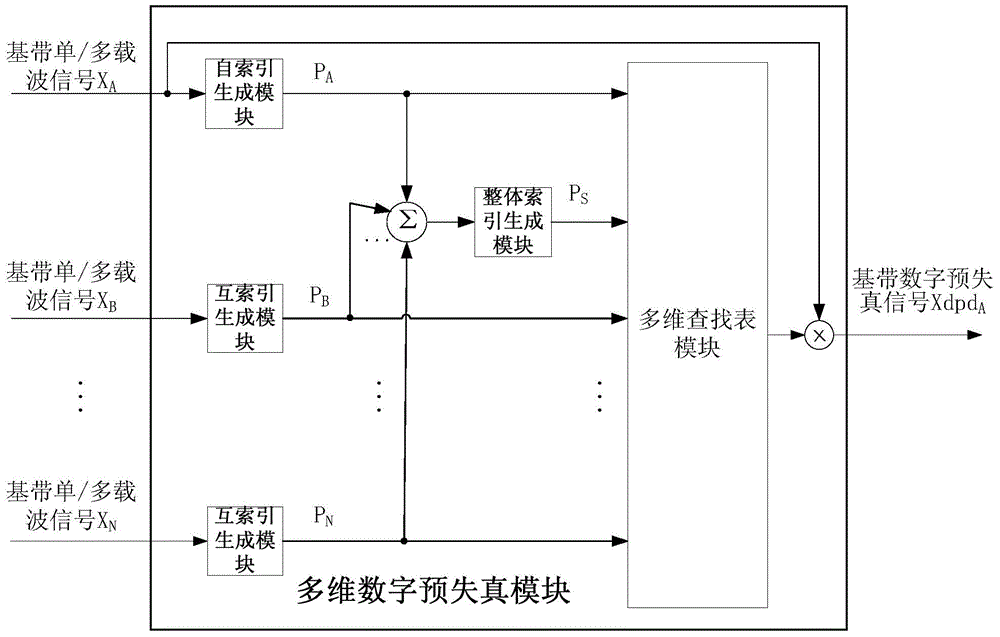

Digital pre-distortion method and device

ActiveCN105763495ASave resourcesGood processing consistencySynchronous/start-stop systemsIntermediate frequencyLookup table

The invention discloses a digital pre-distortion method and device. The method comprises the steps: carrying out the digital pre-distortion processing of baseband signals of a broadband multiband signal at all frequency bands through searching a corresponding multi-dimensional pre-distortion lookup table, and generating digital pre-distortion signals at all frequency bands; respectively carrying out the digital up-conversion of baseband digital pre-distortion signals at all bands, and generating intermediate frequency digital pre-distortion signals at all bands; carrying out the frequency shift path combination of the intermediate frequency digital pre-distortion signals at all bands, and generating a broadband multiband path combination pre-distortion signal; carrying out the multistage frequency selection of the feedback broadband multiband path combination pre-distortion signal, and separating the distortion feedback signals at all bands step by step; and updating the multi-dimensional pre-distortion lookup table corresponding to the frequency band according to the distortion feedback signal and the baseband signal of the frequency band before pre-distortion. Compared with the prior art, the method can reduce the hardware resources, improves the inter-band processing consistency, and reduces the DPD processing rate.

Owner:ZTE CORP

Preparation method of porous oxide semiconductor nano-film

InactiveCN103451609APrecise thickness controlLarge specific surface areaVacuum evaporation coatingSputtering coatingComposite filmCrystallinity

The invention relates to a preparation method of a porous oxide semiconductor nano-film. The technical scheme of the preparation method is as follows: a film is simultaneously or alternately deposited on the surface of a substrate in the presence of Ar or a mixed atmosphere of Ar and O2 by using a co-sputtering technique and adopting an oxide semiconductor target (or a corresponding metal target) and a pore former target, then a composite nano-film with an oxide phase and a pore former phase is preformed, after the preformed composite film is washed by water, a pore former is dissolved, then a porous nano-film is obtained, finally, the film is dried and annealed to obtain a nano-film with good crystallinity, high orientation and high porosity.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

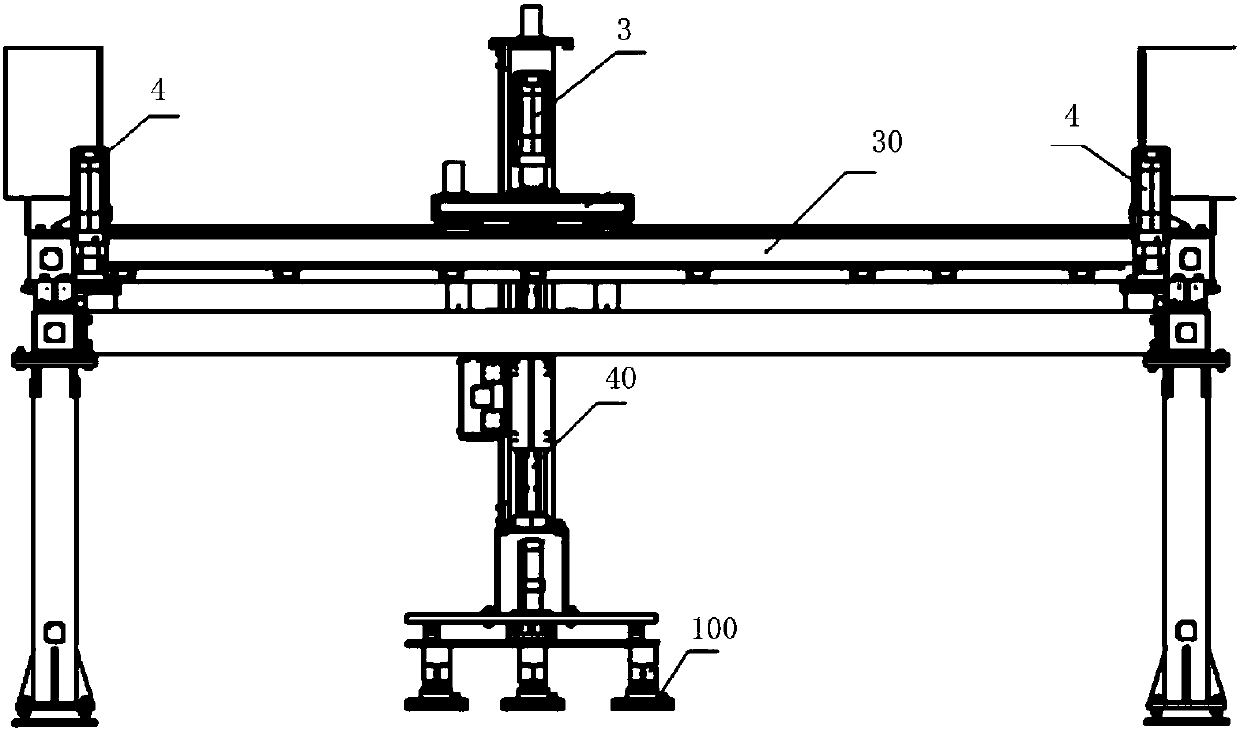

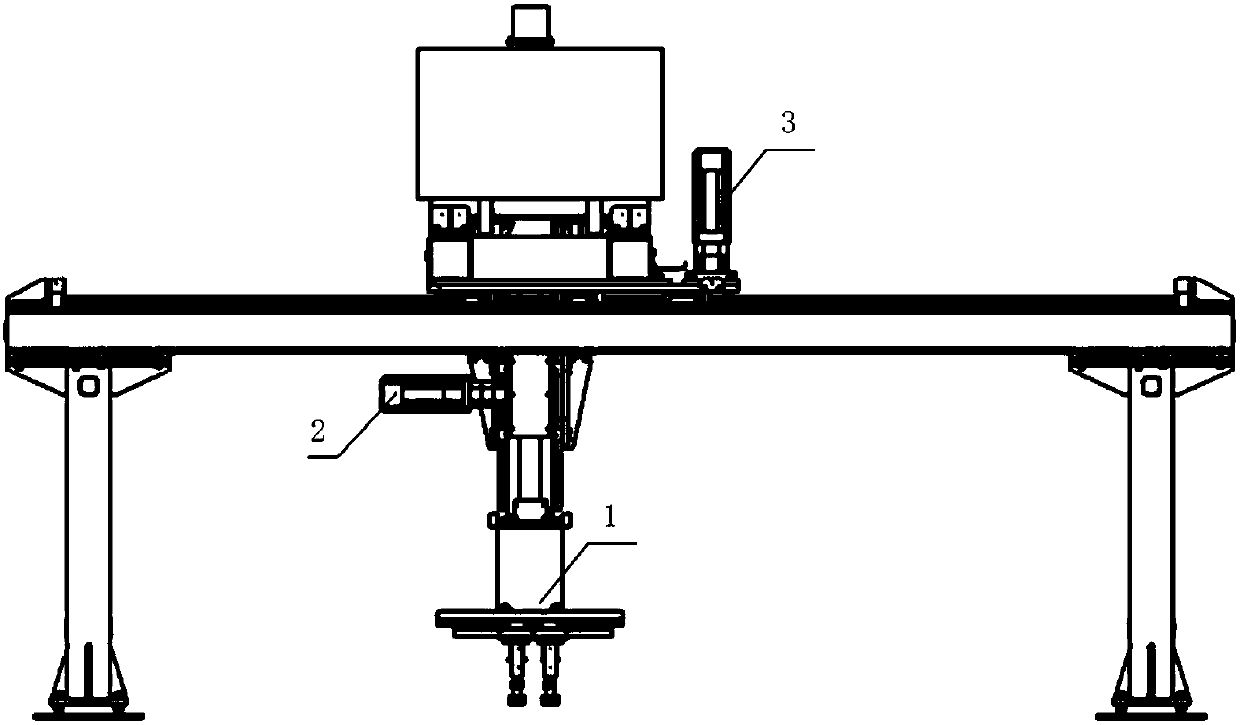

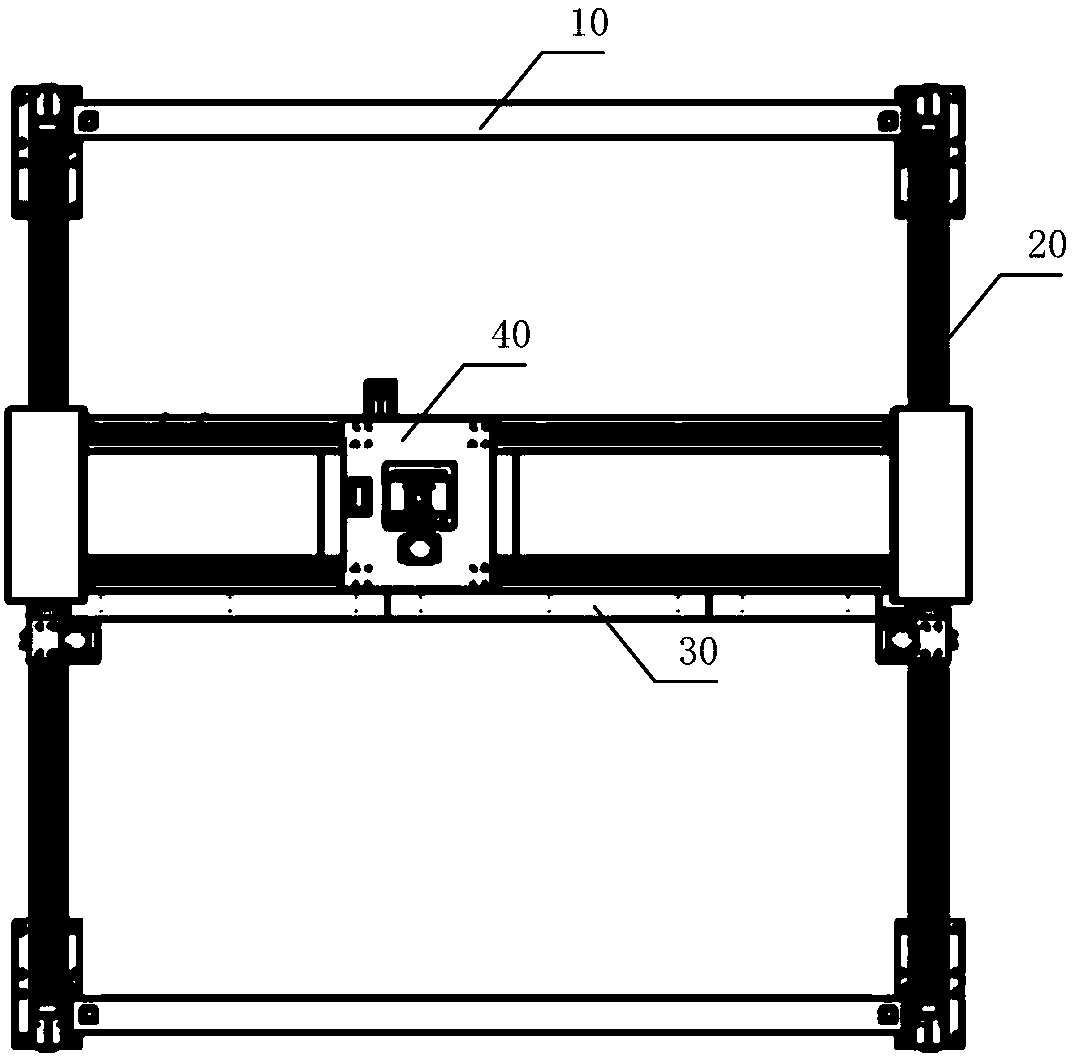

Automatic equipment for bonding ceramic tiles on PC components

InactiveCN107587704AImprove quality consistencyGood processing consistencyBuilding constructionsMovement controlMotion control

The invention provides automatic equipment for bonding ceramic tiles on PC components. The automatic equipment comprises a grabbing part for grabbing multiple ceramic tiles, a grabbing control devicefor controlling the grabbing part to grab the ceramic tiles or to separate from the ceramic tiles, a grabbing part vertical driving device for driving the grabbing part to linearly move in the vertical direction, a grabbing part transverse driving device for driving the grabbing part to linearly move in a horizontal plane in the transverse direction, a grabbing part longitudinal driving device fordriving the grabbing part to linearly move in the horizontal plane in the longitudinal direction, and a motion control device for controlling the grabbing part vertical driving device, the grabbing part transverse driving device and / or the grabbing part longitudinal driving device to drive the grabbing part to move. The automatic equipment for bonding the ceramic tiles on the PC components can grab the ceramic tiles and bond on the PC components to improve the ceramic tile bonding quality and the process consistency.

Owner:NORTHEASTERN UNIV

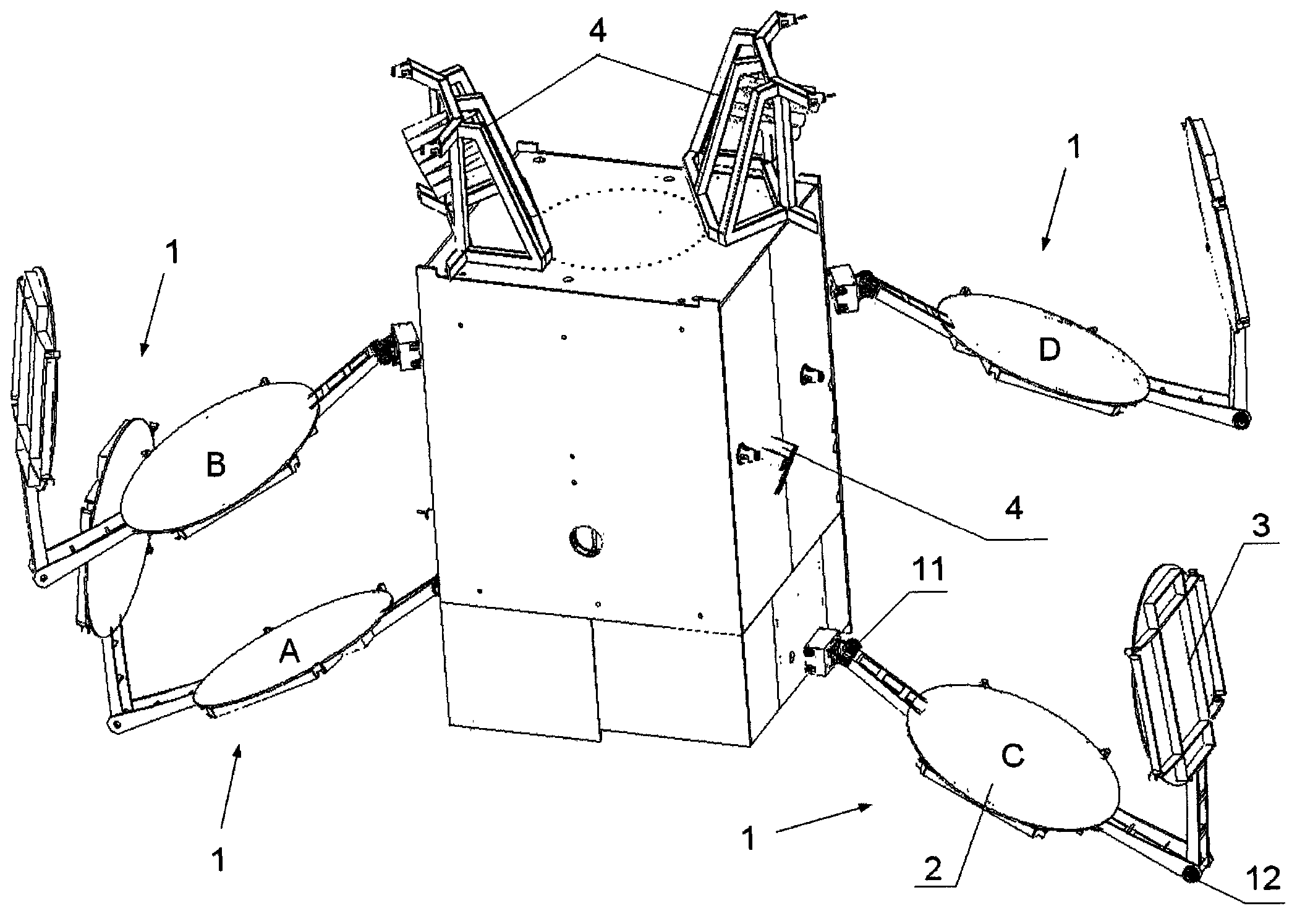

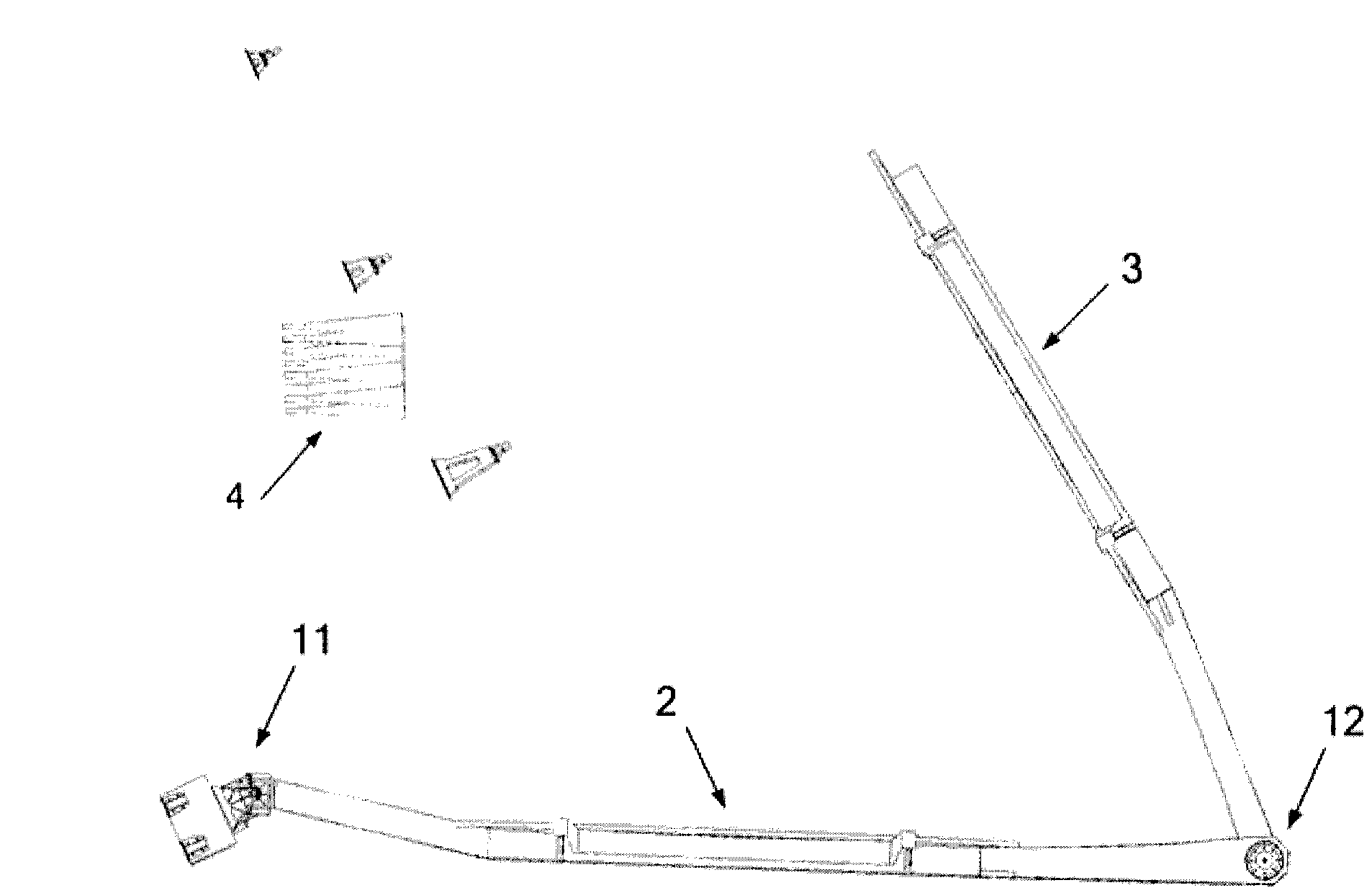

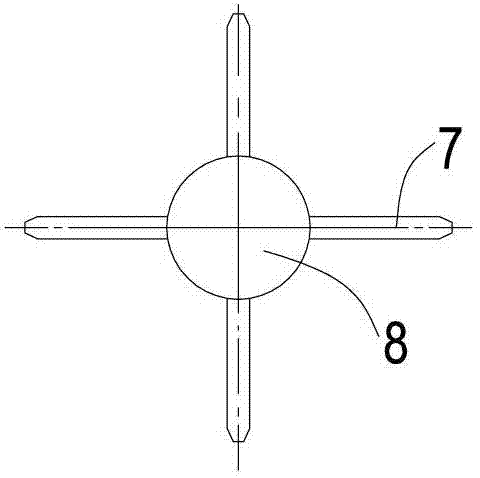

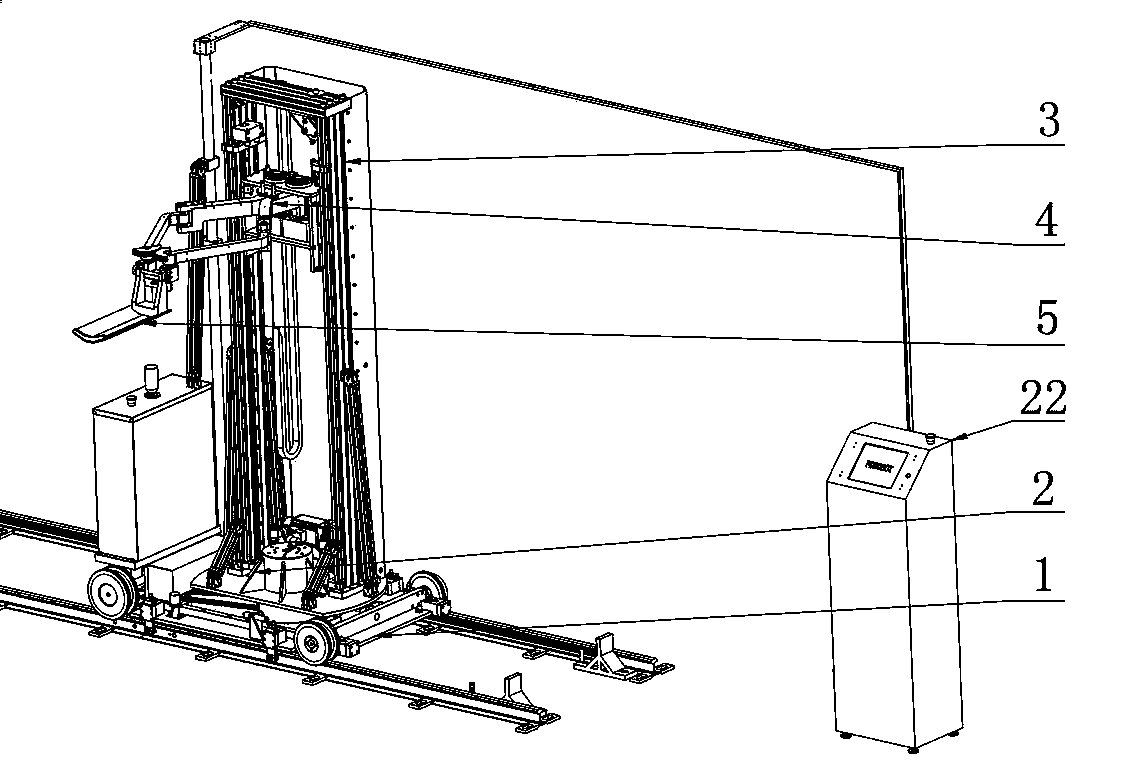

Automatic transfer robot applicable to automatic barrel discharging of glass fibers and working method thereof

ActiveCN103640930AReduce work intensityHigh degree of automationFilament handlingGlass fiberEngineering

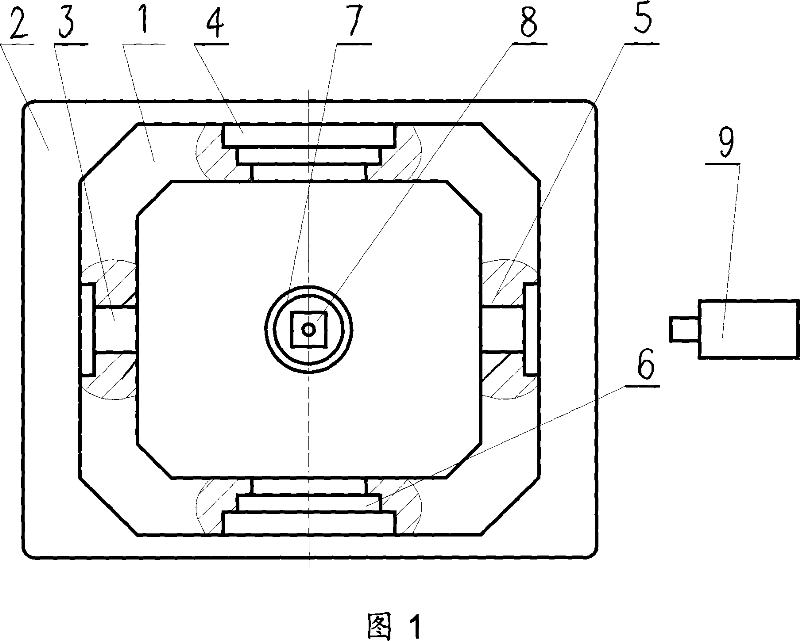

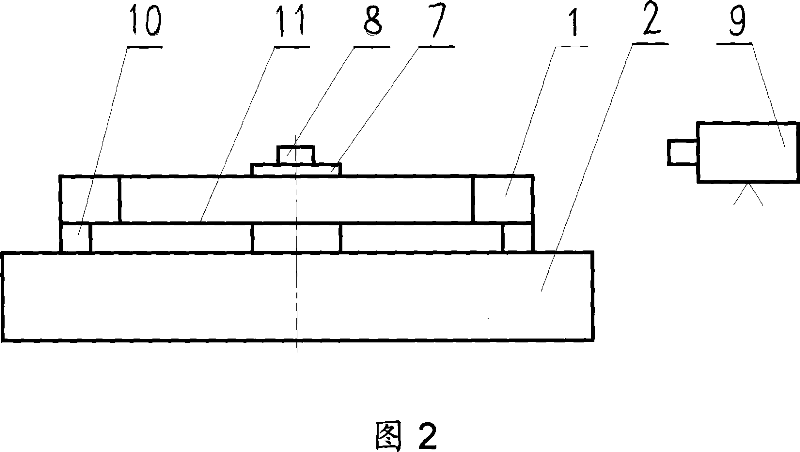

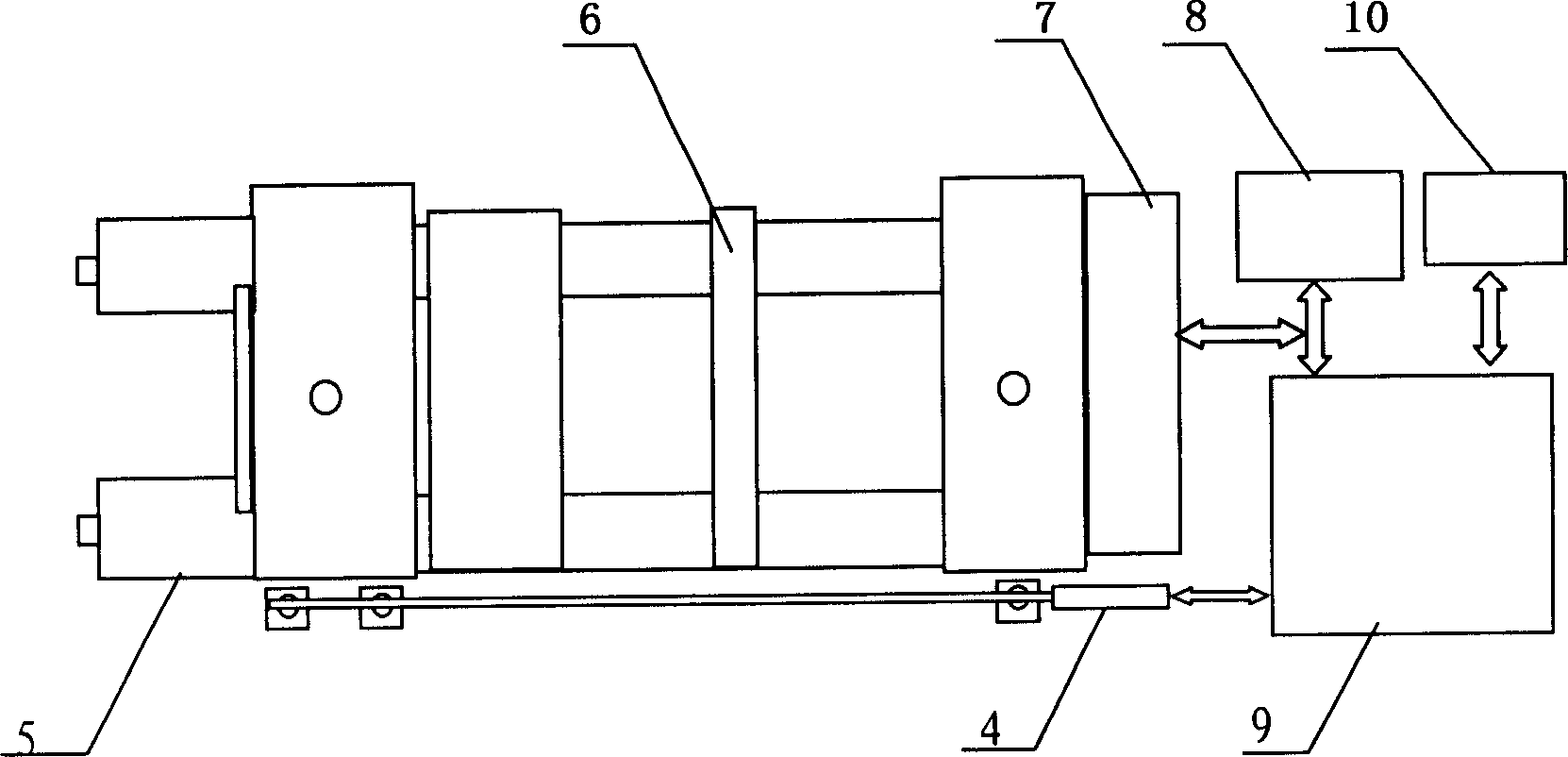

The invention discloses an automatic transfer robot applicable to automatic barrel discharging of glass fibers. The automatic transfer robot comprises a walking mechanism (1), a rotating mechanism (2), a lifting mechanism (3), a telescoping mechanism (4) and a hopper (5). The rotating mechanism (2) rotating around the perpendicular axis is installed on the walking mechanism (1), the lifting mechanism (3) is installed on the rotating mechanism (2), the lifting mechanism (3) comprises a perpendicularly lifting sliding part (6), the telescoping mechanism (4) is fixedly installed on the sliding part (6), the telescoping mechanism (4) comprises telescopic arms (7) telescoping in the horizontal direction, and the hopper (5) is fixedly installed at the ends of the telescopic arms. The invention further discloses a working method of the automatic transfer robot. The automatic transfer robot applicable to automatic barrel discharging of glass fibers and the working method of the automatic transfer robot have the advantages that full-automatic barrel discharging work of the glass fibers can be achieved, the automatic transfer robot can adapt to exiting glass fiber production equipment to the maximum extent and is high in automation degree and good in product machining consistency, production efficiency is improved, and the work intensity of workers is relieved.

Owner:JUSHI GROUP CHENGDU +1

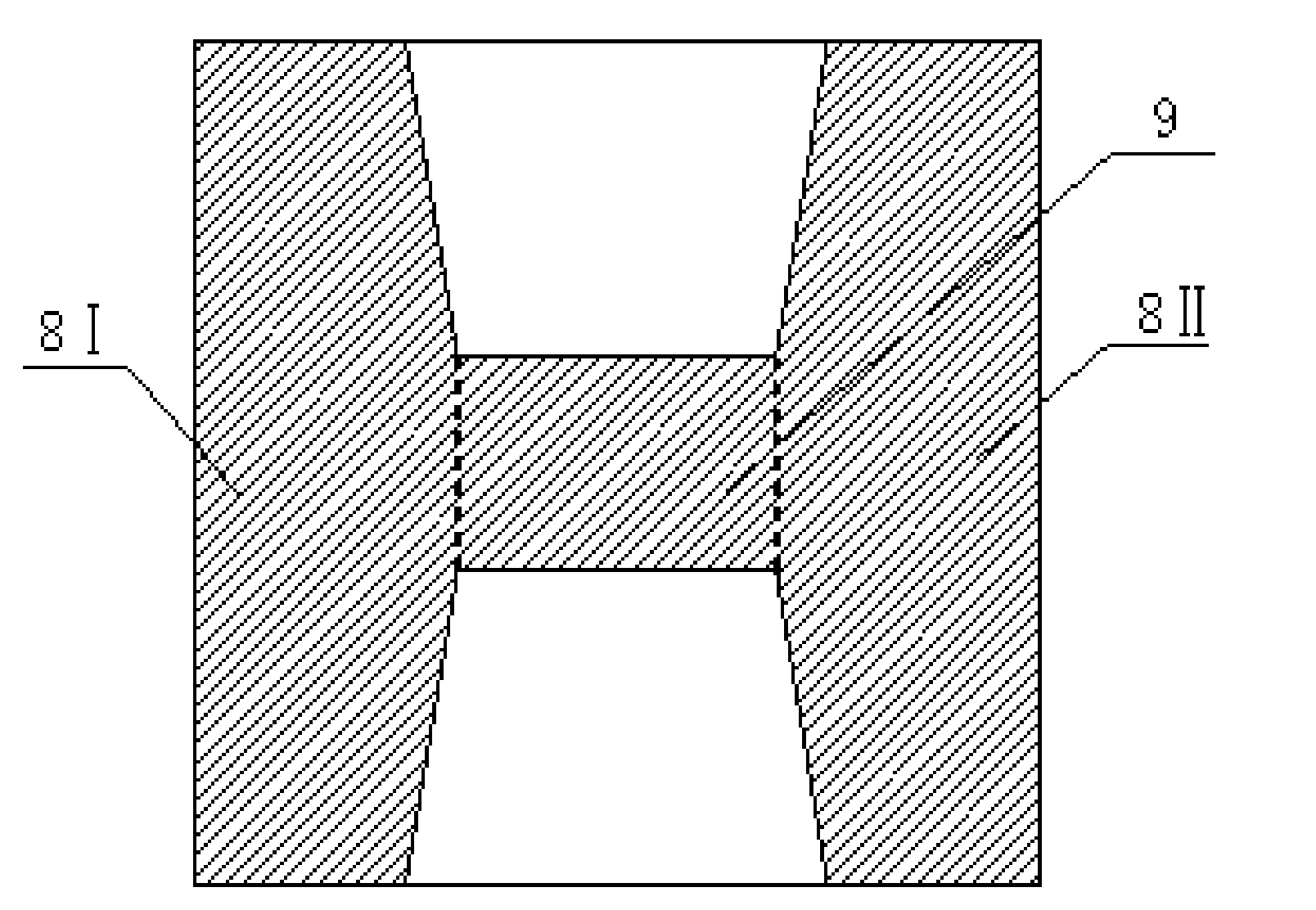

Capacitance coupling structure of medium filter

InactiveCN109755700AGood surface treatmentGood for weight lossWaveguide type devicesCapacitanceCoupling

The invention discloses a capacitance coupling structure of a medium filter. The capacitance coupling structure comprises a medium filter body and two blind holes, wherein the two blind holes are formed in a surface of the medium filter body, each blind hole and a medium filled around each blind hole form a medium resonator, each blind hole is used for debugging a resonant frequency of the mediumresonator, a negative coupling hole is formed in the medium filter body and is arranged between the two medium filters, the negative coupling hole is used for achieving capacitance coupling between the two medium resonators, the negative coupling hole comprises a first through hole and a second through hole which are sequentially arranged from top to bottom, an upper end of the first through holepenetrates through an upper surface of the medium filter body, a lower end of the first through hole communicates with an upper end of the second through hole, a lower end of the second through hole penetrates through a lower surface of the medium filter body, and a conductive layer is plated on an inner wall of the second through hole. The capacitance coupling structure of the medium filter is reasonable in structure, is easy to process, form and surface-processed and is beneficial for weight reduction of the filter.

Owner:SUZHOU PERFECT ELECTRONICS TECH

Making process of C/C heater for monocrystal silicon drawing furnace and polycrystal silicon smelting furnace

The present invention relates to preparation process of C / C heater for monocrystal silicon drawing furnace and polycrystal silicon smelting furnace. The preparation process includes preparing 3D heat isolating screen prefab with carbon fiber; dipping the prefab in pitch or furfural acetone resin and charring repeatedly and treating the compacted heater prefab at high temperature to raise the surface opening rate for several times to reach the density of 1.60 g / cu cm; high temperature purifying the heat isolating screen through introducing chlorine and Freon; and final machining to obtain the C / C heater for monocrystal silicon drawing furnace and polycrystal silicon smelting furnace. The C / C heater for monocrystal silicon drawing furnace and polycrystal silicon smelting furnace has effectively lowered resistivity, low cost and long service life.

Owner:XIAN CHAOMA SCI TECH

Finish machining method of the frame of the rotating table

ActiveCN101036948AAchieve finishingHigh precisionPrecision positioning equipmentMeasurement/indication equipmentsStanding frameAutocollimation

A fine machining method of the rolling stand frame belongs to machine finishing technology field. At first determining center of turning circle position of the fine boring machine table and mounting end face multiple tooth circular dividing table thereon, the tetrahedron is mounted on the end face multiple tooth circular dividing table, and adjusting it to collimate with the photoelectricity autocollimation to determine machineable machine zero position point; the rolling stand frame is mounted on the worktable, and adjusting it to symmetry with the center of gyration; boring the frame side face of each axle hole for the rolling stand frame and the axle hole until achieving to the required precise size, when the frame rotates from one side to another side, rotating relevant angle of the worktable contrasting to graduation value of the end face multiple tooth circular dividing table, the tetrahedron is measured by the photoelectricity autocollimation, fine tuning the worktable to collimate the corresponding face of the tetrahedron with the sending beam of the photoelectricity autocollimation, at this point, the rotating angle is exact value, then processing. The invention operates conveniently and audio-visually, with reliable processing manufacturability, and reducing accumulation of error and improving process precision of the frame.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Quality control method for numerical-control gas pressure welding of rail

InactiveCN1808313AReduce security risksLower skill requirementsControllers with discontinuous output signalNumerical controlAutomatic control

The invention discloses a steel rail digital control air pressure welding quality control method which comprises: getting relationship of temperature- resistance of deformation-deformation by implementing welding heat / pressure simulating test on steel rail for welding, and getting the optimum parameters in the three welding stages, and pre-setting them in the digital controller; controlling the heater swing device with automatic control function, air quality flow control unit, oil pressure adjusting device of the digital control pump station by the digital controller according to the pre-set parameters, to realize closed-loop control on the entire welding process.

Owner:SOUTHWEST JIAOTONG UNIV

Automatic edge-folding machine

ActiveCN105428696AAccurate Folding and FormingGood processing consistencyAssembling battery machinesFinal product manufactureReciprocating motionMachining

The invention relates to an automatic edge-folding machine. The automatic edge-folding machine comprises a worktable used for accommodating a soft package battery, a bracket assembly mounted on the worktable, a horizontal driving mechanism arranged on the bracket assembly, a horizontal sliding block mounted on the horizontal driving mechanism and driven by the horizontal driving mechanism to do a horizontal reciprocating movement, and a baffle arranged opposite to the horizontal sliding block, wherein a tab of the soft package battery is positioned between the horizontal sliding block and the baffle. According to the automatic edge-folding machine, the horizontal sliding block is mounted on the horizontal driving mechanism, the baffle is arranged in a position opposite to the horizontal sliding block, the tab of the soft package battery is positioned between the horizontal sliding block and the baffle, and the baffle presses a tab binding part of the soft package battery; when the horizontal sliding block is driven by the horizontal driving mechanism to do the horizontal reciprocating movement, the tab is accurately folded and formed under the effect of the horizontal sliding block and the baffle; and the automatic edge-folding machine has the advantages of good machining consistency, high efficiency and the like.

Owner:SHENZHEN BETTERPOWER BATTERY

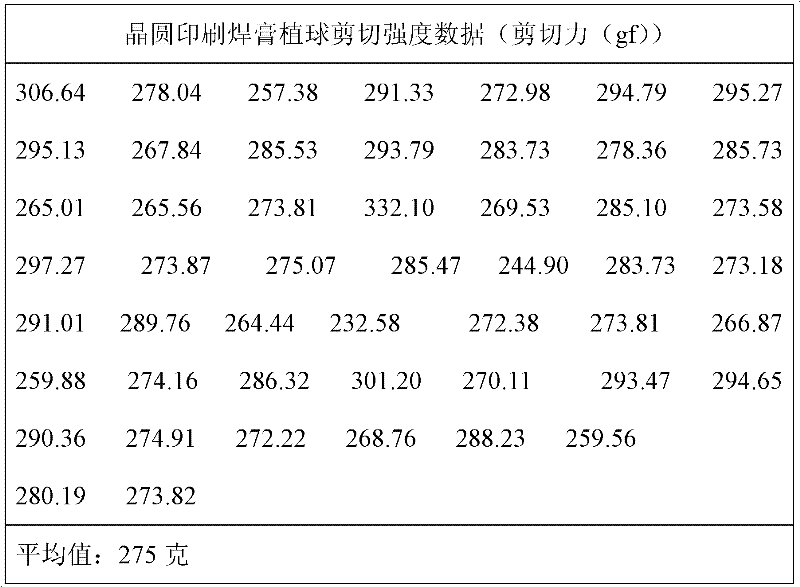

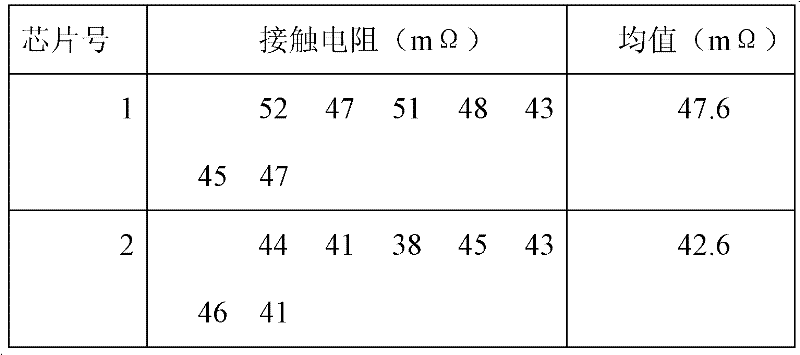

Process for making non-void high-reliability convex points in wafer by vacuum brazing

InactiveCN102371410AHigh height toleranceHigh linear consistencySoldering apparatusHigh volume manufacturingNitrogen

The invention discloses a process for making non-void high-reliability convex points in a wafer by vacuum brazing. A vacuum brazing furnace is used for welding, and the process comprises the following welding steps of: vacuumizing, introducing nitrogen, vacuumizing, preheating to the temperature of 150+ / -10 DEG C in the nitrogen atmosphere, heating to the temperature of 210+ / -10 DEG C, vacuumizing, performing water cooling, and back charging the nitrogen. By combining the process and a through printing method, small-size convex points with the diameter of 150 microns, the height of 100 microns and the distance of 250 microns are made. The process has the advantages of good consistency, simple flow, high production efficiency and low cost, and is suitable for large-batch production. The height tolerance of the through printed ball grid array (BGA) convex points is less than 3.0 microns, the linear consistency of the convex points is less than 5 microns, and the indexes of shearing strength, contact resistance and the like can meet the requirement of reliability.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

Method for preparing high temperature furnace used carbon/carbon insulating cylinders

The invention discloses a method for preparing high temperature furnace used carbon / carbon insulating cylinders, which comprises the following steps: preparing a low-density insulating cylinder prefabricated part by adopting the alternative layering and the radial acupuncture of carbon fiber plain cloth or twill cloth and thin carbon fiber net tire; densifying the insulating cylinder prefabricated part by the combination of gas phase sedimentation and resin dipping; sticking graphite paper on the inner surface and the outer surface of the insulating cylinder after the densification process; and then preparing a high temperature furnace used carbon / carbon insulating cylinder by machining after carbonizing, so that, the density of the carbon / carbon insulating cylinder is 0.25 to 0.50 g / cm<3>. The invention has the following advantages: 1, the conditions of the densification technique is simplified so as to reduce the cost, therefore, the invention is suitable for producing large-sized insulating cylinder products; 2, using resin carbon basal body, the heat conductivity of the carbon / carbon insulating cylinder material is reduced, the thermal field insulating effect is improved, and the energy consumption is saved; and 3, graphite paper is stuck to the inner surface and the outer surface of the insulating cylinder so as to reflect heat effectively and improve the insulation performance.

Owner:XIAN CHAOMA SCI TECH

Spun-dyed polyurethaneurea fibres, a process for their production and their use for producing fabrics

InactiveUS20060210794A1Good lookingGood processing consistencyMonocomponent polyurethanes artificial filamentMonocomponent cellulose artificial filamentFiberModified carbon

Described are elastic polyurethaneurea fibres comprising a cationically modified carbon black as an additive, so that the colour of the fibre is distinctly changed. Also described are a process for producing coloured polyurethaneurea fibres and also their use for producing elastic fabrics and textile goods.

Owner:DORLASTAN FIBERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com