Automatic transfer robot applicable to automatic barrel discharging of glass fibers and working method thereof

A robot and automatic unloading technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems that affect the product processing efficiency and product quality, the operator's work intensity is high, and the production cost is increased. Product processing consistency is good, the effect of reducing the degree of manual intervention and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

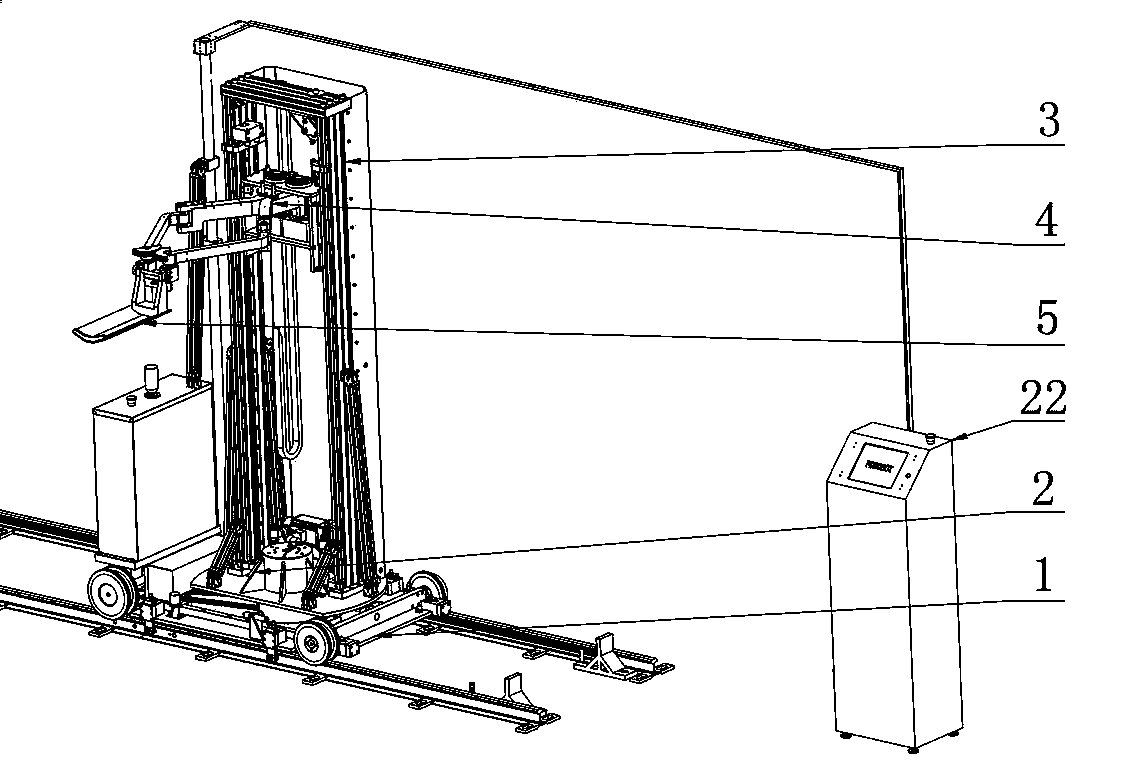

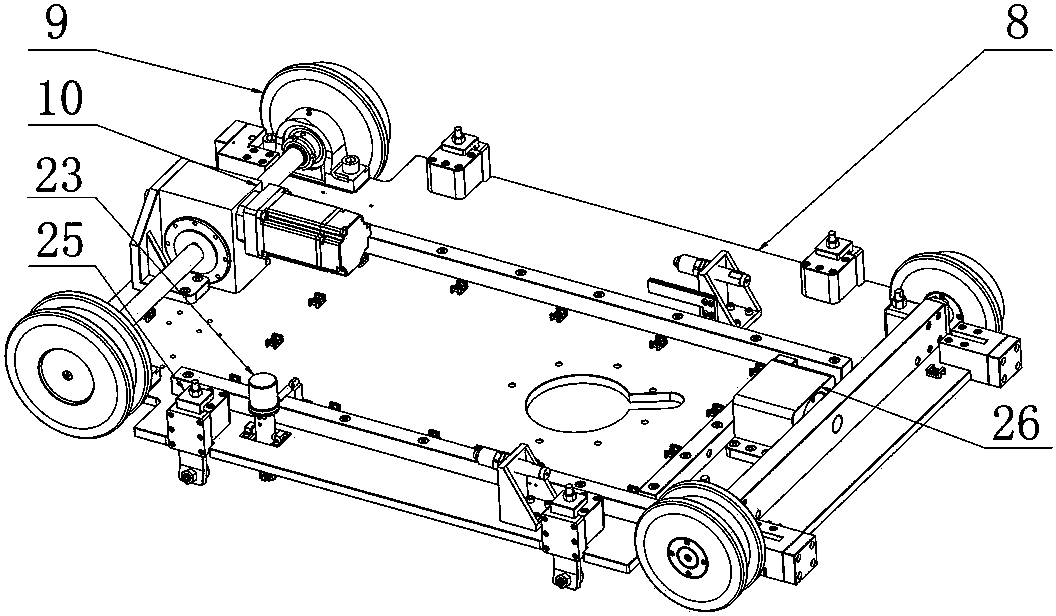

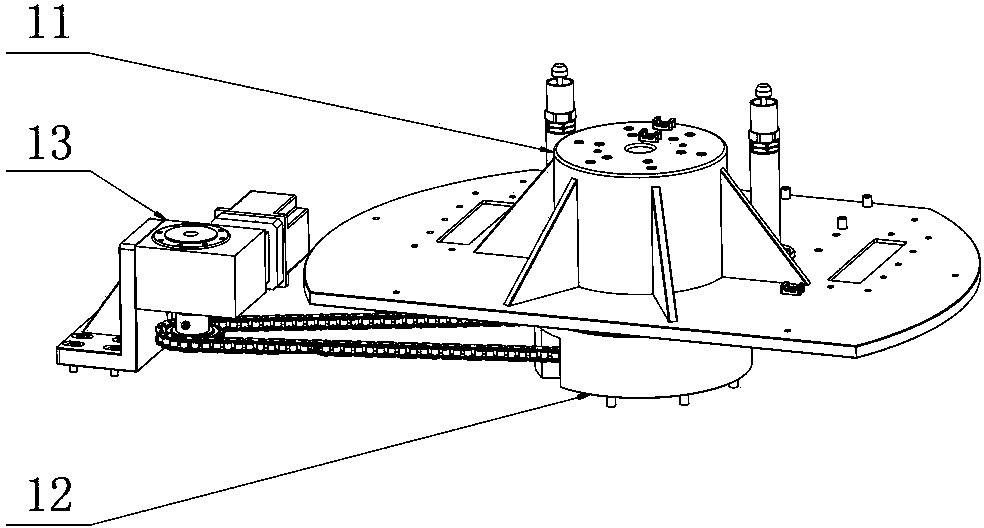

[0027] like figure 1 As shown, the automatic transfer robot suitable for glass fiber automatic unloading cylinders includes a traveling mechanism 1, a rotating mechanism 2, a lifting mechanism 3, a telescopic mechanism 4 and a hopper 5, and the rotating mechanism 2 rotating around a vertical axis is installed on the traveling mechanism 1 Above, the lifting mechanism 3 is installed on the rotating mechanism 2, the lifting mechanism 3 includes a sliding part 6 for vertical lifting, the telescopic mechanism 4 is fixedly installed on the sliding part 6, the telescopic mechanism 4 includes a telescopic arm 7 that expands and contracts in the horizontal direction, and the hopper 5 is fixedly installed at the end of the telescopic arm. The traveling mechanism 1 can move on the ground or on the track; the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com