Completely-integrated impact piece ignitor and preparation method thereof

A fully integrated, point-and-shoot technology, applied in chemical instruments and methods, instruments, offensive equipment, etc., can solve the problems of limited application, difficult to guarantee the vertical verticality of the acceleration chamber, and difficult to guarantee the airtightness and strength of the bonding. Improves flyer speed, facilitates mass production, and improves process consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

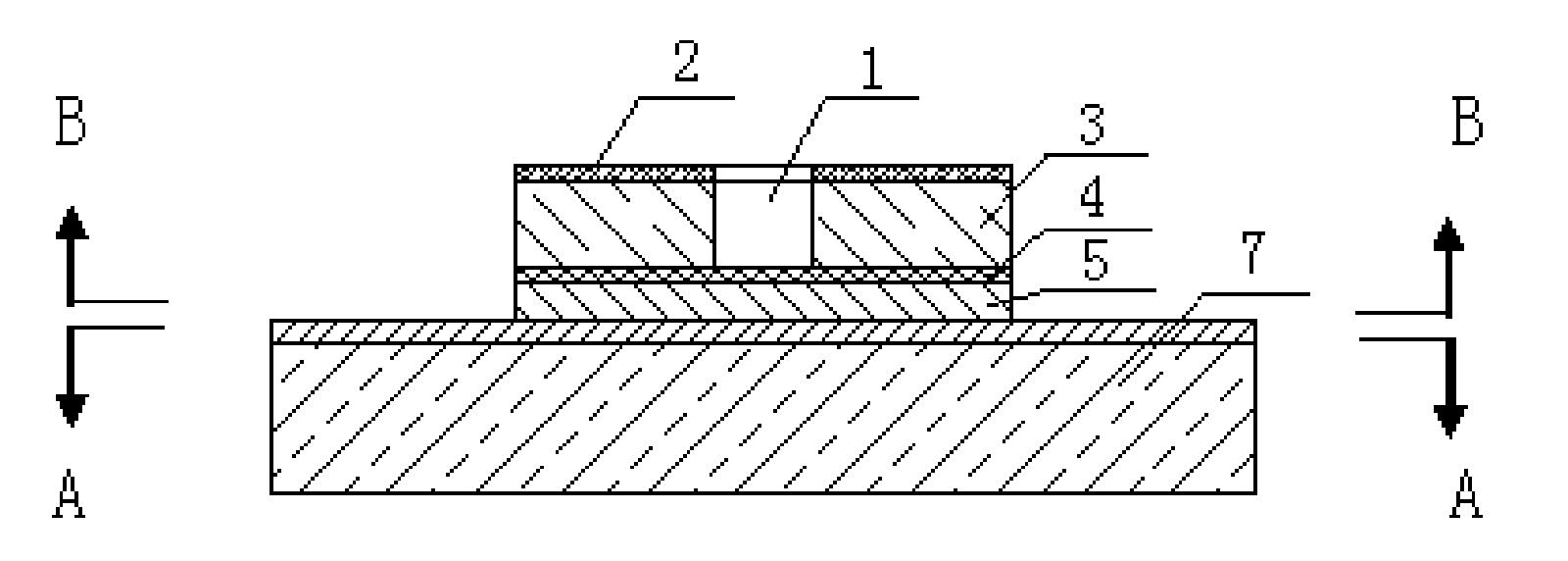

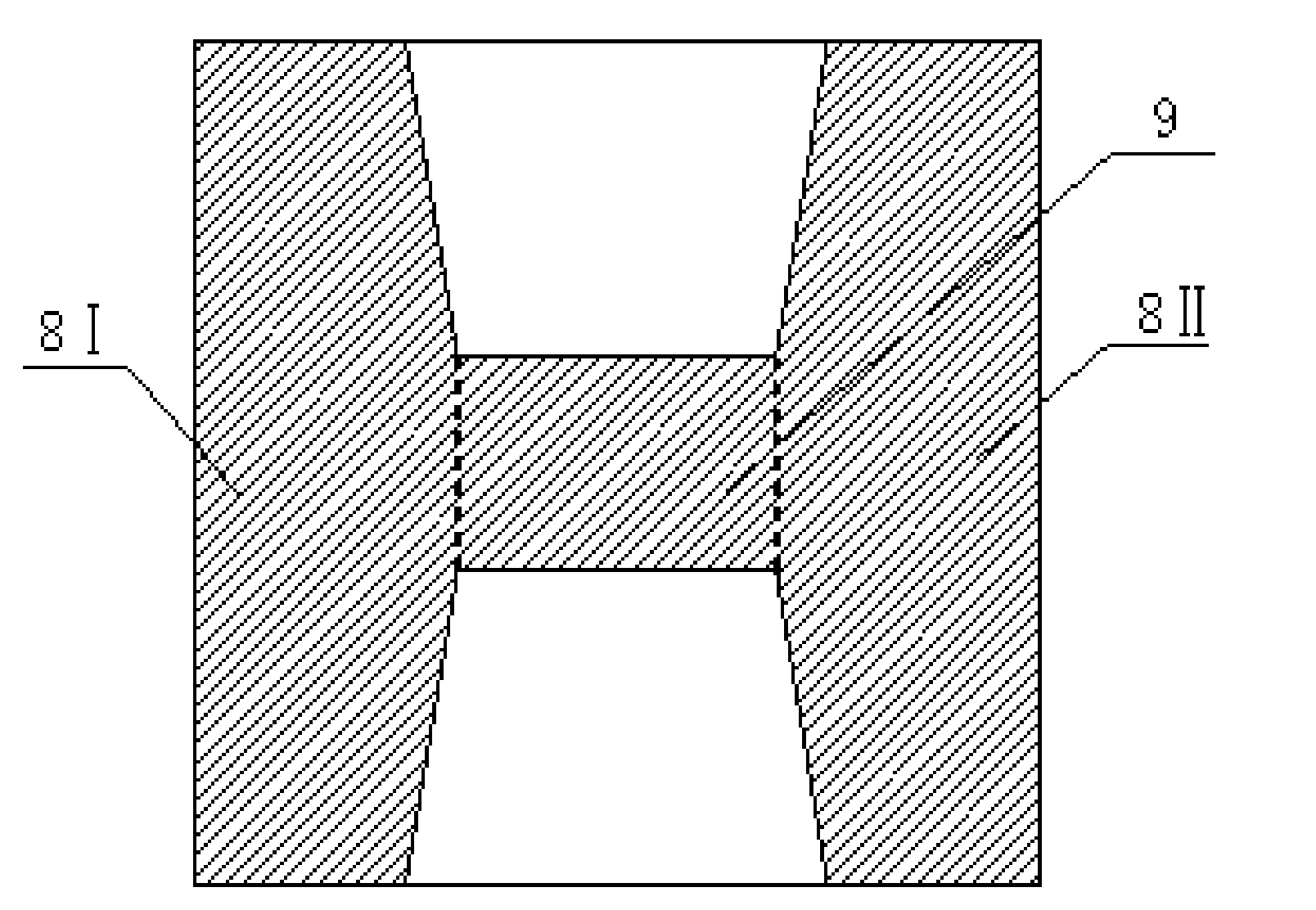

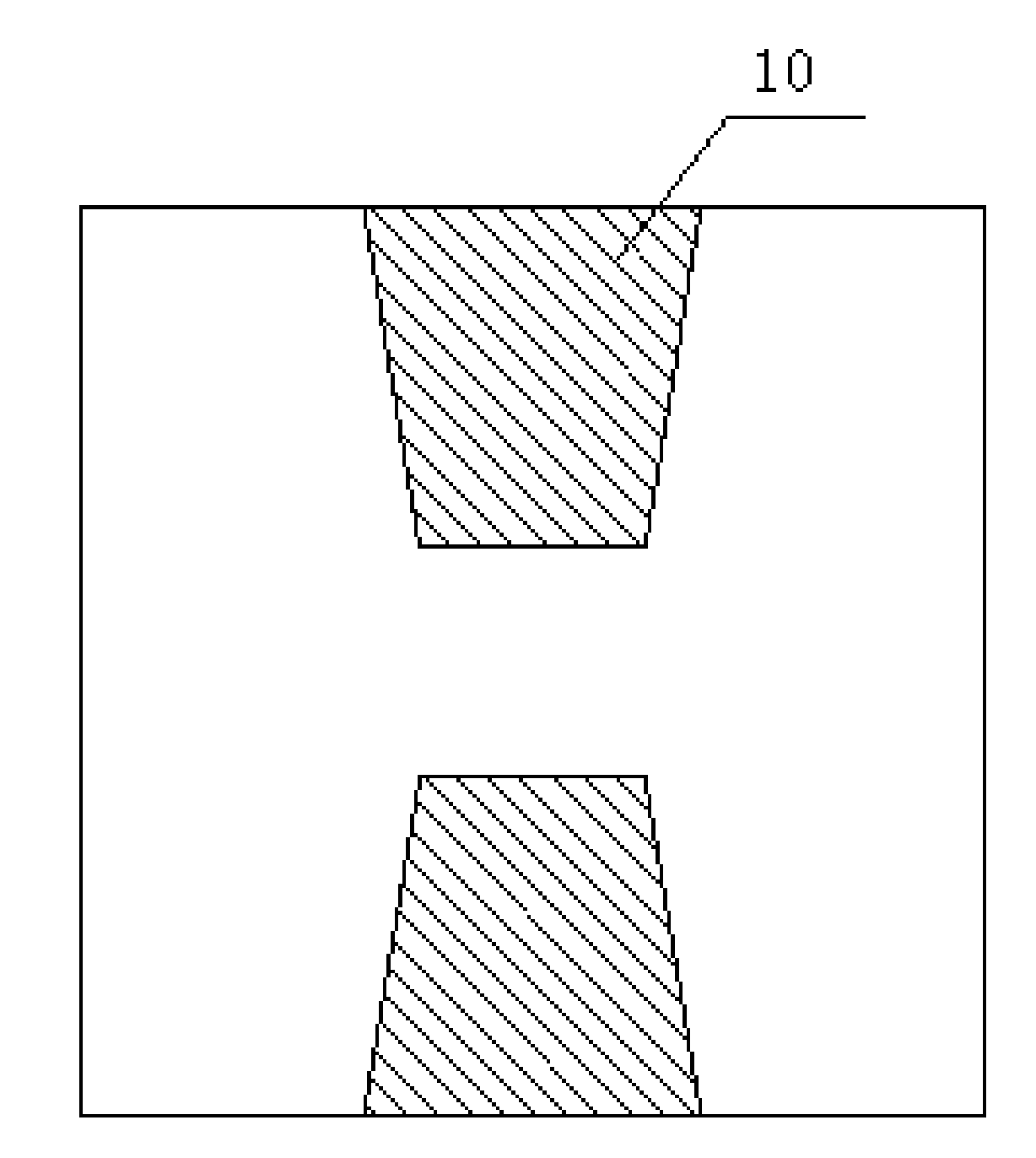

[0021] figure 1 It is a structural schematic diagram of the fully integrated impact plate igniter of the present invention, figure 2 yes figure 1 The schematic diagram of the A-A section in the image 3 yes figure 1 B-B in the cross-sectional schematic diagram, from Figure 1~3 It can be seen from the figure that the fully integrated shock plate igniter of the present invention contains a glass reflector 7 , a metal bridge foil 9 , a silicon flyer 5 and a silicon acceleration chamber 1 . The metal bridge foil 9 is arranged above the glass reflector 7, the metal bridge foil 9 is closely connected with the silicon flyer 5, the silicon acceleration chamber 1 is arranged above the silicon flyer 5, and two Silicon oxide insulating material layer 4 .

[0022] The preparation method of the fully integrated impact plate igniter of the present invention is carried out in sequence as follows:

[0023] a) A copper metal layer with a thickness of 4 mm is sputtered on a borosilicate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com