Pattern rib inlaid-type pore-free tire mold and pattern block thereof

A tire mold and pattern block technology is applied in the field of flower-rib inlaid airless tire molds and pattern blocks, which can solve the problems of reducing product quality, wasting rubber material, hindering the discharge of cavity air, etc., to improve efficiency and consistency. performance, ensuring tire quality, and high rib strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

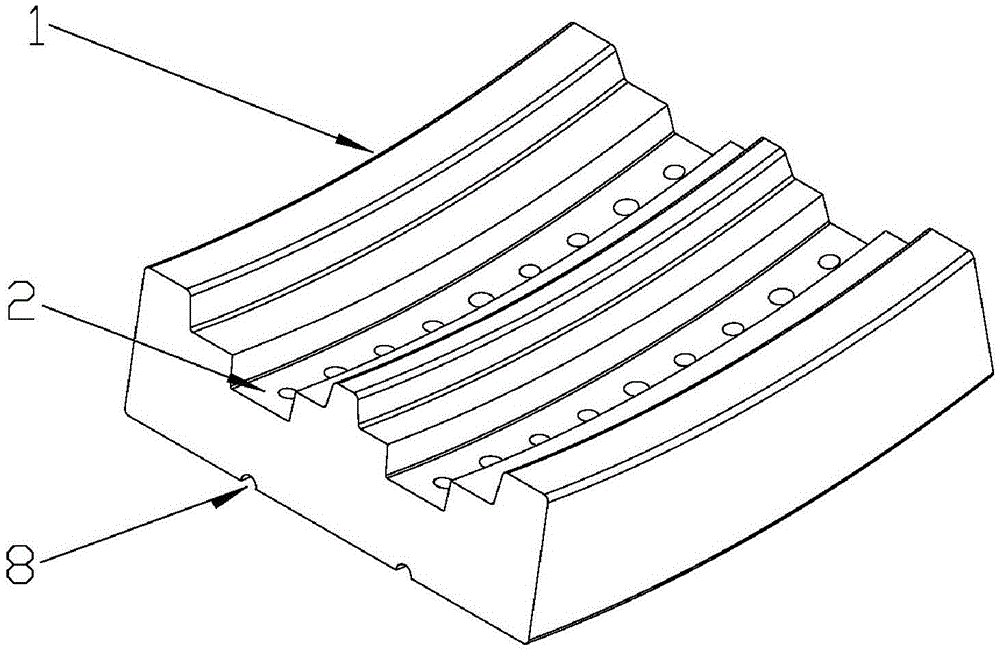

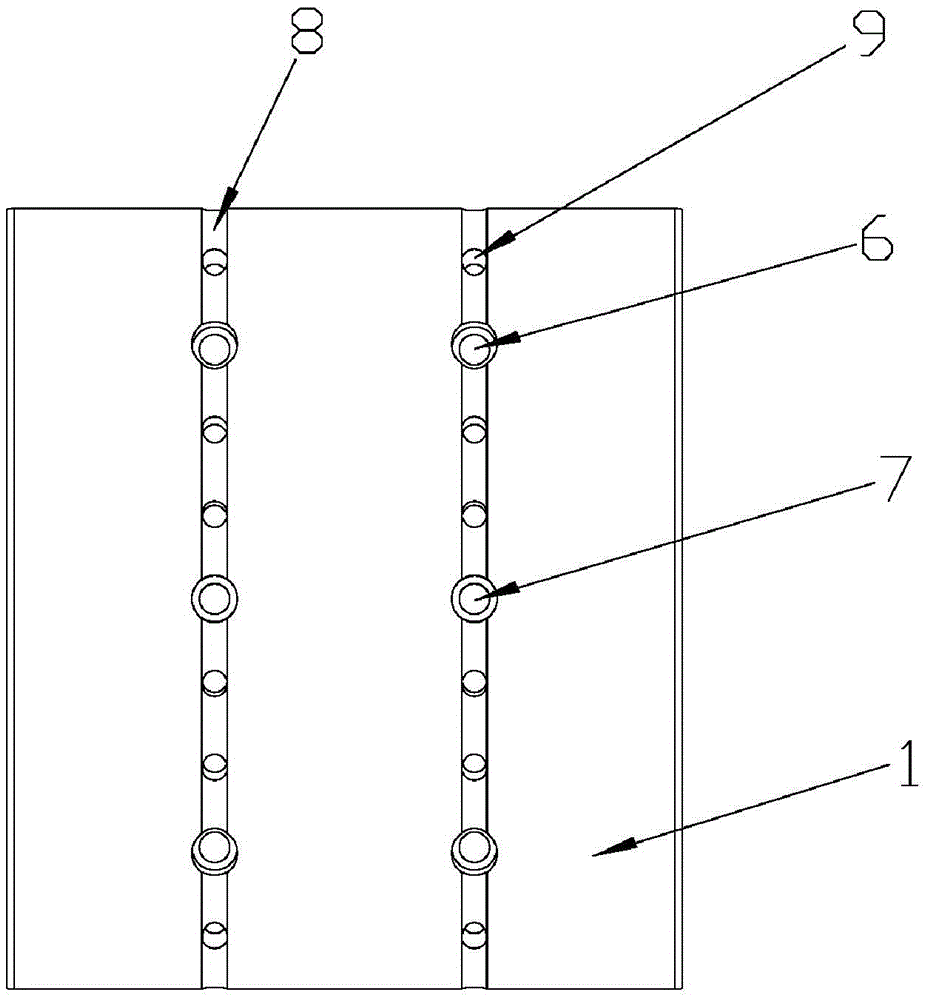

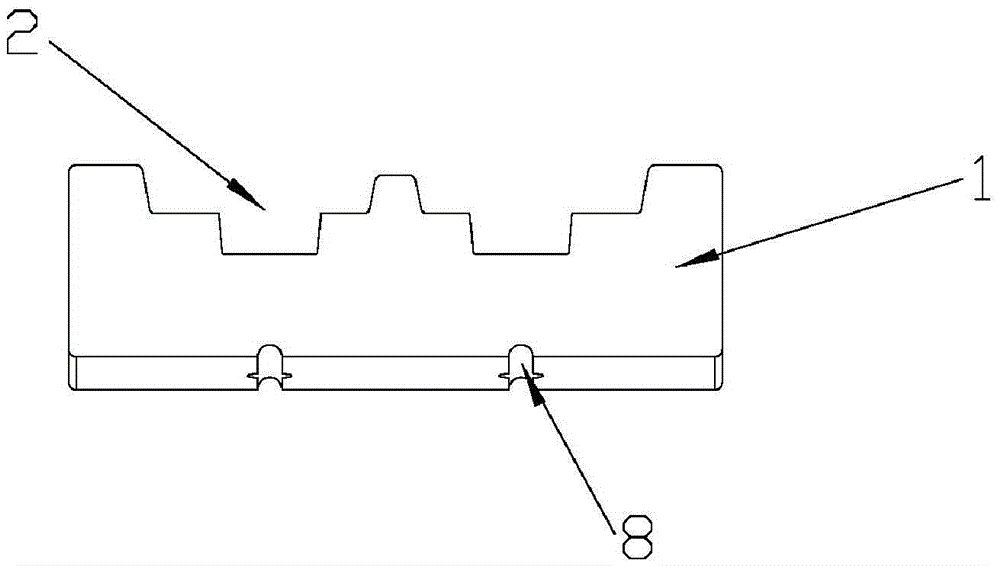

[0039] Such as Figure 1 to Figure 12 As shown, the present invention provides a pattern block of a rib-embedded non-porous tire mold, which includes: a pattern block body 1, the inner wall surface of which is concavely provided with a pattern block embedding groove 2, and the pattern block body 1 is provided with a communication hole The exhaust channel between the inner wall surface of the pattern block and the outer wall surface of the pattern block; the rib main body 3, which includes a rib base 5 and a rib 4, and the rib base 5 is embedded in the rib In the mosaic groove 2, the flower bar 4 is fixed on the inside of the flower bar base 5, and the angle between the flower bar 4 and the flower bar base 5 is provided with a circumferential exhaust line 10, so that The circumferential exhaust line 10 communicates with the exhaust channel.

[0040] Specifically, such as Figure 1 to Figure 7As shown, the exhaust passage includes a plurality of exhaust through holes 9 arrange...

Embodiment approach 2

[0047] The present invention also provides a rib-inlaid non-porous tire mold, which is composed of a plurality of pattern blocks described in Embodiment 1 spliced side by side. The inner cavity of the tire mold, the circumferential exhaust line 10 and the exhaust channel of the pattern block communicate with the inner cavity and the outside of the rib-embedded non-porous tire mold, the structure and exhaust principle of the pattern block The advantages and effects are the same as those of Embodiment 1, and will not be repeated here.

[0048] In one embodiment, the circumferential exhaust lines 10 of a plurality of pattern blocks are spliced side by side to form an annular groove line, and the circumferential exhaust grooves 11 of the plurality of pattern blocks form a line parallel to the circumferential exhaust line 10. Corresponding to the annular groove, in another embodiment, the circumferential exhaust lines 10 of the multiple pattern blocks form multiple groove lines...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com