Process for making non-void high-reliability convex points in wafer by vacuum brazing

A vacuum and wafer technology, applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems that the reliability needs to be further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] After cleaning, the assessment measurement is carried out, and the results are as follows:

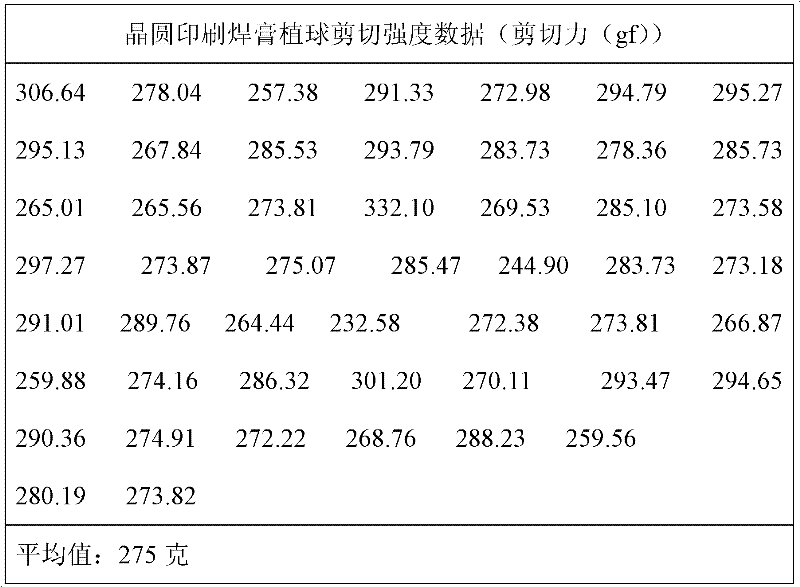

[0011] A. Shear strength test

[0012] The solder balls on the surface of the chip were subjected to a shear force test, and a total of 50 points were tested. The test values are shown in Table 1.

[0013] Table 1 Shear strength test data table

[0014]

[0015] The shear force value is between 244.90g and 332.10g, with an average value of 275g, which is far greater than the national military standard and meets the use requirements.

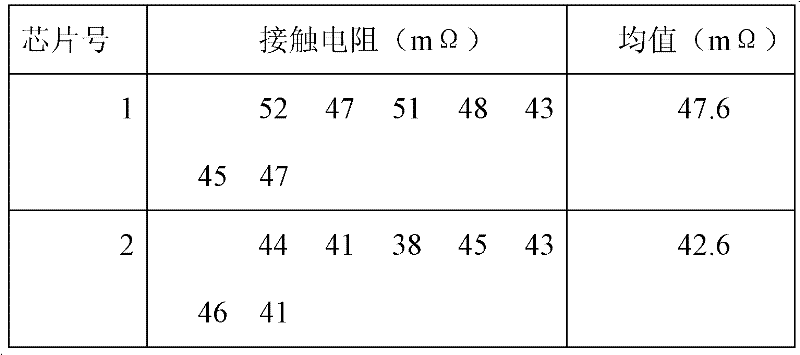

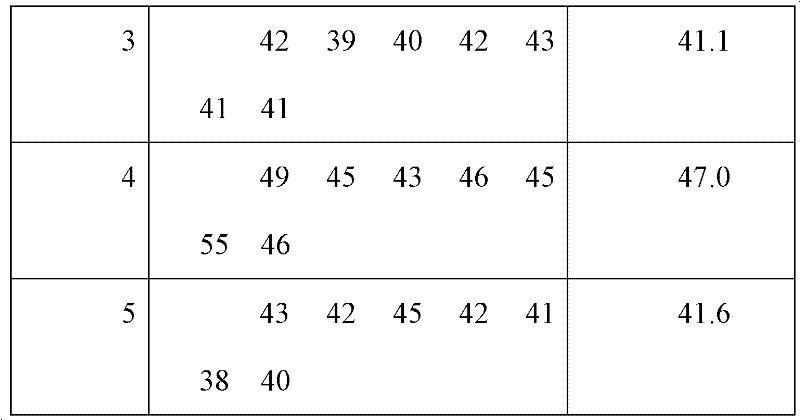

[0016] B. Contact resistance test

[0017] To measure the contact resistance between the missing bumps and the pads, select 5 chips at different positions on a 2-inch silicon wafer, with 7 bumps on each chip, and a total of 35 sets of data. The measurement data are shown in Table 2.

[0018] Table 2 Missing bump and pad contact resistance test data table

[0019]

[0020]

[0021] It can be seen from the data in the table that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com