Technology of drop-out printing for manufacturing micron-sized salient point on wafer

A wafer and missing printing technology, used in printing, printing devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of long time period and high relative cost, and achieve the effect of high production efficiency, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings:

[0022] See figure 1 In the present invention, the above objectives are achieved by optimizing the leakage hole parameters of the stainless steel leakage plate, the thickness of the stainless steel leakage plate, the design leakage hole diameter, and the selection of solder paste parameters.

[0023] The process flow is as follows:

[0024] Drawing and plate making → making solder paste missing printing board → matching (solder paste missing printing) board → printing solder paste → inspection → welding → cleaning → inspection

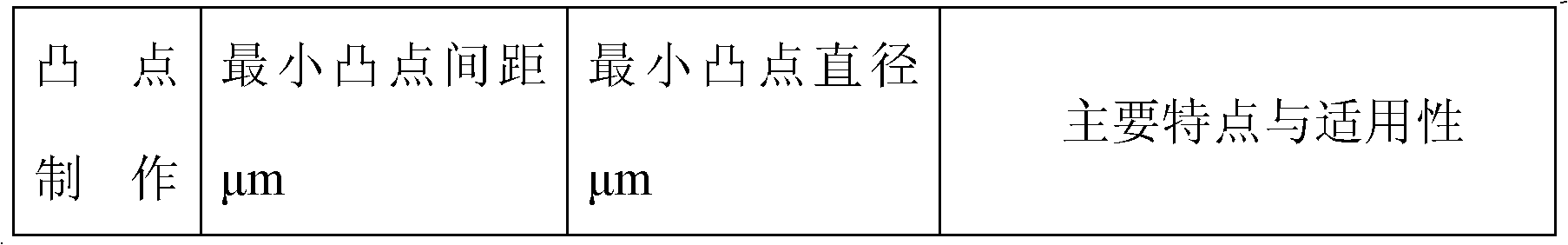

[0025] 5.2 Parameters of solder paste missing printed board:

[0026] Solder paste missing plate material: stainless steel

[0027] Thickness of solder paste missing printing board: 0.1mm~0.15mm

[0028] Land size: 0.1mm~0.25mm

[0029] Leak hole size: 0.15mm~0.3mm

[0030] You can choose stainless steel as the material of the missing plate, and ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com