Finish machining method of the frame of the rotating table

A frame and turntable technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of inability to meet high-precision frame processing requirements, reduce frame processing accuracy, and long production cycle, so as to improve processing accuracy and consistency, convenient and intuitive operation, and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] There are an outer frame, a middle frame and an inner frame on the turntable. The middle frame has 4 shaft holes that need to be processed. The axes of the two opposite shaft holes must be strictly controlled on the same axis. Each shaft hole must be strictly at an angle of 90°, and each shaft hole is composed of multiple holes with different diameters in series, which is the most difficult to process among all the frames of the turntable. The specific implementation of the processing of the frame of the turntable will be described below by taking the processing method of the middle frame of the turntable as an example.

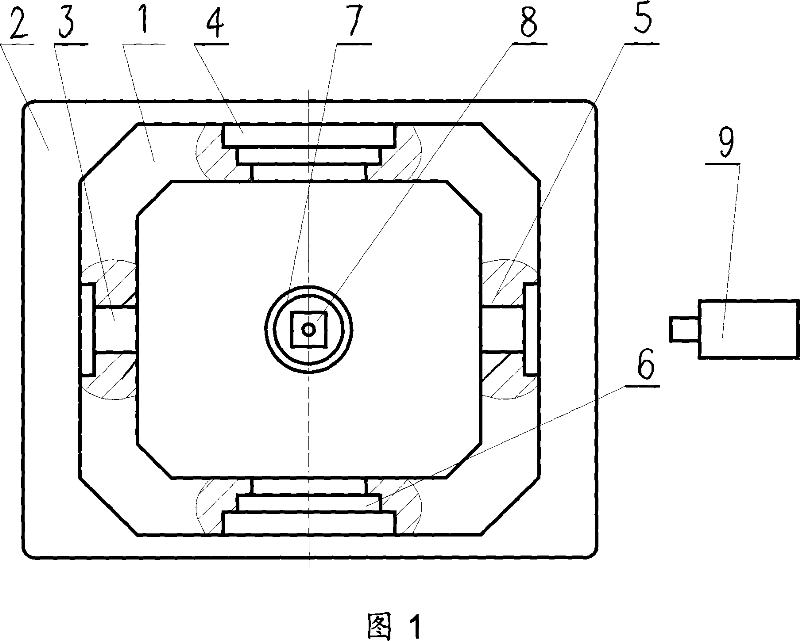

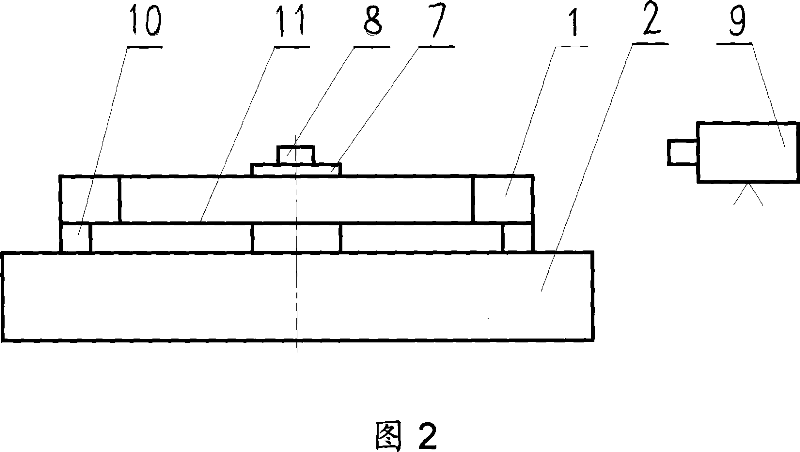

[0016] As shown in Fig. 1 and Fig. 2, firstly, the flatness of the reference plane 11 of the middle frame frame 1 of the turntable is not greater than 0.003 mm by means of scraping and lapping. Grind four pad irons 10 to make them equal in height, ensuring that the height difference is within 0.01mm. Taking the reference plane 11 of the middle frame f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com