Patents

Literature

337results about How to "Easy and intuitive operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

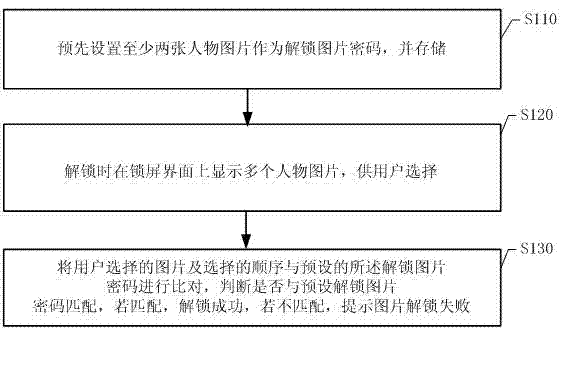

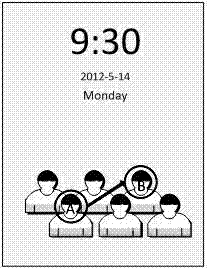

Method and system for carrying out unlocking based on picture face identification, and electronic device

InactiveCN102760042AImprove password securityEasy and intuitive operationDigital data authenticationInput/output processes for data processingComputer graphics (images)Password

The invention discloses a method and system for carrying out unlocking based on picture face identification, and an electronic device. The method comprises the steps of: presetting at least two figure pictures as an unlocking picture password, and storing; displaying multiple figure pictures on a screen lock interface for being selected by users during unlocking; comparing the selected figure picture and the selection order during unlocking with the unlocking picture password, judging whether the selected figure picture and the selection order are matched with the unlocking picture password, if yes, unlocking successfully, and otherwise prompting that the unlocking fails. According to the invention, unlocking can be carried out based on multiple figure pictures stored in the device, and wrong selection or wrong selection sequence of pictures are treated as wrong picture unlocking passwords during unlocking; and the invention has advantages of high safety, convenience and perceptual intuition in operation, no need of real-time collection of the pictures before every unlocking, and convenience provided for the users.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

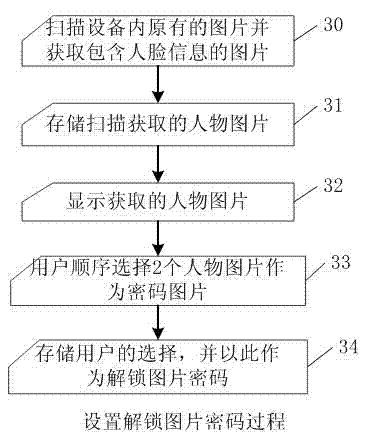

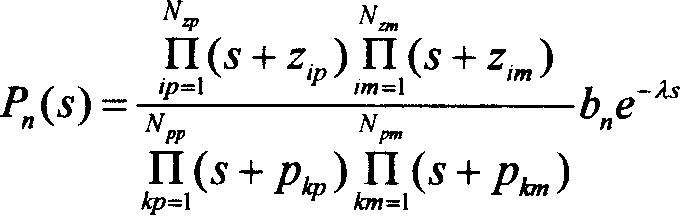

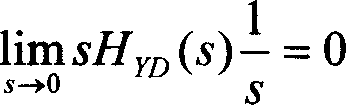

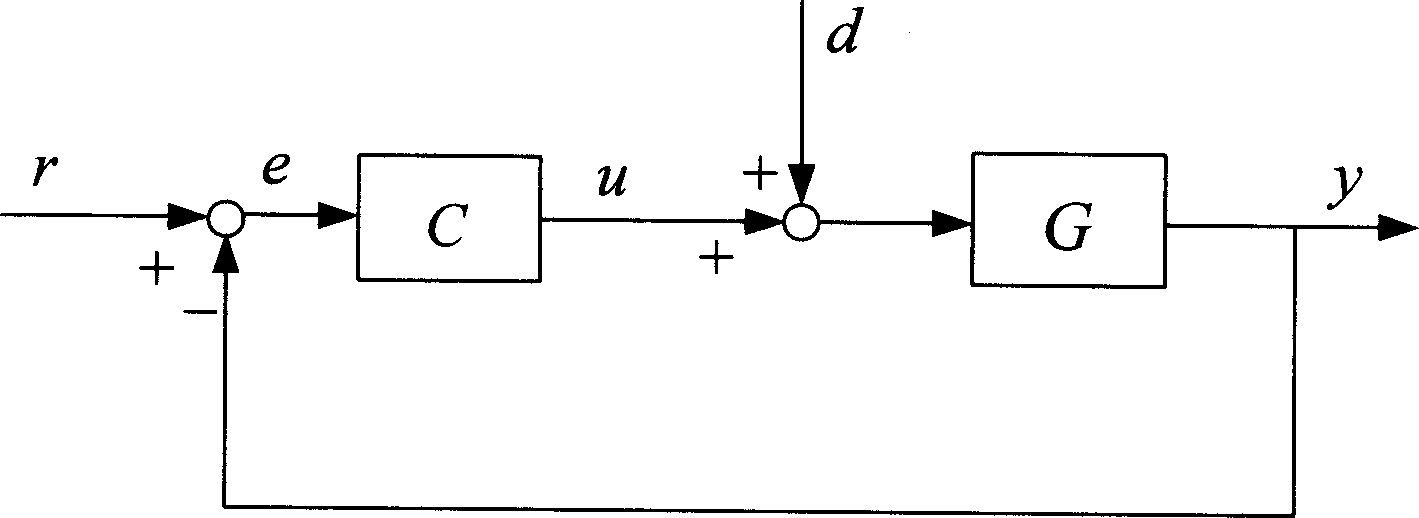

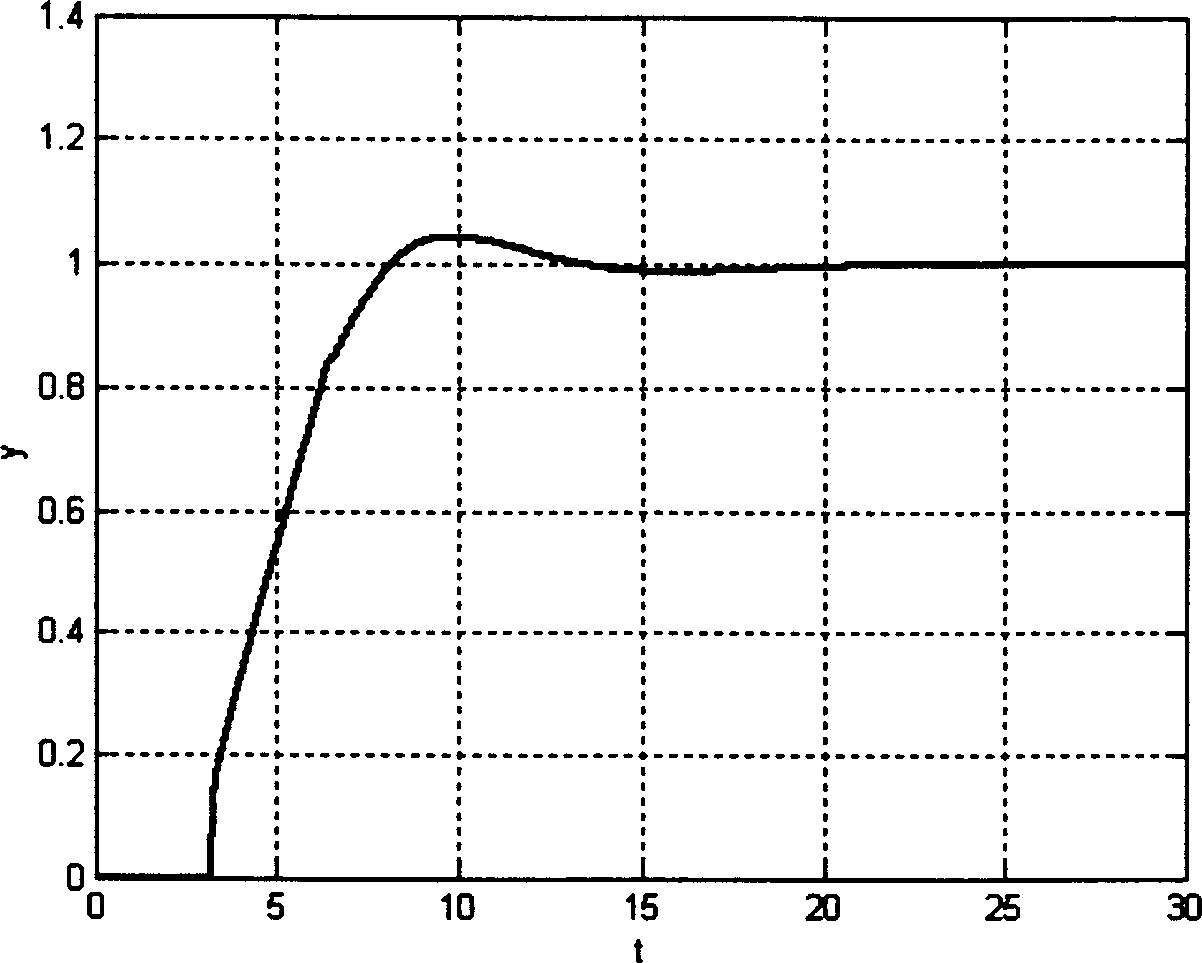

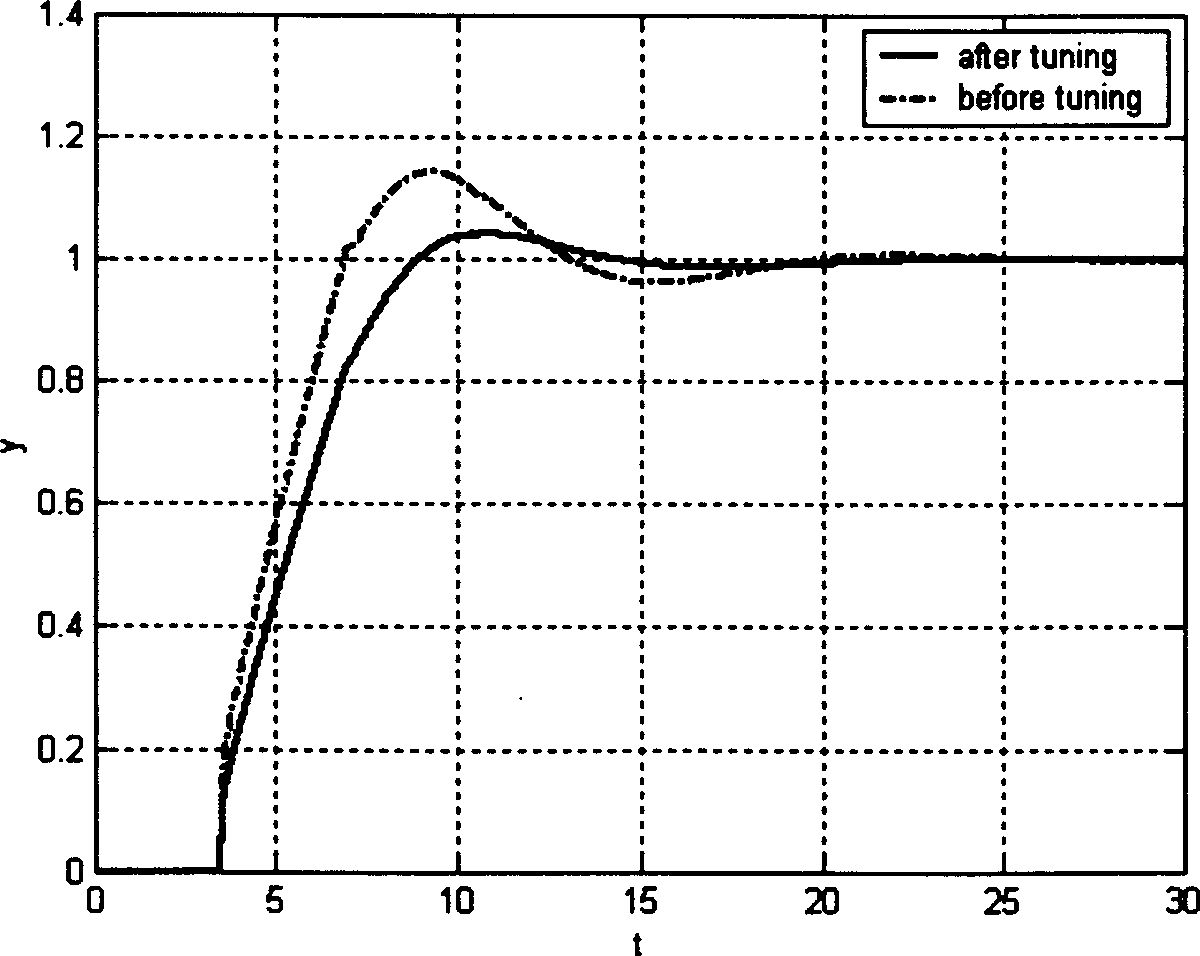

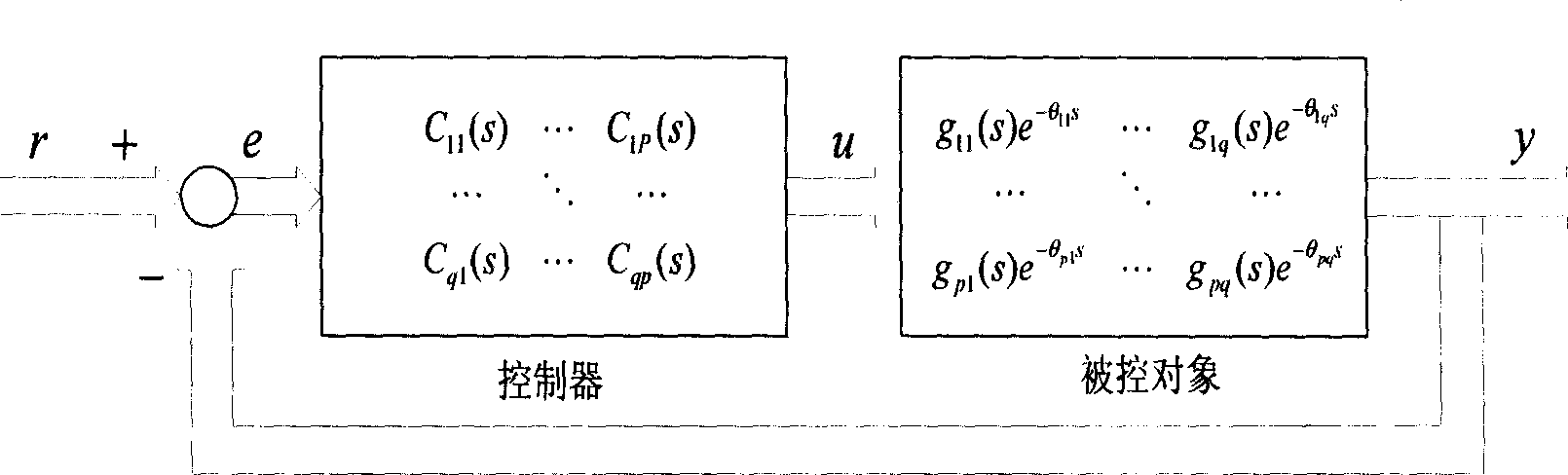

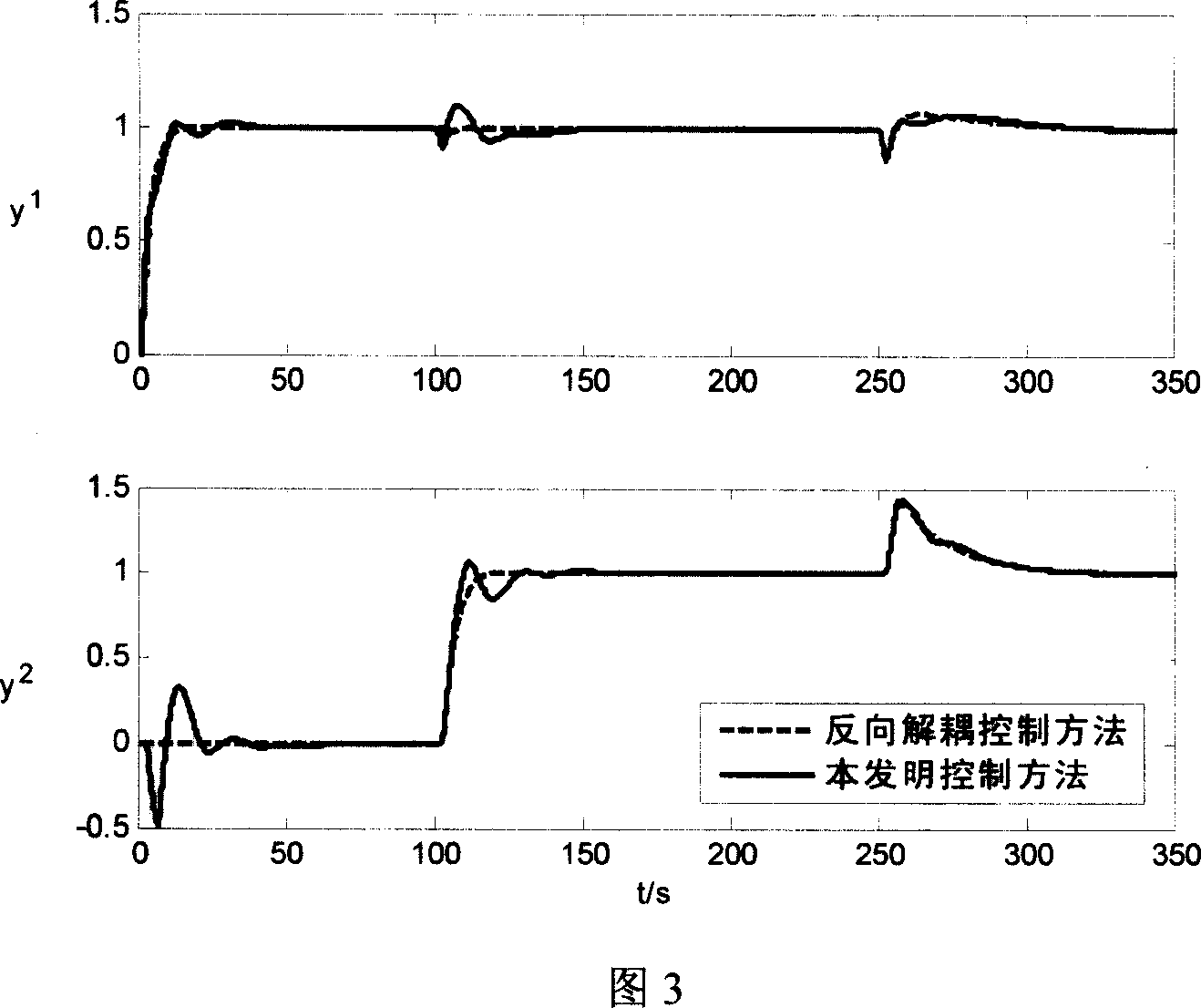

Control method of feed forward, feedback control system for interferential and time delayed stable system

InactiveCN101004592AOutput response is smooth and oscillation-freeImprove stabilityAdaptive controlTransfer function matrixTime lag

A method for designing feedforward-feedback control system of interference and time lag unstable unit includes designing a two-freedom control structure to realize decoupling of set-value response and disturbance response based on augmented least square method and according transfer function matrix identification model and relevant requirements, designing two regulation factors of track control by utilizing robust control theory, designing feedforward controller according to anti-interference requirement and using particle filtering method to eliminate interference for realizing asymptotic track of system.

Owner:SHANGHAI JIAO TONG UNIV

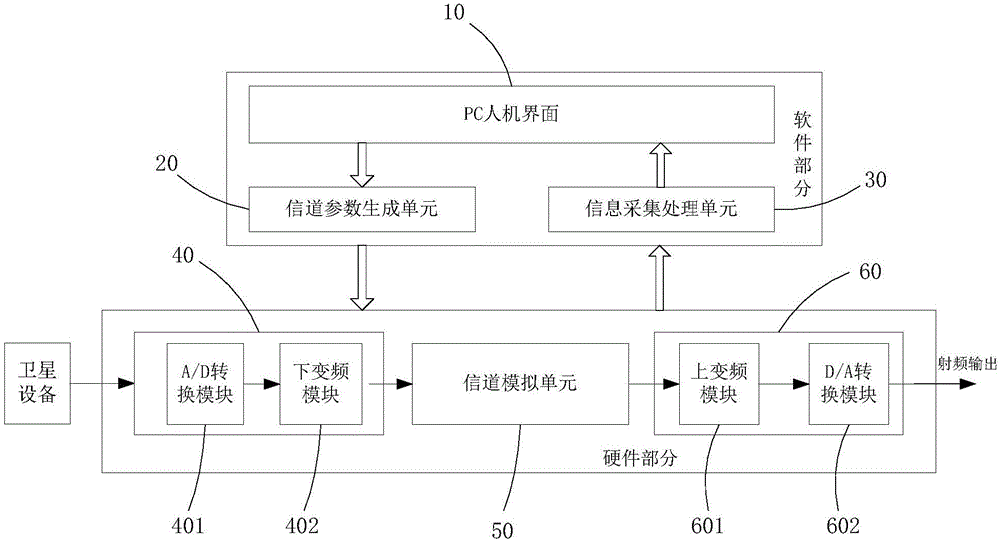

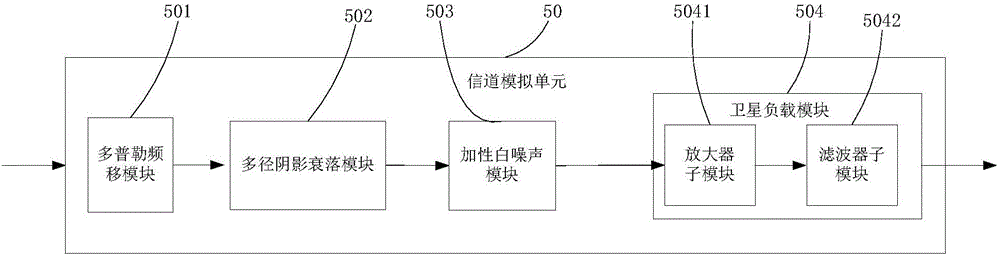

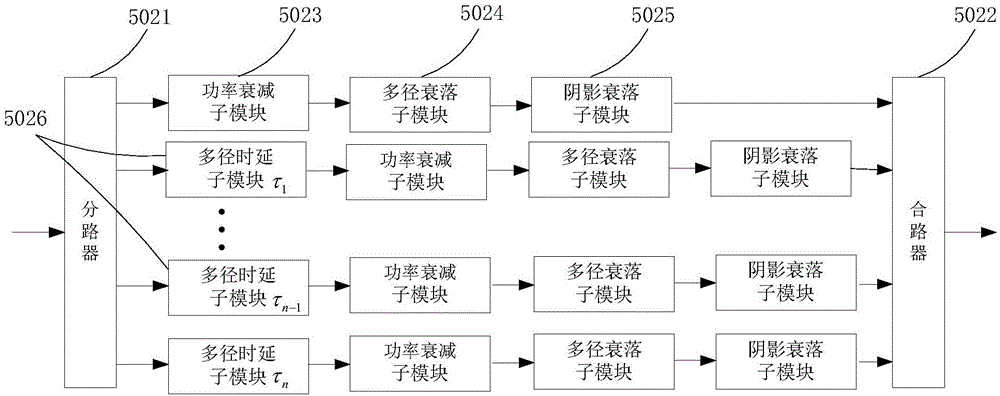

Satellite signal simulator and satellite signal simulation method

InactiveCN106452628AImprove accuracyHigh data reliabilityTransmission monitoringRadio transmissionIntermediate frequencyChannel parameter

The invention discloses a satellite signal simulator and a satellite signal simulation method. The satellite signal simulator comprises a channel parameter generation unit used for calculating channel feature parameters according to satellite channel model parameters, communication frequency points, orbit parameters, terminal parameters and environment parameters; a radio frequency input unit used for converting intermediate-frequency signals of a satellite down to baseband signals; a channel simulation unit used for, according to the channel feature parameters, respectively performing Doppler frequency shift, multipath shadow fading, additive white noise and amplification filtering processing on the baseband signals; and a radio frequency output unit used for converting the signals output by the channel simulation unit into radio frequency signals for output. According to the invention, the simulated channel model types are enabled to be more diversified, the operation is convenient and visual, and the work accuracy and the data reliability of the satellite signal simulator are improved.

Owner:SPACE STAR TECH CO LTD

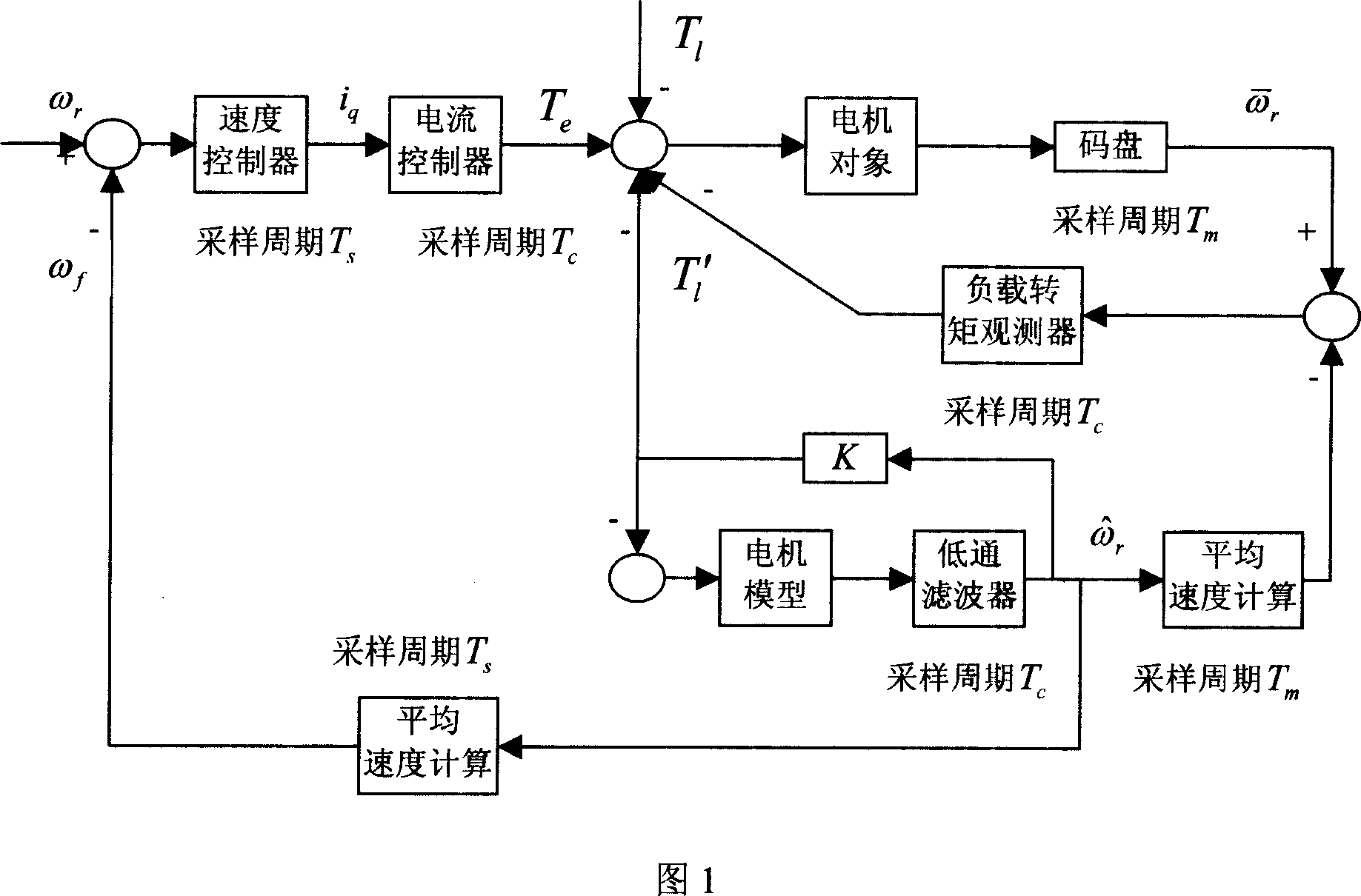

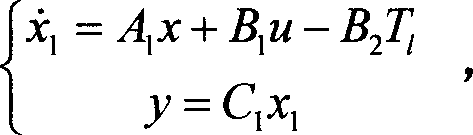

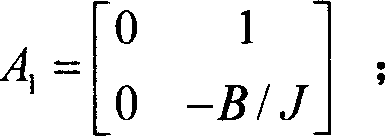

Speed control method for AC motor servo system

InactiveCN101005263ABuild intuitive connectionsAchieve speedElectronic commutation motor controlVector control systemsLow-pass filterControl system

The disclosed method for controlling speed of servo system of AC motor combines inner and outer two control rings. In the inner control ring, using coded disc measures speed of motor based on object of motor. Using load - torque observer carries out feedback control. In the outer control ring, using model of electrical motor through lowpass filter obtains estimated speed of rotor. Calculated average speed is input to feedback loop so as to form feedback control in close loop for whole control system. The method possesses high load capacity and capacity of anti external interference. The invention is suitable to control speed of AC servomotor.

Owner:SHANGHAI JIAO TONG UNIV

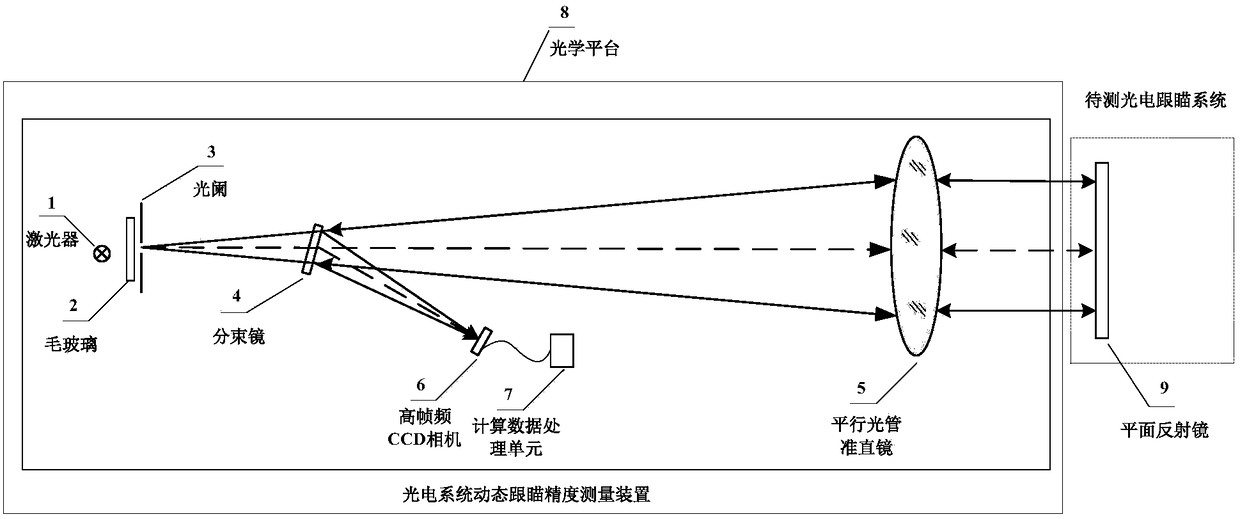

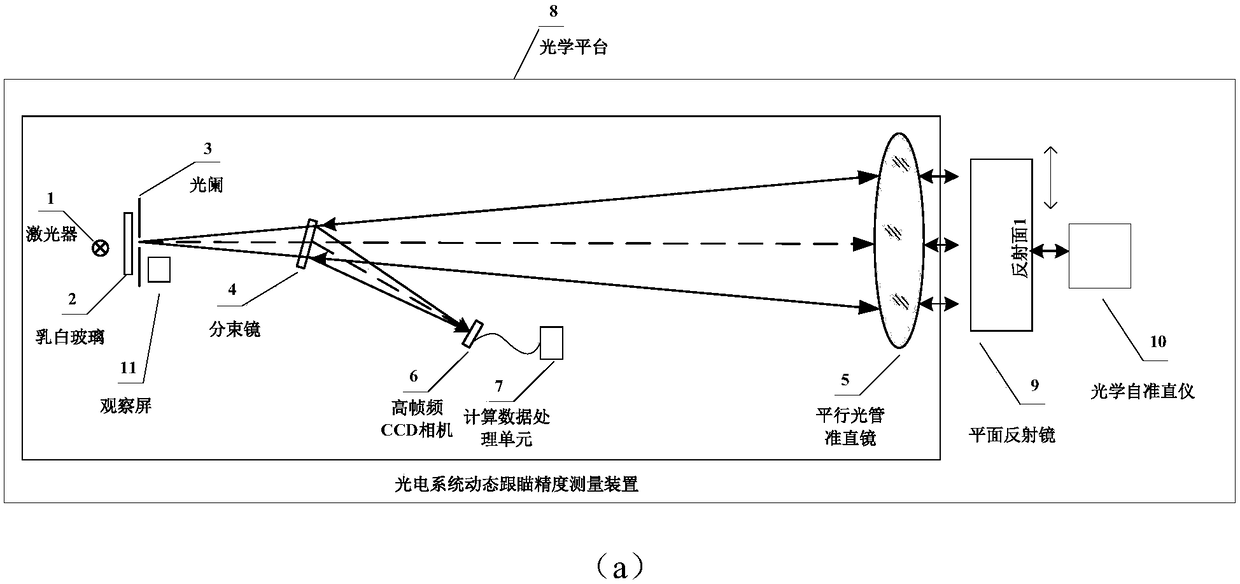

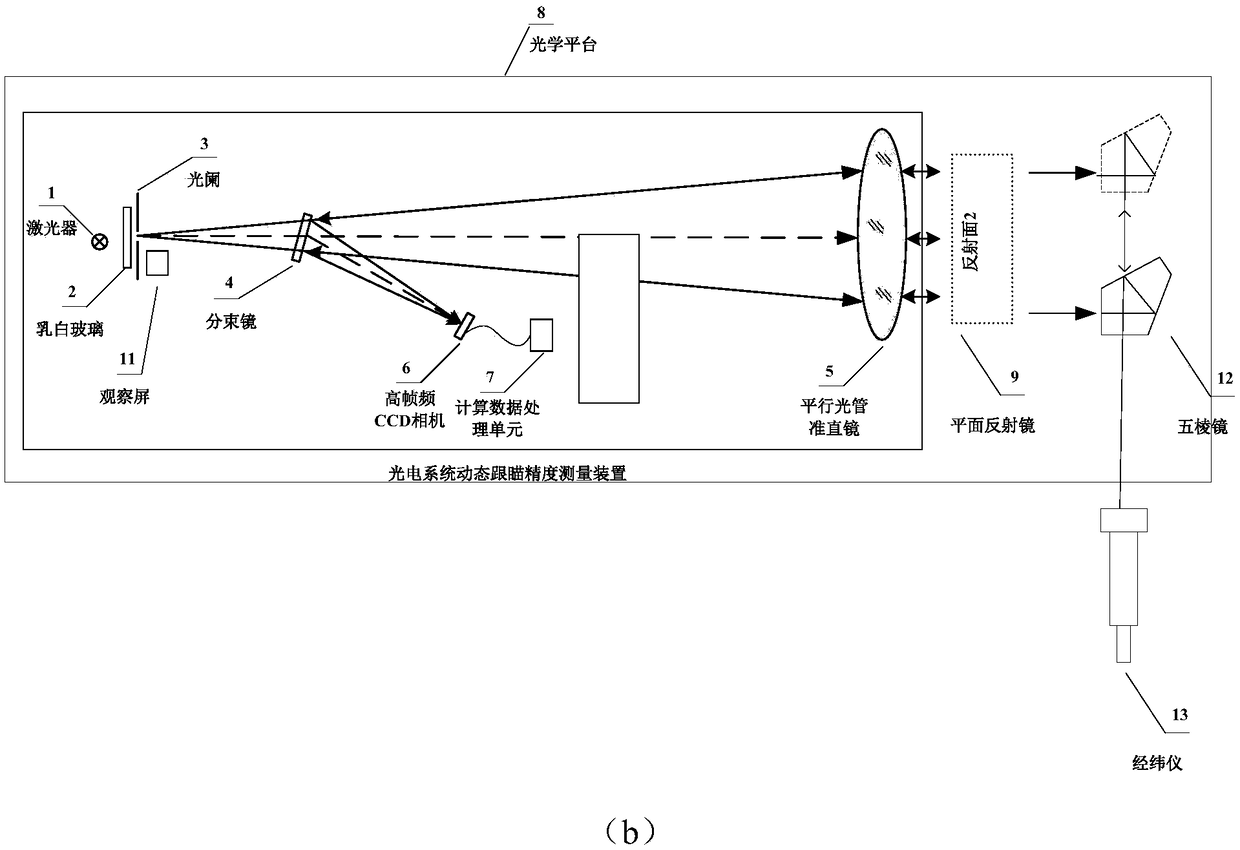

Adjusting and correcting method of light path of photoelectric system tracking-pointing precision measuring device

ActiveCN108152013ASolve adjustment problemsHigh precisionTelevision systemsOptical apparatus testingBeam splitterTheodolite

The invention provides an adjusting and correcting method of a light path of a photoelectric system tracking-pointing precision measuring device. The measuring device is mainly composed of an opticalplatform, a laser light source, ground glass, a small-hole diaphragm, a beam splitter, a parallel light pipe collimating mirror, a high-frame-frequency CCD camera and the like, wherein the laser lightsource, the ground glass, the small-hole diaphragm, the beam splitter, the parallel light pipe collimating mirror, the high-frame-frequency CCD camera and the like are installed on the optical platform. By the adoption of a plane mirror, an optical autocollimation, a pentaprism and a theodolite, the positions of the laser light source, the small hole diaphragm and the high-frame-frequency CCD camera of the photoelectric system tracking-pointing precision measuring device are adjusted and corrected, the adjusting and correcting method has the advantages of being high in precision, easy to operate, convenient and visual, the problem of adjusting and correcting the light path of the photoelectric system tracking-pointing precision measuring device is solved, and not only is technological guarantee provided for the development of a space laser communication tracking-pointing technology, but also a reference basis is provided for designing a space laser communication system tracking-pointing precision measuring device.

Owner:西安应用光学研究所

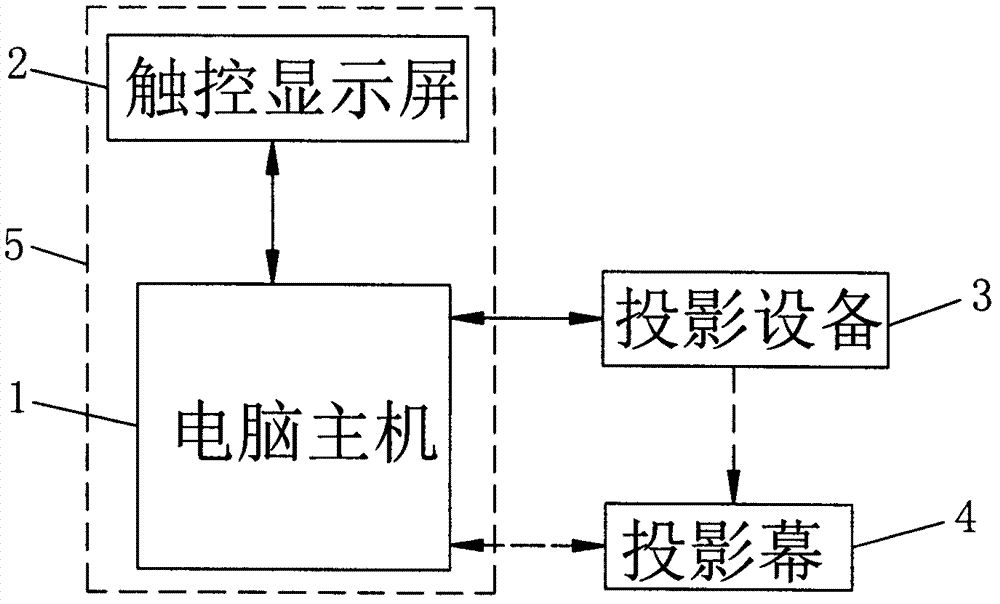

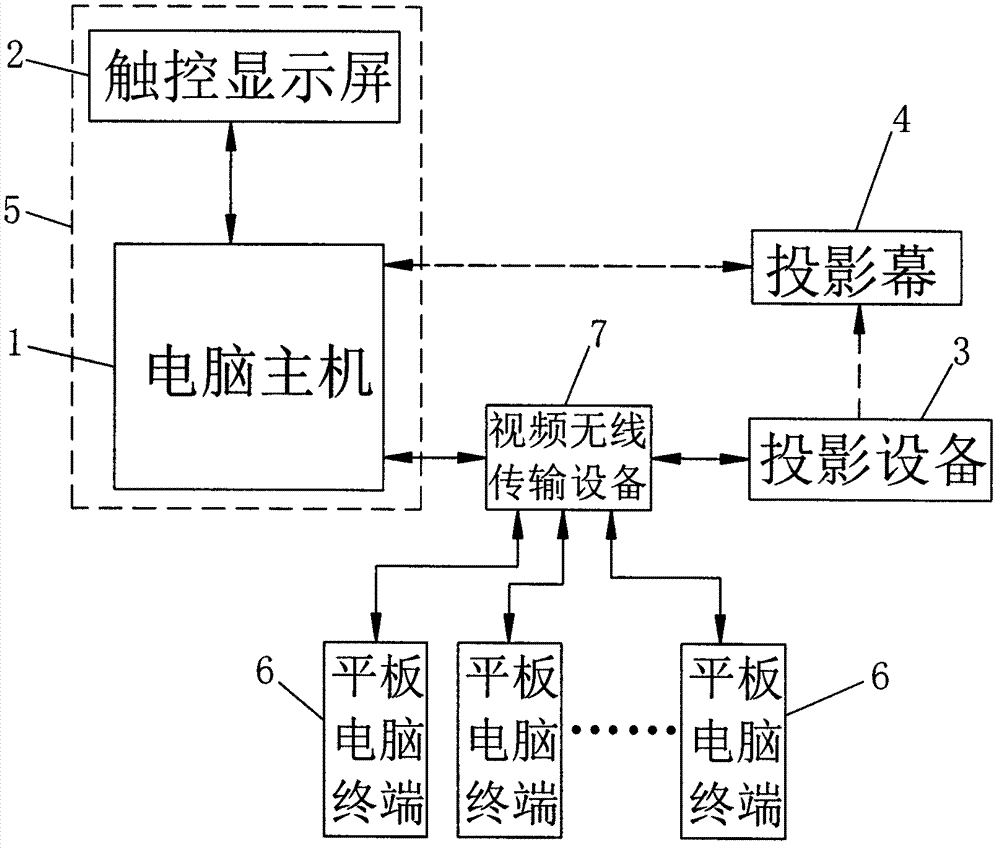

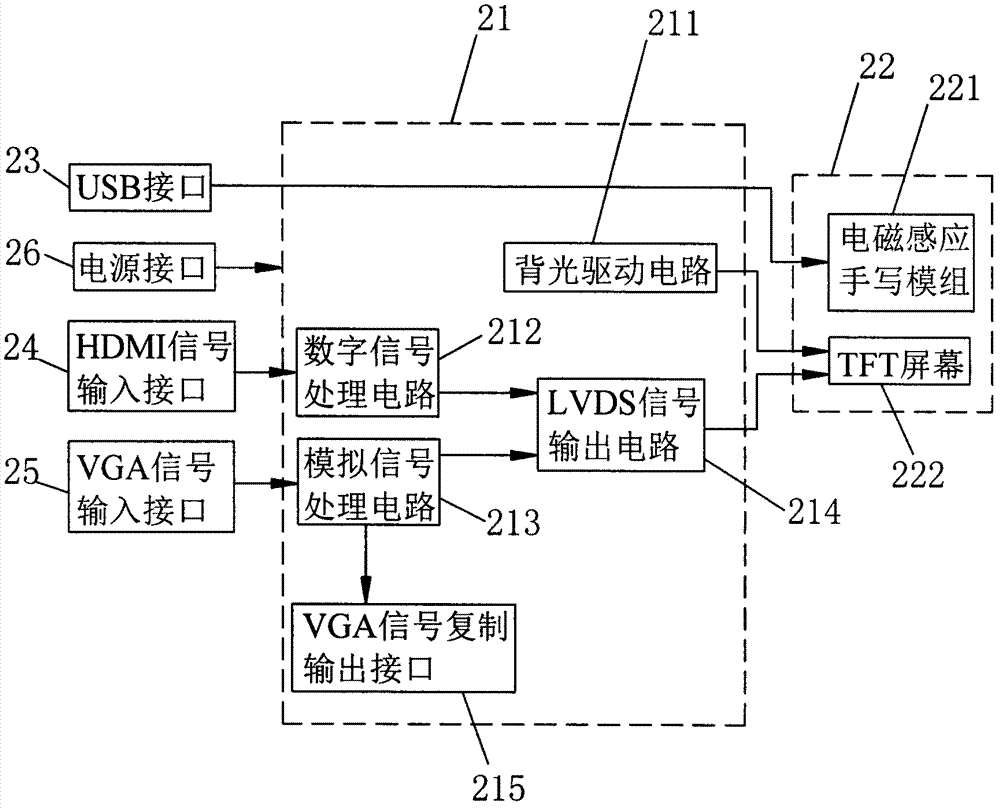

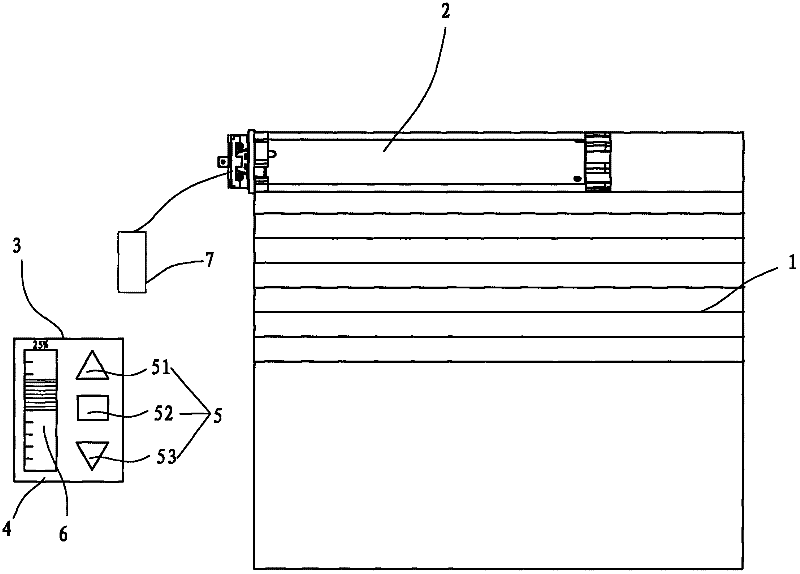

Electronic lecturing system

InactiveCN102881196AEasy and intuitive operationEasy to save and callElectrical appliancesInput/output processes for data processingHandwritingData connection

The invention relates to the technical field of multimedia systems, in particular to an electronic lecturing system. The electronic lecturing system comprises a computer mainframe, a touch control display screen, projection equipment, a projection screen, wherein the touch control display screen and the projection equipment are in data connection with the computer mainframe. According to the electronic lecturing system, the computer mainframe is controlled and information is input by hand through the touch control display screen, and the information is reflected onto the projection screen by the projection equipment in real time, so that paperless lecturing is realized with the adoption of an intelligent multimedia mode. The electronic lecturing system has the advantages as follows: 1, a teacher can completely get rid of blackboard-writing modes with a chalk, an ink pen and the like, and is kept away from the pollution of the traditional chalk powder, and a healthy and neat lecturing and learning environment is created; 2, with the adoption of the touch control display screen, the computer mainframe can be operated visually and conveniently; the teacher can input the information by hand freely in the course of explaining and demonstrating; the input information can be inserted into a lecture file with the real handwriting being reserved, and storage and calling are convenient; and 3, lecturing contents can be transferred in a paperless manner completely, so that low carbon and environmental protection are achieved, and the lecturing effects and the efficiency are improved.

Owner:东莞市沃德电子科技有限公司

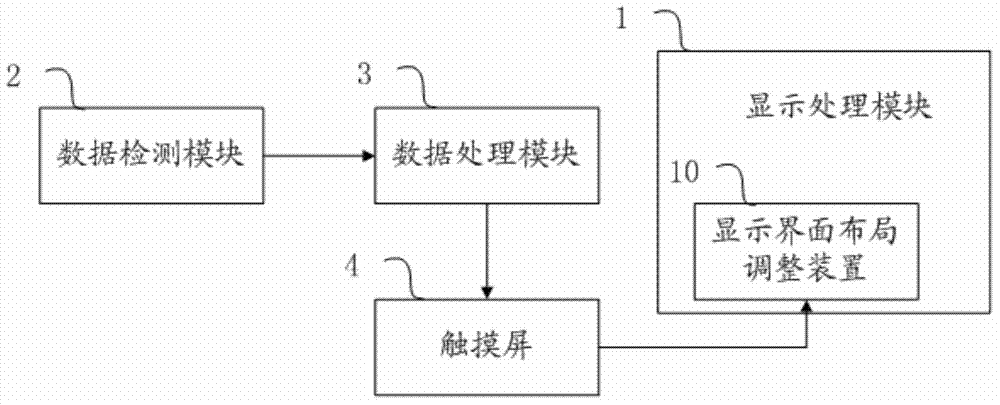

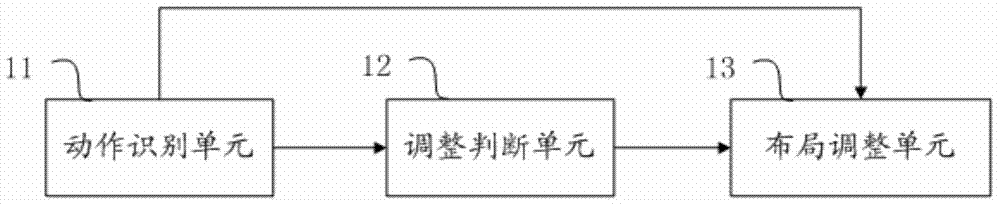

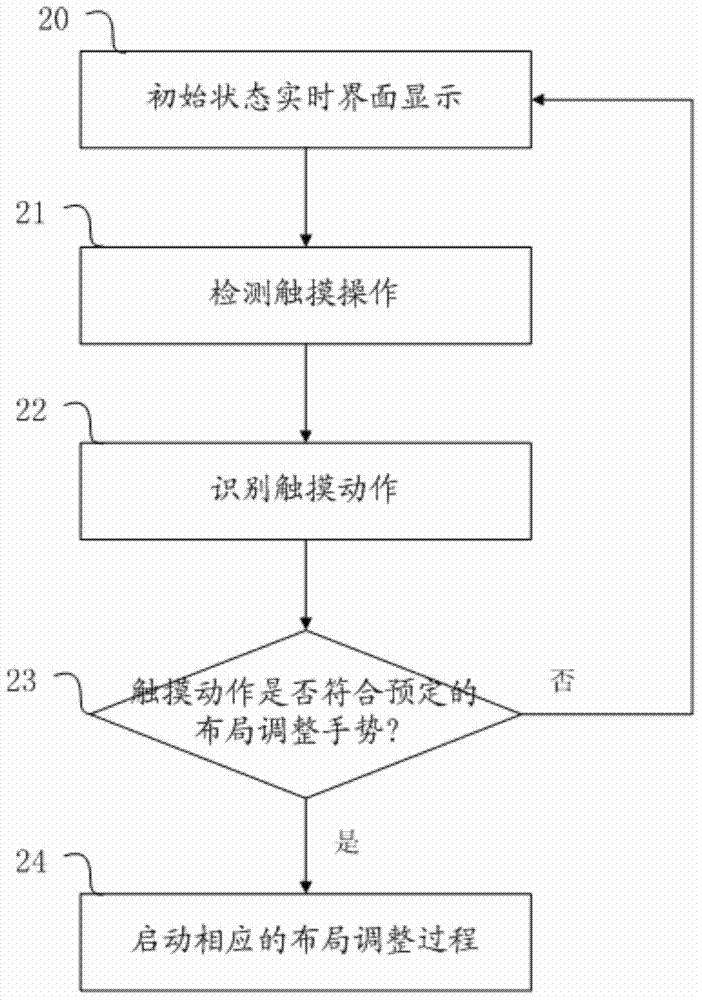

Monitoring equipment and display interface layout adjustment method and device thereof

ActiveCN104750406AReduce stepsImprove experienceSpecial data processing applicationsInput/output processes for data processingMonitor equipmentHuman–computer interaction

The invention discloses monitoring equipment and a display interface layout adjustment method and device thereof. The method includes: detecting touch operations of a user; identifying touch actions; judging whether the touch actions conform to preset layout adjustment gestures or not, and if yes, adjusting display interface layout on the basis of the touch actions of the user. With the method, the user can directly adjust the interface layout in an interface in real time, operation steps of the user are reduced, the touch operations of the user are mainly depended on in adjustment, which is more in line with people's operation habit, the operations are more visual and convenient, efficiency and easiness in layout adjustment are improved, and user experience is improved.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD +1

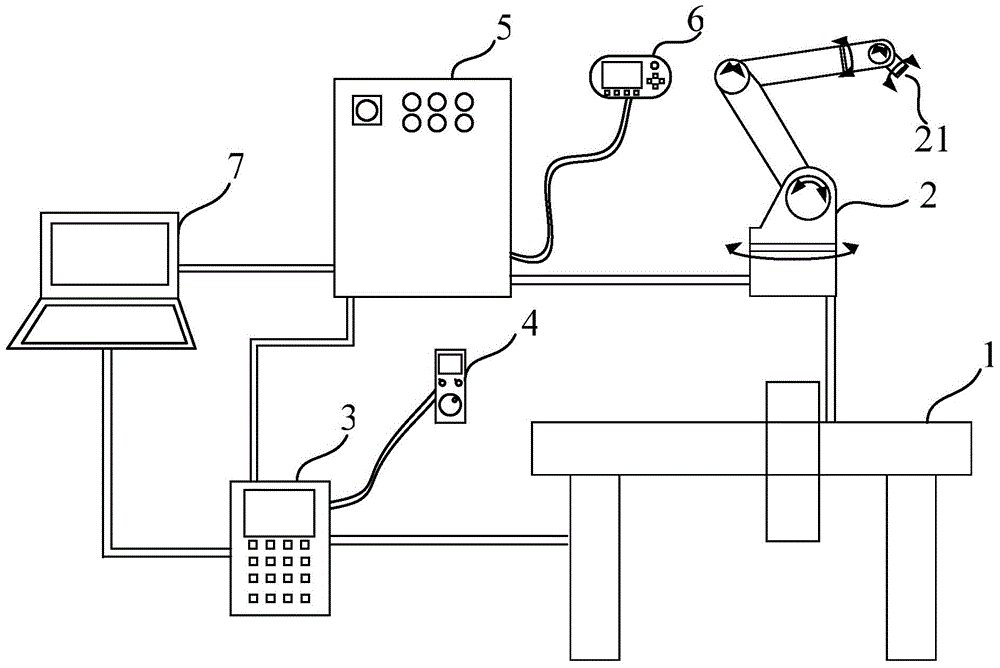

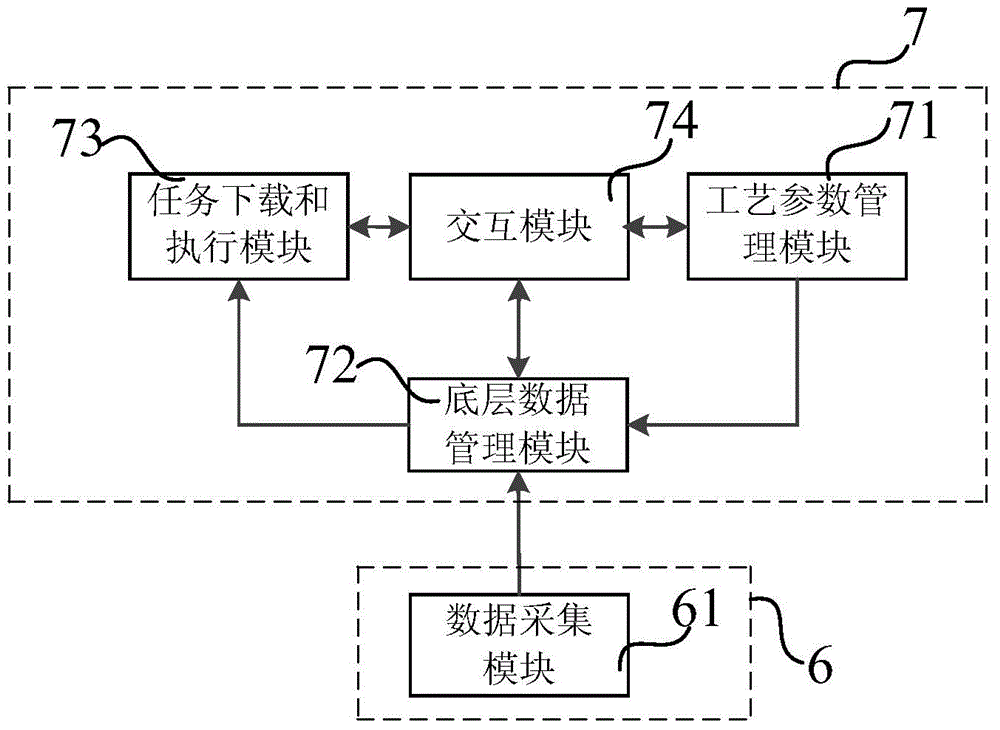

Industrial robot teaching system

ActiveCN104700705AMeet motion synchronization requirementsEasy to set upCosmonautic condition simulationsEducational modelsHand heldControl theory

The invention provides an industrial robot teaching system. The system comprises a mobile platform, an industrial robot, a numerical control system, a hand wheel, an industrial robot controller, a handheld demonstrator and an industrial computer. The industrial robot is fixed on the mobile platform and capable of moving along with the mobile platform and comprises a tail end for performing the technological operation. The numerical control system is in communication connection with the mobile platform to control the moving of the mobile platform. The hand wheel is in communication connection with the numerical control system to be operated by an operator and to control the moving of the mobile platform through the communication with the numerical control system. The industrial robot controller is in communication connection with the industrial robot to control moving and technological operations of the tail end of the industrial robot and is further in communication connection with the numerical control system. The handheld demonstrator is in communication connection with the industrial robot controller for the operator to input acquisition instructions and control the industrial robot to move through the communication with the industrial robot controller and to be used for the operator to input technological marks. The industrial computer is in communication connection with the numerical control system and the industrial robot controller.

Owner:清研同创机器人(天津)有限公司

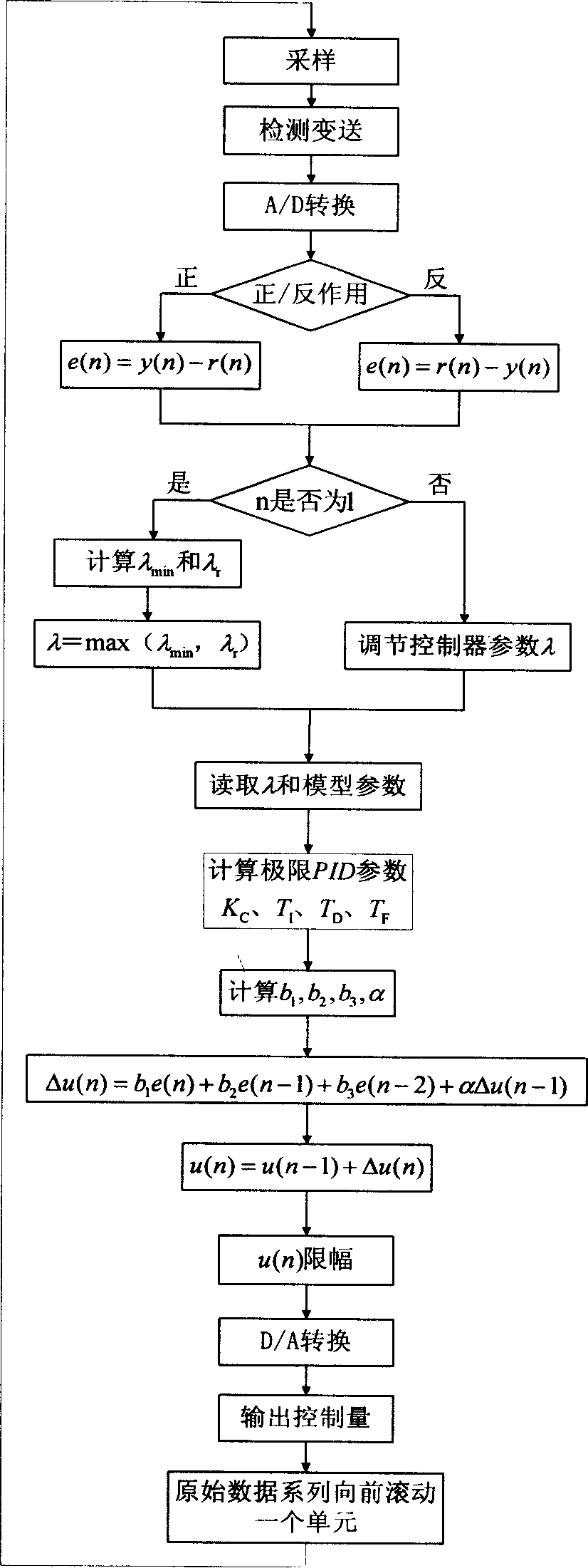

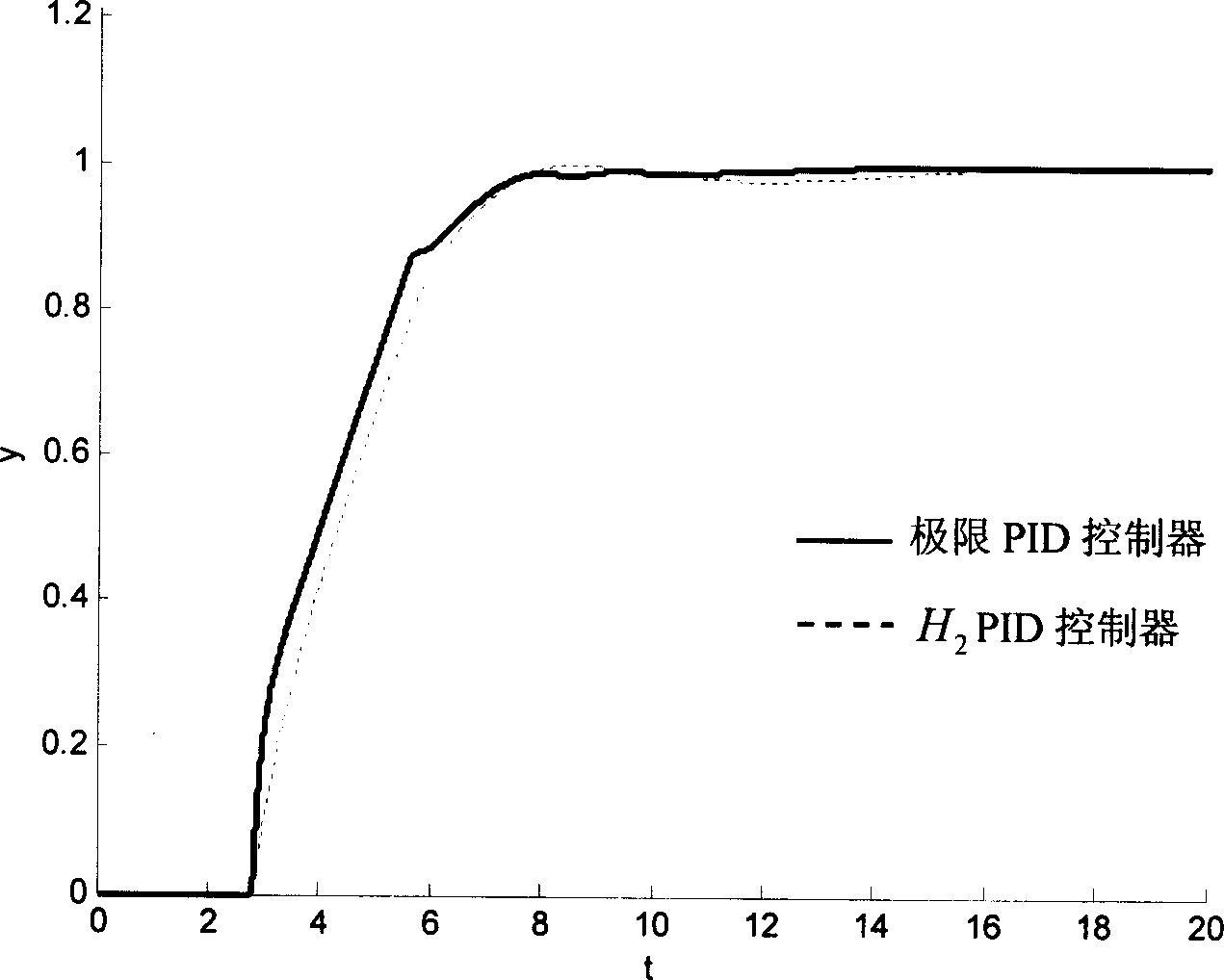

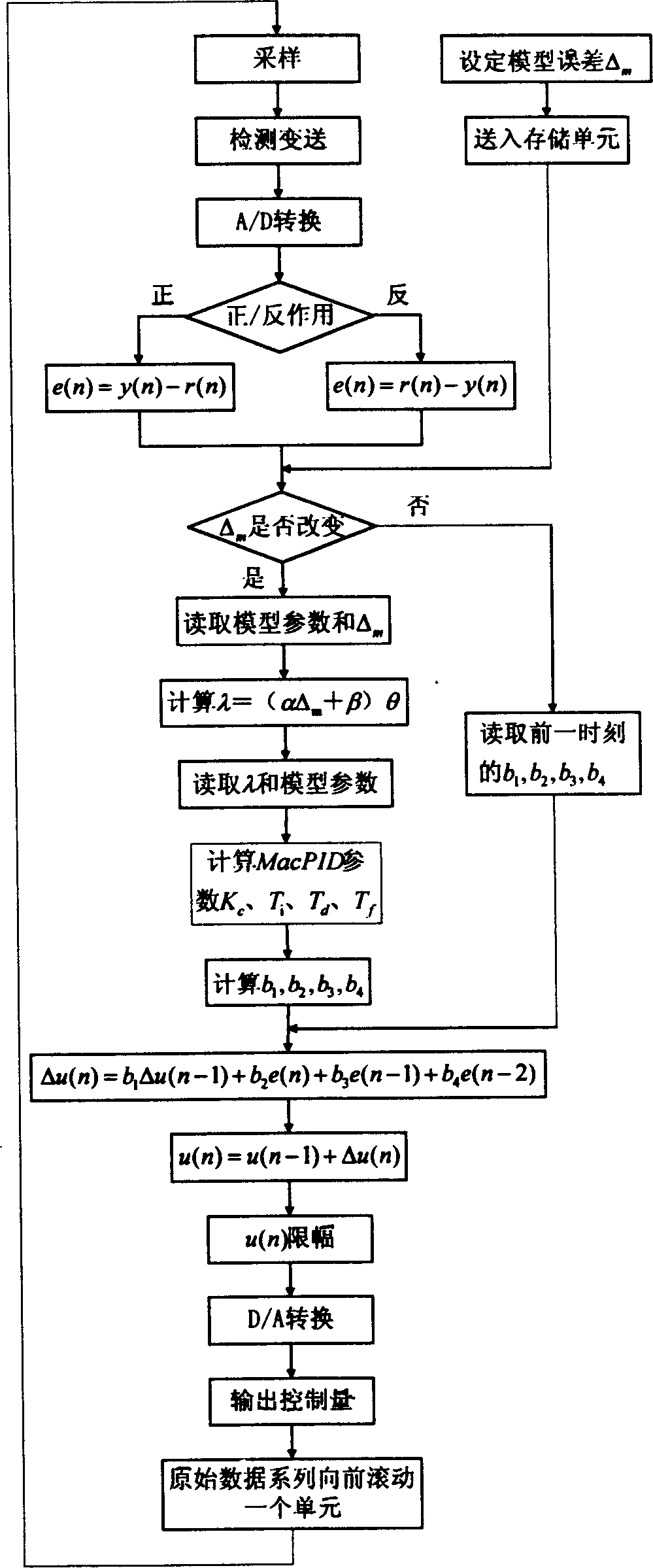

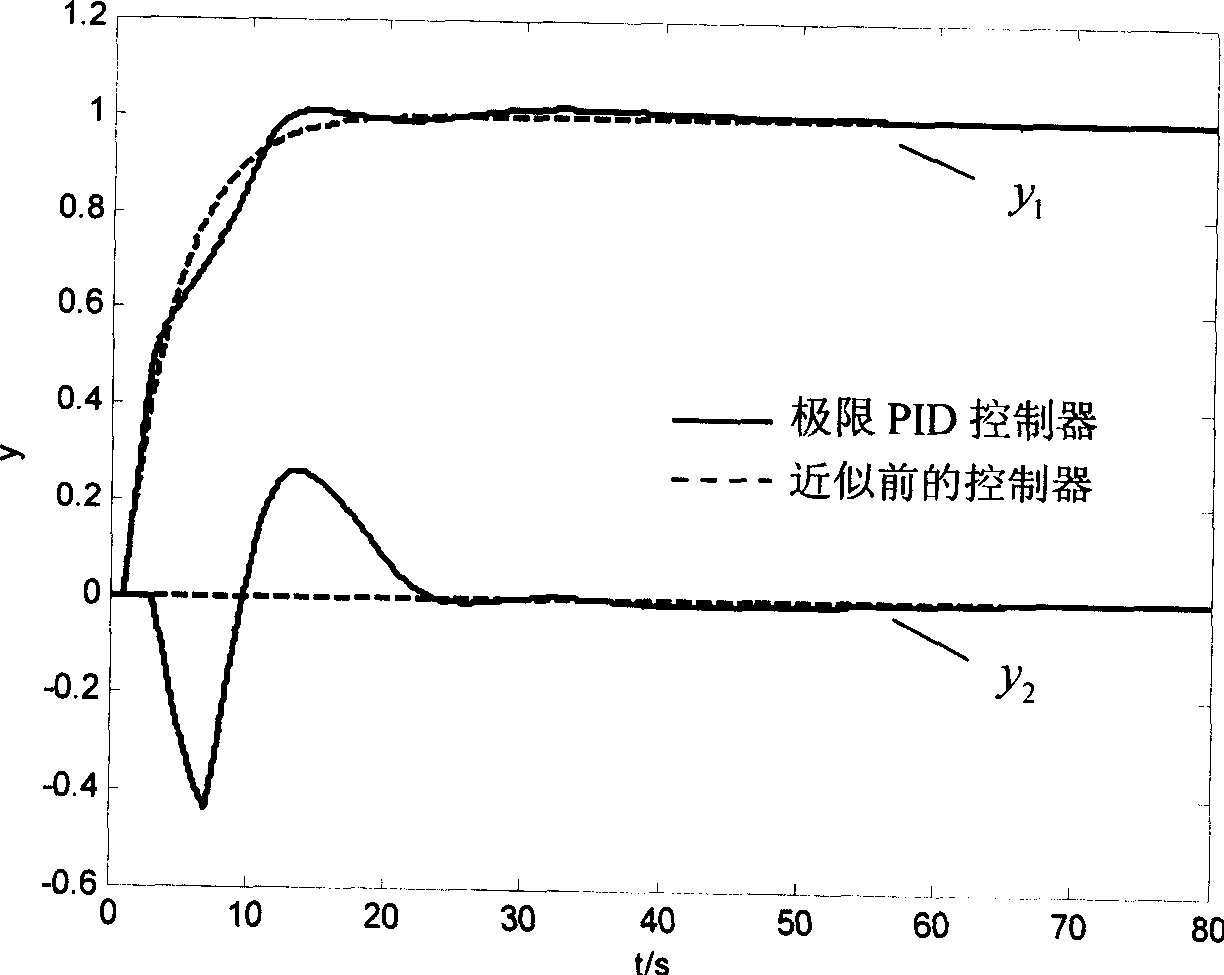

Limsting PID control method of single input single output system

InactiveCN1794118AEasy and intuitive operationImprove control effectControllers with particular characteristicsAdaptive controlLower limitOptimal control

A method for controlling limit PID of single input / single output system includes carrying out identification on object after A / D conversion for obtaining digital signal of sampling signal, ensuring four parameters corresponding to PID controller to be position value by regulating bottom limit of controller parameters, judging polarity of digital amount input signal and calculating error signal according to it, calculating parameter value of limit PID controller and calculating increment value being sent to executor after D / A conversion for operating controlled object in set range.

Owner:SHANGHAI JIAO TONG UNIV

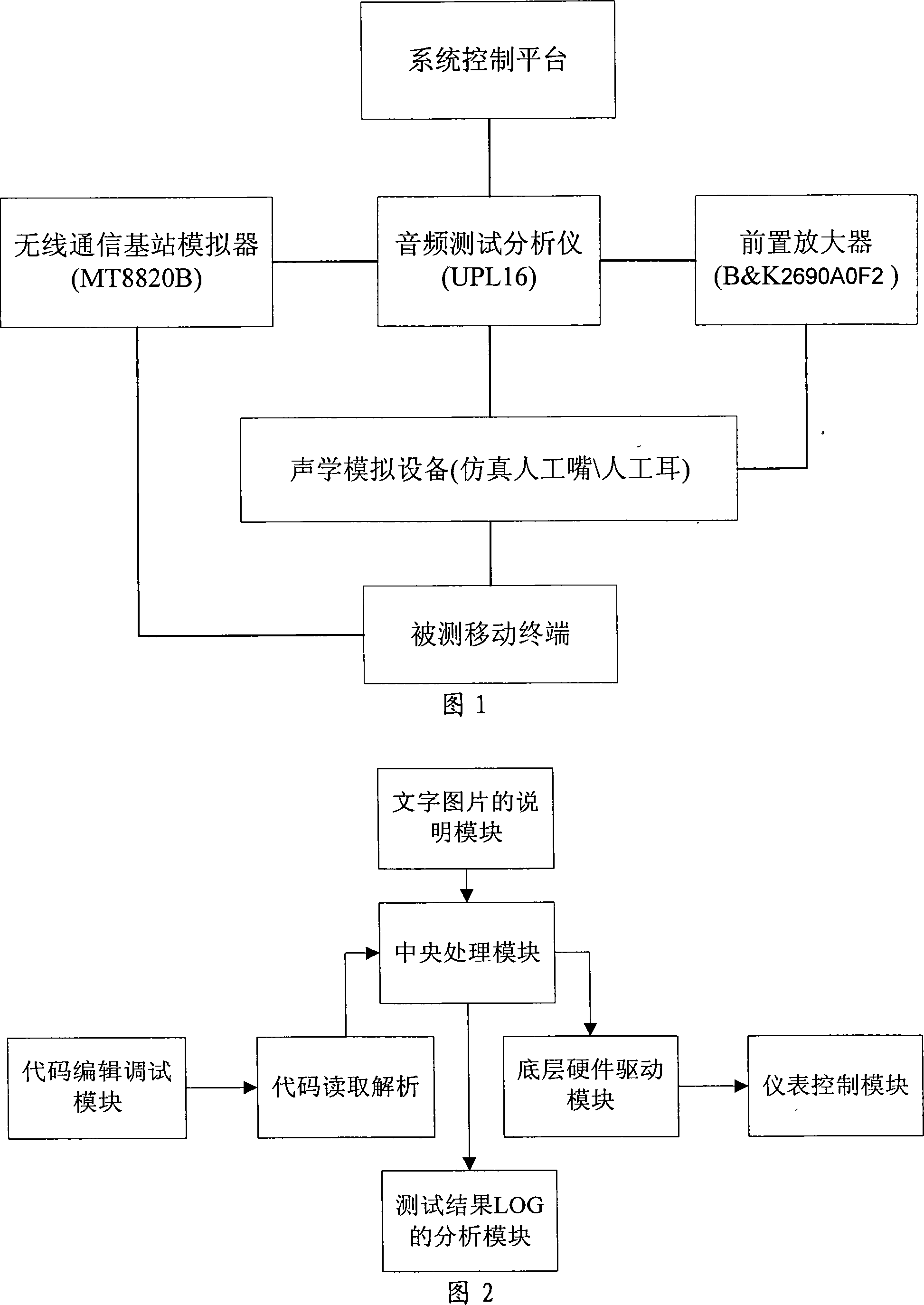

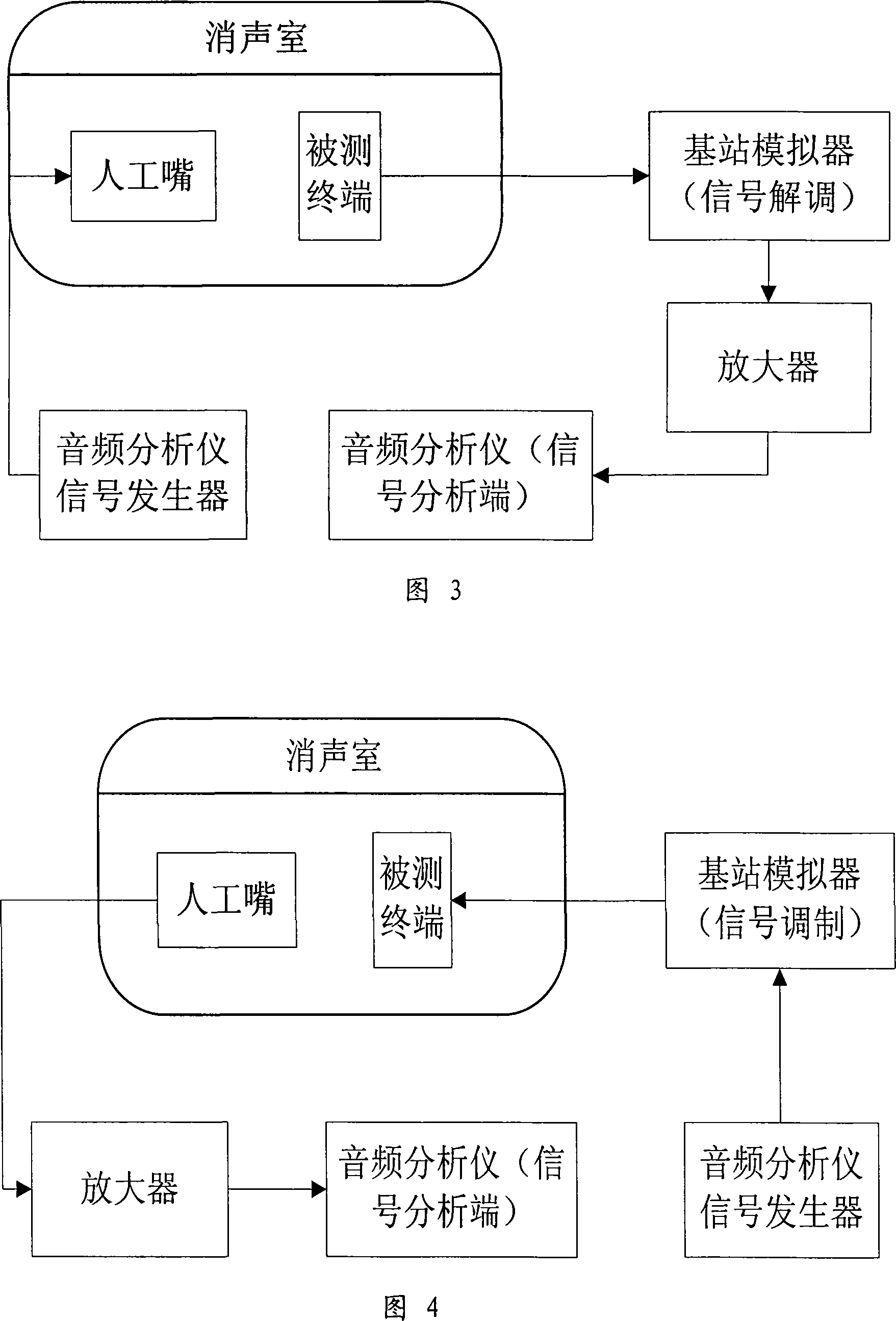

Audio testing system and method for mobile communication terminal

InactiveCN101132594AEasy and intuitive operationIntuitive and convenient analysis methodSupervisory/monitoring/testing arrangementsRadio/inductive link selection arrangementsEnvironmental noiseEngineering

This invention relates to an audio test system and a method of mobile communication terminals, in which, the sytem includes: a radio communication base station simulator, an audio test analyzer, a system control platform, a noise eliminating chamber, a preamplifier and an acoustic simulation device, said method includes test to the evaluation values of transmission loudness and receiving loudness, noise of idle channels, transmission flexibility / frequency character, receiving flexibility / frequency character, evaluation value of side sound mask, loss of stability, echo control of acoustics and T-R distortion, and also includes evaluation value of side sound mask, out-of-band signals and suppression to environmental noise of listeners.

Owner:BEIJING WULONG TELECOM TECH +1

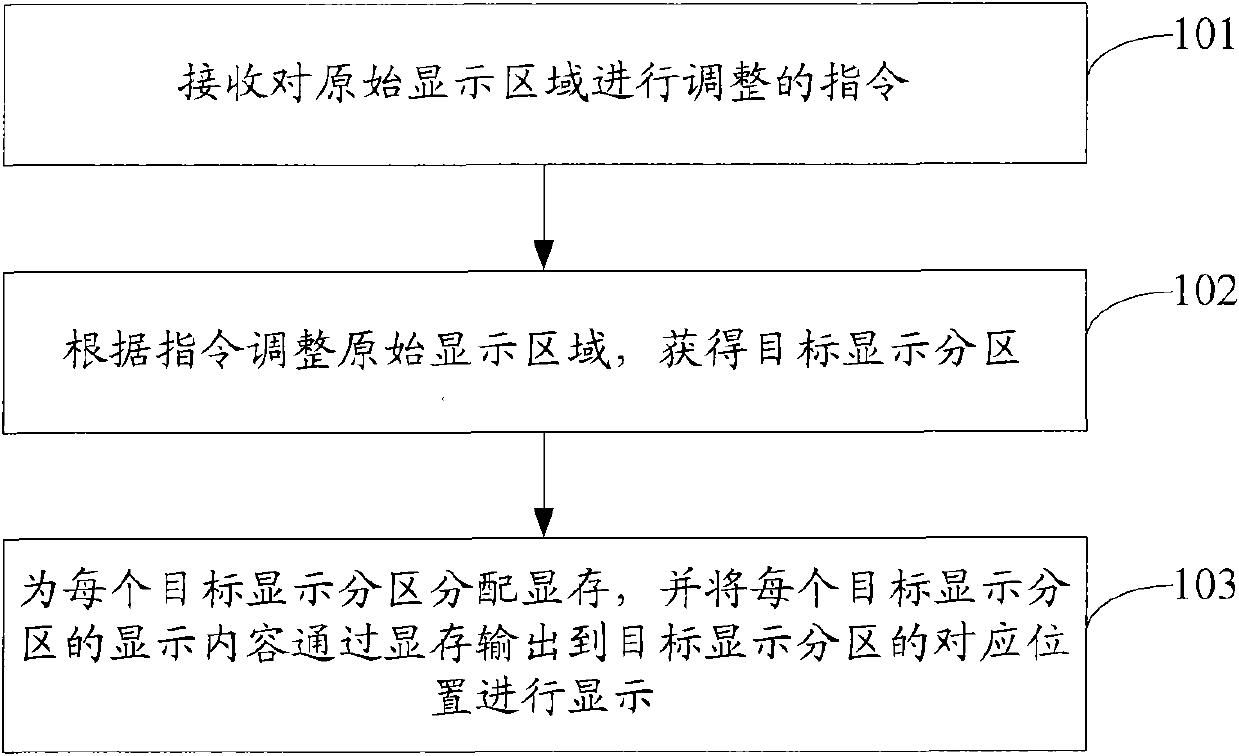

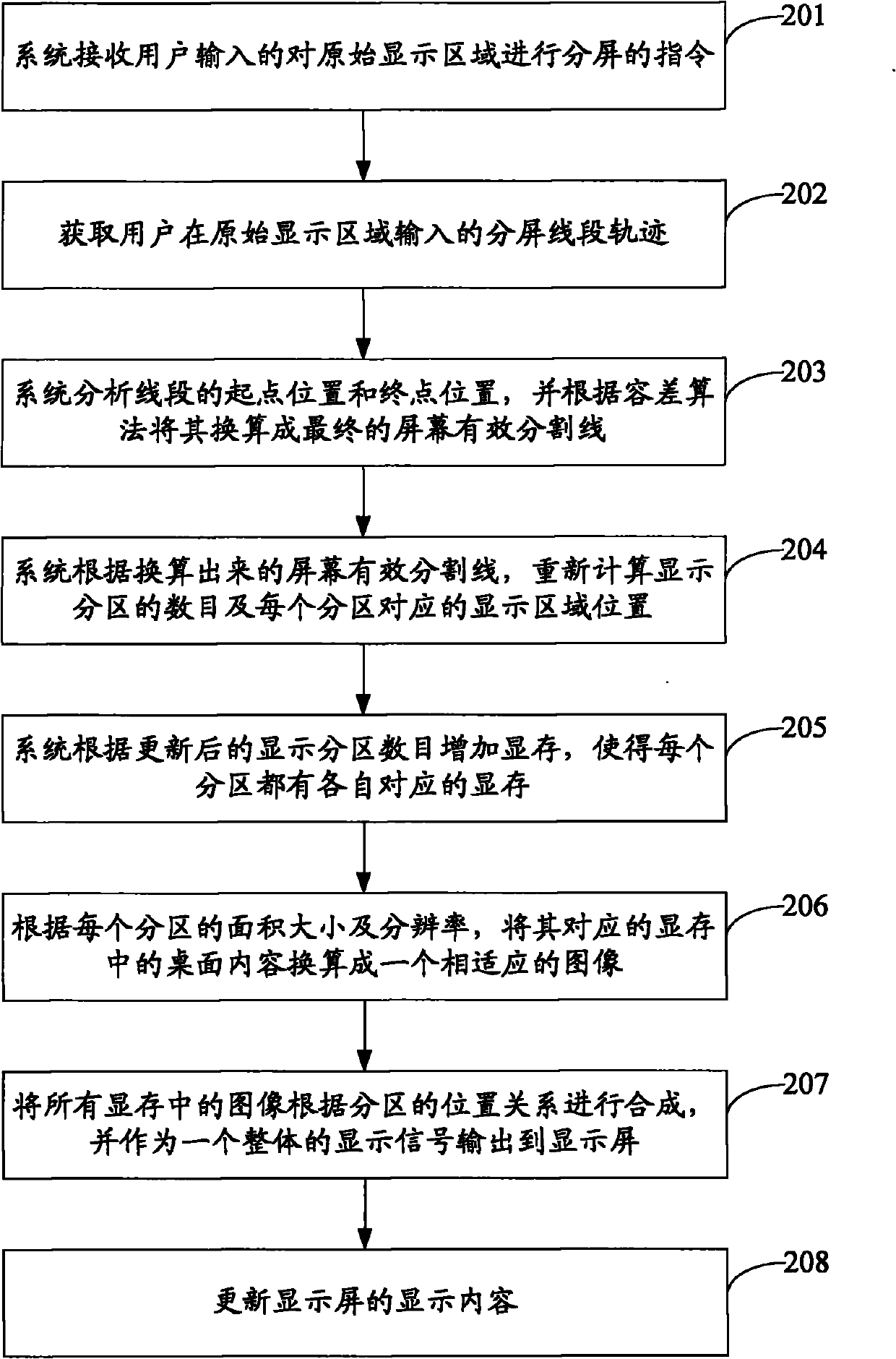

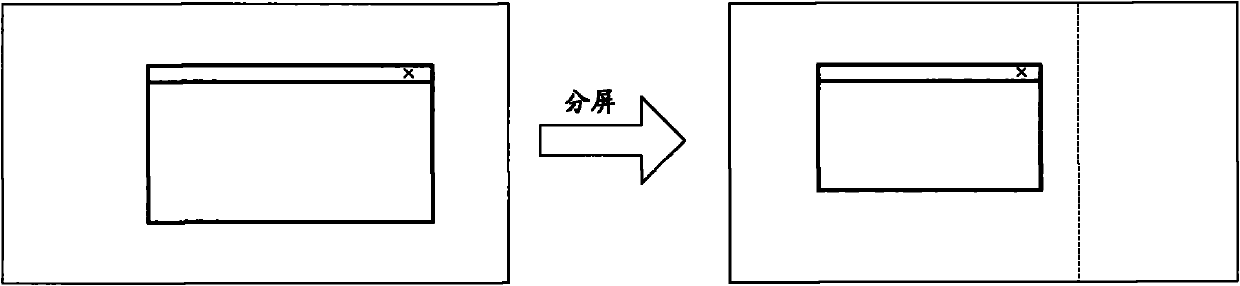

Display method and device

ActiveCN102201221AIncrease flexibility and freedomEasy and intuitive operationCathode-ray tube indicatorsDisplay memoryVideo memory

The embodiment of the invention discloses a display method and device. The method comprises the steps of: receiving an instruction of regulating an original display area; regulating the original display area according to the instruction and obtaining target display subareas; distributing display memories for each target display subarea and outputting display contents of each target display subarea to corresponding positions of the target display subareas through the display memories to display. By means of the display method and device provided by the embodiment of the invention, the flexible split-screen regulation can be carried out on the original display area according to different regulation instructions; the split-screen display can be carried out according to split-screen results; and therefore, the degree of freedom and the flexibility ratio of the split screen are increased, the visual operation can be conveniently carried out by users and the split-screen operation experience of the users is improved.

Owner:LENOVO (BEIJING) CO LTD

Intelligence Proportional-integral-aifferential control method with quantitative positive definite robustness

InactiveCN1445629AEasy and intuitive operationStable controlControllers with particular characteristicsAdaptive controlControl signalComputer science

An intelligent proportional-integral-derivative control method for quantitatively setting up the robustness of system includes such steps as recognizing the model of controlled object by the industrial control system, generally judging the corresponding model error value by user according to the in-situ condition, executing the programmed intelligent PID control program by monitor module, evaluating the optimal controller parameters, and calculating PID controller parameters to obtain the control signal. It can quantitatively set up the system robustness and make a compromise between symmetricity and robustness of the system.

Owner:SHANGHAI JIAO TONG UNIV

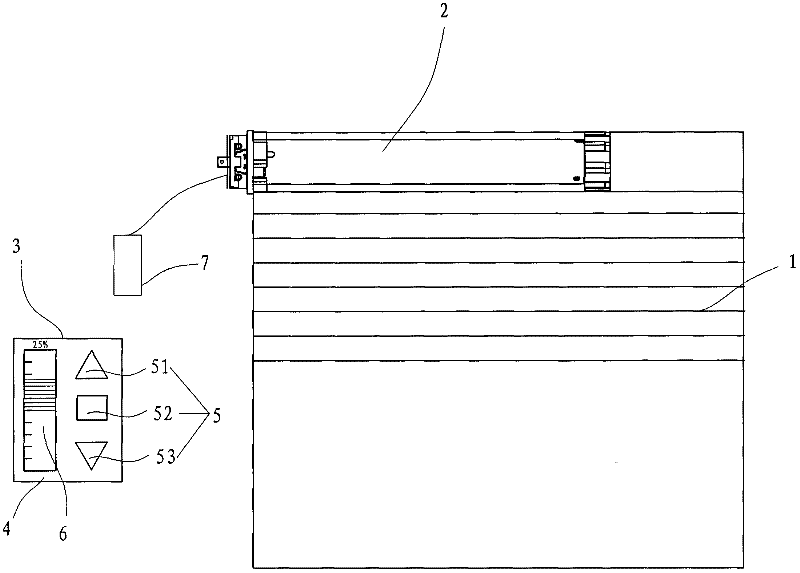

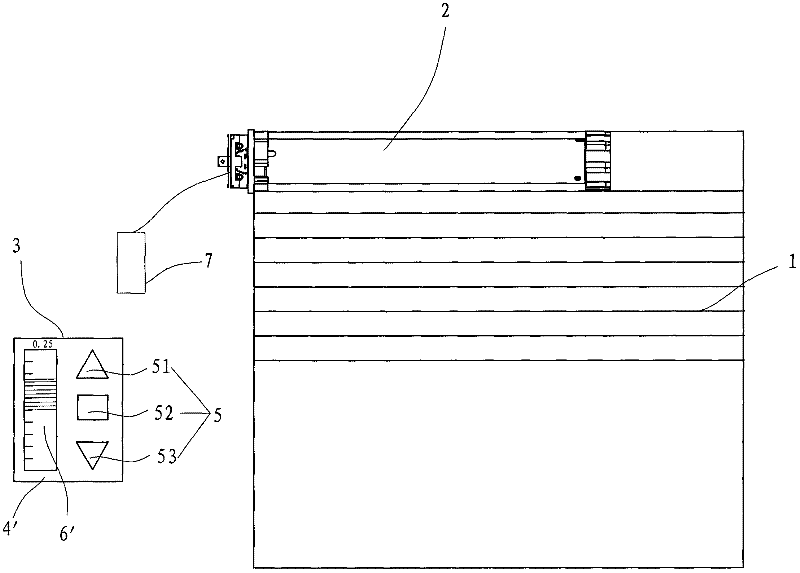

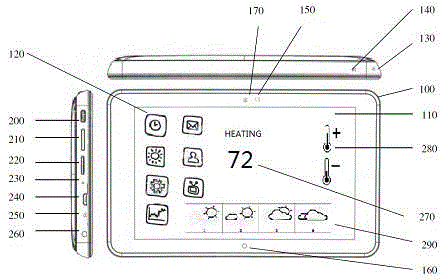

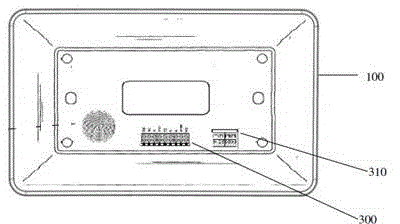

Control device with touch screen and control method thereof

InactiveCN102289319AEasy and intuitive operationInput/output processes for data processingTouchscreenEmbedded system

The invention discloses a control device with a touch screen, comprising a control terminal and a control module connected to the control terminal, characterized in that the control terminal is provided with a touch screen, and the touch screen includes a A display module, the operation control information corresponds to the stroke of the motor controlled by the control module. By setting the touch screen, the stroke can be displayed intuitively through the scale, which greatly facilitates the operation. In addition, a control method of the control device is also disclosed.

Owner:NINGBO DOOYA MECHANIC & ELECTRONICS TECH

Limit PID control method of multi input multi output system

InactiveCN1794119AEasy and intuitive operationWide applicabilityControllers with particular characteristicsAdaptive controlMulti inputTransfer function matrix

A method for controlling limit PID of multi-input / multi-output system includes identifying model as per transfer function matrix of multi-input / multi-output procedure, designing three optimum demodulation factors based on robust control theory, designing optimum controller based on said factors and optimum performance target, simplifying sub controller in controller matrix, obtaining output control signal by calculation and sending it to executor after D / A conversion to act it onto controlled object to let controlled object be operated in set range.

Owner:SHANGHAI JIAO TONG UNIV

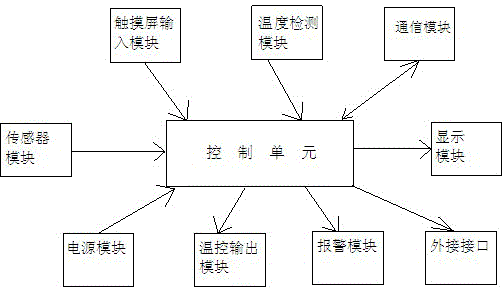

Intelligent energy-saving thermostat

InactiveCN103557580AComprehensive information displayStrong control functionSpace heating and ventilation safety systemsLighting and heating apparatusDisplay deviceTouchscreen

The invention relates to an intelligent energy-saving thermostat. The intelligent energy-saving thermostat is characterized by comprising a central processing unit (CPU) with an ARM framework chip, a touch screen display and other printed circuit motherboard and hardware which are provided with functions of a tablet personal computer as well as further comprising a sensor module, a temperature detection module and a temperature control output module which are needed by the thermostat and a storage module, a power module and an epitaxial device access module. The sensor module, the temperature detection module, the temperature control input and output module, the power module and the epitaxial device access module are all controlled by the central processing unit with the ARM framework chip as well as are communicated with other hardware such as a display module and a camera module of the tablet personal computer. The hardware of the thermostat is provided with an Android operating system and the temperature control function is achieved through the application software (APP). The intelligent energy-saving thermostat is initially designed on base of the hardware of the tablet personal computer with the ARM framework chip and operates the Android operating system, so that the intelligent energy-saving thermostat can have more powerful functions on aspects of intelligent control, air conditioning energy saving, remote control, multimedia information push, control instruction push, software and firmware update of products after sale and the like than a traditional thermostat with single chip and an intelligent home controller.

Owner:高清鸿

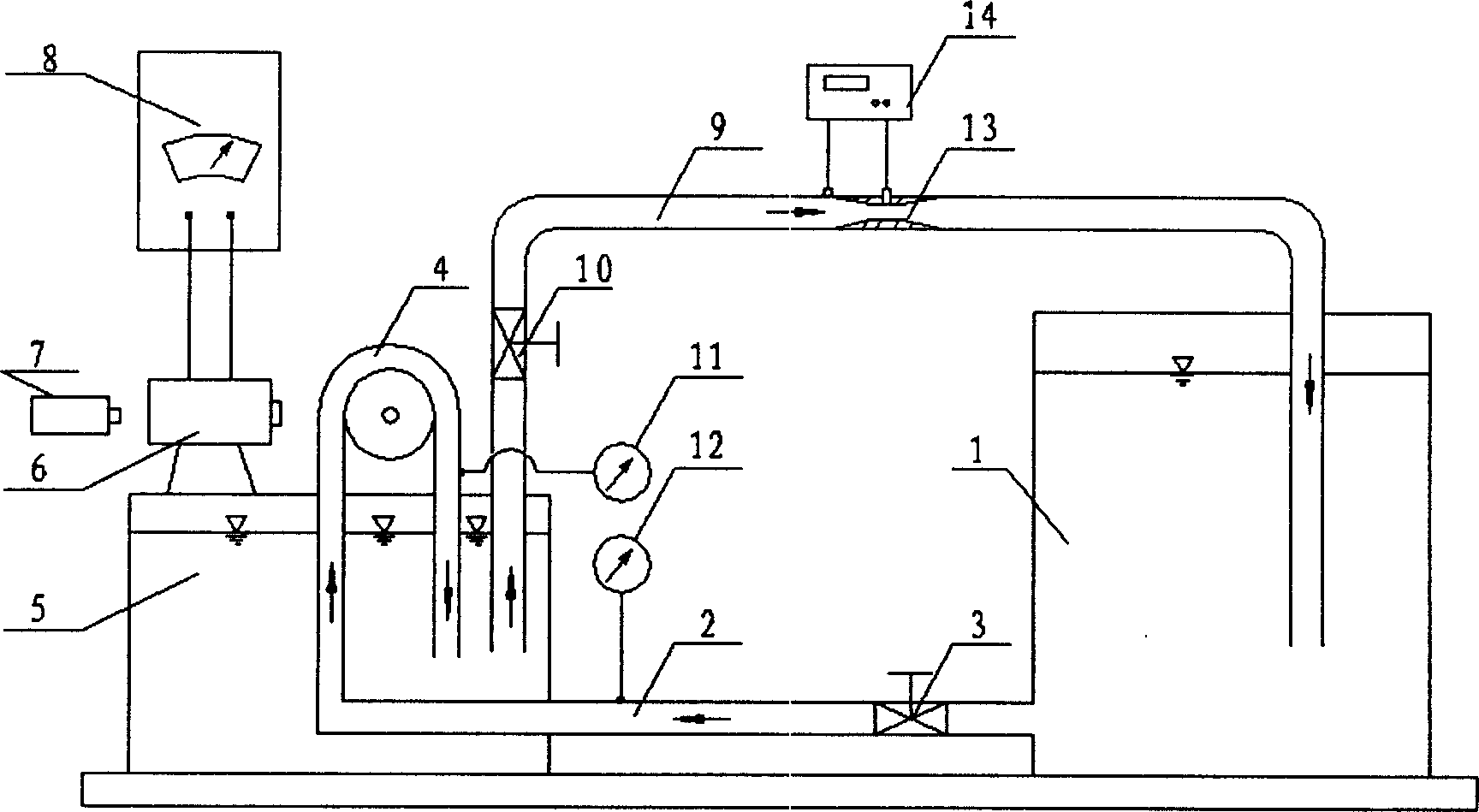

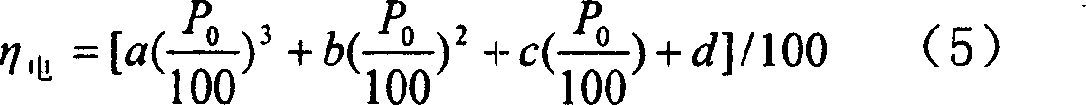

Self circulation pump specific curve test instrument

A self-loop desk-top pump characteristic curve is disclosed, comprising feed water tank, inlet valve on inlet pipe and combined pressure and vacuum gauge, with one end of inlet pipe linking to inlet of experimental pump which is linked to motor, pressure gage installed on outlet of experimental pump where links a stabilization water pressure tank whose outlet with water pipe linking to feed water tank, flow regulating valve and flowmeter with manometer on it installed on water pipe. The invention has simplified large structure; phenomenon of rupture working condition is shown clearly by using inlet valve to control the pressure of water flowing into water pipe; using separate self-loop water supply constant water supply system system and only 220V voltage, it is suitable for modern teaching require and has saved special spot for experiment.

Owner:ZHEJIANG UNIV

Anti-interference PID (proportion integration differentiation) controller for unstable time-lag process and design method thereof

InactiveCN103631139AEliminate load disturbancesImprove anti-interference abilityAdaptive controlTextile manufacturingTime lag

The invention relates to an anti-interference PID (proportion integration differentiation) controller for an industrial unstable time-lag process and a design method thereof. The controller consists of a set value tracking controller, a disturbance resisting controller, a filter, a controlled process identifying model and three signal mixers. The design method of the anti-interference PID controller for the industrial unstable time-lag process provided by the invention can improve the anti-interference capability of a system to a great extent, and compared with the other design methods, the control system is simple in structure, the controller is standard in form, industrial realization is easy, respective performance is adjusted through one-parameter, the operation is convenient and visual, the controlling effect is stable, and better system performance can be realized. The industrial control system can be widely used for controlling the production process of various enterprises in the industries, such as energy, metallurgy, petrifaction, light industry, medicine and textile manufacturing.

Owner:LIAOCHENG UNIV

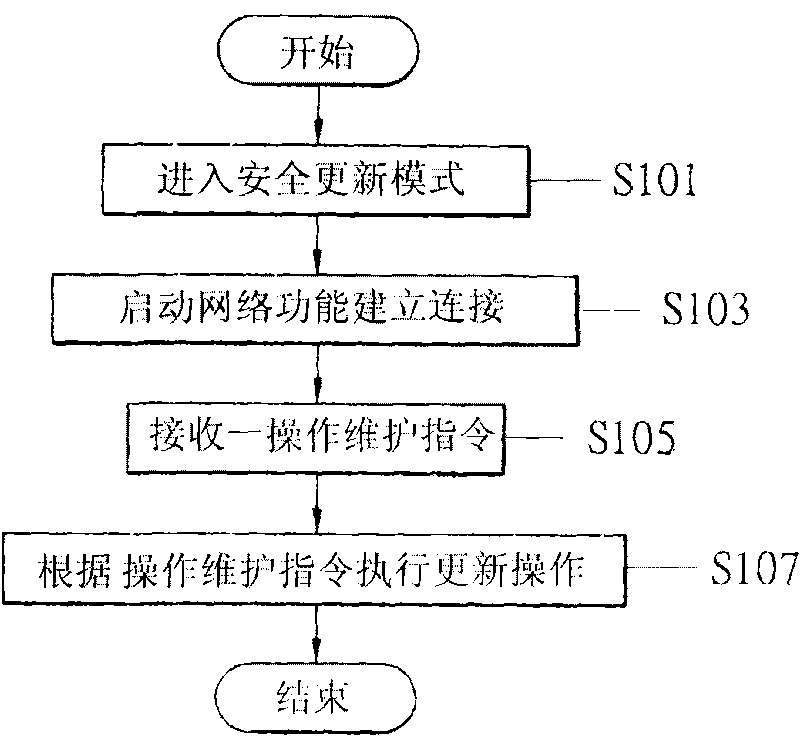

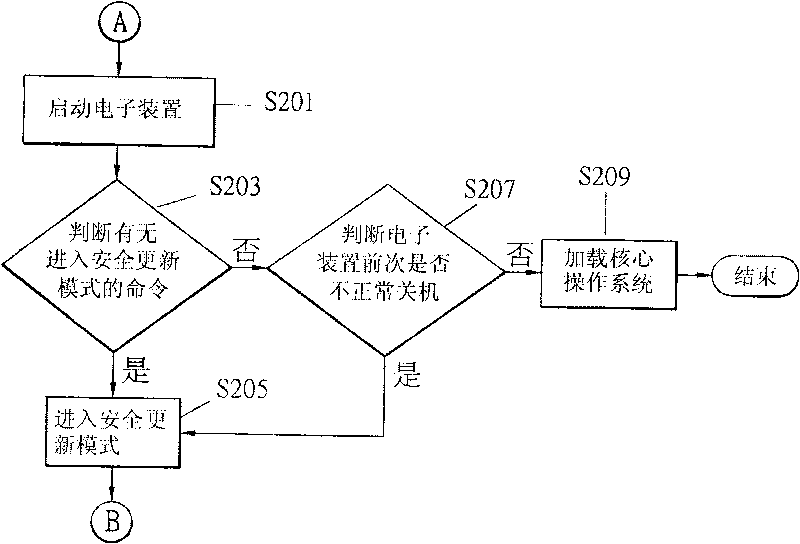

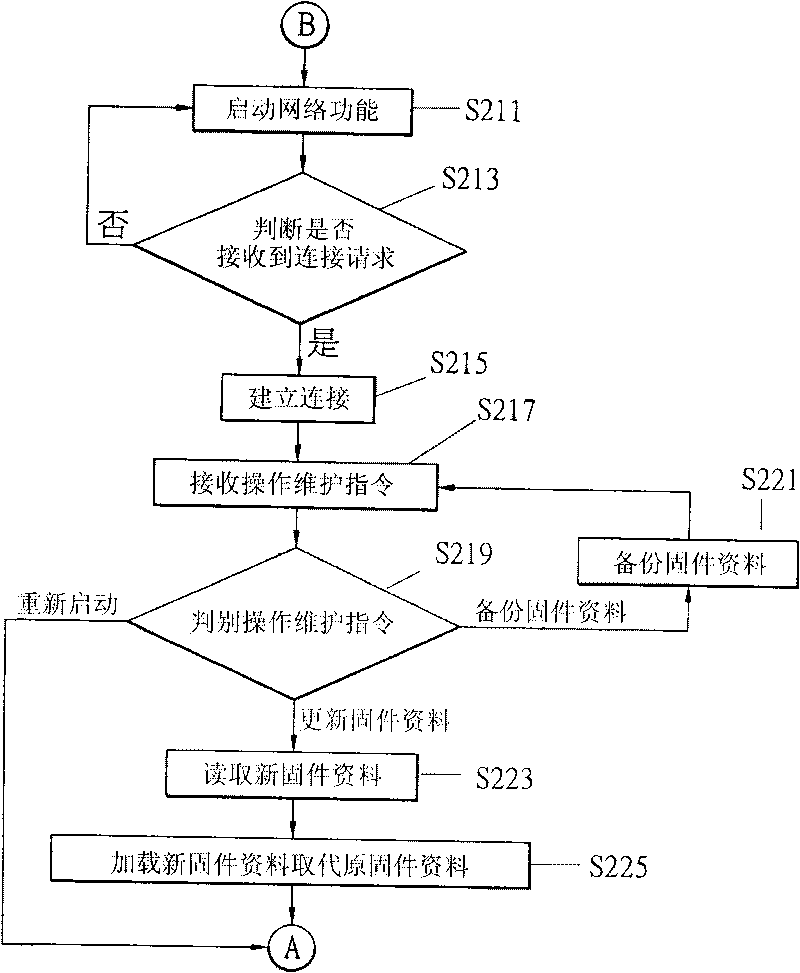

Electronic device firmware updating method and system

InactiveCN101763272AEasy to operateReduce waiting timeData switching by path configurationProgram loading/initiatingOperational systemNetwork connection

The invention discloses an electronic device firmware updating method and system. The electronic device has the network connection function. The method of the invention comprises the following steps: at start-up, entering a security update mode before the operating system is loaded; starting the network service functions of the electronic device in a safe mode, including starting to intercept a connection request; establishing network connection after intercepting the connection request, receiving an operation and maintenance instruction to the firmware data of the electronic device; and according to the operation and maintenance instruction, performing operations to the corresponding firmware data of the electronic device. The system comprises a firmware storing unit and an updating unit, wherein the updating unit contains a network module and a processing module. The system of the invention can update the electronic device firmware safely and easily, save the storage space of the hardware and reduce the waiting time of the user and the maintenance cost.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

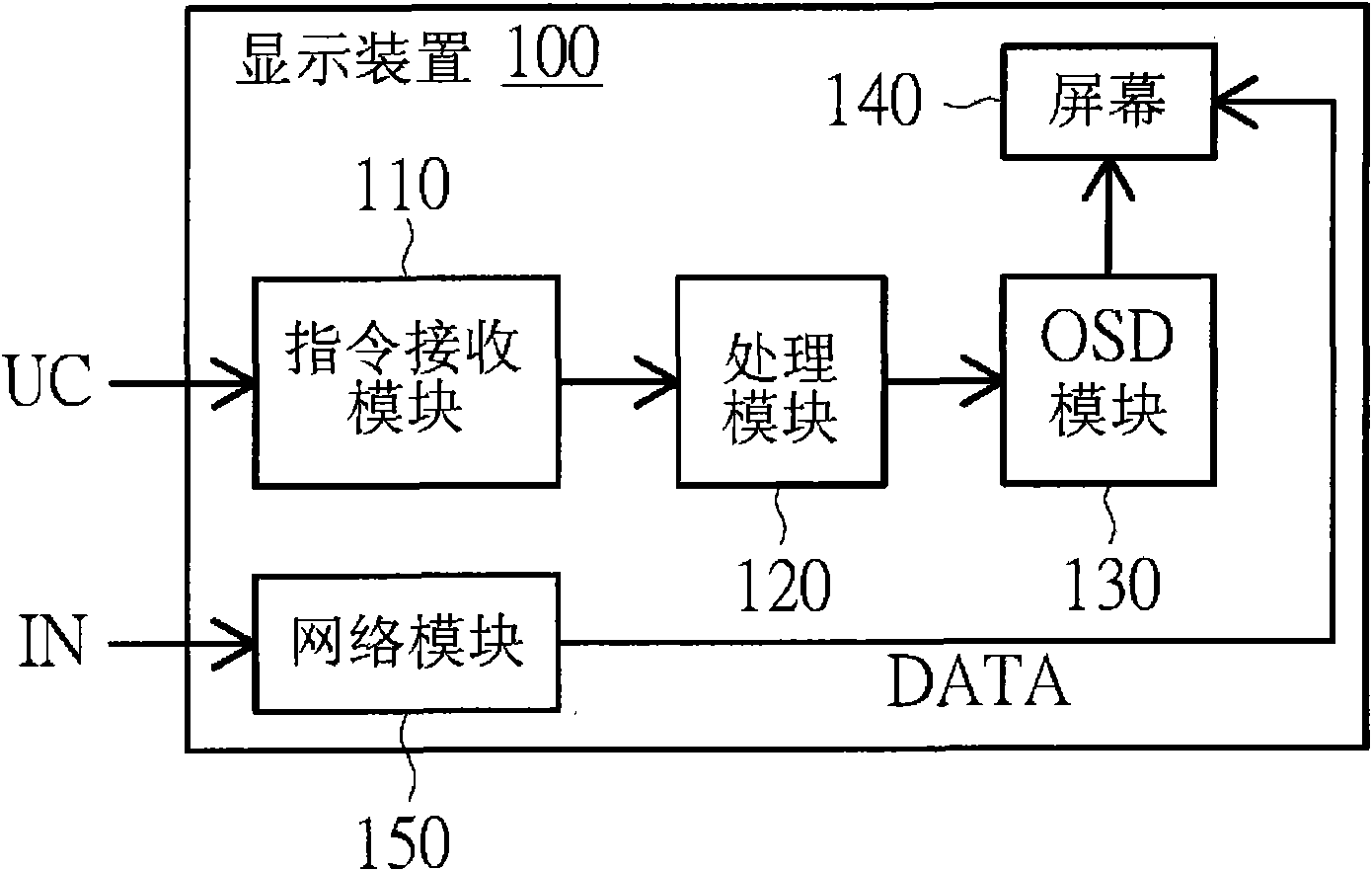

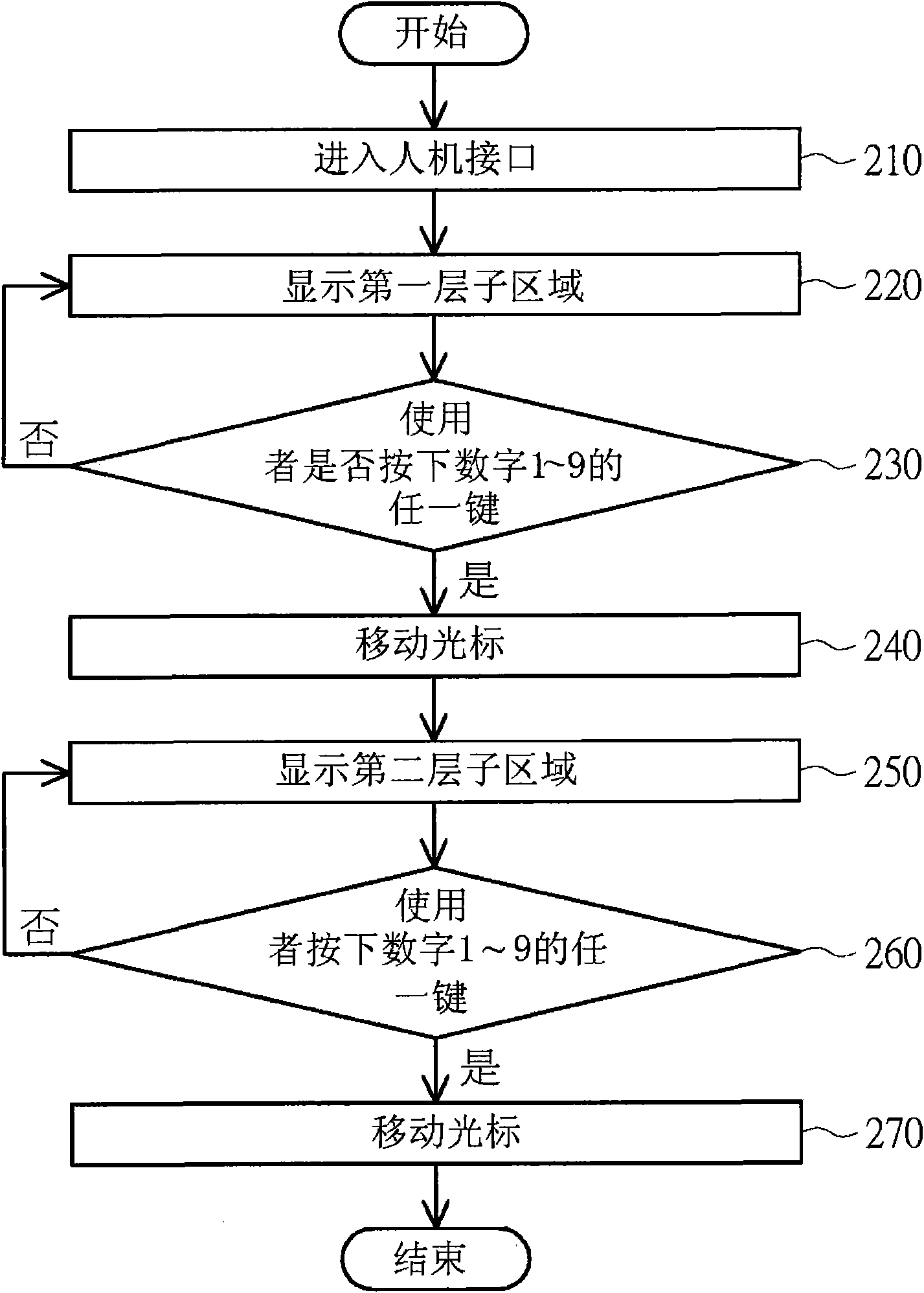

Method for moving cursor and display device employing same

InactiveCN101860695ALow costEasy and Intuitive OperationTelevision system detailsColor television detailsDisplay deviceComputer science

The invention discloses a method for moving a cursor and a display device employing the same. A user presses a corresponding numeric key on a remote controller to move the cursor and execute target selection, so that a simple, convenient and intuitive operating method is provided to the user. The method for moving the cursor comprises the following steps of: responding to a first control instruction, and displaying a plurality of first layer subareas on the display device; responding to a second control instruction, and selecting one of the first layer subareas; and moving the cursor to the selected first layer subarea.

Owner:MSTAR SOFTWARE R&D (SHENZHEN) LTD +1

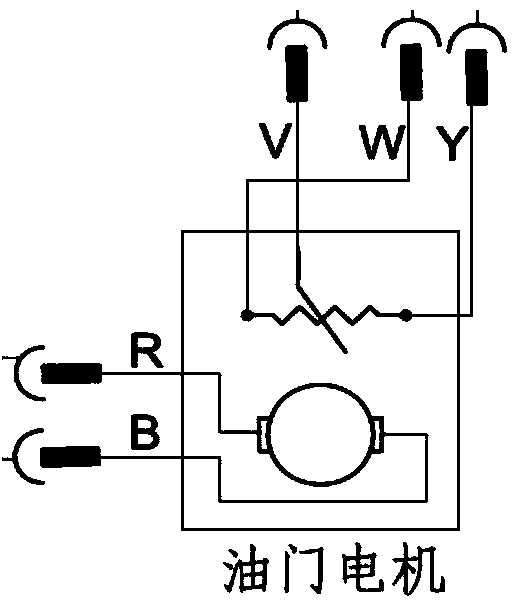

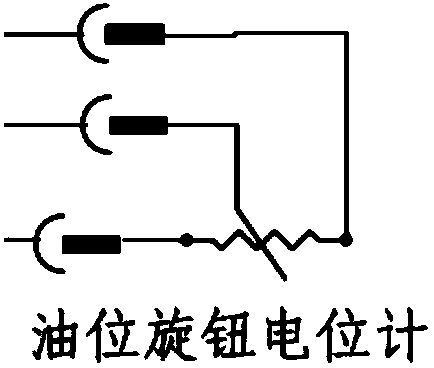

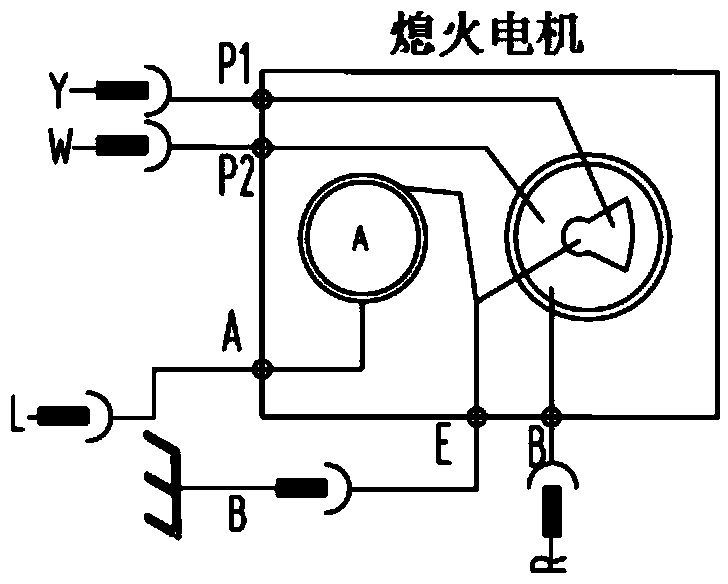

Fault detector of excavator

InactiveCN103954467APrevent return to factoryLower skill requirementsStructural/machines measurementData informationControl system

The invention discloses a fault detector of an excavator. The fault detector of the excavator comprises a detection wiring harness, an electric device drive module, a meter control panel and a power line. The electric device drive module is used for driving to-be-detected electric devices in an air conditioner system, an electronic throttle control system and a flameout system for simulated working state demonstration. The meter control panel comprises an electric device working state demonstration control button, an electric device working state indicator lamp and a display module, wherein the electric device working state demonstration control button is used for controlling the electric device drive module to achieve simulation demonstration of the working state of the to-be-detected electric devices; the electric device working state indicator lamp is used for displaying the working state of the to-be-detected electric devices; the display module is used for displaying related data information and / or related data information change situations of the to-be-detected electric devices in the air conditioner system, the electronic throttle control system and the flameout system under the simulated working state. The fault detector of the excavator can rapidly and accurately detect electric devices which cannot be easily detected or are large in detection difficulty in the maintenance process of the excavator and remove faults, and operation is visual, easy and convenient.

Owner:QINGDAO LOVOL EXCAVATOR

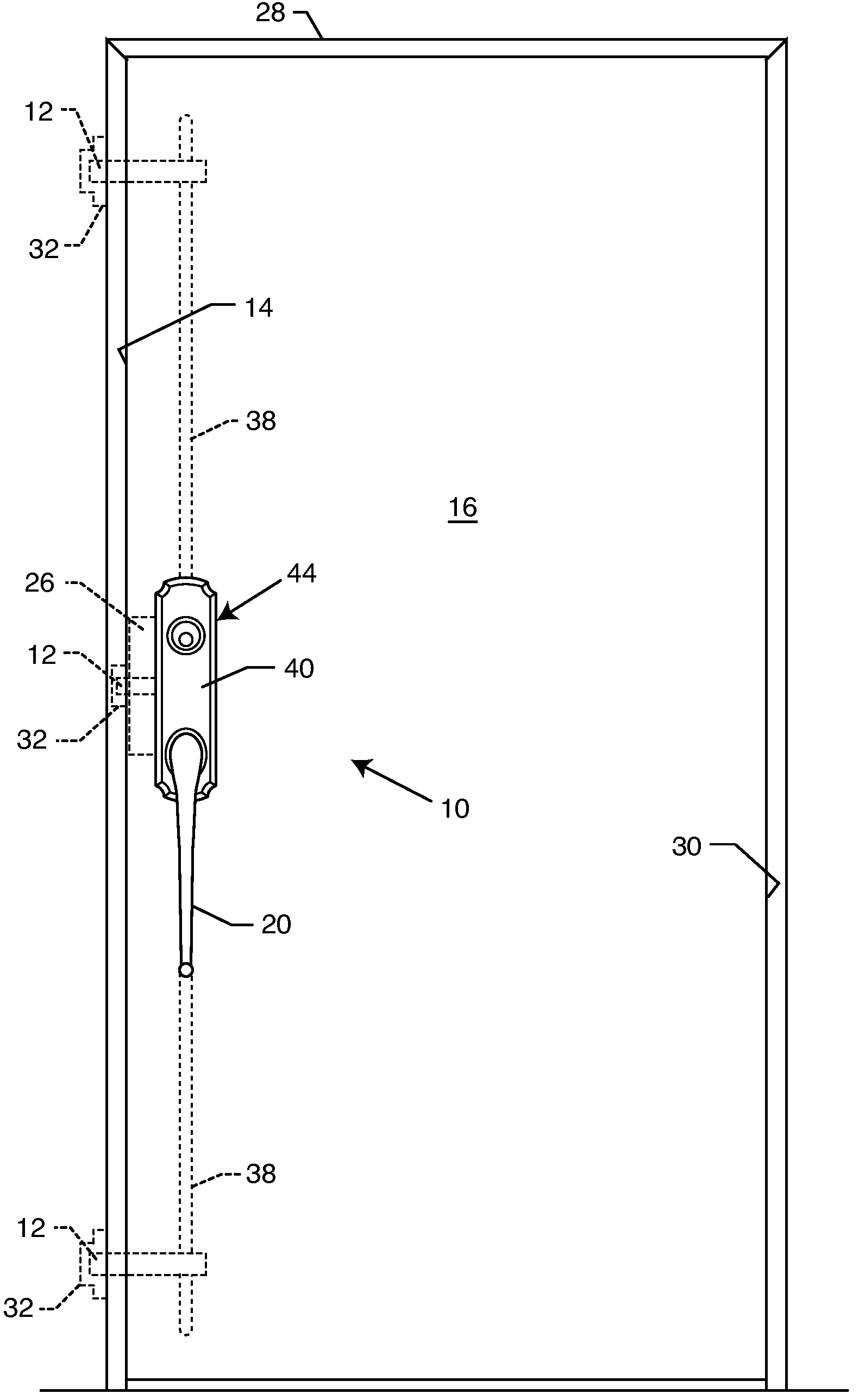

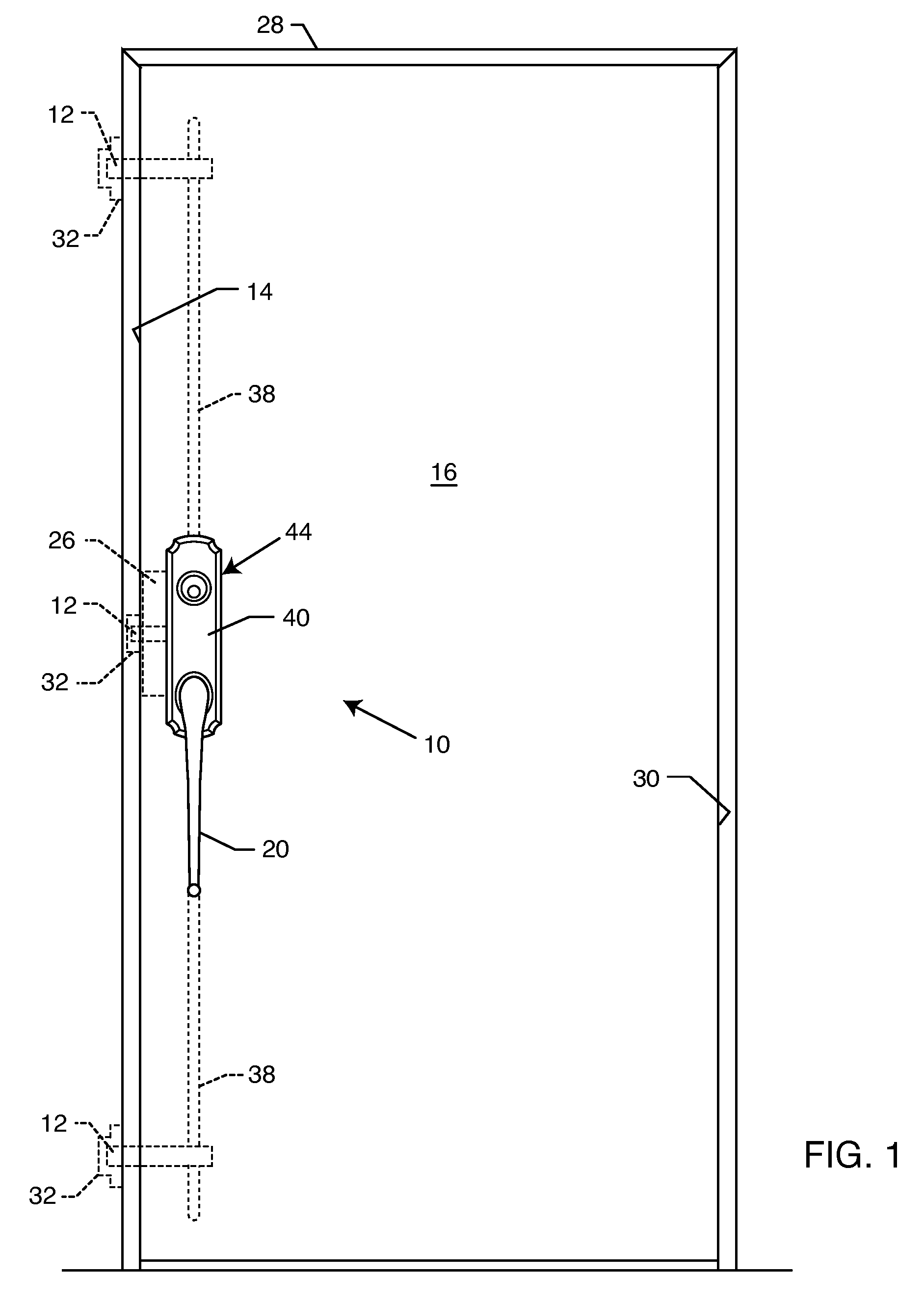

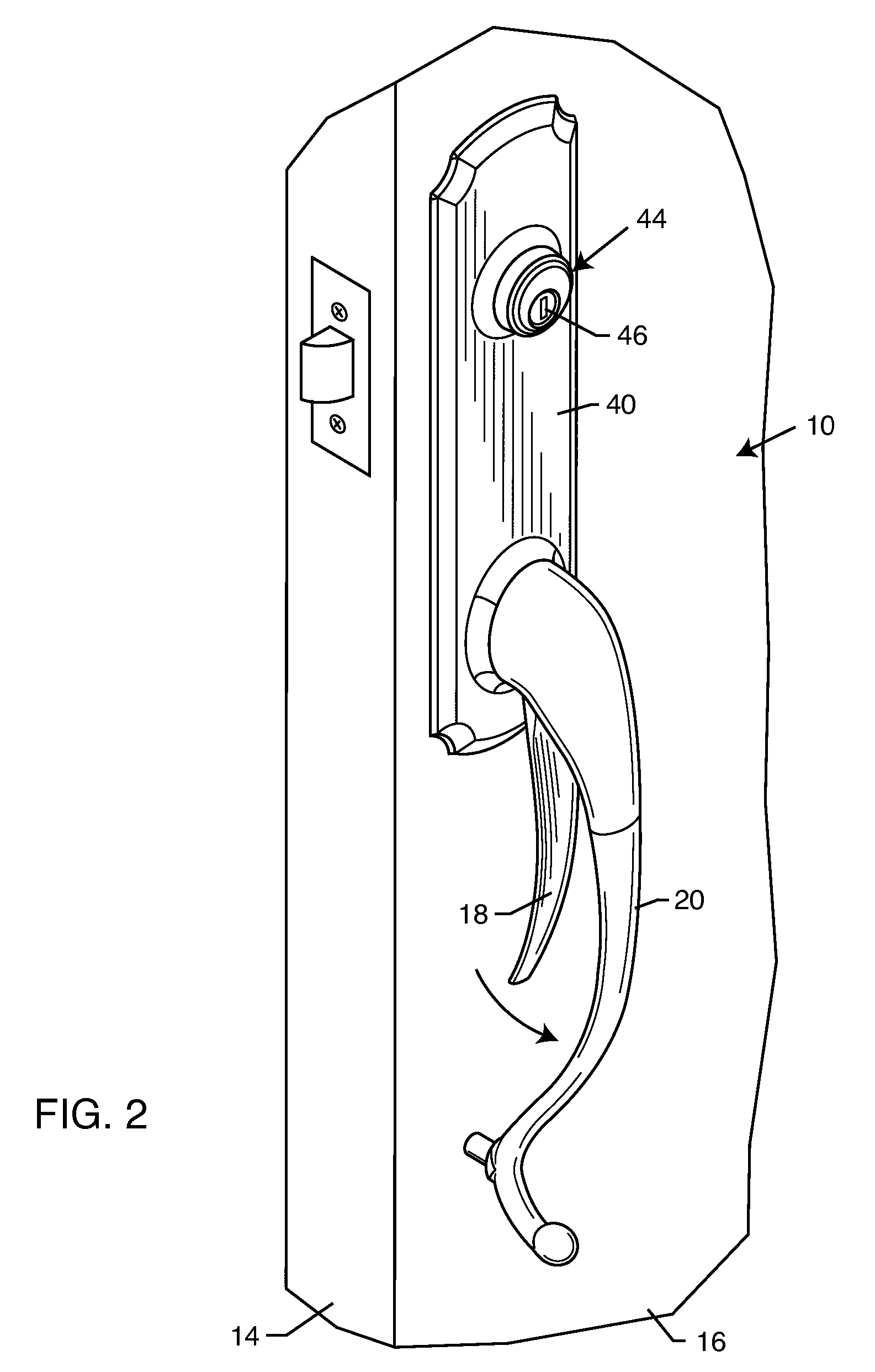

Lever actuated door latch operator

ActiveUS7753418B2Big advantageEasy and intuitive operationWing handlesAnti-theft cycle devicesEngineeringCam

A door latch operator includes a hand grip actuator lever for retracting one or more latch bolts mounted at a free side edge of a door, such as an entry door for a residence or place of business. The actuator lever is pivotally mounted at an inboard side of a manually grasped handle for grasping and squeezing with the fingers against the door handle to operate a torque converter or cam module for indexing a rotary cam through a rotary step. The rotary cam is coupled to a latch bolt retractor mechanism for retracting the latch bolt or bolts and thereby permit opening of the door. In a preferred form, the latch bolt retractor mechanism operates multiple latch bolts mounted along the free side edge of the door.

Owner:ENDURA PRODS

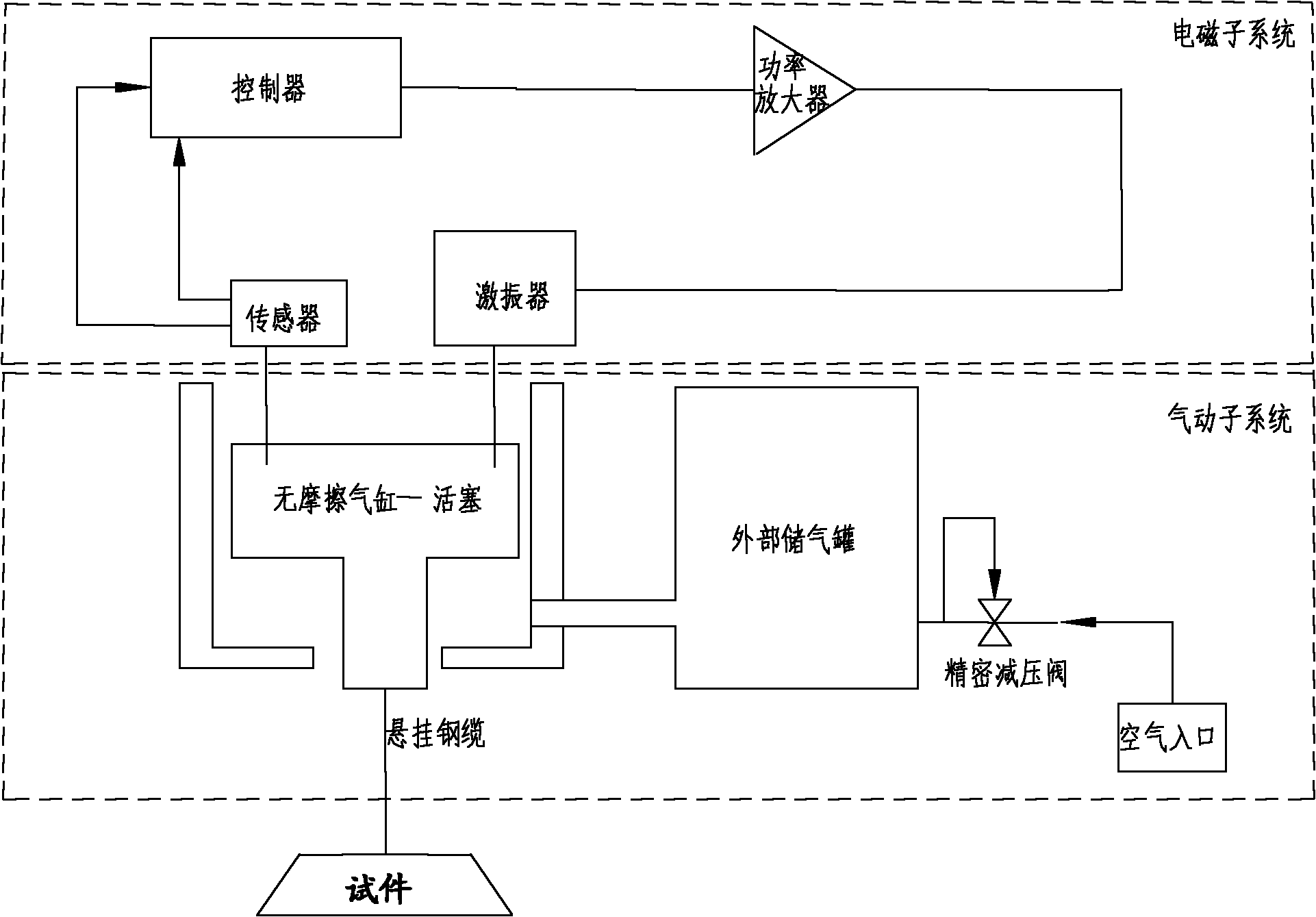

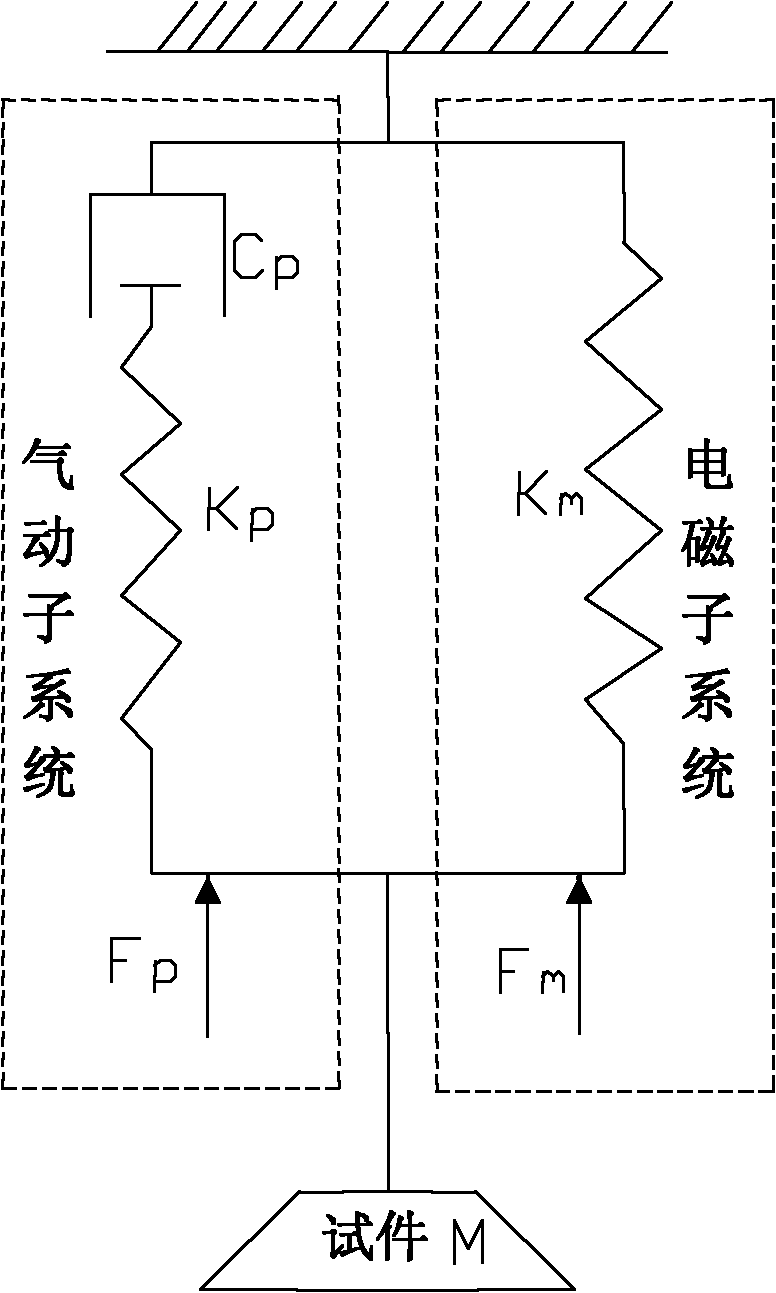

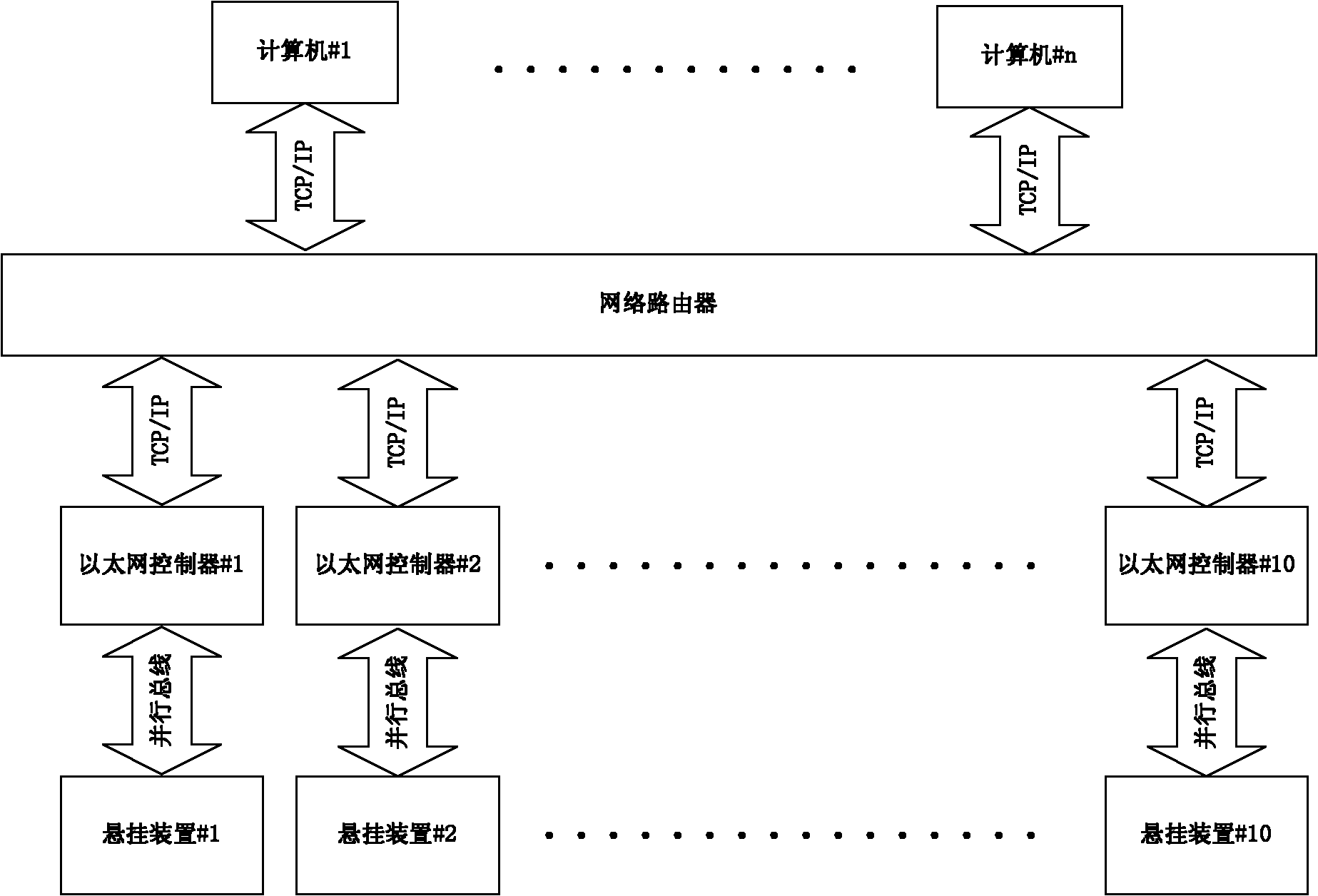

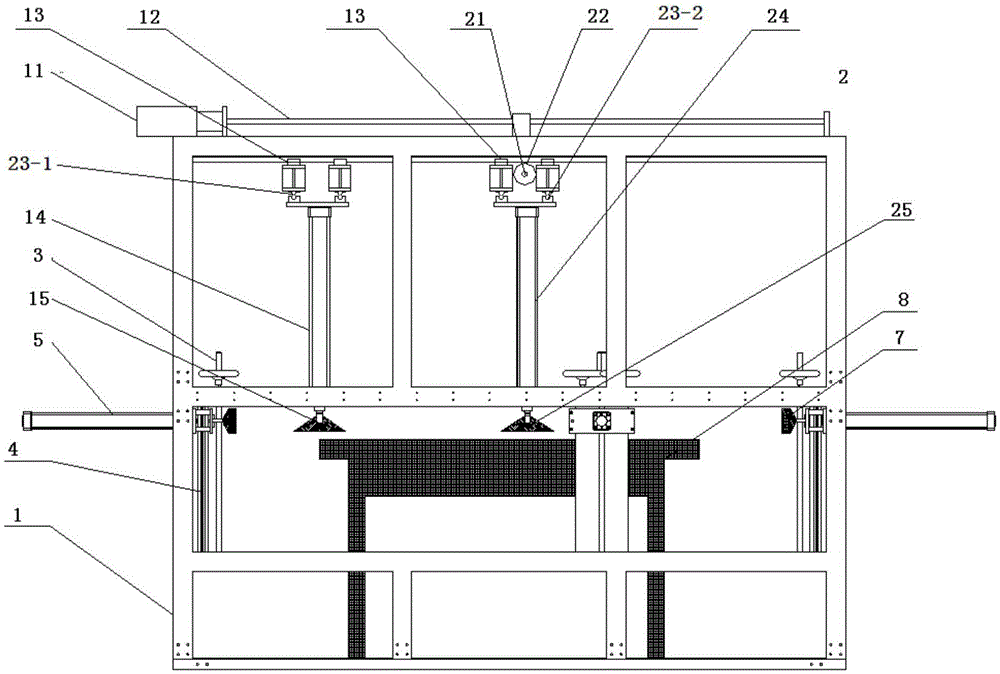

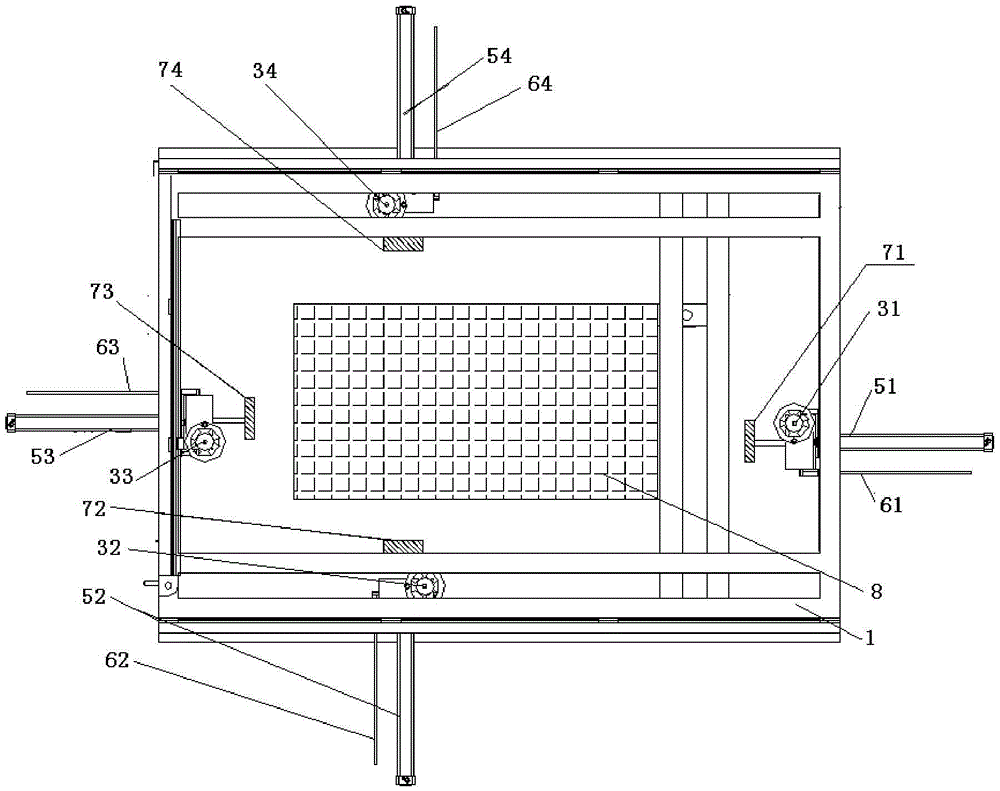

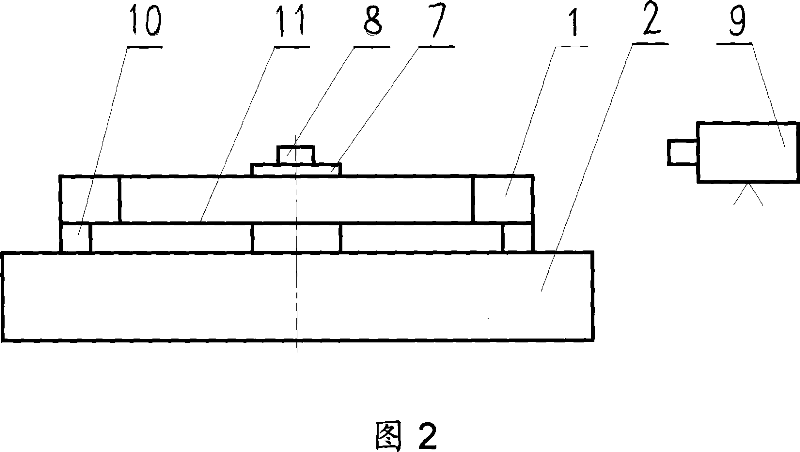

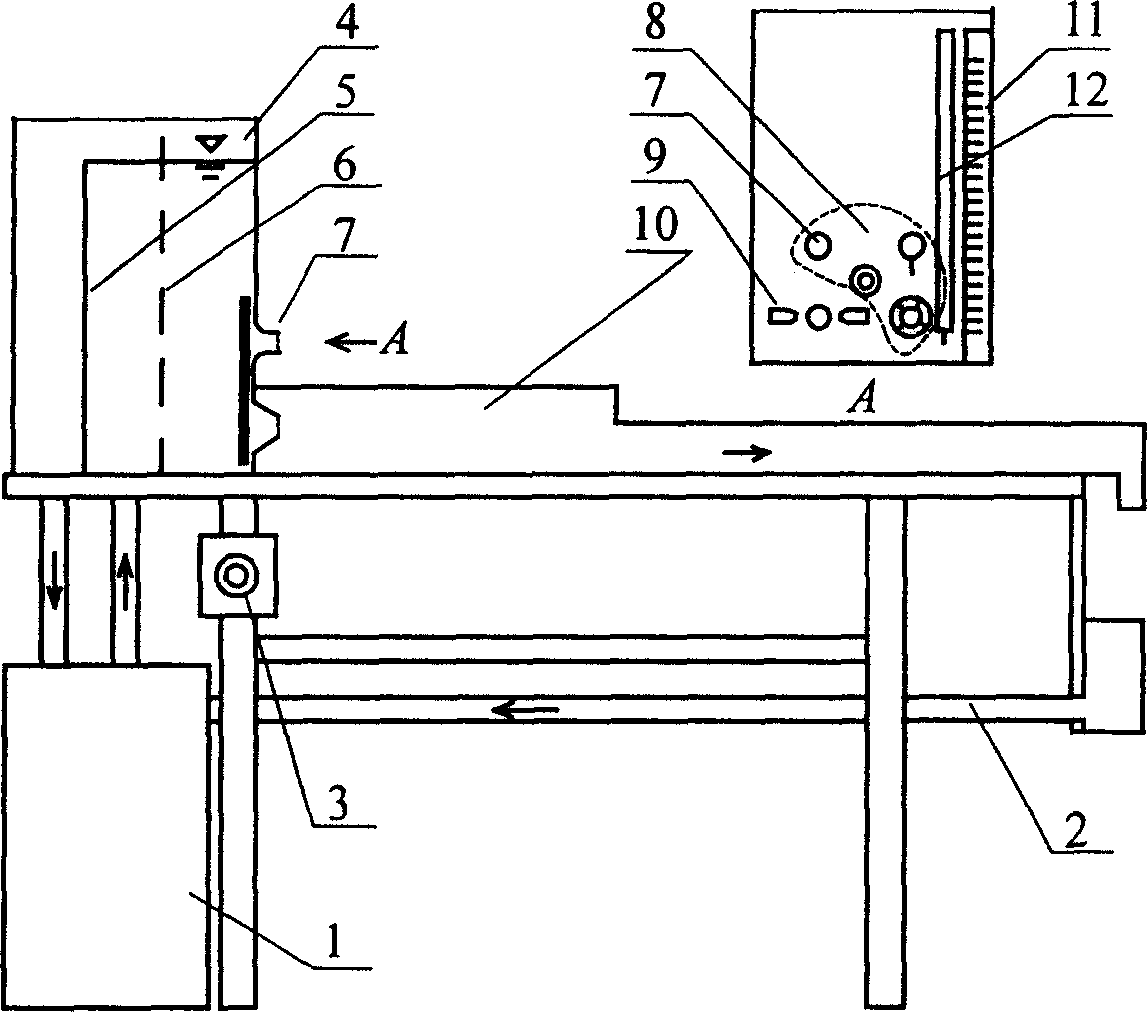

Ultra-low frequency modal test suspension system

ActiveCN101850854AEasy to adjustFlexible and convenient adjustmentCosmonautic condition simulationsTransmission systemsEngineeringDigital control

The invention discloses an ultra-low frequency modal test suspension system, comprising a modal test suspension device and a monitoring computer for realizing remote detection and monitoring. The monitoring computer is connected with an Ethernet router; an air tank and a pneumatic actuator are connected with an air pressure control MPU (Microprocessor Unit); a suspension follower is connected with a linear displacement coder, a suspension force sensor and an electromagnetic force sensor; an electromagnetic actuator is connected with a power amplifier; the linear displacement coder is connected with a CPLD (Complex Programable Logic Device) processing module which is connected with an electromagnetic force control MPU; the suspension force sensor and the electromagnetic force sensor are connected with the electromagnetic force control MPU; the air pressure control MPU and the electromagnetic force control MPU are both connected with a modal suspension control MPU; and the modal suspension control MPU is connected with the Ethernet controller which is connected with the Ethernet. The invention realizes fully digital control, improves the work efficiency, improves the control precision and reduces the influence of the accessories on the modal test.

Owner:ZHEJIANG UNIV OF TECH

Furniture static pressure fatigue test machine

ActiveCN105424516AEasy to replaceEasy to adjustMaterial strength using repeated/pulsating forcesShock testingElectric machineryEngineering

The invention relates to the technical field of quality detection and relates to a furniture static pressure fatigue test machine, in particular to a table, bed and cabinet static pressure fatigue test machine which comprises a machine frame and a central controller. A horizontal motor, a horizontal screw rod, a longitudinal motor and a longitudinal screw rod are fixedly installed at the top of the machine frame. The horizontal screw rod is perpendicular to the longitudinal screw rod. The horizontal motor is connected with the horizontal screw rod, a horizontal track is arranged on the lower portion of the horizontal screw rod, the longitudinal motor is connected with the longitudinal screw rod, and a longitudinal track is arranged on the lower portion of the longitudinal screw rod. The furniture static pressure fatigue test machine is used for simulating tests for testing the strength or bearing capacity of each part of furniture under the condition that the parts are subjected to one-time or repeated loads when the furniture is used normally and misused habitually. The table, bed and cabinet static pressure fatigue test machine is suitable for testing mechanical properties of table, bed and cabinet furniture.

Owner:ZHEJIANG HENGFENG TOP LEISURE CO LTD

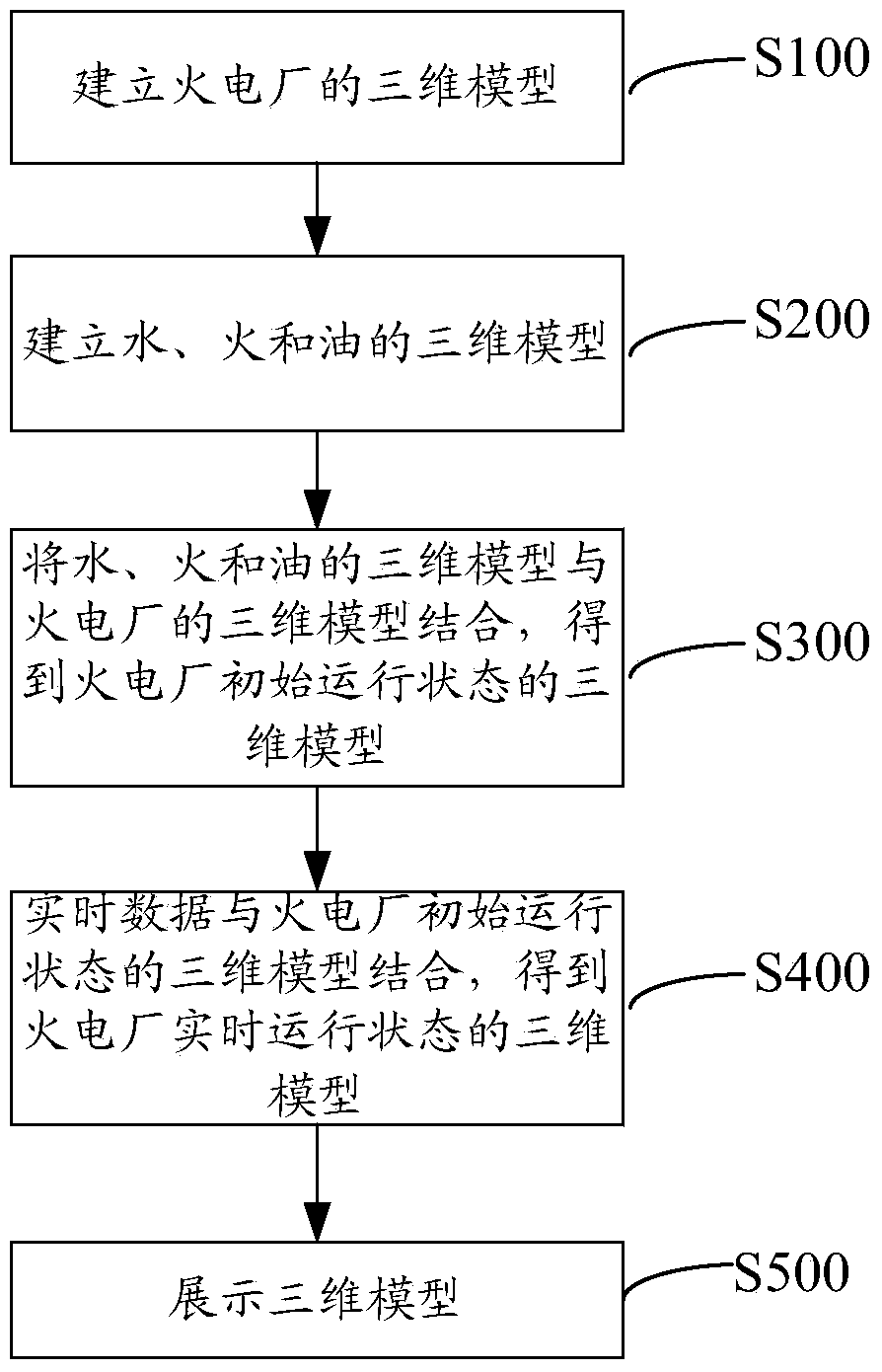

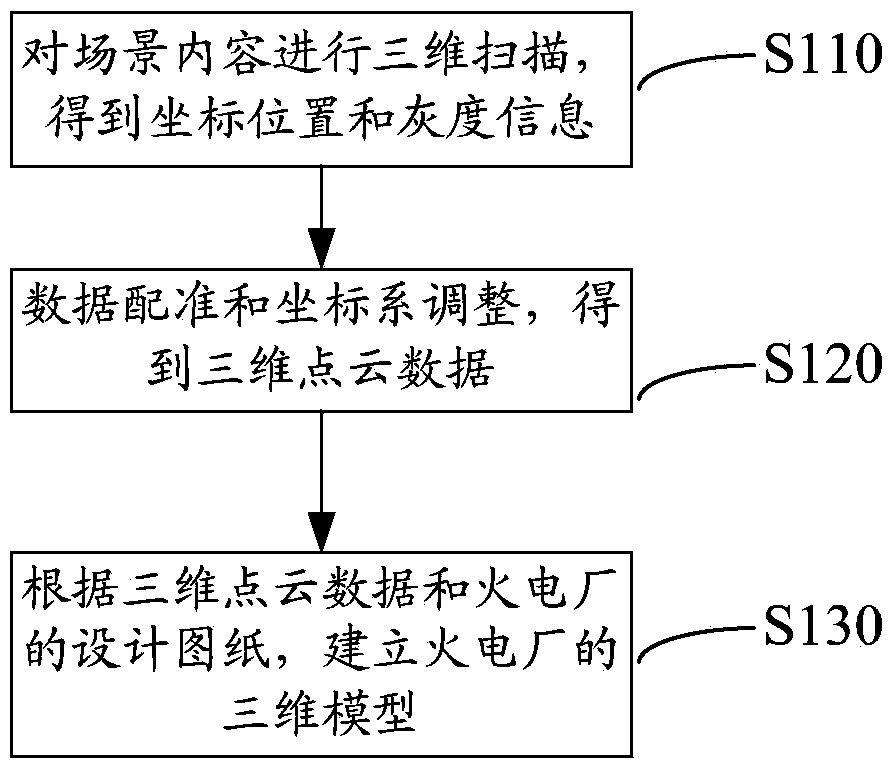

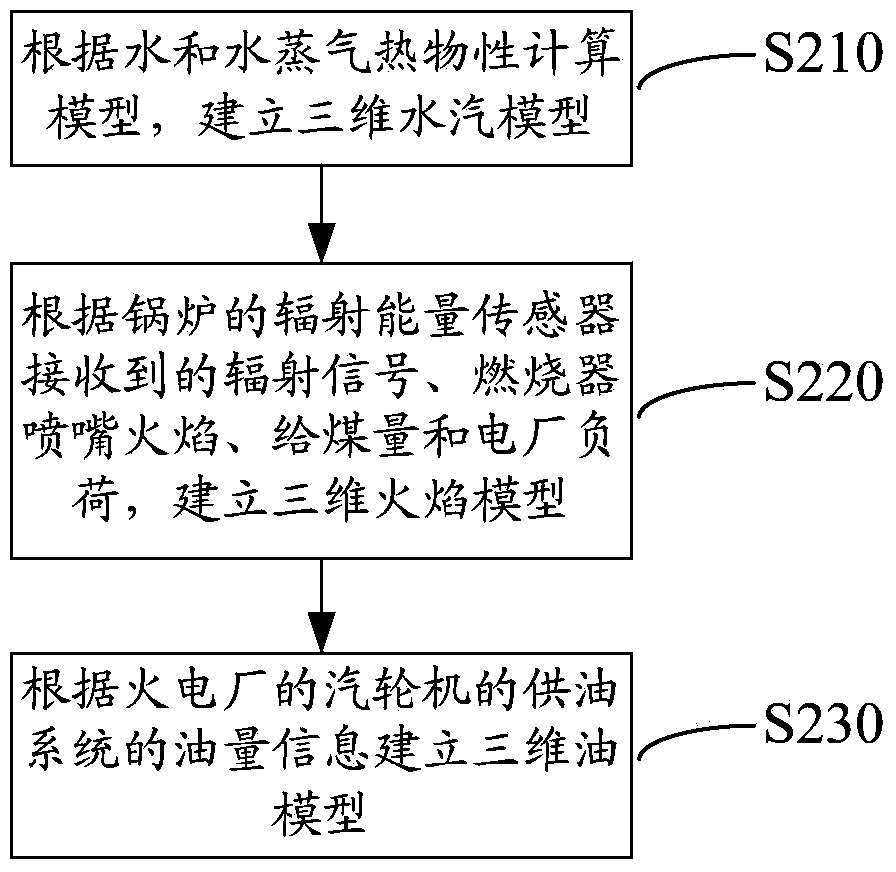

Three-dimensional virtual visualization display method of thermal power plant

ActiveCN103761683AImprove operation and management efficiencyEasy and intuitive operationData processing applications3D modellingManagement efficiencyThree dimensional model

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

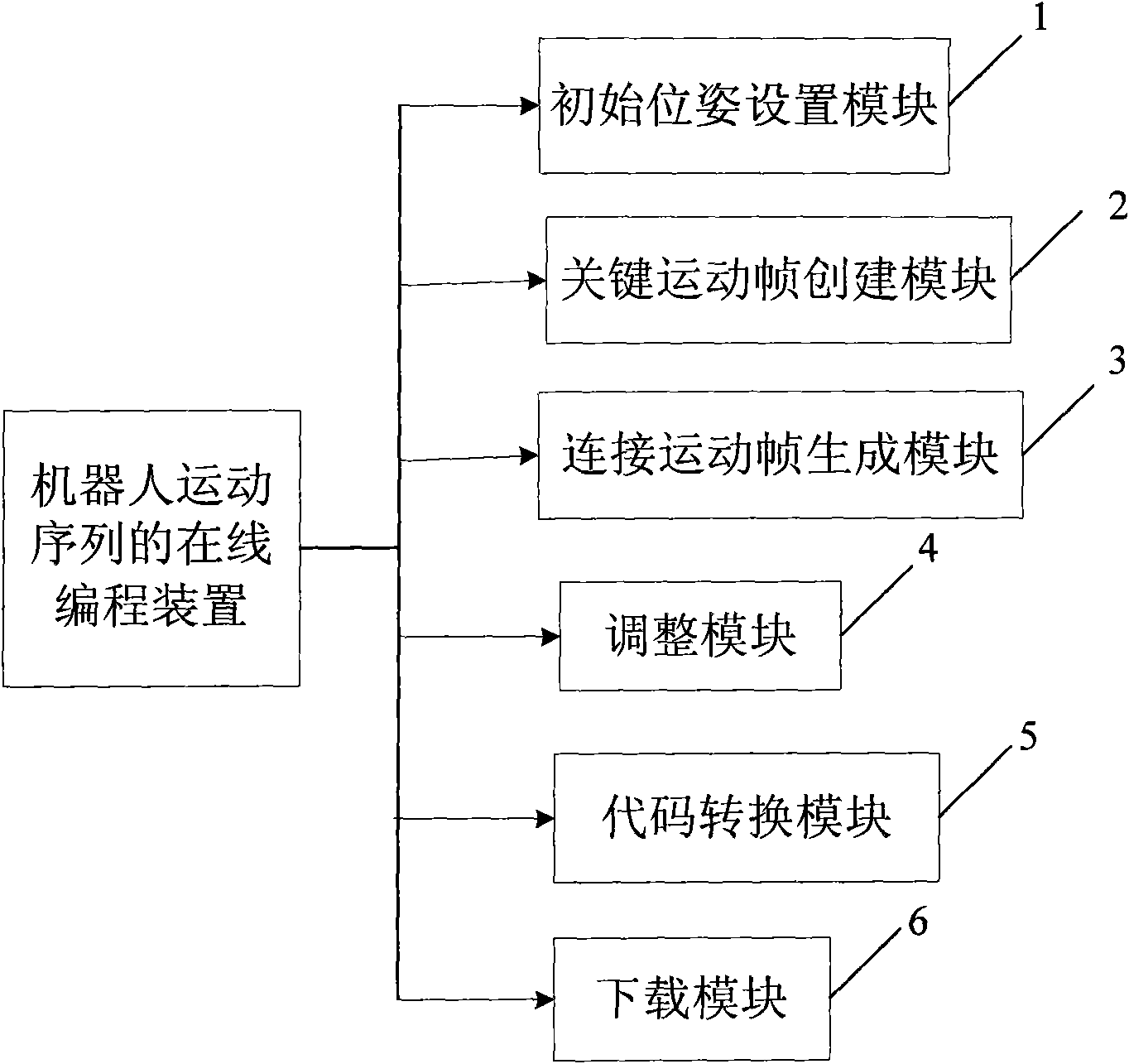

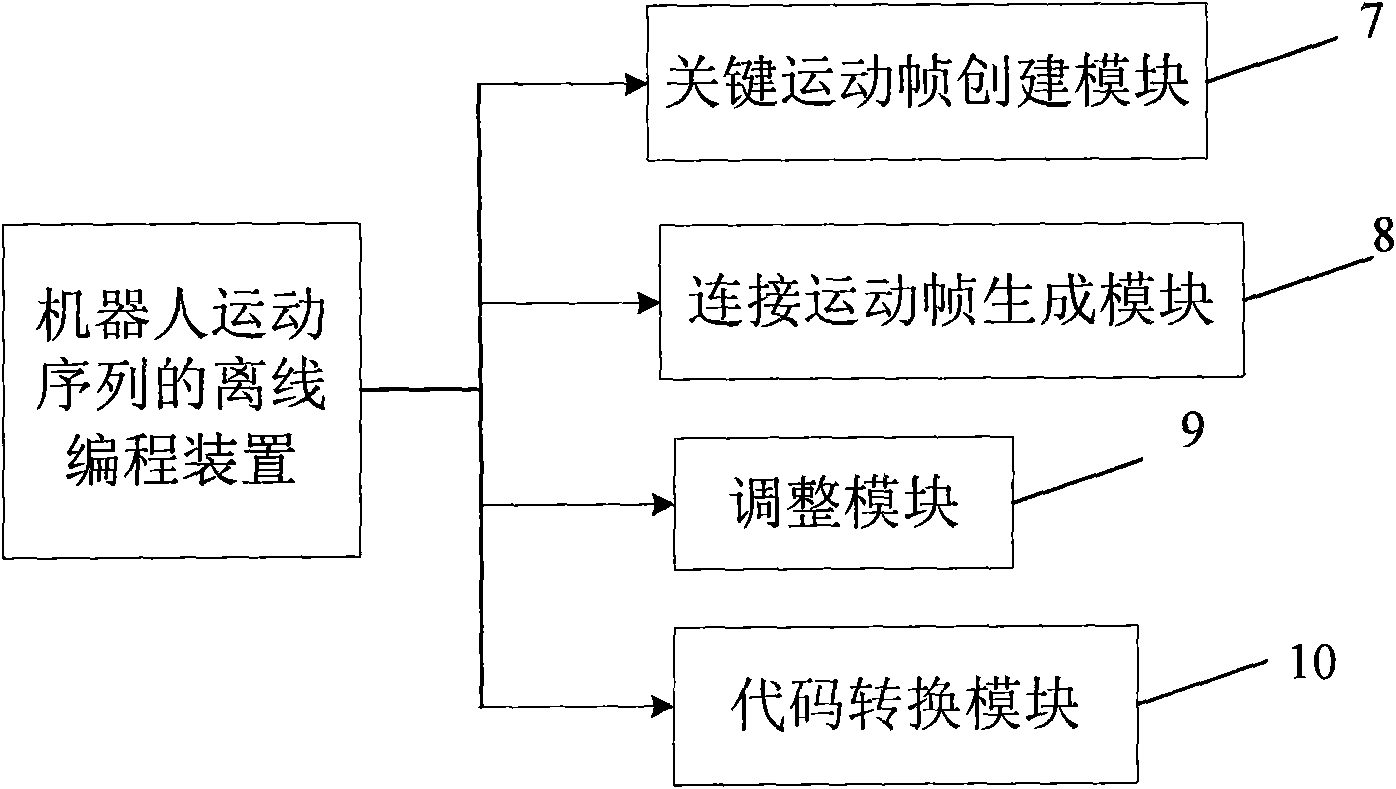

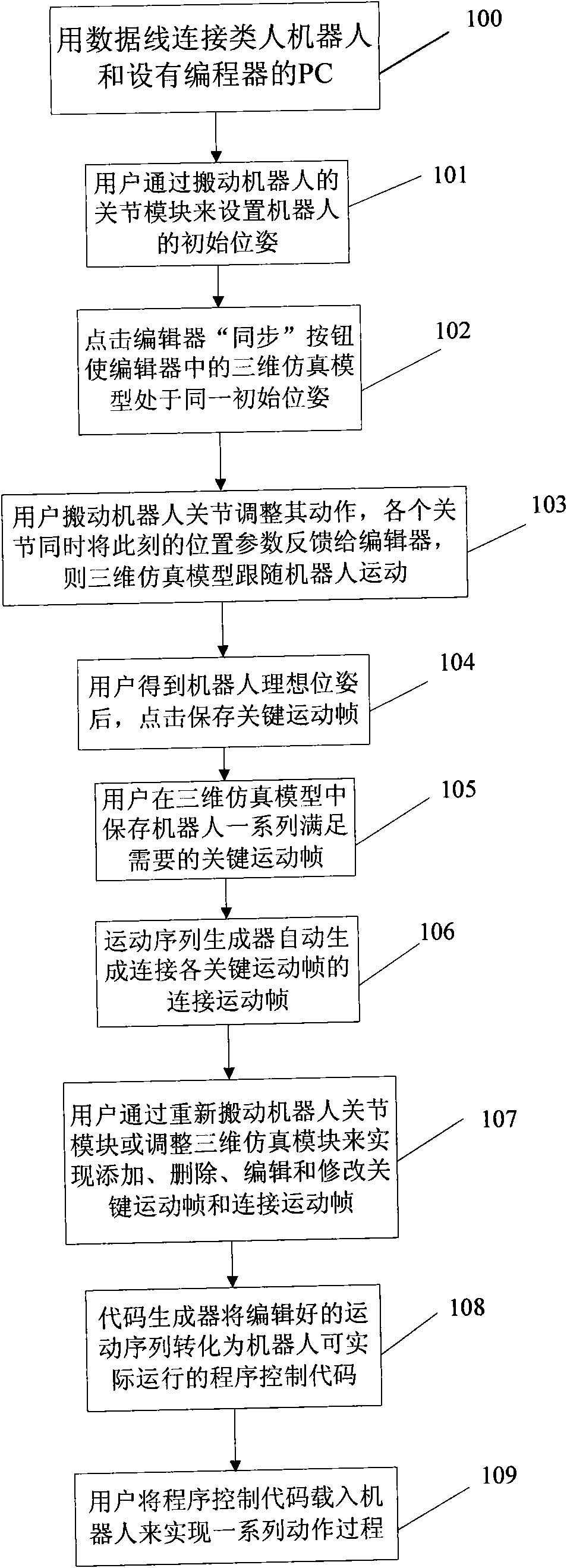

Method and device for programming robot motion sequence

ActiveCN101570020AExpand popularityEasy to useProgramme-controlled manipulatorRecording and playback systemsSimulationProcedural approach

The invention discloses a method and a device for on-line programming for a robot motion sequence. The method comprises the following steps: S1, setting an initial pose of a robot by a user; S2, setting a plurality of poses during the motion of the robot, and storing the poses as a series of key motion frames; S3, automatically generating connection motion frames connected with the series of key motion frames by a motion sequence generator; S4, adjusting the key motion frames or the connection motion frames; S5, converting the motion sequence into a program control code executed by the robot by a code generator; and S6, loading the program control code into the robot. The invention also discloses a method and a device for off-line programming for the robot motion sequence. The operation is more intuitive and convenient, no professional knowledge is needed, the universality of robot motion sequence programming is enlarged, and the programming can be widely used by nonprofessional people. Simultaneously, the method and the device can be popularized for motion programming of all robots with a plurality of joints.

Owner:SHANGHAI XPARTNER ROBOTICS

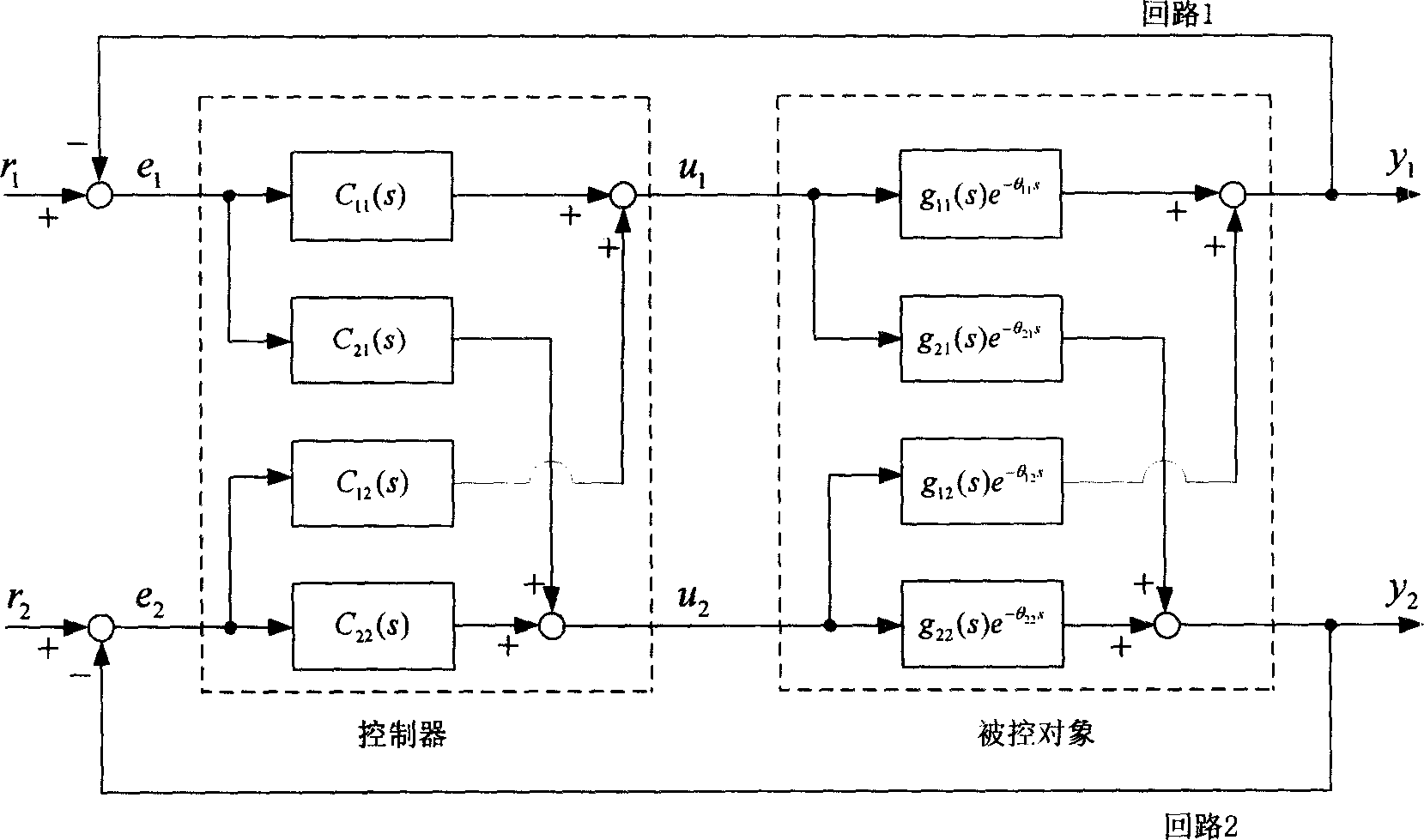

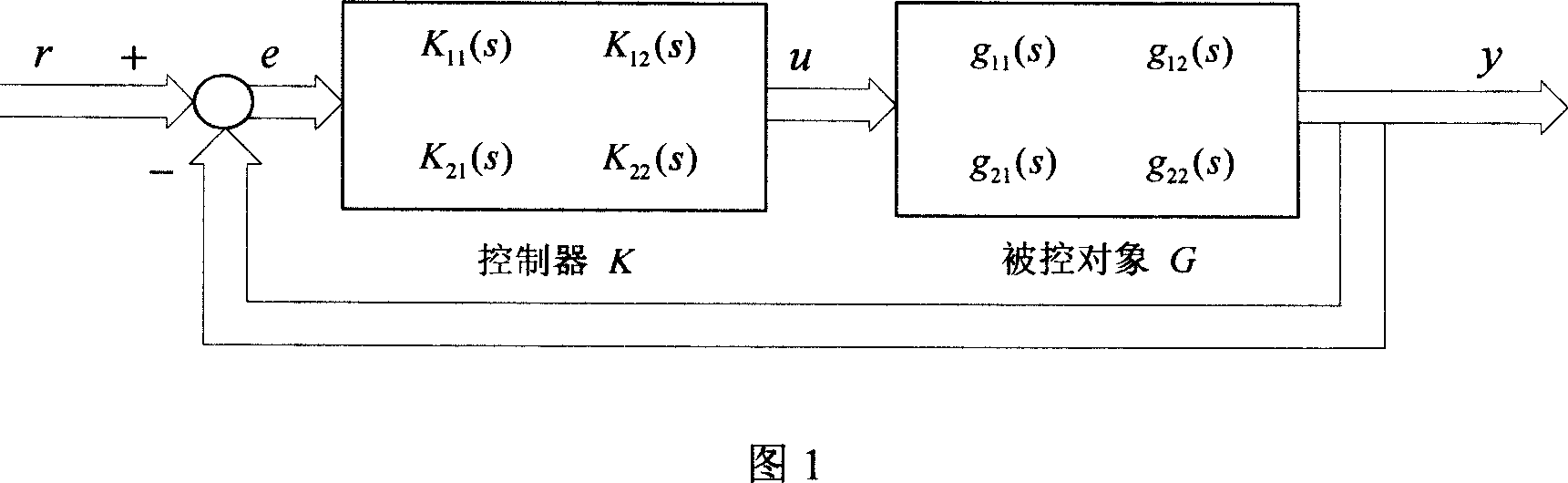

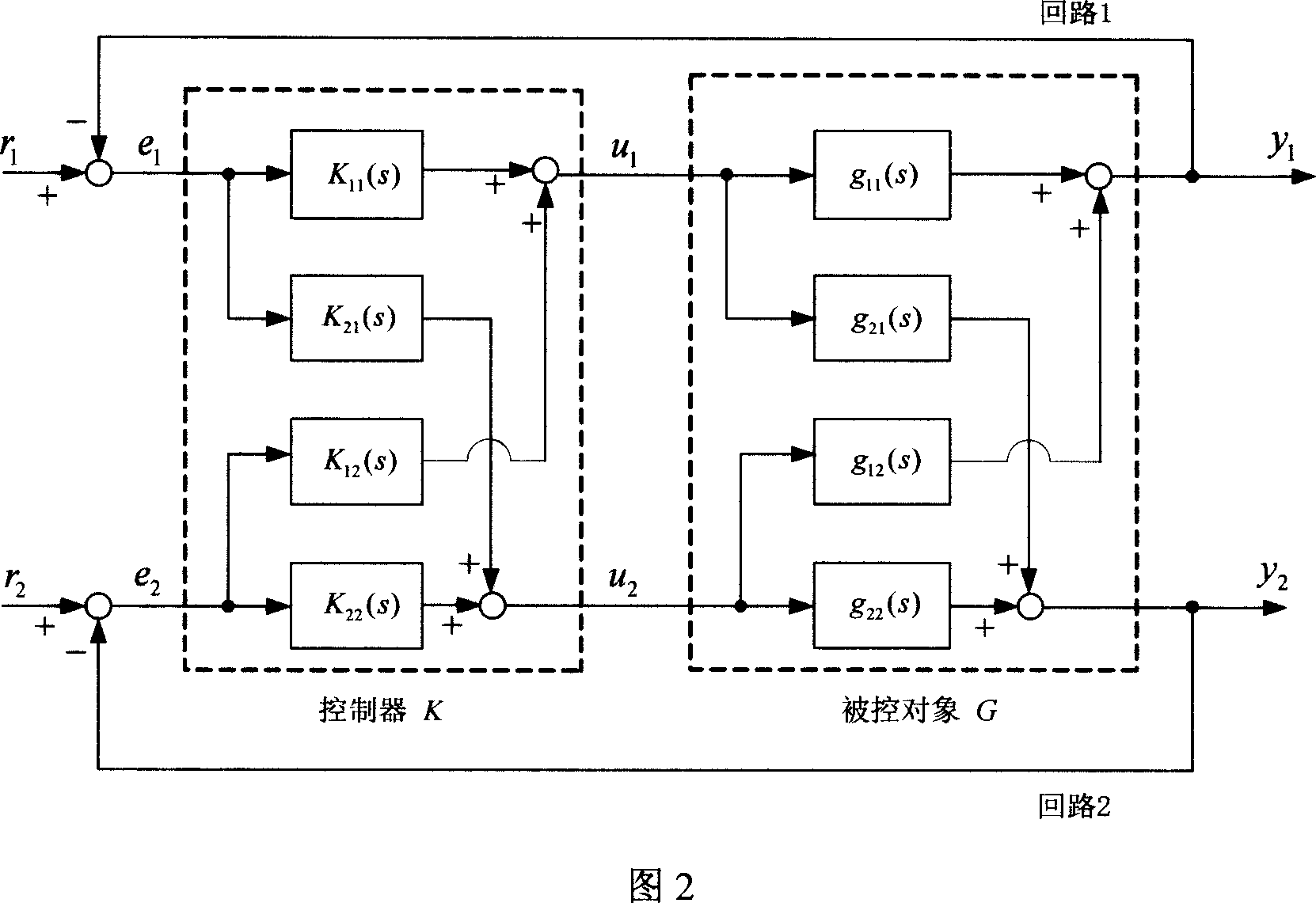

Uncoupling control method for double-inputting and double-outputting system

InactiveCN1932699AEasy to implementEasy to implement onlineAdaptive controlLoop controlDecoupling controller

An industrial process control technology field two-input-output system's decoupling control method, it lets the reverse decoupling structure's decoupling machine and the controller into one decoupling control machine, and it forms the unit feedback control structure. By adding the compensation item, it can eliminate decoupling controller machine's unstable factors. It designs the decoupling controller machine's sub-controller base on the inner module theory, then the final decoupling control machine is almost the easy implement PID / PI controller. When has the actual operating control, the first is deduce the controller parameter's lowest borders which can meet the LuBang stability condition. Then on the base of this border minimum, separately enlarge every loop's control parameter monotonously until gain the system mark capability which complies with the project's requirements. The control method structure of this invention is simple and easy to achieve, and has wide applicability and is easy to operate, it can quickly accurate tuning control parameters and makes the closed loop control system meet the LuBang stability requirement.

Owner:SHANGHAI JIAO TONG UNIV

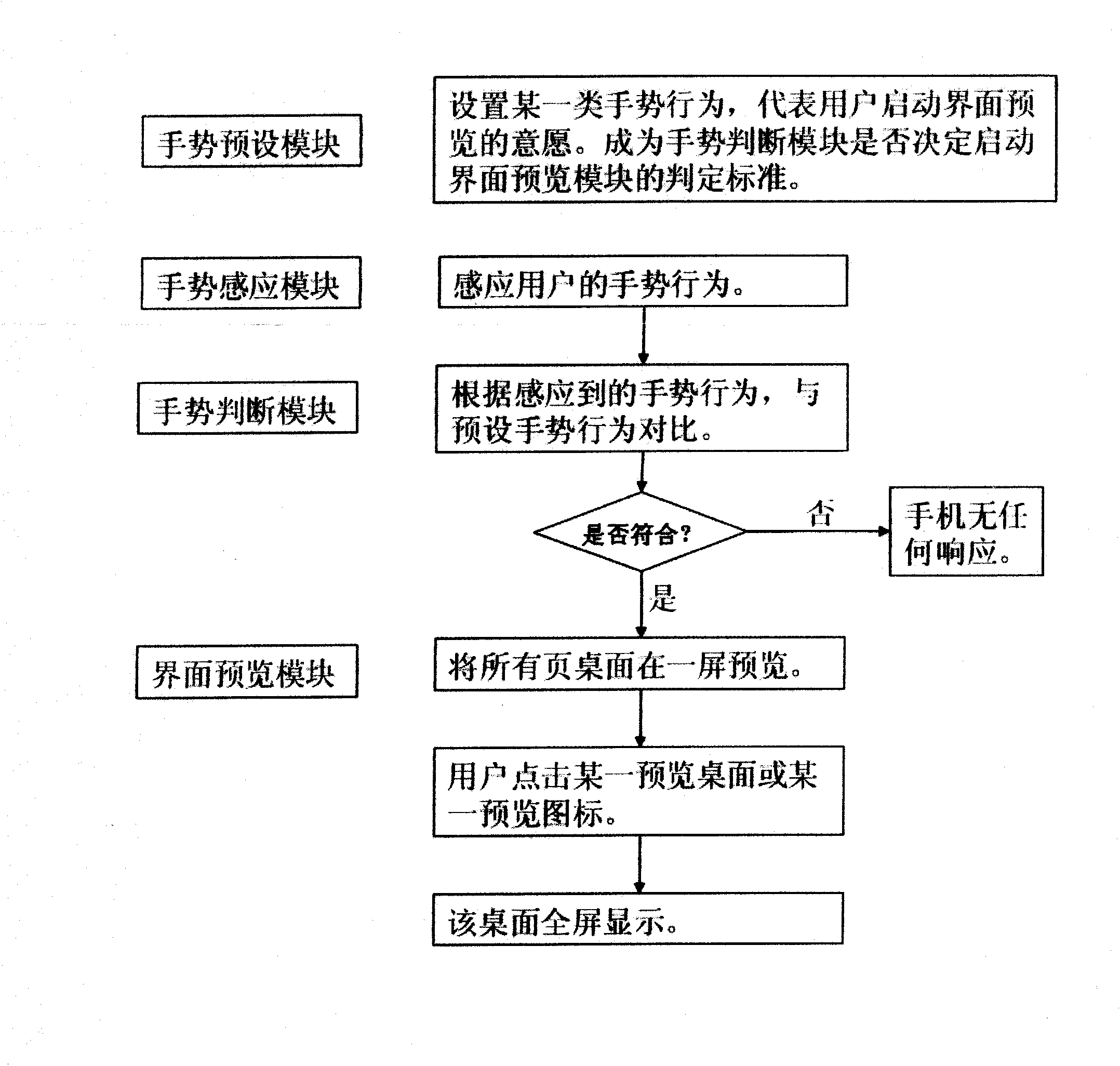

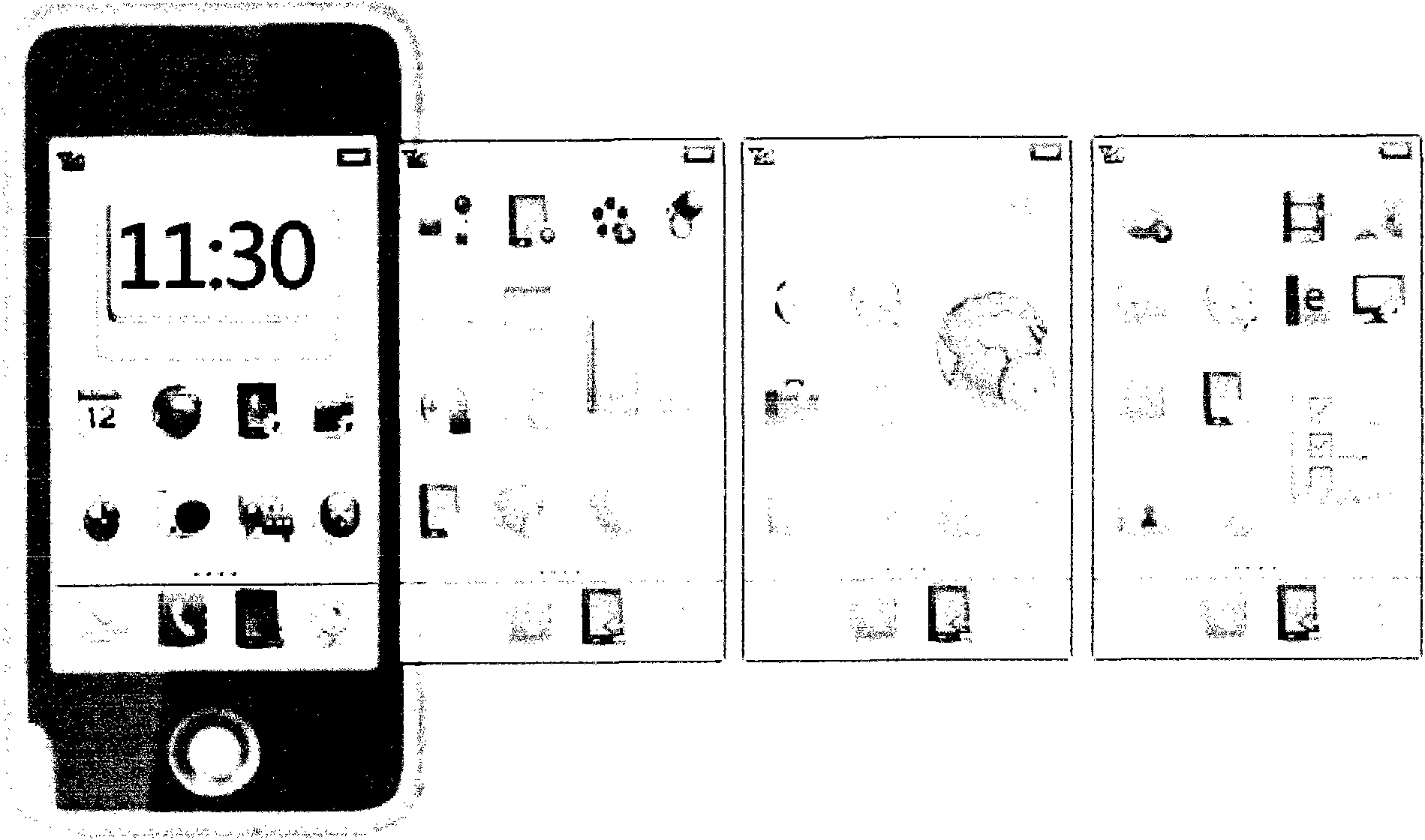

Method for previewing mobile phone multi-screen desktops

InactiveCN101958968AMake up for the defect of many operation stepsEasy and intuitive operationSubstation equipmentComputer scienceOn-screen display

The invention relates to a method for previewing mobile phone multi-screen desktops. The method comprises the following steps of: 1, setting a gesture presetting module in a mobile phone for setting a condition of starting interface preview; 2, setting a gesture induction module in the mobile phone for sensing an action of shaking the mobile phone by a user; 3, setting a gesture judgment module in the mobile phone for judging whether the action of shaking the mobile phone by the user meets the preset condition or not; 4, setting an interface previewing module in the mobile phone, so that when the action of shaking the mobile phone by the user meets the preset condition, the mobile phone previews all pages on one screen; and 5, clicking a desktop or an icon needing to be previewed by the user, and displaying contents of the desktop or icon in a full screen mode by the mobile phone. The method overcomes the disadvantage of multiple operation steps of multi-screen display mobile phones, all screens and icons can be previewed only by shaking the mobile phone, and the operation is convenient and visualized.

Owner:SHENZHEN SANG FEI CONSUMER COMM CO LTD

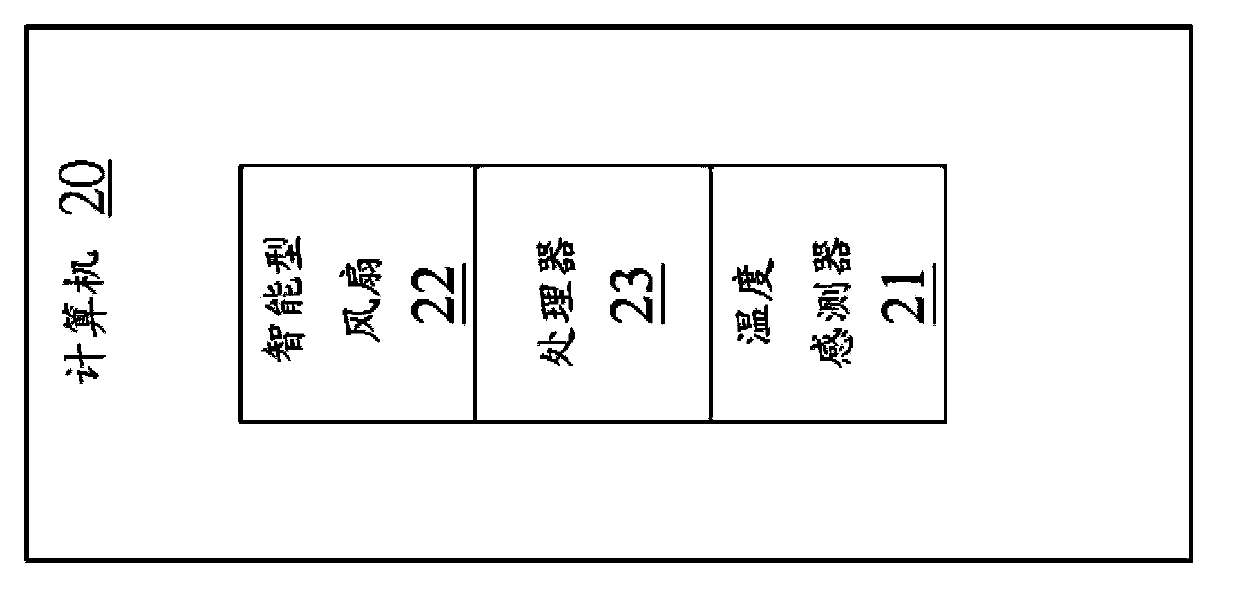

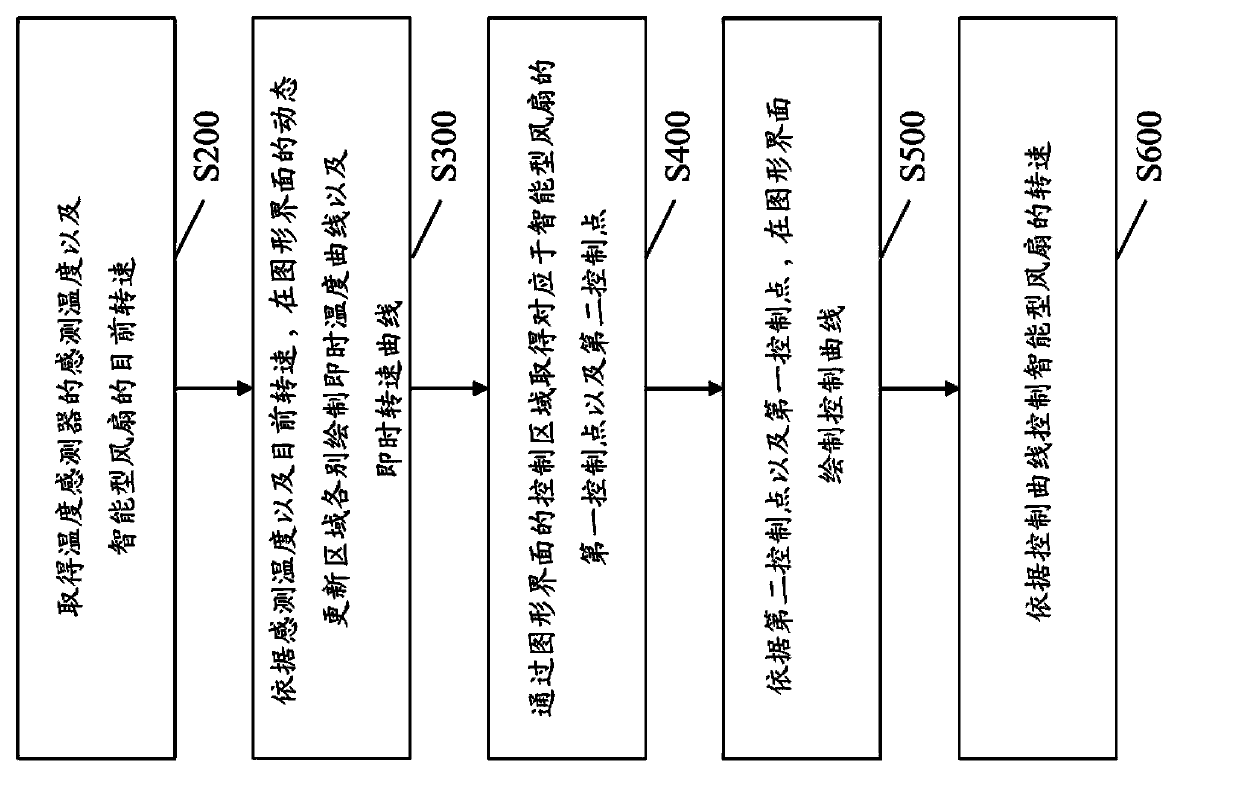

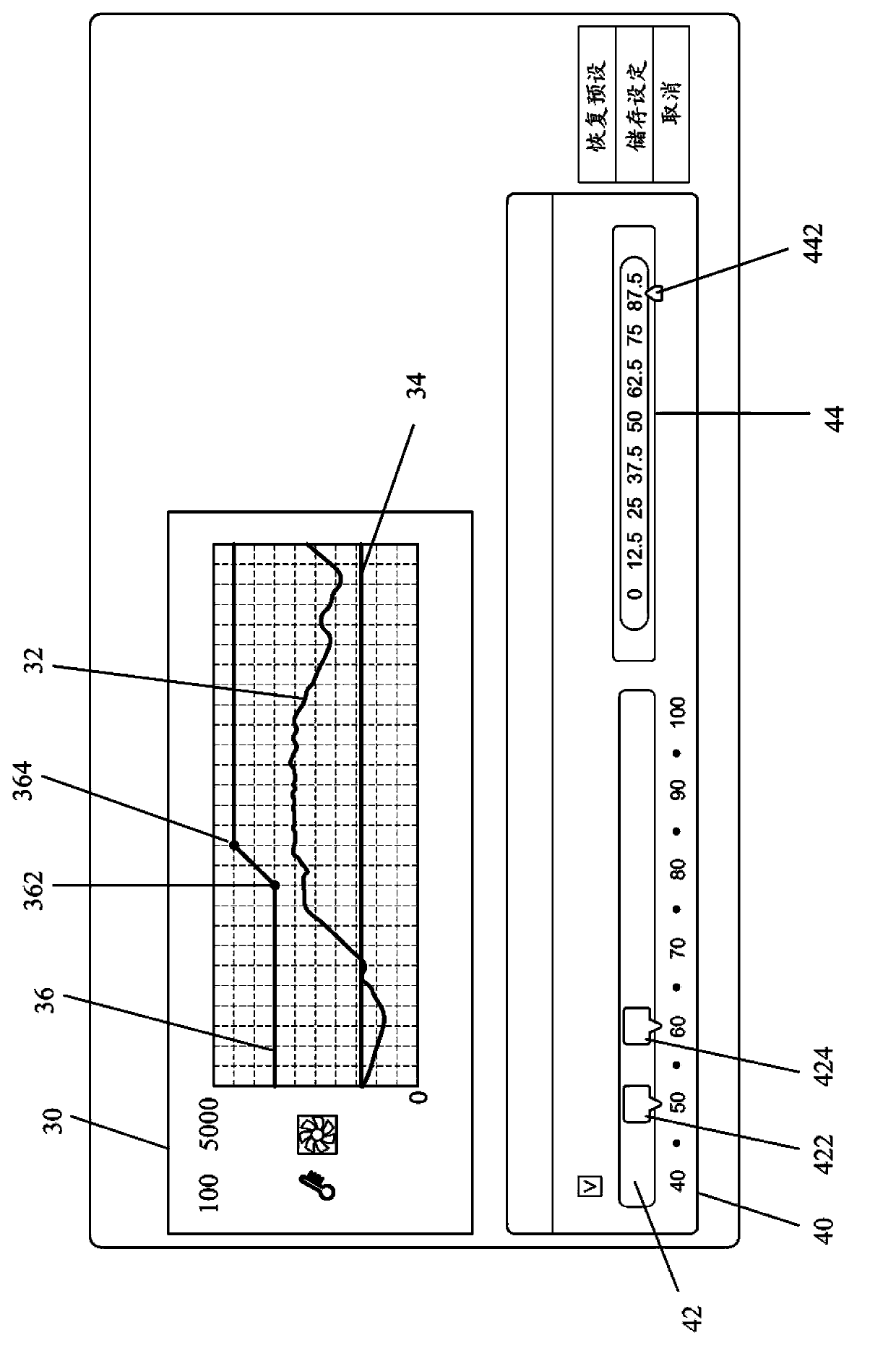

Computer and control method for smart fan thereof

ActiveCN103631348AEasy and intuitive operationEnergy efficient ICTTemperature control with auxillary non-electric powerTemperature curveControl zone

A computer and a control method for smart fan thereof are provided, wherein the computer includes a processor configured to control a smart fan under an UETFI bios mode. A sensed temperature value from a temperature sensor, and a current speed value of the smart fan are acquired. A real-time temperature curve and a real-time speed curve are traced in a dynamic updating zone of a graphical interface respectively according to the current temperature and the current speed value. A first control point and a second control point, which correspond to the smart fan, are obtained via a control zone of the graphical interface. A control curve is traced in the graphical interface according to the first and second control points. The speed of the smart fan is controlled according to the control curve. And therefore the user can set the control points according to the temperature curve and the rotating speed curve.

Owner:MSI ELECTRONICS KUN SHAN

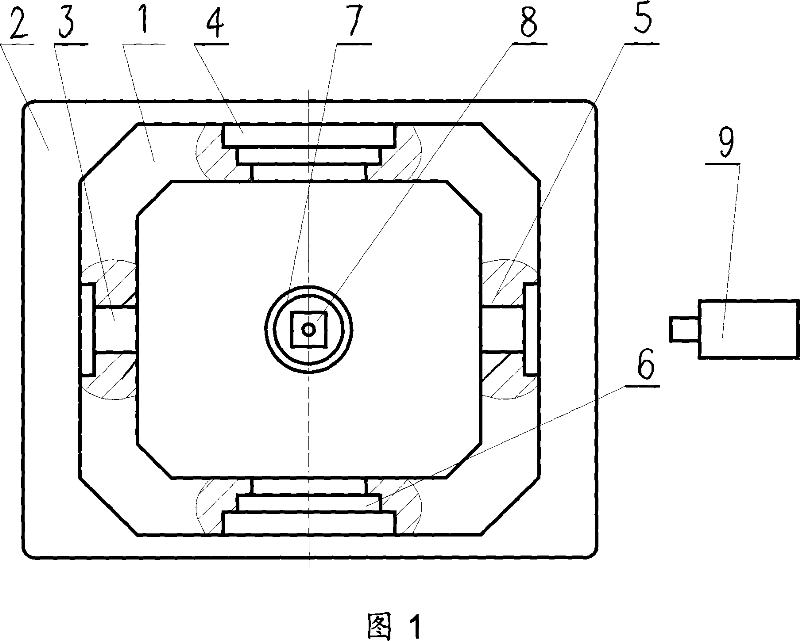

Finish machining method of the frame of the rotating table

ActiveCN101036948AAchieve finishingHigh precisionPrecision positioning equipmentMeasurement/indication equipmentsStanding frameAutocollimation

A fine machining method of the rolling stand frame belongs to machine finishing technology field. At first determining center of turning circle position of the fine boring machine table and mounting end face multiple tooth circular dividing table thereon, the tetrahedron is mounted on the end face multiple tooth circular dividing table, and adjusting it to collimate with the photoelectricity autocollimation to determine machineable machine zero position point; the rolling stand frame is mounted on the worktable, and adjusting it to symmetry with the center of gyration; boring the frame side face of each axle hole for the rolling stand frame and the axle hole until achieving to the required precise size, when the frame rotates from one side to another side, rotating relevant angle of the worktable contrasting to graduation value of the end face multiple tooth circular dividing table, the tetrahedron is measured by the photoelectricity autocollimation, fine tuning the worktable to collimate the corresponding face of the tetrahedron with the sending beam of the photoelectricity autocollimation, at this point, the rotating angle is exact value, then processing. The invention operates conveniently and audio-visually, with reliable processing manufacturability, and reducing accumulation of error and improving process precision of the frame.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Porthole mouthpiece tester with movable contact

InactiveCN1598520AEasy and intuitive operationSuitable for modern teaching requirementsHydrodynamic testingEngineeringSilicon

The invention discloses aperture nozzle experiment device with mobile contact. It has self loop water supplier, in which a pump is arranged, the pump is controlled by controllable silicon stepless speed regulator, the self loop water supplier is connected to constant pressure water box and back groove, the constant pressure water box is arranged with overflow board and water stabling aperture board, the constant pressure water box is connected to water inlet and outlet through the self loop water supplier, the surface facing to the back groove is arranged with aperture nozzle, switching board, scale and pressure measuring pipe, the outlet of the back groove is arranged with a circular back device. The invention uses independent self loop constant water supplying system, it is convenient, the precision is high reaching to 0.01mm.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com