Industrial robot teaching system

A technology of industrial robots and numerical control systems, applied in instruments, simulators, teaching models, etc., can solve the problems of inability to achieve full surface coverage flexibility, complex shapes, and large outer surfaces of sprayed parts, achieving convenient management and short time. , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

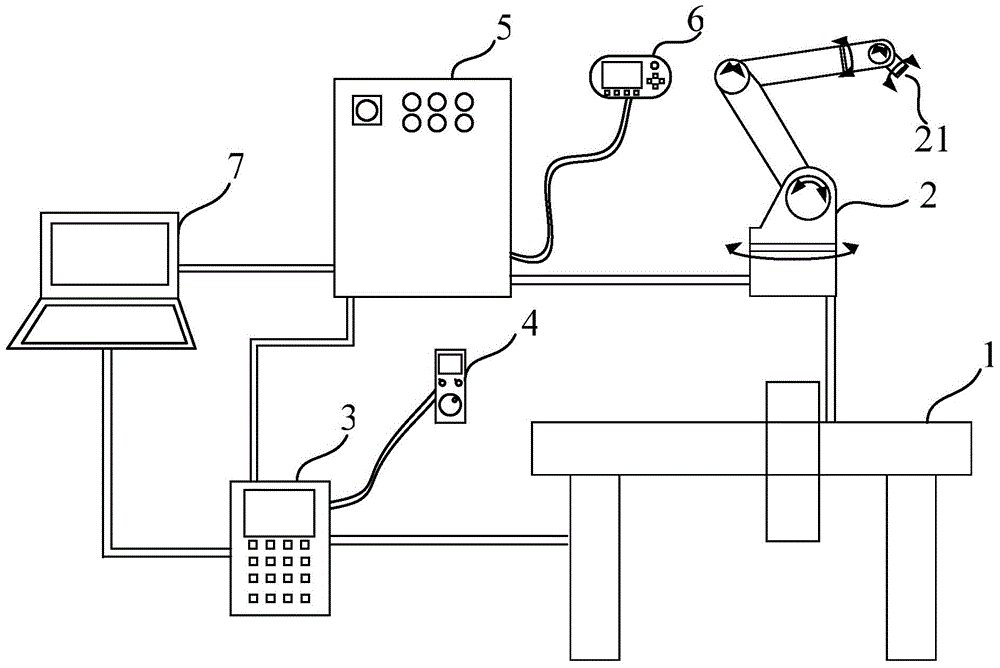

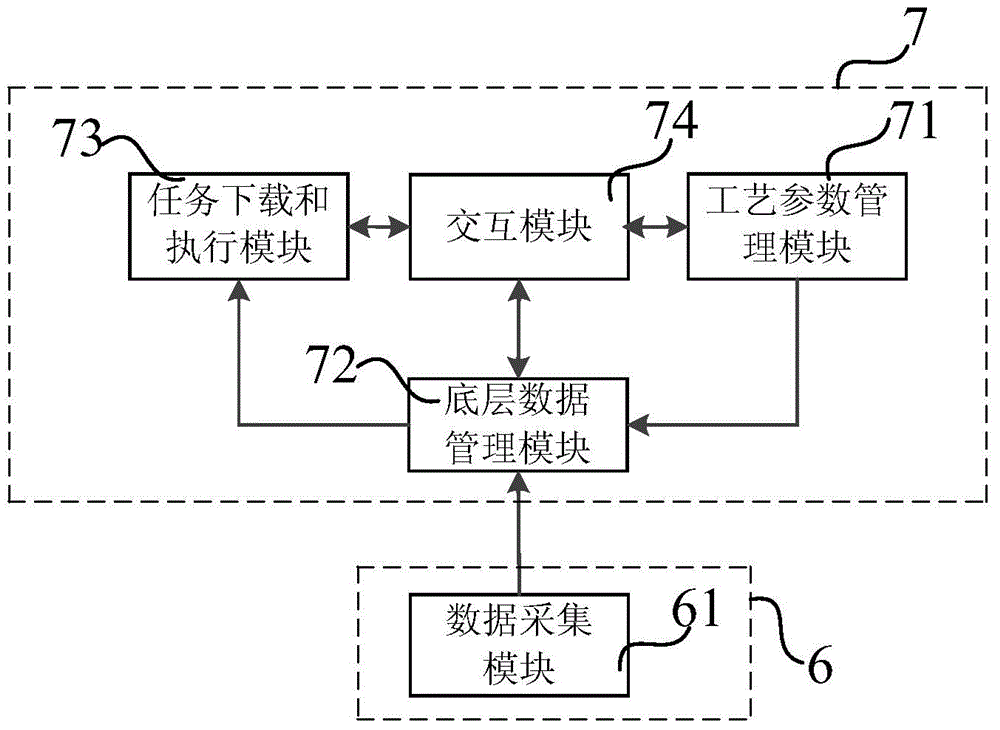

[0017] The industrial robot teaching system according to the present invention will be described in detail below with reference to the accompanying drawings.

[0018] refer to figure 1 with figure 2 , the industrial robot teaching system according to the present invention includes: a mobile platform 1; an industrial robot 2, fixed on the mobile platform 1, so as to be able to move with the mobile platform 1, and has a terminal 21 for performing process operations; a numerical control system 3, The communication is connected to the mobile platform 1 to control the movement of the mobile platform 1; the hand wheel 4 is connected to the numerical control system 3 for the operator to operate and control the movement of the mobile platform 1 through communication with the numerical control system 3; the industrial robot The controller 5 is communicatively connected to the industrial robot 2 to control the motion and process operation of the end 21 of the industrial robot 2, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com