Ultra-low frequency modal test suspension system

A modal test and suspension system technology, applied in the field of suspension system, can solve the problems of reducing the working frequency, the influence of additional components is large, and the control accuracy is low, and achieves the effect of reducing the working frequency, reducing the influence and improving the control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

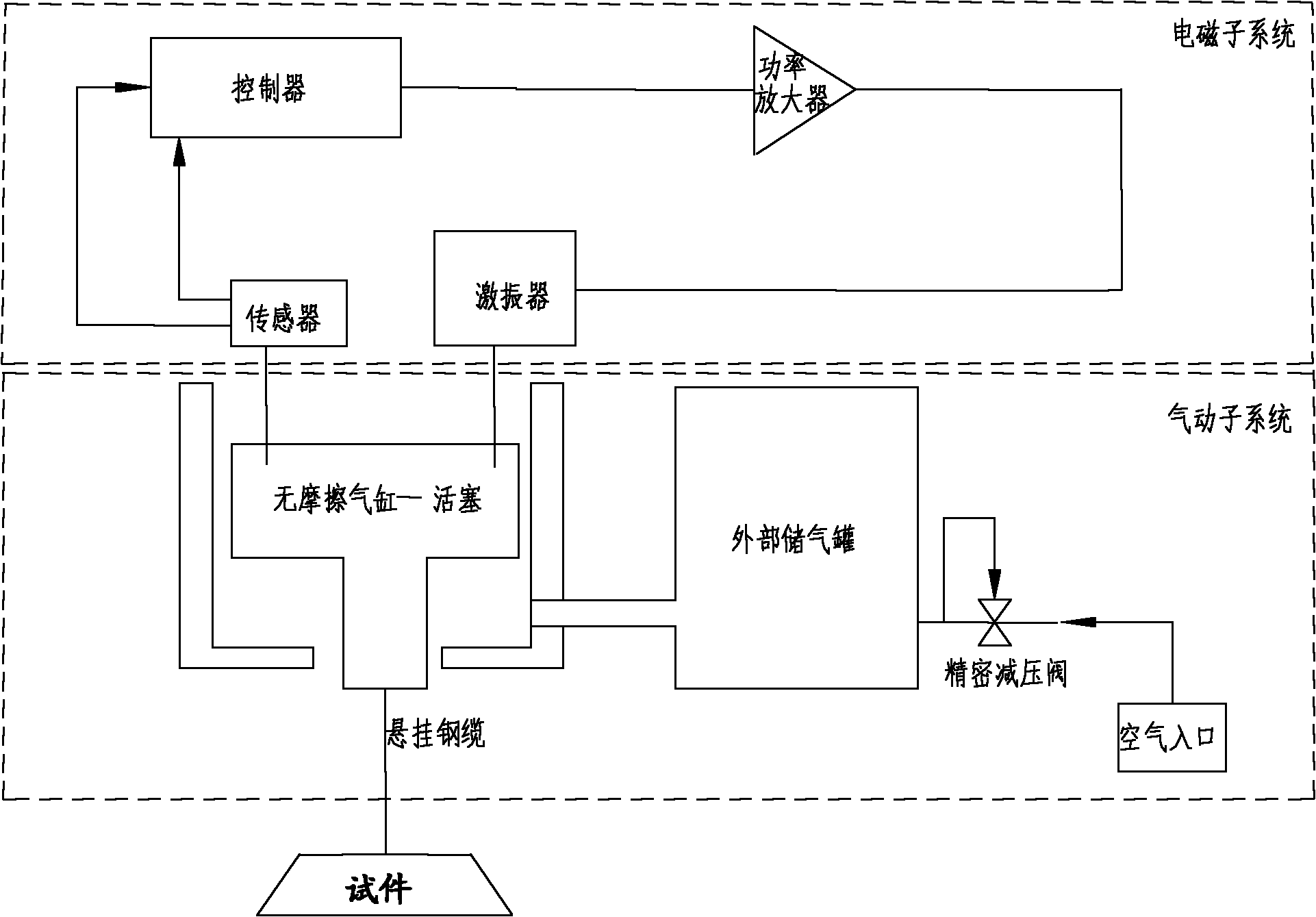

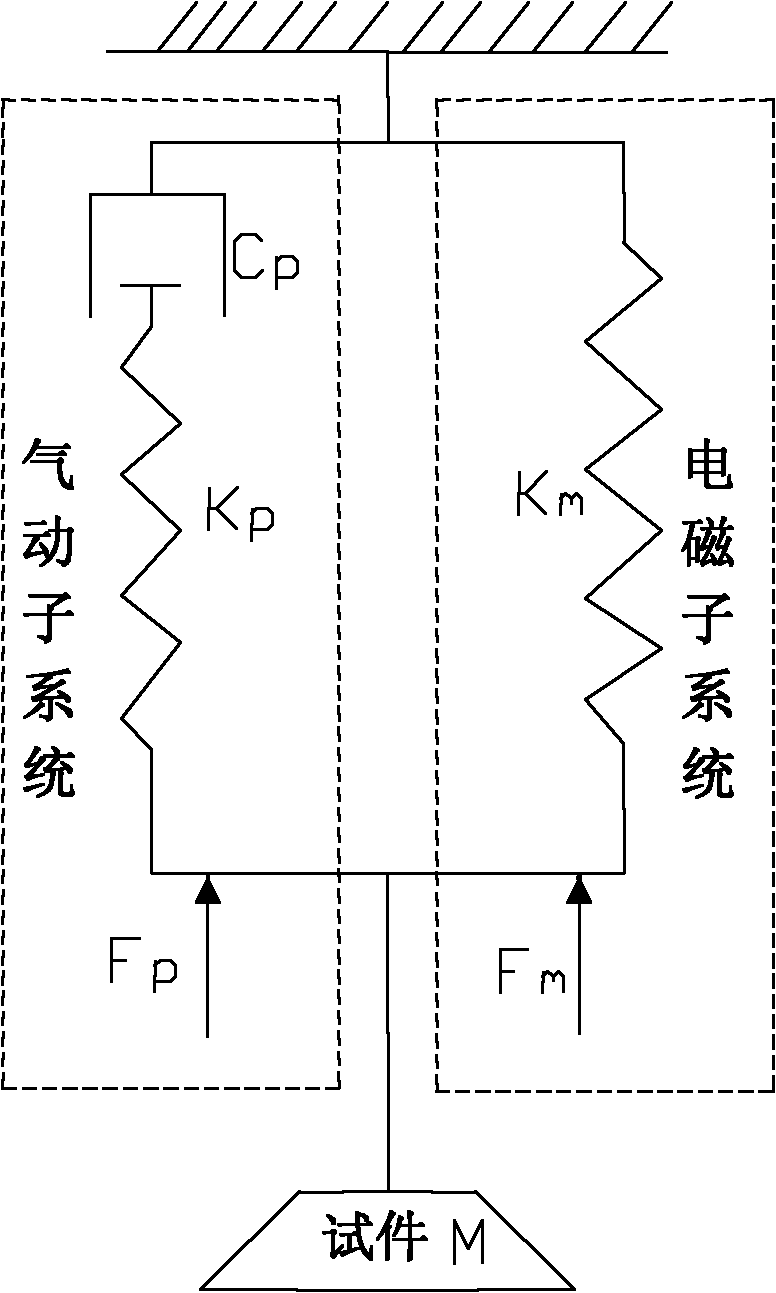

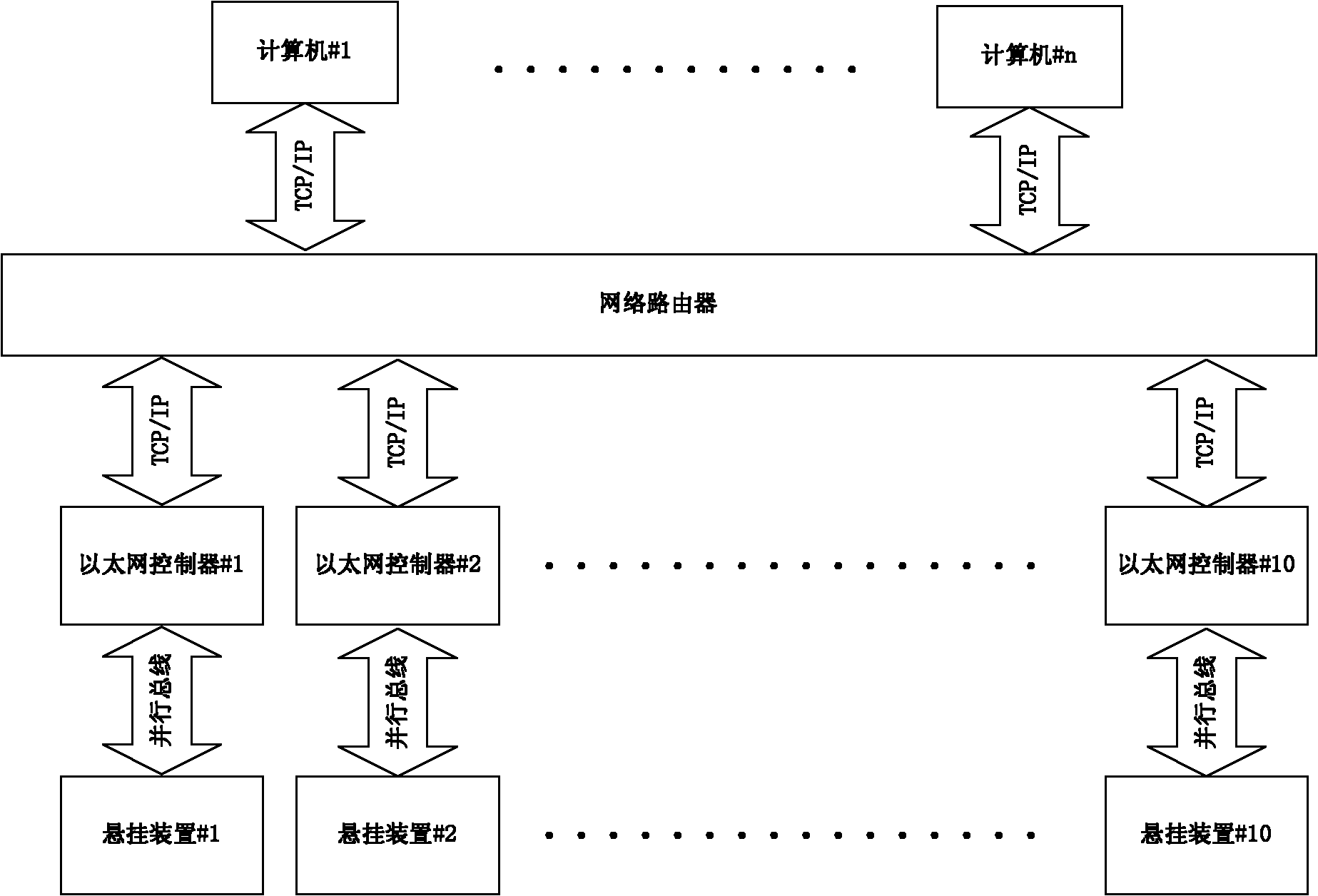

[0030] refer to Figure 1 to Figure 5, a suspension system for ultra-low frequency modal tests, including a modal test suspension device, the suspension system for ultra-low frequency modal tests also includes a monitoring computer for realizing remote monitoring and monitoring, and the monitoring computer is connected with an Ethernet router, The air storage tank and the pneumatic actuator of the modal test suspension device are connected with a digital proportional valve and an air pressure sensor, the digital proportional valve is connected with the air pressure control MPU through the D / A control module, and the air pressure sensor is connected with the air pressure control MPU Connect; the suspension follower part of the modal test suspension device is connected with a linear displacement encoder, a suspension force sensor and an electromagnetic force sensor, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com