Process for producing carbon/carbon heat insulation bottom board for high temperature furnace

A technology for high-temperature furnaces and bottom plates, which is applied in coking ovens, special forms of dry distillation, and the petroleum industry. It can solve problems such as difficulty in forming graphite heat-insulating bottom plates, unstable graphite product structure, and reduced equipment utilization, and achieves practicability. Strong, lightweight, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

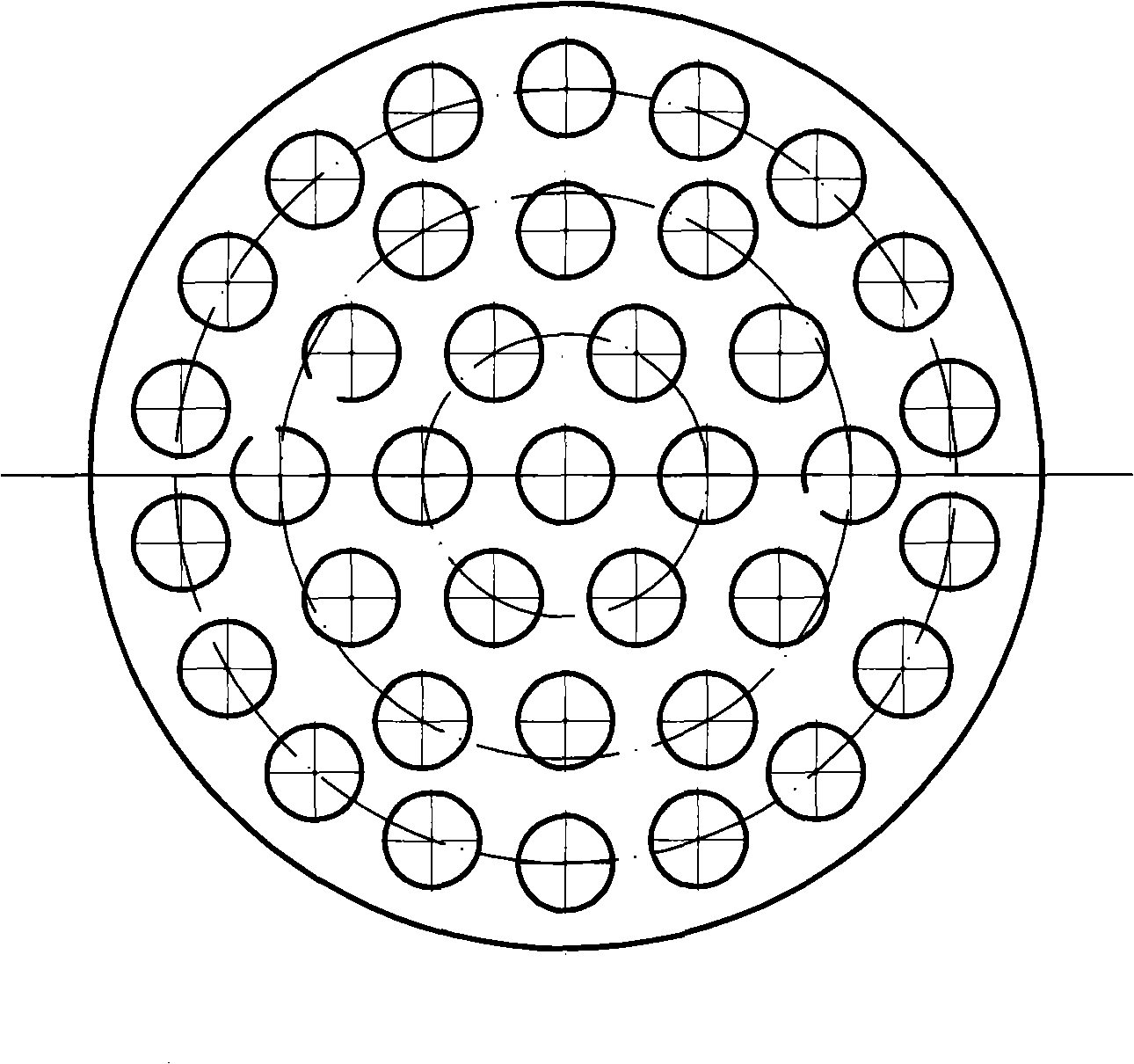

Image

Examples

Embodiment 1

[0025] (1) Use 3K carbon fiber plain or twill cloth and thin carbon fiber mesh tires to alternately lay layers, and axially (that is, the thickness direction of the layer) needling to form a full carbon fiber three-way structure prefabricated body, the needling density is 25 needles / cm 2 ;The density of the prefabricated body with full carbon fiber structure is 0.20g / cm 3 ; where K represents the number of thousands of tows.

[0026] (2) Furfurone resin vacuum impregnation and carbonization densification process: Under the pressure of -0.086MPa, the all-carbon fiber three-way structure prefabricated body in step (1) is immersed in the impregnation tank for 1.5 hours, and then transferred to the carbonization furnace Carry out carbonization treatment at 900°C to produce charcoal / charcoal products.

[0027] (3) The density of charcoal / charcoal products is 0.50g / cm 3 At the end of the densification process, the carbon / carbon products are subjected to high-temperature purificati...

Embodiment 2

[0031] (1) Use 6K carbon fiber plain or twill cloth and thin carbon fiber mesh tires to alternately lay layers, and axially (that is, the thickness direction of the layer) needle-puncture the three-way structure prefabricated body of carbon fiber, and the needle-punching density is 35 needles / cm 2 ;The density of the prefabricated body is 0.30g / cm 3 ; where K represents the number of thousands of tows.

[0032] (2) Furfurone resin vacuum impregnation and carbonization densification process. Under the pressure of -0.092MPa, the all-carbon fiber three-way structure preform in step (1) is immersed in the impregnation tank for 2 hours, and then transferred to carbonization after leaving the tank Carry out carbonization treatment in a furnace at 950°C to produce charcoal / charcoal products.

[0033] (3) The density of charcoal / charcoal products is 0.80g / cm 3 At the end of the densification process, the carbon / carbon products are subjected to high-temperature purification treatment...

Embodiment 3

[0037] (1) Use 12K carbon fiber plain or twill cloth and thin carbon fiber mesh tires to alternately lay layers, and axially (that is, the thickness direction of the layer) needle-puncture the three-way structure prefabricated body of carbon fiber, and the needle-punching density is 40 needles / cm 2 ;The density of the prefabricated body is 0.40g / cm 3 ; where K represents the number of thousands of tows.

[0038] (2) Furfurone resin vacuum impregnation and carbonization densification process. Under the pressure of -0.098MPa, the all-carbon fiber three-way structure preform in step (1) is immersed in the impregnation tank for 2.5 hours, and then transferred to carbonization after leaving the tank Carbonization treatment is carried out in the furnace at 1100°C to produce charcoal / charcoal products.

[0039] (3) The density of charcoal / charcoal products is 1.0g / cm 3 At the end of the densification process, the carbon / carbon products are subjected to high-temperature purification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Needling density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com