Wood-plastic composite with effects of phase-change energy storage and thermal insulation and preparation method of wood-plastic composite

A technology of wood-plastic composite materials and phase-change energy storage materials, which is applied in the field of composite materials, can solve problems such as unsatisfactory heat insulation effects and inability to create a comfortable temperature range for the human body, so as to eliminate incompatibility problems and increase latent heat of phase change , Improve the effect of effective adsorption load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

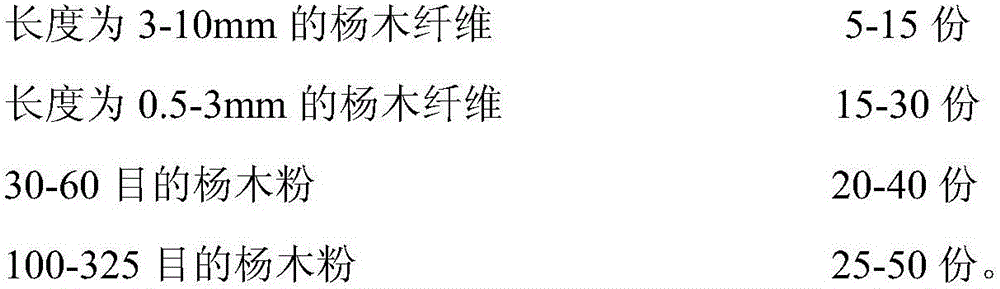

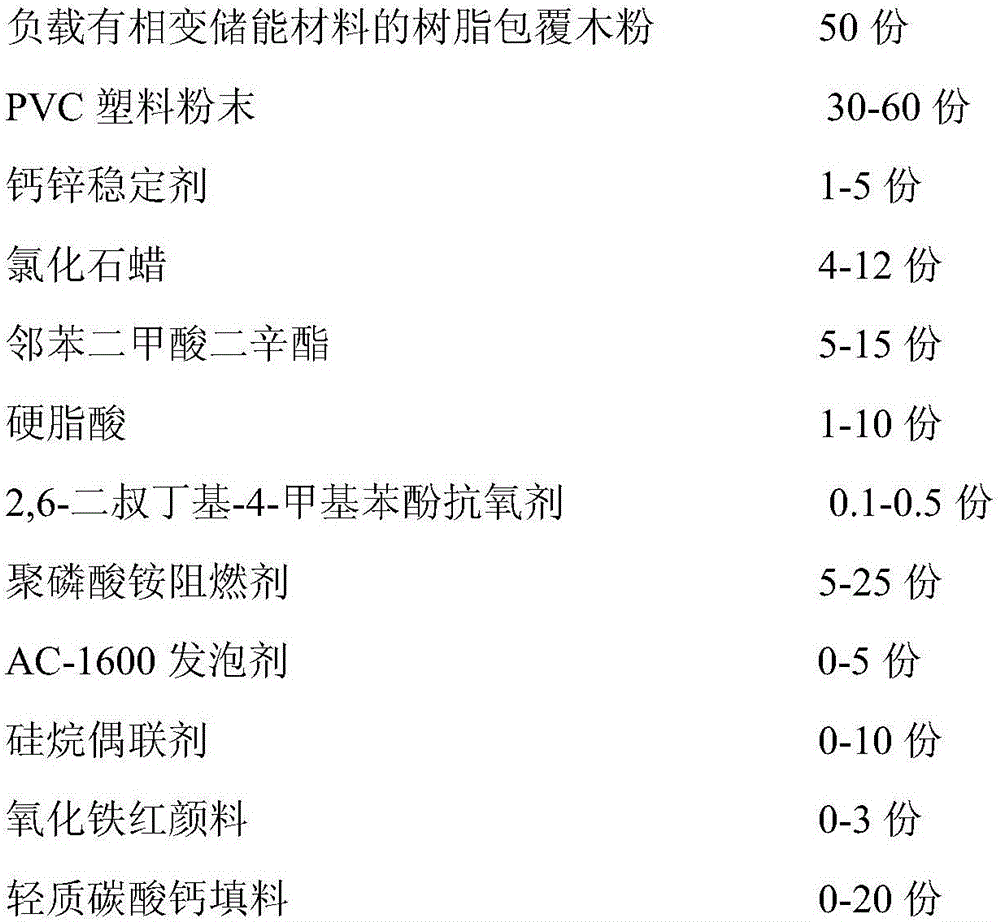

[0061] A wood-plastic composite material for phase-change energy storage and heat preservation in this embodiment, the composite material is a composite phase-change energy storage material that utilizes wood powder and wood fiber to absorb and load polyethylene glycol, and through polyethylene glycol-isocyanate copolymer resin After coating, it is mixed with base plastic and additives, and then it is prepared by kneading and extruding, kneading and pressing, cutting and trimming. The specific manufacturing method of the wood-plastic composite material for phase change energy storage and heat preservation includes the following steps:

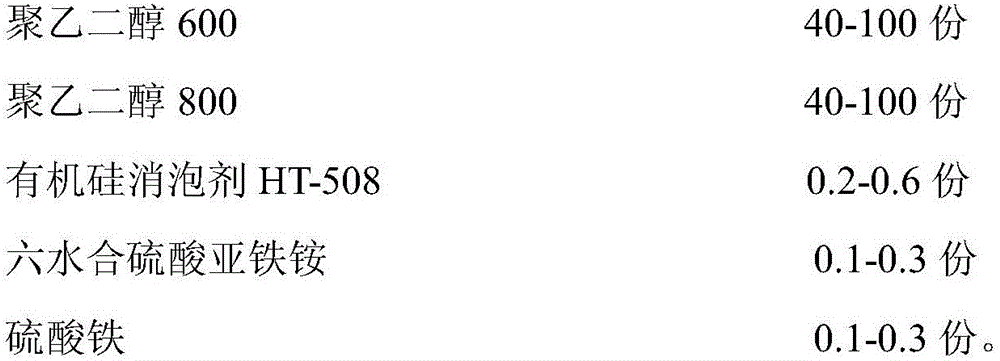

[0062] (1) Add 100kg of polyethylene glycol 600, 100kg of polyethylene glycol 800, and 0.5kg of silicone defoamer HT-508 into the high-speed disperser in turn, and disperse at a high speed of 1000r / min for 10min; Add 0.2kg of ferrous ammonium sulfate and 0.2kg of ferric sulfate successively at the rotation speed of 1000r / min for 25min.

[0063...

Embodiment 2

[0069] A wood-plastic composite material for phase-change energy storage and heat preservation in this embodiment, the composite material is a composite phase-change energy storage material that utilizes wood powder and wood fiber to absorb and load polyethylene glycol, and through polyethylene glycol-isocyanate copolymer resin After coating, it is mixed with base plastic and additives, and then it is prepared by kneading and extruding, kneading and pressing, cutting and trimming. The specific manufacturing method of the wood-plastic composite material for phase change energy storage and heat preservation includes the following steps:

[0070] (1) Add 110kg of polyethylene glycol 600, 90kg of polyethylene glycol 800, and 0.5kg of silicone defoamer HT-508 into the high-speed disperser in turn, and disperse at a high speed of 1000r / min for 10min; Add 0.2kg of ferrous ammonium sulfate and 0.2kg of ferric sulfate successively at the rotation speed of 1000r / min for 25min.

[0071]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com