Patents

Literature

188results about How to "High phase change enthalpy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medium-high temperature composite structural heat storage material, preparation method and application thereof

InactiveCN102888209AHigh phase change enthalpyGood chemical compatibilityHeat-exchange elementsMicro nanoMass ratio

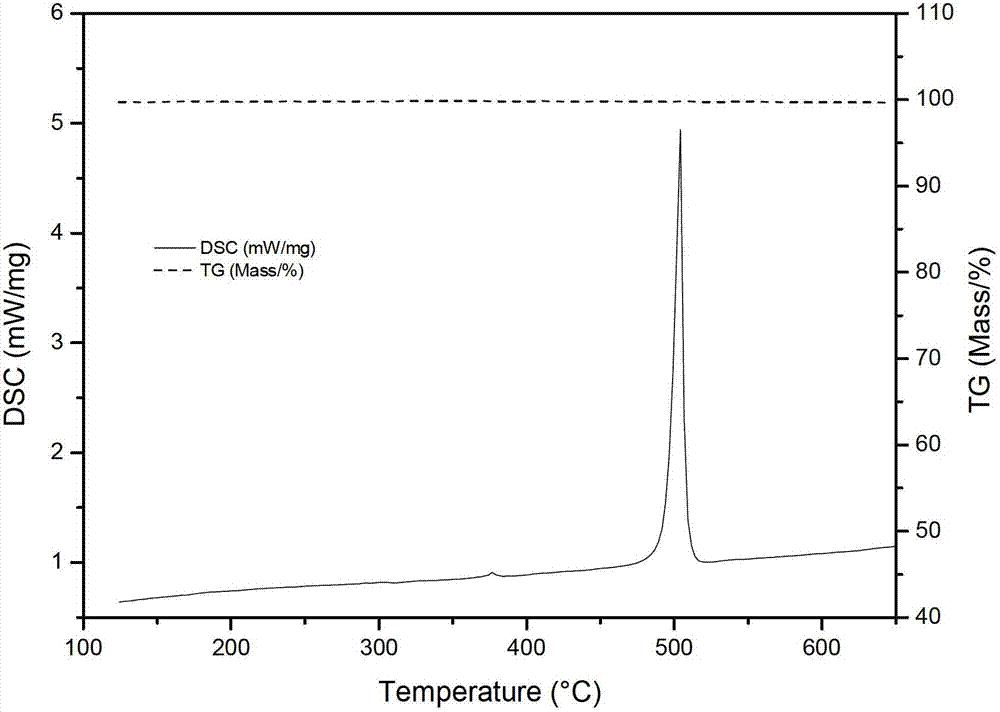

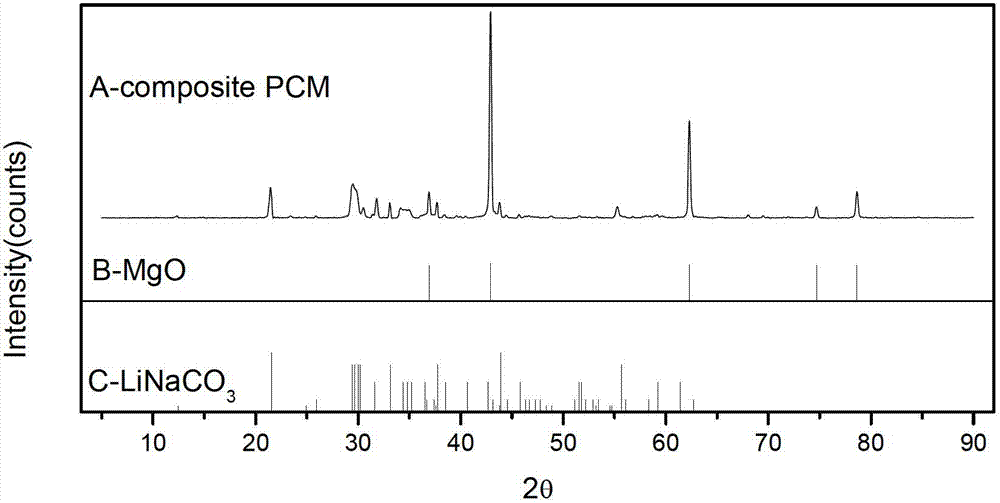

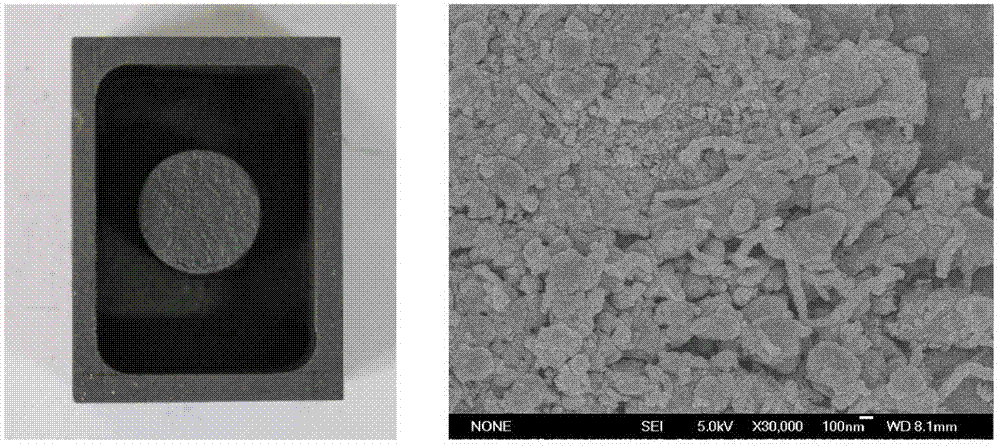

The invention relates to a medium-high temperature (120-1000 DEG C or higher) composite structural heat storage material. The medium-high temperature composite structural heat storage material comprises an inorganic salt phase change latent heat material, a sensitive heat storage material and a heat conduction reinforcing material, wherein the mass ratio of the inorganic salt phase change latent heat material to the sensitive heat storage material is of 1: (0.1-10); and the heat conduction reinforcing material is of 0.0001-1kg / (kg heat storage material) based on mass ratio. The preparation method comprises steps as follows: uniformly mixing the inorganic salt phase change latent heat material with the sensitive heat storage material and the heat conduction reinforcing material; pressurizing to form green blank; and then heating and sintering, so as to obtain the medium-high temperature composite structural heat storage material. The medium-high temperature composite structural heat storage material provided by the invention is capable of obviously reducing the corrosion resistance of the sensitive heat storage material; meanwhile, the thermal conductivity of the composite heat storage material is markedly improved by virtue of the micro-nano doping of the heat conduction reinforcing material; and moreover, high heat storage density is achieved, and wide application prospect is provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Phase-change energy-storage fibre and method for making same

ActiveCN101041911AHigh phase change enthalpyFunction increaseConjugated cellulose/protein artificial filamentsMelt spinning methodsCelluloseWax

The invention discloses a phase-variable energy-storage fiber and relative production, which comprises that using cellulose slurry to prepare cellulose adhesive solution, to be mixed with phase-variable wax fused solution to prepare spinning dope to obtain the phase-variable energy-saving adhesive fiber. The functional fiber is mainly formed by cellulose and wax, while the wax content is 10-40% (relative to the cellulose content). And the inventive production has simple process, significantly reduced phase-variable material loss in the process, improve the phase-variable material content and improve the phase-variable energy-saving function and mechanical function.

Owner:潍坊欣龙生物材料有限公司

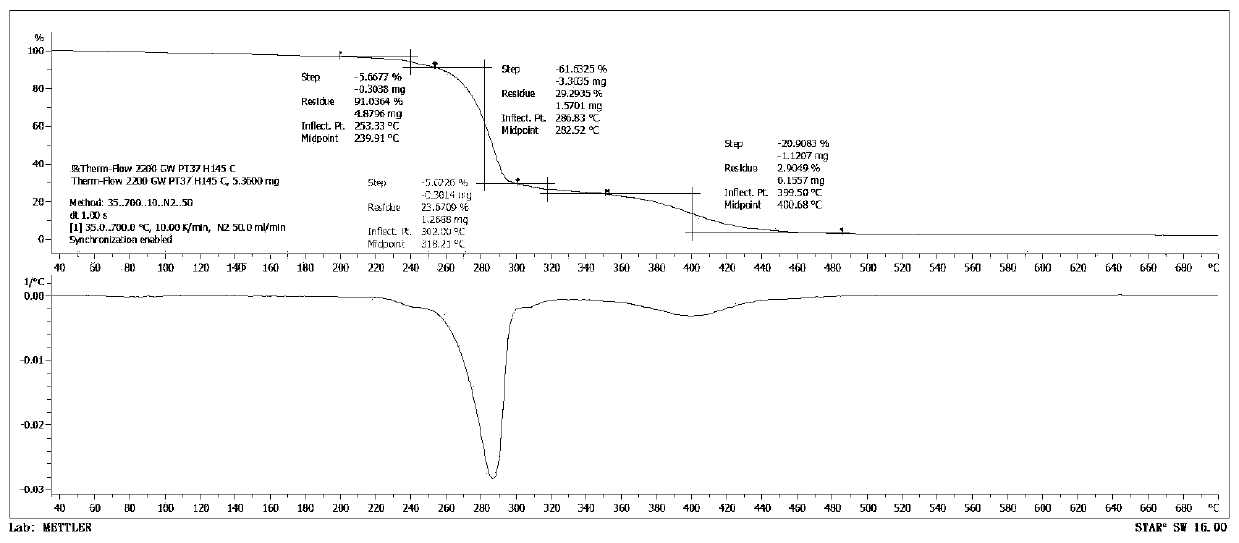

High temperature resistant type phase-change material micro-capsule and preparation thereof

InactiveCN101376800AImprove thermal stabilityLow thermal weight lossHeat-exchange elementsMicroballoon preparationMelamine formaldehydeHeat resistance

The invention relates to a high-temperature resistant phase-change material microcapsule and a preparation method thereof which belong to the technical field of compound materials. The invention needs to solve the technical problem of providing a high-temperature resistant phase-change material microcapsule in the field of melt spinning; the components thereof counted according to weight portions include 100 portions of core phase-change material, 7 to 12 portions of dispersant, 2 to 5 portions of emulsifying agent as well as a wall material prepared by 0.3 to 0.6 portion of modified monomer and 30 to 50 portions of melamine resin. The preparation method of the high-temperature resistant phase-change material microcapsule includes the emulsification of the core, the preparation of the prepolymer of the wall material, the preparation of the microcapsule and the removing of free formaldehyde. The high-temperature resistant phase-change material microcapsule has higher heat stability, heat-resistance as well as uniform grain sizes and can meet the requirements of spinning fibers. The preparation technique is simple, is conveniently operated, can save energies and is environmental friendly; the product is easy for industrialization production and has a better market prospect.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

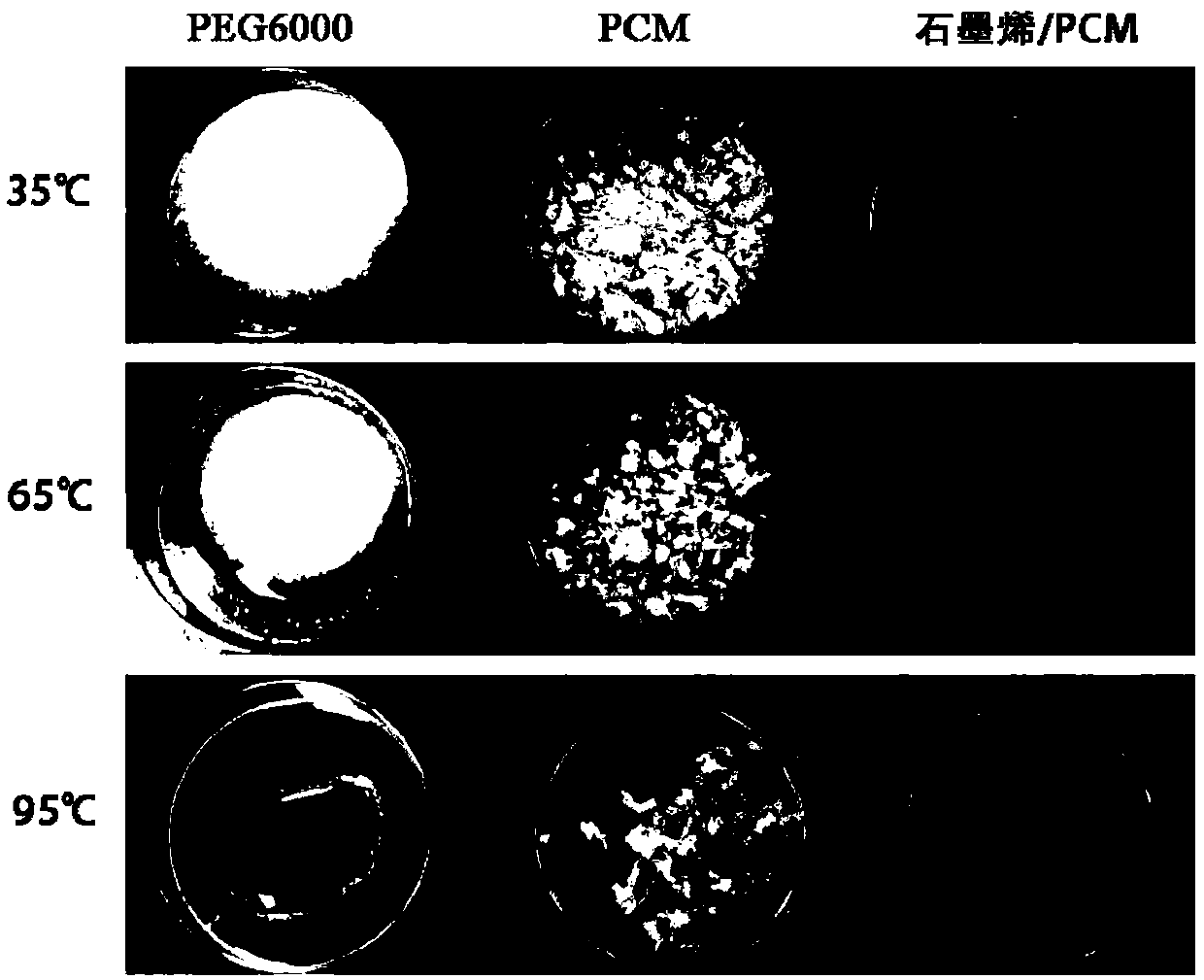

Thermal conductivity enhanced organic composite shaped phase change material and preparation method thereof

ActiveCN108048045AImprove thermal conductivityHigh phase change enthalpyHeat-exchange elementsThermal energyCross-link

The invention relates to a thermal conductivity enhanced organic composite shaped phase change material and a preparation method thereof, and belongs to the technical field of new materials. The thermal conductivity enhanced organic composite shaped phase change material is characterized in that the composite shaped phase change material is prepared from, by mass, 1-50% of coordination cross-linking network polymer, 40-98.9% of organic solid liquid phase change material and 0.1-10% of thermal conductivity enhancer, wherein the coordination cross-linking network polymer is prepared by coordination complexation of a polymer compound with metal ions. The material has a simple synthesis process, convenient application, a large phase change enthalpy value and an excellent shaping effect, and liquid leakage does not occur during operation. The material has a simple synthesis process, convenient application and broad application prospects in the field of thermal energy storage and management.

Owner:DALIAN UNIV OF TECH

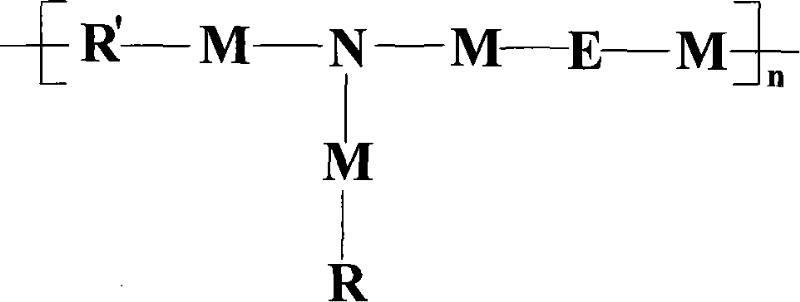

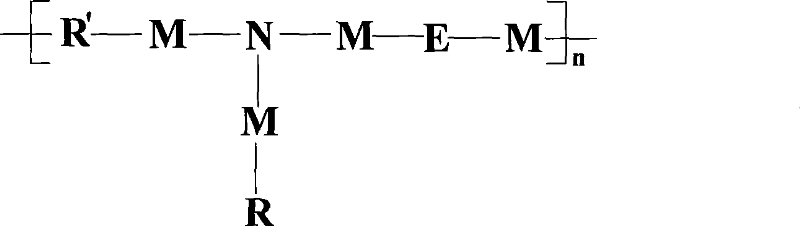

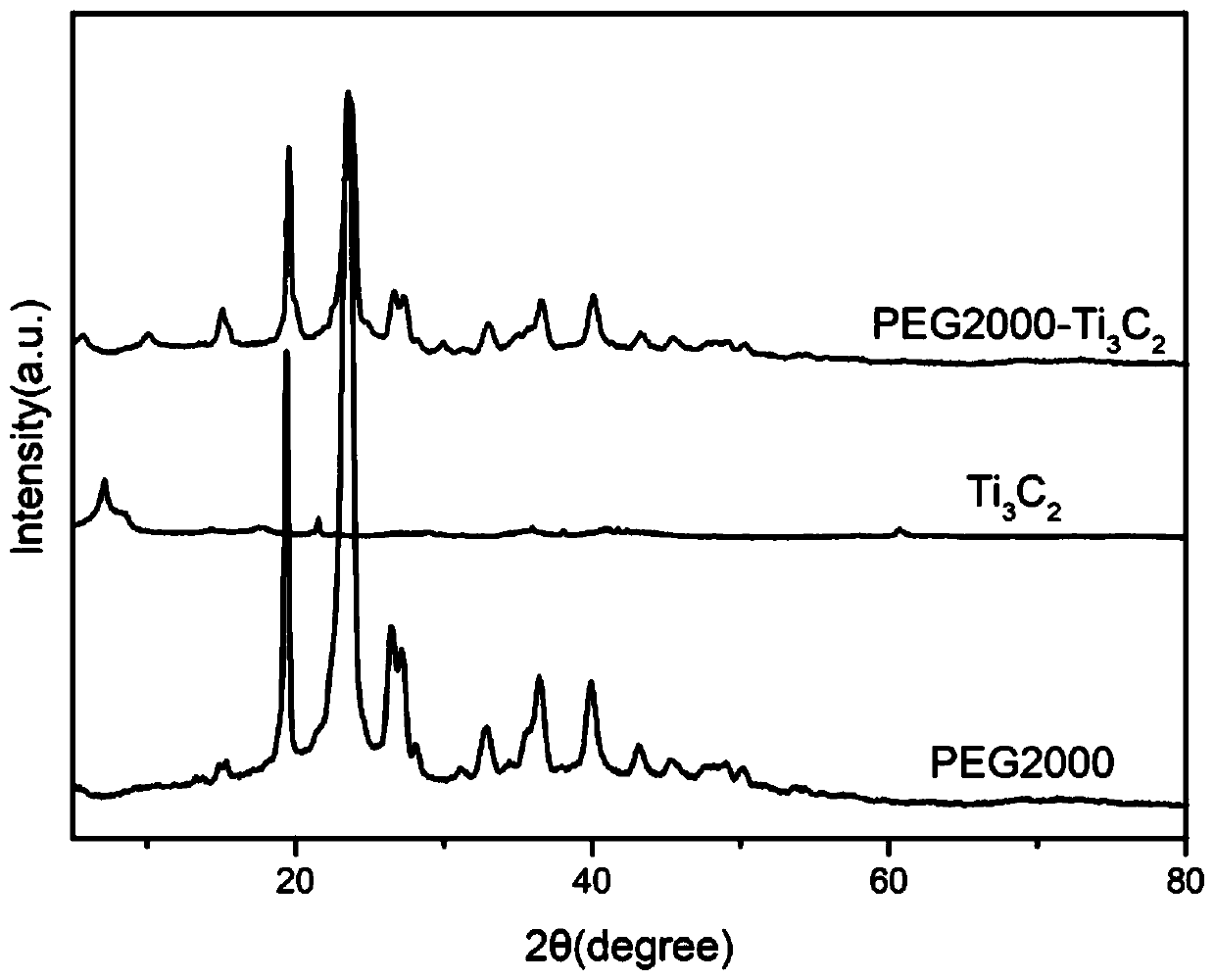

High molecular solid/solid phase changing material with net type and comb type mixed structure and its preparing method

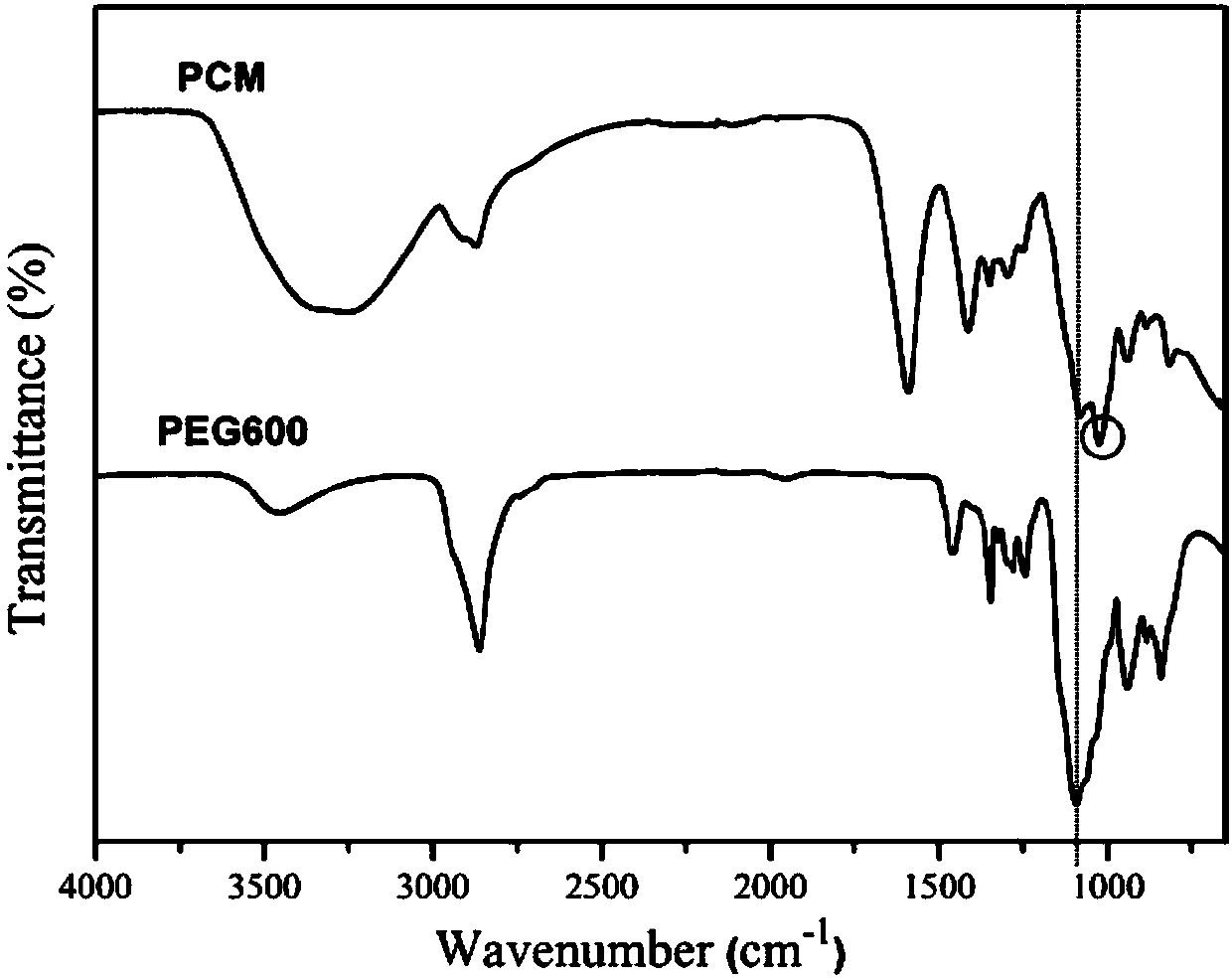

InactiveCN1616588APhase transition temperature is suitableSolid state goodHeat-exchange elementsPhase change enthalpyPolyethylene glycol

The present invention relates to a kind of high molecular solid / solid phase changing material with mixed net and comb structure, and features that polyglycol with two active end radical and polyglycol with one active end radical are fixed onto the high molecular skeleton material to form 3D mixed net and comb structure. The material of the present invention has relatively great phase change enthalpy up to 120 J / g, proper phase change temperature capable of being altered in 0-65 deg.c, stable solid state before and after phase change without supercooling, separating and other unstable phenomenon, high mechanical strength, high solvent resistance, good machining performance, no toxicity, no leakage, no corrosion, no pollution, long service life and other advantages. The present invention may be used widely in solar energy utilization, afterheat recovering, intelligent air conditioner and other fields.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

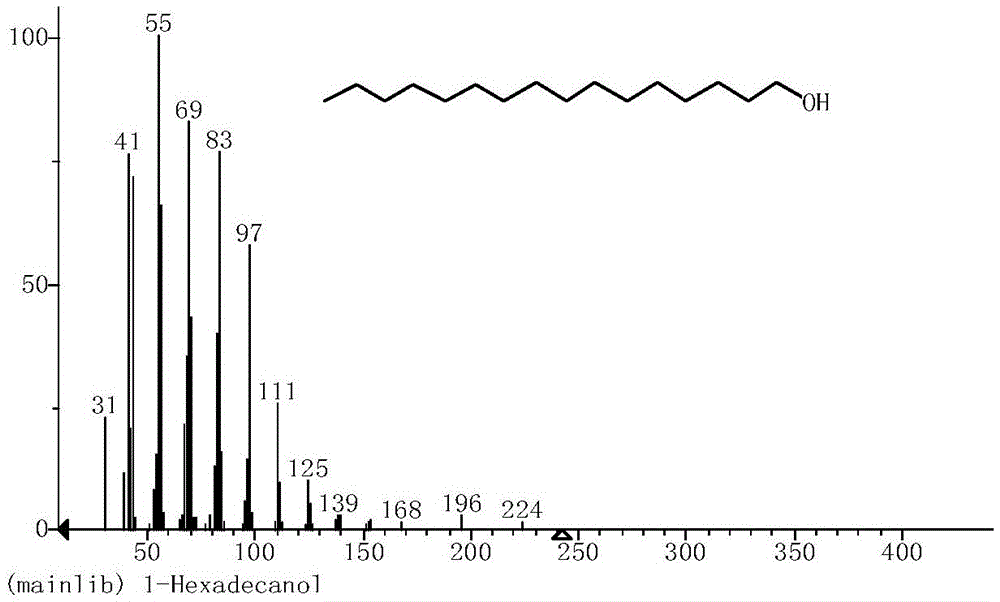

Olefin composite shaping phase-change material and preparation thereof

InactiveCN101434832AReduce leakageHigh phase change enthalpyHeat-exchange elementsLow leakageHigh-density polyethylene

The invention discloses an olefin-typed compound shape-stabilized phase change material and a preparation method thereof; the olefin-typed compound shape-stabilized phase change material is prepared by the following methods: (1) according to the mass percentage, 81-99.5 percent of olefin, 0.5-10 percent of polyol acetal compound and 0-9 percent of high density polyethylene are weighed and taken; (2) the polyol acetal compound and the high density polyethylene are added to the olefin, heated and mixed till being completely dissolved to prepare the mixture; and (3) the mixture is poured in a die, naturally cooled and taken out of the die. The olefin-typed compound shape-stabilized phase change material uses the olefin as the heat-storage material, and takes the spatial network structure formed by small molecule gelator as the supporting material of the olefin; furthermore, the high density polyethylene is added or not added as the supporting material, thus obtaining the shape-stabilized phase change material which has low leakage, high transformation enthalpy, low preparation cost and excellent application performance.

Owner:TIANJIN UNIV

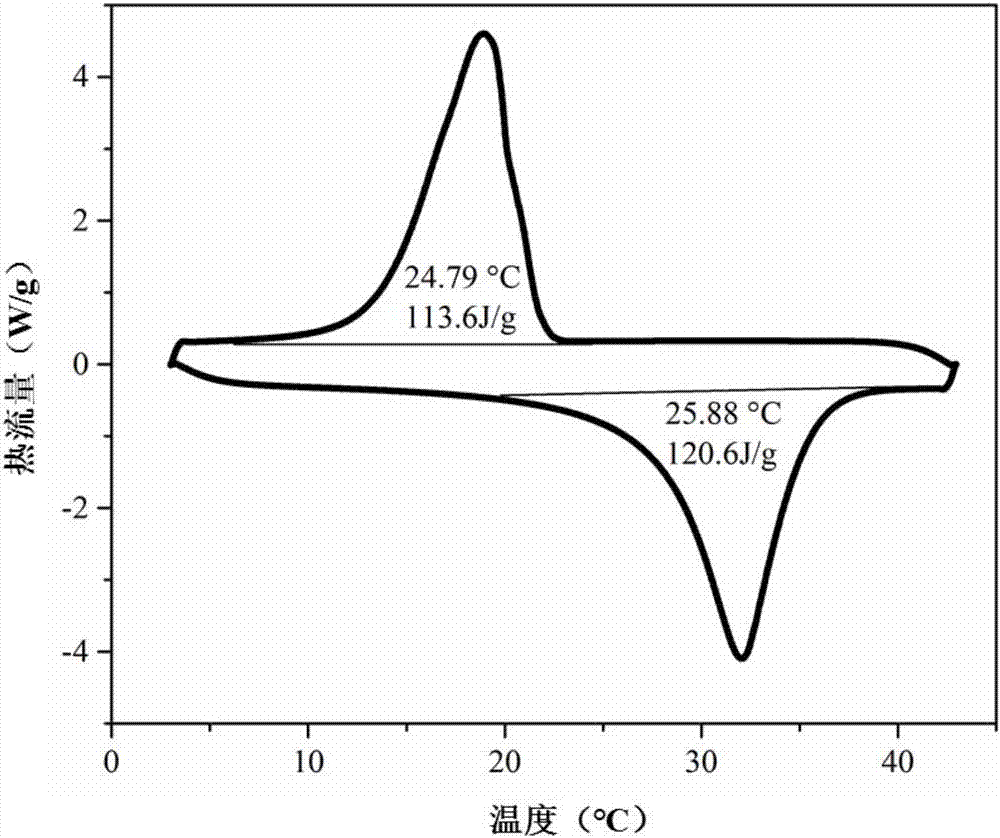

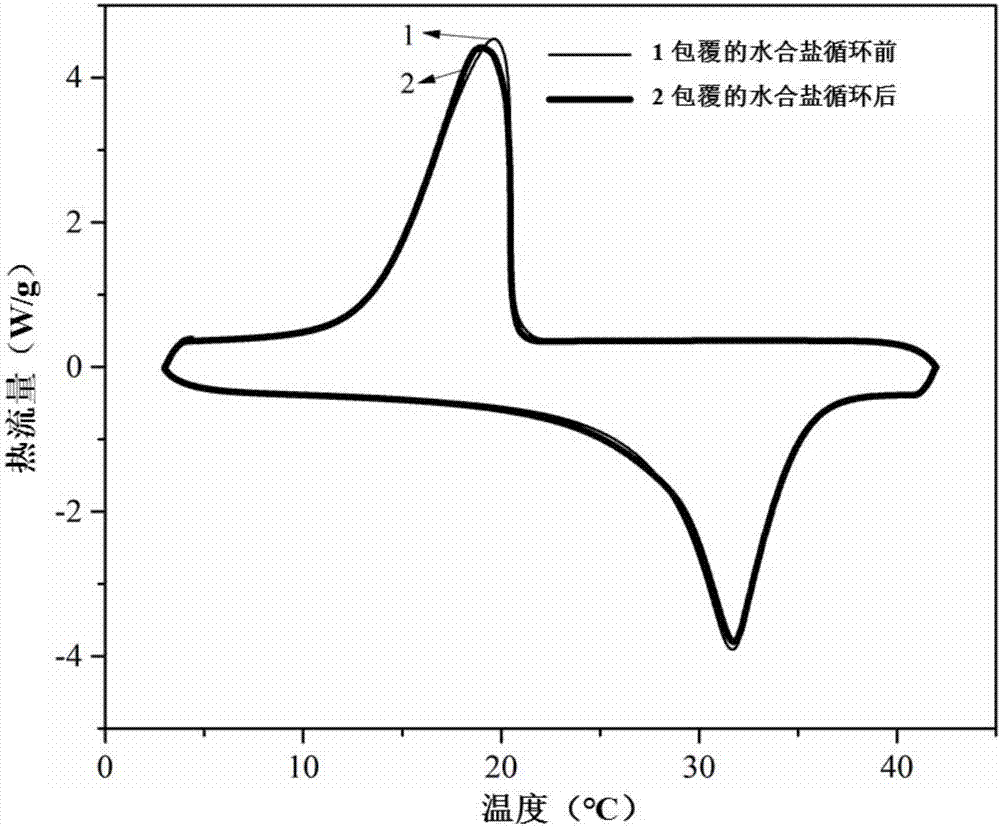

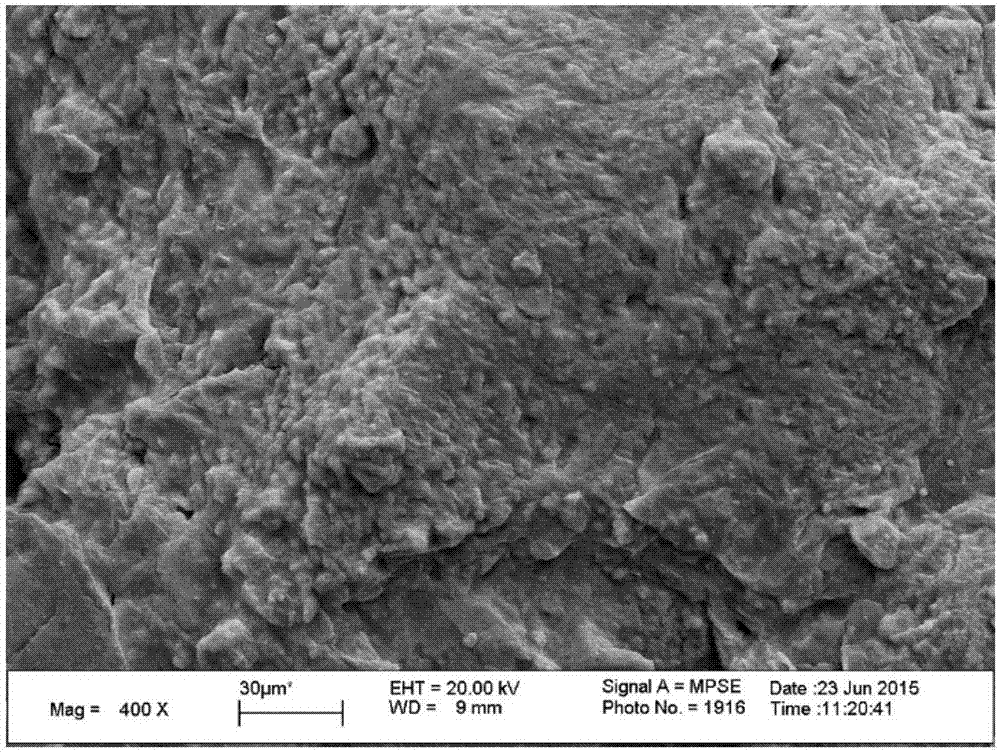

Coated hydrous salt heat-storage material and preparation method

InactiveCN107216859AHigh phase change enthalpyImprove cycle performanceHeat-exchange elementsInorganic saltsHeat storage material

The invention discloses a coated hydrous salt heat-storage material and a preparation method. The coated hydrous salt heat-storage material is composed of an inner core material and an outer wall material. The preparation method comprises the following steps of: firstly, dissolving inorganic salt, a nucleating agent and a thickener in water to obtain a mixed solution; mixing a porous adsorption material with the mixed solution and uniformly mixing the mixture to obtain a composite material; crystallizing the composite material to prepare a compound phase change material; preparing a photocured resin solution by a resin monomer and a prepolymer; and spraying the photocured resin to the composite phase change material, and lighting the material under an UV lamp after uniform spraying to obtain the coated hydrous salt heat-storage material. The heat storage material prepared by the method has the advantages of non-phase separation, no toxicity and corrosion, small degree of supercooling, no liquid leakage and the like. Meanwhile, the heat storage material has the advantage of great heat conductivity coefficient of a carbon material, and the heat storage performance and the heat stable performance are good.

Owner:SOUTH CHINA UNIV OF TECH

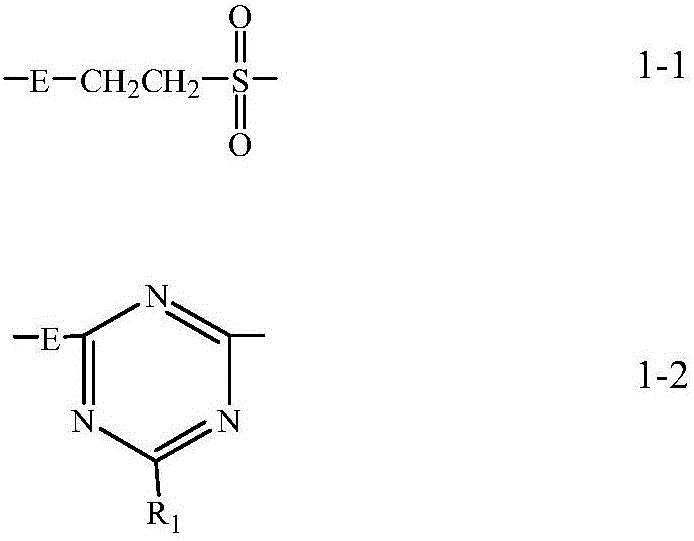

Solid-solid phase-change energy-storage material and preparation method thereof

InactiveCN101037590AHigh phase change enthalpyExcellent performanceHeat-exchange elementsSolid phasesSide chain

The invention relates to a solid-solid phase-change energy-storage material in macromolecule material field and preparing method thereof. The preparing method of the phase-change energy-storage material includes steps: forming branched chain macromolecule monomer of the material by small molecule of N, M and R; synthesizing structural unit of polymer with main side chain structure from the branched chain macromolecule monomer and small molecular of R', M, N and E by method of graft copolymerization; forming the three-dimensional high-density comb shaped solid-solid phase-change energy-storage material from 1-59 structural unit(s); wherein N is trihydroxy compound, M is diisocyanate compound, R is polyethylene glycol compound, R' is low polymer of glycol compound, and E is aromatic diamines compound. Advantages of the prepared solid-solid phase-change energy-storage material are: controlled high phase-change enthalpy value, fitting temperature for phase-change, good heat stability, non-flowing quality, good machine-shaping property, simple preparing process, reusable solvent, and low cost.

Owner:DONGHUA UNIV

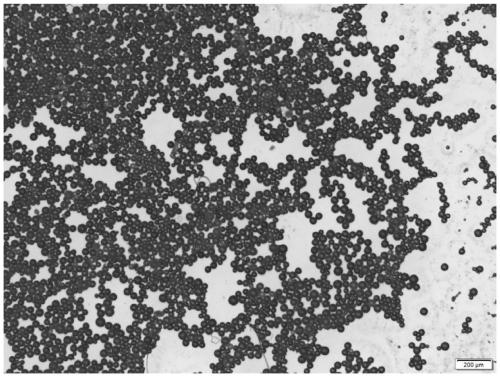

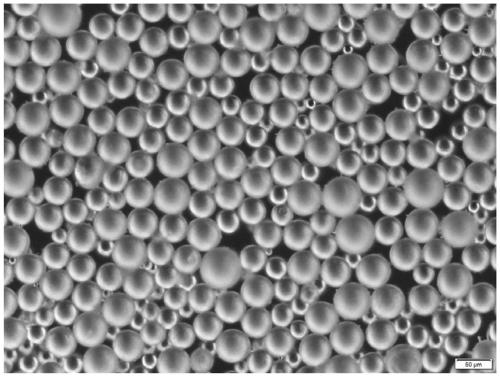

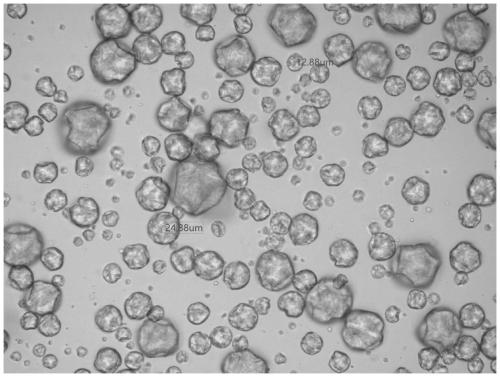

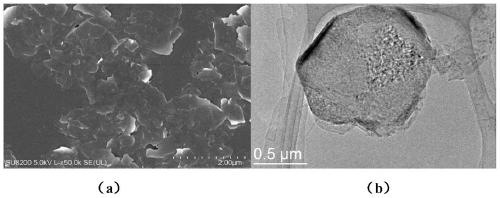

Preparation method for nanometer TiO2 modified composite phase change microcapsule

ActiveCN105056854AHigh phase change enthalpyConstant phase transition temperatureMicroballoon preparationMicrocapsule preparationAlkaneCross-link

The invention discloses a preparation method for a nanometer TiO2 modified composite phase change microcapsule. The preparation method comprises the following steps: preparing a core material from n-alkane and alkyl stearate, preparing a wall material from methyl methacrylate, butyl acrylate, ethyl acrylate, a cross-linking agent and nanometer TiO2 and mixing the core material with the wall material so as to obtain an oil phase A; dissolving a reactive emulsifier in deionized water so as to prepare a water phase B; adding the oil phase A into the water phase B and carrying out ultrasonic dispersion so as to form an O / W pre-emulsion; heating the O / W pre-emulsion and adding an initiator into the O / W pre-emulsion so as to prepare a nanometer TiO2 modified composite phase change microcapsule emulsion; and subjecting the nanometer TiO2 modified composite phase change microcapsule emulsion to standing and carrying out filtering, washing and drying so as to obtain the nanometer TiO2 modified composite phase change microcapsule. According to the preparation method, under the condition of usage of reactive emulsifier, nanometer TiO2 is used to modify the wall material, so the phase change microcapsule with a small and uniform size is prepared.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing linear polyurethane phase change material

The invention discloses a method for preparing a linear polyurethane phase change material. The method comprises the following steps: dissolving polyethylene glycol and diisocyanate into solvent in inert atmosphere, reacting in the presence of optional catalyst, adding tertiary amine type chain extender containing hydroxyl for chain extension, adding an optional neutralizer for salt formation so as to obtain the linear polyurethane phase change material, wherein the molar ratio of the sum of hydroxyl of polyethylene glycol and hydroxyl of chain extender to the isocyanate group of diisocyanate is 1:1, the add amount of the catalyst accounts for 0-1% the total weight of the polyethylene glycol, diisocyanate and chain extender, the molar ratio of neutralizer to tertiary amine type chain extender is 0-1, and the molecular weight of the polyethylene glycol is higher than 2000. The linear polyurethane phase change material prepared by the method has a linear structure and large enthalpy of phase change, has a simple preparation method, is low in cost, has stable property, can be stored for long time, is not solidified and cross-linked, is easy to process and shape, and is beneficial to large-scale popularization and application.

Owner:温州东润新材料科技有限公司

Heat conduction enhanced heat energy storage shape-stabilized phase-change composite material and preparation method thereof

ActiveCN110684510AHigh thermal conductivityImproved shape stabilityHeat-exchange elementsFluid phasePhase-change material

The invention relates to the technical field of phase change materials, in particular to a heat conduction enhanced heat energy storage shape-stabilized phase-change composite material and a preparation method thereof. The heat conduction enhanced heat energy storage shape-stabilized phase-change composite material is prepared from an organic phase change material and a foam frame structure material, and the foam frame structure material is prepared from a polymer and a two-dimensional lamellar material. The two-dimensional lamellar material is assembled into the porous foam frame structure material, so that a heat conduction path can be constructed from a small amount of the two-dimensional lamellar material, and is taken as the framework of the phase change composite material; and the organic phase change material is introduced into the framework, so that the shape stability of the phase change material can be improved, and the heat conduction performance of the phase change materialcan be better enhanced by the effective heat conduction path. Therefore, the heat conduction enhanced heat energy storage shape-stabilized phase-change composite material has the advantages of high phase change enthalpy value, good heat transfer performance, good shape stability and small volume change before and after solid-liquid phase change.

Owner:GUANGDONG UNIV OF TECH

Organic phase stabilization, phase transition and energy storage material and preparation method thereof

ActiveCN104910868AImprove energy storage performanceHigh phase change enthalpyHeat-exchange elementsThermal transitionMaterial synthesis

The invention relates to an organic phase stabilization, phase transition and energy storage material and a preparation method thereof. The organic phase stabilization, phase transition and energy storage material comprises 30-90wt% of an organic solid-liquid phase transition and energy storage material and 10-70wt% of an organic polymeric phase stabilization and phase transition supporting material. The organic solid-liquid phase transition and energy storage material is introduced into the polymeric phase stabilization and phase transition supporting material in order to make the organic phase stabilization, phase transition and energy storage material have good energy storage performance, adjustable phase transition temperature and high phase transition enthalpy; and when B in the polymeric phase stabilization and phase transition supporting material is an azo structure, anthraquinone, naphthalene amide and pyrene amide, the organic phase stabilization, phase transition and energy storage material can absorb visible light, and realizes photo-thermal transition and storage. The organic phase stabilization, phase transition and energy storage material has the advantages of simple synthesis process, convenient application, and wide application prospect.

Owner:DALIAN UNIV OF TECH

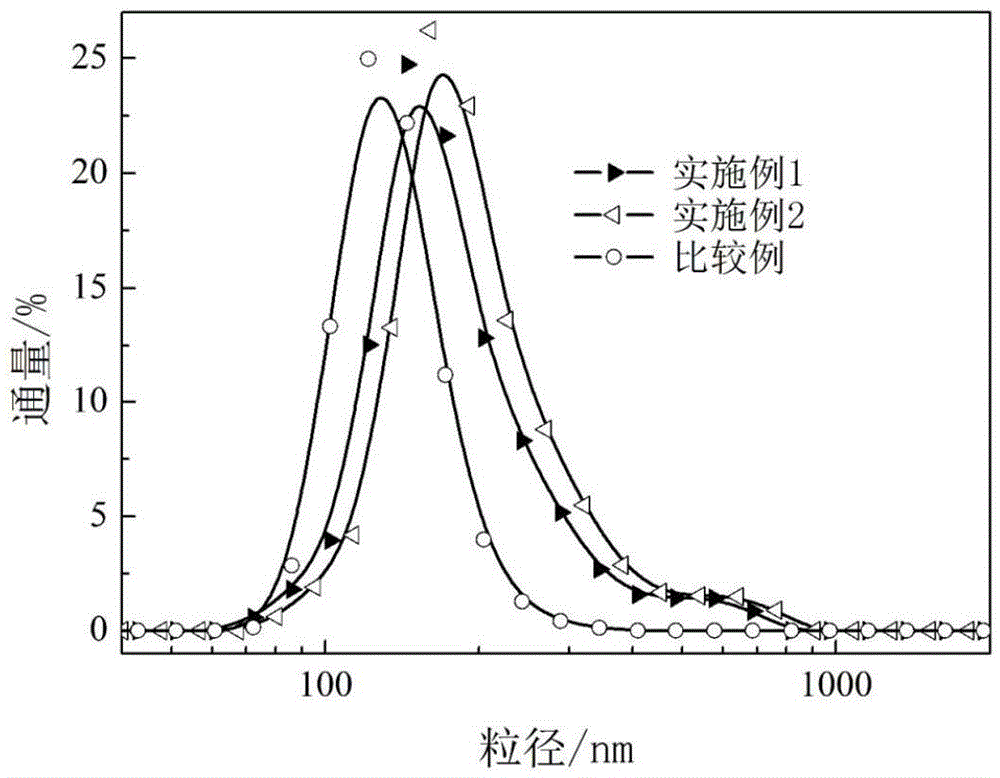

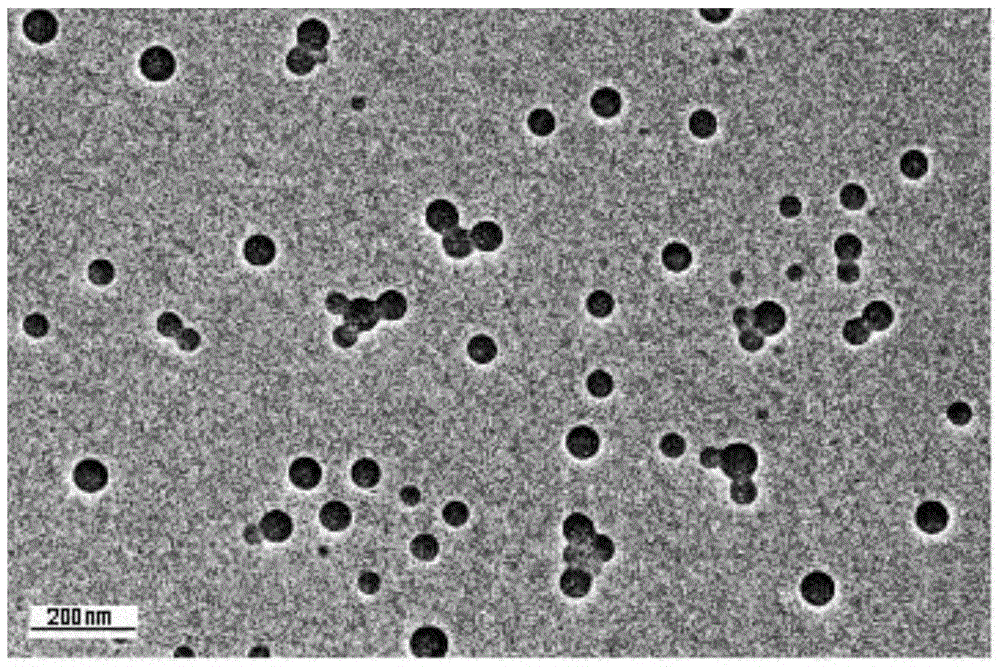

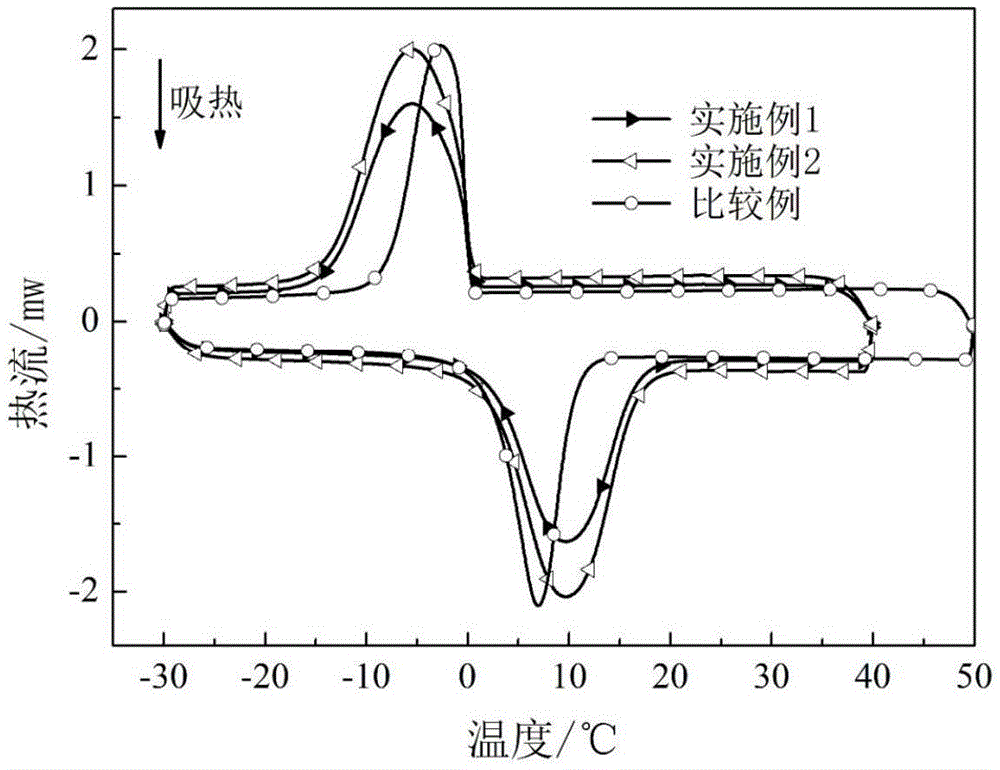

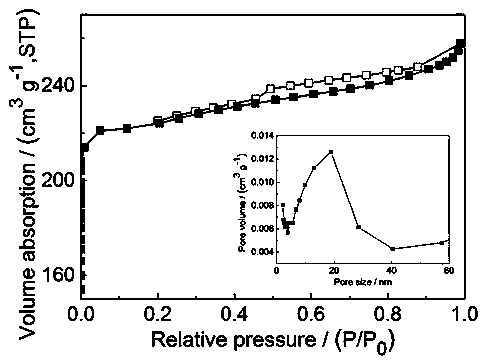

Inorganic/organic composite casing layer nanometer phase-change capsule cool-storage fluid and preparation method thereof

InactiveCN105542051ASmall particle sizeHigh phase change enthalpyHeat-exchange elementsMetal alkoxideIn situ polymerization

The invention belongs to the field of a phase change material technology for cool storage, and discloses an inorganic / organic composite casing layer nanometer phase-change capsule cool-storage fluid and a preparation method thereof. The preparation method comprises the following steps: hydrolysis and condensation are carried out for metal alkoxide, modification is carried out with an organosilicon coupling agent, modified metal oxide sol is obtained; a styrene monomer, an acrylic ester comonomer, a chain transferring agent, an initiator and an alkane core material are mixed for forming an oil phase, the oil phase is added into an emulsifier and deionized water for forming a water phase, homogeneous emulsification is carried out, and miniemulsion is obtained; the miniemulsion is heated to 40-80 DEG C, in situ polymerization is carried out for 10-50 minutes, the modified metal oxide sol is added drop by drop, and after a reaction, a composite casing layer nanometer phase change capsule emulsion is obtained; the emulsion is added into an antifreeze, water is added for dilution, and the product is obtained. Metal oxide and organic polymers are compounded into a casing layer; the product has the advantages of high heat conduction performance, high specific heat capacity and good mechanical stability at the same time, and the product can be used as phase-change cool-storage fluid for cool storage air-conditionings.

Owner:SOUTH CHINA UNIV OF TECH

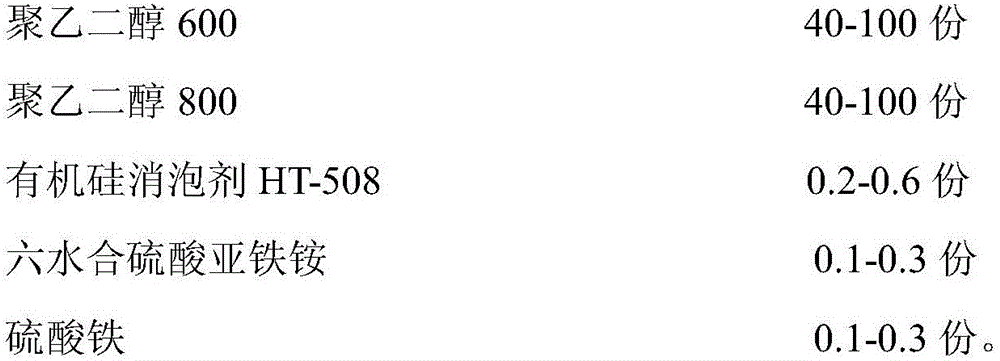

Phase change energy storage temperature-adjusting internal wall coating and preparing method thereof

ActiveCN105062241AHigh phase change enthalpyImprove energy storage performanceCoatingsBalance waterDefoaming Agents

The invention provides a phase change energy storage temperature-adjusting internal wall coating and a preparing method thereof. The phase change energy storage temperature-adjusting internal wall coating comprises, by mass, 30%-50% of emulsion, 0.5%-1.5% of dispersing agents, 0.5%-2% of antifreezing agents, 1%-3% of coalescing agents, 1%-2% of thickening agents, 0.5%-1% of defoaming agents, 5%-15% of titanium dioxide, 5%-10% of functional padding, 15%-30% of composite phase change materials and the balance water. According to the phase change energy storage temperature-adjusting internal wall coating and the preparing method, the attapulgite-based paraffin composite phase change materials serve as temperature-control base materials, the obtained phase change coating has good energy storage performance, cheap in price and excellent in weather resistance, energy consumption is saved, the indoor comfort is improved, the phase change coating is not limited by the territory and weather in use due to the adjustable phase change temperature, the application field of the phase change coating is broadened, and the coating has the good economic benefits and environment benefits and wide application prospects.

Owner:盱眙凹土能源环保材料研发中心 +1

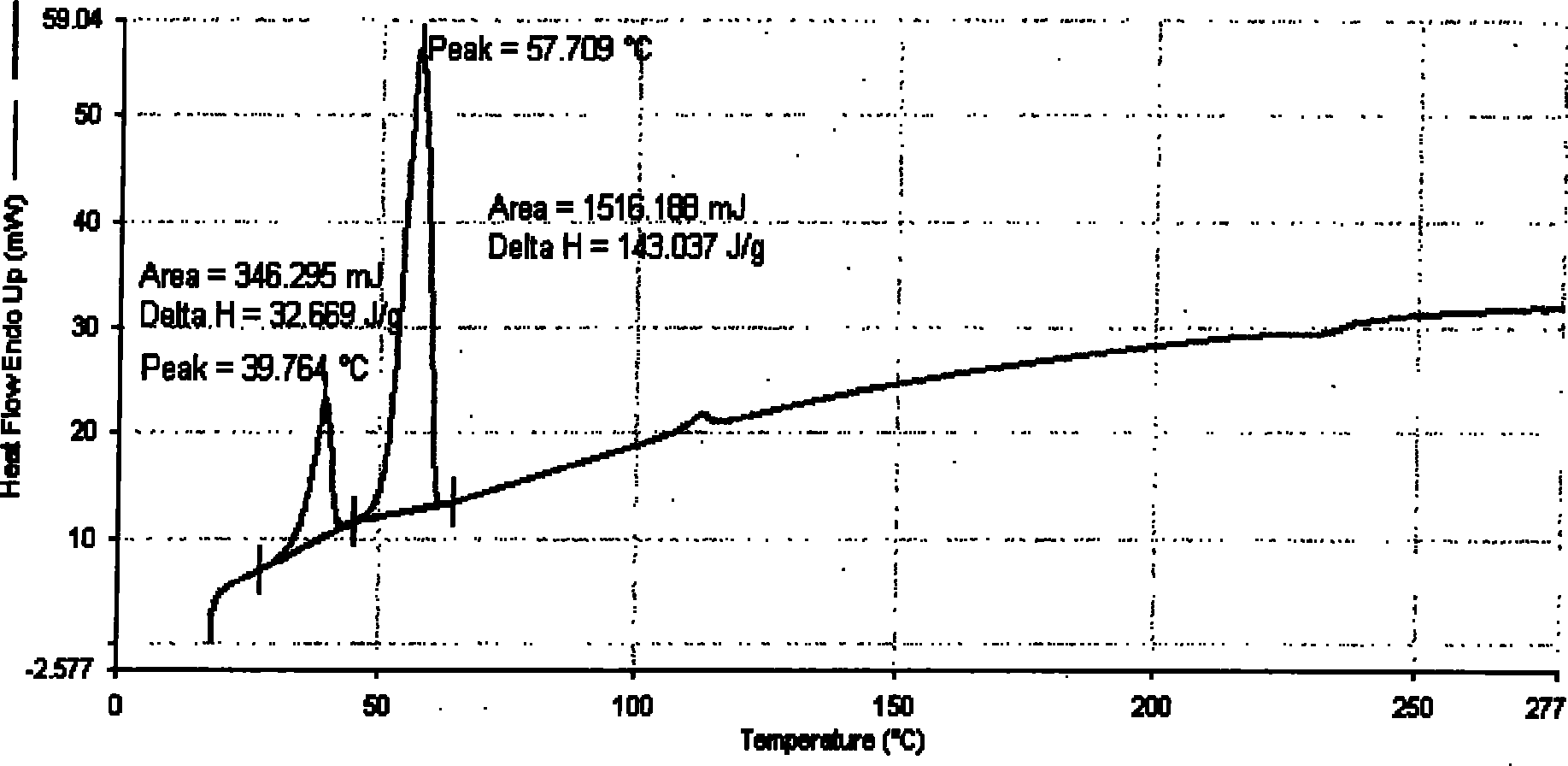

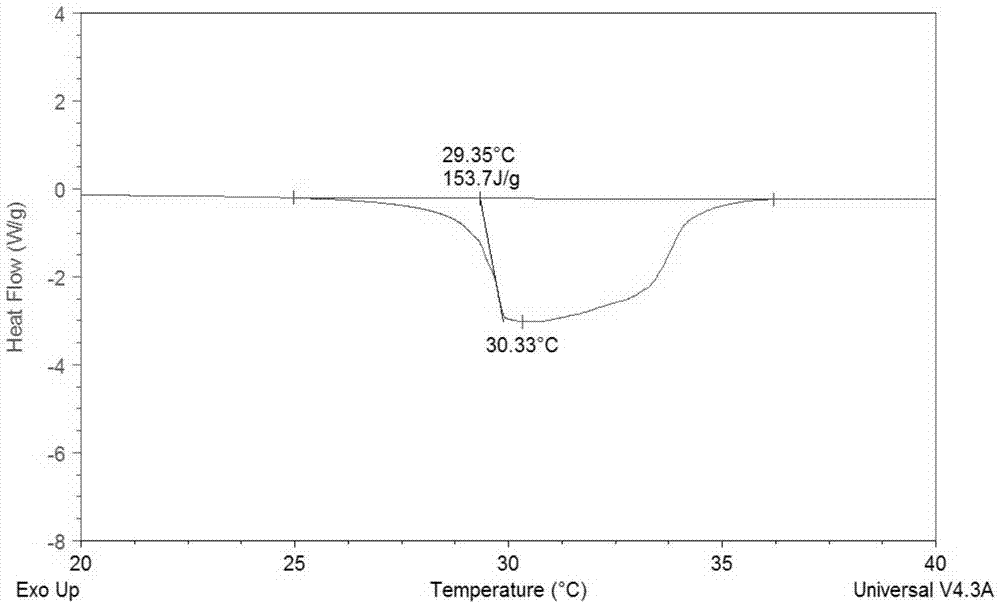

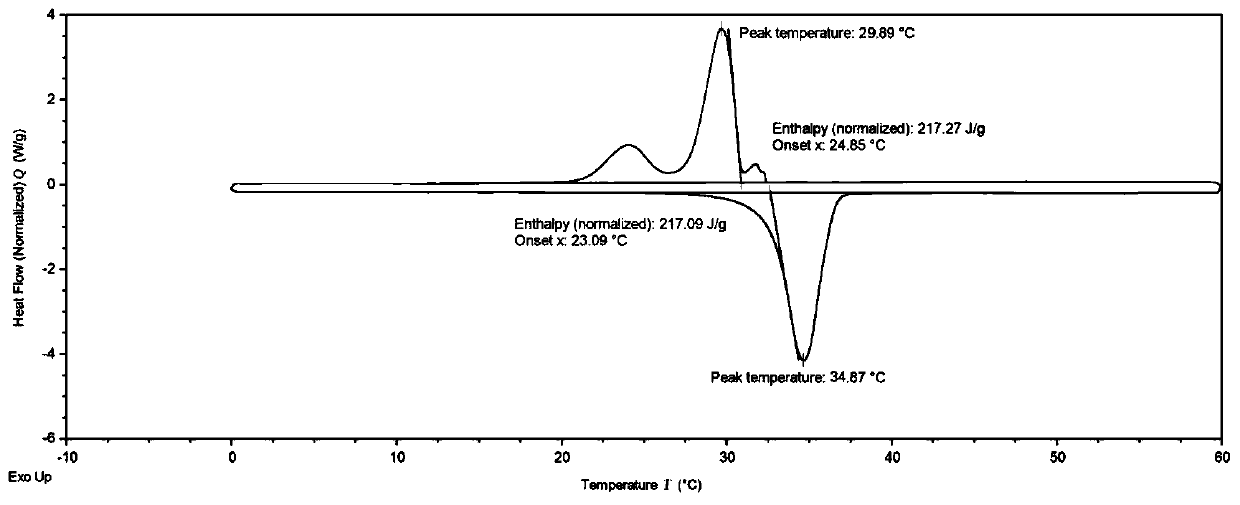

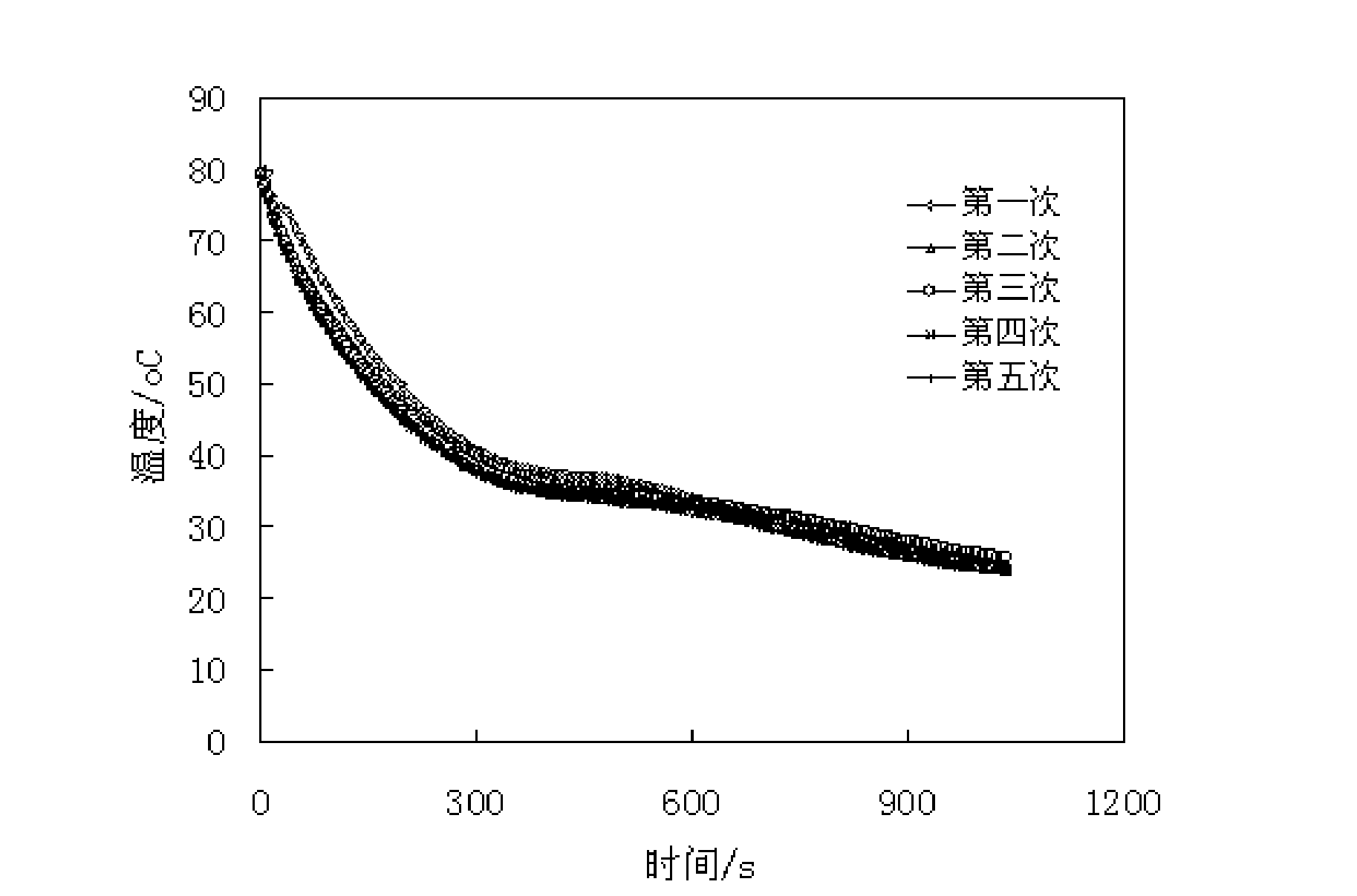

Low-temperature calcium chloride hexahydrate heat-storage material and preparation method

InactiveCN103923613AHigh phase change enthalpyPhase transition temperature is suitableHeat-exchange elementsCelluloseCalcium Chloride Hexahydrate

The invention discloses a low-temperature calcium chloride hexahydrate heat-storage material and a preparation method. The prepared low-temperature calcium chloride hexahydrate phase-change heat-storage material comprises a nucleating agent and a thickener according to mass percent, wherein the nucleating agent is borax, alumina or sodium metasilicate nonahydrate, the thickener is sodium carboxymethl cellulose (CMC), wherein calcium chloride hexahydrate is a phase-change base material, and the usage amount of the calcium chloride hexahydrate is 95%-98%; the preparation method comprises the step of: respectively adding 1wt% of borax and 1% of CMC or 1% alumina and 4% of CMC or 1% of sodium metasilicate nonahydrate and 2% CMC for modifying the calcium chloride hexahydrate, to obtain the low-temperature calcium chloride hexahydrate heat-storage material. The phase-change latent heat of the low-temperature calcium chloride hexahydrate heat-storage material is about 150J / g, the phase-change temperature of the low-temperature calcium chloride hexahydrate heat-storage material is at 25-30DEG C, the cooling degree is less than 2DEG C, and the heat suction and release performances of the low-temperature calcium chloride hexahydrate heat-storage material after being circulated for 3000 times are stable. The low-temperature calcium chloride hexahydrate heat-storage material has excellent application prospects in agricultural facilities and residential housing.

Owner:NORTHWEST A & F UNIV

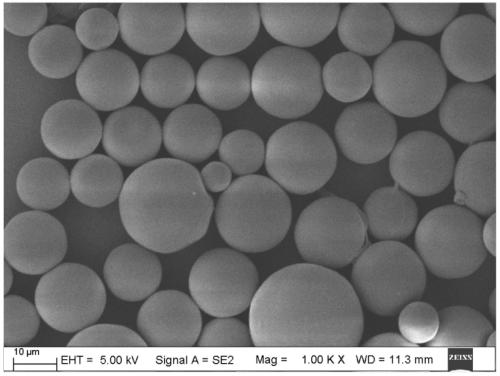

Phase change energy storage microcapsule taking polyurethane modified organic silicon resin as shell material and preparation method of phase change energy storage microcapsule

ActiveCN111054283AImprove flame retardant performanceReduce manufacturing costHeat-exchange elementsMicroballoon preparationPolymer sciencePtru catalyst

The invention relates to a phase change energy storage microcapsule taking polyurethane modified organic silicon resin as a shell material and a preparation method of the phase change energy storage microcapsule, and particularly discloses the preparation method which comprises the following steps: (1) uniformly mixing monomers for generating organic silicon resin, adding a catalyst, and prepolymerizing to obtain a prepolymer of polysiloxane; (2) adding the polyurethane prepolymer into the step (1), and carrying out a reaction to obtain a polyurethane modified organic silicon resin prepolymer;(3) uniformly mixing a core material with the shell material prepolymer to obtain a core material and shell material prepolymer mixture; (4) preparing an aqueous solution of a surfactant; and (5) mixing and emulsifying the core material and shell material prepolymer mixture and the aqueous solution of the surfactant to obtain an emulsion, adding a catalyst until the reaction is finished, separating, and drying to obtain the polyurethane modified organic silicon resin shell phase change energy storage microcapsule. The method is green, pollution-free and simple to operate, and the obtained microcapsule is smooth in surface, good in compactness, adjustable in phase change temperature, controllable in particle size, good in heat resistance and high in phase change enthalpy value.

Owner:SHENZHEN INST OF ADVANCED ELECTRONICS MATERIALS

Water-based phase-change microcapsule film and preparation method thereof

InactiveCN110330945AExcellent thermal conductivity and thermal stabilityHigh phase change enthalpyHeat-exchange elementsAdhesiveHeat stability

The invention provides a water-based phase-change microcapsule film and a preparation method thereof. The phase-change microcapsule film comprises the following components by mass: 3-60% of an adhesive, 40-95% of phase-change microcapsules, 0-1% of a defoaming agent, 0.1-5% of a thickening agent, 4-20% of a flame retardant, 0-20% of a high-thermal-conductivity carbon material and the balance of water. The phase change microcapsule film is high in enthalpy value, excellent in energy storage performance and good in heat conductivity and heat stability. The film is adjustable in shape, size and thickness, high in strength, good in flexibility, resistant to bending, simple in production mode, environmentally friendly, suitable for large-scale industrial production and wide in application range.

Owner:杭州英诺克新材料有限公司

Inorganic hydrated salt porous carbon composite phase change material and preparation method thereof

ActiveCN108676550AReduce overflowReduce precipitationHeat-exchange elementsHydration reactionPhase change enthalpy

The invention discloses an inorganic hydrated salt porous carbon composite phase change material and a preparation method thereof, wherein the preparation method comprises the following steps: firstly, preparing biomass-based porous carbon subjected to activation treatment, and weighing an inorganic hydrated salt phase change material, the biomass-based porous carbon and a pore sealing agent in proportion; and then preparing a saturated solution from the inorganic hydrated salt phase change material, adding biomass-based porous carbon, impregnating, carrying out vacuum pressurization and adsorbing; and finally, adding the pore sealing agent, stirring, wind-drying, and grinding and pulverizing, to obtain the inorganic hydrated salt porous carbon composite phase change material. The composite phase change material prepared by the method has the advantages of difficult liquid leakage, no phase separation, small supercooling degree, high phase change enthalpy, no toxicity, no corrosion, good thermal stability, good durability, low preparation cost and the like, and has broad market prospects in the fields of building and energy-storage materials.

Owner:SHANDONG JIANZHU UNIV

Paraffin energy storage medium for phase change energy storage wall material, and preparation method thereof

ActiveCN103131393ANarrow distributionThe effect of energy storage and energy saving is obviousWallsHeat-exchange elementsHigh energyDistillation

The present invention relates to a paraffin energy storage medium for a phase change energy storage wall material, and a preparation method thereof, wherein a petroleum cerate at third atmospheric side stream is adopted as a raw material, and processes such as pressure reduction distillation, sweating and refinement are performed to prepare the paraffin energy storage medium. The preparation method has characteristics of rich raw material source, simple process, flexible unit operation, and stable product quality. The product prepared by the method has characteristics of high n-alkane content, narrow carbon distribution, and high energy storage density, and can meet requirements of the paraffin energy storage medium for domestic phase change energy storage wall materials.

Owner:NO 2 OIL PRODION PLANT HENAN OIL FIELD BRANCHCORP SINOPEC

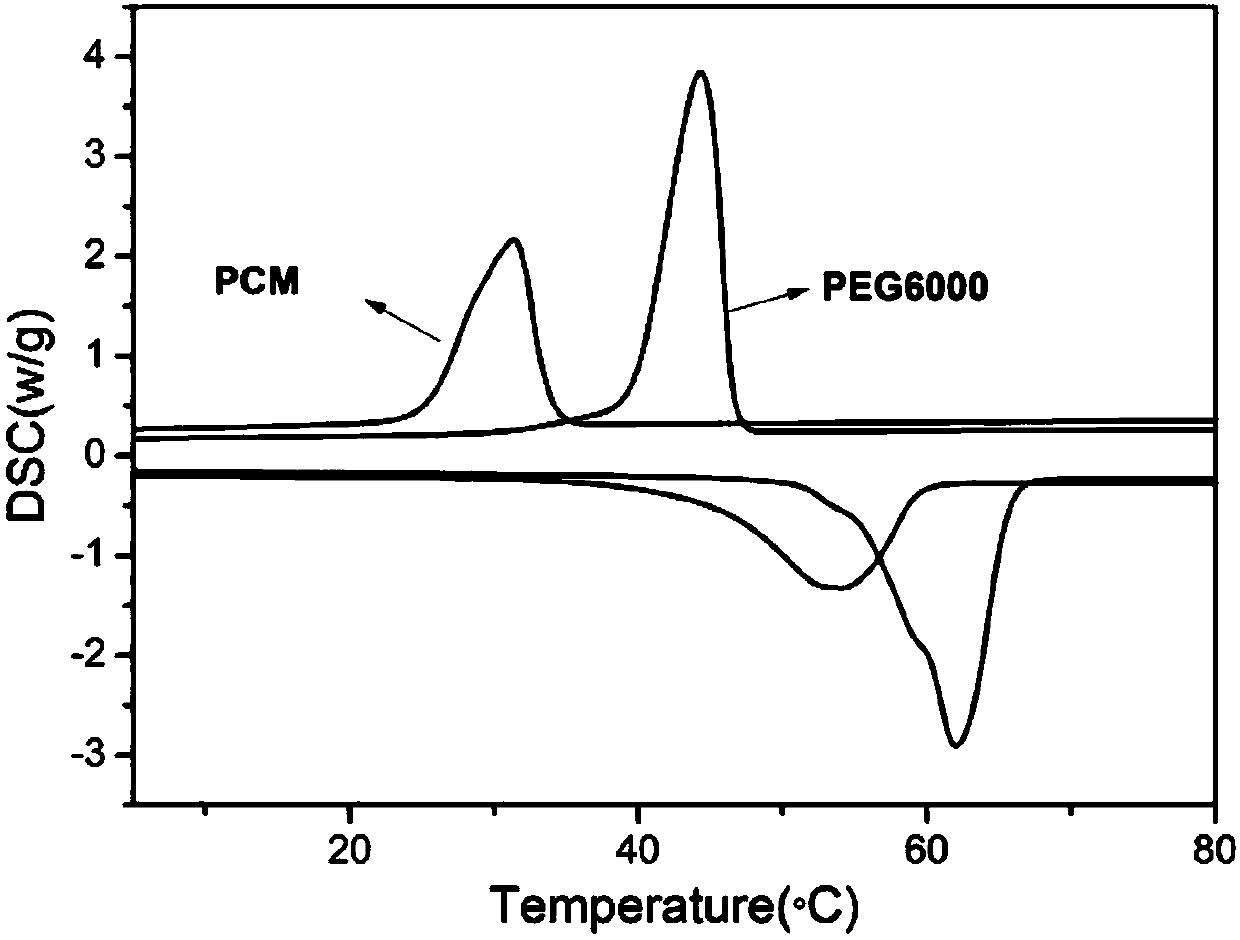

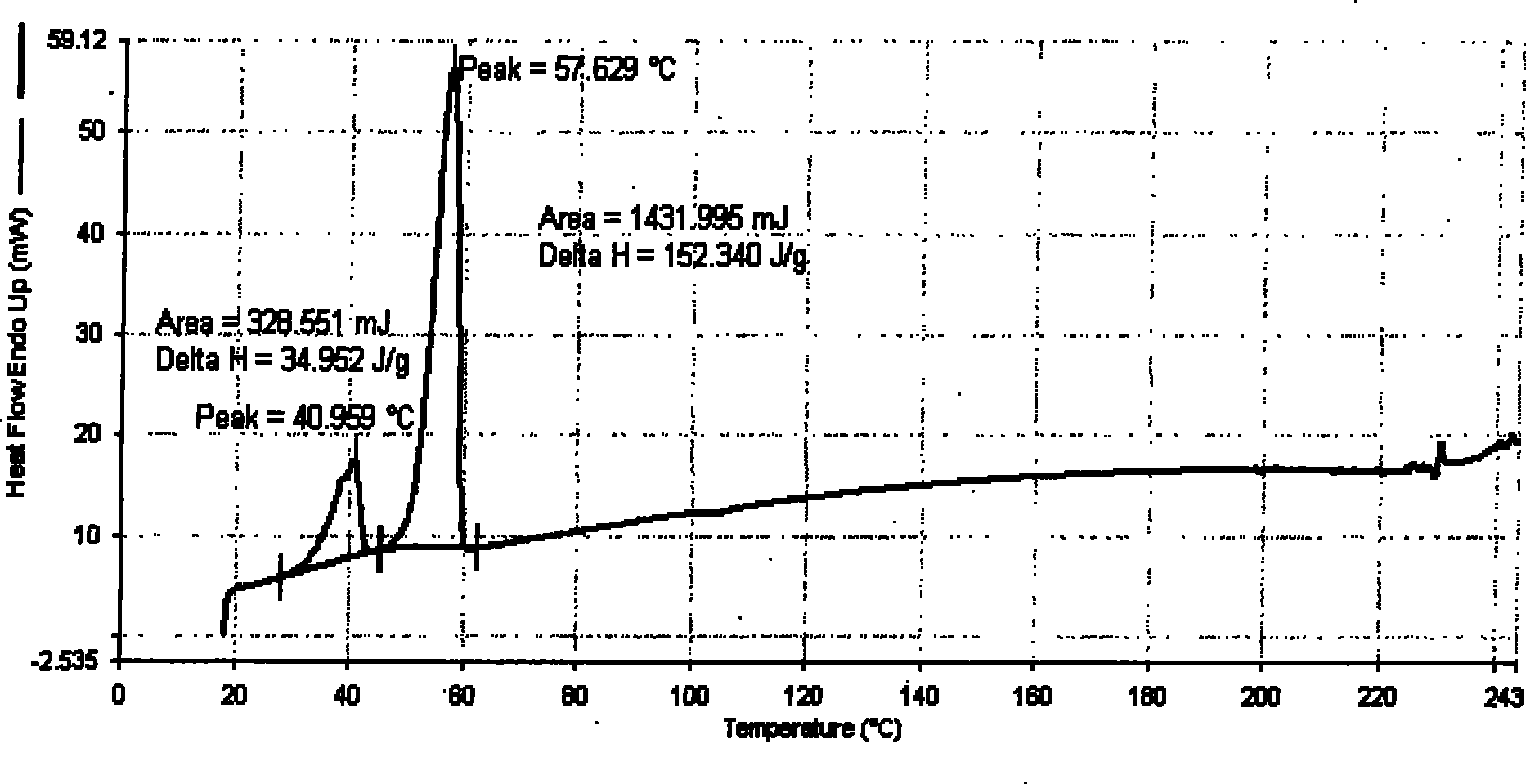

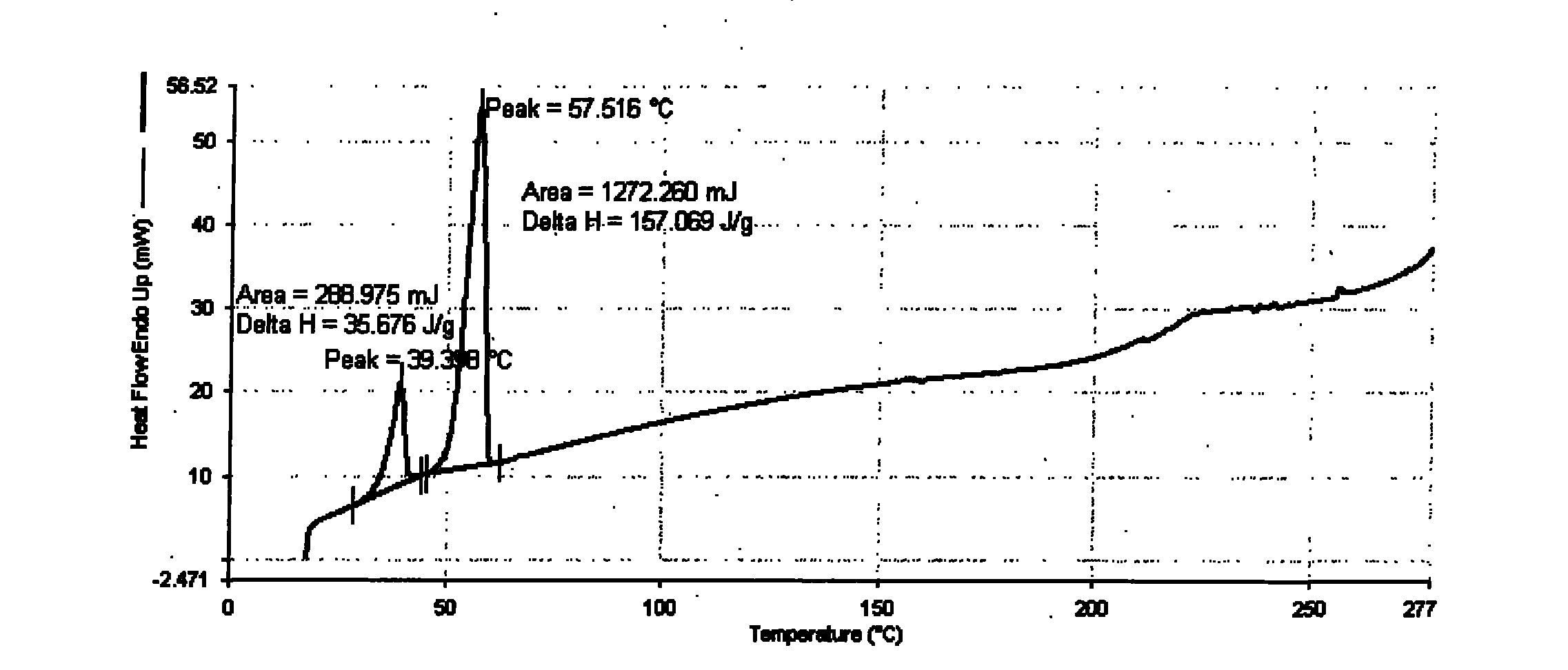

Method for improving phase transition behavior of polyethyleneglycol/terylene solid-to-solid transition material using different molecular weight polyethyleneglycol eutectic

The invention discloses a method for improving phase-change performance of polyethylene glycol / polyester solid-solid phase change material (PEG / PET PCM) through utilizing eutectic simultaneously used by polyethylene glycols with different molecular weights, which comprises the steps that the polyethylene glycols with different molecular weights are simultaneously used in a certain mass ratio to synthesize the PEG / PET PCM so as to improve phase transition enthalpy of the PEG / PET PCM with a controllable phase-change temperature and a narrowing phase-change peak width. The method has the advantages that the phase transition enthalpy of the PEG / PET PCM synthesized chemically by graft copolymerization through PEG eutectic is up to 157.17J / g, which is improved by 35 percent and is larger than the phase transition enthalpy of the PEG / PET PCM which is synthesized by PEGs with two kinds of different molecular weights singly and the PET, and the product has no toxicity and no harm, improved production yield, low cost, and good application prospect.

Owner:XUZHOU COLLEGE OF INDAL TECH

Phase change energy storage material with skin-core fiber structure and preparation method thereof

ActiveCN109576823AReduce inconvenienceImprove production efficiencyHollow filament manufactureArtificial filament washing/dryingPhase change enthalpyFreeze-drying

The invention belongs to the field of phase change energy storage materials, and discloses a phase change energy storage material with a skin-core fiber structure and a preparation method thereof. Polyacrylonitrile is dissolved in an organic solvent, the phase change energy storage materials are added into the solvent and uniformly mixed, and an oil phase solution is obtained. Water-soluble phasechange materials are dissolved in deionized water or the deionized water is directly used as an aqueous phase solution; the aqueous phase solution is added into the oil phase solution, an emulsifyingagent is added for homogenization and dispersion, oil in water emulsion is obtained, and a composite fiber material with the skin-core structure is obtained through electrostatic spinning; a hollow fiber material is obtained through freeze-drying; finally pre-oxidation and carbonization treatment are performed in an inert atmosphere, and the phase change energy storage material with the skin-corefiber structure is obtained. The fiber preparation technology is combined with the high-performance phase change material, the phase change energy storage material has higher phase change enthalpy and reversible capacity, and multi-scene application of the phase change energy storage material is achieved.

Owner:SOUTH CHINA UNIV OF TECH

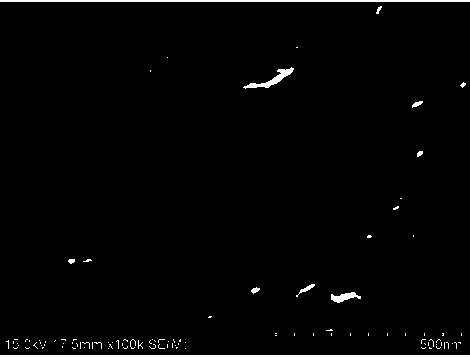

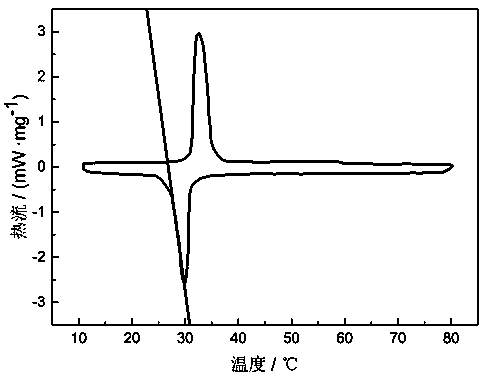

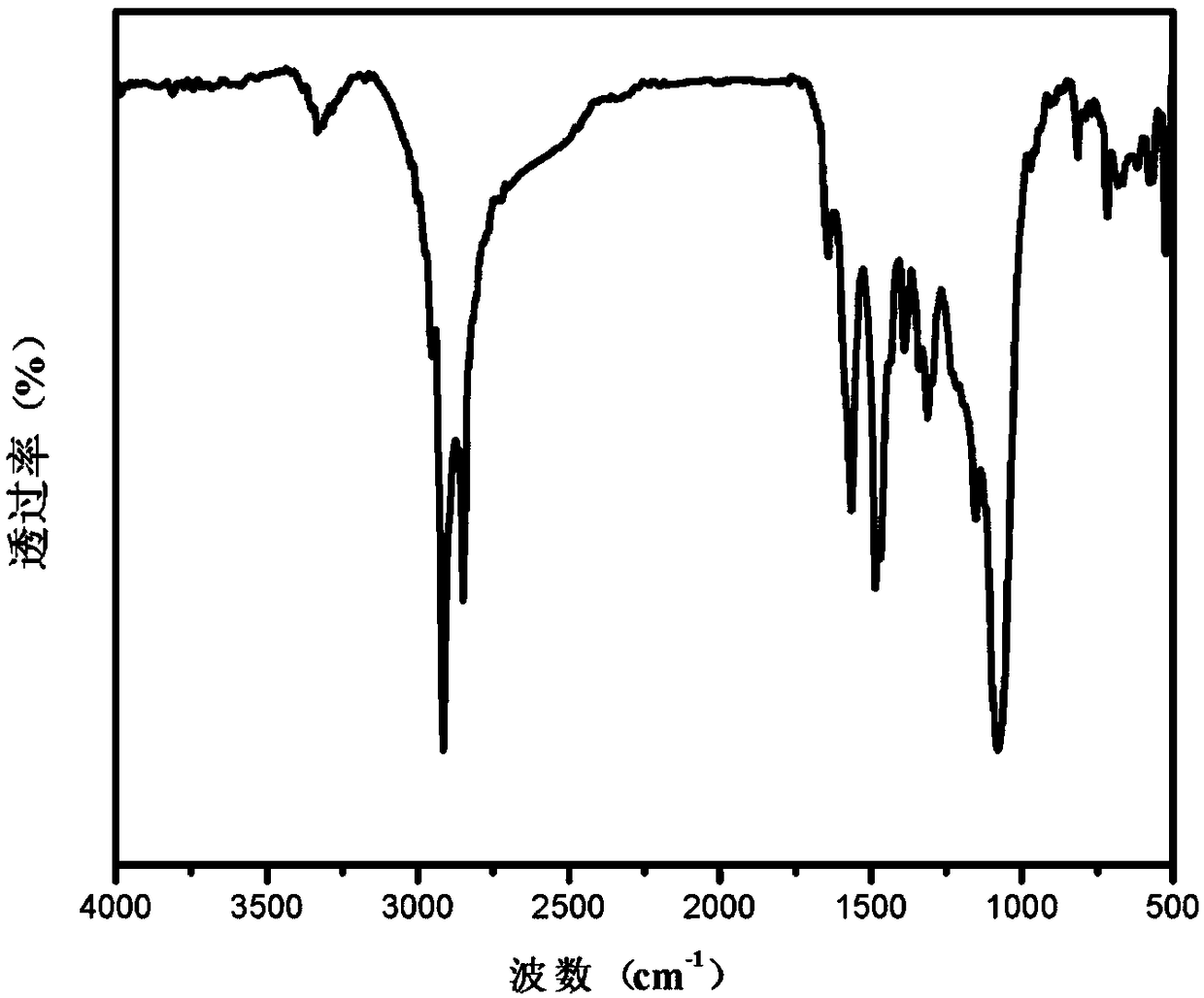

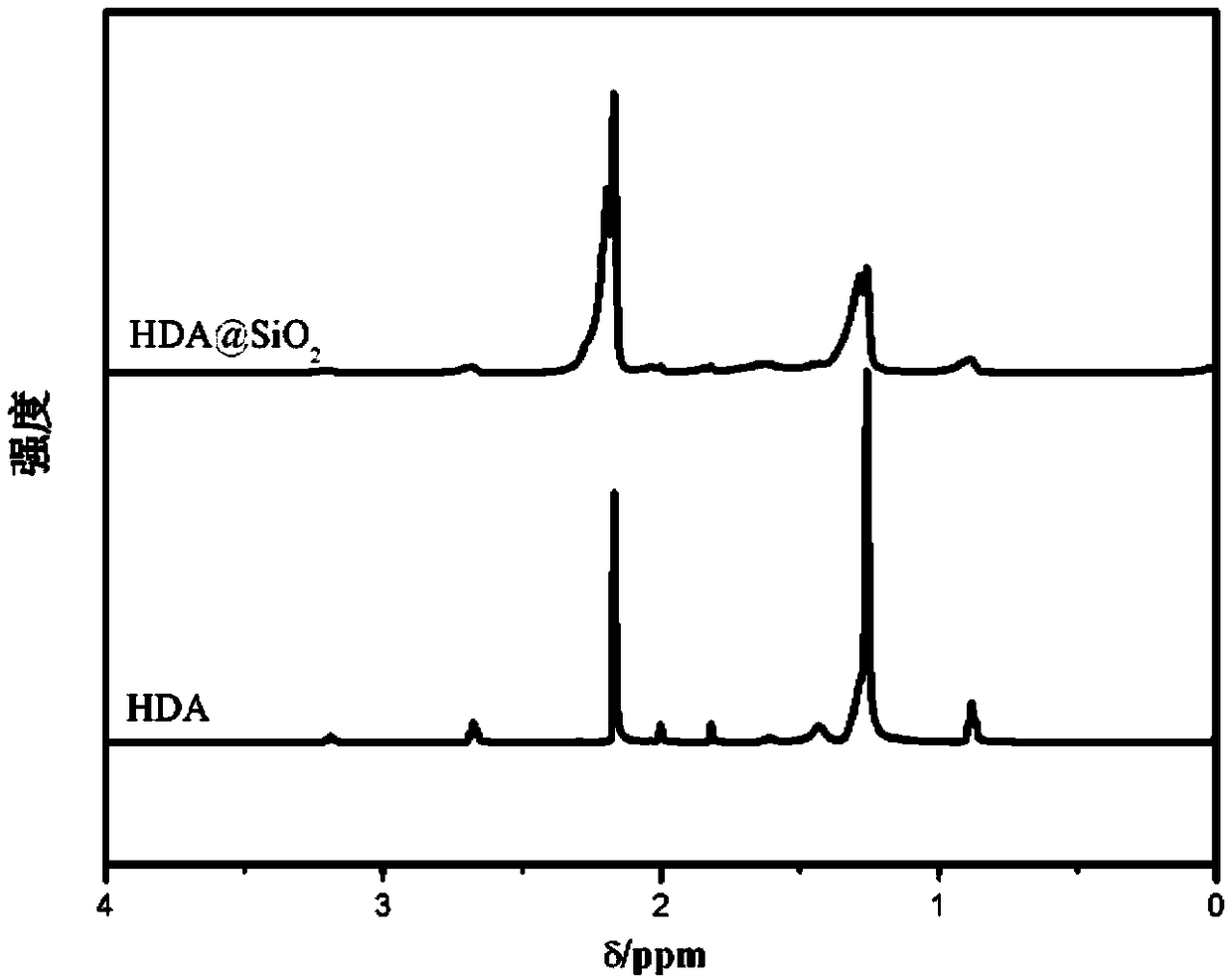

Cetylamine/ silicon dioxide composite phase-change energy storing material and preparation method thereof

ActiveCN108753256AEfficient packagingPrevent leakageHeat-exchange elementsHeat conductingPhase change

The invention discloses a cetylamine / silicon dioxide composite phase-change energy storing material and a preparation method thereof. The method comprises the following steps: dissolving cetylamine in isopropanol; dispersing a silicone source in the mixture; and slowly adding deionized water to obtain the product. The method is simple in processes, and the product can be formed without any surfactant; the prepared cetylamine / silicon dioxide composite phase-change energy storing material is a novel composite phase-change energy storing material, is high in enthalpy of phase change, high in sealing effect and heat conducting capacity, and simple in product conveying; and the problem of liquid phase leaking in use of the material can be effectively solved.

Owner:WENZHOU UNIVERSITY

Highly heat-conducting phase change heat storage material and preparation method therefor

InactiveCN105154021AHigh thermal conductivityFast heat absorption and releaseHeat-exchange elementsPorosityVoid ratio

The invention discloses a highly heat-conducting phase change heat storage material and a preparation method therefor. The heat storage material is prepared by compounding 67.5% by mass of paraffin, 7.5% by mass of expanded graphite and 25% by mass of through-hole foamed aluminum. The melting point of selected paraffin in the materials is 40-60 DEG C, and the porosity of the selected through-hole foamed aluminum in the materials is over 90%. The material has the advantages that the material is fast in heat absorption and heat release speed and great in heat storage, and is not varied in shape after phase change.

Owner:JIANGSU QIZHENG NEW ENERGY

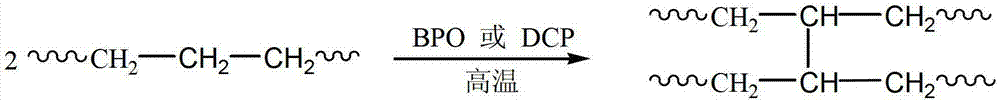

Preparation method of modified paraffin

InactiveCN103194260AHigh phase change enthalpyImprove energy storage performancePetroleum chemical modificationMolten stateParaffin wax

The invention provides a preparation method of modified paraffin. The modified paraffin is obtained by crosslinking paraffin in a molten state at appropriate temperature by taking organic peroxide as a crosslinking agent; and the obtained modified paraffin has the characteristics of high phase change enthalpy value, good energy storage property, good heat stability, high chemical stability, and the like. The preparation method provided by the invention is economic, simple, convenient, practical and easy to popularize and apply; the paraffin is a byproduct during petroleum extraction and is rich in source; and the preparation method provided by the invention also provides an effective way for the comprehensive utilization of the industrial by-product and has application prospect in multiple technical fields of solar energy storage, energy utilization and transformation, waste coolness and waste heat utilization, and the like.

Owner:SHAANXI UNIV OF TECH

Method for preparing high phase transition enthalpy phase transition temperature-adjusting fiber from hydrolysis products of waste acrylic yarn

InactiveCN102220660ASolving the Recycling DilemmaReduce pollutionHeat-exchange elementsMonocomponent synthetic polymer artificial filamentYarnPolymer science

The invention relates to a method for preparing high phase transition enthalpy phase transition temperature-adjusting fiber from hydrolysis products of waste acrylic yarn, comprising the following steps of: reacting the hydrolysis products of the waste acrylic yarn, such as hydrolysis polyacrylonitrile and polyethylene glycol, according to proportion to prepare graft copolymer polyethylene glycolgrafted hydrolysis polyacrylonitrile; completely dissolving the polyethylene glycol grafted hydrolysis polyacrylonitrile in water, adding boric acid, stirring and completely dissolving, standing and defoaming to obtain a spinning stock solution; and preparing the spinning stock solution into high phase transition enthalpy phase transition temperature-adjusting fiber through wet spinning. Comparedwith the existing phase transition temperature-adjusting fiber, the phase transition temperature-adjusting fiber prepared by the method has the advantages of high phase transition enthalpy, stable phase transition and excellent durability and the like, and can be widely applied to the fields of textile and apparel, energy-saving building materials and certain special fields such as military industry, aerospace, etc.

Owner:DALIAN POLYTECHNIC UNIVERSITY

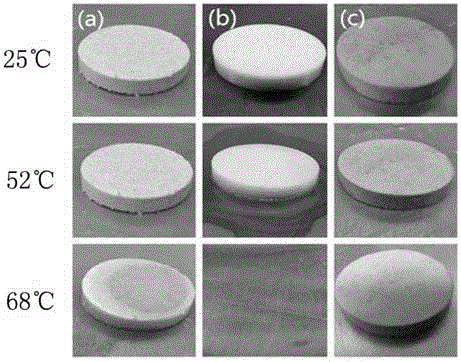

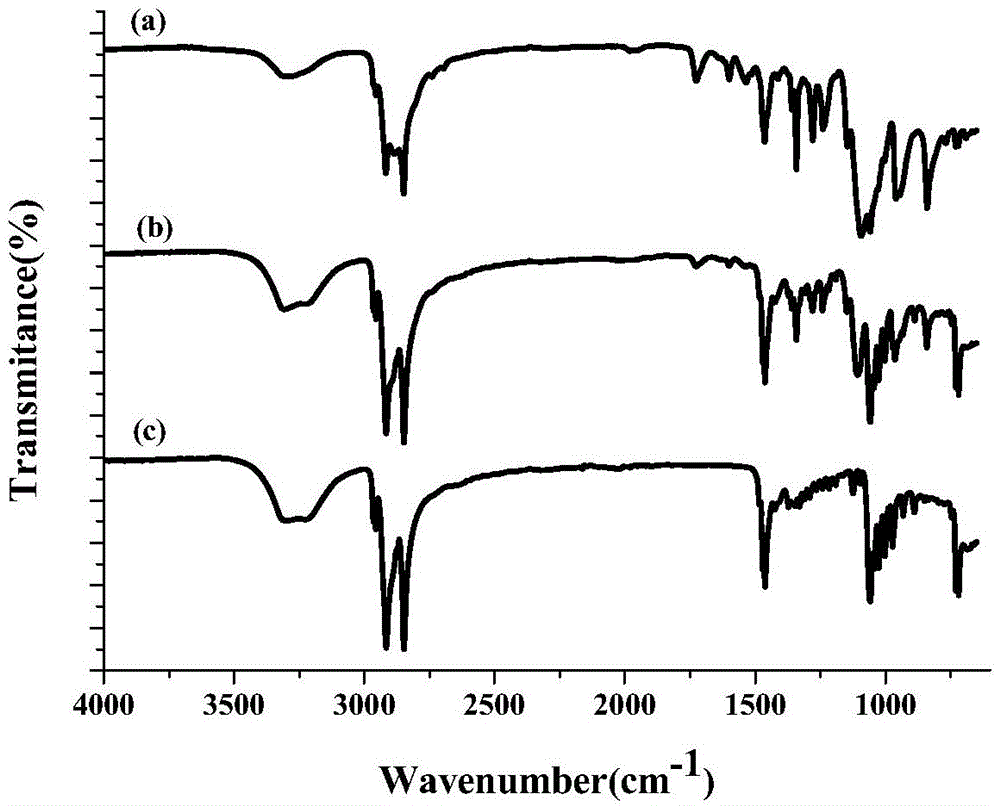

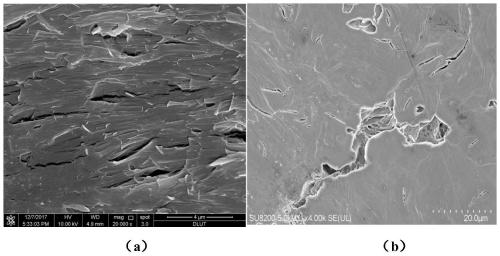

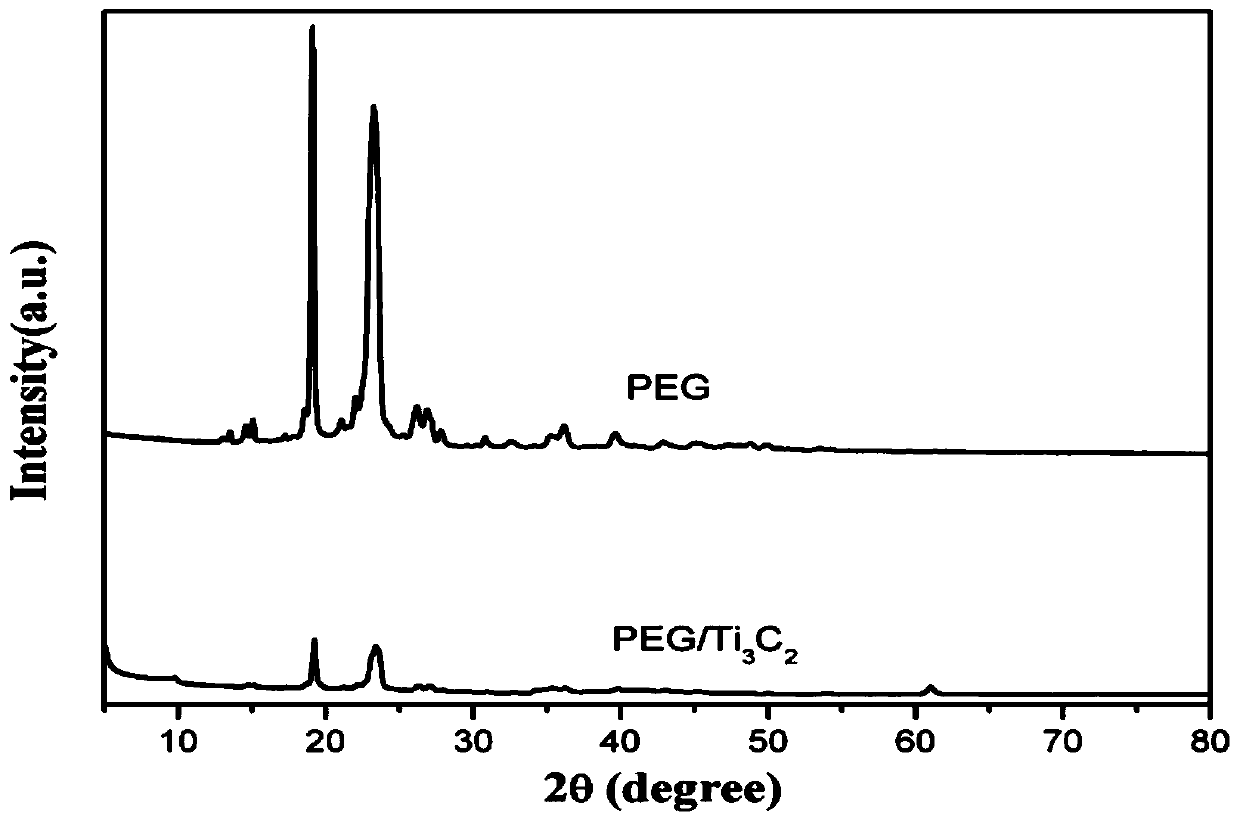

Light-heat energy conversion and heat energy storage shape-stabilized phase-change compound material and production method thereof

ActiveCN109852349AHigh phase change enthalpyImproved shape stabilityOther chemical processesHeat-exchange elementsPhase change enthalpyAlcohol

The invention discloses a light-heat energy conversion and heat energy storage shape-stabilized phase-change compound material, and belongs to the field of functional compound materials. The light-heat energy conversion and heat energy storage shape-stabilized phase-change compound material is composed of a supporting material and an organic phase-change material, wherein a mass ratio of the supporting material to the organic phase-change material is (3 to 1) to (7 to 9), the supporting material is in a slice-layer shape, and layers of the supporting material are evenly filled with the organicphase-change material to form a laminated stacked structure; the supporting material is nanosheets of Ti2C or Ti3C2 or Ti3CN or V2C or Nb2C or TiNbC or Nb4C3 or Ta4C3 or (Ti0.5Nb0.5)2C or (V0.5Cr0.5)3C2; and the organic phase-change material is paraffin or fatty acid or aliphatic ester or alcohol. The compound material has a high phase change enthalpy value and excellent shape stability and heatstability, and has wide prospects in the field of heat energy storage and use.

Owner:DALIAN UNIV OF TECH

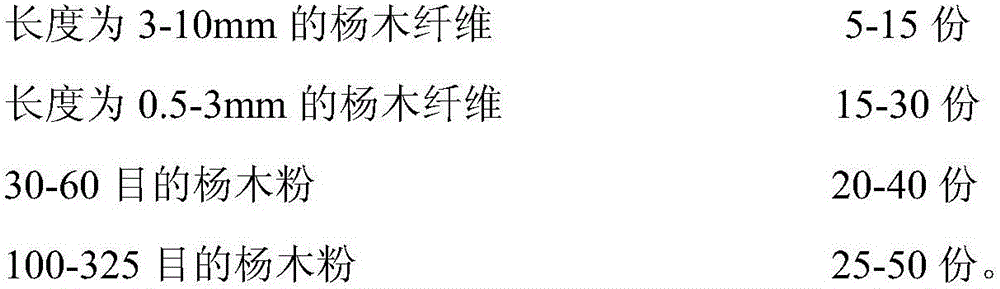

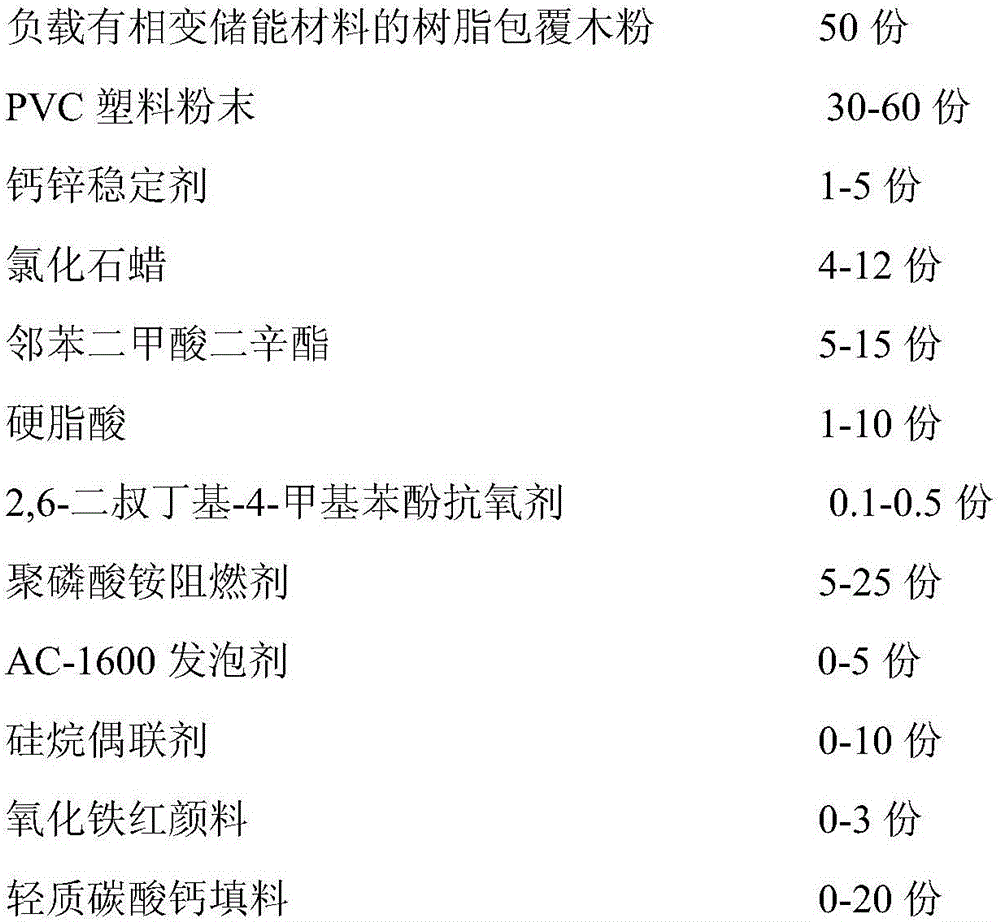

Wood-plastic composite with effects of phase-change energy storage and thermal insulation and preparation method of wood-plastic composite

ActiveCN106674815AIncrease the rate of crystallizationHigh latent heat of phase changeHeat-exchange elementsThermal insulationPolyvinyl chloride

The invention discloses a wood-plastic composite with effects of phase-change energy storage and thermal insulation. The material is prepared from resin coated wood flour supported with a phase-change energy storage material, matrix plastic and additives, wherein the resin coated wood flour supported with the phase-change energy storage material comprises composite wood flour, a polyethylene glycol composite phase-change energy storage material supported on the composite wood flour and polyethylene glycol-isocyanate copolymer resin covering the composite wood flour and the polyethylene glycol composite phase-change energy storage material. The wood-plastic composite with the effects of phase-change energy storage has good energy storage and thermal insulation performance, avoids leakage of the phase-change material and is good in mechanical strength. On the other hand, the invention provides a preparation method of the wood-plastic composite with the effects of phase-change energy storage and thermal insulation. The wood-plastic composite is prepared from the wood flour supported with the phase-change energy storage material and PVC (polyvinyl chloride) plastic powder and the additive through mixing, kneading, extruding, open-milling, pressing, cutting and trimming.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

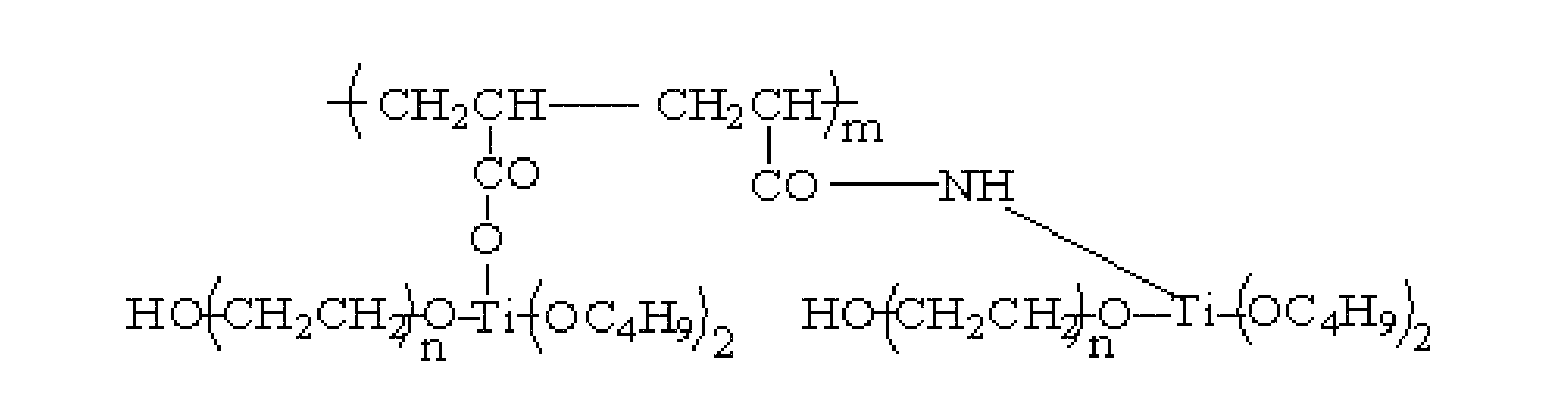

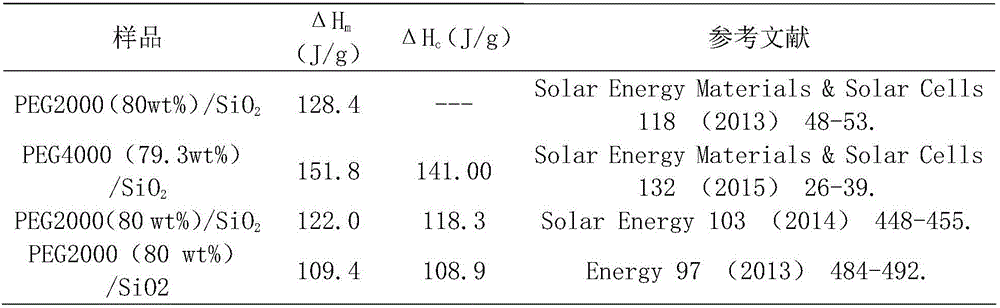

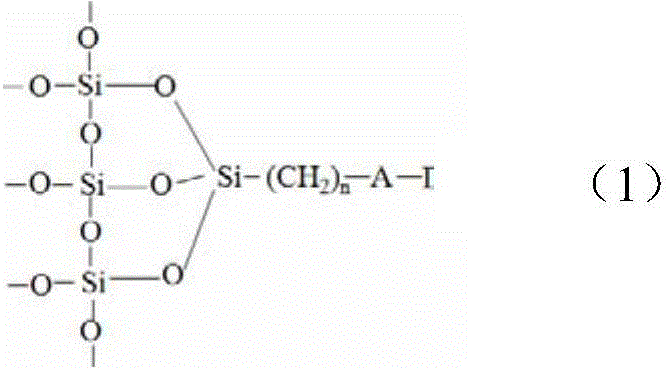

Photothermal conversion type organic/inorganic composite phase-change energy storage material and preparation method thereof

ActiveCN106047305AIncreased durabilityGood compatibilityHeat-exchange elementsChemical LinkageDye absorption

The invention belongs to the technical field of energy storage, and in particular discloses a photothermal conversion type organic / inorganic composite phase-change energy storage material and a preparation method thereof. Polyethylene glycol (PEG) is taken as an organic phase-change component, and dye modified silicon dioxide is taken as an inorganic support material. The structural formula of the support material is as shown in formula (1) in the specification. In the formula, n is greater than or equal to 2 and less than or equal to 5; n is an integer; A is a linking group; D is a dye color base. According to the material, dye is combined to a silicon dioxide support material in a chemical band mode, visible light can be absorbed by dye, converted into heat and stored in the phase-change material PEG, and conversion and storage integration of solar energy is achieved. In addition, by adopting the modified support material, the covering amount for PEG can be effectively improved, and the heat storage density can be increased. The material can be applied to conversion and storage of solar energy, and is simple in synthesis process, convenient to use and wide in application prospect.

Owner:SHENYANG RES INST OF CHEM IND

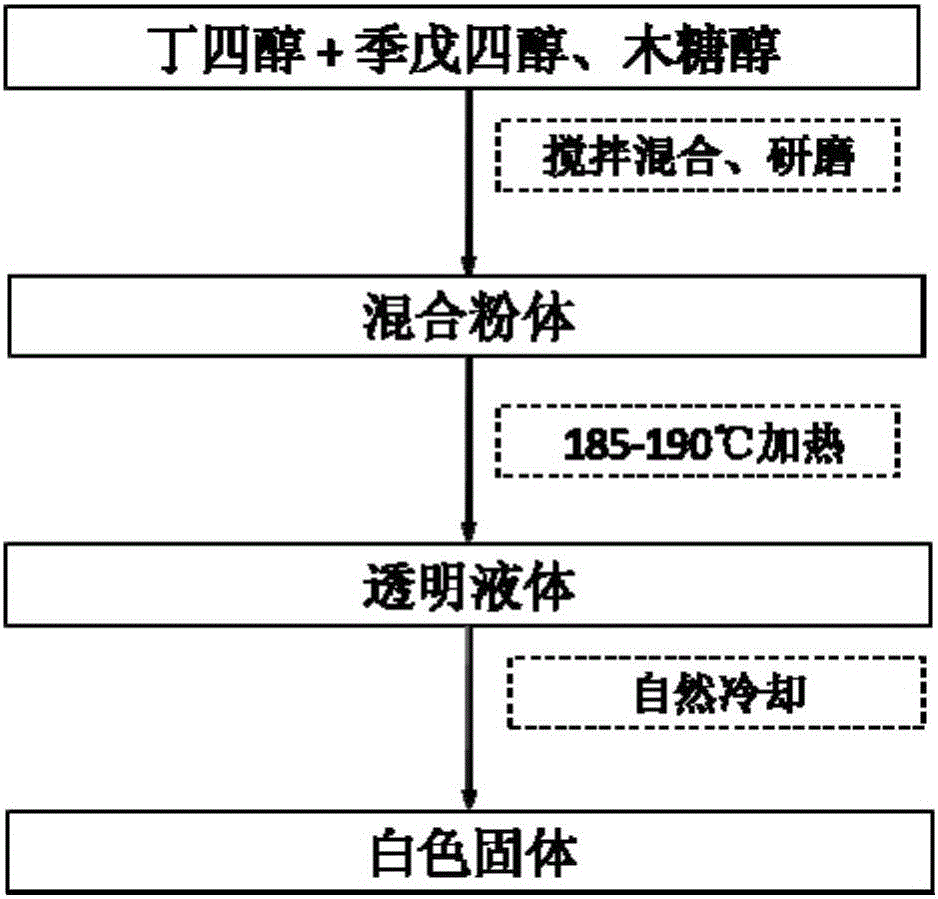

Polylol compound phase-change material and preparation method thereof

ActiveCN106281235AIncrease enthalpyHigh phase change enthalpyHeat-exchange elementsThermal energyPhase change enthalpy

The invention relates to a polylol compound phase-change material and a preparation method thereof. The compound phase-change material takes butantetraol, pentaerythrotol and xylitol powder as raw materials and is prepared through the following steps: carrying out manual grinding, ball milling or sand milling on a mixture of the butantetraol, the pentaerythrotol and the xylitol for 1h to 3h; then heating the mixture at 185 DEG C to 190 DEG C for 3h to 6h until all the powder is completely melted to form transparent liquid; finally, naturally cooling the transparent liquid to form the white and solid polylol compound phase-change material, wherein the mass percent content of the butantetraol is 60 percent to 75 percent, the mass percent content of the pentaerythrotol is 24 percent to 35 percent and the mass percent content of the xylitol is 1 percent to 5 percent. The polylol compound phase-change material has the advantages of high phase-change enthalpy value, small super-cooling degree, stable melting point and the like, and can be used in the fields of solar heat energy storage, industrial residual heat recycling and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Flame-retardant microcapsule phase-change material

InactiveCN105112020AWon't happenNot volatileHeat-exchange elementsMicroballoon preparationBenzoyl peroxideSolvent

The invention relates to a flame-retardant microcapsule phase-change material. The flame-retardant microcapsule phase-change material is prepared from a core material, a flame-retardant wall material, an emulsifier, benzoyl peroxide (BPO) and deionized water, wherein the core material is fatty acid ester, the flame-retardant wall material is a crosslinking polymer of reactive phosphonate monomer and tetramethylol methane tetraacrylate, and the emulsifier is a mixture of nonionic surfactant and ionic surfactant. The flame-retardant microcapsule phase-change material provided by the invention has excellent performance and is safe and environment-friendly; since reactive phosphonate-modified acid ester polymer is used as the microcapsule wall material, good flame retardation effect, good water resistance and good solvent resistance are obtained, and reduction in phase change enthalpy of the phase-change material caused by an additive flame retardant can be avoided; and since aliphatic ester is used as a phase-change material, better thermal stability and chemical stability are obtained, and a heat release rate is lower.

Owner:NINGBO GREENTECH ENERGY SAVING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com