Thermal conductivity enhanced organic composite shaped phase change material and preparation method thereof

一种定形相变材料、导热增强的技术,应用在热交换的材料、化学仪器和方法等方向,能够解决蓄热量利用率低、小导热系数、传热性能差等问题,达到优异定形效果、大相变焓值、导热性能提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Take 0.3158g of sodium alginate in a three-necked flask, add 20mL of water, and stir at 70°C for 20min to obtain a sodium alginate solution;

[0034] (2) Add 6g of PEG-6000 (sodium alginate and polyethylene glycol mass ratio is 5:95) and graphene aqueous dispersion (containing graphene 0.0064g, the mass fraction of thermal conductivity enhancer graphene in the material is 1%), continue to stir for 60min, drop calcium chloride solution (0.05mol / L) to form a gel, and obtain a composite calcium alginate gel;

[0035] (3) Vacuum drying at 40° C. for 24 hours to obtain an organic composite shape-fixed phase change material.

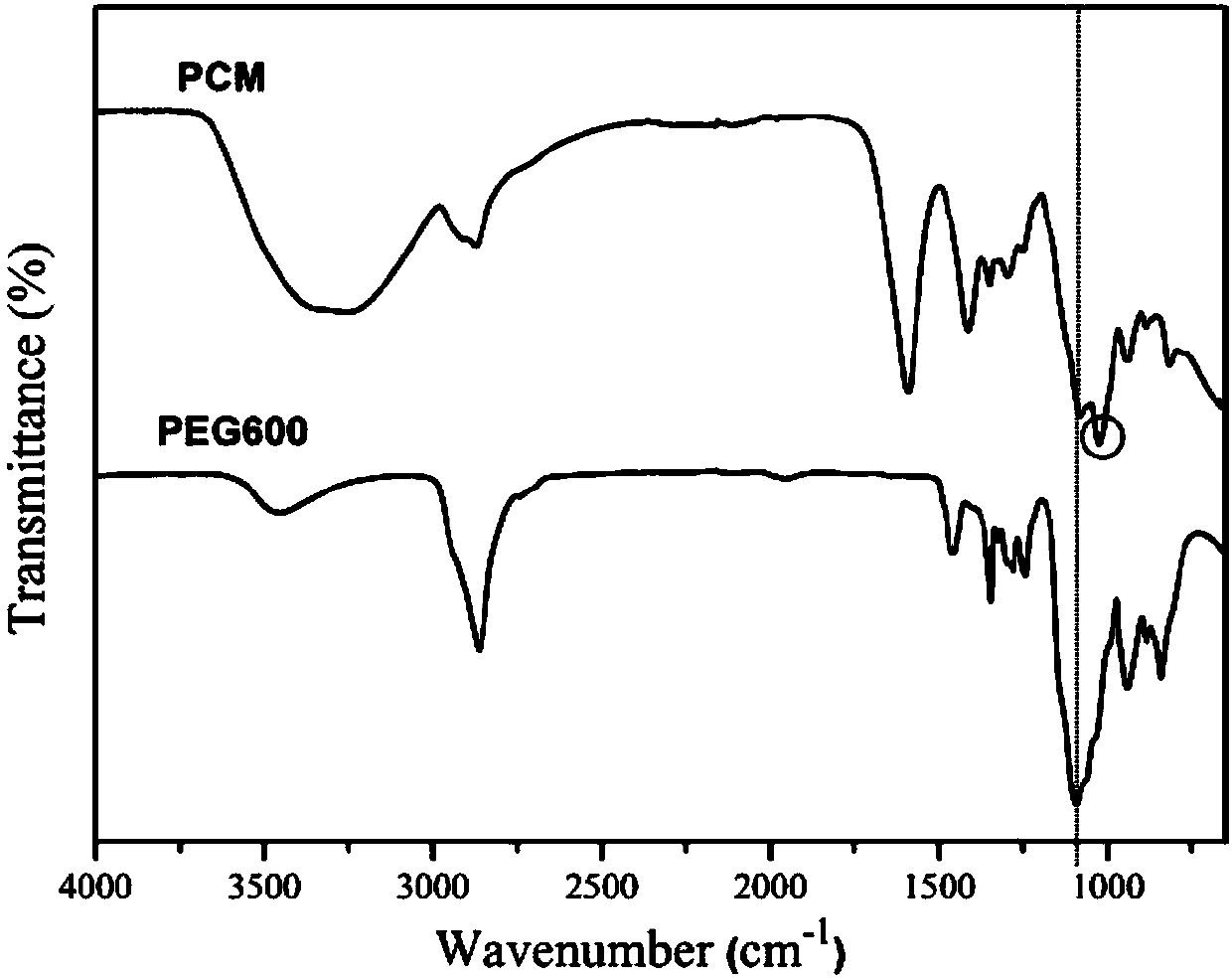

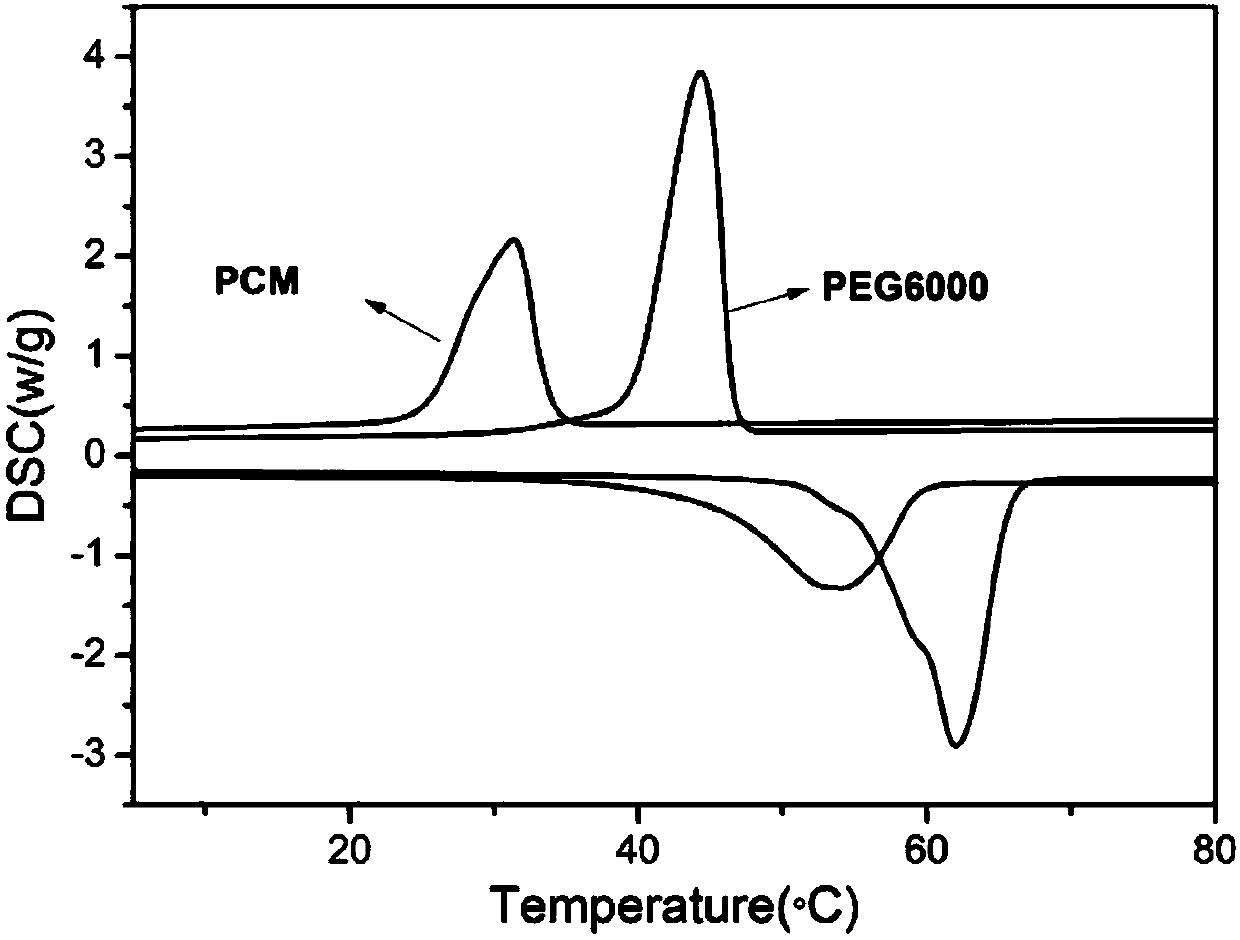

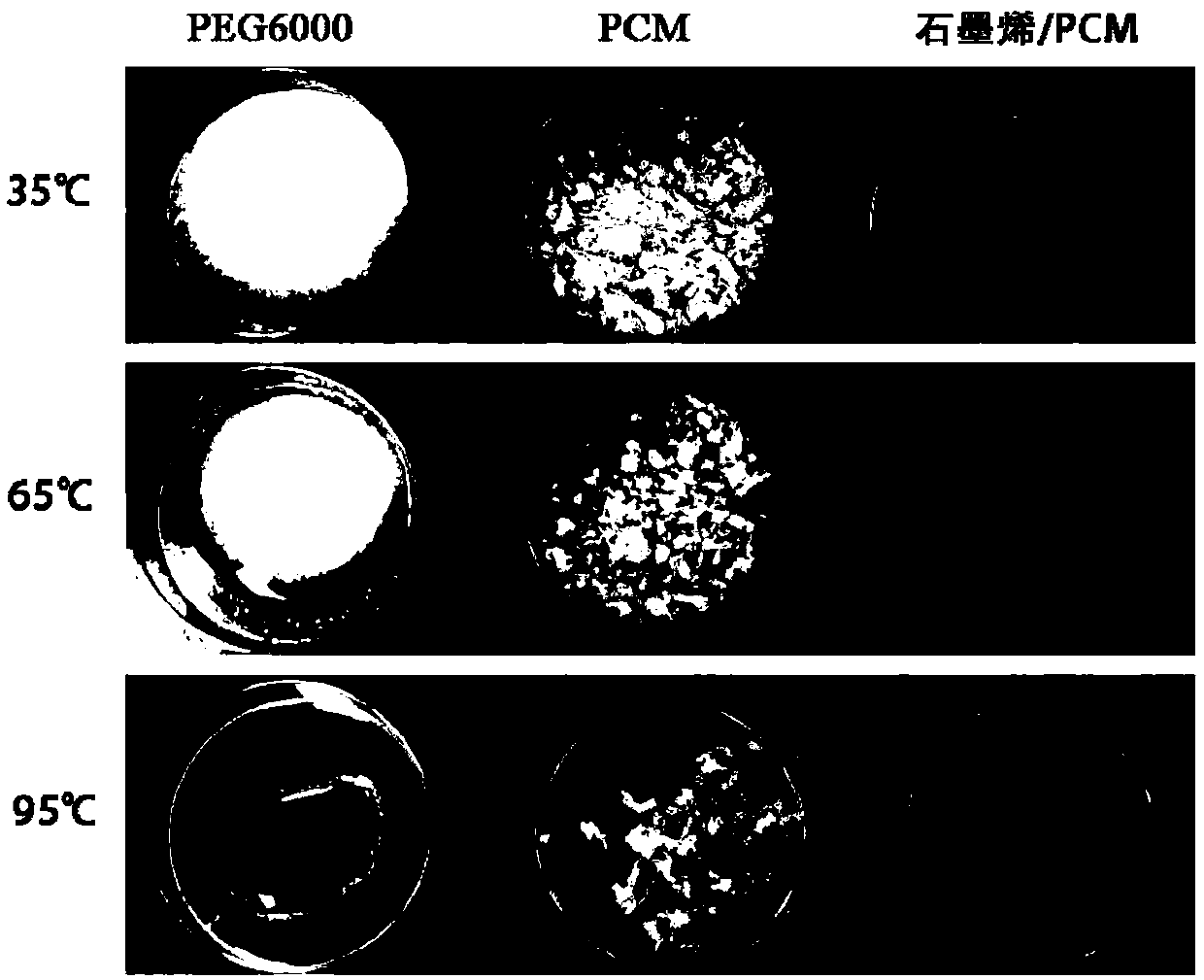

[0036] figure 1 It is the infrared spectrogram of the thermal conductivity-enhanced organic composite shape-setting phase change material in Example 1, wherein: a, pure polyethylene glycol, b, thermal conductivity-enhanced organic composite shape-setting phase change material. It can be seen from the figure that the infrared peak of the composite ...

Embodiment 2-4

[0038] The mass ratios of sodium alginate and polyethylene glycol (Mn=6000) were changed to 50:50, 25:75, and 10:90 respectively to obtain the corresponding organic composite shape-setting phase change material, and other conditions were consistent with those in Example 1. The measurement results show that the prepared thermal conductivity-enhanced organic composite shape-setting phase change material has a good shape-setting effect.

Embodiment 5-9

[0040] Sodium polyacrylate, potassium polymaleate, polyvinylpyridine, carboxymethyl cellulose, and polyvinyl alcohol are used as polymer materials that need to be coordinated to obtain corresponding heat conduction-enhanced organic composite shape-setting phase change materials. Other conditions and examples 1 consistent. The measurement results show that the prepared thermal conductivity-enhanced organic composite shape-setting phase change material has a good shape-setting effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| composition ratio | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com