Inorganic hydrated salt porous carbon composite phase change material and preparation method thereof

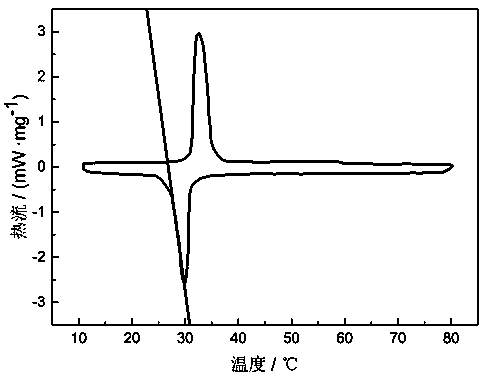

A technology of composite phase change materials and inorganic hydrated salts, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as easy overcooling, poor durability, low phase change enthalpy, etc., achieve high phase change enthalpy, improve Easy supercooling and phase separation, the effect of small supercooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

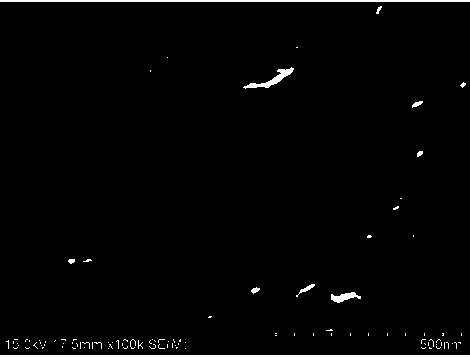

[0040](1) The biomass-based porous carbon was put into a nitric acid solution with a molar concentration of 1 mol / L for activation treatment. The biomass-based porous carbon was coconut shell activated carbon material, and the stirring speed was 600 r / min for 60 min. Then wash and dry to obtain biomass-based porous carbon with water content ≤10%, pore size 490 nm, particle size 45 μm, strength ≥95%, and expansion ratio 28;

[0041] (2) Weigh the inorganic hydrated salt phase change material, the pore sealing agent and the biomass-based porous carbon obtained in step (1) in proportion, and the mass ratio of the inorganic hydrated salt phase change material: biomass-based porous carbon: pore sealing agent is: 20:15:1, the inorganic hydrated salt phase change material is Mn(NO 3 ) 2 ·6H 2 O, the pore sealing agent is commercially available paraffin, for subsequent use;

[0042] (3) adding the inorganic hydrated salt phase change material in step (2) into deionized water to pre...

Embodiment 2

[0047] (1) The biomass-based porous carbon was put into a nitric acid solution with a molar concentration of 1 mol / L for activation treatment. The biomass-based porous carbon was coconut shell activated carbon material, and the stirring speed was 500 r / min for 55 min. Then wash and dry to obtain biomass-based porous carbon with water content ≤ 10%, pore size 480 nm, particle size 40 μm, strength ≥ 95%, and expansion ratio 24;

[0048] (2) Weigh the inorganic hydrated salt phase change material, the pore sealing agent and the biomass-based porous carbon obtained in step (1) in proportion, and the mass ratio of the inorganic hydrated salt phase change material: biomass-based porous carbon: pore sealing agent is: 20:10:1, the inorganic hydrated salt phase change material is Mn(NO 3 ) 2 ·6H 2 O, the pore sealing agent is commercially available paraffin, for subsequent use;

[0049] (3) adding the inorganic hydrated salt phase change material in step (2) into deionized water to ...

Embodiment 3

[0054] (1) The biomass-based porous carbon was put into a nitric acid solution with a molar concentration of 1 mol / L for activation treatment. The biomass-based porous carbon was coconut shell activated carbon material, and the stirring speed was 550 r / min for 50 min. Then wash and dry to obtain biomass-based porous carbon with water content ≤10%, pore size 470 nm, particle size 50 μm, strength ≥95%, and expansion ratio 20;

[0055] (2) Weigh the inorganic hydrated salt phase change material, the pore sealing agent and the biomass-based porous carbon obtained in step (1) in proportion, and the mass ratio of the inorganic hydrated salt phase change material: biomass-based porous carbon: pore sealing agent is: 15:15:1, the inorganic hydrated salt phase change material is Mn(NO 3 ) 2 ·6H 2 O, the pore sealing agent is commercially available paraffin, for subsequent use;

[0056] (3) adding the inorganic hydrated salt phase change material in step (2) into deionized water to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com