Patents

Literature

599results about "Aluminium fluorides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

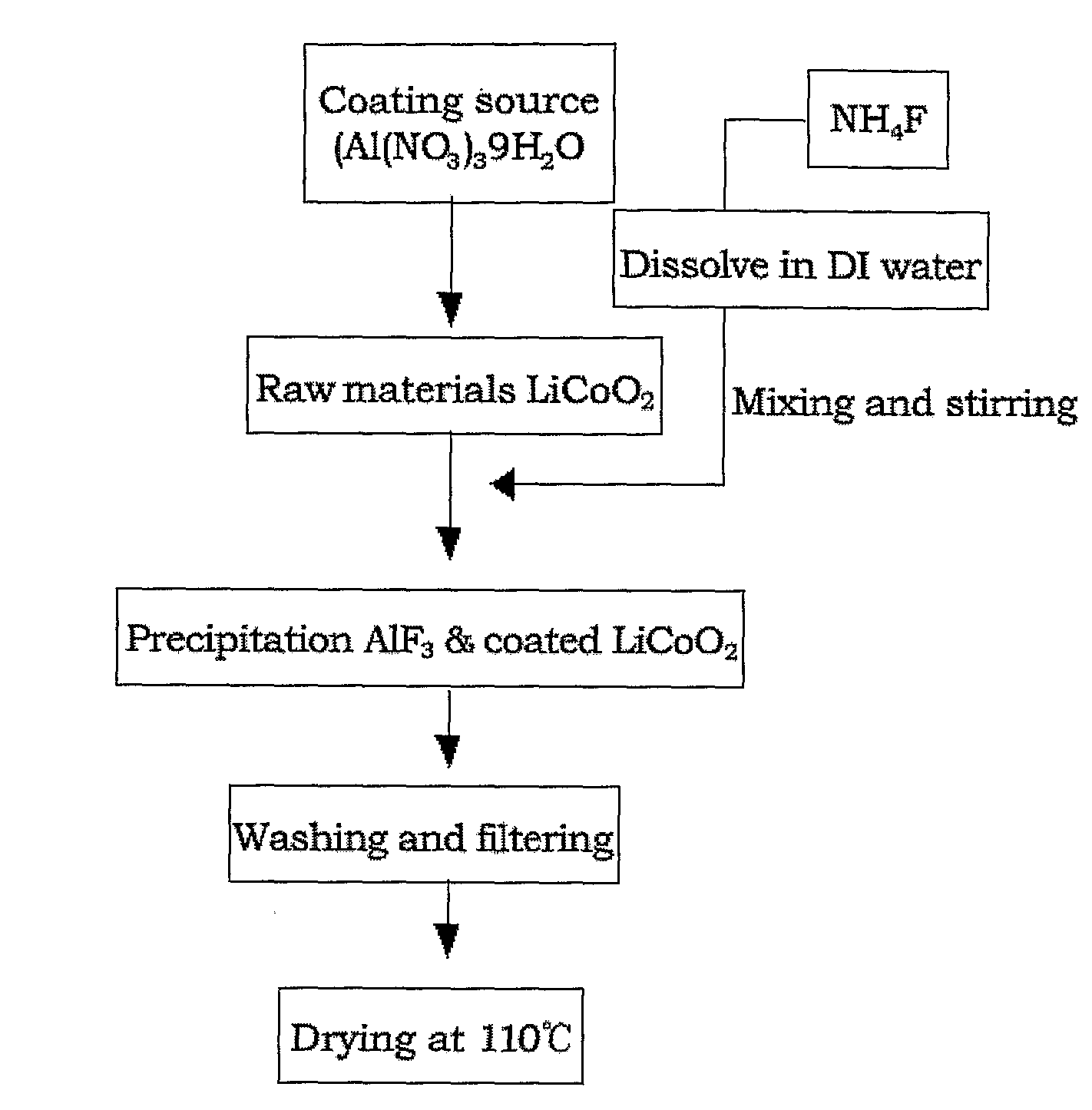

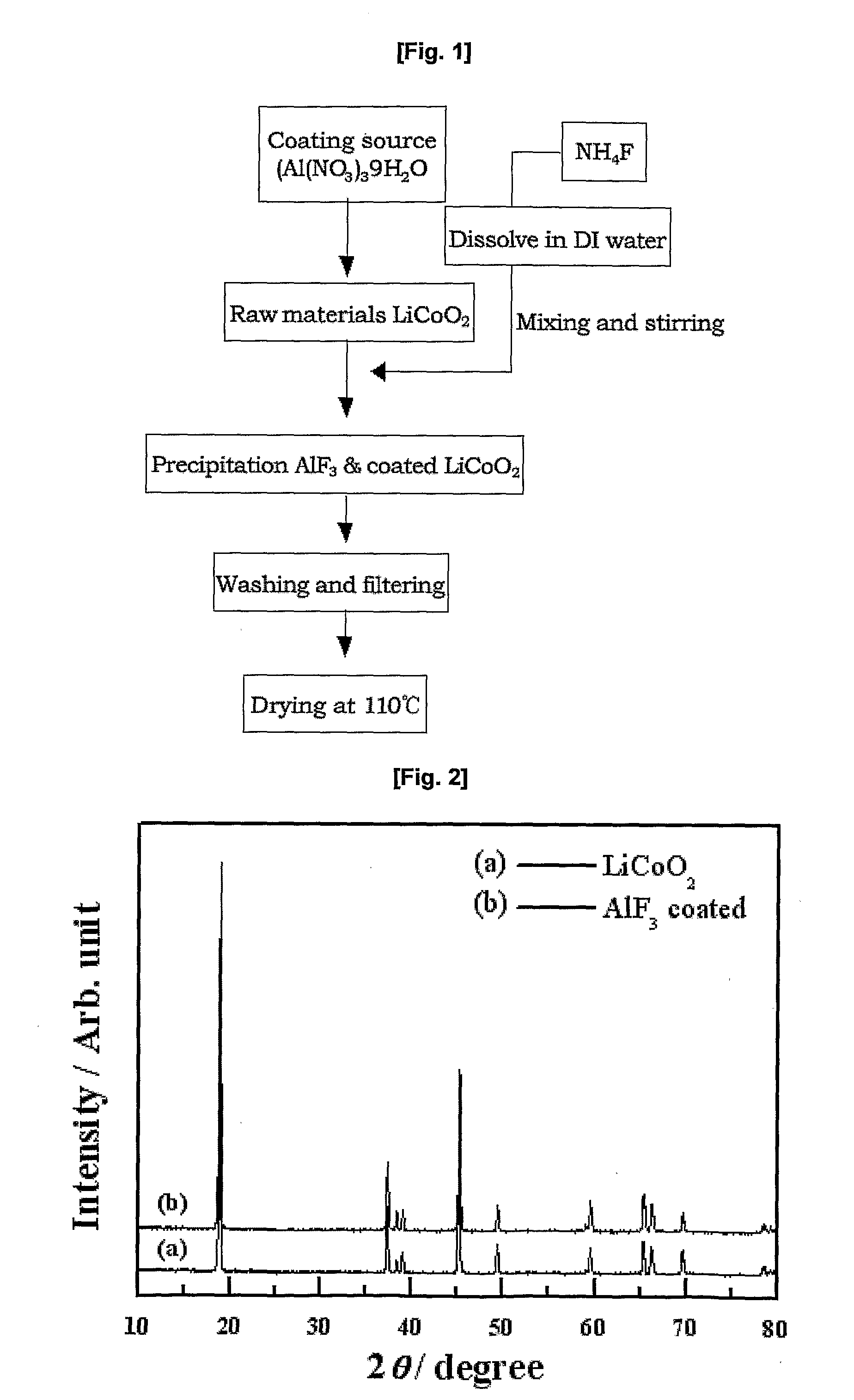

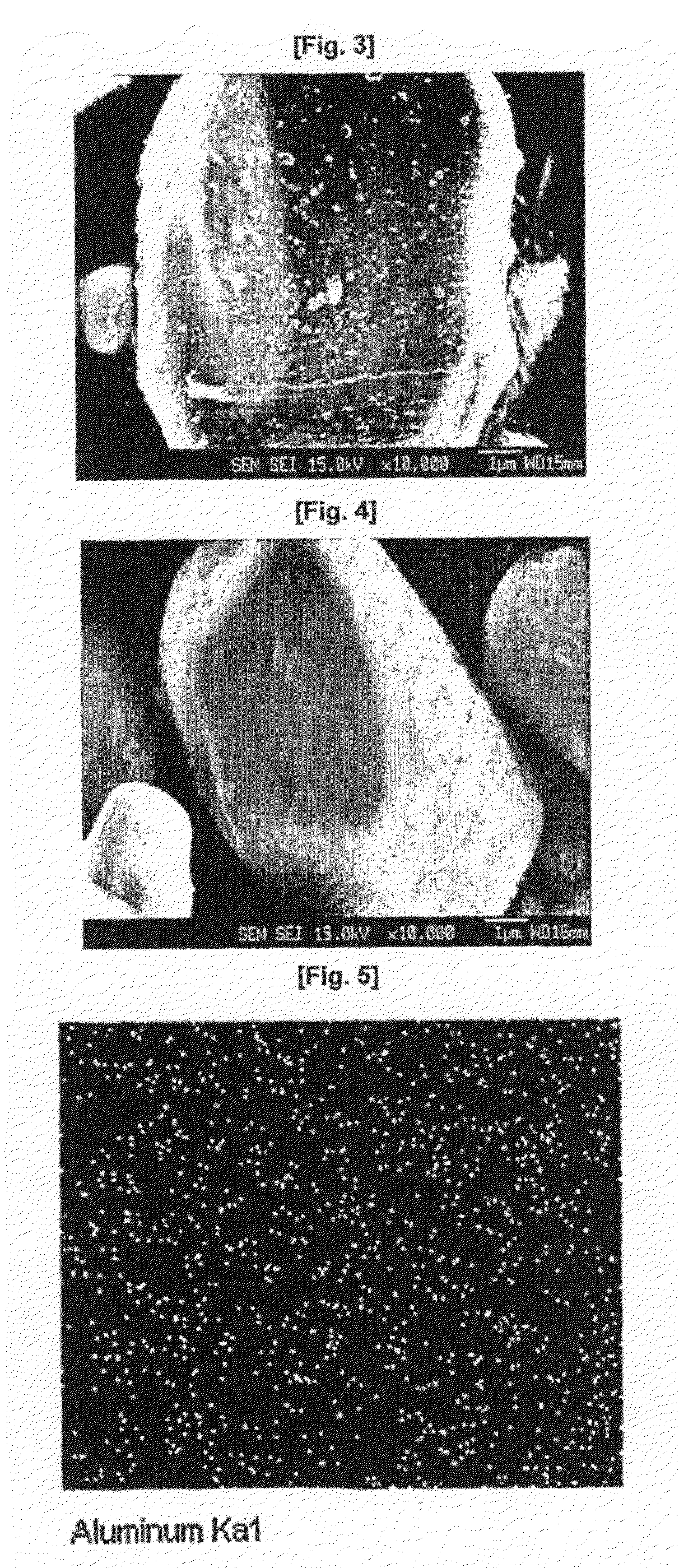

Cathode Active Material Coated With Fluorine Compound for Lithium Secondary Batteries and Method for Preparing the Same

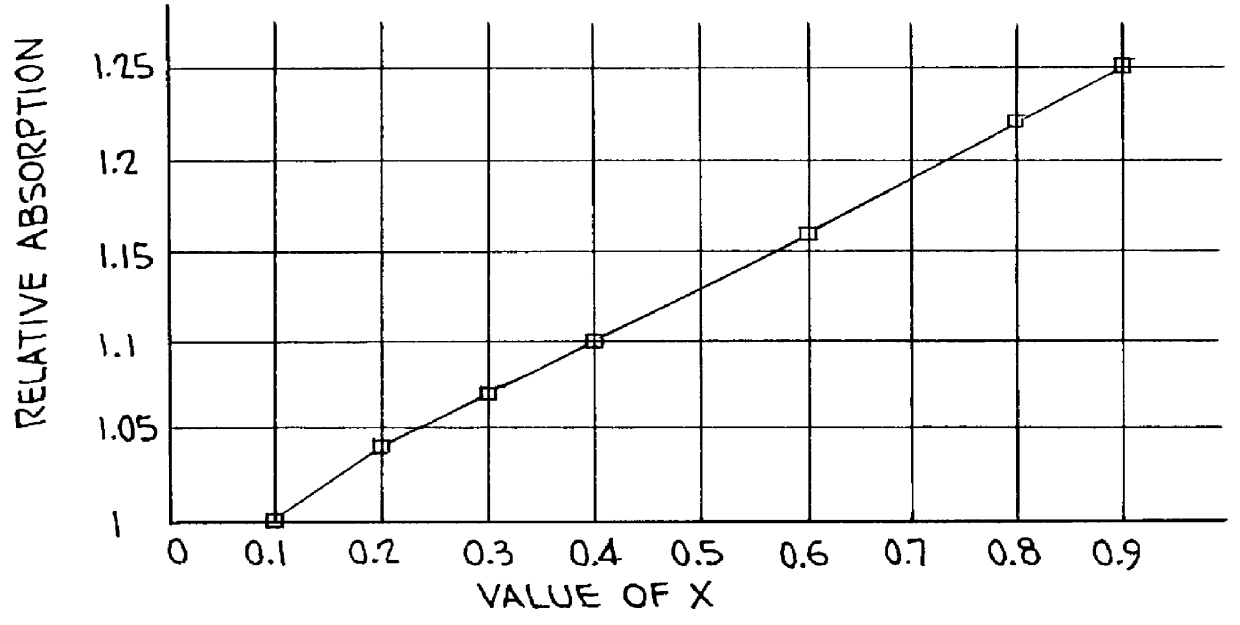

InactiveUS20090087362A1Inhibition of performance deteriorationHigh voltageElectrode manufacturing processesLithium compoundsLithiumHigh rate

Disclosed herein is a cathode active material coated with a fluorine compound for lithium secondary batteries. The cathode active material is structurally stable, and improves the charge-discharge characteristics, cycle characteristics, high-voltage characteristics, high-rate characteristics and thermal stability of batteries.

Owner:ENERCERAMIC

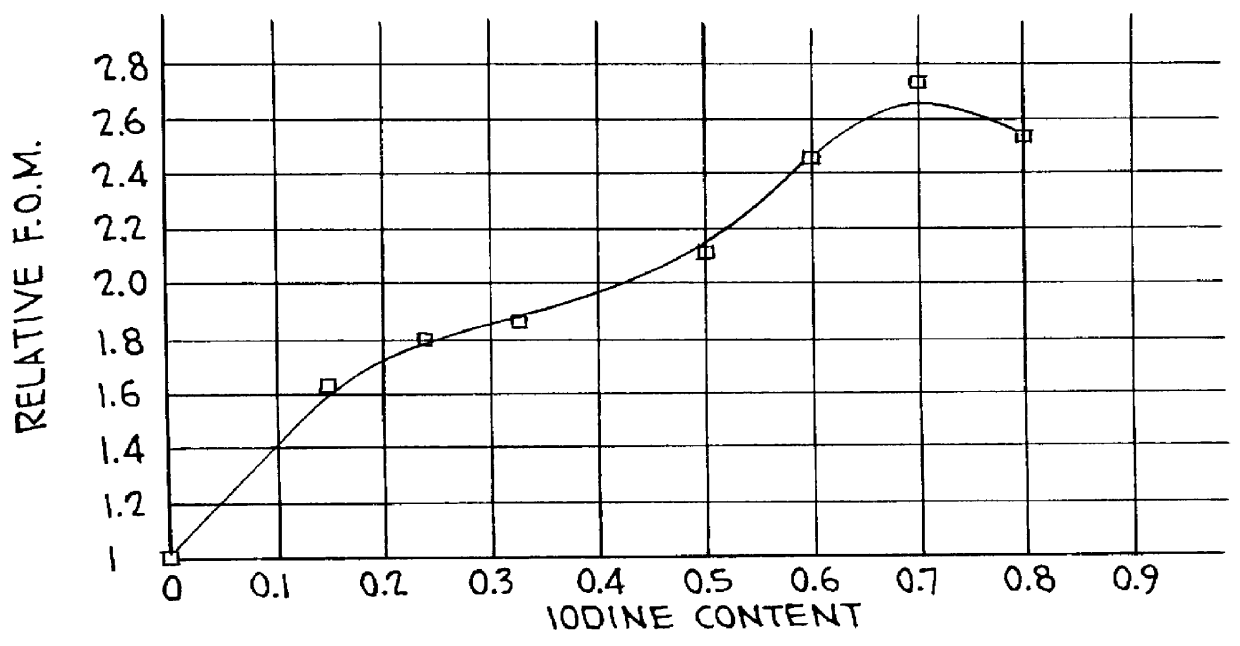

Photostimulable phosphor

InactiveUS6045722AImprove clarityLow noise contentX-ray/infra-red processesRadiation applicationsPhosphorMetal

There is provided a photostimulable phosphor according to formula (I)Ba1-x-y-p-3q-zSrxMy2+M2p1+M2q3+F2-a-bBraIb:zEuwherein: M1+ is at least one alkali metal selected from the group consisting of Li, Na, K, Rb and Cs; M2+ is at least one metal selected from the group consisting of Ca Mg and Pb; M3+ is at least one metal selected from the group consisting of Al, Ga, In, Tl, Sb, Bi, Y, La, Ce, Pr, Nd, Sm, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu; 0<x< / =0.30, 0< / =y< / =0.10, 0< / =p< / =0.3, 0< / =q< / =0.1, 0.05< / =a< / =0.76, 0.20< / =b< / =0.90, a+b<1.00 and 10-6< / =z< / =0.2.

Owner:AGFA HEALTHCARE NV

Method of preparing positive active material for rechargeable lithium batteries

InactiveUS6949233B2Improved cycle life characteristicsHigh discharge rateElectrode manufacturing processesPhosphatesPhysical chemistryHeat treated

Owner:SAMSUNG SDI CO LTD

Composite precursor for aluminum-containing lithium transition metal oxide and process for preparation of the same

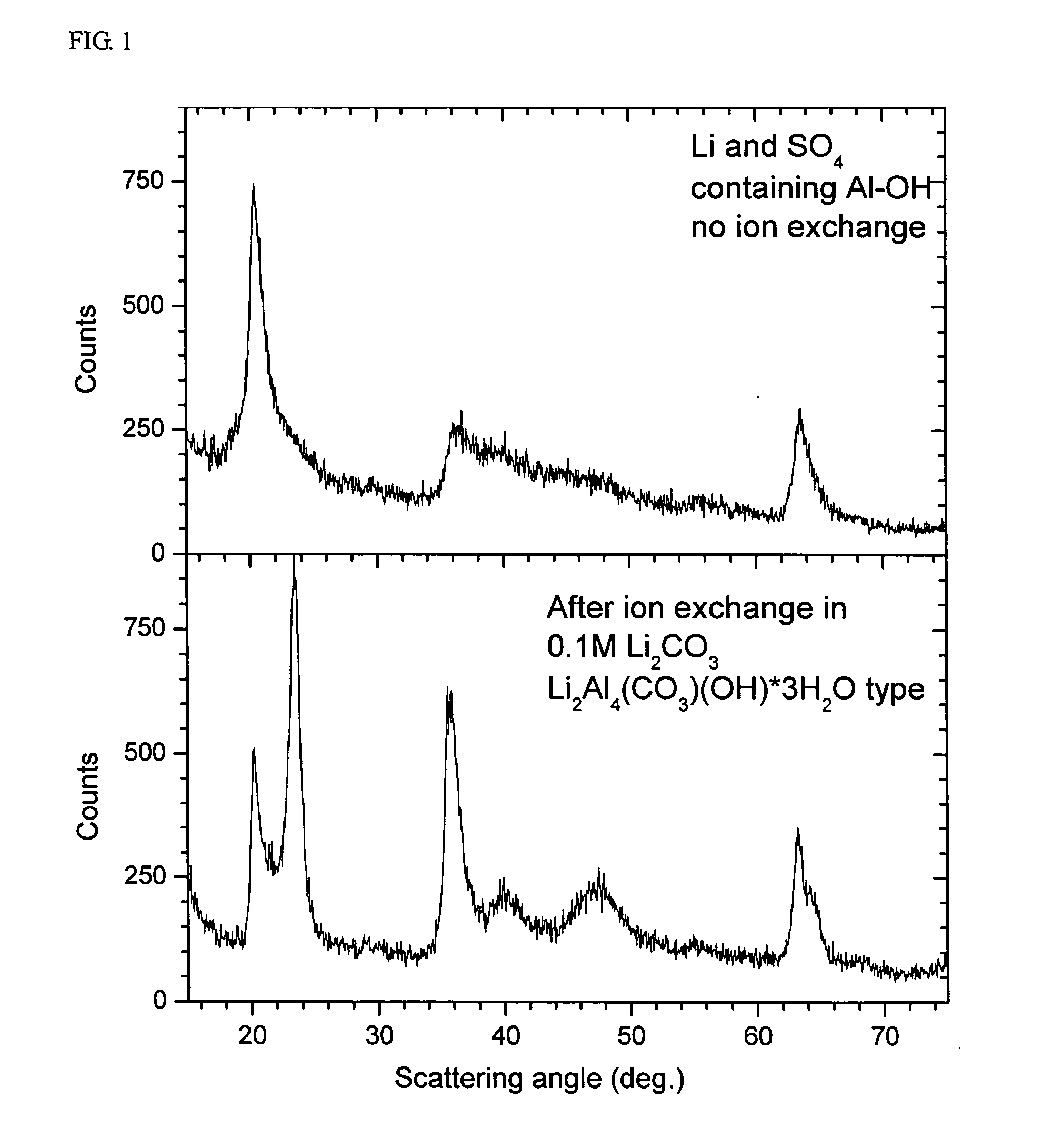

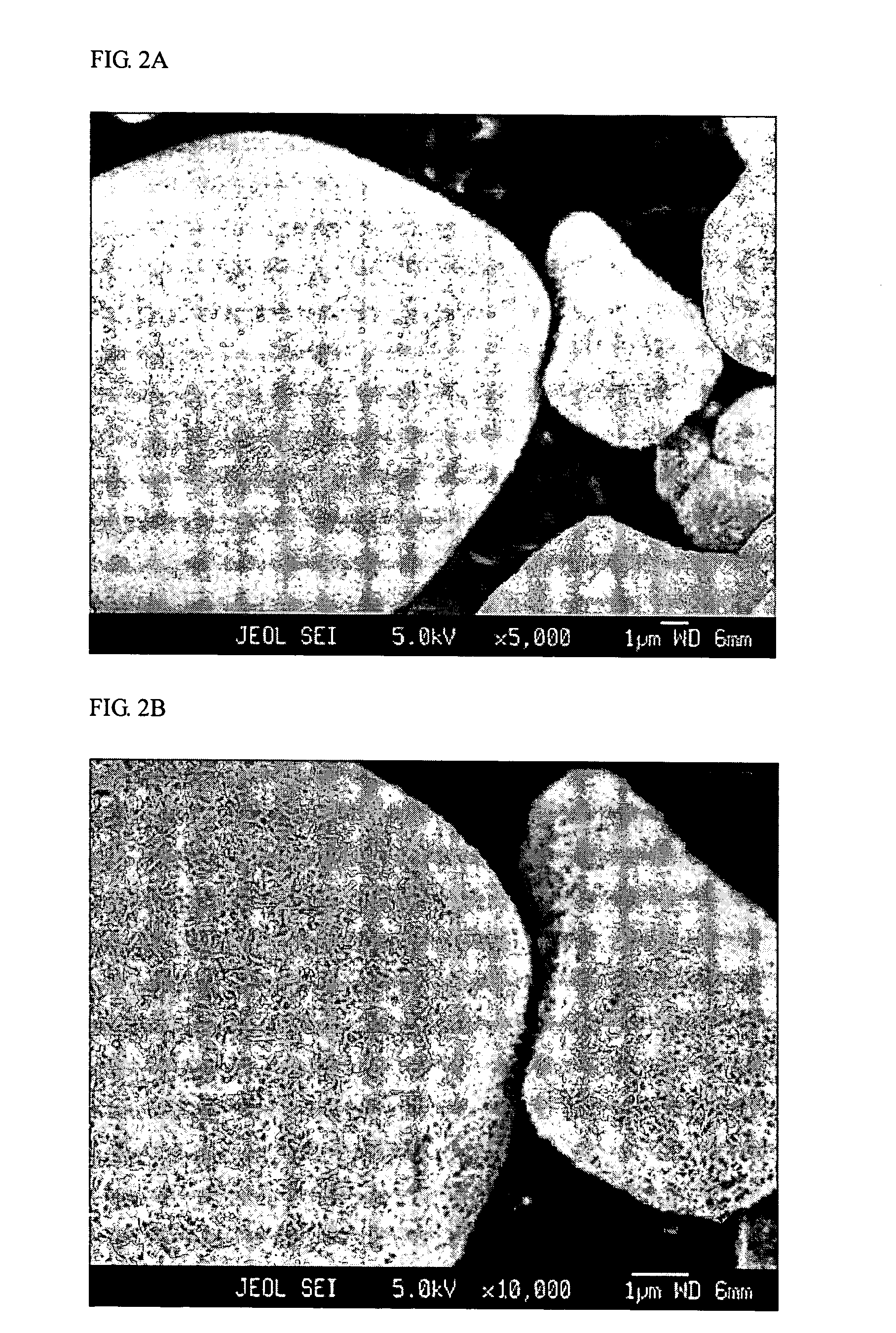

ActiveUS20060068289A1Coating stabilityEasy to replaceElectrode manufacturing processesConductive materialWater basedAluminium hydroxide

The present invention provides a powdery composite precursor, which comprises a core of a lithium transition metal oxide, and an aluminum hydroxide-based precipitate layer coated on the surface of the core, and a process to prepare the composite precursor. The preparation process comprises the formation of a water based slurry by dispersing lithium transition metal oxide powder in water, and a precipitation reaction of an aluminum salt solution with a base solution where the lithium transition metal particles act as seed particles, whereby a mechanically stable precipitate layer of homogeneous thickness can be achieved. The composite precursor can be converted into aluminum-containing, e.g., aluminum-doped, lithium transition metal oxide suitable for a cathode active material of lithium rechargeable battery by heat treatment.

Owner:LG ENERGY SOLUTION LTD

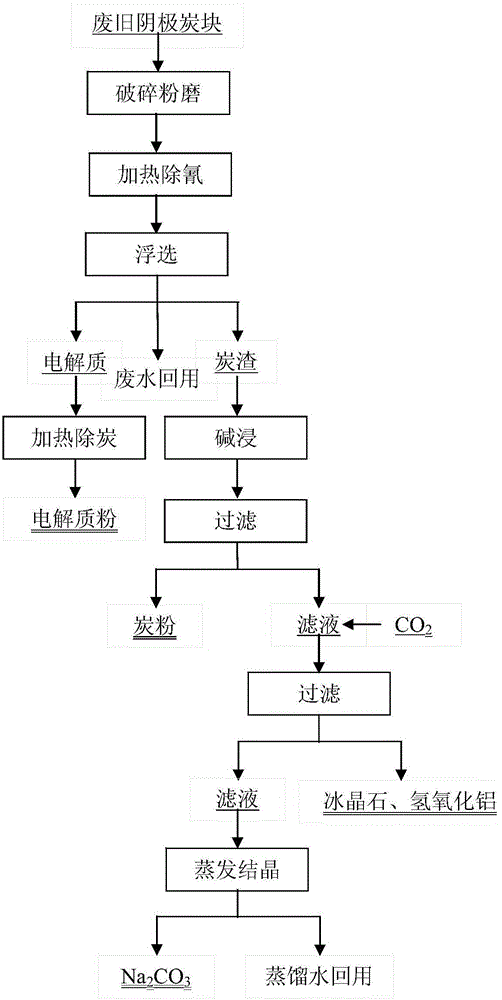

Comprehensive recovery method of waste and old cathode charcoal block of aluminium electrolytic tank

ActiveCN106064813AReduce consumptionShorten the alkaline leaching timeAluminium fluoridesAluminium oxides/hydroxidesRecovery methodElectrolysis

The invention relates to a comprehensive recovery method of waste and old cathode charcoal block of an aluminium electrolytic tank, and belongs to the technical field of comprehensive utilization of industrial solid waste resources. The method is as below: crushing and grinding waste and old cathode charcoal block of the aluminium electrolytic tank at 200-400 DEG C, insulating, removing cyanide, conducting flotation separation on the material with cyanide removed to obtain carbon slag and electrolyte slag, heating the electrolyte slag at 550-800 DEG C to remove carbon impurities, so as to obtain an electrolyte powder, removing to soluble substances in the electrolyte slag by alkali leaching to obtain a carbon powder with high purity, and precipitating a mixture of cryolite and aluminium hydroxide form the alkali leaching liquid by CO2. The invention has the advantages of reasonable process design, simple process, high treatment efficiency, high recovery rate and recycling rate of each material and no secondary pollution, and is applicable to large-scale industrial application.

Owner:CENT SOUTH UNIV

Alkali-type dissolving method of carbon powder in electrolytic aluminum scraps

The invention discloses an alkali-type dissolving method of carbon powder in electrolytic aluminum scraps, characterized by comprising the following steps: crushing electrolytic aluminum scraps in a wet type, floating and magnetically separating to remove iron and silicon and obtain carbon powder A; putting the carbon powder A in an alkali solution to dissolve; dissolving fluoride in the carbon powder A; and then, adding carbon dioxide to separate out cryolite B. The invention adopts the technical scheme that the theory that fluoride has a certain solubility in caustic soda is utilized to design an alkali-method process, i.e. carbon powder primarily separated at normal pressure is dissolved in an alkali type, and CO2 generated in the product-drying process is utilized to carbonize so as to separate out the cryolite. Tested by the proposer to the product, high-purity cryolite achieving the national standard can be obtained. Iron and silicon in the carbon powder can be eliminated by the secondary floatation of the carbon powder because the fluoride carrier is damaged, and the processed carbon powder (with 1-2 percent of ash content) can reach a high-purity carbon powder level.

Owner:贵州铝城铝业原材料研究发展有限公司

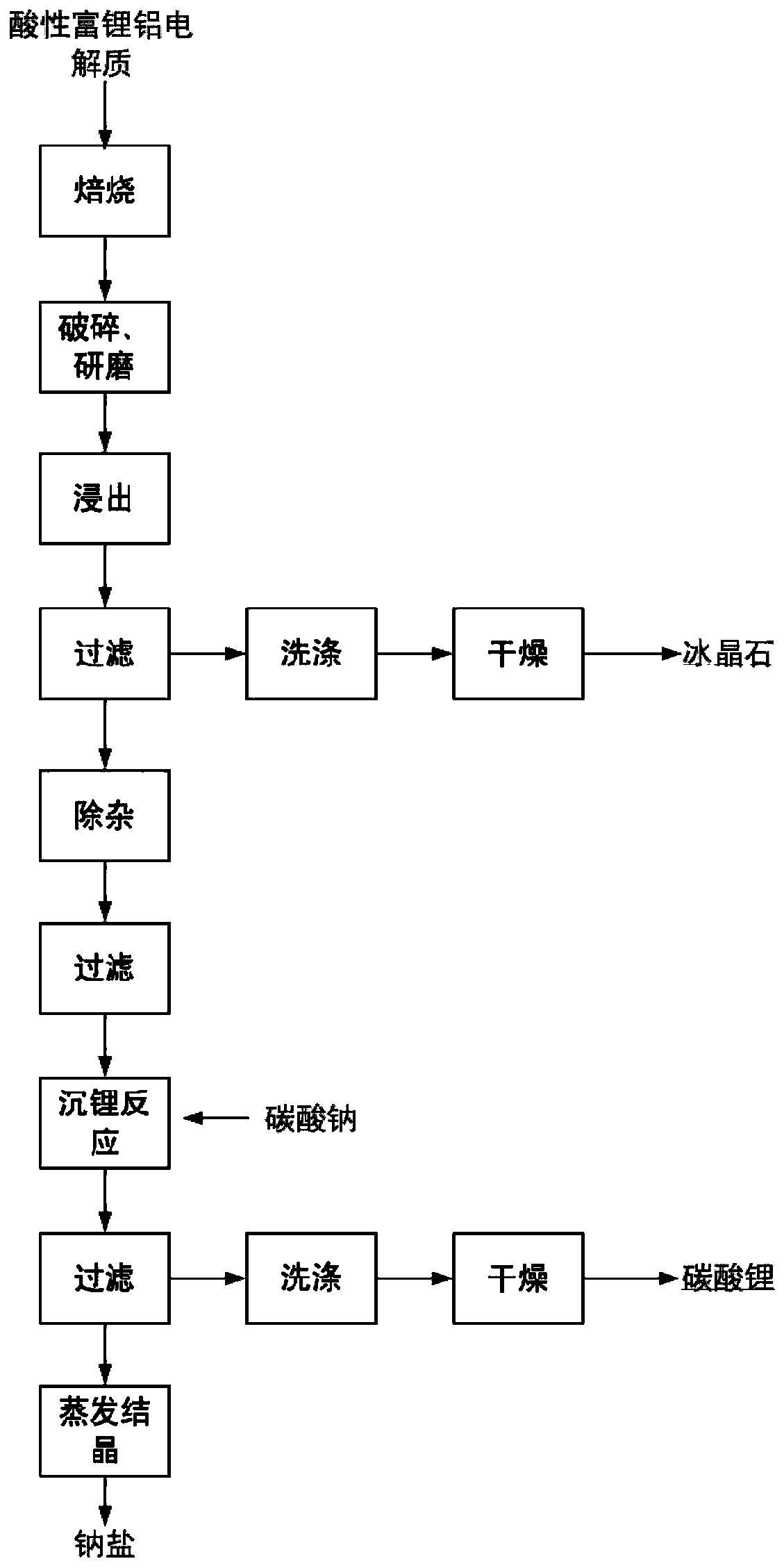

Method for separating lithium carbonate from electrolyte acidic leachate

InactiveCN107935015AEfficient extractionReduce energy consumptionMagnesium fluoridesCalcium/strontium/barium fluoridesEvaporationCarbonate

The invention discloses a method for separating lithium carbonate from electrolyte acidic leachate. The method comprises the following steps of: S1, adding a soluble salt solution to aluminum electrolyte acidic leachate while stirring and heating are performed, monitoring the acidity and the concentration of fluoride ions, and stopping the addition when the pH value is greater than 5 and the concentration of the fluoride ions is less than 0.01 g / L, wherein the soluble salt is one or more selected from MeSO4, MeNO3 and MeCl, and Me is metal which can produce precipitate with F<->; S2, performing filtration on reactants, performing washing and drying on filter residues to obtain a fluoride salt of the metal Me, adding a soluble carbonate solution into the obtained filtrate with stirring andheating, and terminating the reaction when the concentration of lithium ions is less than 0.08 g / L; S3, filter the filtrate, performing washing and drying on the filter cake to obtain lithium carbonate, and performing evaporation, crystallization, washing and drying on the filtrate to obtain inorganic salts. According to the method for separating lithium carbonate from the electrolyte acidic leachate, the reaction process is controlled by controlling the concentration of the fluoride ions and the acidity, so that the lithium ions are separated from other ions, lithium carbonate with high recovery rate is obtained, and meanwhile high-purity fluoride and inorganic salt products are obtained.

Owner:NORTHEASTERN UNIV

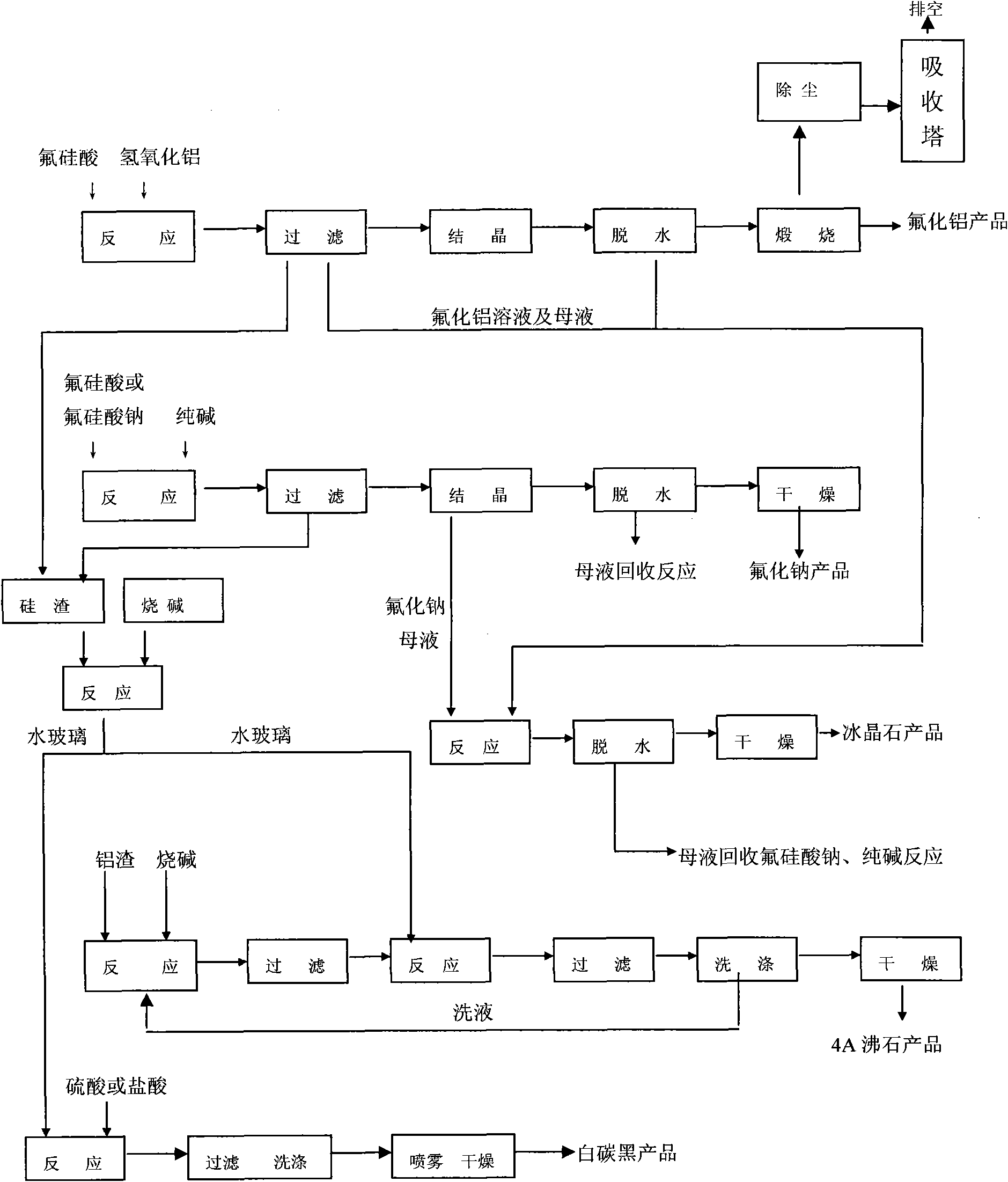

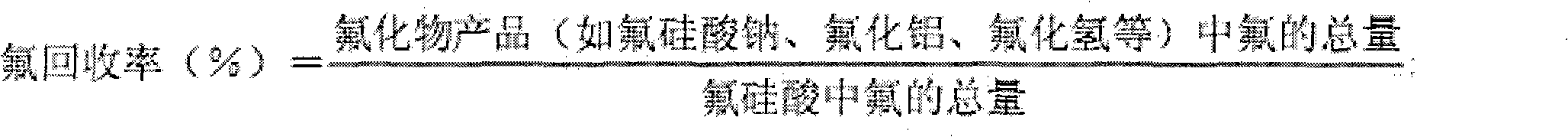

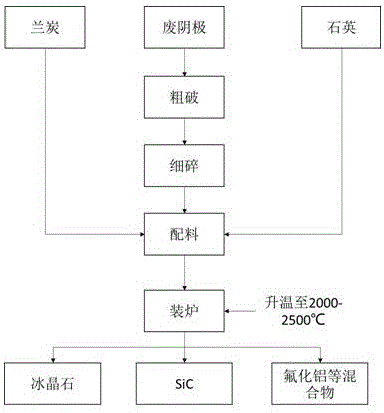

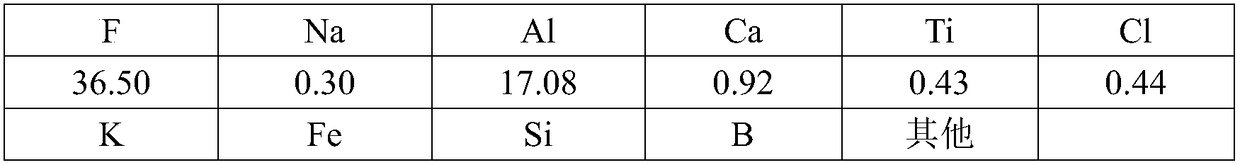

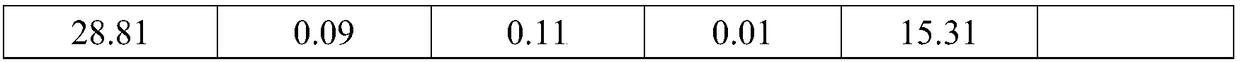

Process method for producing fluorine compounds and silicon compounds by cleanly utilizing fluosilicic acid

ActiveCN101913637AHigh recovery rateTake advantage ofSilicaAlkali metal silicatesChemical industrySlag

The invention discloses a process method for producing fluorine compounds and silicon compounds by cleanly utilizing fluosilicic acid. The process method comprises the following steps of: preparing fluosilicic acid as a phosphorus chemical by-product into an anhydrous aluminum fluoride product, a sodium fluoride product and a cryolite product, and combining with other industrial waste silicon slags and aluminum slags to prepare a 4A zeolite product. The process method comprehensively utilizes the fluosilicic acid and has high resource recovery rate, wherein the recovery rate of the fluorine element reaches higher than 90 percent. Waste silicon dioxide slags generated in the process can be recycled to produce white carbon black and the 4A zeolite, and a mother liquor, a cleaning solution and waste gas which are generated in the production process are all recycled, thereby the environmental pollution is reduced, and the purposes of zero emission and no pollution are truly achieved, thus the method completely meets the requirement for clean production. The invention has the advantages of advanced production process, good product quality and high value, wherein the fluorine content of the aluminum fluoride is high and between 63-65 percent; the quality index of the obtained white carbon black meets the requirement on the standard of the chemical industry; and the quality of the 4A zeolite product meets the requirements on the national standard and the standard of European and American developed countries.

Owner:四川励志环保科技有限公司

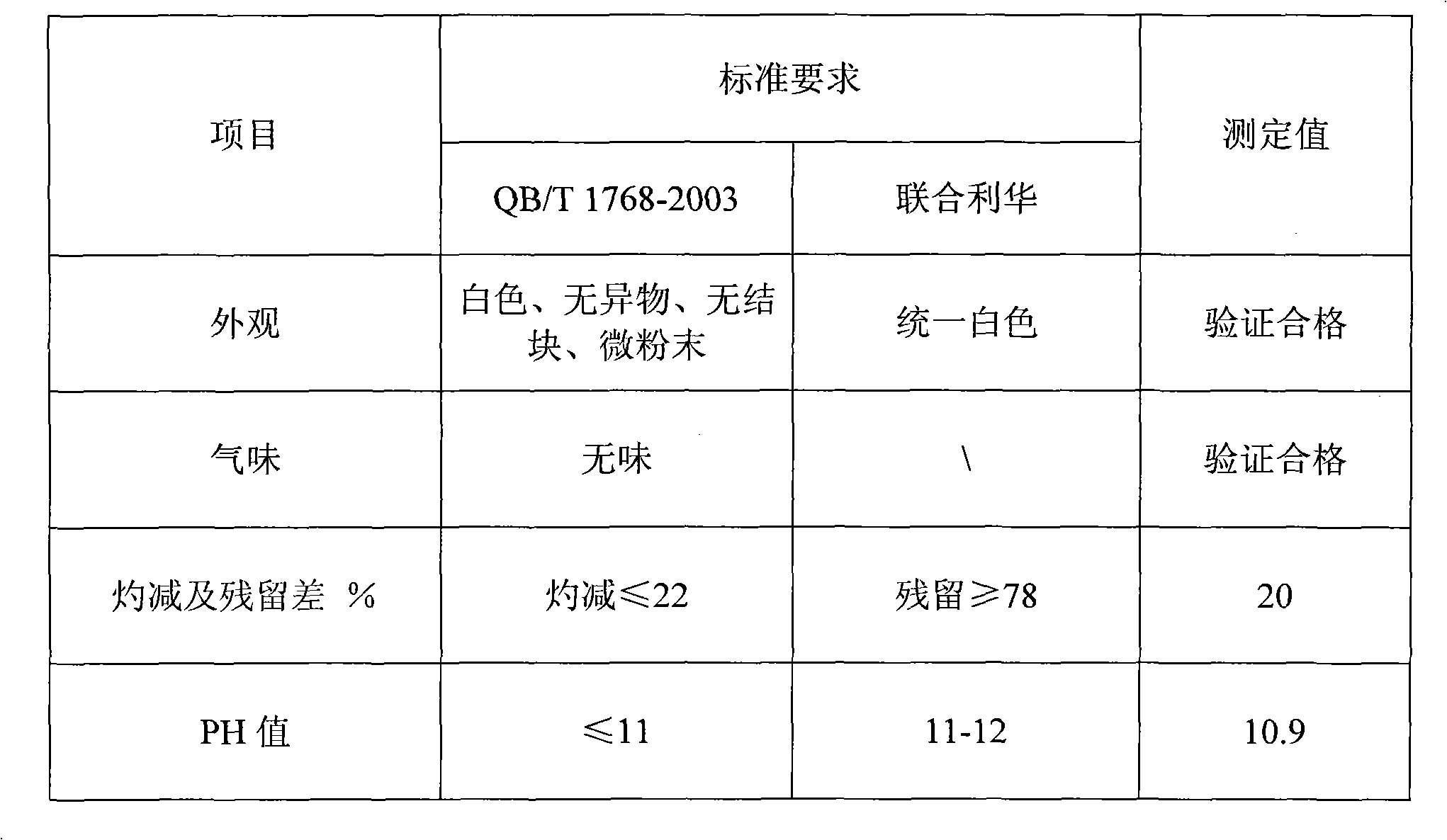

Method for treating spent cathodes of spent potlinings of aluminum electrolysis cells

InactiveCN106517209ARealize comprehensive utilizationReduce the cost of electrolytic productionFluoride preparationCarbon compoundsElectrolysisCyanide

The invention relates to a method for resource utilization of solid wastes of aluminum electrolysis cells, in particular to a method for treating spent cathodes of spent potlinings of aluminum electrolysis cells. The method includes adding a carbon material and quartz sand into the spent cathodes of the spent potlinings of the aluminum electrolysis cells, conducting high-temperature carbothermic reduction in a high-temperature reacting furnace to obtain SiC, enabling cryolite to form melts to sink, making the melts and the generated SiC to undergo solid-liquid separation, and subjecting a fluoride salt to furnace gas evaporation prior to gas-solid separation from the generated SiC so as to obtain SiC; collecting the sunk cryolite melts and conducting condensation recovery so as to obtain cryolite; collecting evaporated furnace gas and cooling so as to obtain the fluoride salt. The method has the advantages that the SiC is prepared through a high-temperature carbothermic reduction method, fluoride and electrolytes are recovered, the electrolytes are reused for the aluminum electrolysis industry, and cyanide in the spent potlinings is decomposed and removed, so that comprehensive resource utilization of the spent potlinings of the aluminum electrolysis cells is achieved and electrolysis production cost is reduced.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method used for preparing fluorine salt taking aluminium fluoride as main component from electrolyte-containing material produced in aluminium electrolysis

ActiveCN110194478AElectrolyte composition is stableEfficient recyclingIron oxides/hydroxidesAluminium fluoridesAluminium electrolysisAluminium fluoride

The invention provides a method used for preparing a fluorine salt taking aluminium fluoride as a main component from electrolyte-containing material produced in aluminium electrolysis. The method comprises following steps: the electrolyte-containing material is mixed with a soluble aluminium salt or an aluminium salt solution, and reaction is carried out at 50 to 100 DEG C; a reaction product issubjected to solid liquid separation, after separation, an obtained solid product is washed and dried so as to obtain the fluorine salt taking aluminium fluoride as a main component, and a liquid solid product obtained through separation and a solid product washing solution obtained in washing of the solid product are mixed so as to obtain a mixture, a strong basicity hydroxide or a solution of the strong basicity hydroxide is added into the mixture to remove calcium and iron impurities in the mixture; evaporation concentration desalting is carried out, and separation is carried out so as to obtain a concentrated mother liquor; a carbonate or a solution of the carbonate is added to remove Lithium-ion impurities in the concentrated mother liquor, after impurity removing, an obtained solution is adopted in diluting or washing step in the method. The method is capable of converting the excess electrolyte-containing material produced in aluminium electrolysis into aluminum fluoride, so that effective circulation of fluoride element in aluminium electrolysis enterprises is realized, and great meaning on aluminium electrolysis industry development of China is achieved.

Owner:郑州于斯新创科技有限公司

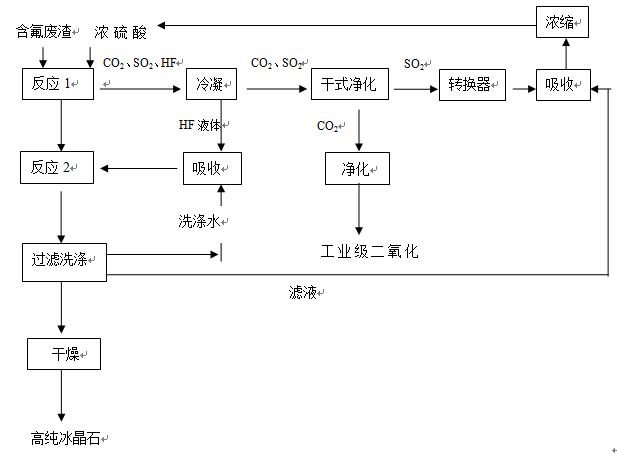

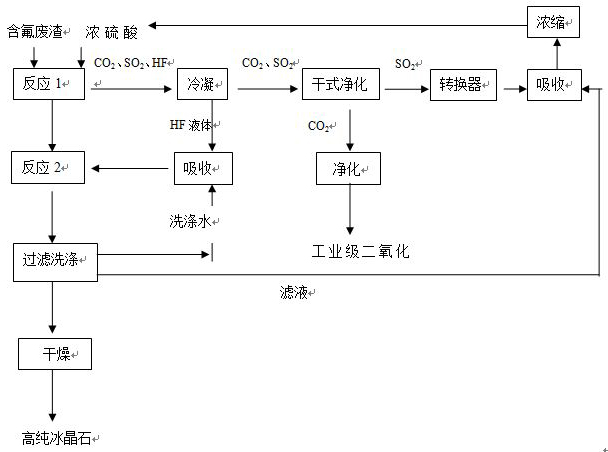

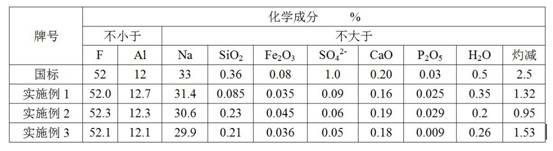

Method for producing cryolite by using fluorine-containing waste residues of electrolytic aluminium

ActiveCN102079534AQuality improvementReduce manufacturing costWaste processingSolid waste disposalPhysical chemistryEnvironmental engineering

The invention belongs to the technical field of aluminum industry smelting, and relates to a method for producing cryolite by using fluorine-containing waste residues of electrolytic aluminium. The technical scheme adopted by the invention is as follows: the fluorine-containing waste residues of the electrolytic aluminium and concentrated sulfuric acid are taken as raw materials to produce the cryolite. The method provided by the invention is used to improve the use ratio of the cryolite, prevent the waste of fluorine resources, and reduce the environmental pollution.

Owner:BAIYIN ZHONGTIAN CHEM

Method for preparing cryolite by alkaline leachate of cathode carbon block of aluminum electrolytic cell

The invention relates to a method for preparing cryolite by alkaline leachate of a cathode carbon block of an aluminum electrolytic cell, and belongs to a leachate preparation method. The method comprises the steps of grinding the cathode carbon block of the aluminum electrolytic cell to a certain particle size, mixing the ground cathode carbon block with alkaline liquid, carrying out size mixing, carrying out stirring leaching at a heating temperature of 20-90 DEG C, filtering to obtain first filtrate and a first filter residue, adding sodium fluoride and a small amount of Na3AlF6 solids into the first filtrate, controlling the introducing velocity of CO2-rich gas to generate precipitates while heating and stirring, after the reaction is finished, filtering to obtain second filtrate and a second filter residue, and drying the second filter residue at 100-150 DEG C, so as to obtain a cryolite product. According to the method, acidy leaching is replaced with alkaline leaching, so that the equipment requirements in the production process are reduced, processing processes such as flotation are omitted, an absorption process of hydrogen fluoride is omitted, and the processing process is simplified; a high-temperature processing process is saved, so that the energy consumption is reduced; and by adding crystal seeds, high-quality cryolite with the uniform particle size is generated when airflow rate is controlled. The method has the beneficial effects that the process is simple, a closed loop is utilized, the resource utilization rate is high, and the secondary pollution is avoided.

Owner:CENT SOUTH UNIV

Method for producing cryolites by using aluminum electrolytic cell cathode carbon block alkaline leaching solution

The invention relates to a method for preparing cryolites by using an aluminum electrolytic cell cathode carbon block alkaline leaching solution, and belongs to preparation methods of the cryolites. The method comprises the following steps: grinding aluminum electrolytic cell cathode carbon blocks finely to a certain particle size, performing slurry mixing with alkali liquor, and performing agitation leaching at a heating temperature of 20-90 DEG C; then performing filtration to obtain a first filtrate and a first filter residue; adding sodium fluoride and a small amount of Na3AlF6 solids into the first filtrate; then controlling the speed of introducing NH3-rich gas or adding NH4F to generate a deposit under the action of heating agitation; and after reaction, performing filtration to obtain a second filtrate and a second filter residue, and drying the second filter residue at 100-150 DEG C to obtain a cryolite product. According to the method provided by the invention, by replacing acid leaching with alkali leaching, the requirement of a production process on equipment is reduced, treatment processes including floatation are reduced, an absorption process of hydrogen fluoride is reduced, and the treatment process is simplified; a high-temperature treatment process is not used, so that the energy consumption is reduced; and by adding a crystal seed, high-quality cryolites with uniform particle sizes are generated under the condition that the airflow rate is controlled. The method provided by the invention is simple in process, achieves closed cycle, is high in resource utilization rate and avoids secondary pollution.

Owner:CENT SOUTH UNIV

Harmlessness and reclamation treatment method of aluminum scrap electrolyte

ActiveCN108677020AEfficient decompositionSolve environmental problemsSulfate/bisulfate preparationAlkali metal nitrate preparationAluminum fluorideElectrolysis

The invention discloses a harmlessness and reclamation treatment method of aluminum scrap electrolyte and belongs to the technical field of inorganic chemistry. The method comprises the main steps that 1, aluminum scraps are electrolyzed and subjected to crushing and screening, and aluminum electrolyte particles are obtained; 2, acid liquor with the concentration of 1 mol / L and an aluminum salt solution with the concentration of 1 mol / L are prepared for standby application; 3, the aluminum electrolyte particles obtained in the step 1 are placed in the acid liquor prepared in the step 2 and leached on the heating and stirring conditions, the PH of the solution is controlled to be smaller than 5, when the fluorinion leaching rate is higher than 94%, leaching is finished, impurities are filtered, and a leaching solution is obtained; 4, the aluminum salt solution prepared in the step 2 is added to the leaching solution in the step 3, the mixture is heated and stirred, Al3+ / Na+ is controlled to be larger than 0.3, when sediment is generated in the solution, the solution is filtered, filter residues and filter liquor are obtained, and the filter residues are washed and dried to obtain alkali type aluminum fluoride products; and 5, the filter liquor in the step 4 is evaporated and crystallized to obtain sodium salt products.

Owner:NORTHEASTERN UNIV

Magnetic selection method for electrolytic aluminum waste material

ActiveCN101811090AImprove the effect of magnetic separationHigh market valueAluminium fluoridesMagnetic separationMagnetiteMagnetic separator

The invention discloses a magnetic selection method for an electrolytic aluminum waste material. The electrolytic aluminum waste material is subjected to wet-type breakage and floating selection. The method is characterized by comprising the following steps of: adding a reducing agent into the electrolytic aluminum waste material; converting the surface of a hematite-contained particle in the waste material into magnetite; and removing ferrum and silicon in magnetic selecting equipment and separating to obtain carbon powder and other raw materials. The hematite (Fe2O3) on the surface of an impurity particle is converted into the magnetite (F3O4) with strong magnetism by utilizing the trace reducing agent in the process of floating selection, the effect of the magnetic selection is greatly improved, and the effect of a gradient magnetic separator can be achieved by adopting a common magnetic separator. Then, the initially separated carbon powder is subjected to alkali type dissolving, the cryolite (Na3AlF6) is separated, and the processed carbon powder (ash content being 1-2 percent) reaches the grade of high-purity carbon powder and greatly improves the market value of products.

Owner:周俊和 +1

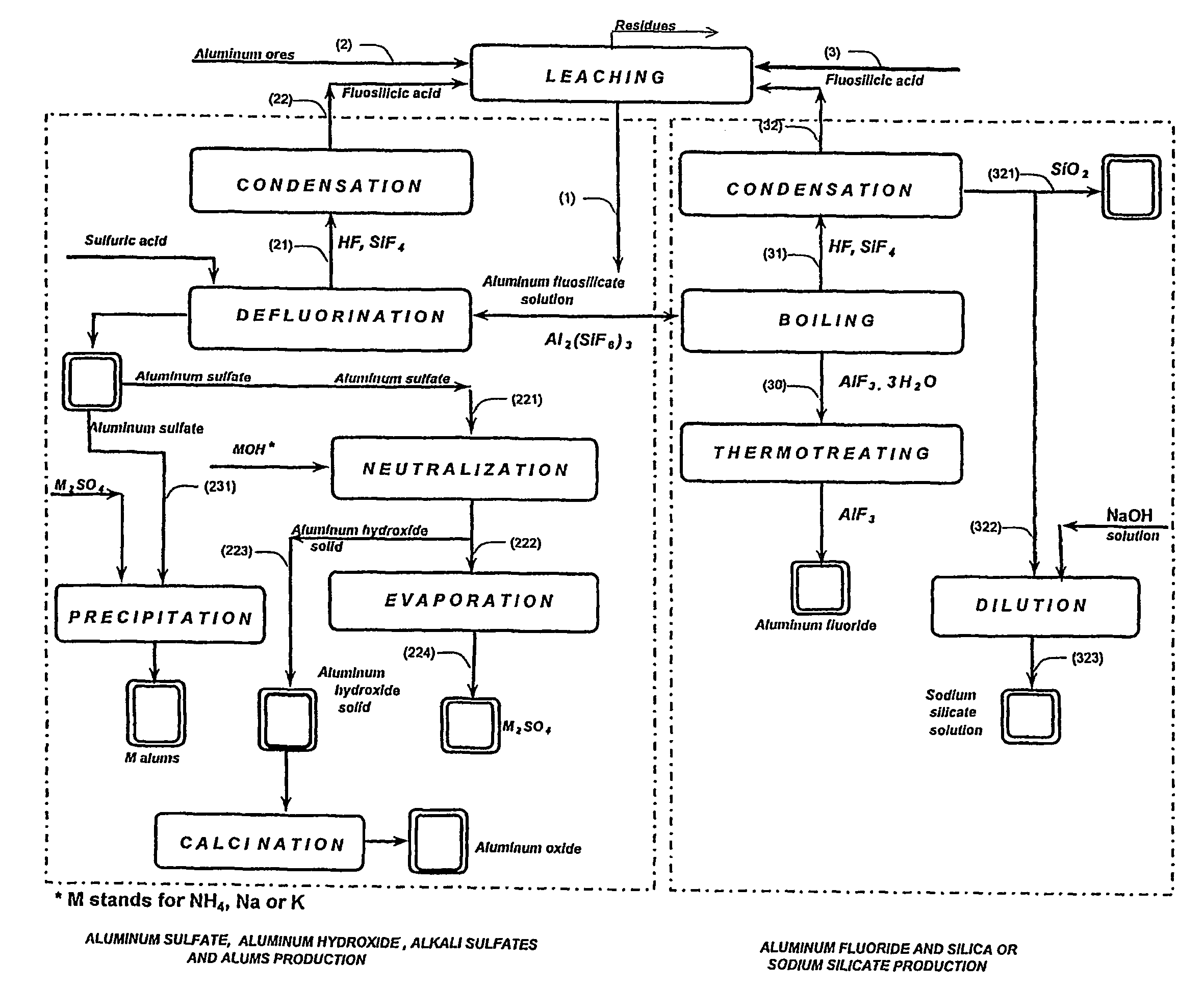

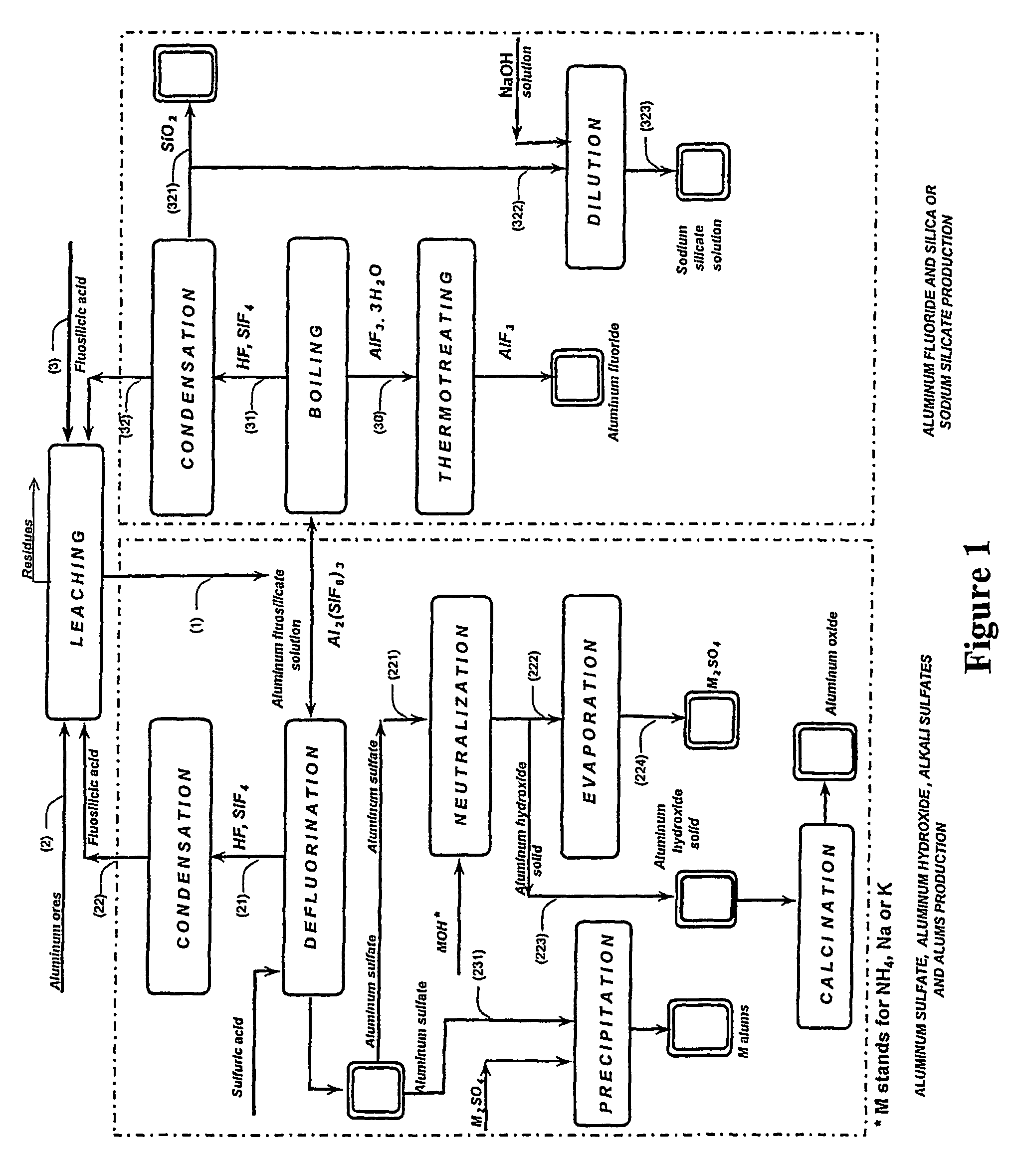

Production of aluminum compounds and silica from ores

A method for the production of inorganic aluminum substances and amorphous silica from aluminum oxide containing ores, comprising: (a) leaching of said ores with fluorosilicic acid to obtain aluminum fluosilicate solution; (b) filtering said leached solution from insoluble materials; and (c) washing said insoluble materials.

Owner:ATI ALUMINUM TECH ISRAEL

Process for producing lithium-containing composite oxide for positive electrode for lithium secondary battery

InactiveUS20070026314A1Improve securityImprove featuresElectrode manufacturing processesFluoride preparationAlkaline earth metalOrganic solvent

It is to provide a positive electrode active material for a lithium secondary battery, which has a large volume capacity density, high safety, excellent properties for uniform coating, excellent durability for charge and discharge cycles and low temperature characteristics even at a high charge voltage. A process for producing a lithium-containing composite oxide represented by the formula LipNxMmOzFa (wherein N is at least one element selected from the group consisting of Co, Mn and Ni, M is at least one element selected from the group consisting of Al, alkaline earth metal elements and transition metal elements other than N, 0.9≦p≦1.2, 0.9≦x<1.00, 0<m≦0.03, 1.9≦z≦2.2, x+m=1 and 0≦a≦0.02), which comprises using a solution comprising a complex containing the M element (M element-containing complex) dissolved in an organic solvent, an N source and a lithium source, and if necessary, a fluorine source, by means of a mixing step, an organic solvent removal step and a firing step.

Owner:SEIMI CHEM CO LTD

Comprehensive utilization method of coal gangue

ActiveCN104258804AHigh yieldOvercoming the problem of poor solubilityOther chemical processesSolid waste disposalSilicon dioxideMaterials science

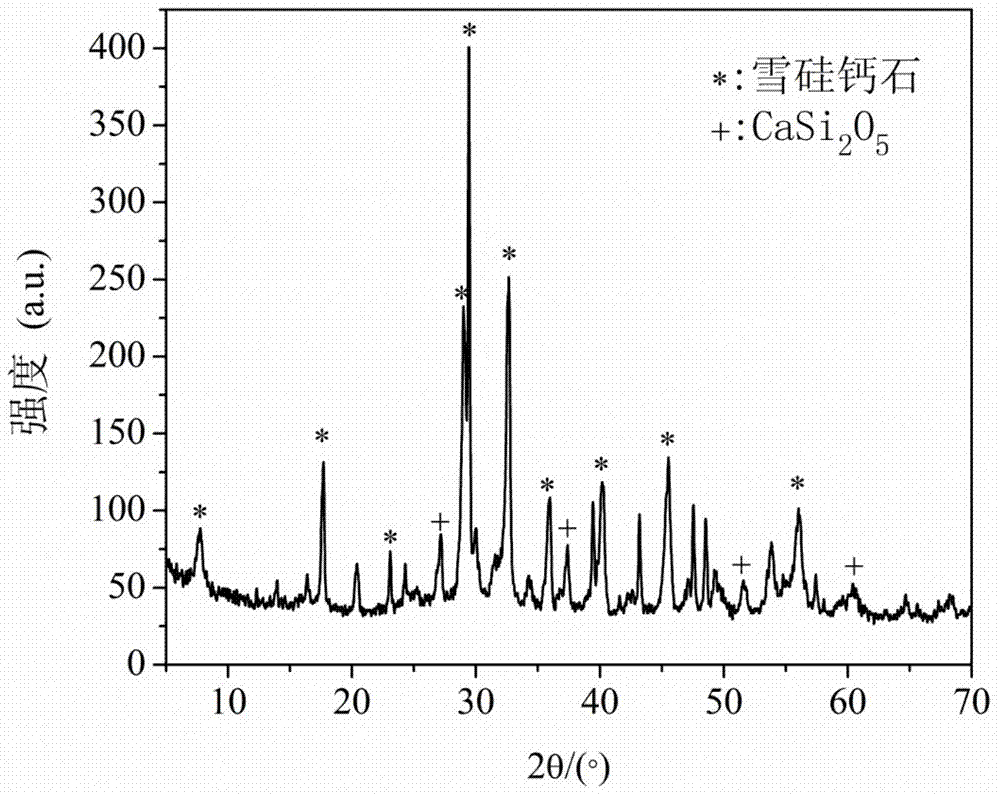

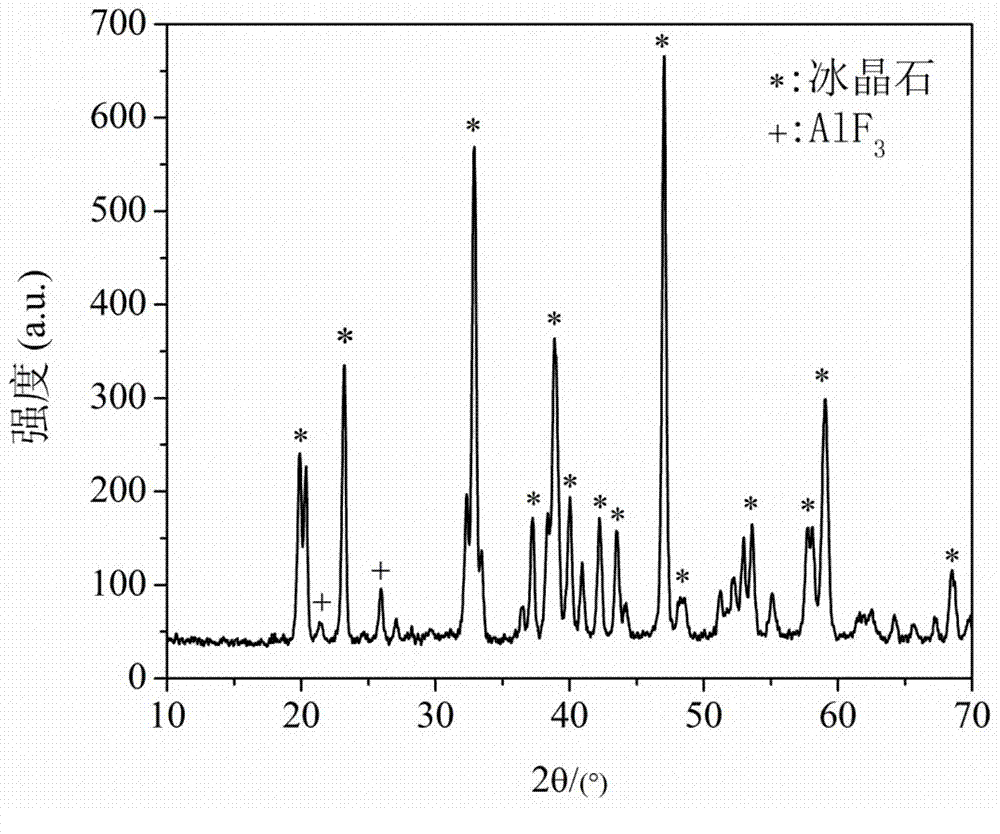

The invention discloses a comprehensive utilization method of coal gangue. The comprehensive utilization method of the coal gangue comprises the following steps: separating alumina-silica of coal gangue by adopting a baking, crushing, sulfuric acid leaching and centrifugal separation method, thereby obtaining an aluminum salt Al2(SO4)3 solution and filter residues (SiO2); adding slaked lime (Ca(OH)2) into the filter residues, adding caustic soda NaOH according to the molar ratio of Ca / Na of 1 to (1.0-2.0), and carrying out hydrothermal autoclaved reaction at 160-180 DEG C for 16-18 hours by adopting a hydrothermal autoclaved method so as to synthesize a tobermorite sewage treatment adsorption material with a good crystallization state; compounding sodium hydrogen fluoride NaHF2 formed by sodium fluoride NaF and hydrofluoric acid HF with the leached supernate Al2(SO4)3 solution, and carrying out full reaction under stirring for 1-1.5 hours so as to synthesize cryolite. The invention provides a solution for preparing the tobermorite sewage adsorption material by utilizing silicon dioxide in coal gangue and preparing cryolite by utilizing the alumina component; and the obtained materials have a favorable application prospect, and the aim of preparing materials with high additional value by comprehensively utilizing coal gangue is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

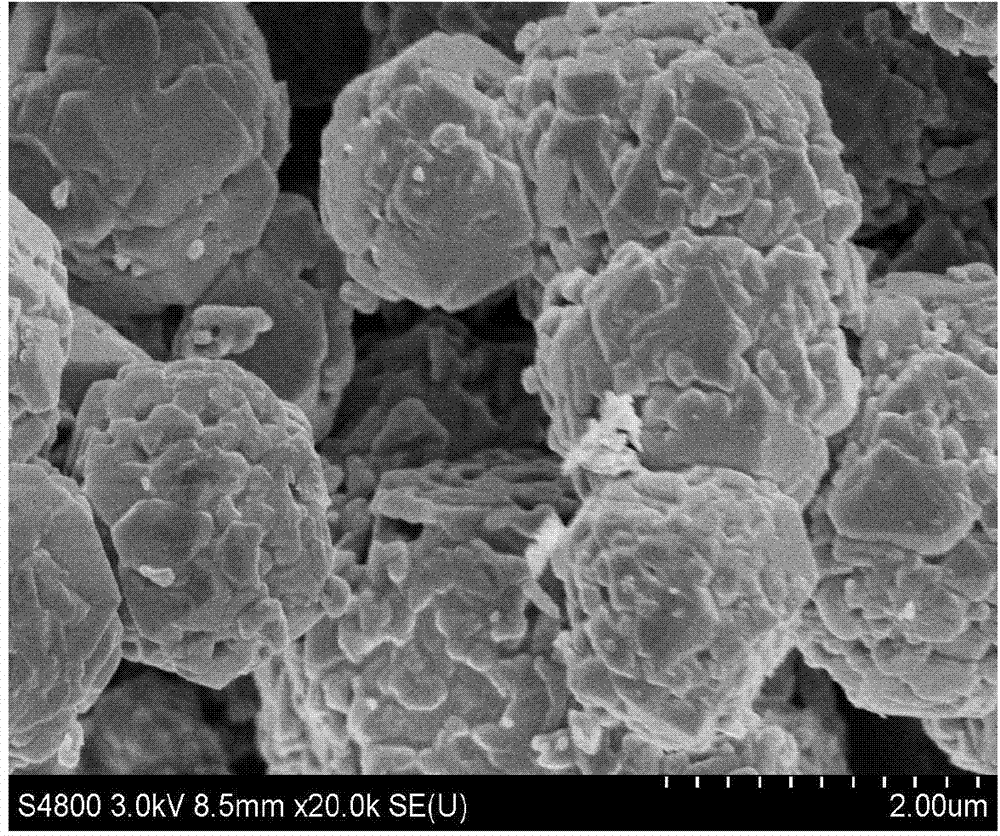

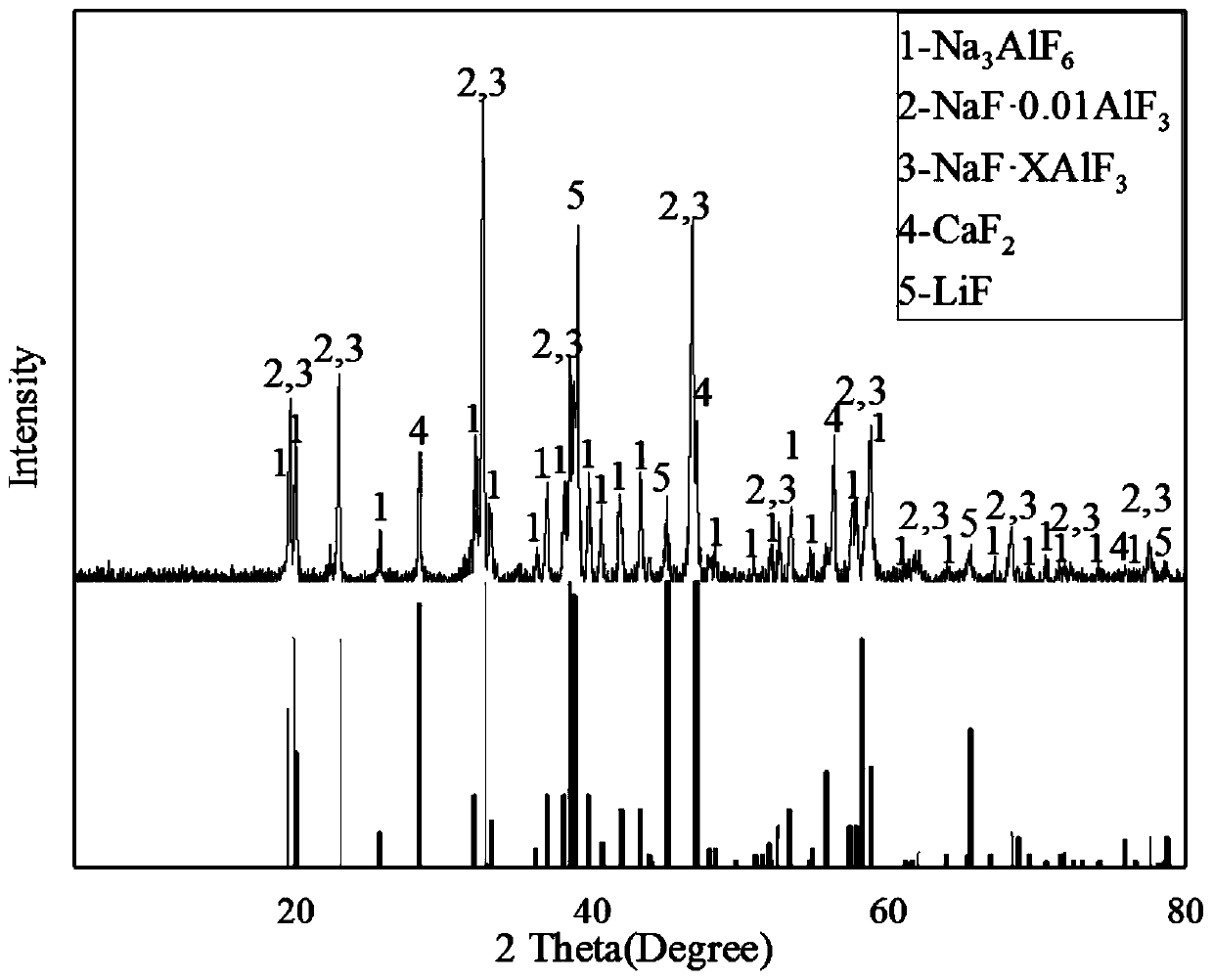

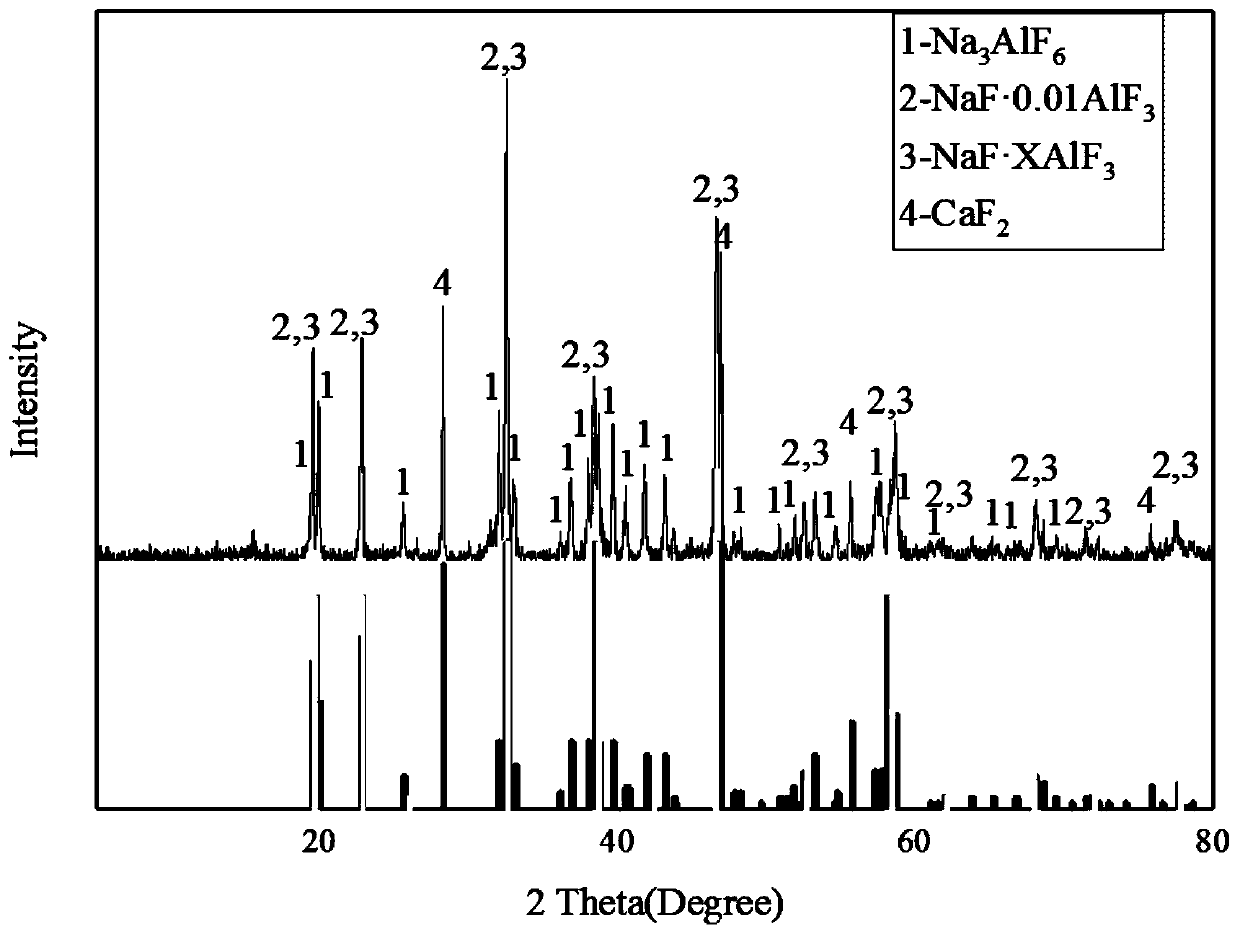

Resource treatment method for lithium-rich aluminum electrolyte

ActiveCN110240182AChange molecular ratioEasy to operateCalcium/strontium/barium fluoridesAlkali metal nitratesAluminum IonInorganic salts

The invention relates to a resource treatment method for a lithium-rich aluminum electrolyte. The method comprises the following steps: firstly performing heat treatment on the lithium-rich aluminum electrolyte to obtain a product A; performing leaching treatment on the roasting product A with a water-soluble inorganic salt as a leaching agent in water, and performing filtering to obtain a filter residue B and a filtrate B; adding an alkali or an aqueous solution of the alkali to the filtrate B to remove aluminum ions in the filtrate B to obtain a filtrate C; and adding a water-soluble carbonate or an aqueous solution of the carbonate to the filtrate C to make lithium ions in the filtrate C be converted into lithium carbonate precipitation, and then performing filtering to obtain lithium carbonate and a filtrate D. The technical problem perplexing aluminum electrolysis industry of rich and high content lithium in an excess aluminum electrolyte and inefficient utilization of valuable metals is solved, the economic benefit is improved, and stable production of an electrolytic aluminum enterprise is promoted.

Owner:CENT SOUTH UNIV

Method for producing aluminun fluoride

The present invention relates to process of producing aluminum fluoride with fluorosilicic acid and aluminum hydroxide as material. The process includes the following steps: 1. reacting fluorosilicic acid solution and sodium sulfate for 10-60 min, filtering to obtain solid sodium fluorosilicate and waste sulfuric acid solution to be treated and drained; 2. decomposing aluminum fluorosilicate at 300-800 deg.c for 1-5 hr to produce solid sodium fluoride and silicon tetrafluoride gas; 3. absorbing silicon tetrafluoride gas with water and hydrolyzing, filtering to obtain fluorosilicic acid solution to be returned to the step 1 and solid silica, and washing and drying silica to obtain carbon white; 4. reacting solid sodium fluoride and sulfuric acid, condensing, rectifying to obtain anhydrous hydrofluoric acid and solid sodium sulfate returned to the step 1; and 5. reacting anhydrous hydrofluoric acid and aluminum hydroxide to produce aluminum fluoride product. The process is environment friendly.

Owner:DO FLUORIDE CHEM CO LTD

Process for producing lithium-containing composite oxide for positive electrode for lithium secondary battery

ActiveUS20070254214A1Improve featuresLarge volume capacity densityElectrode manufacturing processesFluoride preparationAlkaline earth metalVolumetric Mass Density

To provide a process for producing a lithium-containing composite oxide for a positive electrode for a lithium secondary battery, which is excellent in the volume capacity density, safety, charge and discharge cycle durability and low temperature characteristics. A process for producing a lithium-containing composite oxide represented by the formula LipNxMmOzFa (wherein N is at least one element selected from the group consisting of Co, Mn and Ni, M is at least one element selected from the group consisting of Al, alkaline earth metal elements and transition metal elements other than N, 0.9≦p≦1.2, 0.97≦x<1.00, 0<m≦0.03, 1.9≦z≦2.2, x+m=1 and 0≦a≦0.02), which process comprises is firing a mixture of a lithium source, an N element source and an M element source, and if necessary, a fluorine source, in an oxygen-containing atmosphere, characterized in that as the M element source, an aqueous solution of a ketocarboxylate compound having the M element, at least one carboxyl group and at least one carbonyl group in its molecule, is used.

Owner:SUMITOMO CHEM CO LTD

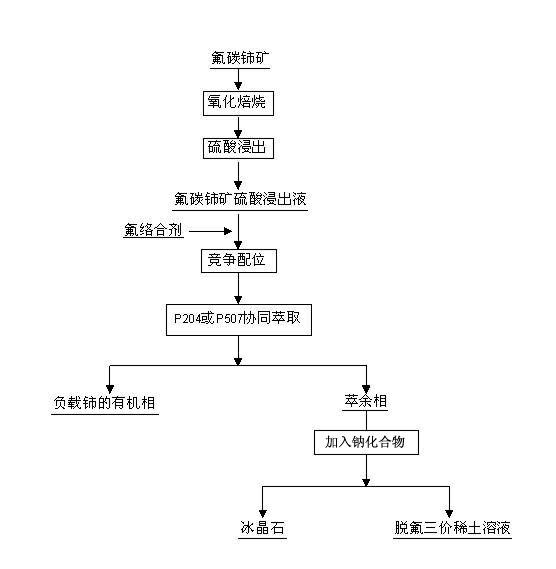

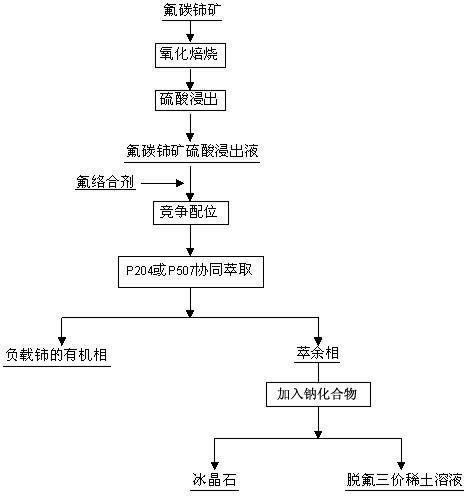

Method used for separating rare earth from bastnaesite sulphuric acid leach solution and preparing ice stone

InactiveCN102653823AAchieve the purpose of separationGood coordination abilityAluminium fluoridesProcess efficiency improvementPregnant leach solutionCerium

The invention belongs to the technical field of rare earth hydrometallurgy, and specifically relates to a method used for separating rare earth from a bastnaesite sulphuric acid leach solution and preparing an ice stone. The method comprises the following steps of: adding aluminium salt as a fluorine complexing agent in a bastnaesite sulphuric acid leach solution, mixing an extraction agent and a diluting agent to obtain an organic phase, mixing the organic phase and the bastnaesite sulphuric acid leach solution according to the volume ratio of (1-10):1, vibrating for 5-60 minutes, and splitting phase after standing for 10-60 minutes; and obtaining the organic phase of loading cerium and an extractive surplus phase containing fluorine and trivalence rare earth, adding a sodium compound in the extractive surplus phase, adjusting pH to 2-5, obtaining Na3AlF6 precipitation, namely the ice stone, carrying out solid-liquid separation, and obtaining the trivalence rare earth solution after defluorination. Compared with the prior art, the method provided by the invention reduces the generation of three wastes containing fluorine due to fluorine recovery, greatly lightens the environmental pollution from a flow, can carry out reclamation utilization on fluorine in a water phase, and reduces the waste of a fluorine resource.

Owner:NORTHEASTERN UNIV LIAONING

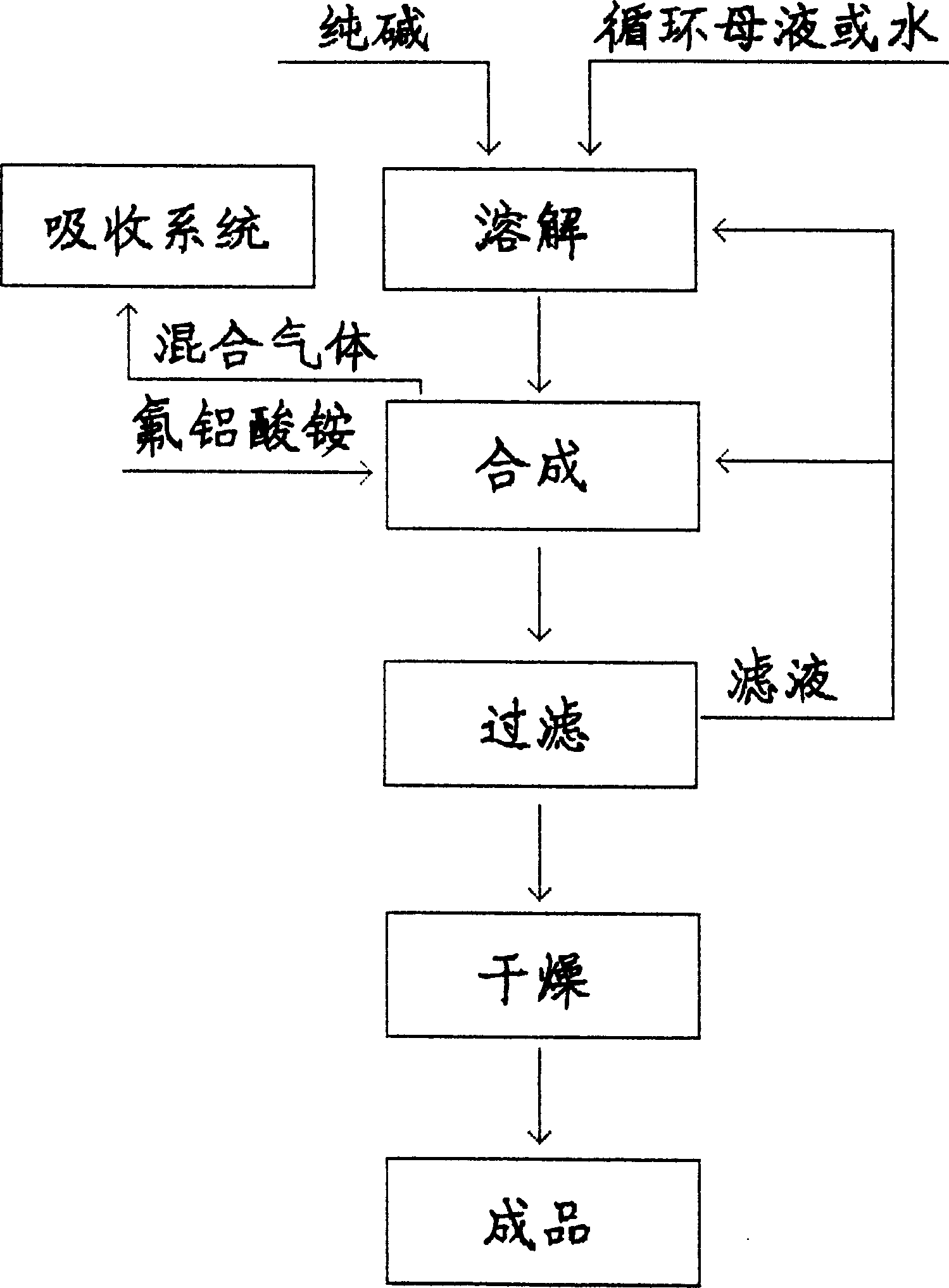

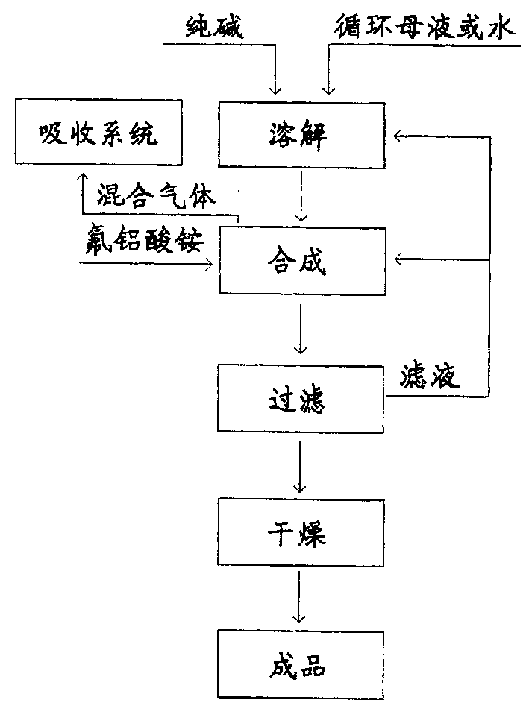

Method for producing cryolite

InactiveCN1456507ALess investmentReduce manufacturing costAluminium fluoridesAqueous solutionAmmonium

A process for preparing cryolite includes such steps as reacting between ammonium fluoroaluminate and sodium carbonate in water plase at 90-100 deg.C, filtering, and drying at 150-300 deg.C. The gas generated by reaction can be absorbed to obtain by-product. Its advantages are simple process and no environmental pollution.

Owner:DO FLUORIDE CHEM CO LTD

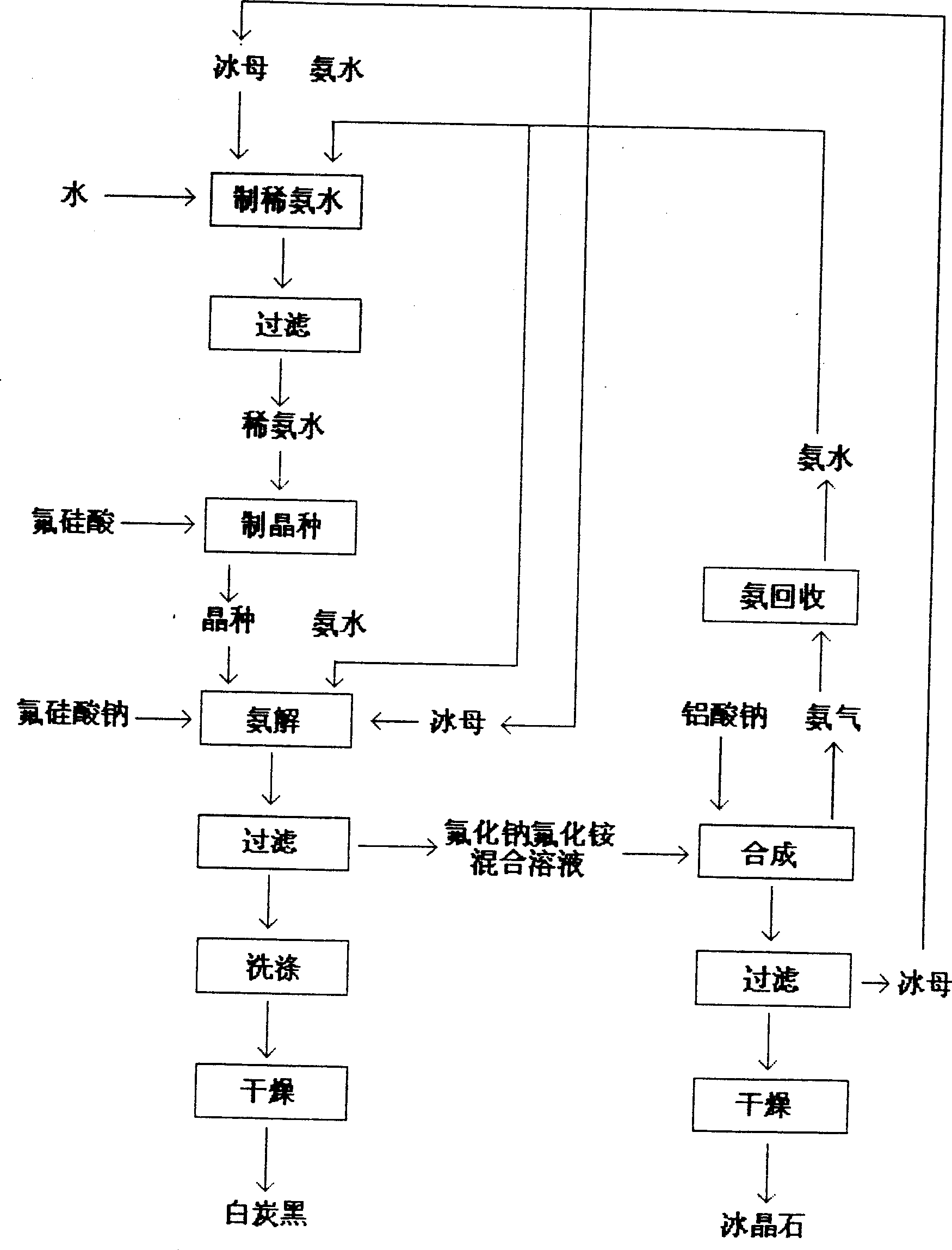

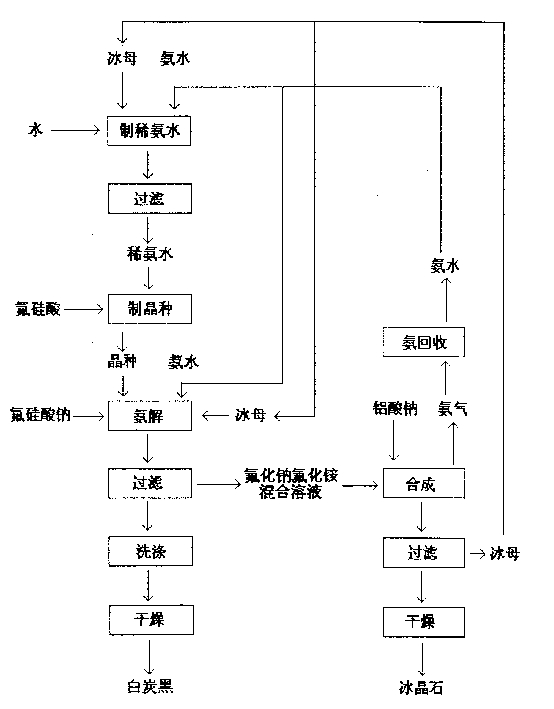

Method for simultaneously producing sodium aluminofluoride and silica white

InactiveCN1515493ALower molecular ratioHigh puritySilicon oxidesAluminium fluoridesReaction temperatureSodium aluminate

The method for producing ice spar and coproducing white carbon black includes the following steps: (1) adding ice mother and ammonia water in water to prepare dilute ammonia water, making fluorosilicic acid solution react with dilute ammonia water to obtain white carbon black crystal seed, controlling pH value of white carbon black in 6-8 and reaction temp. at 30-40 deg.C; (2). adding a certain quantity of white carbon black crystal seed into ammonolysis cell, in which the added quantity of crystal seed can be regulated according to the requirements, adding proper quantity of ice mother, in the presence of crystal seed making sodium fluorosilicate and ammonia water implement ammonolysis reaction at about 60 deg.C to obtain white carbon black slurry, filtering and washing to obtain white carbon black ointment, drying to obtain its finished product; (3). providing the steps for obtain ice spar product.

Owner:DO FLUORIDE CHEM CO LTD

Method for recycling and utilizing electrolytic aluminum fluorine-containing resources

The invention relates to the technical field of recycling and utilization of fluorine-containing resources in the electrolytic aluminum industry, in particular to a method for recycling and utilizingelectrolytic aluminum fluorine-containing resources. The method for recycling the electrolytic aluminum fluorine-containing resources comprises the step of leaching electrolytic aluminum fluorine-containing waste residues, and the step of leaching the electrolytic aluminum fluorine-containing waste residues is: mixing the electrolytic aluminum fluorine-containing waste residues with a leaching agent, and adding water to prepare a mixed reaction solution with a solid content of 3 to 60%, and performing leaching reaction on the mixed reaction solution at 10 to 150 DEG C to obtain a mixed leaching solution. The method for recycling and utilizing the electrolytic aluminum fluorine-containing resources, which is provided by the invention, mainly uses the leaching agent to leach fluorides in theelectrolytic aluminum fluorine-containing waste residues, and transfers valuable elements fluorine and aluminum in the electrolytic aluminum fluorine-containing waste residues to a liquid phase; thesum of the mass percentages of the fluorine element and the aluminum element in filtrate obtained by filtration is 1 to 50%. The method for recycling and utilizing the electrolytic aluminum fluorine-containing resources, which is provided by the invention, provides a possibility for further treatment to obtain fluorine-containing and aluminum-containing products.

Owner:湖南绿脉环保科技股份有限公司

Crystal form transformation method of lithium-containing aluminum electrolyte

ActiveCN107587167AIncrease productionReduce energy consumptionAluminium fluoridesProcess efficiency improvementAluminum fluorideLithium

The invention discloses a crystal form transformation method of lithium-containing aluminum electrolyte and relates to the technical field of extraction and recycling of aluminum electrolyte. The crystal form transformation method comprises the following steps: S1, crushing the lithium-containing aluminum electrolyte; S2, mixing an additive with the aluminum electrolyte powder; uniformly mixing toobtain a mixed material, wherein the additive is one or more of alkali metal oxide except lithium, alkali metal oxysalt except the lithium, which can be transformed into alkali metal oxide under a high-temperature roasting condition, and alkali metal halide except the lithium, and the mol ratio of alkali metal fluoride in the aluminum electrolyte, alkali metal fluoride which is directly added into the additive and alkali metal fluoride which can be formed by the additive under the high-temperature roasting condition to aluminum fluoride in the mixed material is greater than 3; S3, roasting the mixed material at high temperature. According to the crystal form transformation method disclosed by the invention, insoluble lithium salt in the aluminum electrolyte can be transformed into solublelithium salt so that the leaching rate of the lithium salt is improved, the purity of the aluminum electrolyte is improved and the production energy consumption of electrolytic aluminum is reduced.

Owner:NORTHEASTERN UNIV

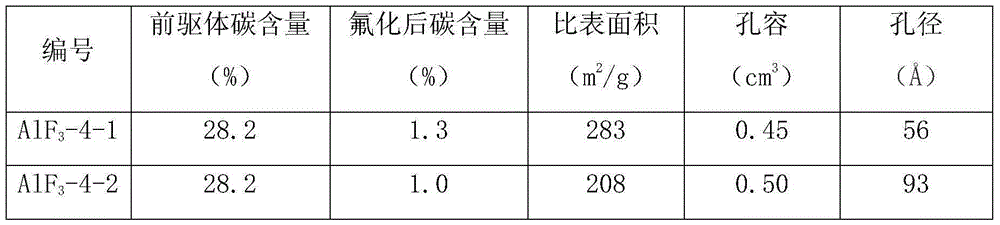

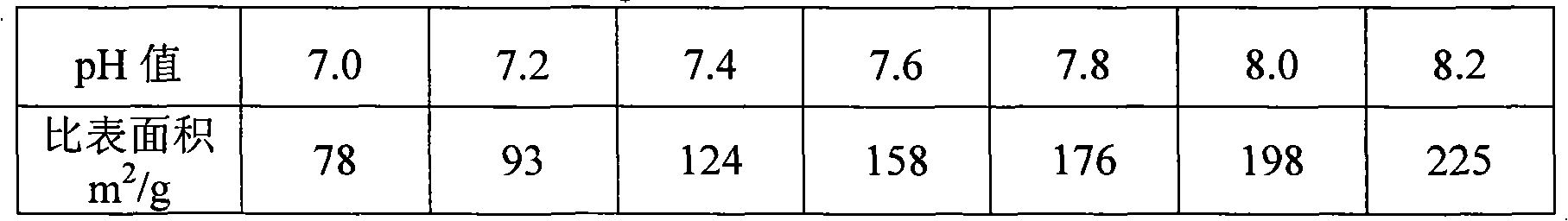

Aluminum fluoride catalyst with high specific surface area and application thereof

ActiveCN106256429AShorten the fluoridation timeWon't clogPreparation by hydrogen halide split-offPhysical/chemical process catalystsAluminum fluorideAlcohol

The invention discloses an aluminum fluoride catalyst with a high specific surface area. Ethyl ether of HF and / or an alcoholic solution are / is firstly added into an organic aluminum solution for reacting to obtain a catalyst precursor, and then the aluminum fluoride catalyst is obtained through fluoridation. The specific surface area of the aluminum fluoride catalyst can reach 200 m<2> / g to 320 m<2> / g, and the aluminum fluoride catalyst is suitable for synthesis of 1-chloro-2,2,2-halothane or 3,3,3-trifluoropropene or 1,1,1,2,3-pentachloropropane or 2,3,3,3-tetrafluoropropene.

Owner:陕西中化蓝天化工新材料有限公司 +2

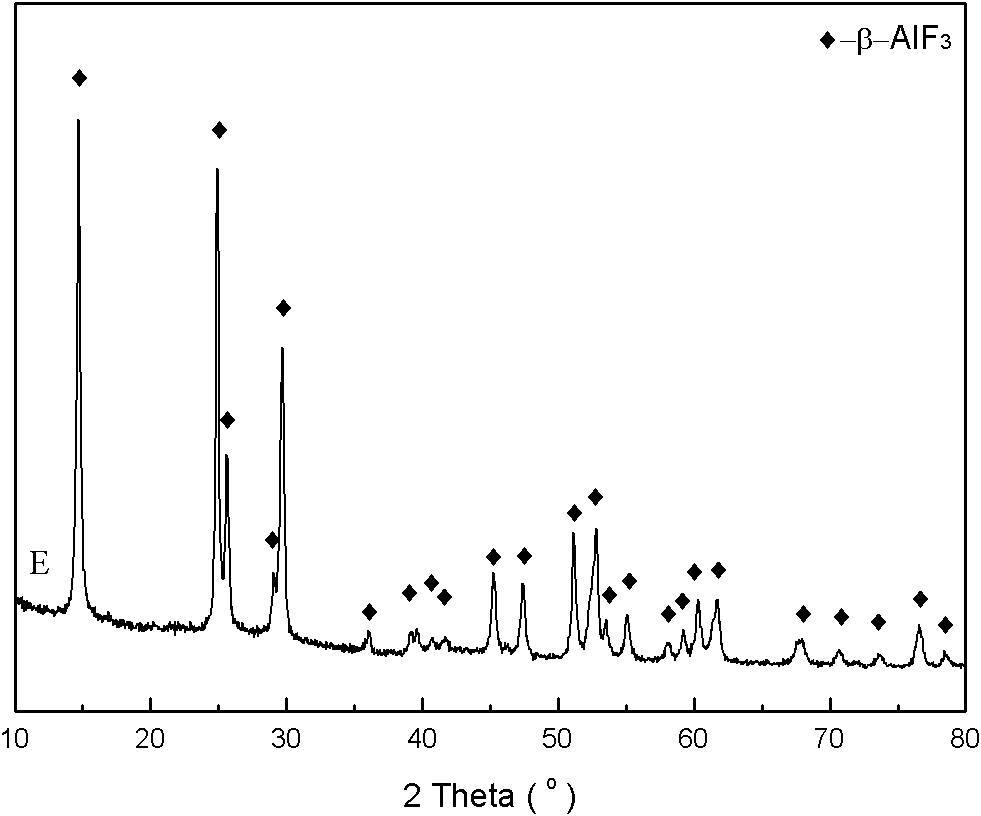

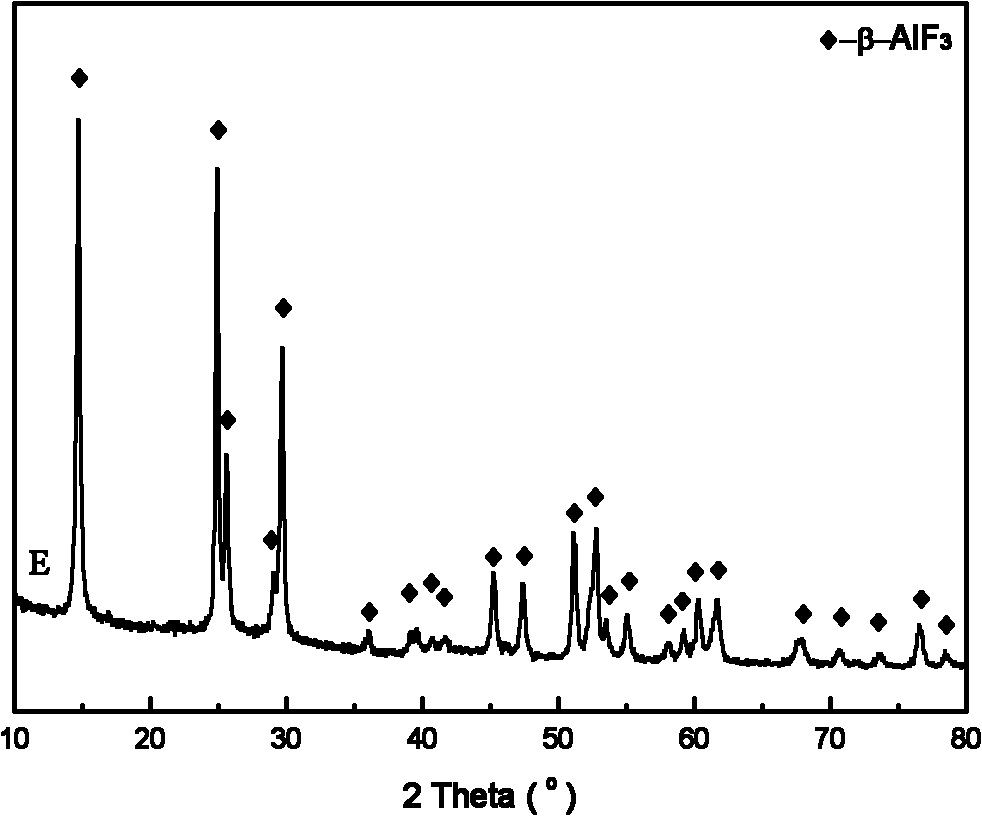

Preparation method of beta-aluminum fluoride with high specific surface area

InactiveCN101863502ALarge specific surface areaHigh purityAluminium fluoridesAluminum fluorideAqueous solution

The invention relates to a preparation method of beta-aluminum fluoride with high specific surface area. Against for the defects of the prior art for preparing the aluminum fluoride with high specific surface area that the preparation process is complicated, the preparation period is long, the operation and the control are difficult, and the corrosion on the device is large, the invention provides a preparation method of beta-aluminum fluoride with high specific surface area with simple preparation process, short preparation period, easy operation and control and small corrosion on the device. The invention adopts the technical scheme that: gamma-alumina, carbon source and HF gas are adopted as raw materials, water solution of carbon source is soaked into the gamma-alumina in an equivalent soaking method, the gamma-alumina after being soaked with the carbon source is dried and carbonized to obtain gamma-alumina containing carbon, then the gamma-alumina containing the carbon is reacted with HF gas to obtain the aluminum fluoride containing carbon, and finally the aluminum fluoride containing the carbon is decarbonized, acidified, washed, dried and roasted to obtain the beta-aluminum fluoride with high specific surface area.

Owner:ZHEJIANG NORMAL UNIVERSITY

Method for continuously producing aluminium electrolysis raw materials high-fluorine alumina, cryolite and sodium silicate with aluminum dust

ActiveCN101823741ASolve pollutionReduce energy consumptionAlkali metal silicatesAluminium fluoridesAluminium electrolysisEvaporation

The invention discloses a method for continuously producing aluminium electrolysis raw materials high-fluorine alumina, cryolite and sodium silicate with aluminum dust, which comprises the following steps that: aluminum gray is added with water, soaked and filtered, the filtrate is evaporated and concentrated to obtain a NaCl and KCL mixed crystal; filter residue is calcined for 15 to 60min at 750 to 950DEG C; 0.5 to 10 percent HF solution which contains 10 to 40ml of oxidant is added into a calcined product by the solid-liquid ratio of 1:1 to 1:10 to be soaked and react for 30 to 180min under the stirring at 100 to 1000r / min; the solution is filtered, the solid after the evaporation and the concentration of the filtrate is dried to prepare cryolite according to the prior art; the cryolite evaporation mother liquor reacts with NaOH to prepare the sodium silicate according to the prior art; and the filter residue is dried for 12h at 90 to 110 DEG C, and the high-fluorine alumina which contains MgF2 is obtained. The method can continuously produce high- fluorine alumina, cryolite and sodium silicate with high activity for an electrolyzer, is environmental-friendly during the production process, has energy consumption far lower than that of a traditional process and short process, and is simple to operate.

Owner:中南大学科技园(湖南)发展有限公司

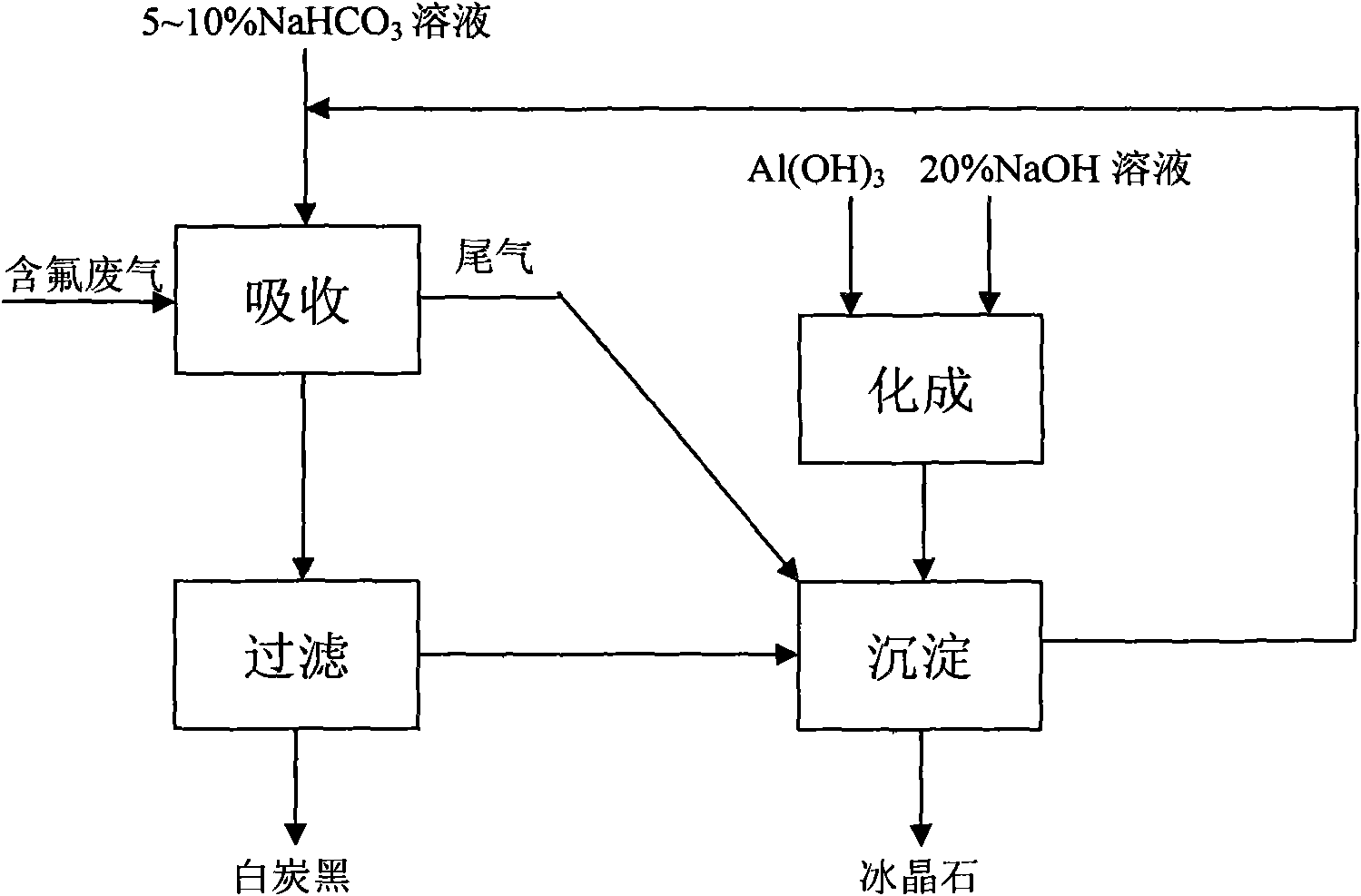

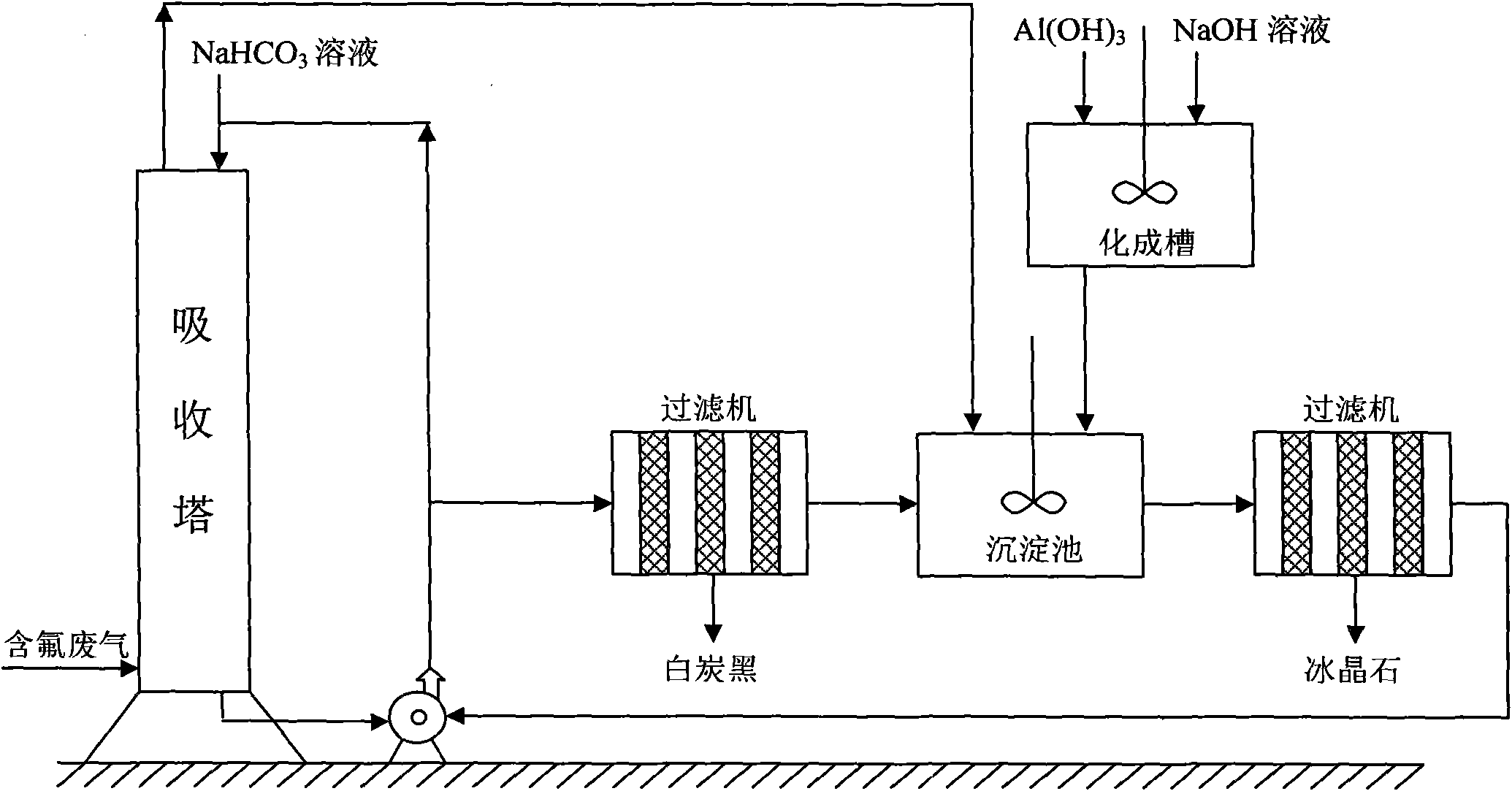

Method for preparing high-molecule-ratio cryolite by using phosphoric acid industrial fluorine-containing waste gas

InactiveCN102464347AAvoid pollutionTake advantage ofAluminium fluoridesSodium bicarbonatePhosphoric acid

The invention relates to a method for preparing high-molecule-ratio cryolite by using phosphoric acid industrial fluorine-containing waste gas, belonging to the field of inorganic chemical engineering. Fluorine-containing waste gas is absorbed by adopting circulation of a sodium bicarbonate solution, so that the problems of secondary pollution and high processing cost in a process of treating the fluorine-containing waste gas are solved, and chemical products such as cryolite, white carbon black, and the like with high additional value are prepared at low cost by using the fluorine-containing waste gas. The principle is as follows: HF and SiF4 in the fluorine-containing waste gas are absorbed by using sodium bicarbonate so as to generate NaF and SiO2.H2O; by using the characteristic that the NaF is slightly dissolved in water and SiO2.H2O is not dissolved in a NaHCO3 solution, the SiO2.H2O is removed through filtering and further processed into white carbon black; and the white carbon black with high specific surface area can be prepared through changing the pH of an absorption solution. The filtered NaF solution reacts with NaAlO2, and CO2 is blown, so that the cryolite can be prepared; and the cryolite with molecule ratio of more than 2.90 can be prepared through controlling excessive percentage of the NaF. The invention can be used in treatment of the fluorine-containing waste gas in phosphoric acid and phosphatic fertilizer industries.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com