Method for recycling and utilizing electrolytic aluminum fluorine-containing resources

A technology of electrolytic aluminum and resources, applied in the direction of aluminum fluoride, aluminum halide, etc., can solve problems such as environmental hazards and waste of valuable resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

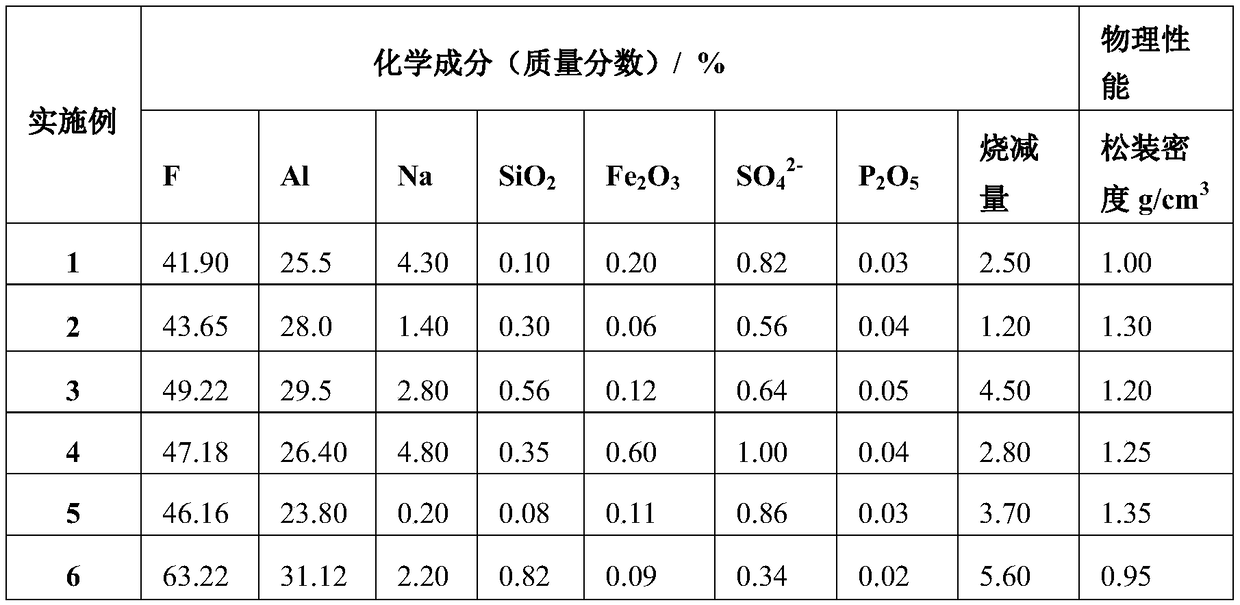

Embodiment 1

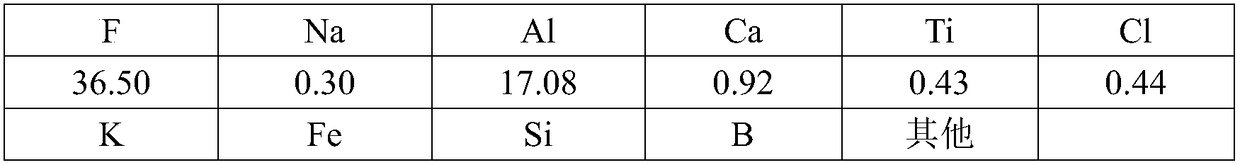

[0022] Get 200kg of high-molecular-ratio electrolytes pulled out from the electrolyzer. The analysis of electrolyte components is as shown in Table 1. Grind it into powder, add 400kg of water to make raw material slurry; prepare 400kg of leaching agent, the consumption is 40%. The ratio is 25% of aluminum sulfate, 5% of sodium sulfate, and the rest is water. The raw material slurry and the leaching agent were mixed and stirred in the reactor, heated to 86°C, and kept for 1.5h. After the reaction was completed, 35kg of the dissolved residue was obtained by filtration, and the filtrate was neutralized with NaOH to obtain 213kg of precipitate, which was roasted at 550°C to obtain 182kg The product, the component analysis of gained product is shown in Table 7.

[0023] Table 1 Analysis of the electrolyte components taken out of the electrolyzer

[0024] F

Embodiment 2

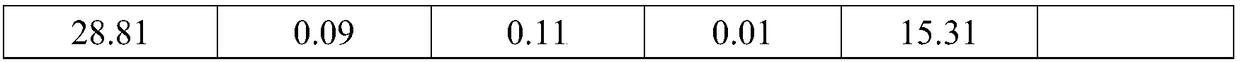

[0026] Take 500kg of carbon slag fished out from the electrolytic cell. The composition analysis of the carbon slag is shown in Table 2. Add the carbon slag to the wet mill, add 2t of water during the grinding process, and 600kg of leaching agent. The ratio of the leaching agent is aluminum nitrate 55%, sodium chloride 25%, aluminum chloride 20%, grind for 2 hours to make slurry 2.1t. Transfer the prepared slurry to the reaction kettle, heat it to 72°C, and keep it warm for 1 hour. After the reaction is completed, filter to obtain 115kg of dissolved residue. The filtrate is neutralized with NaOH to obtain 375kg of precipitate, which is roasted at 680°C to obtain 310kg of product , the composition analysis of the obtained product is shown in Table 7.

[0027] Table 2 Carbon slag composition analysis

[0028] F

Embodiment 3

[0030] Get the regenerated cryolite obtained by 300kg carbon slag flotation, the component analysis of the regenerated cryolite is shown in Table 3, this regenerated cryolite is added in the slurry tank, add water 1.6t, leaching agent 200kg, the ratio of leaching agent is Aluminum chloride 74%, aluminum sulfate 26%, made into slurry 2.1t. Transfer the prepared slurry to the reaction kettle, heat it to 94°C, and keep it warm for 3 hours. After the reaction is completed, filter to obtain 43kg of dissolved residue. The filtrate is neutralized with NaOH to obtain 308kg of precipitate, which is roasted at 660°C to obtain 278kg of product , the composition analysis of the obtained product is shown in Table 7.

[0031] Table 3 Composition analysis of cryolite regenerated by carbon slag flotation

[0032] F

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com