Method for preparing high-molecule-ratio cryolite by using phosphoric acid industrial fluorine-containing waste gas

A technology of cryolite and waste gas, applied in the direction of aluminum fluoride and aluminum halide, etc., can solve the problems of lack of green fluorine-containing waste gas, not put into use, high energy consumption, etc., achieve the effect of non-toxic raw materials, avoid pollution, and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

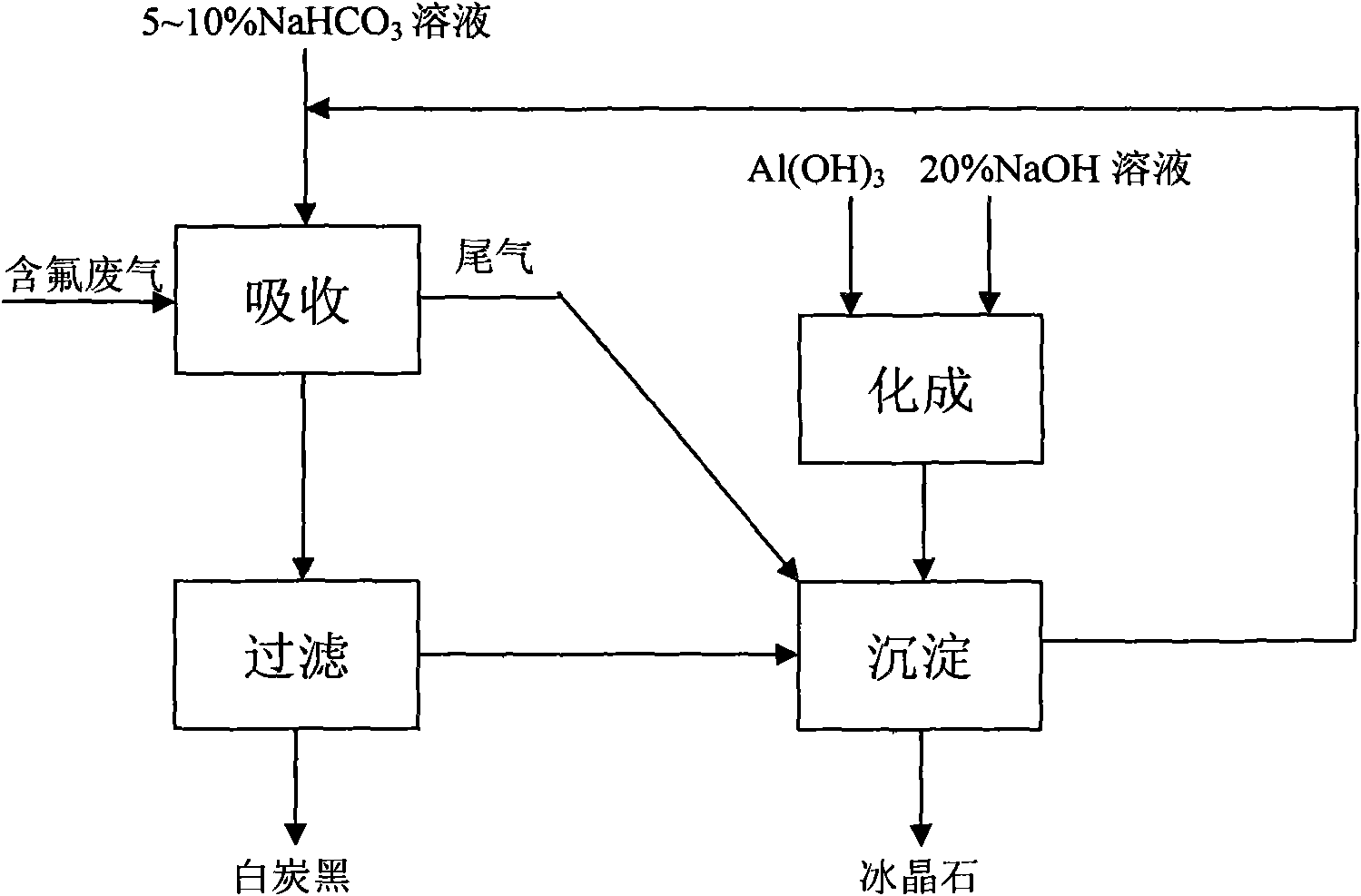

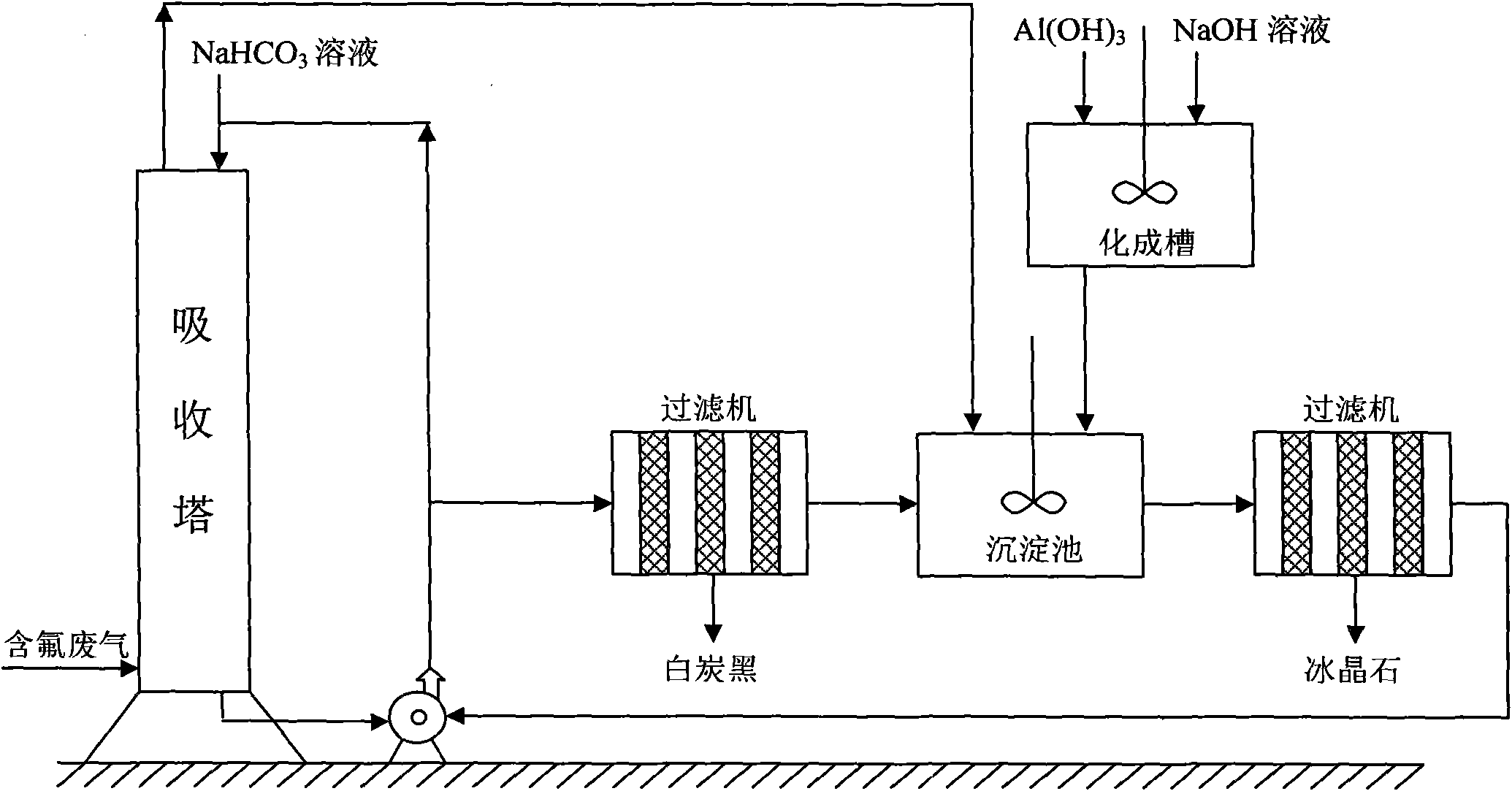

Method used

Image

Examples

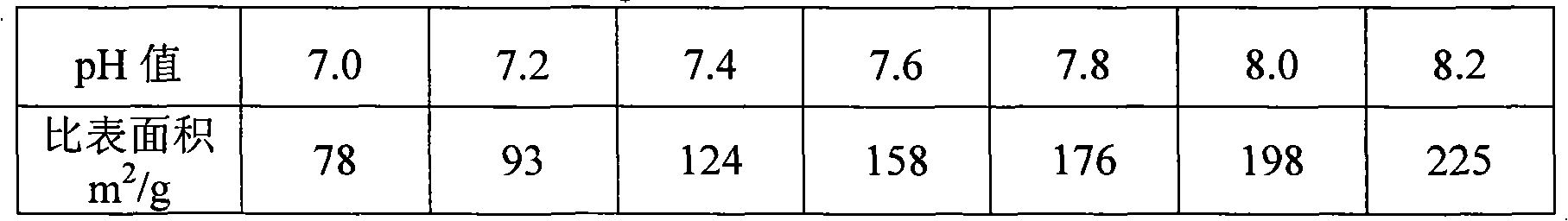

Embodiment 1

[0046] Will be composed of 2.5% (volume ratio) HF and 1.7% (volume ratio) SiF 4 The fluorine-containing waste gas composed of air and ceramic Raschig ring packed tower is absorbed with 5% sodium bicarbonate solution. Control the reflux ratio = 5, make the pH of the absorption solution = 7.5, and the tail gas contains 0.023% HF and SiF after detection 4 0.028%, that is, the absorption rate of HF has reached 99.1%, and the absorption rate of SiF 4 The absorption rate reached 98.4%. Raise the temperature of the absorption solution to 90°C, add polyacrylamide with a total amount of 0.05% of the precipitate into the solution as a flocculant, keep it warm for 2 hours, cool to 30°C at a cooling rate of 15°C / h and filter, and wash the filter residue twice with water , then dried at 110°C for 2h, and calcined at 250°C for 3h to obtain a specific surface area of 147m 2 / g of white carbon black. Then the theoretical amount of 95% aluminum hydroxide is reacted with 20% sodium hydro...

Embodiment 2

[0056] The ceramic Raschig ring in the absorption tower packing in the embodiment 1 is replaced by the plastic Pall ring, adopts 8% NaHCO 3 The solution absorbs. Control the reflux ratio = 6, make the pH of the absorption solution = 7.8, and the tail gas contains 0.014% HF and SiF after detection 4 0.013%, that is, the absorption rate of HF reaches 99.4%, and the absorption rate of SiF 4 The absorption rate reached 99.2%. Raise the temperature of the absorption solution to 90°C, add polyacrylamide with a total amount of 0.08% of the precipitate into the solution as a flocculant, keep it warm for 2 hours, cool to 40°C at a cooling rate of 10°C / h and filter, and wash the filter residue with water 4 times , then dried at 120°C for 2h, and calcined at 300°C for 2h to obtain a specific surface area of 172m 2 / g of white carbon black. Then react the theoretical amount of 98% aluminum hydroxide with 20% sodium hydroxide solution to obtain ~29% sodium metaaluminate solution, th...

Embodiment 3

[0066] The gas composition is still the same as that of the above-mentioned embodiment, and the packing of the absorption tower adopts a plastic Pall ring, and adopts 10% NaHCO 3 The solution absorbs. Control the reflux ratio = 6, make the pH of the absorption solution = 8.0, and the tail gas contains 0.012% HF and SiF after detection 4 0.011%, that is, the absorption rate of HF has reached 99.5%, and the absorption rate of SiF 4 The absorption rate reached 99.4%. Raise the temperature of the absorption solution to 90°C, add polyacrylamide with a solid content of 0.1% in the solution as a flocculant, keep it warm for 3 hours, cool to 40°C at a cooling rate of 10°C / h and filter, wash the filter residue 4 times with water, and then Dry at 120°C for 1 hour, then calcinate at 300°C for 2 hours to obtain a specific surface area of 196m 2 / g of white carbon black. Then react the theoretical amount of 95% aluminum hydroxide with 20% sodium hydroxide solution to obtain 28% sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com