Patents

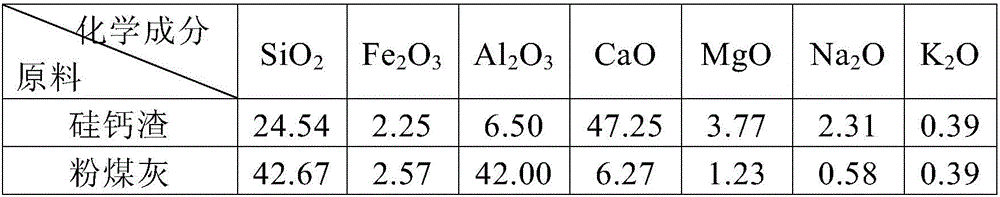

Literature

99 results about "Tobermorite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

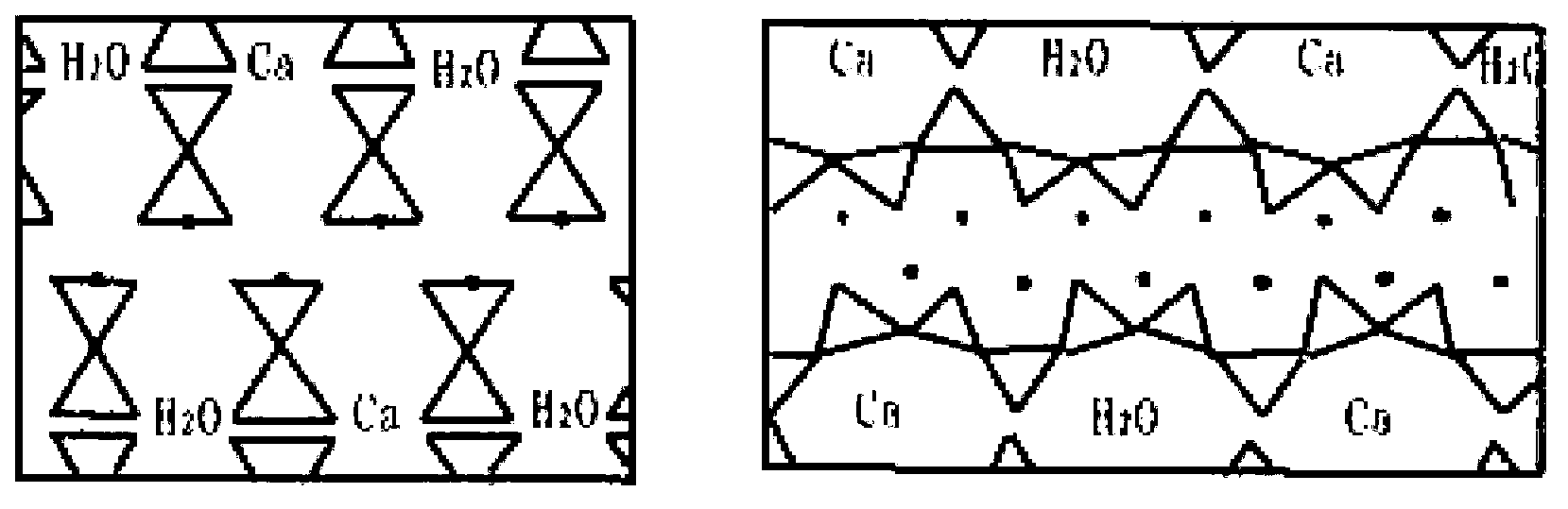

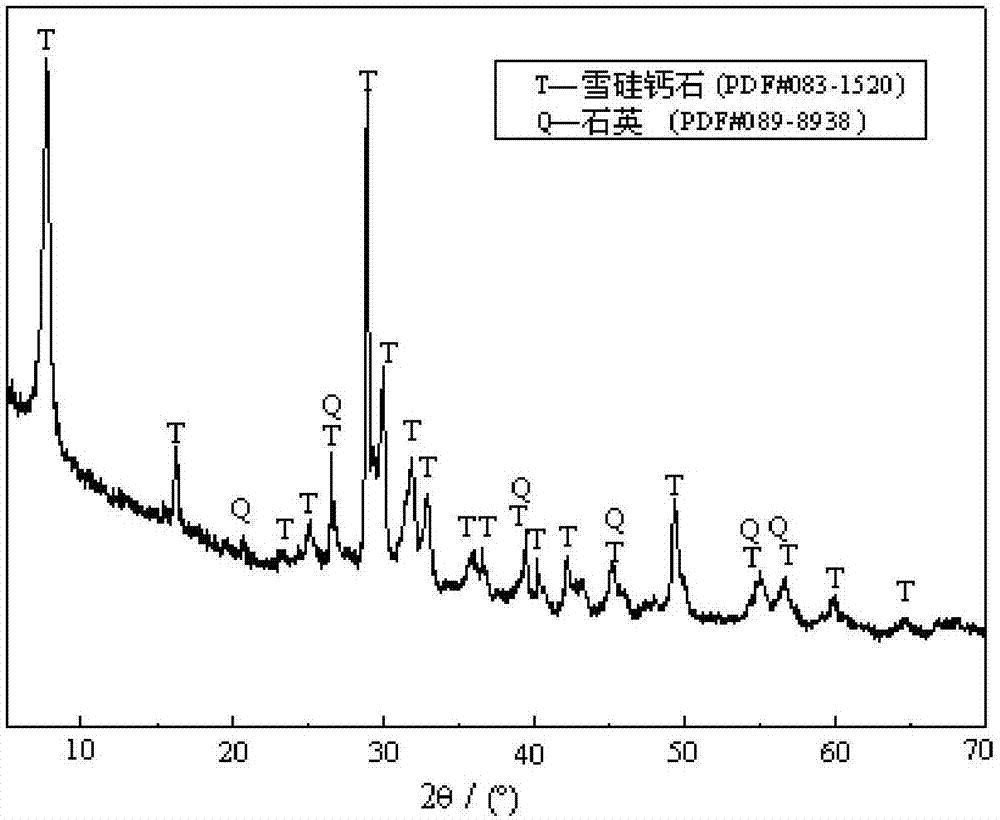

Tobermorite is a calcium silicate hydrate mineral with chemical formula: Ca₅Si₆O₁₆(OH)₂·4H₂O or Ca₅Si₆(O,OH)₁₈·5H₂O. Two structural varieties are distinguished: tobermorite-11 Å and tobermorite-14 Å. Tobermorite occurs in hydrated cement paste and can be found in nature as alteration mineral in metamorphosed limestone and in skarn. It has been reported from the Maqarin Area of north Jordan and in the Crestmore Quarry near Crestmore Heights, Riverside County, California.

Preparing method for complex function repairing agent for treatment of heavy metal contaminated soil

InactiveCN105419805AImprove fertilityTo achieve the purpose of pollution controlAgriculture tools and machinesOrganic fertilisersCalcium silicatePhosphate

The invention relates to a preparing method for a complex function repairing agent for treatment of heavy metal contaminated soil. Biomass charcoal, quick lime and a siliceous material serve as raw materials, biomass charcoal based tobermorite is synthesized through a hydrothermal reaction, and a biomass charcoal based hydroxyl calcium phosphate complex agent can be generated by biomass charcoal based tobermorite in a phosphate solution. In land utilization, the complex agent has the function of enhancing soil fertility and can also effectively stabilize heavy metal ions in the soil, the mobility and the bio-availability of heavy metal are reduced to the maximum, and the purpose of in-situ repair of the heavy metal contaminated soil is achieved. The prepared complex function repairing agent has the advantages of being high in content of active ingredients, long in heavy metal stabilizing effect, wide in application range, small in using quantity, easy to prepare, low in cost and the like, and can be used for long-acting on-situ repair of farmland heavy metal contaminated soil or other industrial heavy metal contaminated soil.

Owner:TONGJI UNIV

High-temperature-resistant well cementation cement paste system

ActiveCN111072350ALower requirementReduce dosageDrilling compositionHydration reactionPortland cement

The invention discloses a high-temperature-resistant well cementation cement paste system, and relates to the technical field of cement paste systems. The system comprises the following components: 60-75% of Portland cement; 15-25% of a strength recession resisting agent; 2-8% of a crystal form stabilizer; 0.5%-6% of a high-temperature retarder; and 3-8% of a high-temperature fluid loss agent, wherein the Portland cement is one of D-grade oil well cement or low-heat cement, and the specific surface area of the Portland cement is 280-350 m<2> / kg; the SiO2 content in the strength recession resisting agent is greater than 90%, and the mesh number is greater than or equal to 150 meshes; the content of SiO2 in the crystal form stabilizer is greater than 30%, and the mesh number is greater thanor equal to 600 meshes. The crystal form stabilizer is added and participates in hydration reaction when cement is hydrated, metal ions enter the structure of hydrated calcium silicate, so that conversion of tobermorite in a hydration product into xonotlite is prevented, the set cement is kept in a compact structure, and therefore, good high-temperature stability is achieved.

Owner:JIAHUA SPECIAL CEMENT +1

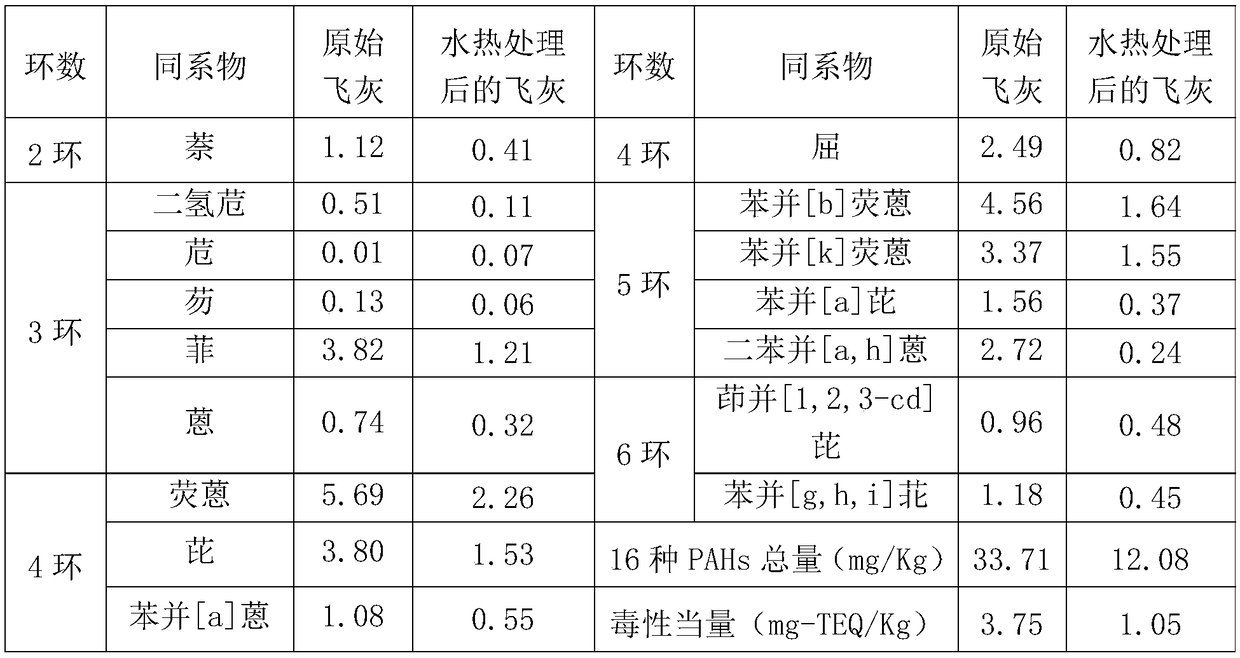

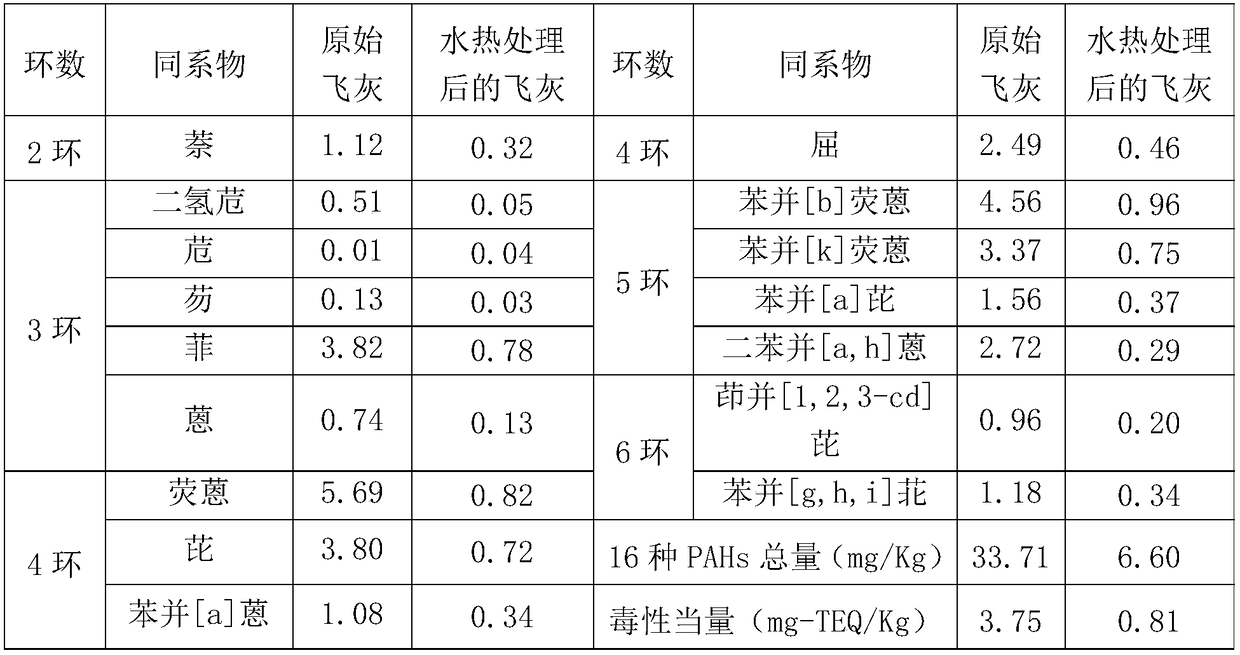

Method of synchronously stabilizing heavy metals and degrading polycyclic aromatic hydrocarbons from waste incineration fly ash

ActiveCN108721824AStable degradationReduce contentWaste processingSolid waste disposalSlurryMaterials science

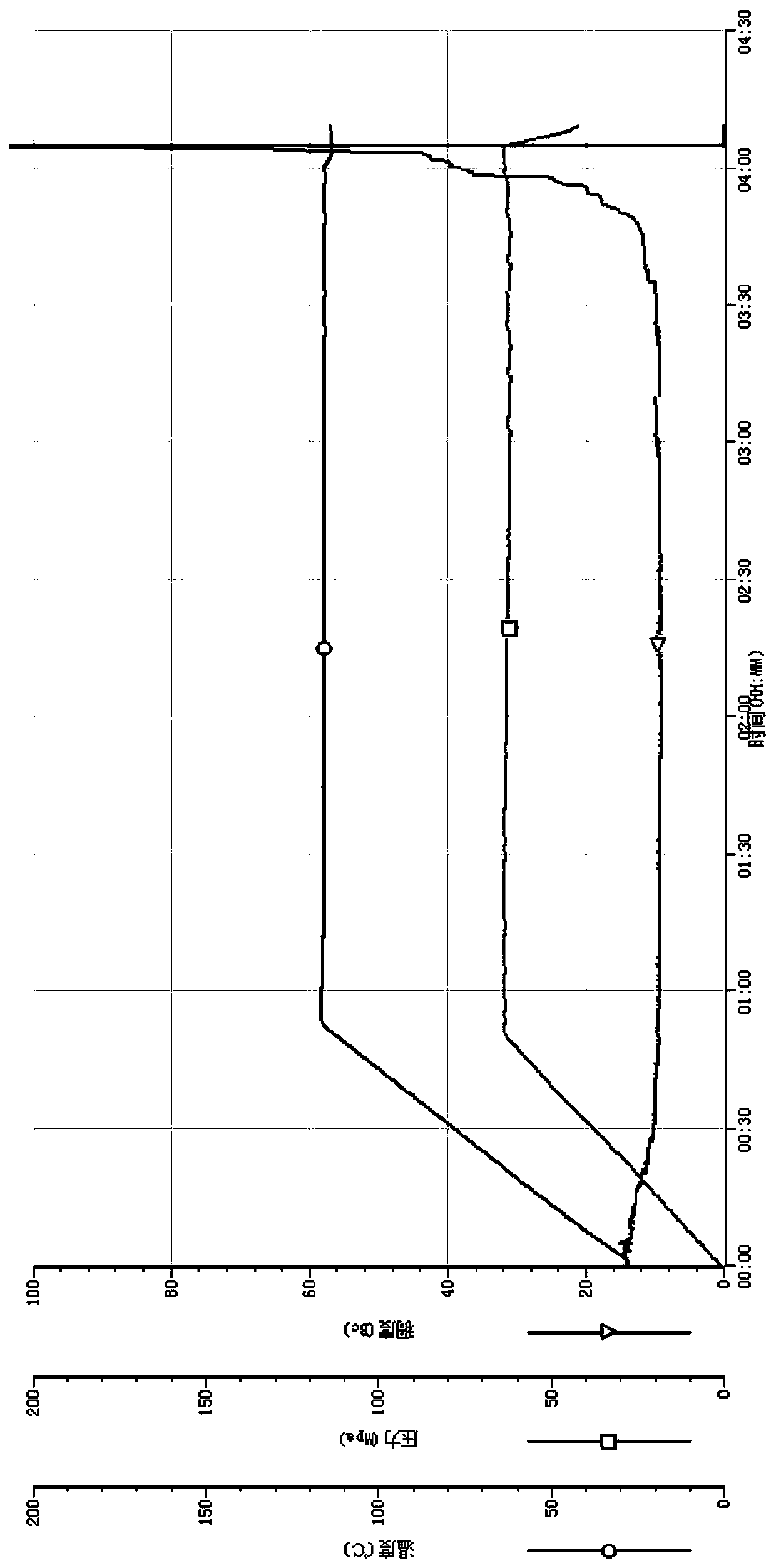

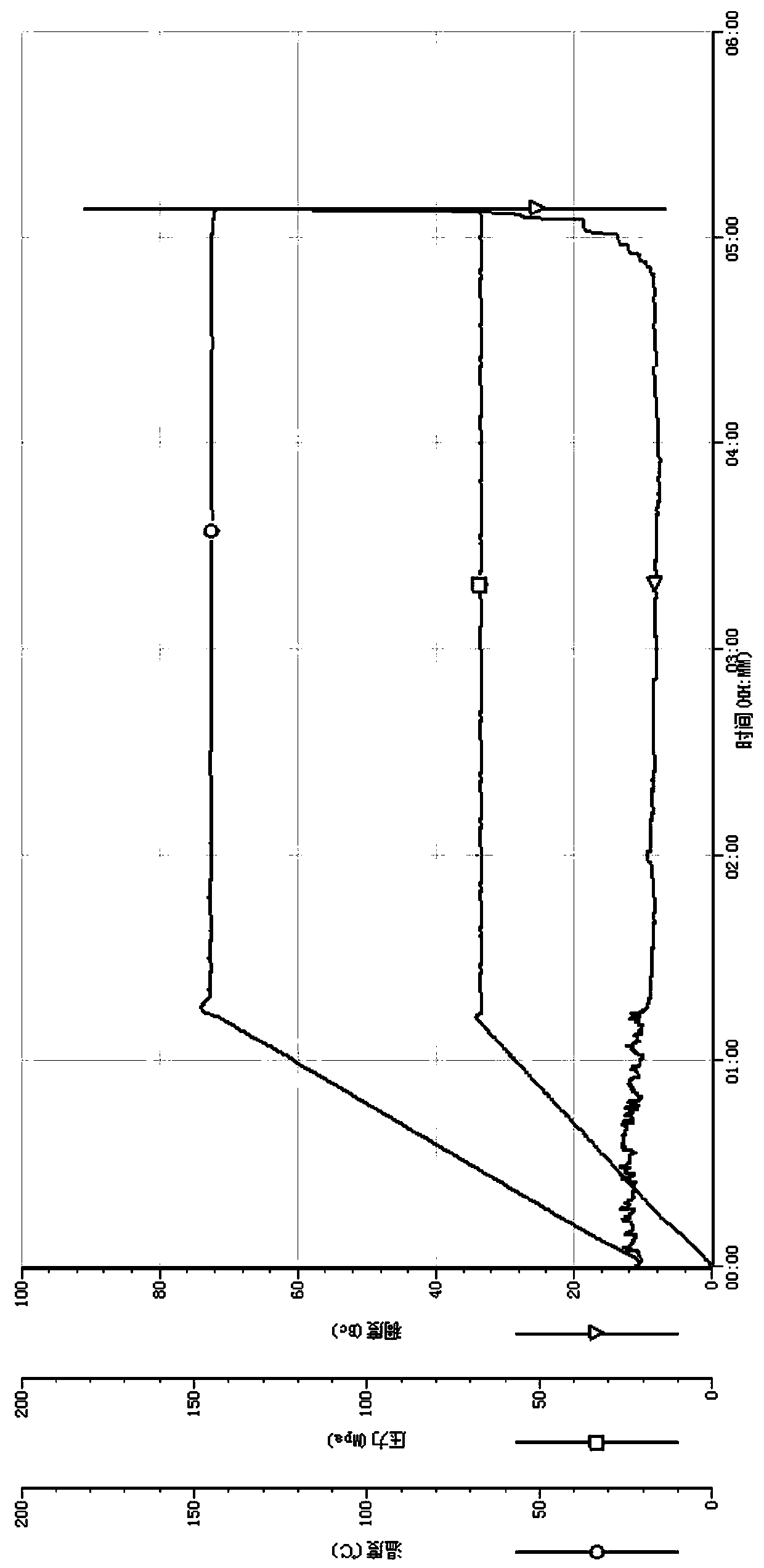

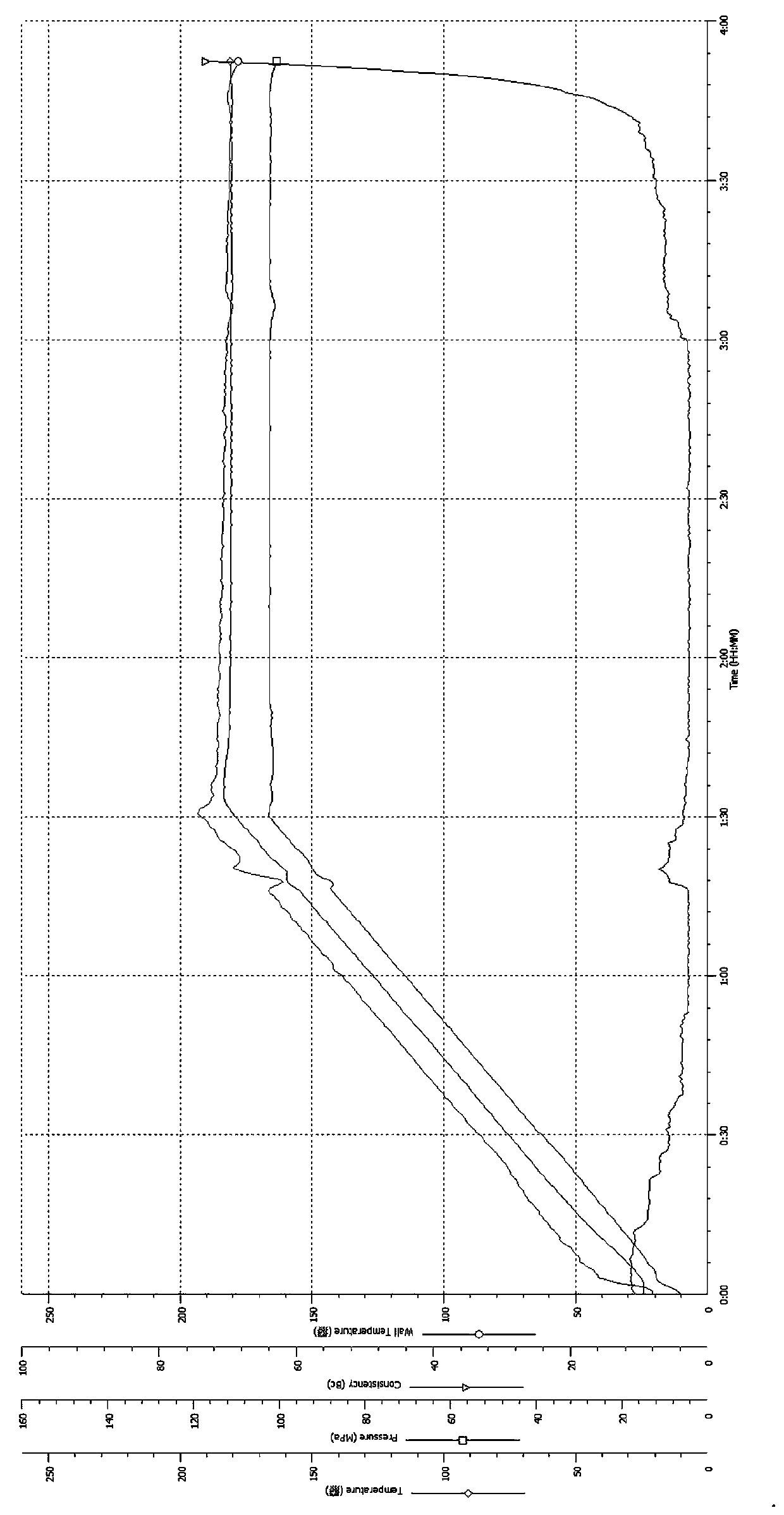

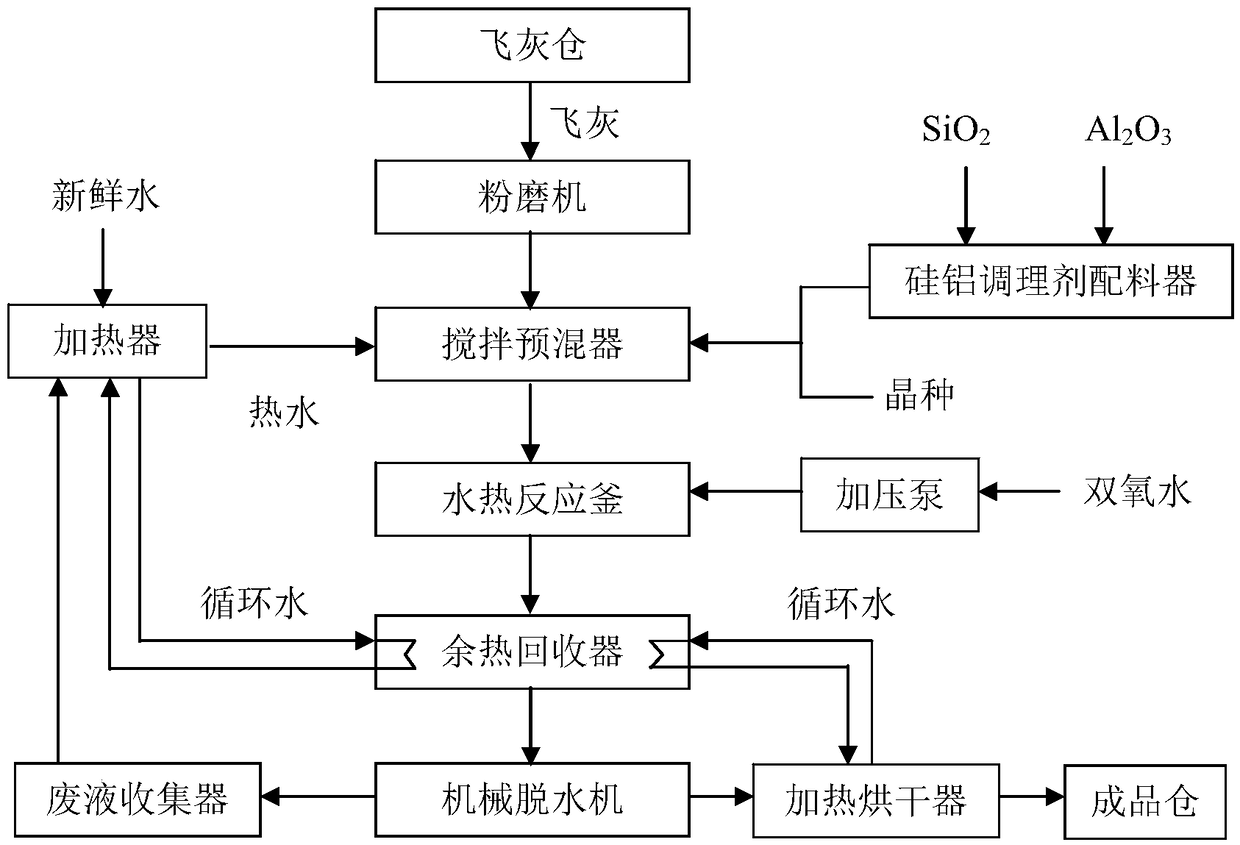

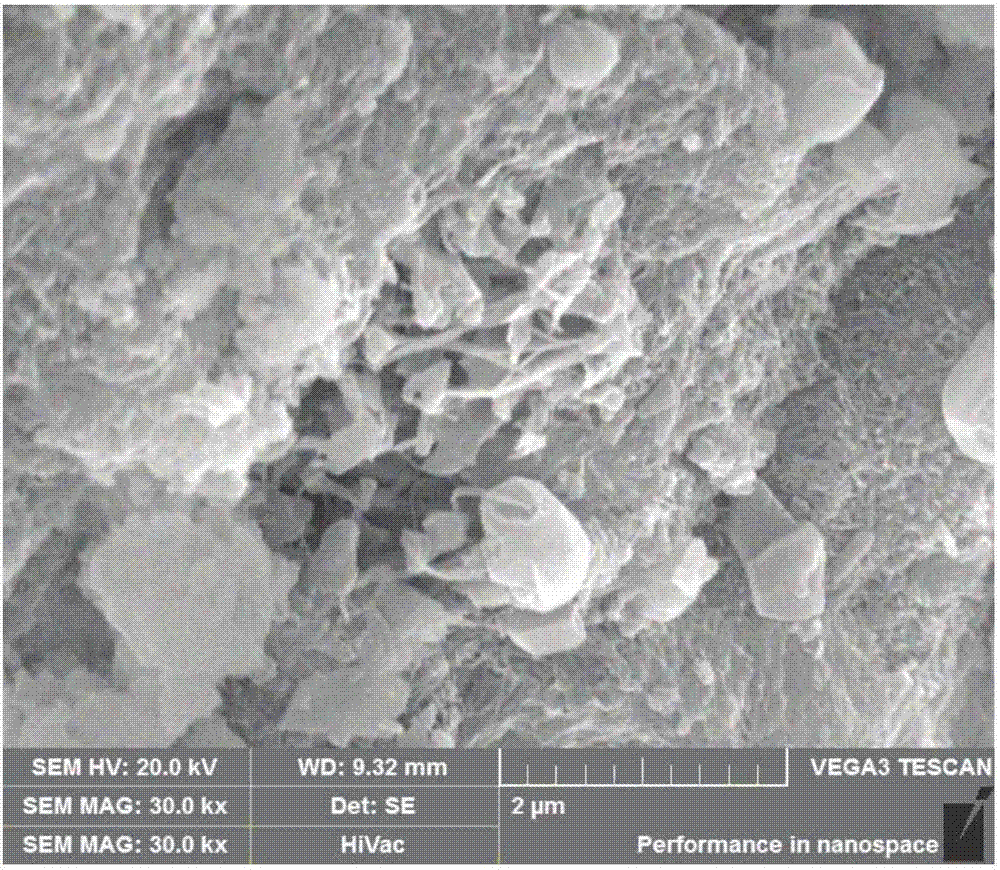

The invention relates to a method of synchronously stabilizing heavy metals and degrading polycyclic aromatic hydrocarbons from waste incineration fly ash. The method comprises the following steps: 1)pretreatment: grinding the fly ash, wherein the grain sizes of the fly ash are smaller than or equal to 80 [mu]m; 2) blending: adding a silicon-aluminum conditioning agent into the pre-treated fly ash to obtain a mixed ash sample, adding hot water into the mixed ash sample, and stirring and activating the mixed ash sample for 8-10 h to obtain mixed slurry, wherein the molar ratio among calcium, silicon and aluminum in the mixed slurry meets the generation demand of a zeolite aluminosilicate mineral tobermorite, and the liquid-solid ratio of water and the mixed ash sample in the mixed slurry is (5-10): 1 mL / g; 3) hydrothermal reaction: adding the mixed slurry into a closed hydrothermal reaction kettle, pumping hydrogen peroxide into the hydrothermal reaction kettle and then raising the temperature to 150-200 DEG C for the hydrothermal reaction, wherein the mass fraction of the hydrogen peroxide is 30%, and the liquid-solid ratio of the hydrogen peroxide and the mixed ash sample is 0.25-1 mL / g; and 4) separation: carrying out dehydrating separation on a product obtained by the hydrothermal reaction to obtain a solid phase product and waste liquor.

Owner:CHONGQING UNIV

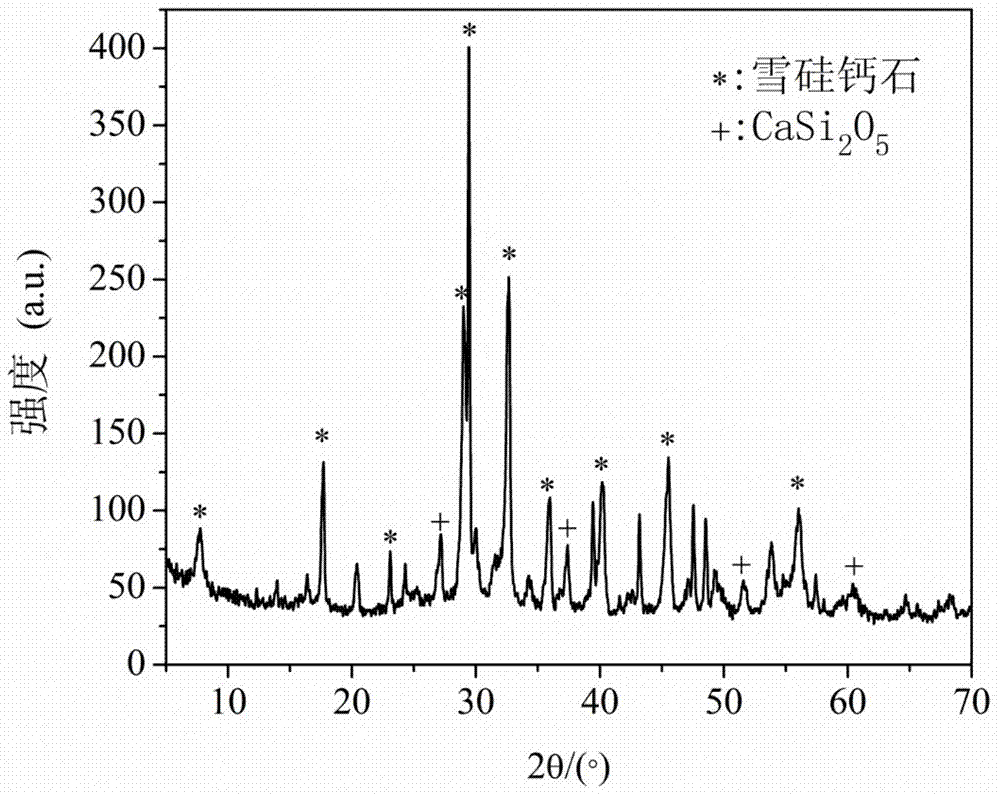

Preparation method of tobermorite

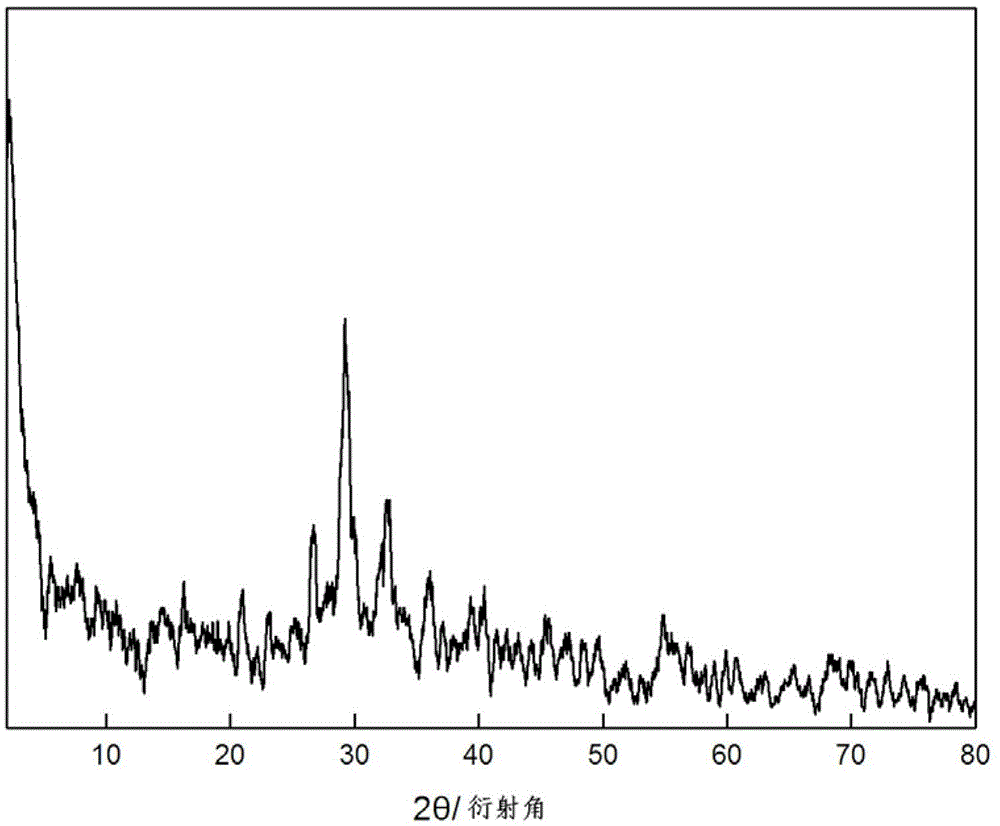

ActiveCN103708478ACrystal stableAlkaline concentration decreasedAlkaline-earth metal silicatesPulverized fuel ashSODIUM SILICATE SOLN

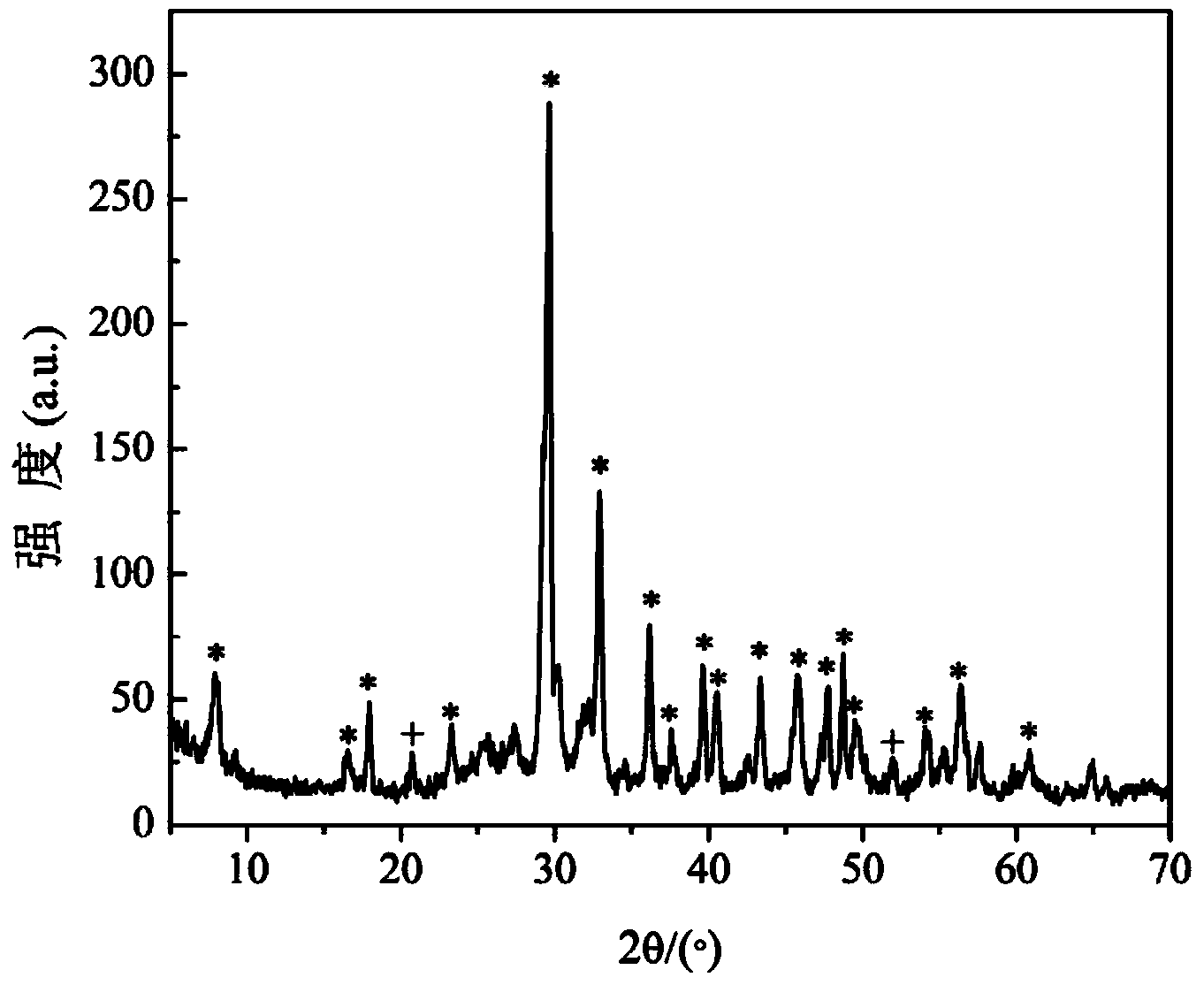

The invention discloses a preparation method of tobermorite. The preparation method comprises the following steps: removing amorphous activated SiO2 in pulverized fuel ash by use of sodium hydroxide alkaline liquor so as to obtain a sodium silicate solution with an appropriate concentration, wherein the sodium silicate solution is used as a siliceous material; further performing hydro-thermal synthesis with refined lime milk to finally obtain a tobermorite product.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

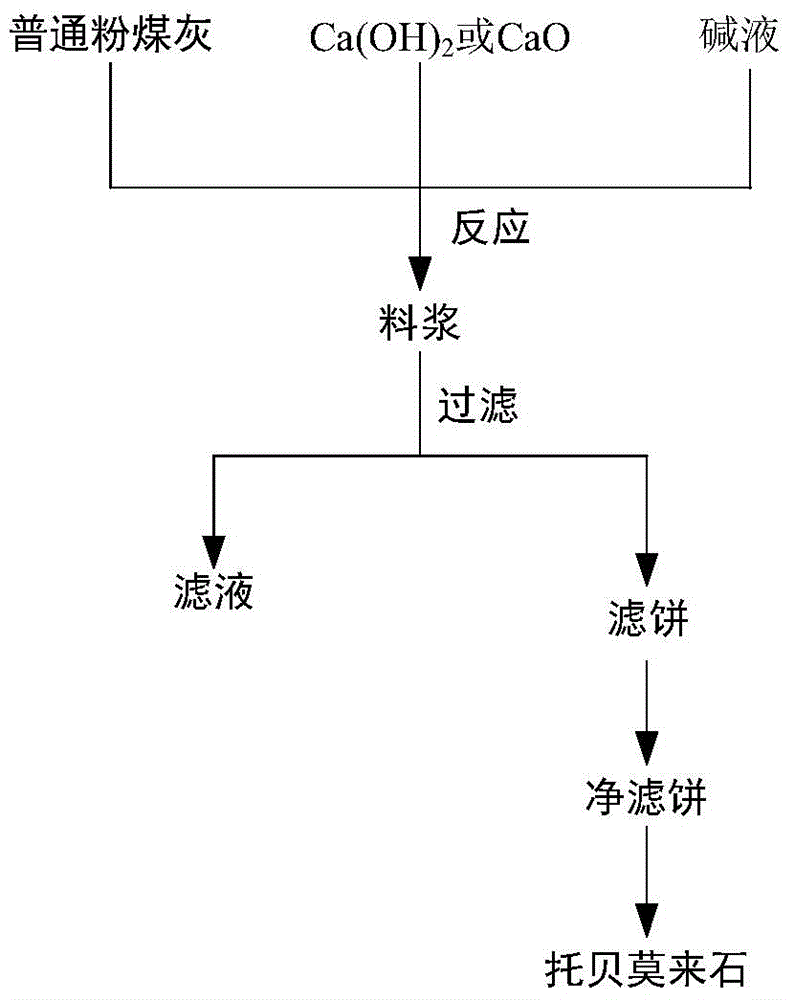

Method of preparing tobermorite from fly ash and application thereof

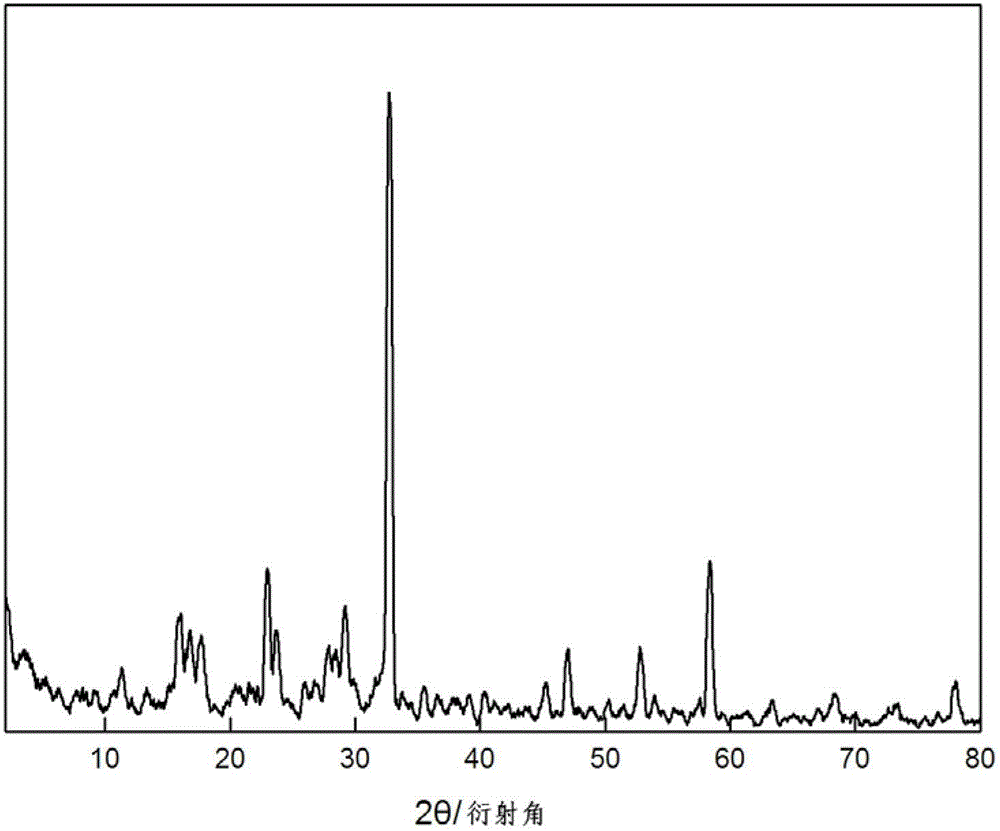

ActiveCN104828834AObvious superioritySolve the problem of accumulating and polluting the environmentAlkaline-earth metal silicatesCalcium in biologyReaction temperature

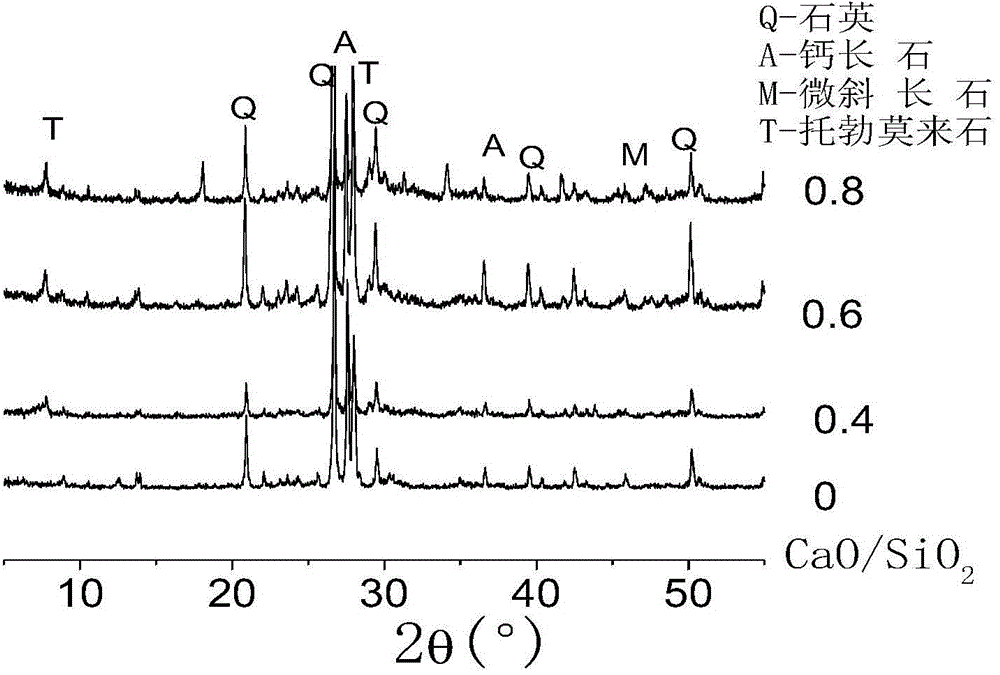

The invention belongs to the field of recycle of solid wastes, and particularly, relates to a method of preparing tobermorite from fly ash and an application thereof. The method comprises following steps: (1) material preparation: mixing the fly ash and a calcium raw material with a molar ratio of CaO to SiO2 being 0.4-1.4 to prepare a mixed material, and dissolving the mixed material in an alkaline solution according to the ratio of 1:10-1:40 to obtain a mixed slurry material; (2) reaction: performing a synthetic reaction in a sealed container to the mixed slurry material at 100-250 DEG C for 3-30 h, and filtering a reaction product to obtain tobermorite wet residue. A press-moulded product of the tobermorite is low in volume weight and is excellent in performance. Compared with a conventional method in which the tobermorite is synthesized through an autoclaved curing process with a silicon raw material and a calcium raw material, the method is better in mass transfer of the reaction process so that the method is lower in energy consumption.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

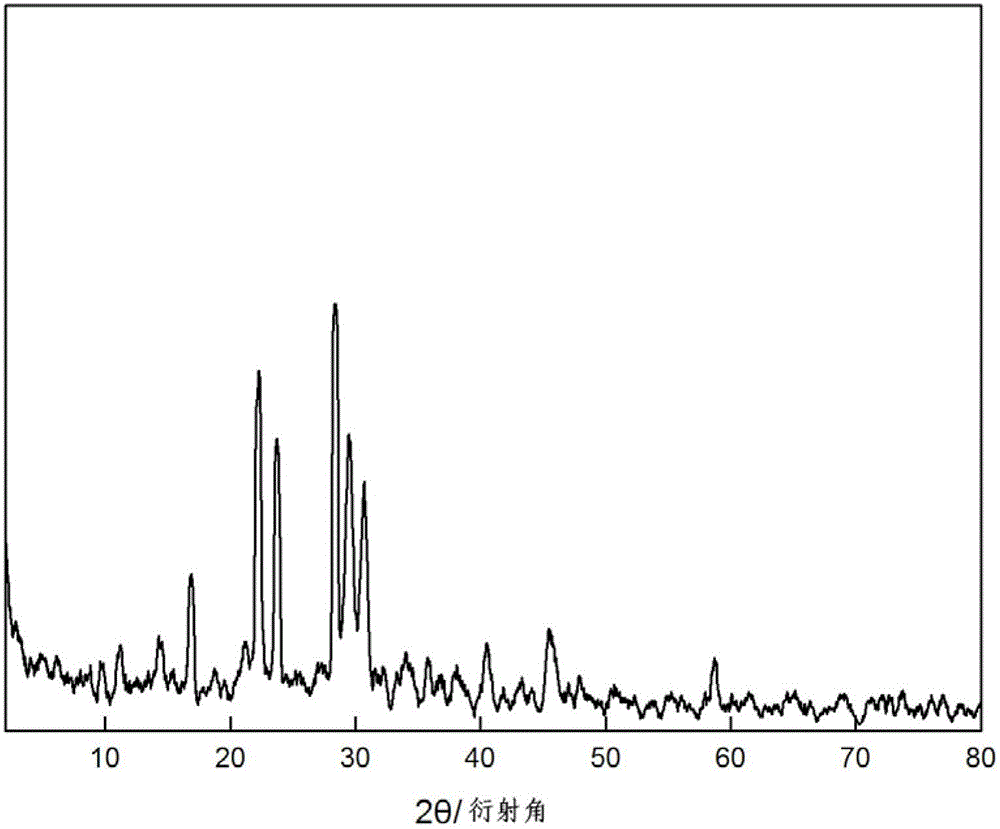

Preparation method for synthesizing tobermorite through using blast furnace slag as raw material

ActiveCN102745700ALess investmentThe production process is simple and easy to controlSolid waste disposalAlkaline-earth metal silicatesSlagGranularity

The invention relates to a preparation method for synthesizing tobermorite through using blast furnace slag as a raw material. The tobermorite is obtained through the hydrothermal synthesis of raw materials comprising 50-70% by mass of the blast furnace slag, 10-25% by mass of quicklime and 10-25% by mass of silica. The preparation method comprises the following steps: 1, grinding the 50-70% of blast furnace slag until the granularities are 100-200 meshes, uniformly mixing the materials comprising 50-70% of the ground blast furnace slag, 10-25% of the quicklime and 10-25% of the silica, and water with a molar ratio of CaO / SiO2 being 0.8-1.2, and pouring the obtained mixture to a reaction vessel; 2, heating the reaction vessel, and reacting at 150-220DEG C for 6-10h; and 3, cooling and filtering after reaction ending to obtain white solid substances, washing, and drying to obtain the tobermorite. The tobermorite is synthesized through the hydrothermal synthesis of a blast furnace iron making byproduct which is used as the primary raw material, so waste utilization is effectively carried out. The prepared tobermorite has a good phosphorous removal effect when the tobermorite is used for phosphorus-containing wastewater treatment.

Owner:HUBEI FORBON TECH

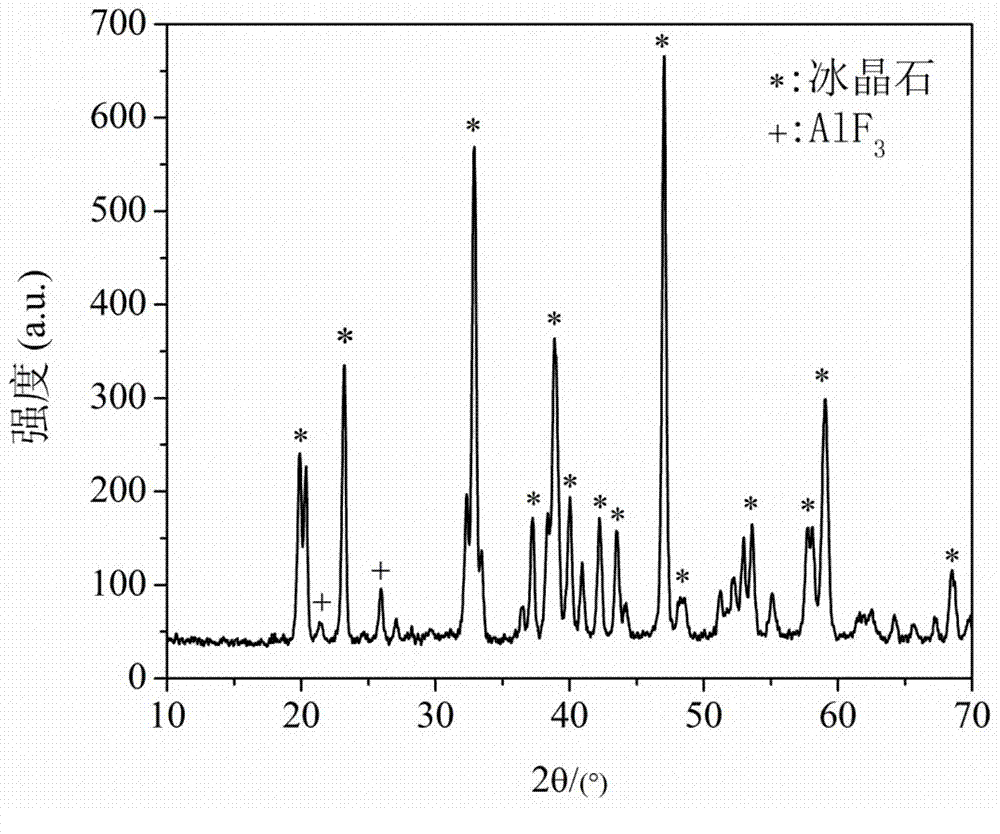

Comprehensive utilization method of coal gangue

ActiveCN104258804AHigh yieldOvercoming the problem of poor solubilityOther chemical processesSolid waste disposalSilicon dioxideMaterials science

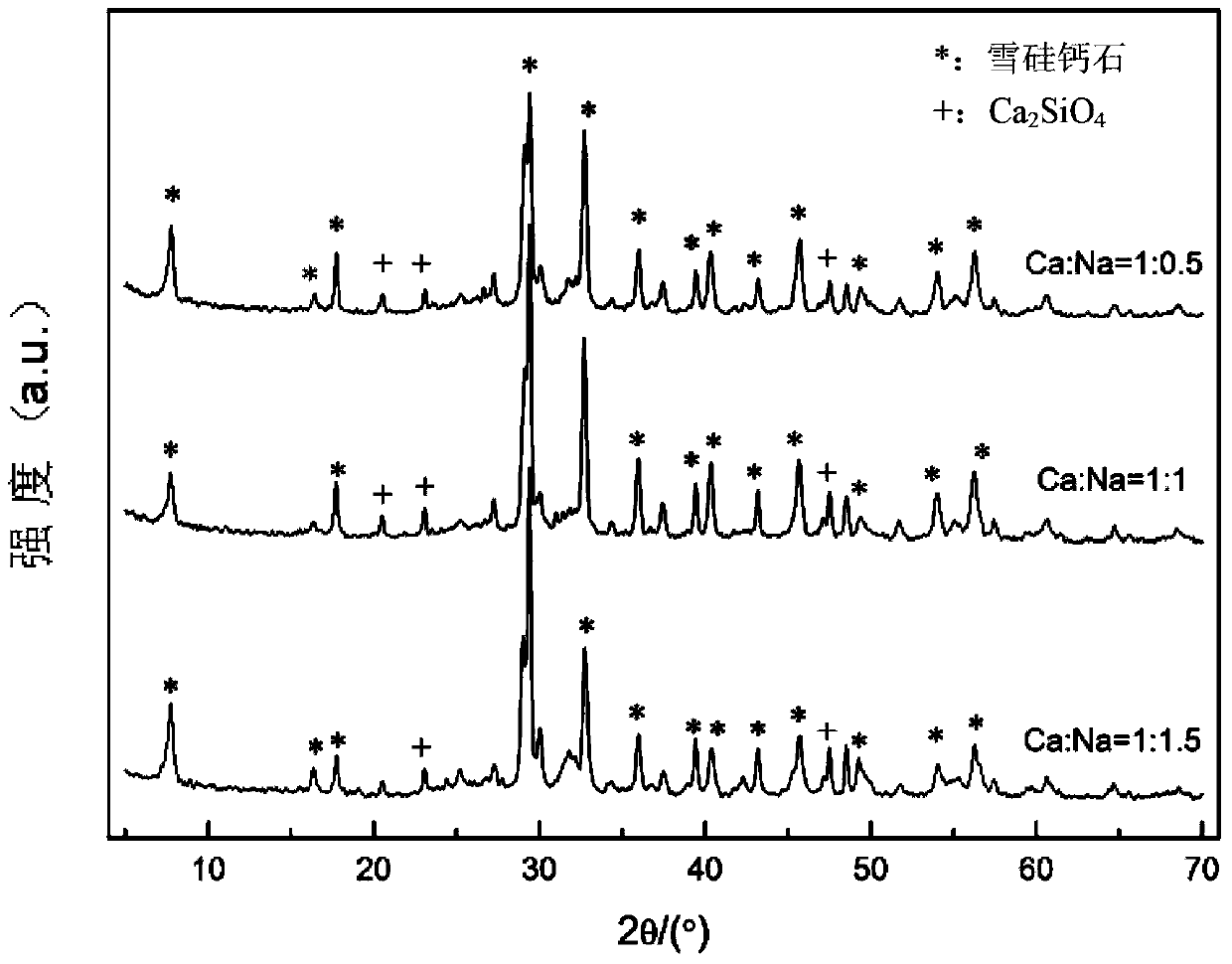

The invention discloses a comprehensive utilization method of coal gangue. The comprehensive utilization method of the coal gangue comprises the following steps: separating alumina-silica of coal gangue by adopting a baking, crushing, sulfuric acid leaching and centrifugal separation method, thereby obtaining an aluminum salt Al2(SO4)3 solution and filter residues (SiO2); adding slaked lime (Ca(OH)2) into the filter residues, adding caustic soda NaOH according to the molar ratio of Ca / Na of 1 to (1.0-2.0), and carrying out hydrothermal autoclaved reaction at 160-180 DEG C for 16-18 hours by adopting a hydrothermal autoclaved method so as to synthesize a tobermorite sewage treatment adsorption material with a good crystallization state; compounding sodium hydrogen fluoride NaHF2 formed by sodium fluoride NaF and hydrofluoric acid HF with the leached supernate Al2(SO4)3 solution, and carrying out full reaction under stirring for 1-1.5 hours so as to synthesize cryolite. The invention provides a solution for preparing the tobermorite sewage adsorption material by utilizing silicon dioxide in coal gangue and preparing cryolite by utilizing the alumina component; and the obtained materials have a favorable application prospect, and the aim of preparing materials with high additional value by comprehensively utilizing coal gangue is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

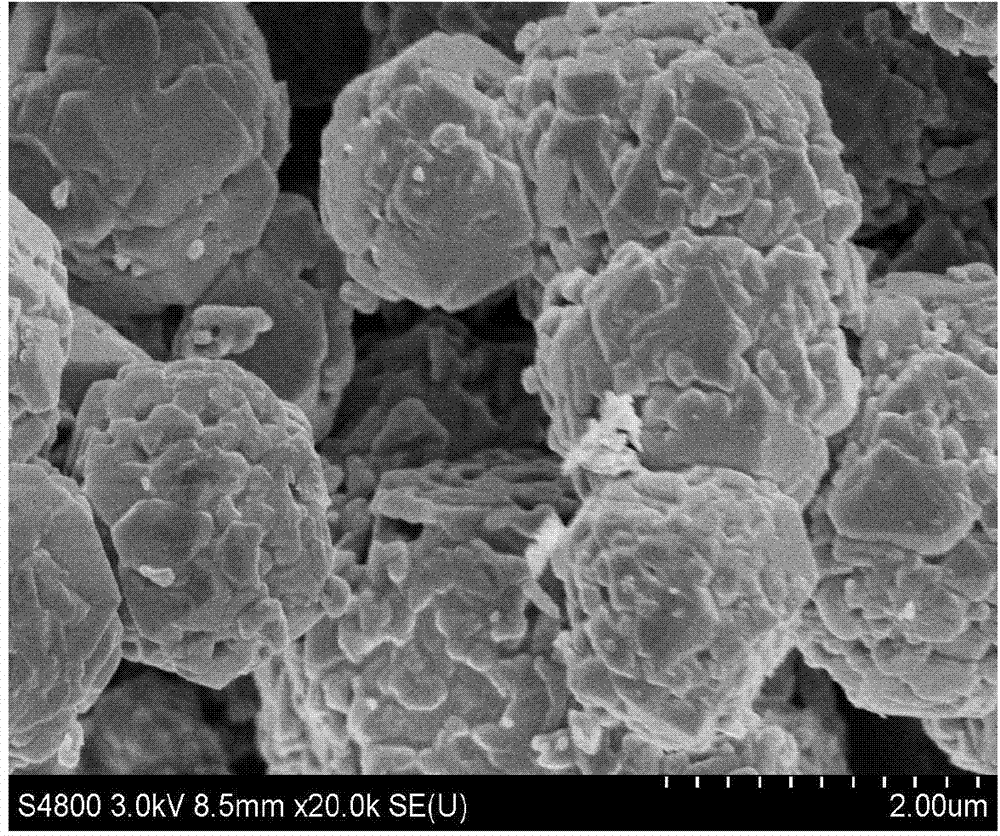

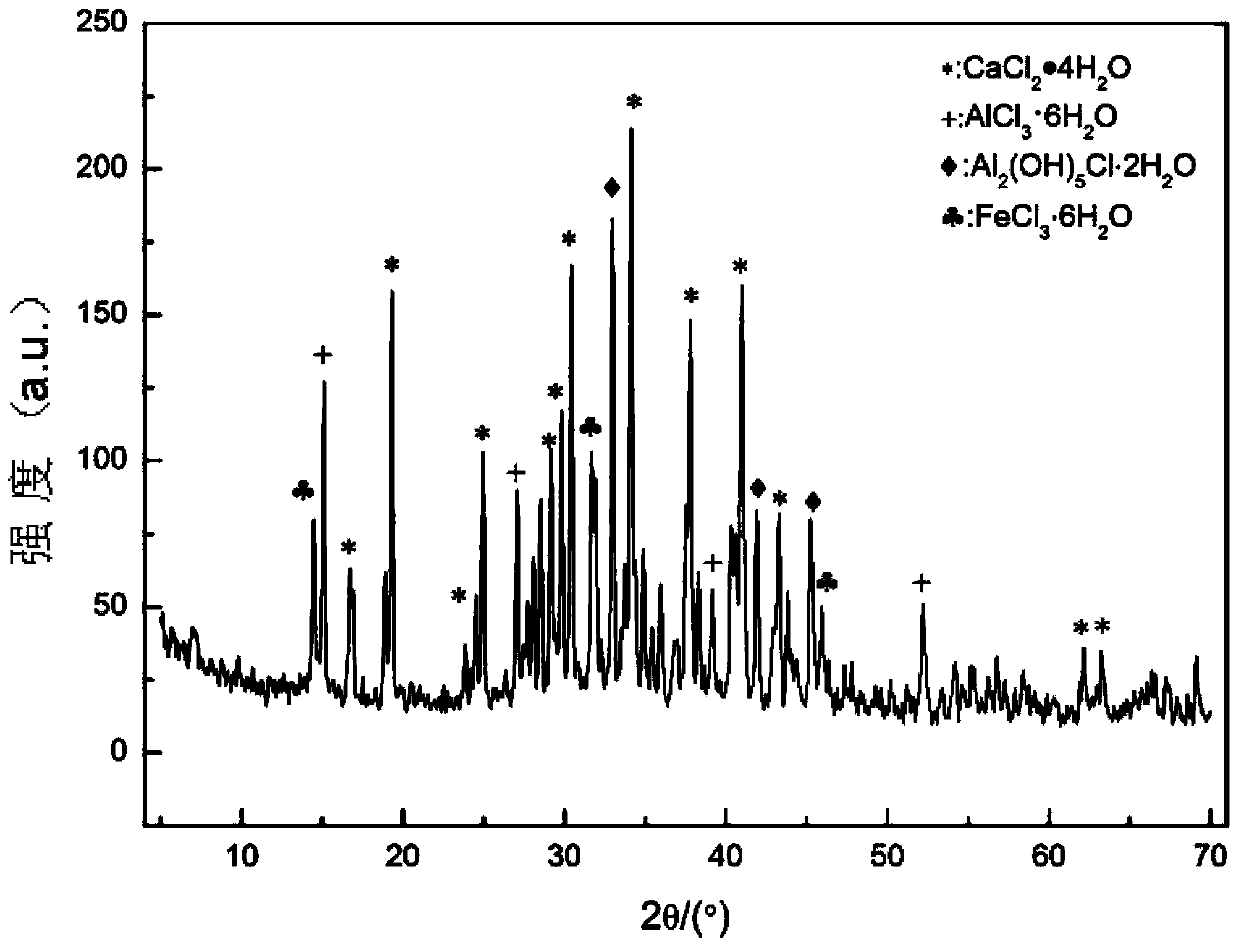

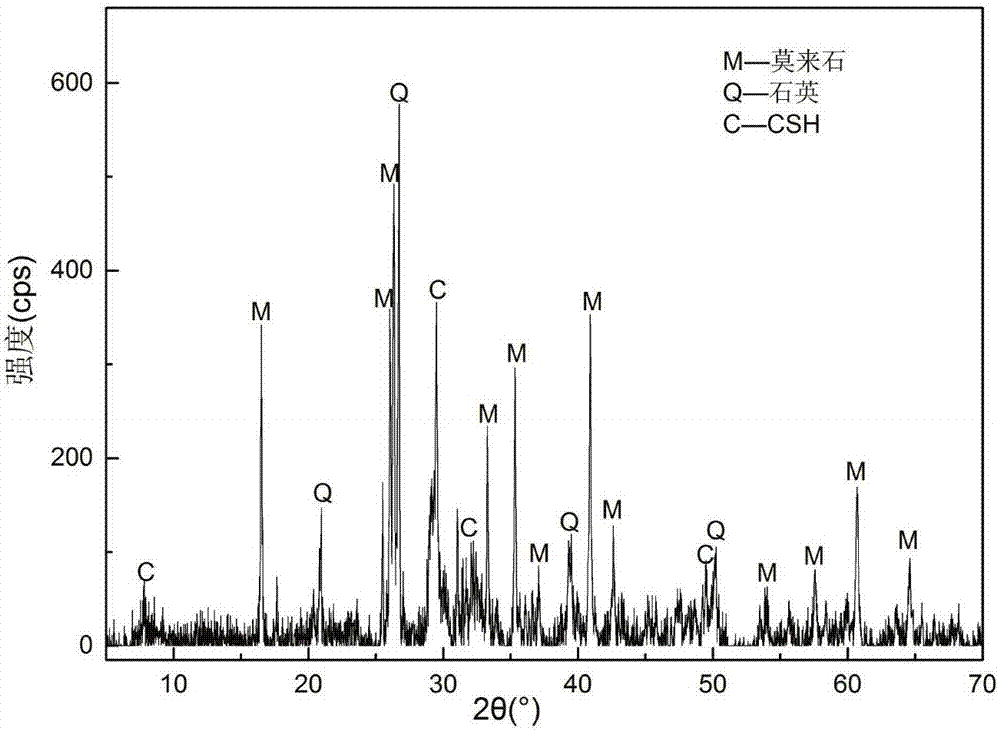

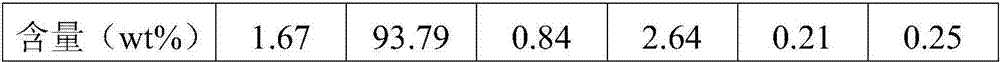

Comprehensive utilization method for coal ash solid waste

InactiveCN103420384AGood adsorption and cation exchange capacityHigh application prospectAlkaline-earth metal silicatesSilicon oxidesChemistryAluminium

A comprehensive utilization method for coal ash solid waste comprises the following steps: grinding and sieving coal ash after being calcined, and soaking in a hydrochloric acid of 20-30% mass concentration to respectively obtain ferro-aluminium chlorination liquor and solid residue; adding Ca(OH)2 and Al(OH)3 in the ferro-aluminium chlorination liquor, and adjusting the basicity to 45-55%, controlling the pH value at 3.5-5.0 through the hydrochloric acid, performing water thermal polymerization at the temperature of 105-110 DEG C, and obtaining a poly ferro-aluminium chlorination liquor after concentration and drying; washing and drying the solid residue, adding Ca(OH)2 at the molar ratio of n(Ca)to n(Si) of 5:6, adding NaOH at the molar ratio of n[Ca(OH)2] to n(NaOH) of 1:(0.5-1.5), and performing thermal reaction at the temperature of 180-220 DEG C to obtain a tobermorite sewage disposal material. According to the method, a comprehensive solution that aluminium oxide and a small amount of ferric oxide and calcium oxide in the coal ash are adopted to prepare poly ferro-aluminium chlorination purifying agent, and the components of silicon dioxide are adopted to prepare the tobermorite sewage disposal material is offered, so that the purpose that the coal ash is comprehensively used to prepare the environment material with higher added value is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

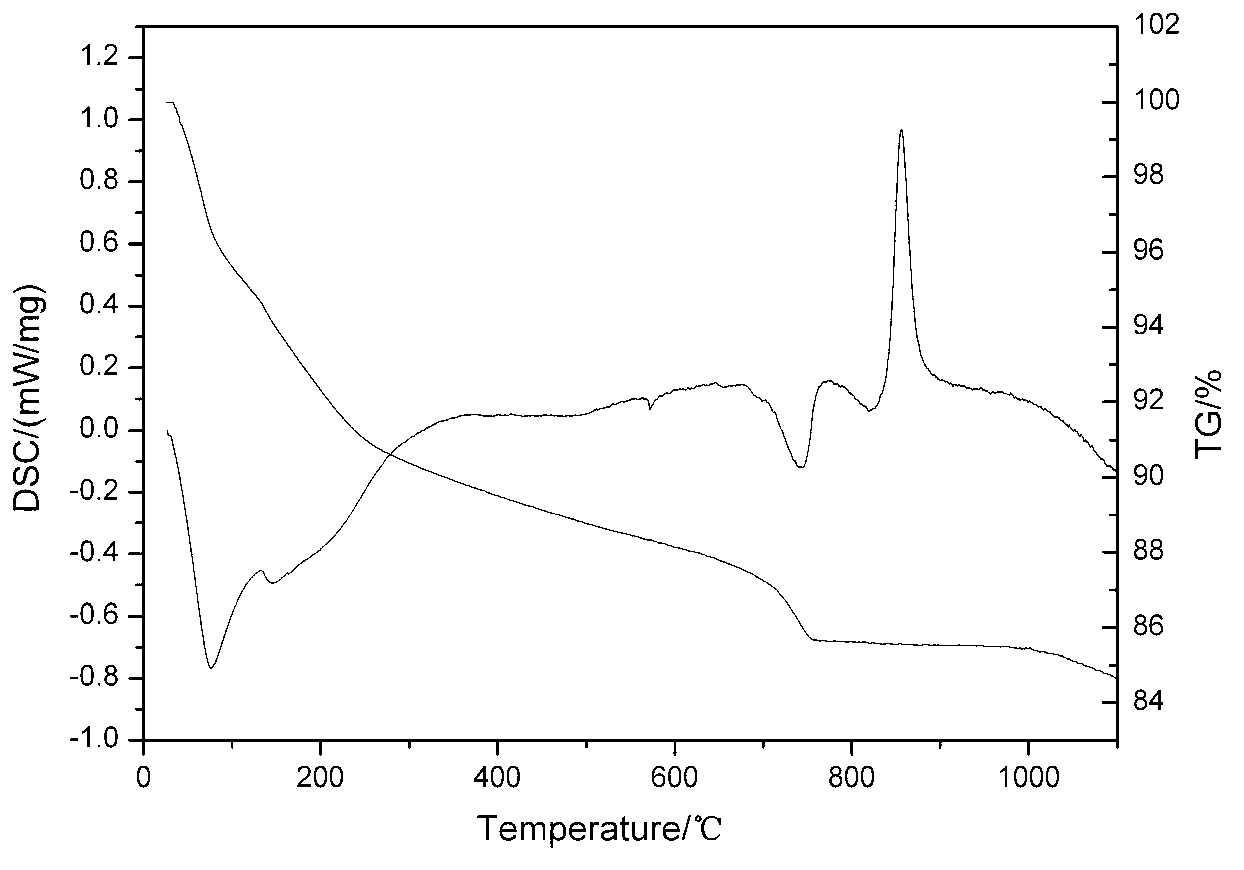

Tobermorite type heat-insulating material made from calcium silicate slag and preparation method

ActiveCN106187052ALow raw material costDisposal of solid wasteSolid waste managementFiberCalcium silicate

The invention provides a tobermorite type heat-insulating material made from calcium silicate slag and a preparation method. The tobermorite type heat-insulating material provided by the invention comprises the following raw materials: mixture, reinforced fibers and sodium silicate, wherein the mixture comprises calcium silicate slag, coal ash and silicon source supplement agent; the mole ratio of CaO to SiO2 in the mixture is 0.79-0.96; the weight of the reinforced fibers and sodium silicate is respectively 2-10% and 0.5-3% of the weight of the mixture. The invention also relates to the preparation method for the tobermorite type heat-insulating material. According to the invention, the raw materials including calcium silicate slag and coal ash are utilized to prepare the tobermorite type heat-insulating material. The tobermorite type heat-insulating material has the advantages of low cost, short reaction time, low energy consumption, product performance meeting related standard requirements, capability of digesting solid wastes including calcium silicate slag and coal ash and obvious social, economic and environmental benefits.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Method for preparing heat preservation material tobermorite by using zirconium-silicon slag

The invention discloses a method for preparing heat preservation material tobermorite by using zirconium-silicon slag. The method comprises the following steps: washing the zirconium-silicon slag by water and enabling the pH (potential of hydrogen) value of the treated zirconium-silicon slag to be 6-7; adding calcium raw material and water into the water-washed zirconium-silicon slag and mixing to homogenize; adding the mixed homogenized raw materials into a reaction kettle and reacting; adding reinforced fibre into the kettle after the reaction is finished, and blending to mix; casting and moulding; and, drying to obtain the heat preservation material tobermorite after moulding. The heat preservation material tobermorite is widely applied to the ceramic, chemical, metallurgical and architectural fields. Meanwhile, the tobermorite is a good fireproof building material. The method provided by the invention does not need any special equipment, uses relatively simple process, and is easy to popularize. The economical benefit and the social benefit are great. The problems on the recovery and utilization of a lot of zirconium-silicon slag generated in the production process of zirconium oxychloride are well solved. The production cost of the enterprises is reduced.

Owner:BENGBU ZHONGHENG NEW MATERIALS SCI & TECH CO LTD +2

Method for activating waste aerated concrete blocks

InactiveCN102838301ASolve resource reuseSolve stacking problemsCement productionCalcium silicateExperimental methods

The invention discloses a method for activating waste aerated concrete blocks. The method comprises the following steps of: firstly, breaking the waste aerated concrete blocks to form aerated concrete fragments; burning the aerated concrete fragments, and cooling to normal temperature; and finally arranging the aerated concrete fragments subjected to the treatments in a ball mill and carrying out ball-milling treatment. Main hydrate tobermorite stone calcium silicate hydrate in the activated waste aerated concrete blocks is in an amorphous state and has excellent hydrolyzing property and reacting property. The activated waste aerated concrete is subjected to activity check according to provisions in a 'GB / T 12957-2005 activity experimental method for cement mixing material industrial waste residues', the data show that the activated waste aerated concrete has the activity like a pozzolanic material, the 28-day compression strength can reach about 90% of the standard cement gel sand test block. With the adoption of the method, recycling the waste aerated concrete blocks is realized and the application prospect of the waste aerated concrete blocks is expanded.

Owner:NANJING UNIV OF SCI & TECH

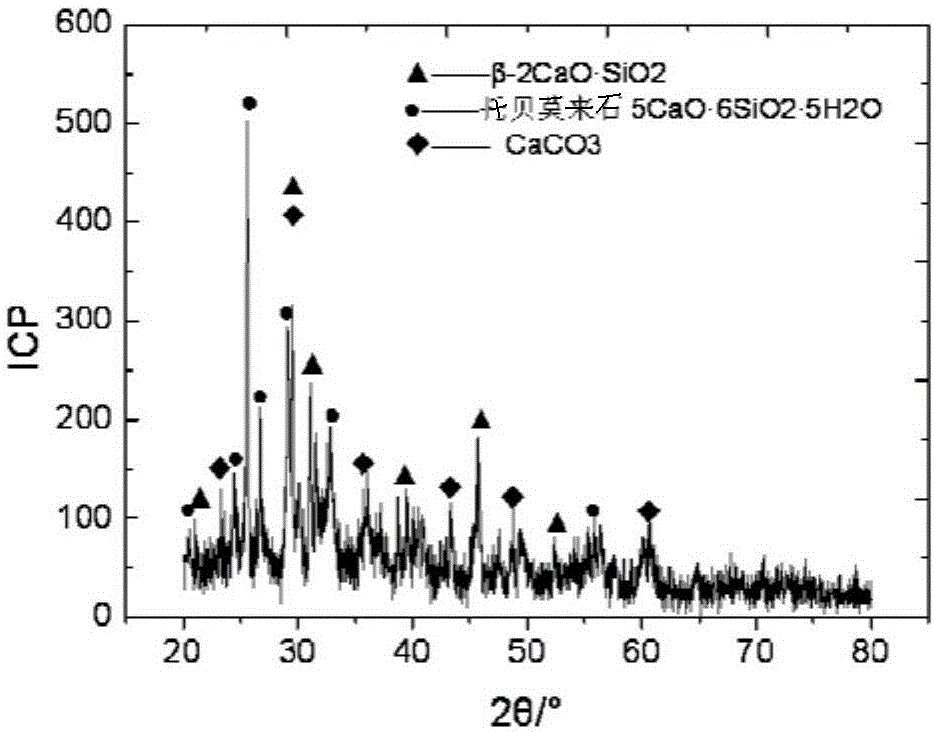

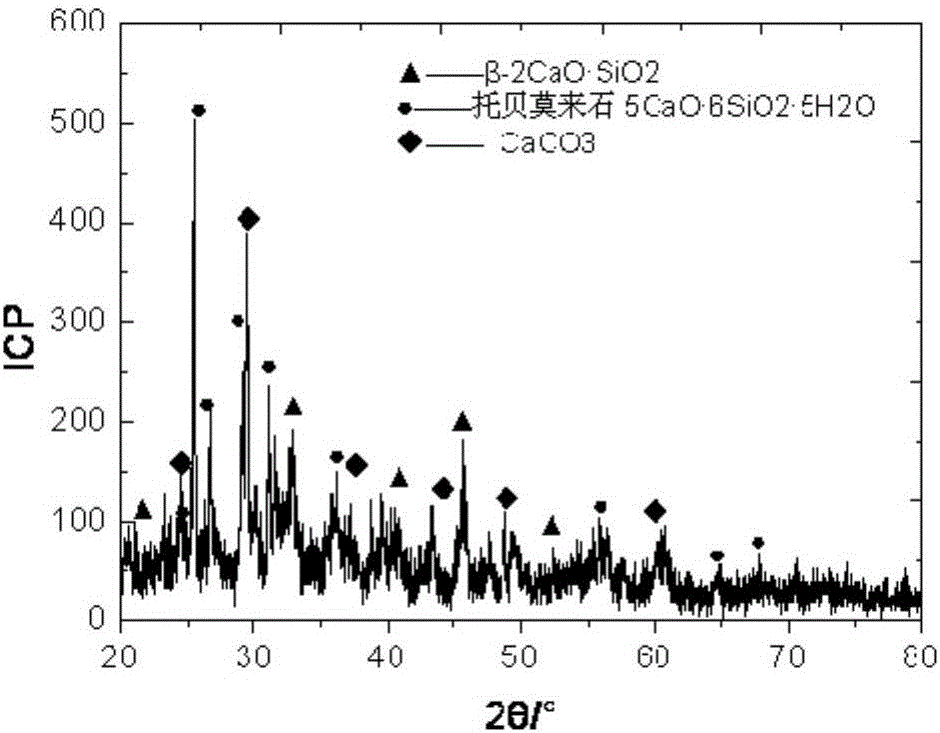

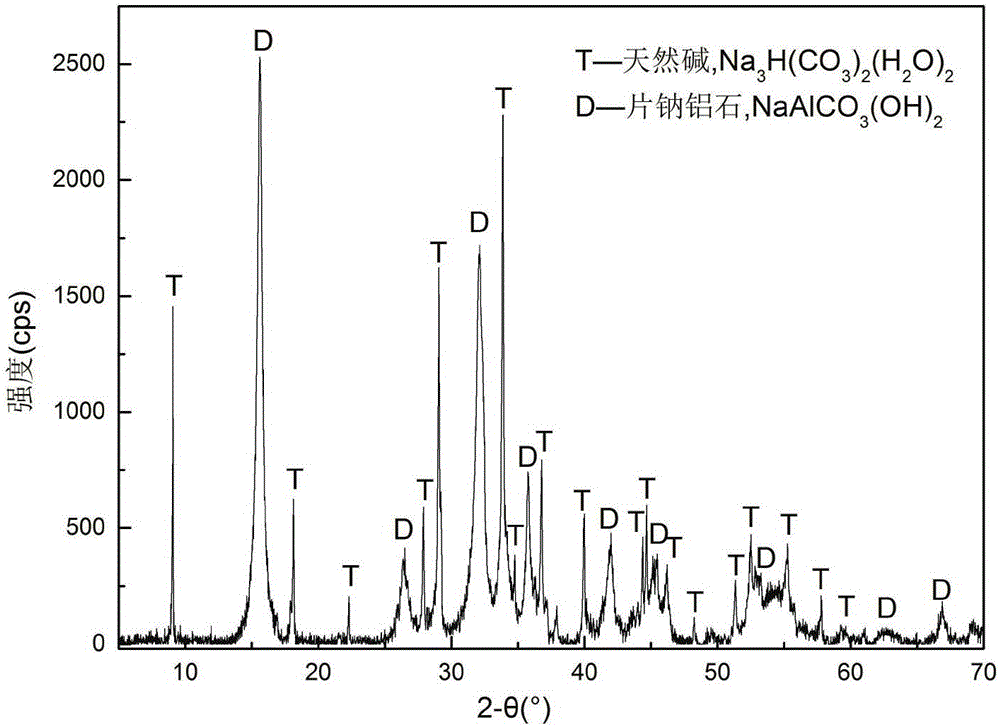

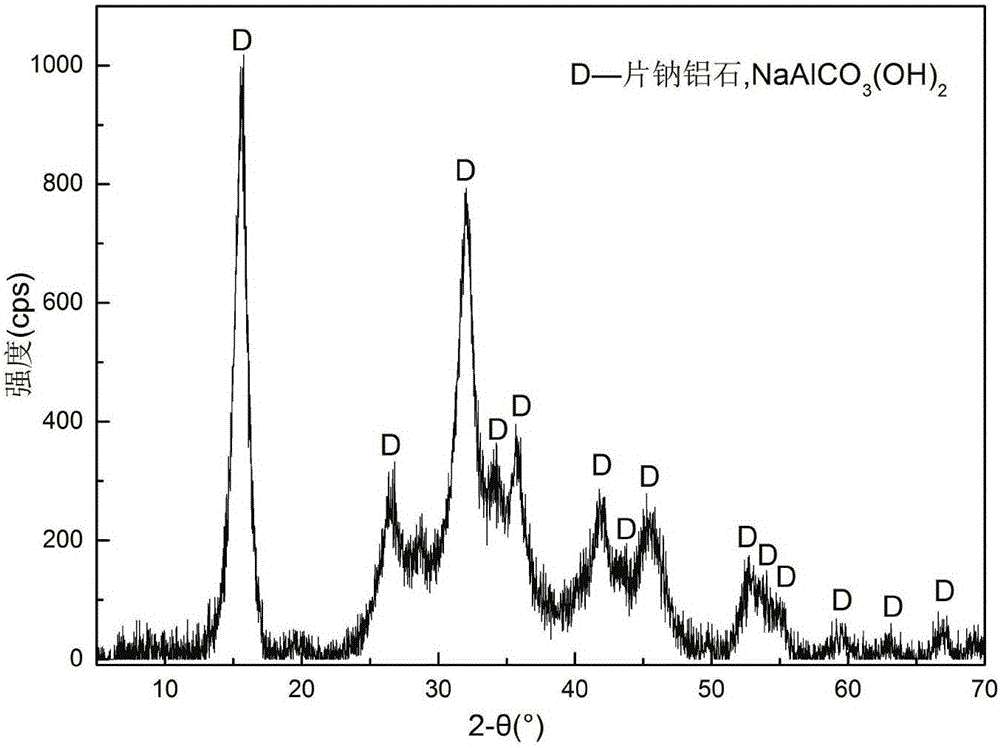

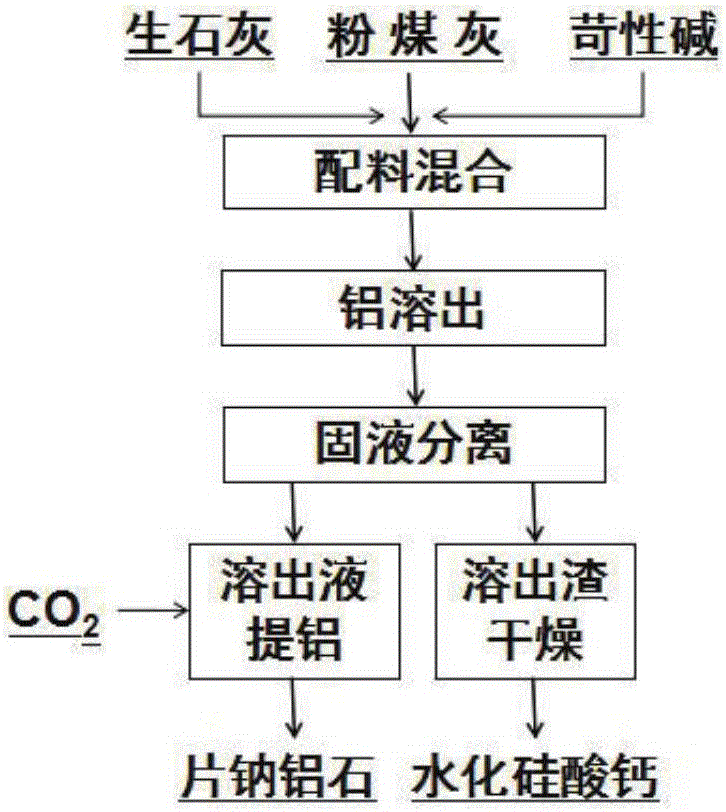

Method for co-producing dawsonite and tobermorite from fly ash

ActiveCN106542551AHigh activityHigh purityAluminium compoundsAlkaline-earth metal silicatesCalcium silicateSlag

The invention provides a method for extracting alumina from fly ash. According to the mol ratio of CaO to SiO2 being 0.3 to 1.5 and the liquid-to-solid ratio being 5ml / g to 50ml / g, quick lime, fly ash and water ingredients are mixed; 5g / L to 100g / L of NaOH is added for regulating the pH value of slurry; the reaction is performed for 0.5h to 12h in a high-pressure sealed container with the temperature being 120 DEG C to 260 DEG C; through solid-liquid separation, digestion solution containing sodium metaaluminate as main ingredients and digestion slag containing tobermorite as main ingredients are obtained; then, CO2 gas with the volume concentration being 10 percent to 100 percent is introduced into the digestion solution; along with the reduction of the pH of the solution, aluminum oxide compounds are separated out in a crystal form; when the pH is 9.5 to 8.0, the gas introduction is completed; then, through the solid-liquid separation operation, crystals containing the dawsonite as the main ingredients are obtained. The method has the advantages that the low-cost recovery and utilization on aluminum resources in the fly ash can be realized; the obtained dawsonite can be used for producing aluminum salt chemical products, or can be used for producing metallurgy grade aluminum oxide and the like after being purified; the obtained tobermorite is used as ingredients for producing cement and concrete, and the product intensity can be improved.

Owner:CENT SOUTH UNIV

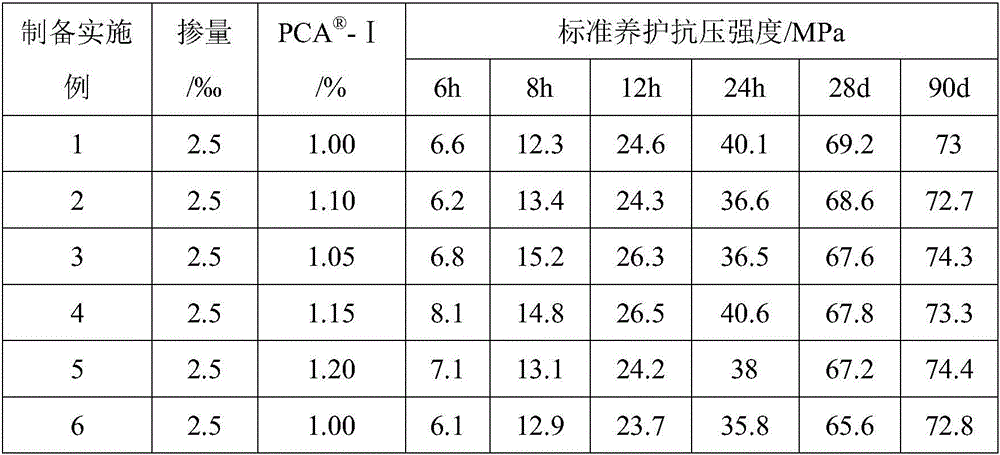

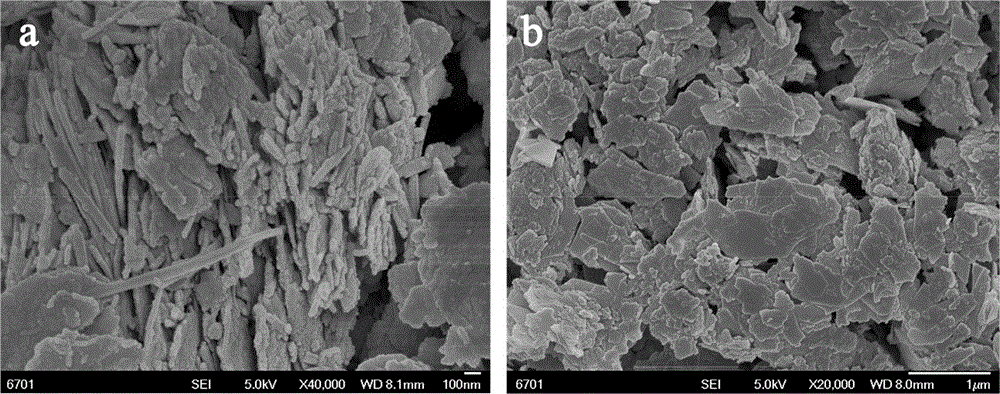

Preparation method of concrete early strength agent

Owner:JIANGSU SOBUTE NEW MATERIALS +1

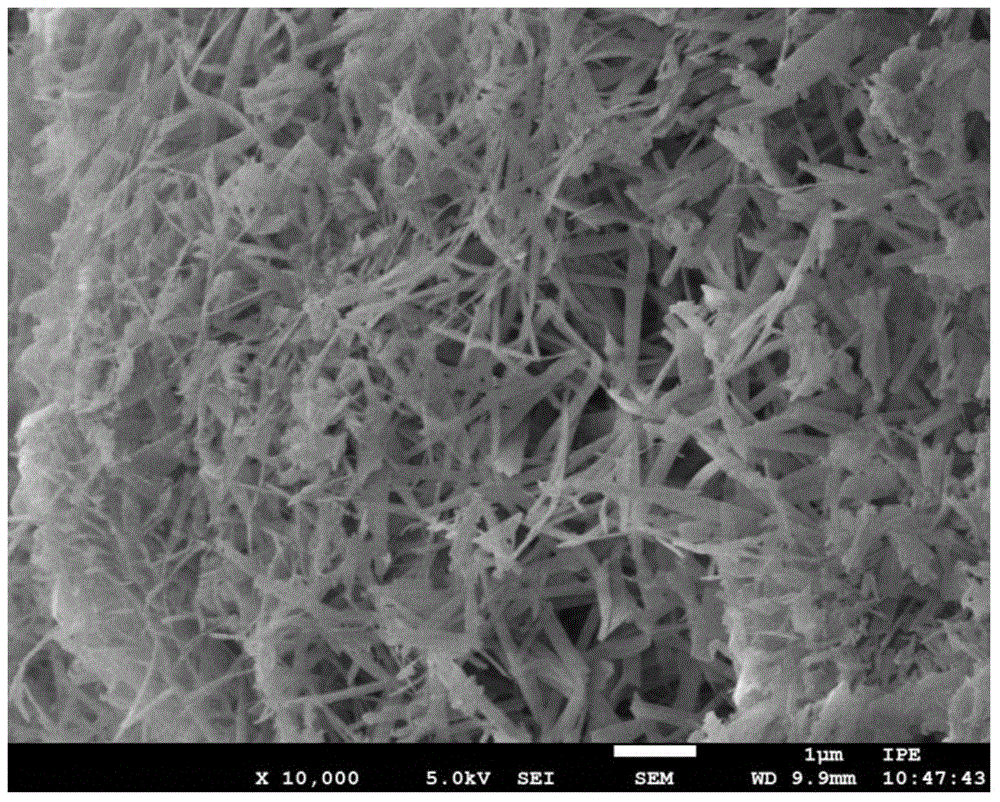

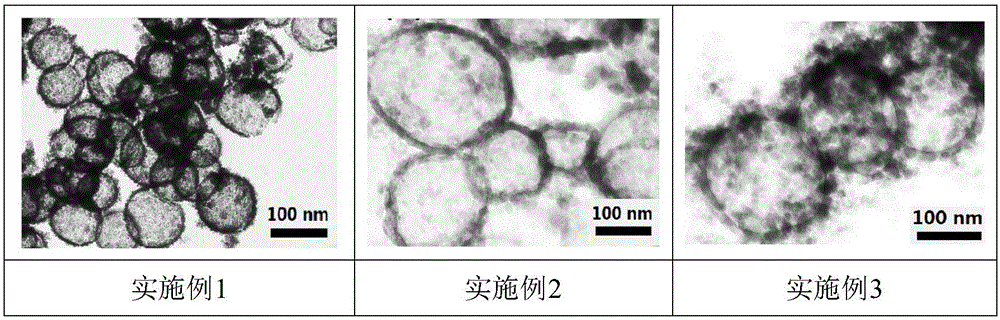

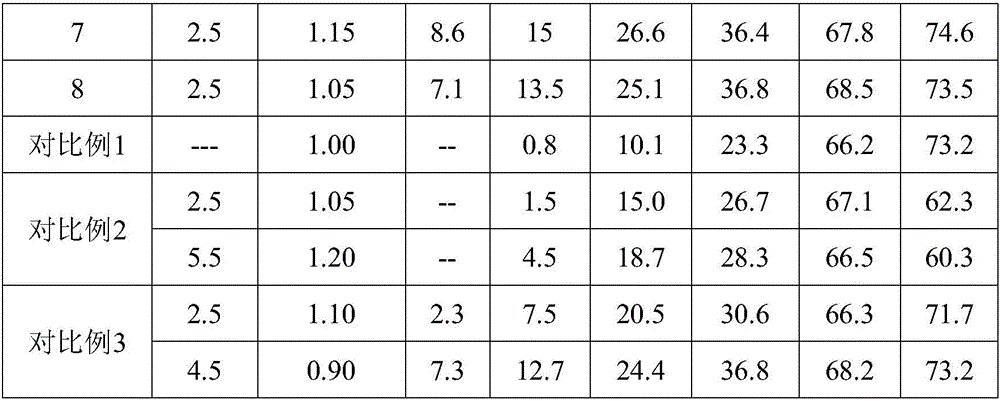

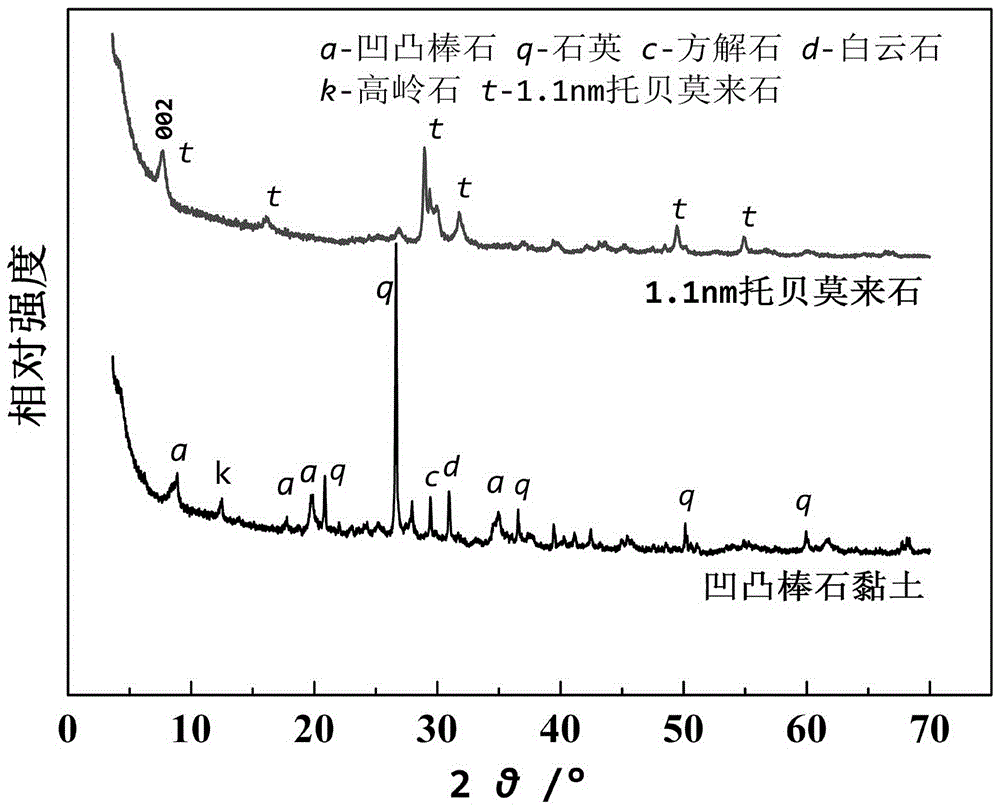

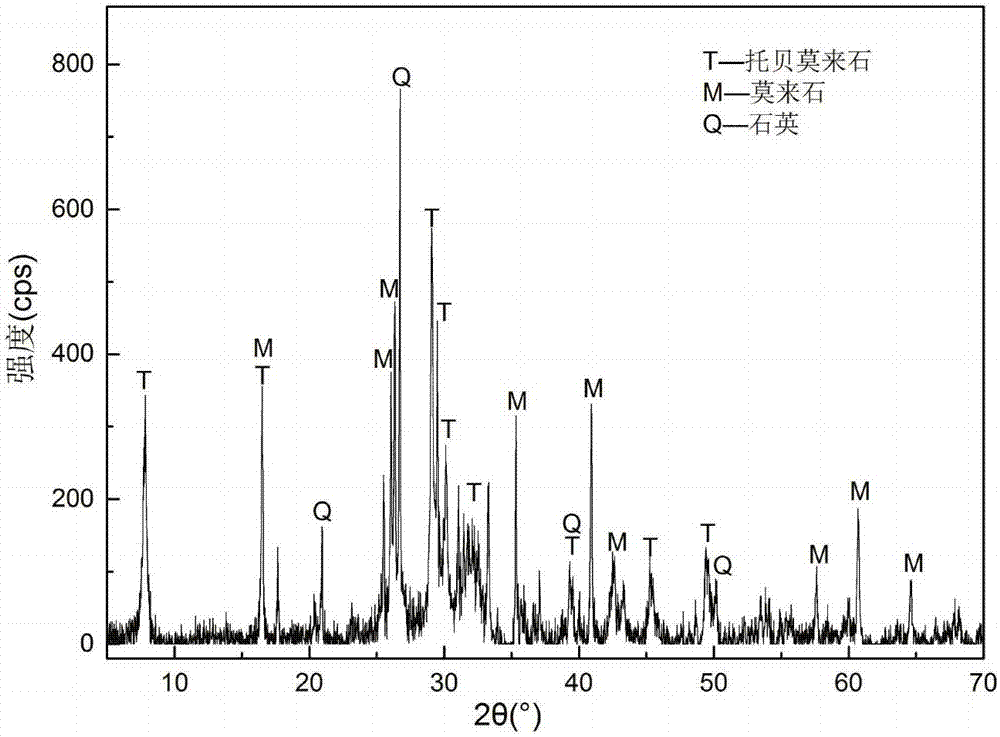

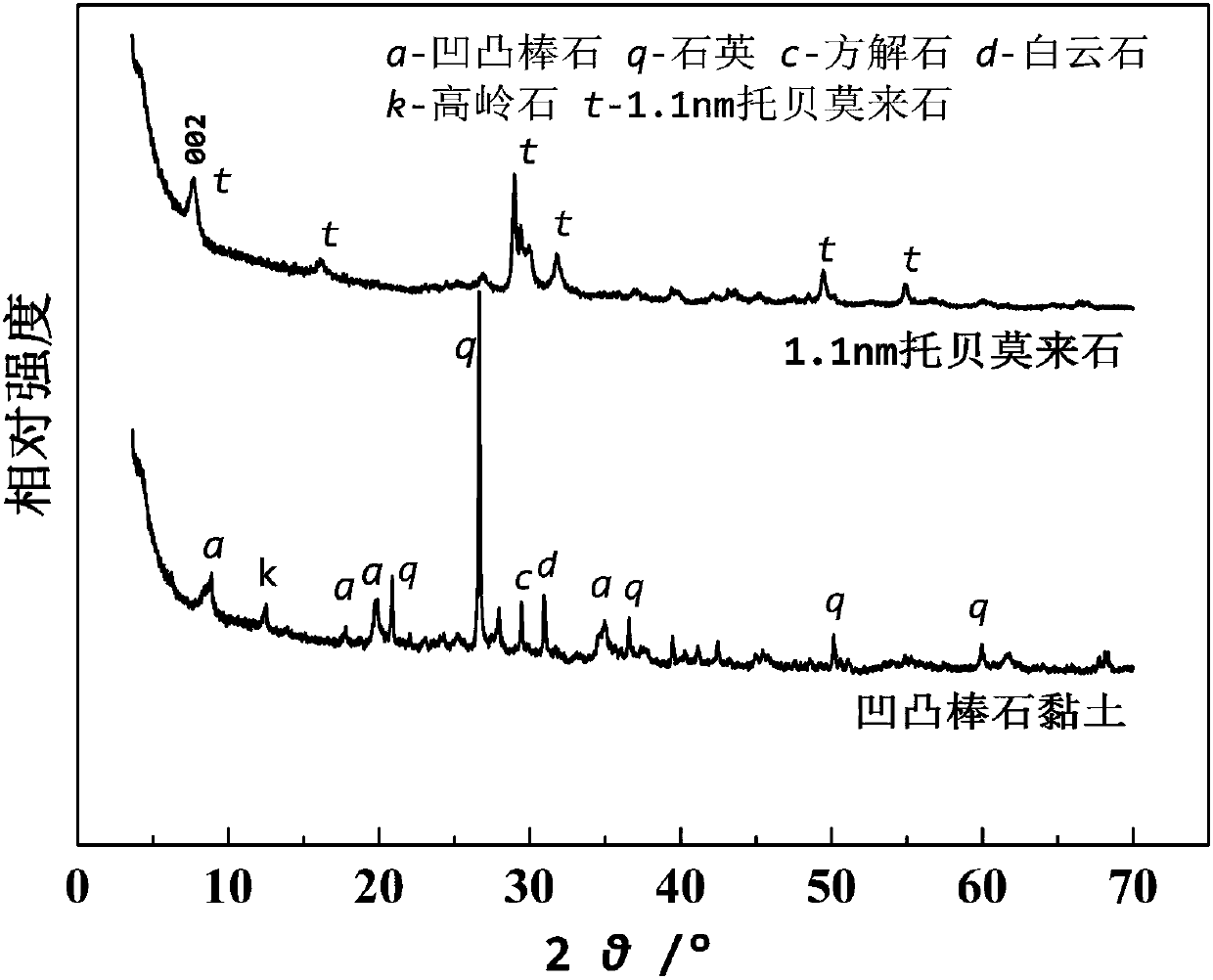

Method for preparing 1.1 nm tobermorite from low-grade attapulgite clay

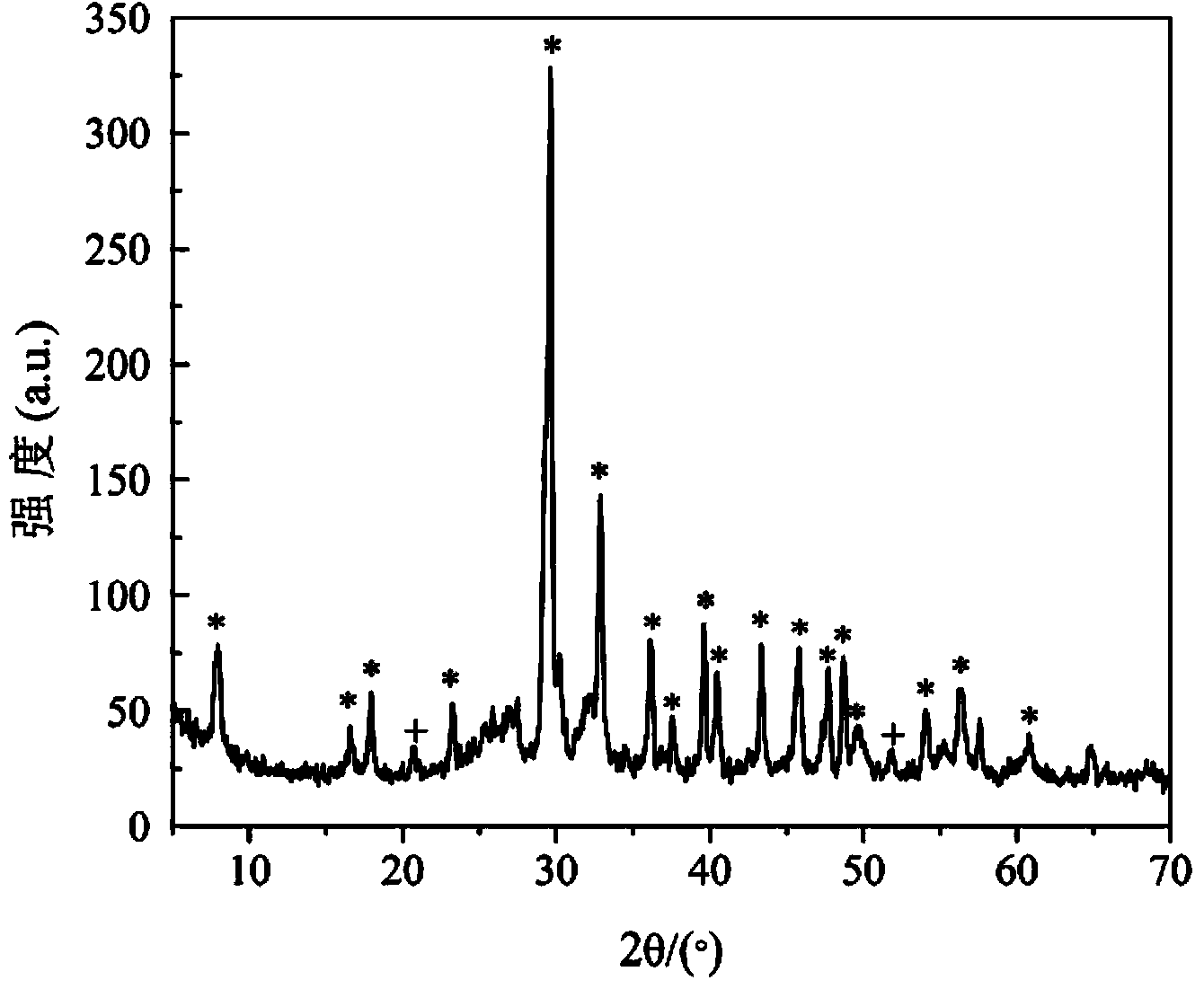

ActiveCN106315605ARealize high-value utilizationSimple preparation processAluminium silicatesNanotechnologyClay mineralsChemical reaction

The invention discloses a method for preparing 1.1 nm tobermorite from low-grade attapulgite clay. The method comprises steps as follows: low-grade attapulgite clay minerals are smashed, 150-300-mesh powder is obtained and dispersed in an aqueous silicate solution, a mixed solution is subjected to microwave activation for 5-10 min, and a stable suspension liquid A is formed; calcium salt is dispersed in water, and a uniform dispersion liquid B is formed; the dispersion liquid B is slowly added to the suspension liquid A during fast stirring and is sufficiently and uniformly mixed, and a precursor suspension liquid is obtained; the precursor suspension liquid is transferred into a hydrothermal reaction kettle to be subjected to a hydrothermal reaction, and then is cooled to the room temperature; solid products are separated, washed, dried and smashed, and the 1.1 nm tobermorite is obtained. According to the method, components of the attapulgite clay are subjected to the chemical reaction with silicon salt and calcium salt in a hydrothermal process, so that a crystal form is converted and recombined, the 1.1 nm tobermorite with good stability and uniform granularity is formed, and a product is good in uniformity, stable in performance and applied to adsorbents for substances such as heavy metals, dyes, antibiotics and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing high-strength autoclaved aerated concrete

InactiveCN101905964AGood dispersionSimple structureCeramic shaping apparatusWater contentTobermorite

The invention discloses a method for preparing autoclaved aerated concrete, which comprises the following steps: firstly, generating nano calcium carbonate emulsion in a carbonization reactor, dehydrating to obtain nano calcium carbonate slurry with a water content of 40 to 60 percent; and secondly, adding the nano calcium carbonate slurry into concrete slurry, mixing, stirring, pouring, forming a gas, static cutting, autoclaving for maintenance and forming, wherein the dry mass of the added nano calcium carbonate slurry is 1 percent based on the total mass of dry materials. Pressure strength tests show that the pressure strength of finished autoclaved aerated concrete with nano calcium carbonate is much higher than that of a reference test piece without nano calcium carbonate. In the invention, the structural strength, homogeneity and compactness of the product are improved and enhanced by adding the nano calcium carbonate slurry into the autoclaved aerated concrete slurry and by using the micro aggregate effect of the nano calcium carbonate; meanwhile, nano calcium carbonate particles function as crystal nuclei to improve the crystallinity of tobermorite, so the macro strength of the product is further improved.

Owner:ZHEJIANG UNIV

Preparation method of humidity controlling material

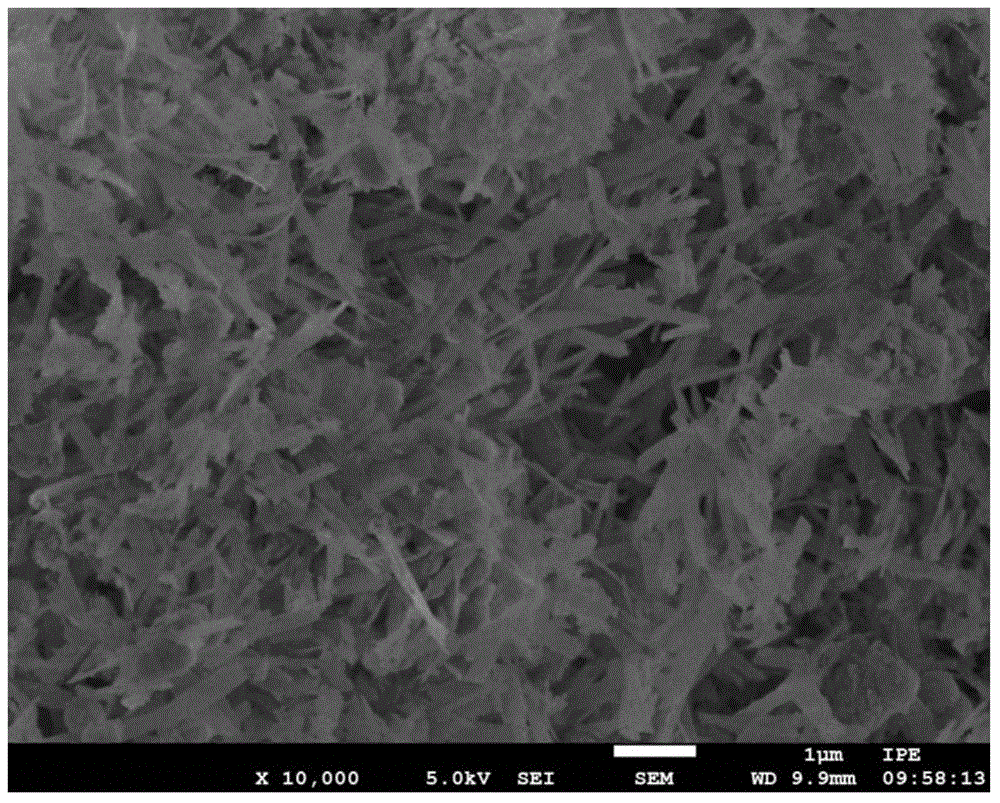

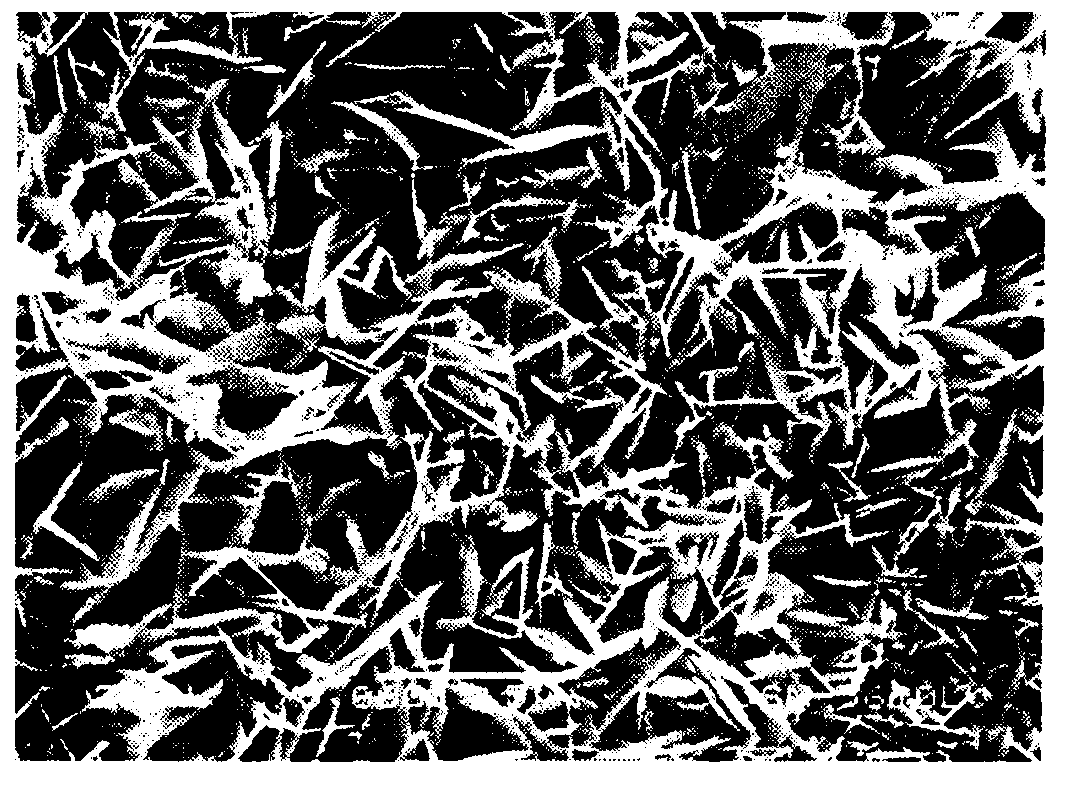

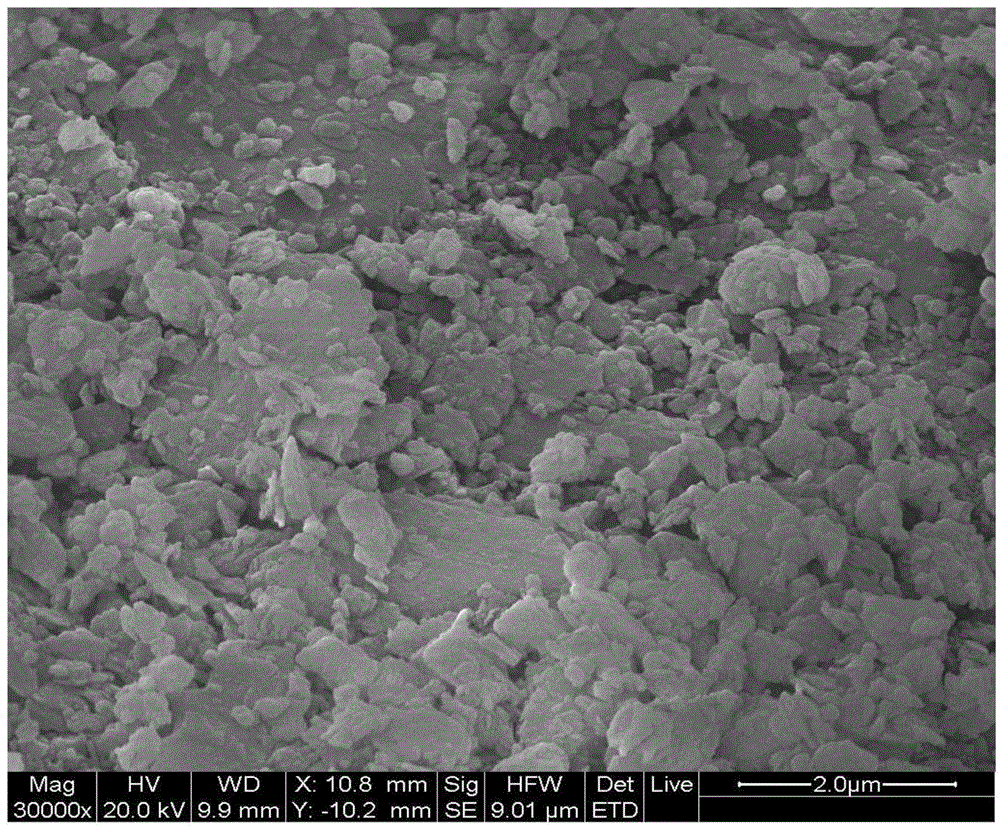

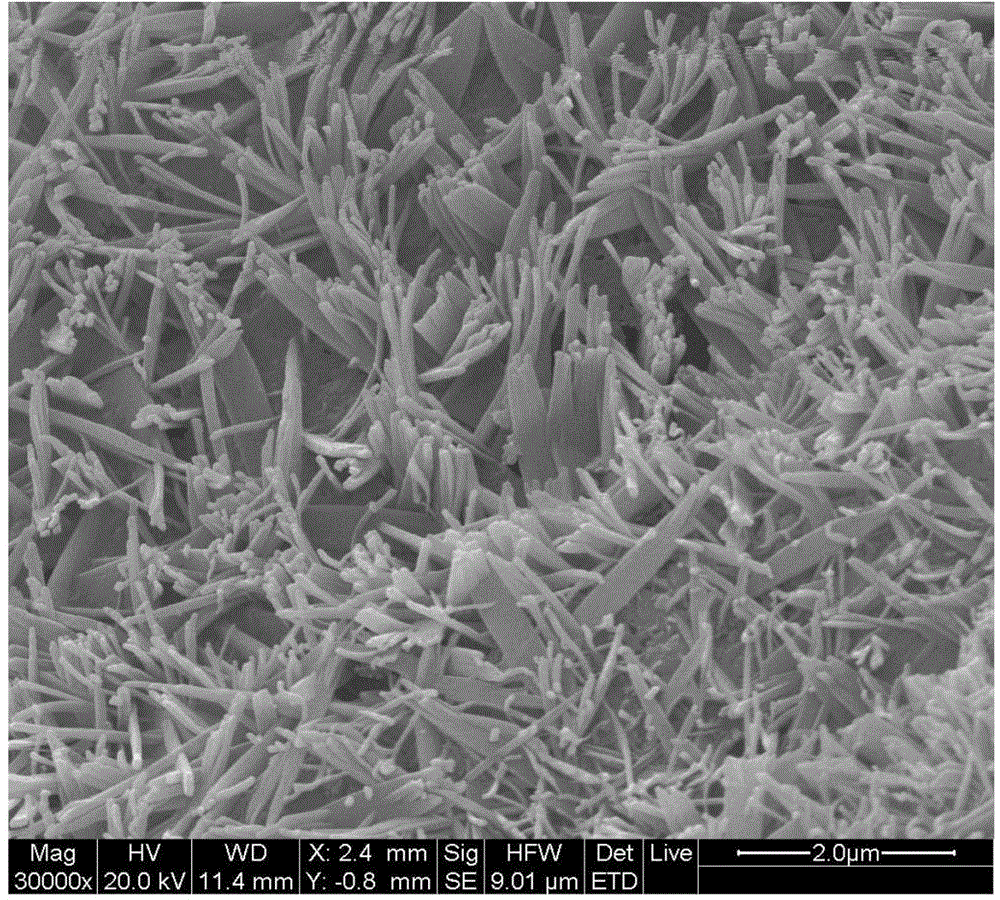

ActiveCN104527155ALow costSynthesis temperature is lowWater-setting substance layered productBedroomInorganic materials

The invention relates to a preparation method of a humidity controlling material. Massive gathered river alluvial sediments and meerschaum wide in distribution are raw materials and react under saturated vapor pressure of a hydrothermal kettle, an original porous structure of most of the meerschaum is reserved, needle-shaped tobermorite is generated, a composite porous material is formed, and the air humidity in a room can be adjusted to keep 40-70%. The humidity controlling material comprises the newly generated tobermorite and the meerschaum modified river alluvial sediments, the river alluvial sediments and hydrated lime are mixed and serve as the base material, the graded composite technology is adopted, and the superior building humidity controlling material is prepared. The indoor humidity of a bedroom, an office, a warehouse workshop, a museum and the like can be effectively adjusted and keeps within the needed proper humidity range. The humidity controlling material is a novel inorganic material with the self-humidity controlling characteristic and can replace an existing humidity controlling system.

Owner:TONGJI UNIV

Method for preparing aluminum tobermorite adsorbing material by using fire coal ash wastes

ActiveCN104107676AImprove use valueImprove adsorption capacityOther chemical processesSilicon compoundsRoom temperatureAdditional values

The invention discloses a method for preparing an aluminum tobermorite adsorbing material by using fire coal ash wastes. The method comprises the following steps: calcining fire coal ash in an electric heating furnace, cooling to room temperature and grinding to obtain fine ash powder; subsequently leaching the fine ash powder by using diluted hydrochloric acid and then filtering, washing and drying to obtain a precursor ash powder body; grinding and mixing the ash powder body and Ca(OH)2, then adding NaOH into the mixture and grinding and mixing to be uniform to obtain a mixture; spraying a water glass solution to the mixture and rotationally rolling to form a spherical granular aluminum tobermorite reactant precursor; putting the aluminum tobermorite reactant precursor into a stainless steel wire cage drawer of a reaction kettle, performing a hydrothermal water-proof stilling reaction for 16-20 hours at the temperature of 170-190 DEG C; cooling and releasing the pressure after the reaction ends, and then separating out reaction products and drying to obtain the aluminum tobermorite adsorbing material. The material prepared by the method disclosed by the invention has good adsorption and decontamination effects and achieves the aim of preparing an environmental material with a relatively high additional value by using the fire coal ash.

Owner:SHAANXI UNIV OF SCI & TECH

Application of hydrated calcium silicate fiber to prepare aerated concrete blocks

ActiveCN107500642APromote quality improvement and reduce consumptionThe principle is simpleCeramicwareCalcium silicateFiber

The invention relates to an application of hydrated calcium silicate fiber to prepare aerated concrete blocks, and belongs to the technical field of green energy-saving building materials. The hydrated calcium silicate fiber is used as an additive for producing aerated concrete blocks. The diameter of hydrated calcium silicate fiber is 0.01-0.5 mum, the length is 0.5-5 mum, and the calcium-to-silicon atomic ratio is 0.5-2. It is found through many researches that by using hydrated calcium silicate fiber having a certain structure as a mineralizing inducer of an aerated concrete hydration process, tobermorite can be induced to form in a production process, and the overall performance of the product (that is the aerated concrete blocks) is improved. The hydrated calcium silicate fiber is a reaction product of hydro-thermal synthesis of a thick liquid which is made of a siliceous raw material and a calcareous raw material. The hydrated calcium silicate fiber is simple in preparation process and low in cost. In a low addition of the hydrated calcium silicate fiber, tobermorite can be induced to form in the aerated concrete blocks, so that the mechanical strength of the aerated concrete blocks is improved.

Owner:CENT SOUTH UNIV

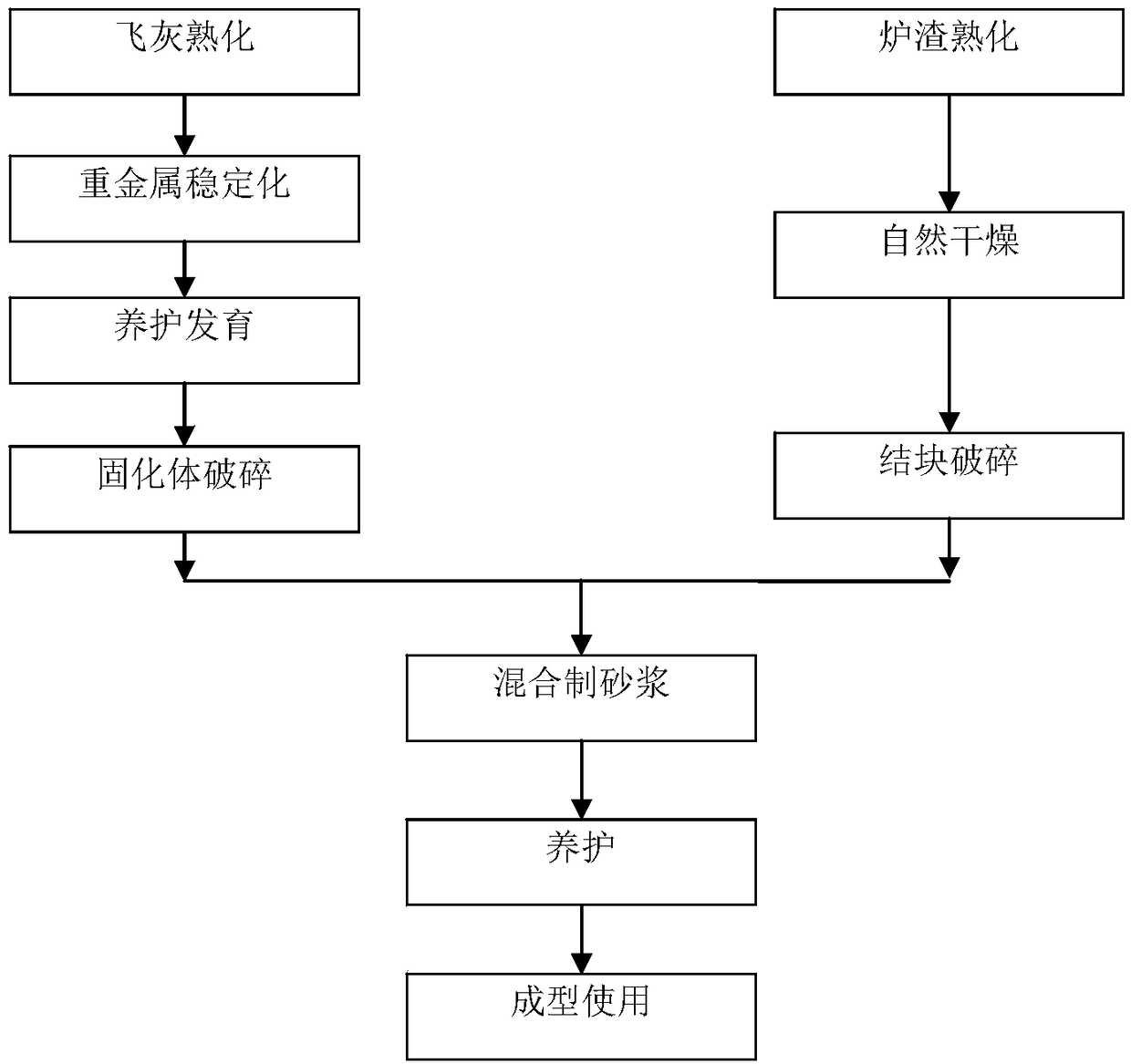

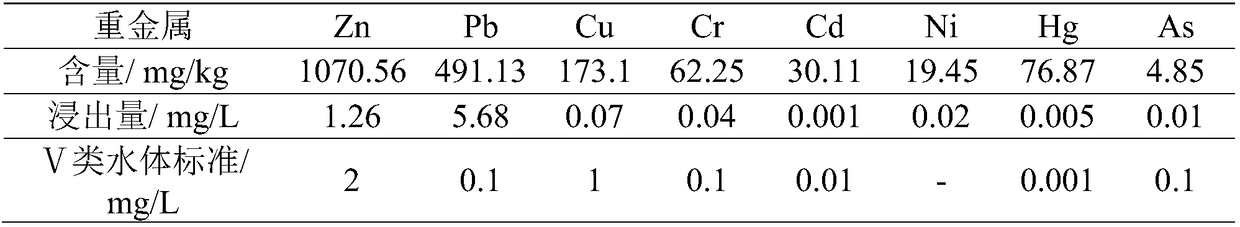

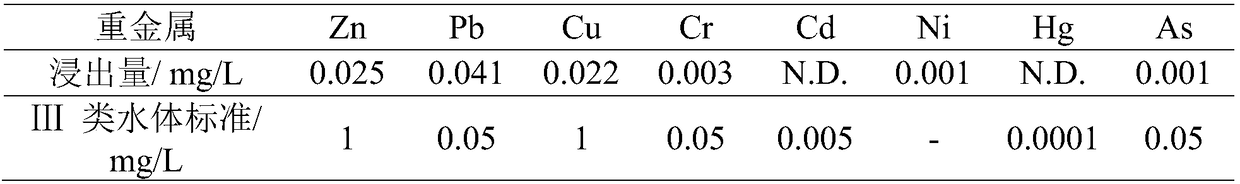

Method used for making bricks from domestic waste incineration fly ash and furnace slag

ActiveCN108314366AAchieve recyclingExcellent curing and stabilization effectCement productionCalcium silicateBrick

The invention discloses a method used for making bricks from domestic waste incineration fly ash and furnace slag. The method comprises following steps: 1, CaO in domestic waste incineration fly ash is subjected to slaking; 2, a sulfur containing compound and cement are added into a material obtained via slaking, and an obtained mixture is subjected to stirring homogenizing and heavy metal stabilization; 3, a product obtained via heavy metal stabilization is subjected to curing so as to obtain a fly ash heavy metal solidified body; 4, the fly ash heavy metal solidified body is subjected to crushing so as to obtain a fly ash powder material; 5, CaO in furnace slag is subjected to slaking; 6, a product material obtained via slaking of CaO in furnace slag is subjected to drying so as to obtain furnace clinker; 7, the furnace clinker is subjected to crushing so as to obtain furnace slag powder; 8, the fly ash powder material, the furnace slag powder, fly ash, NaOH, and water are mixed so as to obtain a mortar; and 9, the mortar is subjected to curing and moulding so as to obtain bricks. According to the method, geopolymeric gel and tobermorite are adopted to prepare building materials,resource utilization on fly ash and furnace slag is realized, brick mechanical properties are improved, and multistage solidification stabilization of heavy metal in fly ash is realized.

Owner:TSINGHUA UNIV

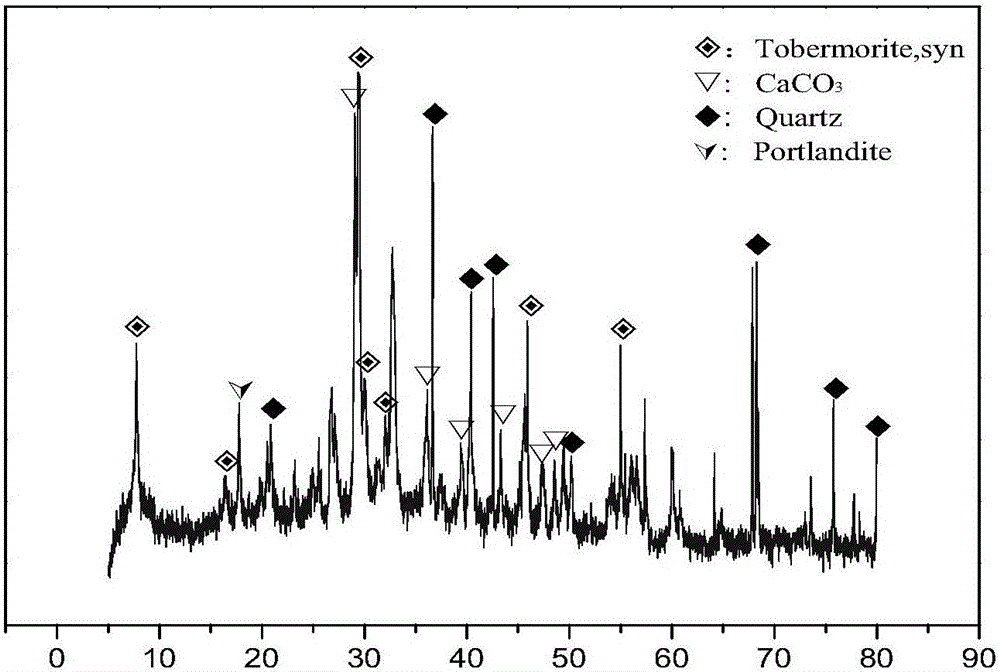

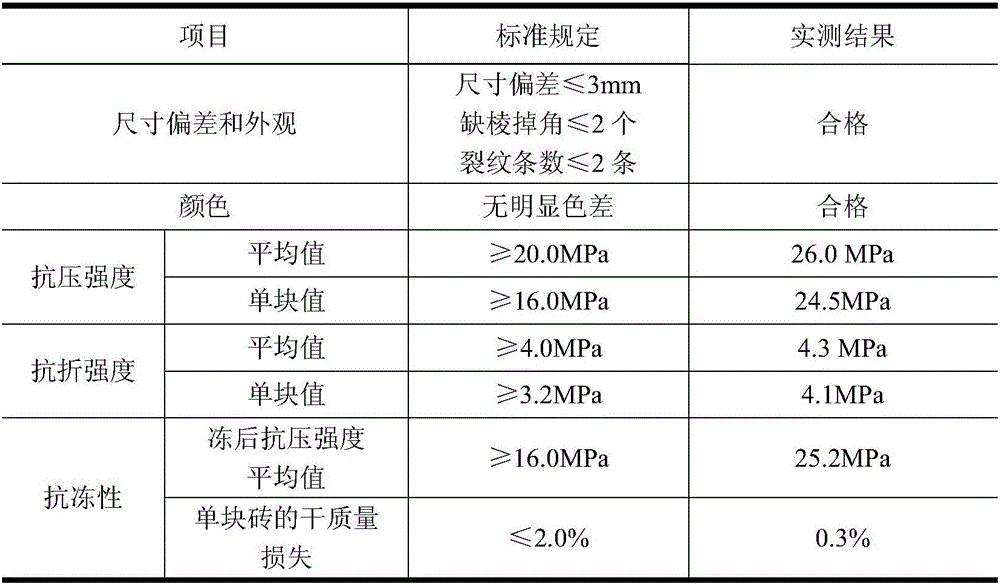

Autoclaved muck solid brick containing aluminous tobermorite and rapid preparation method of autoclaved muck solid brick

ActiveCN106830841ANo practical industrial application valueNo industrial application valueSolid waste managementBrickResource utilization

The invention discloses a method for producing an autoclaved solid brick taking muck as a raw material and containing aluminous tobermorite and a production technology. The solid brick is prepared from components in percentage by mass as follows: 70%-85% of muck, 12%-20% of cement, 2%-5% of sodium sulfate and 0-0.05% of an additive, and the sum of the mass percentages of all the components is 100%. A preparation method comprises the steps as follows: firstly, the muck is dried, ball-milled and sieved, muck with the particle size smaller than 10 mm is taken as the raw material, then, all the components are weighed and mixed with part of water, uniform mixing is performed, the obtained mixture is conveyed to a forming shop to be pressed, a standard green brick is obtained and subjected to autoclaved curing, and a finished product is obtained. The treatment amount of muck and residual mud is large, the cost is low, the preparation cycle is short, and batch resource utilization of construction waste and the low-carbon city development goal are achieved. Aluminum-containing minerals in the muck react to produce aluminous tobermorite, the good intensity and durability of the green brick are guaranteed, and the product has the good appearance and few defects and meets the requirement of Autoclaved Sand-lime Brick (GB11945-1999) MU20 level performance.

Owner:深圳市航天新材科技有限公司

Concrete antifreezer

The invention discloses a concrete antifreezer. The antifreezer comprises, by weight 40-50 parts of tobermorite and 50-60 parts of antifreezing component, wherein the antifreezing component comprises potassium acetate or sodium acetate and lithium acetate or lithium nitrate, and the molar ratio of lithium and potassium or sodium in the antifreezing component is 0.1-0.8. According to the concrete antifreezer, the production process is simple and feasible, the cost is low and the concrete antifreezer is suitable for industrial production.

Owner:JURONG NINGWU CHEM

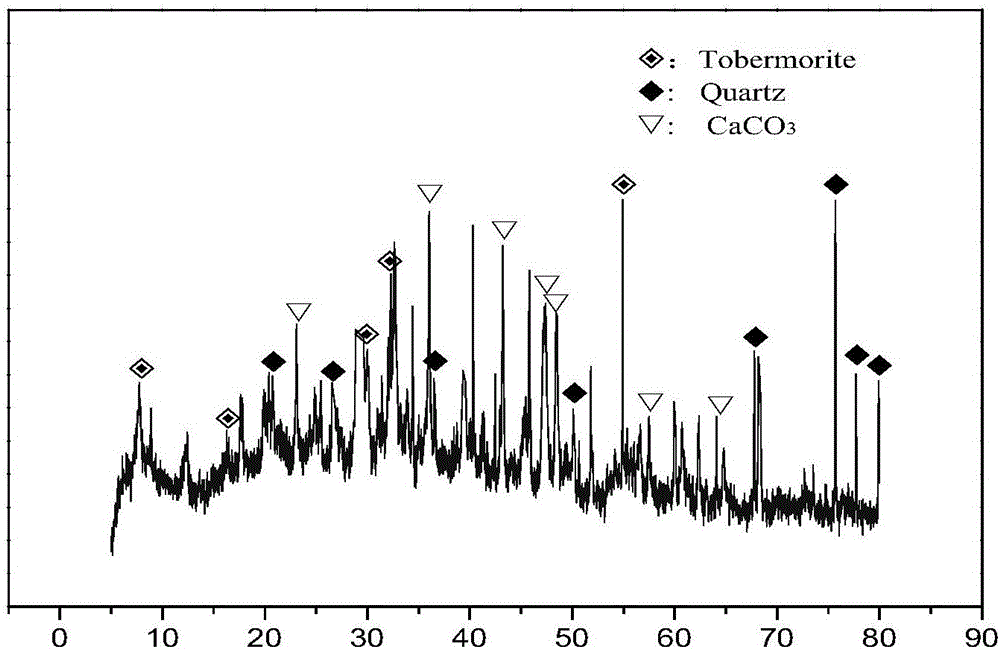

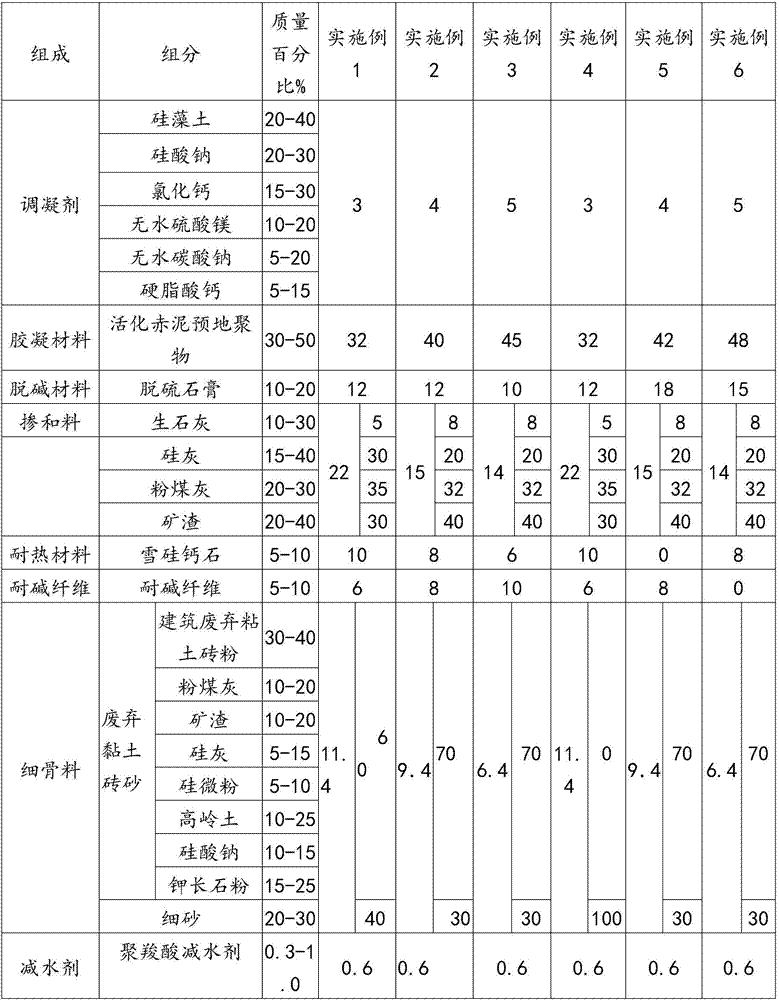

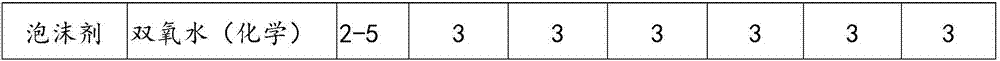

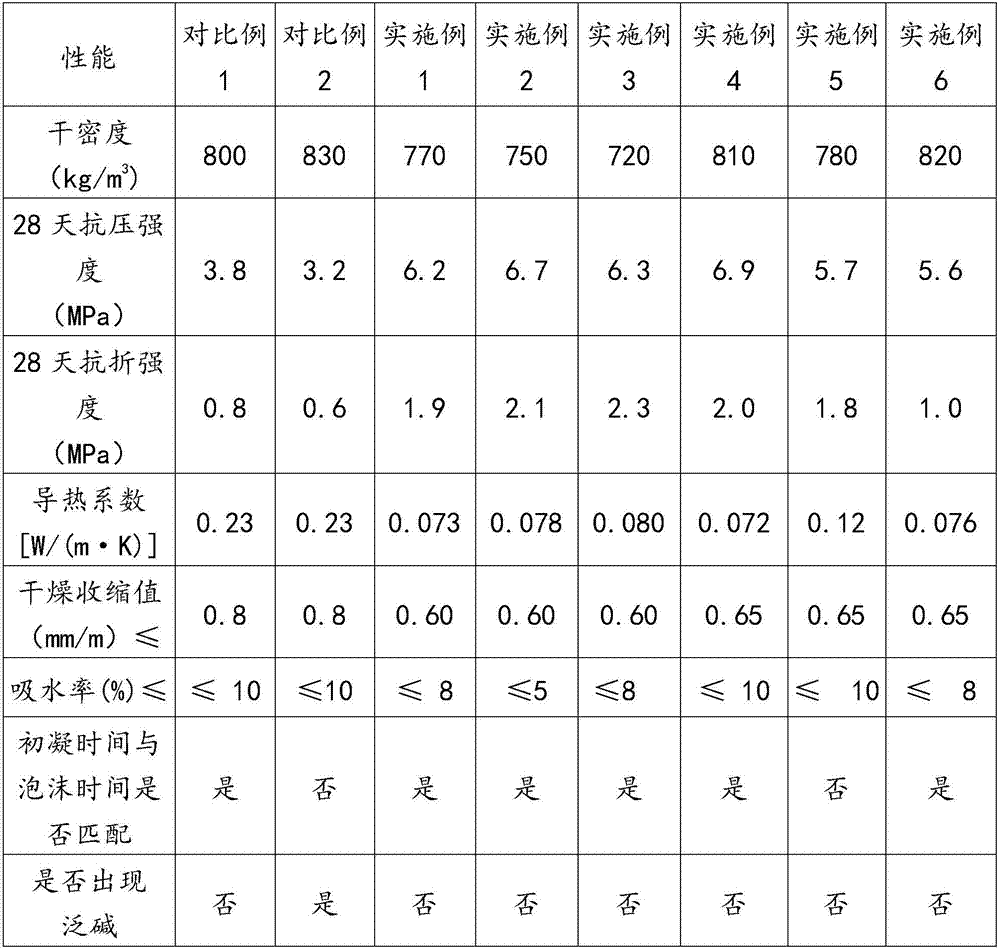

Red mud geopolymer foam building block and preparation method thereof

InactiveCN107572920ASolve the ubiquitous problemImprove thermal insulation performanceCement productionCeramicwareFiberThermal insulation

The invention provides a red mud geopolymer foam building block and a preparation method thereof. The red mud geopolymer foam building block is prepared from the following components in percentage bymass: 30-50% of activated red mud pre-geopolymer, 6-15% of fine aggregate, 10-20% of desulfurized gypsum, 10-25% of admixture, 2-8% of thickening time control agent, 5-10% of tobermorite, 5-8% of alkali-proof fiber and 3-5% of hydrogen peroxide. By adopting the technical scheme of the invention, the problem of efflorescence of a red mud lightweight wall building block is solved; meanwhile, by adding the tobermorite with excellent thermal insulation property, the thermal insulation property of the red mud and foam building blocks is remarkably enhanced.

Owner:南宁恒慕科技有限责任公司 +1

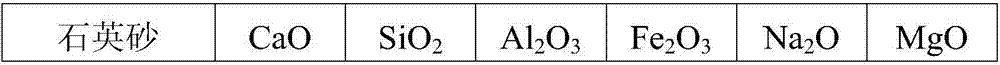

Method for preparing tobermorite by using silicon-calcium slag

The invention provides a method for preparing tobermorite by using silicon-calcium slag. The method comprises the following steps: (1) mixing and grinding a calcium-containing raw material and a silicon-containing raw material to obtain a mixture; (2) after mixing the mixture with water, carrying out hydro-thermal synthesis reaction, and filtering, washing and drying a reaction product to obtain the tobermorite, wherein the calcium-containing raw material is the silicon-calcium slag; and the silicon-containing raw material is selected from more than one of silicon ash, quartz sand, diatomite, silica gel and white carbon. The method is extensive in sources of raw materials, low in cost, simple in preparation process and short in synthesis reaction time; the production efficiency can be greatly improved; unit production costs are reduced; and the popularization and application prospect is good.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

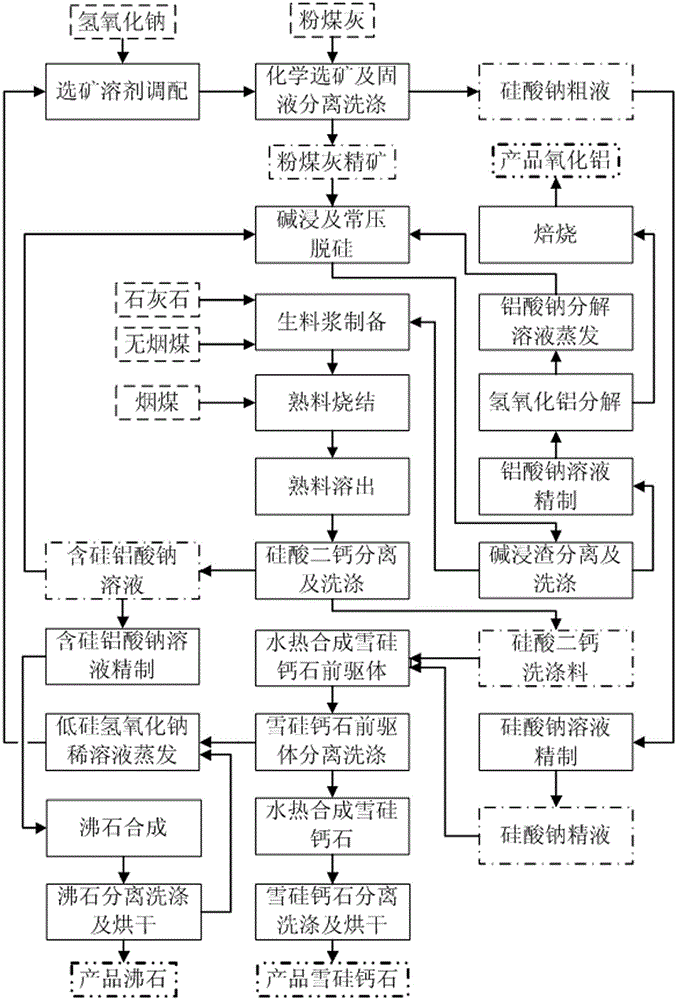

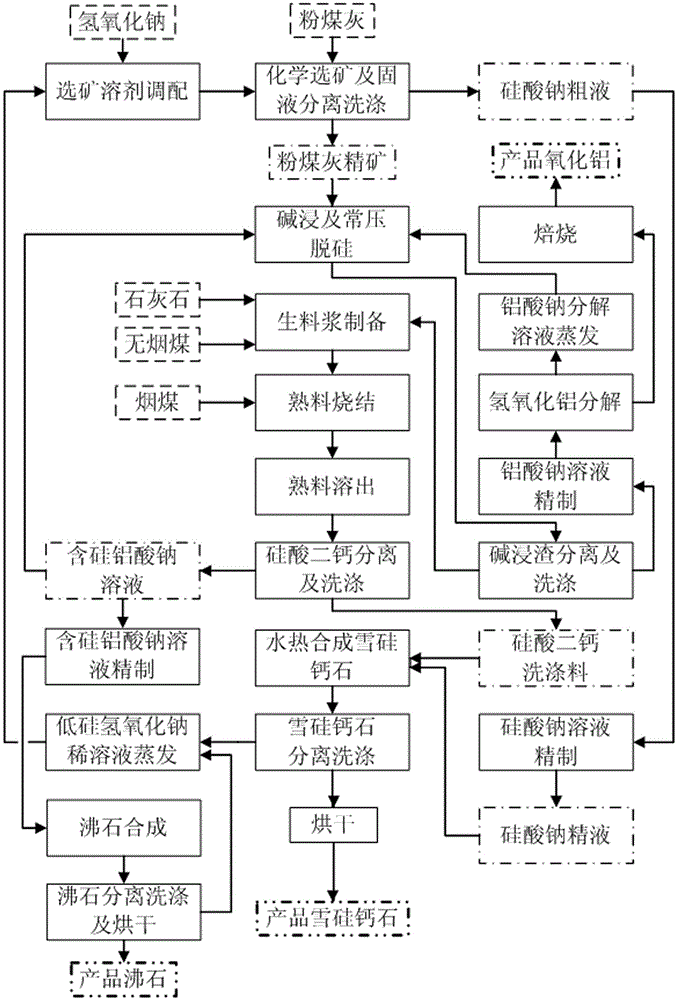

Method for producing tobermorite and aluminum oxide by using coal ash alkaline leaching sintering hydrothermal method

ActiveCN104477927AThere is littleGood market demandWaste processingSolid waste disposalSlagEngineering

The invention discloses a method for producing tobermorite and aluminum oxide by using a coal ash alkaline leaching sintering hydrothermal method. The method comprises the following steps: (1) performing chemical ore separation; (2) producing aluminum oxide through alkaline leaching; (3) preparing raw material slurry; (4) sintering to prepare clinker; (5) dissolving, separating and washing the clinker; (6) preparing tobermorite precursor raw material slurry; (7) performing hydro-thermal synthesis to prepare a tobermorite precursor; (8) performing hydro-thermal synthesis to prepare tobermorite slurry. By adopting the method, the problems and the defects that in the prior art a great deal of limestone is consumed, the energy consumption is large and a great deal of slag is generated are effectively solved, both tobermorite and aluminum oxide can be produced, a silicon mineral resource is saved, a monohydrallite resource is replaced, sources such as soil are also saved, and large-scale economic production is achieved.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

Nickel pollution soil repair agent

InactiveCN106590682AReduce the content of leached nickelNo secondary pollutionContaminated soil reclamationOrganic fertilisersSoil remediationHypnea chordacea

The invention discloses a nickel pollution soil repair agent. The repair agent comprises the following raw materials, by mass, of 22-30 parts of tobermorite, 5-8 parts of giant uronemaconfervicolum, 5-8 parts of hypnea chordacea and 4-7 parts of modified rhodonite, wherein the dosage ratio of the giant uronemaconfervicolum to the hypnea chordacea is 1:1. The preparation of the modified rhodonite comprises super micro-grinding, mixing with N-maleyl chitosan, dispersing, ultrasonic treatment and drying. The giant uronemaconfervicolum and the hypnea chordacea are smashed and screened, and powder is obtained. The tobermorite is calcinated; a dextrotartaric acid aqueous solution is added to conduct soaking treatment; the treated tobermorite is taken out, refrigerated and mixed with the giant uronemaconfervicolum, the hypnea chordacea and the modified rhodonite; and ultrasonic treatment and drying are conducted, and the nickel pollution soil repair agent is obtained. According to the nickel pollution soil repair agent, the compound mode containing four components, namely, the tobermorite, the giant uronemaconfervicolum, the hypnea chordacea and the modified rhodonite is adopted, the content of leached nickel in the soil can be significantly reduced, and meanwhile, secondary pollution to the repaired soil is not caused.

Owner:ZHENGZHOU YUANRAN BIOLOGY TECH CO LTD

Modified aerated concrete

InactiveCN107935620AImprove microstructureHigh compressive strengthCeramicwareCalcium silicateColloid

The invention discloses modified aerated concrete, which comprises, by weight, 80-105 parts of an aerated concrete base material and 1-10 parts of a crystal seed. The crystal seed is made from a hydro-thermal synthetic silicate material containing tobermorite and hydrated calcium silicate colloid. The modified aerated concrete is made through production technology of conventional aerated concrete.Through addition of the crystal seed, the hydro-thermal synthetic reaction of concrete is promoted, and the colloid is converted to tobermorite colloid. The total amount of hydrated calcium silicateand the crystal-colloid ratio are improved, and the microstructure of aerated concrete is improved. The compressive strength of aerated concrete is improved by 20%, and the drying shrinkage value is reduced to 0.2-0.3 mm / m.

Owner:盐城市建筑设计研究院有限公司

Method for preparing 1.1nm tobermullite by using low-grade attapulgite clay

ActiveCN106315605BRealize high-value utilizationSimple preparation processAluminium silicatesNanotechnologyClay mineralsChemical reaction

The invention discloses a method for preparing 1.1 nm tobermorite from low-grade attapulgite clay. The method comprises steps as follows: low-grade attapulgite clay minerals are smashed, 150-300-mesh powder is obtained and dispersed in an aqueous silicate solution, a mixed solution is subjected to microwave activation for 5-10 min, and a stable suspension liquid A is formed; calcium salt is dispersed in water, and a uniform dispersion liquid B is formed; the dispersion liquid B is slowly added to the suspension liquid A during fast stirring and is sufficiently and uniformly mixed, and a precursor suspension liquid is obtained; the precursor suspension liquid is transferred into a hydrothermal reaction kettle to be subjected to a hydrothermal reaction, and then is cooled to the room temperature; solid products are separated, washed, dried and smashed, and the 1.1 nm tobermorite is obtained. According to the method, components of the attapulgite clay are subjected to the chemical reaction with silicon salt and calcium salt in a hydrothermal process, so that a crystal form is converted and recombined, the 1.1 nm tobermorite with good stability and uniform granularity is formed, and a product is good in uniformity, stable in performance and applied to adsorbents for substances such as heavy metals, dyes, antibiotics and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

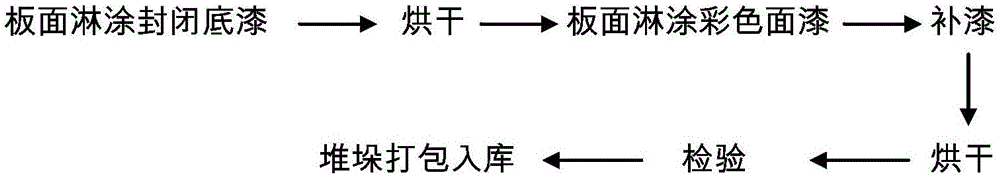

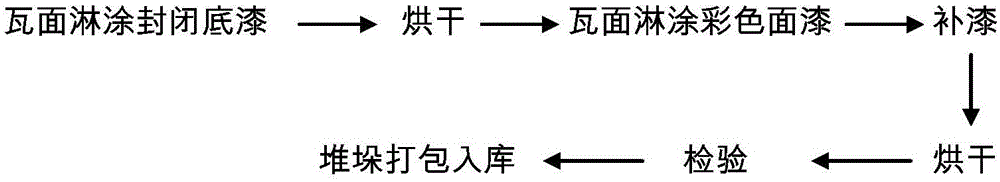

Permanent heavy metal waste curing method

According to the present invention, powder-like or slurry-like heavy metal waste, quick lime, gypsum powder, quartz powder or porcelain clay, fibers and an additive are matched according to a certain ratio, the heavy metal waste is directly used as the reference material and is permanently cured in the Tobermorite crystal through the stable structure Tobermorite crystal, the extrusion method is used to produce so as to substantially improve the production efficiency, a plurality of the irregularly shaped structures can be produced, the utilization of the heavy metal waste is accelerated, and the important significance is provided for the national treatment of heavy metal pollution; material matching, slurry preparing, black preparing molding and steam curing are performed so as to finally form the Tobermorite crystal wrapping the heavy metal waste particles; and with the production method, the permanent heavy metal waste curing purpose can be achieved only requiring 1-2 day, such that the production period is substantially shortened, and the treatment capacity on the heavy metal waste is increased so as to achieve the purpose of the present invention.

Owner:肖德意

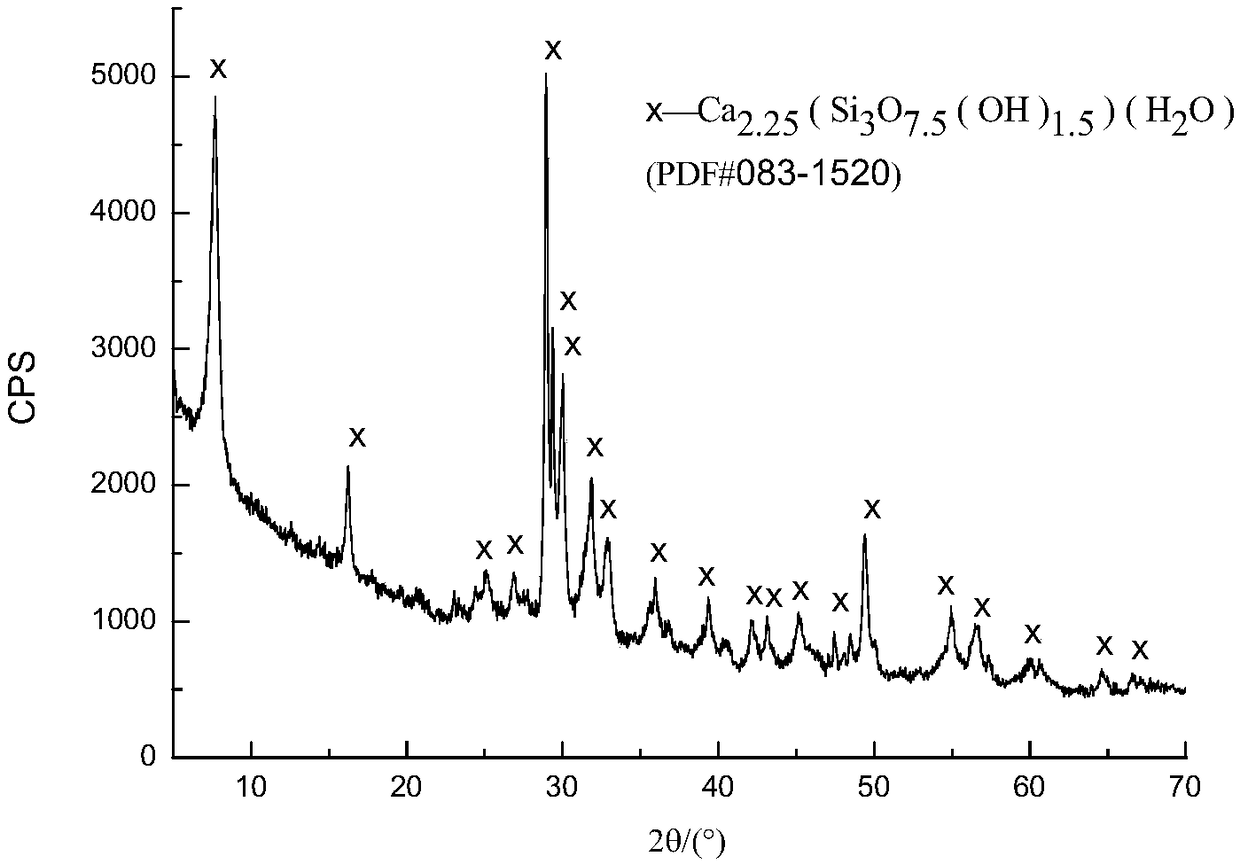

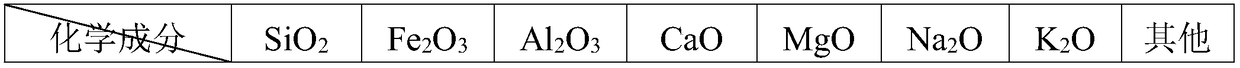

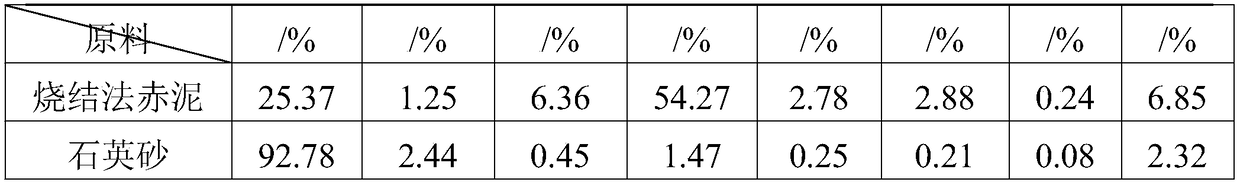

Method for preparing tobermorite type thermal-insulating and fireproofing material from sintered red mud

The invention relates to a method for preparing a tobermorite type thermal-insulating and fireproofing material from sintered red mud, and belongs to the field of inorganic thermal insulating materials. Raw materials of the tobermorite type thermal-insulating and fireproofing material comprise a mixture, a trace additive, reinforced fibers, an inorganic glue and a waterproof agent. The method comprises the following steps: injecting the mixture and water into a dynamic reactor, carrying out hydrothermal synthesis for 1.0-8.0 h by using 180-240 DEG C superheated steam to obtain a tobermorite slurry, and adding the reinforced fibers; filtering the obtained slurry, and sequentially adding the inorganic glue and the waterproof agent; and carrying out compression molding, and performing dryingto obtain the tobermorite type thermal-insulating and fireproofing material. The main raw material sintered red mud is a solid waste formed by extracting alumina from bauxite or high-alumina fly ash through a soda lime sintering process, so the production cost of tobermorite is greatly reduced, the raw materials have wide sources, the reaction time is short, and the obtained thermal-insulating andfireproofing material has a high strength, a light unit weight and a good water repellency; and the method for preparing the tobermorite is simple, can consume the solid waste generated in the alumina production process, and is suitable for being industrially promoted.

Owner:内蒙古中建亚太建材科技有限公司

Nucleating agent, copper tailing autoclaved aerated concrete product, preparation method and application

The invention relates to the technical field of building materials, and particularly discloses a nucleating agent, a copper tailing autoclaved aerated concrete product, a preparation method and application. The nucleating agent comprises the following raw materials: blast furnace slag, nano calcium carbonate, fly ash, acicular wollastonite powder, polycarboxylic acid, triterpenoid saponin and sodium silicate. The nucleating agent can be used for preparing autoclaved aerated concrete blocks by utilizing the characteristics of early enhancement and tobermorite crystallization induction, and by generating enough tobermorite to be inserted into CSH gel, the compressive strength is effectively improved, the shrinkage of the product is reduced, the dry density is low, and the problems that in the prior art, when copper tailings are used as raw materials for preparing autoclaved aerated concrete blocks, produced products are low in compressive strength, high in volume weight and large in shrinkage are solved. The provided preparation method is simple, can be used for rapidly and efficiently preparing the nucleating agent, and has a wide market prospect.

Owner:江西省建筑材料工业科学研究设计院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com