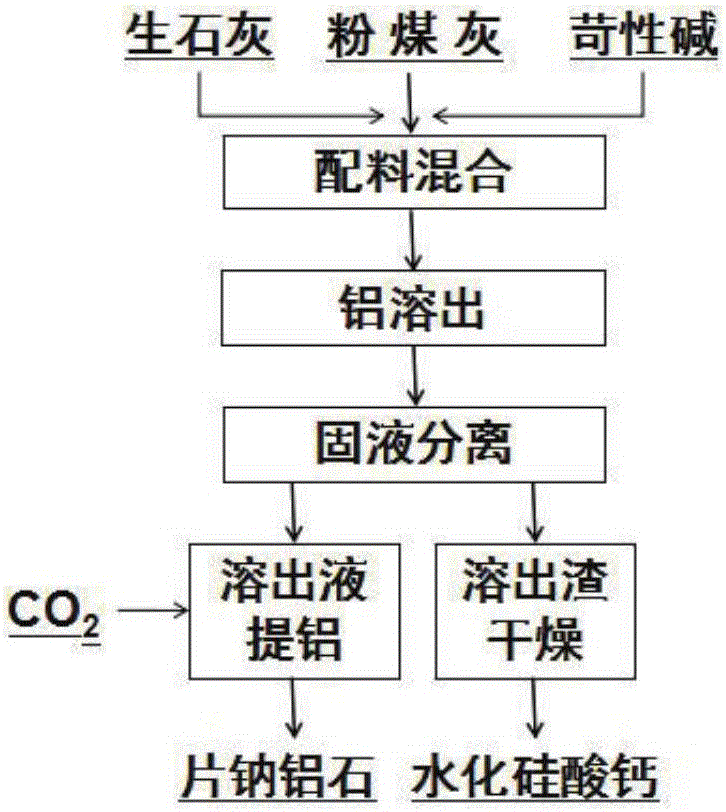

Method for co-producing dawsonite and tobermorite from fly ash

A technology for hydrating calcium silicate and dawsonite, which is applied in the field of solid waste resource utilization, can solve the problems of low purity of Si/Al separation, low purity of sodium aluminate eluate, and low aluminum-silicon ratio. Low-level problems, to achieve the effect of wide adaptability of raw materials, comprehensive utilization of low cost and high added value, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

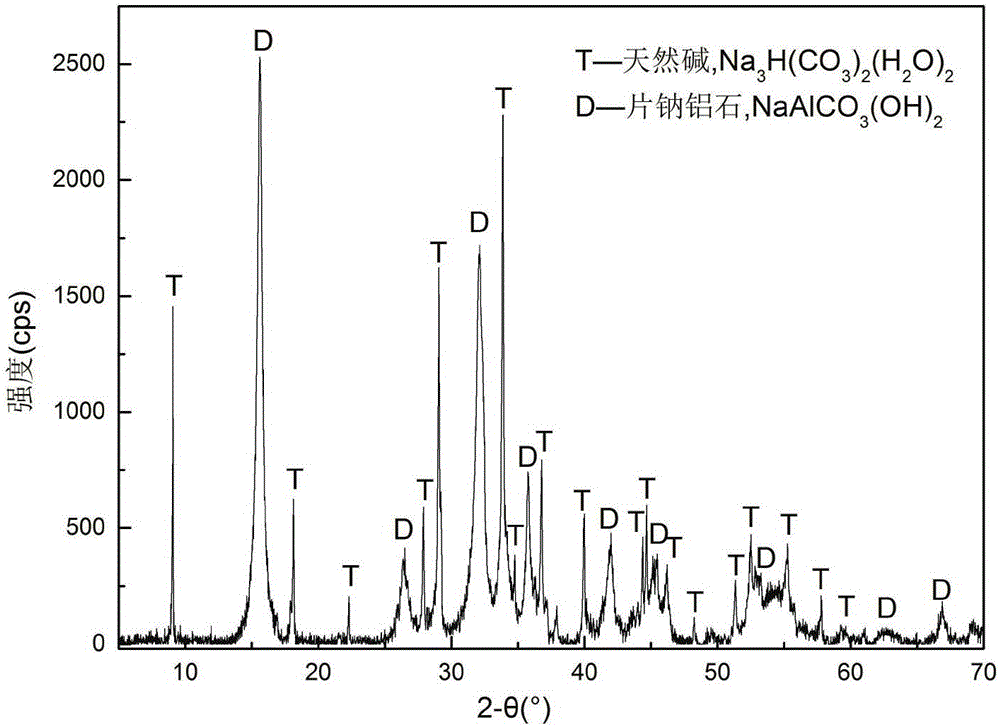

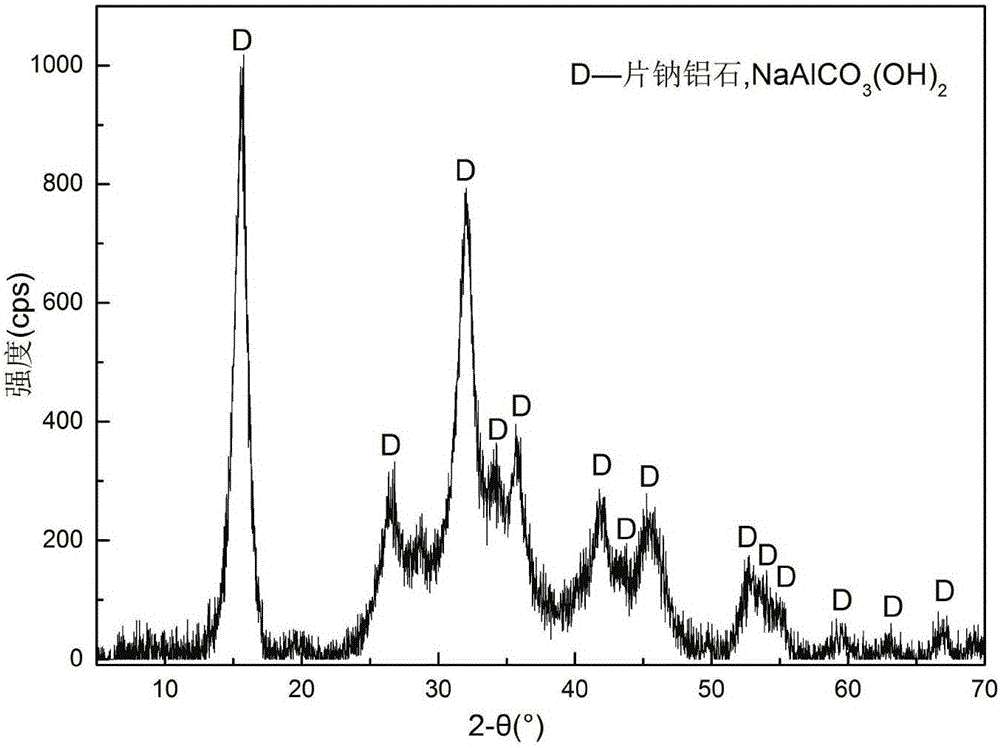

Embodiment 1

[0053] Prepare suspension slurry according to liquid-solid ratio of 10ml / g and calcium-silicon molar ratio of 1.5, add 10g / L sodium hydroxide (based on the slurry) to adjust the pH value of the slurry, stir and mix well and put it into high-pressure reaction In the kettle, hydrothermal reaction was carried out at 240°C and 3.2MPa pressure for 3h. After the reaction is finished, the solid-liquid separation of the reaction product is carried out to obtain the elution liquid and elution slag of aluminum. At a temperature of 35°C, a volume concentration of 30% CO was introduced into the eluate. 2 Gas (CO 2 / N 2 Mixed atmosphere), when the pH value of the solution drops to about 8.5, stop the aeration, and undergo solid-liquid separation to obtain aluminum-containing crystals. The dissolved slag and aluminum-containing crystals were dried at a temperature of 75° C. to constant weight. The dissolved slag and aluminum-containing crystals were weighed to prepare samples, and analy...

Embodiment 2

[0055] Prepare the suspension slurry according to the liquid-solid ratio of 20ml / g and the calcium-silicon molar ratio of 1.2, add 20g / L sodium hydroxide (based on the slurry) to adjust the pH value of the slurry, stir and mix well and put it into the high-pressure reaction In the kettle, hydrothermal reaction was carried out at 220°C and 2.2MPa pressure for 5h. After the reaction is finished, the solid-liquid separation of the reaction product is carried out to obtain the elution liquid and elution slag of aluminum. At a temperature of 55°C, the volume concentration of 50% CO 2 Gas (CO 2 / N 2 mixed atmosphere), when the pH value of the solution drops to about 9.0, stop the aeration, and undergo solid-liquid separation to obtain aluminum-containing crystals. The dissolved slag and aluminum-containing crystals were dried at a temperature of 75° C. to constant weight. The dissolved slag and aluminum-containing crystals were weighed to prepare samples, and analyzed by XRD and...

Embodiment 3

[0057] Prepare the suspension slurry according to the liquid-solid ratio of 30ml / g and the calcium-silicon molar ratio of 1.0, add 40g / L sodium hydroxide (based on the slurry) to adjust the pH value of the slurry, stir and mix well and put it into the high-pressure reaction In the kettle, hydrothermal reaction was carried out at 200°C and 1.8MPa pressure for 7h. After the reaction is finished, the solid-liquid separation of the reaction product is carried out to obtain the elution liquid and elution slag of aluminum. Under the condition of the temperature of 75°C, the eluate was passed through CO with a volume concentration of 70%. 2 Gas (CO 2 / N 2 Mixed atmosphere), when the pH value of the solution drops to about 8.5, stop the aeration, and undergo solid-liquid separation to obtain aluminum-containing crystals. The dissolved slag and aluminum-containing crystals were dried at a temperature of 75° C. to constant weight. The dissolved slag and aluminum-containing crystals ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com