Method used for making bricks from domestic waste incineration fly ash and furnace slag

A technology of domestic waste incineration and fly ash, applied in cement production and other directions, can solve the problems of restricting the market and development of fly ash resource-based bricks, restricting the use range of fly ash resource-based bricks, poor mechanical properties and environmental friendliness, etc. Thermal and mechanical properties, good effects, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1, utilize domestic waste to incinerate fly ash and slag to make brick

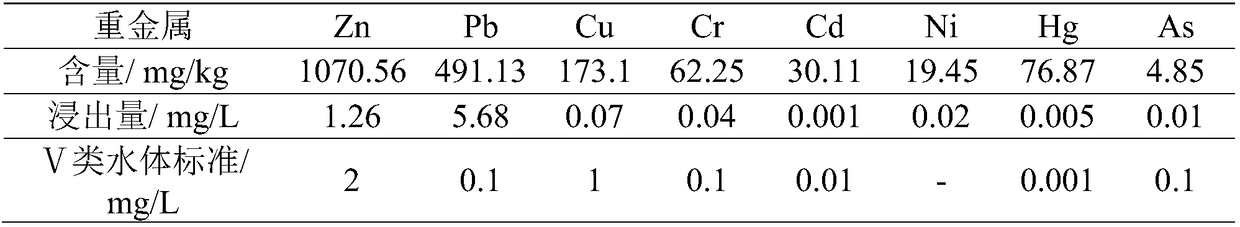

[0062] The fly ash samples and slag samples came from a waste incineration plant in Daxing District, Beijing. The content and leaching amount of heavy metals in the fly ash samples are shown in Table 1. For the leaching method, refer to the Horizontal Oscillation Method for Toxic Leaching of Solid Wastes (HJ557-2010), and for the limit standard, refer to the standard for Class V water bodies in the Environmental Quality Standards for Surface Water (GB3838-2002). It can be seen from Table 1 that the leaching amount of Pb seriously exceeds the standard.

[0063] Table 1 Content and leaching amount of heavy metals in fly ash of a waste incineration plant in Daxing, Beijing

[0064]

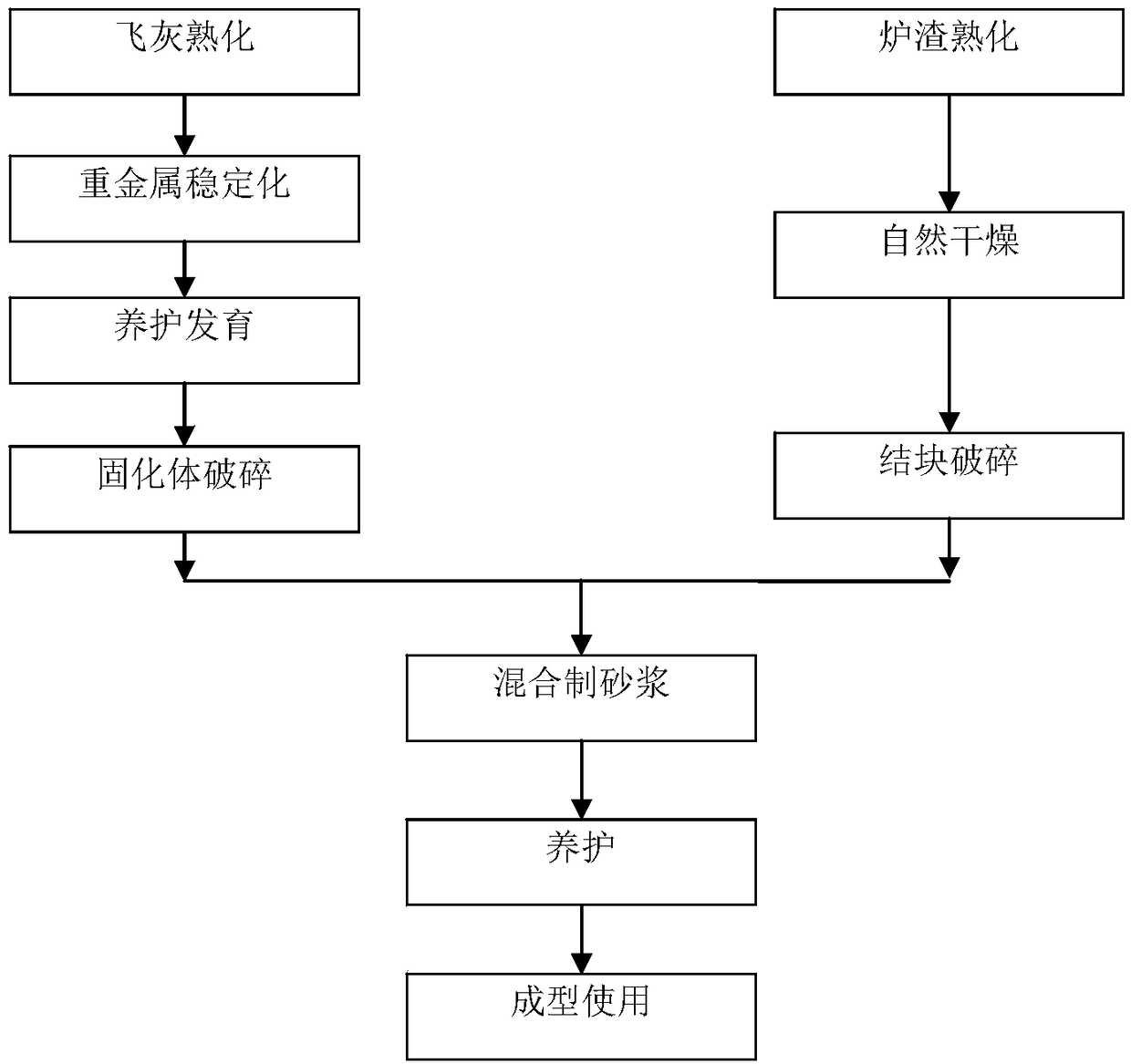

[0065] according to figure 1 The flow chart shown uses domestic waste incineration fly ash and slag to make bricks, and the specific steps are as follows:

[0066] (1) Fly ash aging:

[0067] The fly ash...

Embodiment 2

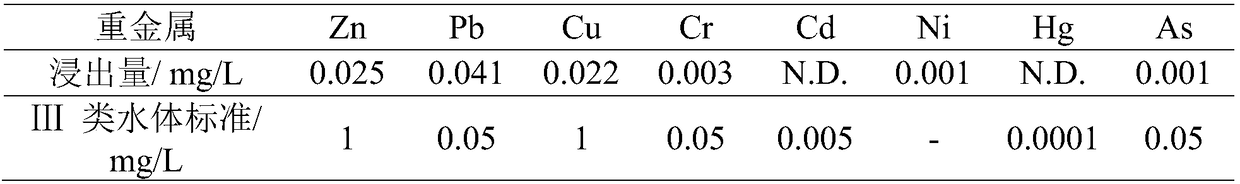

[0088] Embodiment 2, utilize domestic waste to incinerate fly ash and slag to make brick

[0089] The fly ash samples and slag samples came from a waste incineration plant in Xingtai, Hebei. The content and leaching amount of heavy metals in the fly ash samples are shown in Table 3. For the leaching method, refer to the Horizontal Oscillation Method for Toxic Leaching of Solid Wastes (HJ557-2010), and for the limit standard, refer to the standard for Class V water bodies in the Environmental Quality Standards for Surface Water (GB3838-2002). It can be seen from Table 3 that the leached amounts of Pb and Zn seriously exceed the standard.

[0090] Table 3 Heavy metal content and leaching amount in fly ash of a waste incineration plant in Xingtai, Hebei

[0091]

[0092]

[0093] according to figure 1 The flow chart shown uses domestic waste incineration fly ash and slag to make bricks, and the specific steps are as follows:

[0094] (1) Fly ash aging:

[0095] The fly ...

Embodiment 3

[0116] Embodiment 3, utilize domestic refuse to incinerate fly ash and slag to make brick

[0117] The fly ash samples and slag samples came from a waste incineration plant in Linqu, Shandong. The content and leaching amount of heavy metals in the fly ash samples are shown in Table 5. For the leaching method, refer to the Horizontal Oscillation Method for Toxic Leaching of Solid Wastes (HJ557-2010), and for the limit standard, refer to the standard for Class V water bodies in the Environmental Quality Standards for Surface Water (GB3838-2002). It can be seen from Table 5 that the leaching amount of Pb and Cr exceeds the standard.

[0118] Table 5 Heavy metal content and leaching amount in fly ash of a waste incineration plant in Linqu, Shandong

[0119]

[0120] according to figure 1 The flow chart shown uses domestic waste incineration fly ash and slag to make bricks, and the specific steps are as follows:

[0121] (1) Fly ash aging:

[0122] The fly ash is mixed with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com