Method for preparing aluminum tobermorite adsorbing material by using fire coal ash wastes

A technology of tobermorite and coal-burning ash, which is applied in the field of preparation of aluminum-substituted tobermorite adsorption materials, can solve problems such as complex methods, high preparation costs, and difficulty in popularization, and achieve strong adsorption and cation exchange capacity, It is beneficial to environmental governance and improves the effect of comprehensive utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

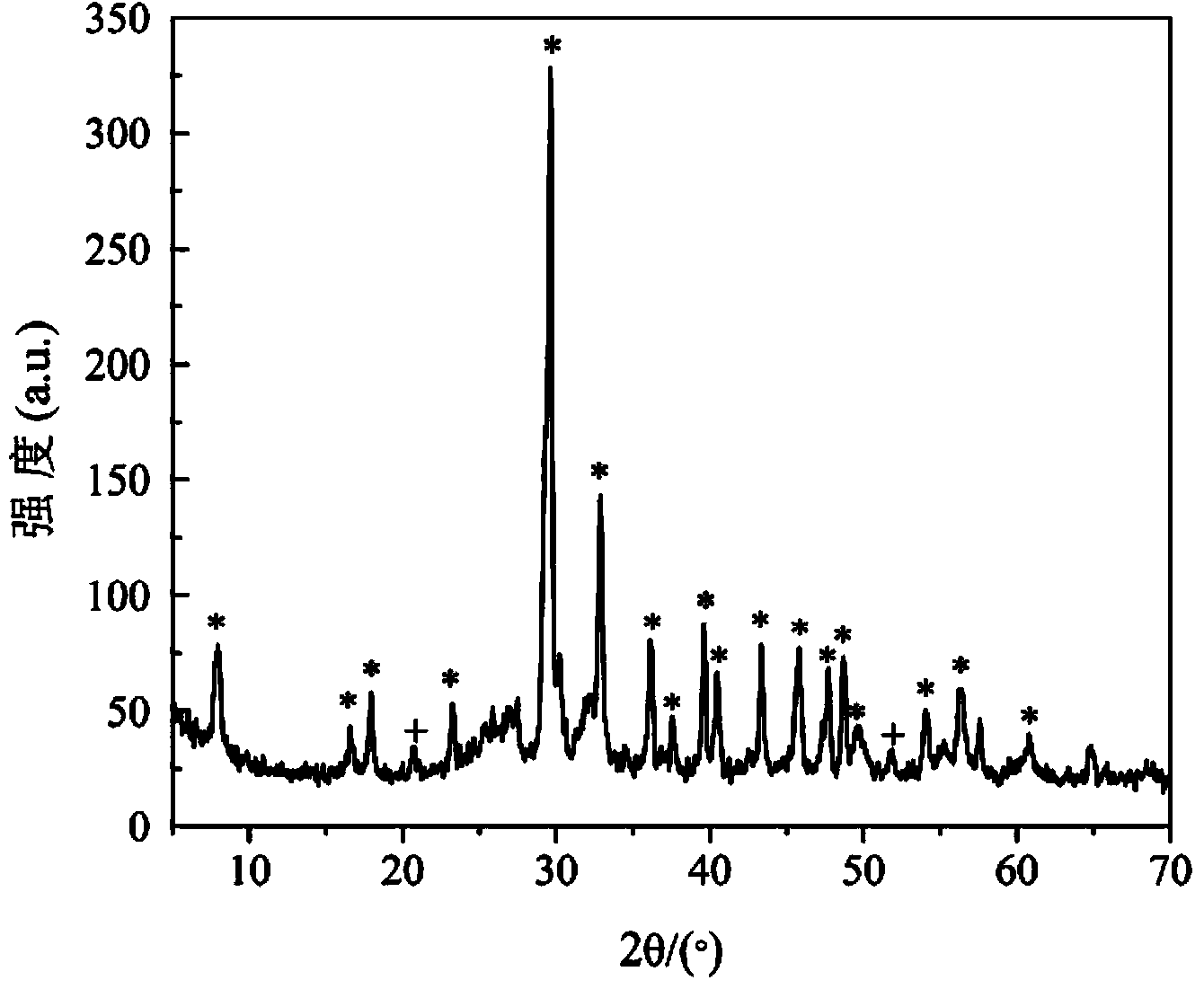

Embodiment 1

[0027] 1) Put coal-fired ash in a ceramic crucible, calcinate in an electric furnace at 700°C for 1.5 hours, then cool to room temperature, and grind the calcined product thoroughly to obtain fine ash powder;

[0028] 2) Add dilute hydrochloric acid with a mass concentration of 1.5% to the ash fine powder according to the liquid-solid ratio of 5mL: 1g, heat and stir at 80°C for 2.0h to carry out acid leaching, filter, wash and dry after acid leaching, Obtain precursor ash powder;

[0029] 3) Combine ash powder, Ca(OH) 2Grinding and mixing, then adding NaOH therein and grinding and mixing uniformly to obtain a mixture; spraying a water glass solution on the mixture, and rotating and rolling to form a spherical particle of the tobermorite reactant precursor; wherein, Ca(OH) 2 Ca in and SiO in ash powder 2 The molar ratio of Si contained is 5:6; Ca(OH) 2 The molar ratio with NaOH is 1:1;

[0030] 4) Add water into the hydrothermal reaction kettle, and then set up a stainless ...

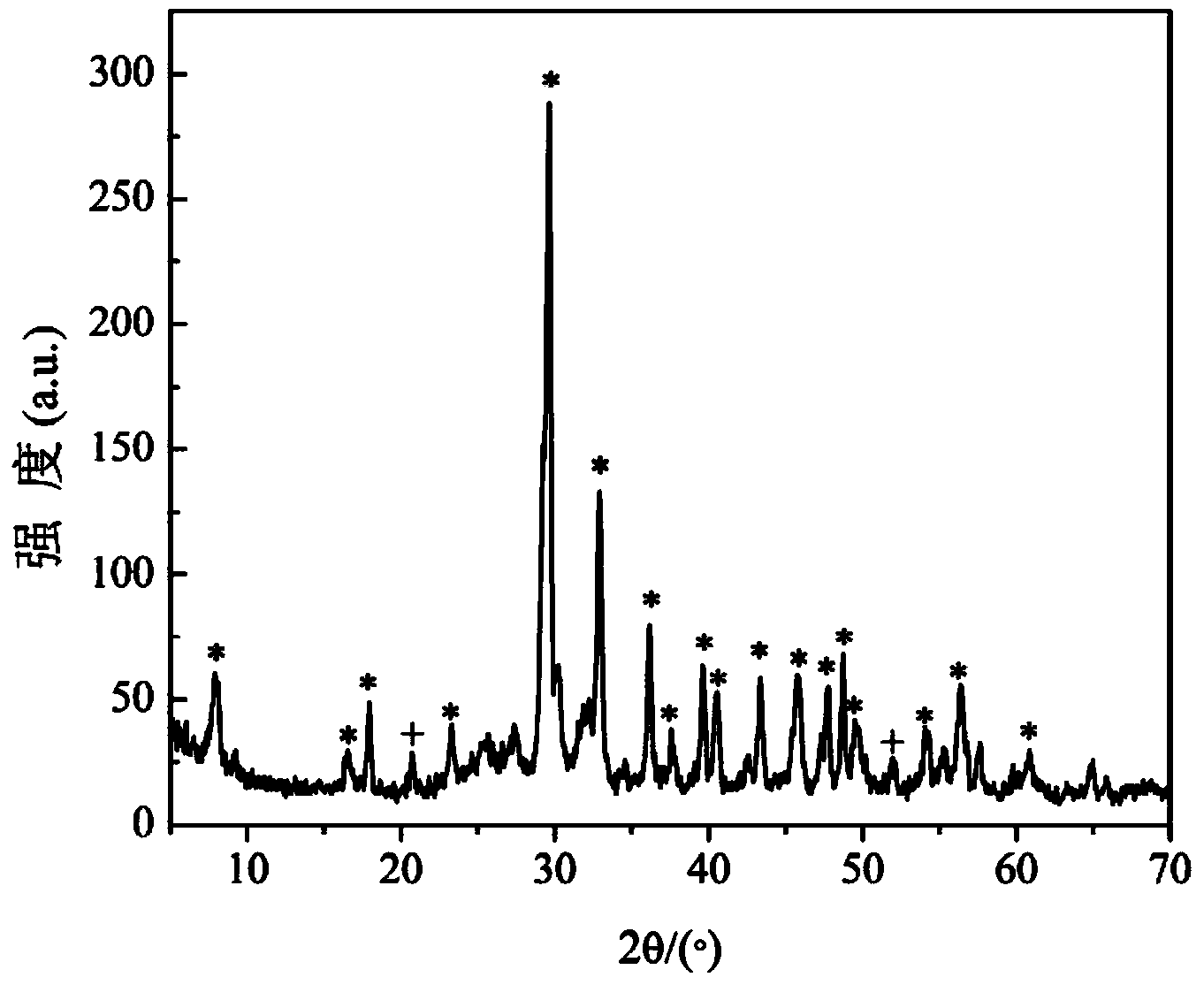

Embodiment 2

[0040] 1) Put the coal-fired ash in a ceramic crucible, calcinate it in an electric furnace at 650°C for 1.5 hours, then cool it to room temperature, and grind the calcined product thoroughly to obtain fine ash powder;

[0041] 2) Add dilute hydrochloric acid with a mass concentration of 1.6% to the ash fine powder according to the liquid-solid ratio of 4.8mL: 1g, heat and stir at a constant temperature of 70°C for 2.5h to carry out acid leaching, filter, wash and dry after acid leaching , to obtain the precursor ash powder;

[0042] 3) Combine ash powder, Ca(OH) 2 Grinding and mixing, then adding NaOH therein and grinding and mixing uniformly to obtain a mixture; spraying a water glass solution on the mixture, and rotating and rolling to form a spherical particle of the tobermorite reactant precursor; wherein, Ca(OH) 2 Ca in and SiO in ash powder 2 The molar ratio of Si contained is 5:6; Ca(OH) 2 The molar ratio with NaOH is 1:1.5;

[0043] 4) Add water into the hydrother...

Embodiment 3

[0045] 1) Put coal-fired ash in a ceramic crucible, calcinate in an electric furnace at 750°C for 1.0 h, then cool to room temperature, and grind the calcined product fully to obtain fine ash powder;

[0046] 2) Add dilute hydrochloric acid with a mass concentration of 1.3% to the ash fine powder according to the liquid-solid ratio of 5.3mL: 1g, heat and stir at a constant temperature of 75°C for 2.2h to carry out acid leaching, filter, wash and dry after acid leaching , to obtain the precursor ash powder;

[0047] 3) Combine ash powder, Ca(OH) 2 Grinding and mixing, then adding NaOH therein and grinding and mixing uniformly to obtain a mixture; spraying a water glass solution on the mixture, and rotating and rolling to form a spherical particle of the tobermorite reactant precursor; wherein, Ca(OH) 2 Ca in and SiO in ash powder 2 The molar ratio of Si contained is 5:6; Ca(OH) 2 The molar ratio with NaOH is 1:1.2;

[0048] 4) Add water into the hydrothermal reaction kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com