Tobermorite type heat-insulating material made from calcium silicate slag and preparation method

A technology of tobermolite and thermal insulation materials, which is applied in the field of thermal insulation materials, can solve problems such as restricting development, environmental pollution, and occupation of cultivated land, and achieve the effects of eliminating coal-based solid waste, reducing production costs, and reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

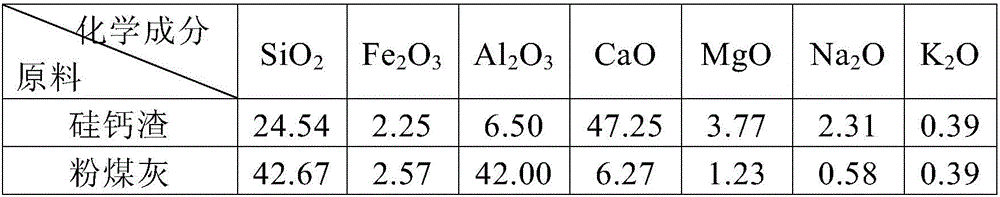

[0035] The parts by weight of silicon-calcium slag, fly ash and quartz powder in the mixture are respectively: 68 parts of silicon-calcium slag, 22 parts of fly ash and 10 parts of quartz powder. Among them, the chemical composition of calcium silicate slag and fly ash is shown in Table 1, the particle size of quartz powder is less than 200 mesh, and the SiO in quartz powder 2 The content is not less than 85%.

[0036] Through the above ratio, the CaO and SiO in the mixture 2 The molar ratio is about 0.96.

[0037] The chemical composition (wt%) of table 1 calcium silicate slag and fly ash

[0038]

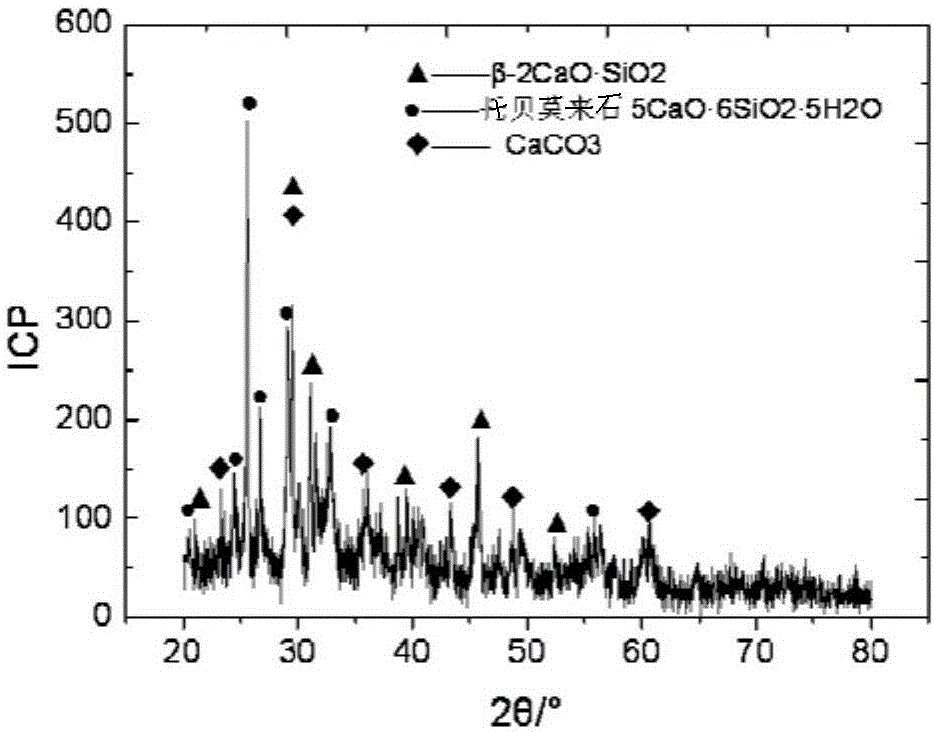

[0039] Mix the above mixture evenly, ball mill it to 320 mesh, and mix it with about 600 parts by weight of water (that is, the mass ratio of water to the mixture is about 6:1), inject it into the reaction kettle, and the pressure is about 1.9MPa 1. React for 4 hours at a temperature of about 210° C., and then continue to react for 3 hours at a pressure of 1.7 MPa and a temp...

Embodiment 2

[0044] The parts by weight of silicon-calcium slag, fly ash and quartz powder in the mixture are respectively: 64 parts of silicon-calcium slag, 25 parts of fly ash and 11 parts of quartz powder. Wherein, the silicon-calcium slag is according to the method described in Example 1 of the patent application CN103332710A (a method for pre-desilication of high-alumina fly ash to simultaneously reduce alkali content), and high-alumina fly ash is pre-desiliconized and soda lime is used Calcium-silicate slag by-product obtained after alumina extraction by sintering method. Fly ash is provided by High-alumina Coal Resource Development and Utilization Research Center of Datang International Power Generation Co., Ltd. The particle size of quartz powder is less than 200 mesh, and the SiO in quartz powder 2 The content is not less than 85%.

[0045] Through the above ratio, the CaO and SiO in the mixture 2 The molar ratio is about 0.95.

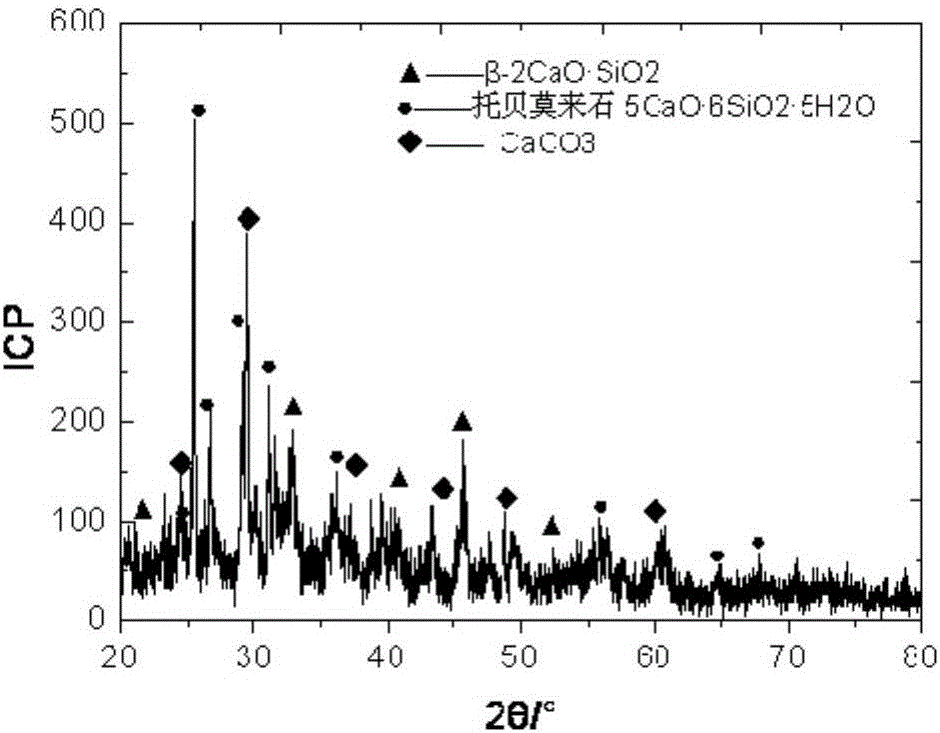

[0046] Mix the above raw materials evenly, ball m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com