Patents

Literature

73results about How to "Short synthesis reaction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

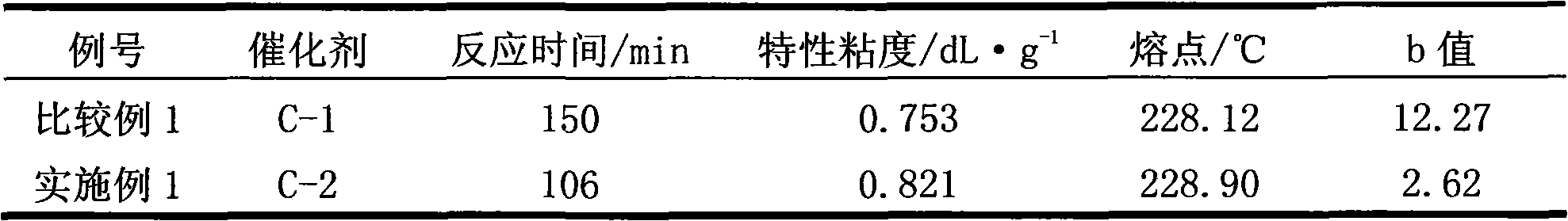

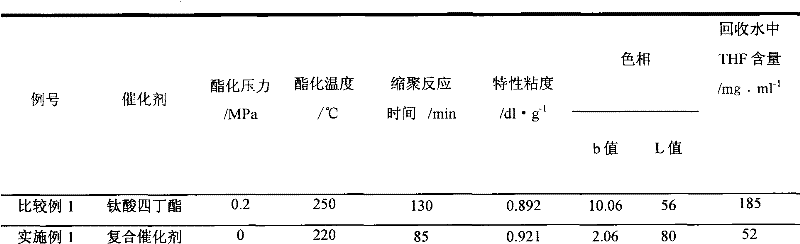

Preparation method of polybutylene terephthalate/adipate butanediol copolyester

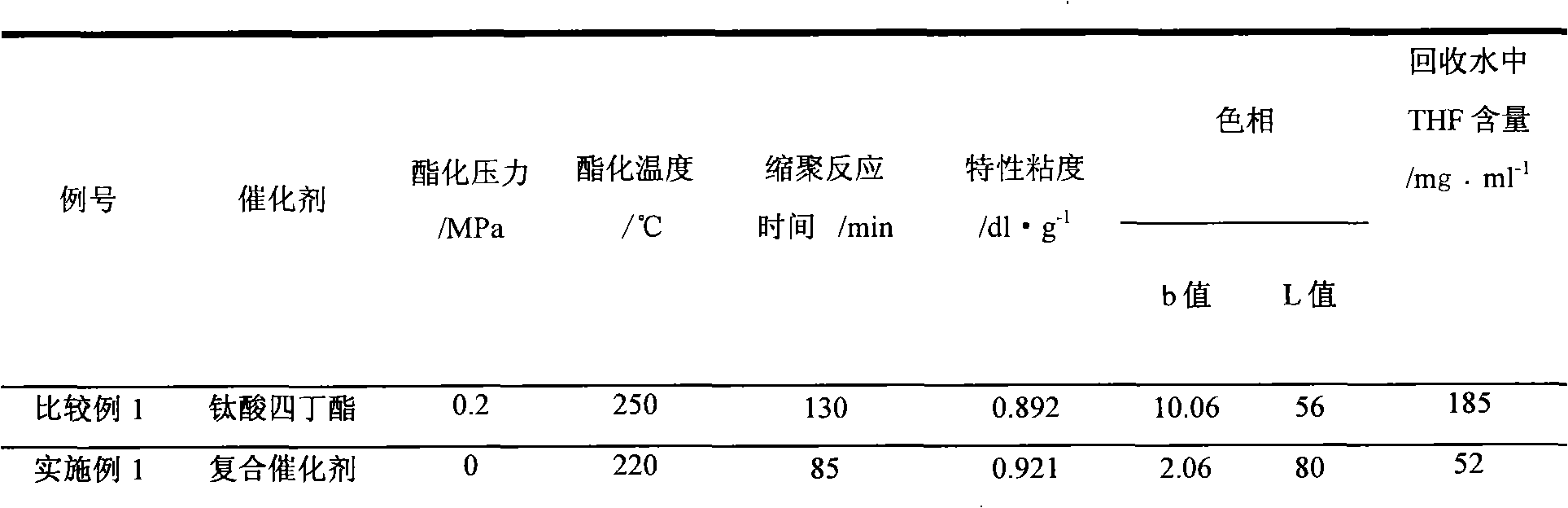

The invention relates to a preparation method of polybutylene terephthalate / adipate butanediol copolyester, which utilizes a titanium compound and an antimony compound as the composite catalyst, the mole ratio of terephthalic acid to adipate is 3:7-8:2, the ratio of the total mole of the terephthalic acid and the adipate to the mole of 1,4-butanediol is 1:1.0-1.8, esterification is carried out at normal pressure and the temperature of 150-220 DEG C, the pressure is reduced to high vacuum 10-150 Pa for the reaction, the final temperature for the reaction is 265-280 DEG C, and inert gas is utilized to recover the pressure to be normal to obtain the copolyester. The reaction time is shortened, the production amount of tetrahydrofuran is small, the intrinsic viscosity of copolyester chips is 0.90-1.32 dL / g, the hue b value of the product is between 0 and 8, the L value is between 68 and 85, and the product of the polybutylene terephthalate / adipate butanediol copolyester can be used in the fields of various soft package plastic products.

Owner:PETROCHINA CO LTD

Preparation method of water-in-water cation polyacrylamide

InactiveCN101735388AImprove solubilityImprove stabilityWater/sewage treatment by flocculation/precipitationWater bathsPolyethylene glycol

The invention relates to a method for synthesizing water-in-water cation polyacrylamide. The method takes an inorganic salt water solution as a reaction medium, adopts a mixed dispersion stabilizing agent containing polyethylene glycol PEG series, polyvinylpyrrolidone and polyvinyl alcohol (the mass ratio of the polyethylene glycol PEG series to the polyvinylpyrrolidone to the polyvinyl alcohol is 1:1:1) and enables acrylamide and a quaternary ammonium organic compound with double bonds to generate a free radical copolymerization reaction so as to generate water-in-water cation polyacrylamide emulsion. The preparation method of the water-in-water cation polyacrylamide comprises the following steps: (A) adding acrylamide, a cationic monomer, inorganic salt, a dispersant, a screening agent and deionized water into a four-neck flask, dissolving evenly, putting into water bath of 50 DEG C, introducing nitrogen, deoxidizing and stirring at the speed of 1000rpm; (B) when reacting for 0.5 hour and 1.5 hours respectively, adding a certain amount of initiator; and (C) after adding the initiator for the second time, reacting for 3-4 hours continuously so as to obtain a product. The emulsion has the characteristics of high dissolving speed, good stability and convenient use and transportation and can not cause secondary pollution to the environment.

Owner:TONGJI UNIV

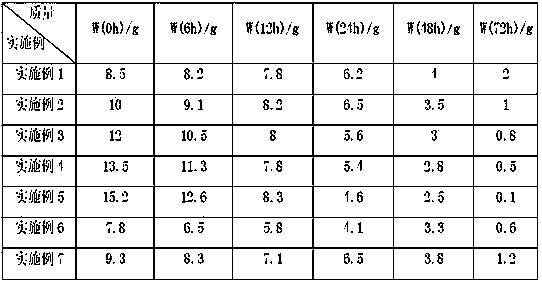

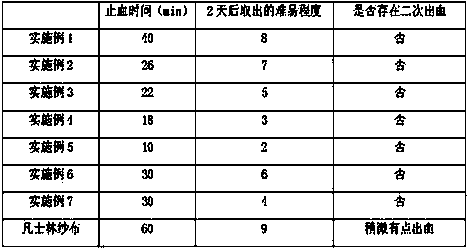

Preparation method of biodegradable nasal hemostatic sponge

ActiveCN104031287AShort synthesis reaction timeReduce dosageAbsorbent padsBandagesPolymer sciencePtru catalyst

Owner:SAIKE SAISI BIOTECH CO LTD

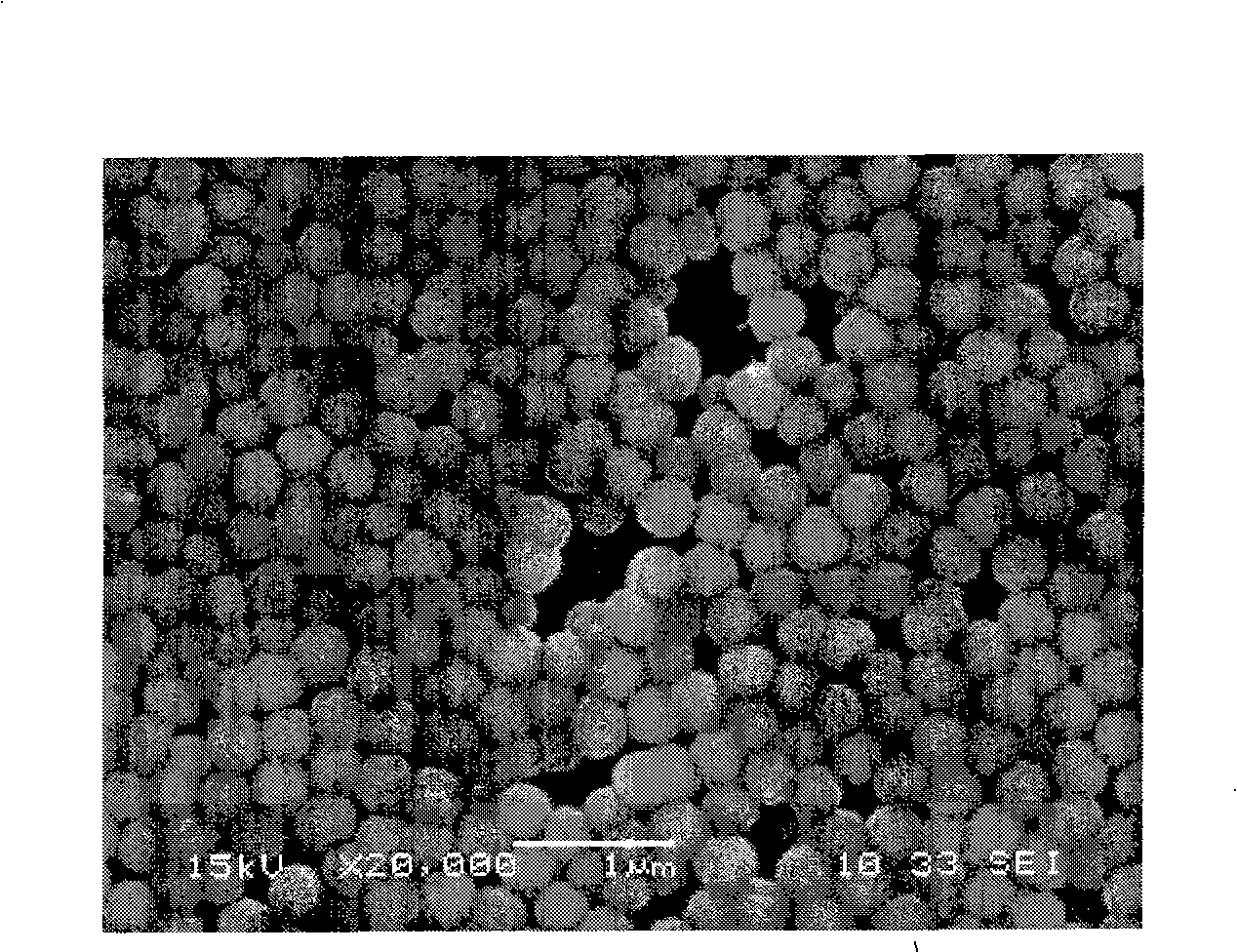

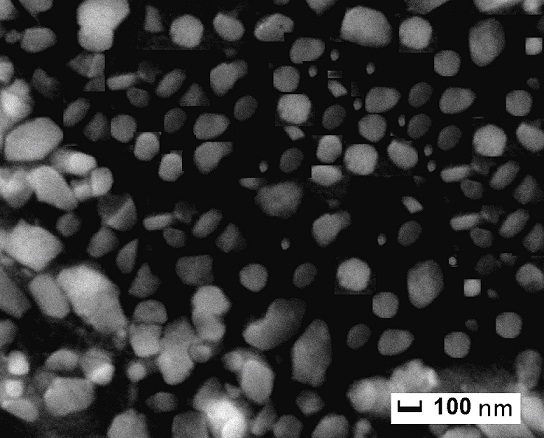

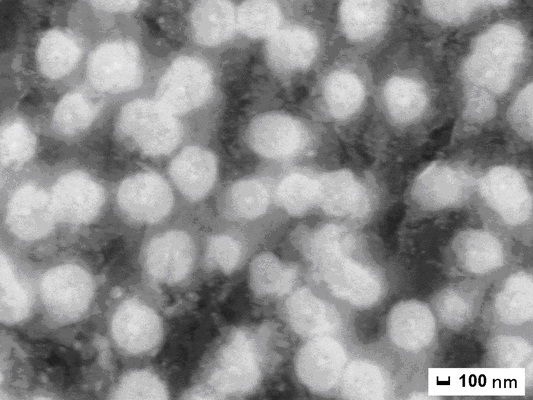

Synthetic method of hydrophilic monodisperse carboxyl superparamagnetic microsphere

InactiveCN101353181APromote hydrolysisShort synthesis reaction timeFerroso-ferric oxidesDispersion stabilityMicrosphere

A method for synthesizing a hydrophilic monodisperse carboxyl super paramagnetic microsphere belongs to the inorganic chemistry field. In the invention, soluble iron ion salt, urea, water and carboxylic acid or carboxylate are taken as raw materials, dissolved in ethylene glycol and made into nano-ferroferric oxide super paramagnetic microsphere with carboxylated surface by reduction reaction with polyol at the temperature of 160-250 DEG C, and a series of magnetic microspheres with different diameters and densities of surface carboxyl groups are obtained by controlling reaction parameters. The surface carboxylated microsphere obtained by the method is characterized by uniform size, dispersion stability with a great pH range, high specific saturation magnetization and the like; the raw materials are nontoxic, environmental friendly, cheap; and the method has simple operation, low equipment requirements, high yield, and is applicable to large-scale industrialized production. The application of the bead to the biomedical field can be further expanded by inorganic or polymer surface coating of the super paramagnetic microsphere, on the basis of the bead.

Owner:SHANGHAI JIAO TONG UNIV

Boron nitride-based ceramic composite material and preparation method thereof

The invention relates to a boron nitride-based ceramic composite material and a preparation method thereof. The invention solves the problems that the preparation of the traditional boron nitride-based ceramic composite material has high cost, long production period and difficulty in manufacturing products with large size. The boron nitride-based ceramic composite material is prepared from carbonized boron powder, silicon powder and diluent powder. The boron nitride-based ceramic composite material is prepared by the steps of raw material drying, ball milling and mixing, blank production and self-propagating synthesis of the blank. The method has short production period and low cost and can realize the production of products with large size.

Owner:HARBIN INST OF TECH

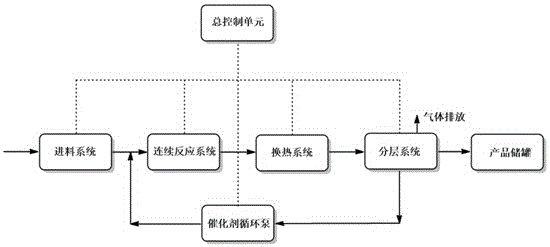

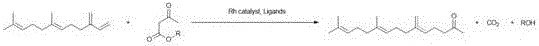

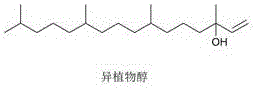

Method for synthesizing ketone compounds by continuous cyclic catalytic reaction

InactiveCN105859534AReduce contentReduce churnOrganic compound preparationCarbonyl compound preparationAcetone productKetone

The invention provides a method for synthesizing ketone compounds through continuous circular catalytic reaction. The method is carried out according to the following steps: 1. Parameter setting and input; 2. Input of raw material liquid and catalyst; 3. Mixed liquid and heating and pressurizing catalytic synthesis reaction; 4. Lowering temperature and lowering pressure treatment; . Delivery of farnesyl acetone products; 7. Recycling of catalysts. The method changes the method of stepwise reaction synthesis of farnesyl acetone into one step reaction synthesis, and can reduce the content of rhodium element in the organic phase. The method makes the catalyst in the reaction be recycled repeatedly, and greatly reduces the precious metal rhodium The loss improves the catalytic efficiency and shortens the synthesis reaction time, and the method can not only produce farnesyl acetone, but also produce condensate intermediates.

Owner:能特科技(石首)有限公司

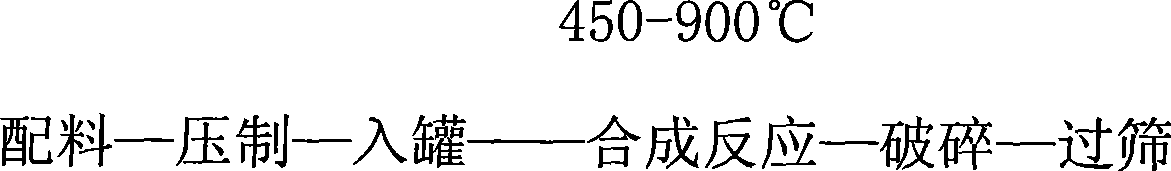

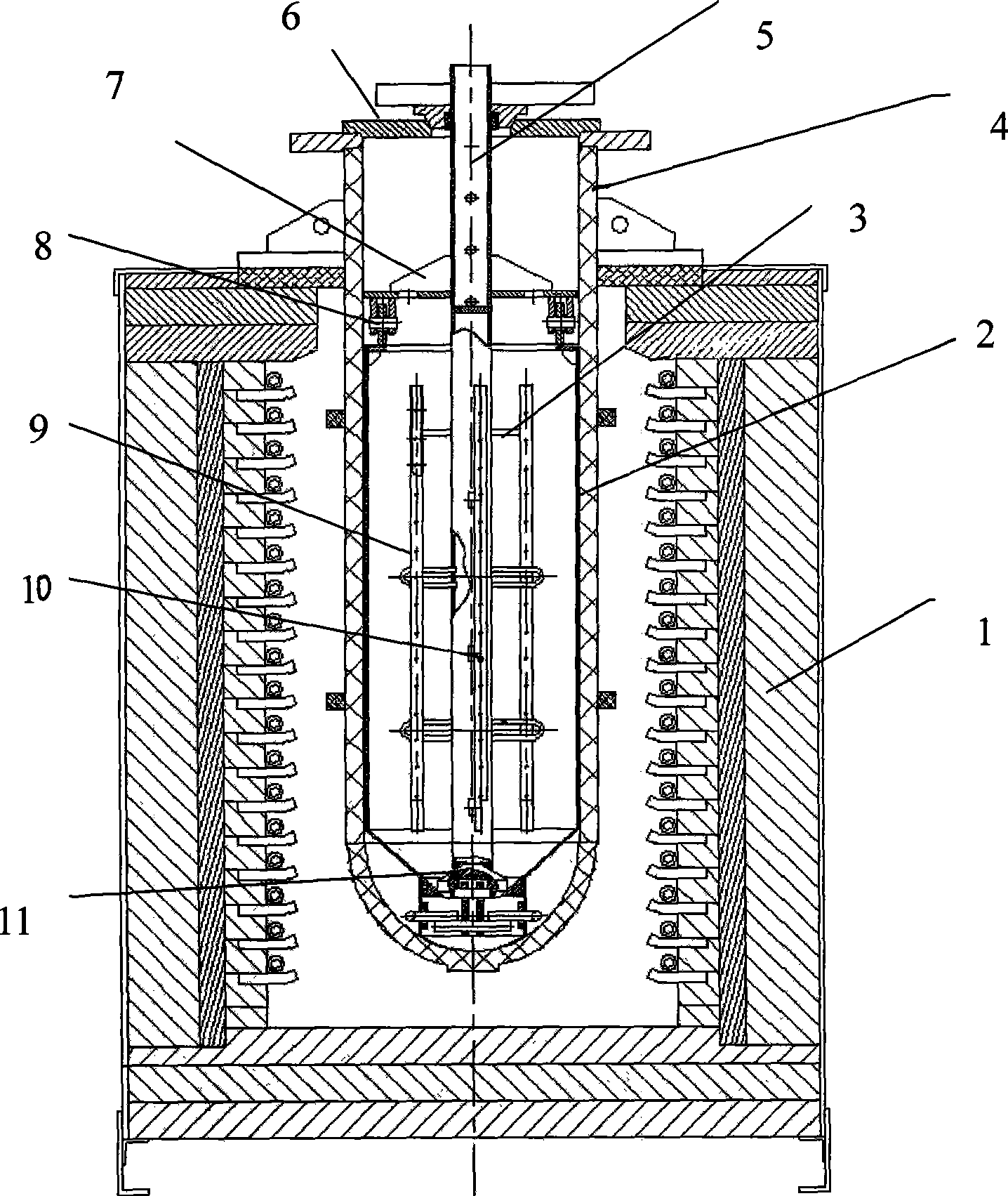

Method for preparing novel conductive ceramic evaporation boat by combustion synthesis

The invention discloses a method for preparing a conductive ceramic evaporation boat by combustion synthesis, which relates to a method for preparing the conductive ceramic evaporation boat. The method solves the problems that the method for preparing a conductive ceramic material of a conventional conductive ceramic evaporation boat has large energy consumption, high cost and long production period and a massive material of the conductive ceramic evaporation boat has poor uniformity. The method comprises the steps of: 1, weighing raw materials; 2, performing ball-mill mixing on the raw materials; 3, performing pressure forming to obtain a preformed blank, and then igniting to make preformed blank perform a self-propagating combustion reaction to obtain a conductive ceramic composite material; and 4, cutting and processing the conductive ceramic composite material to obtain the conductive ceramic evaporation boat. The method has the advantages of low energy consumption, low cost and short production period, finishes the reaction within a few minutes, adopts a hot isostatic pressing method to pressurize the material, obtains the composite material with good uniformity, and further obtains the evaporation boat with good uniformity. The method can manufacture the large-size material of the conductive ceramic evaporation boat with the diameter of between 40 and 200mm and the length of between 50 and 1,000mm.

Owner:HARBIN INST OF TECH

Method for synthesizing particle reinforced composite material under composite action of current and magnetic field

InactiveCN102140599AImprove mechanical propertiesIncrease reaction rateIndustrial scaleAlternate current

The invention relates to the technical field of preparation of particle reinforced aluminum-based composite materials, in particular to a method for synthesizing a particle reinforced aluminum-based composite material through direct reaction of a melt under the composite action of current and a magnetic field. The method is mainly characterized in that: in the process of synthesizing the particlereinforced aluminum-based composite material by a direct melt reaction method, current is introduced into the melt and the magnetic field is applied so as to promote melt reaction and control the appearance, size, motion and distribution of particles through electromagnetic oscillation effect generated by interaction of the current and the magnetic field. In the scheme, alternating current and a static magnetic field can be composited, and direct current and an alternating magnetic field also can be composited. By the method, the synthesis reaction rate and yield can be obviously improved, obvious effects of controlling the appearance of the particles and promoting dispersion are achieved, and the method is suitable for preparing high-performance particle reinforced composite materials onan industrial scale.

Owner:JIANGSU UNIV

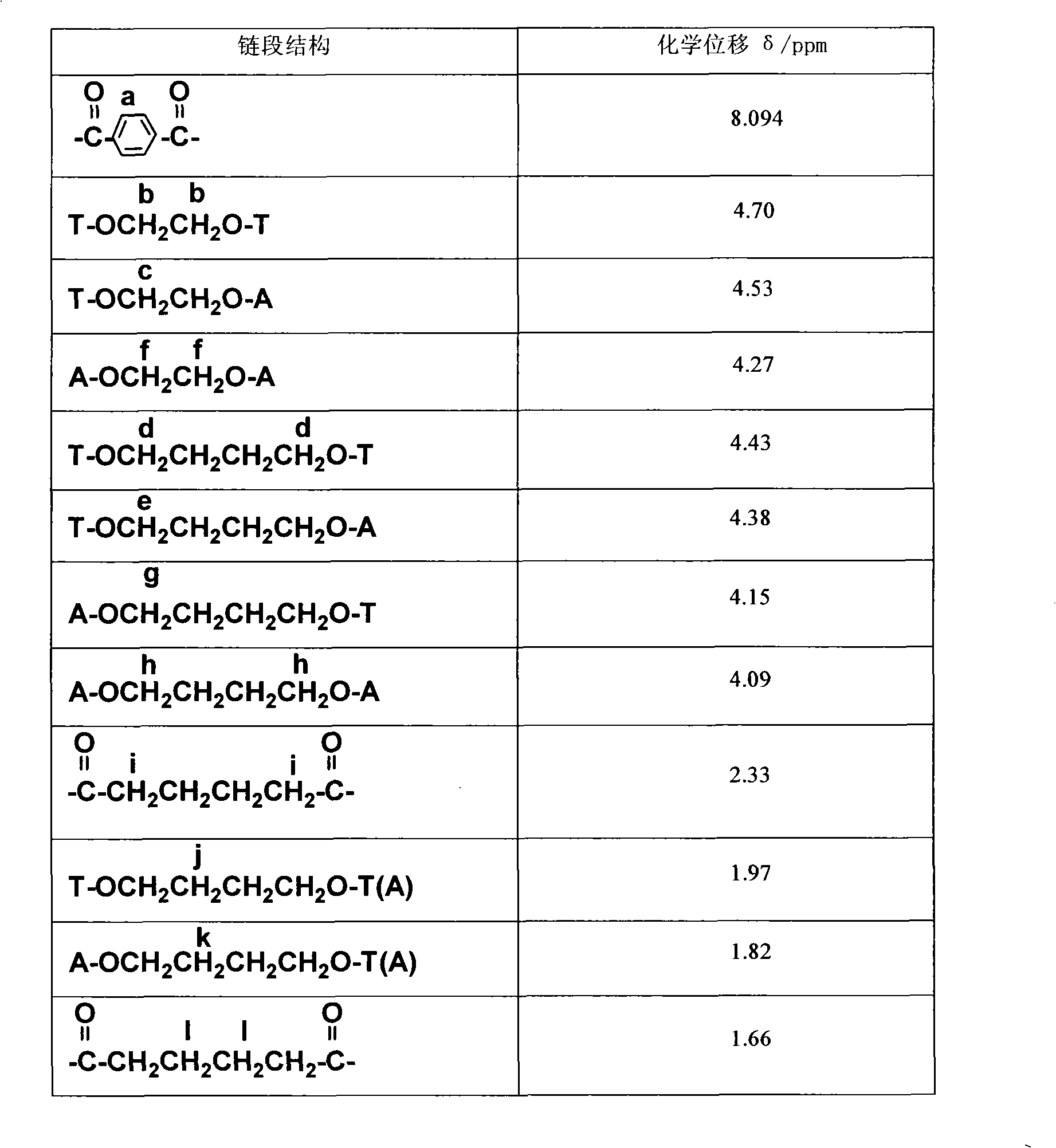

Biodegradable copolyester and preparation method thereof

ActiveCN102140165AHigh intrinsic viscosityOvercome the disadvantage that it cannot be carried out under normal pressureCopolyesterEsterification reaction

The invention relates to biodegradable copolyester and a preparation method thereof. The preparation method comprises the following steps of: undergoing an esterification reaction on pure terephthalic acid, hexanedioic acid, 1,4-butylene glycol and ethylene glycol under normal pressure at the temperature of between 150 DEG C and 220 DEG C, wherein the molar ratio of the pure terephthalic acid to the hexanedioic acid is (3:7)-(8:2), the molar ratio of the ethylene glycol to the 1,4-butylene glycol is (1:9)-(9:1), and the ratio of the total mole number of the pure terephthalic acid and the hexanedioic acid to the total mole number of the ethylene glycol and the 1,4-butylene glycol is 1:(1.0-1.8); and undergoing condensation polymerization under the pressure of between 10 Pa and 150 Pa to obtain the copolyester, wherein the dosage of a titanium compound is 200-1,200 ppm relative to the total weight of terephthalic acid and the hexanedioic acid, the dosage of an antimony compound is 100-600 ppm relative to the total weight of the terephthalic acid and the hexanedioic acid, and the dosage of a phosphorous compound is 50-400 ppm relative to the total weight of the terephthalic acid and the hexanedioic acid. The biodegradable copolyester has the advantages of low raw material price, reaction at low temperature and under low pressure and high inherent viscosity.

Owner:PETROCHINA CO LTD

Production method for high-purity lithium metal and special equipment thereof

The invention relates to a preparation method for lithium metal. The production method for high-purity lithium metal comprises two steps of synthetic reaction and reducing reaction, the synthetic reaction comprises the steps that raw material lithium carbonate and kalk or aluminium hydroxide are mixed, then are put into a reaction vessel to be calcinated at the temperature of 650 to 850 DEG C, after carbon dioxide and moisture are removed, intermediate products are prepared and are sieved and set aside; the reducing reaction comprises the steps that duriron or aluminium powder are added into the intermediate products prepared during the synthetic reaction to be as reducing agent, after being mixed, the intermediate products are pressed into spherical or cylindrical, then reducing reaction is performed under the vacuum and high-temperature condition, and the lithium metal is prepared. The production method has the advantages that the flow of the synthetic reaction is simplified, the production efficiency is effectively improved, the product purity is greatly enhanced, no waste material is generated, the side product is lithium-containing compound, which can be directly applied to the electrolytic aluminum industry, and all the required raw materials can be solved internally.

Owner:DALIAN TIANXI TECH DEV

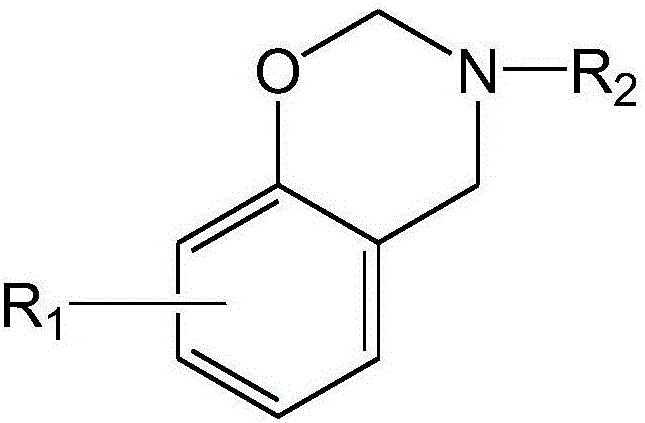

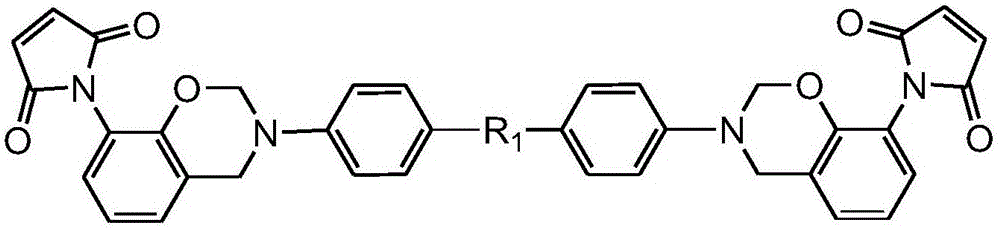

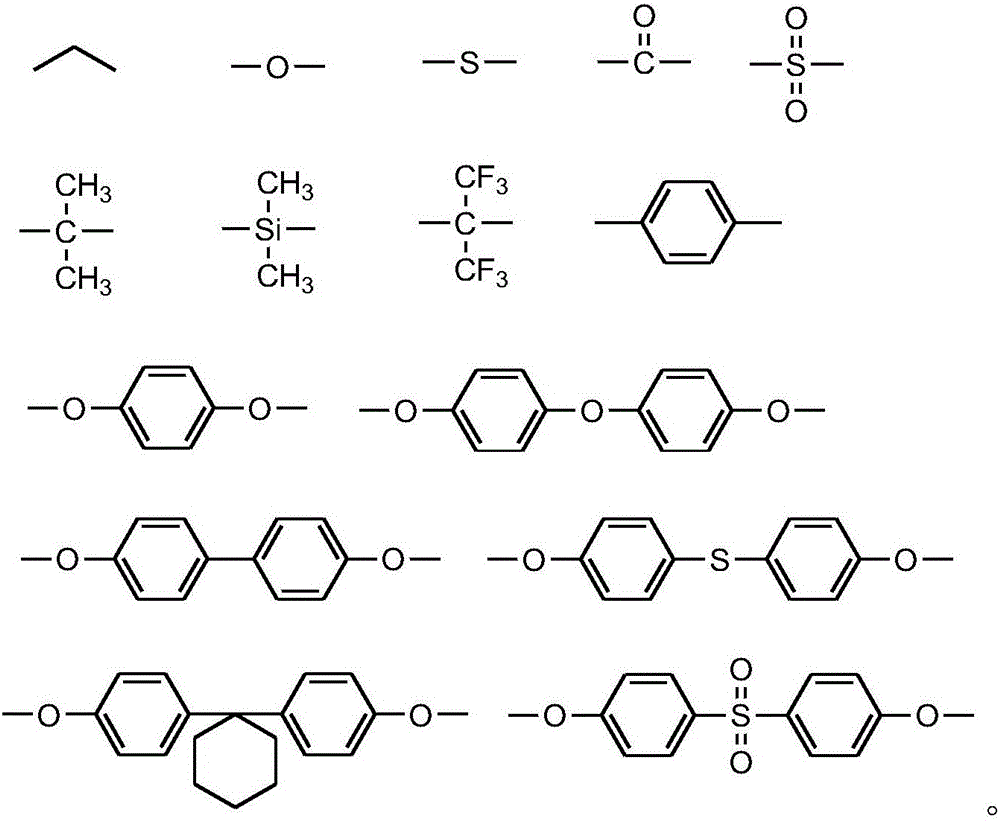

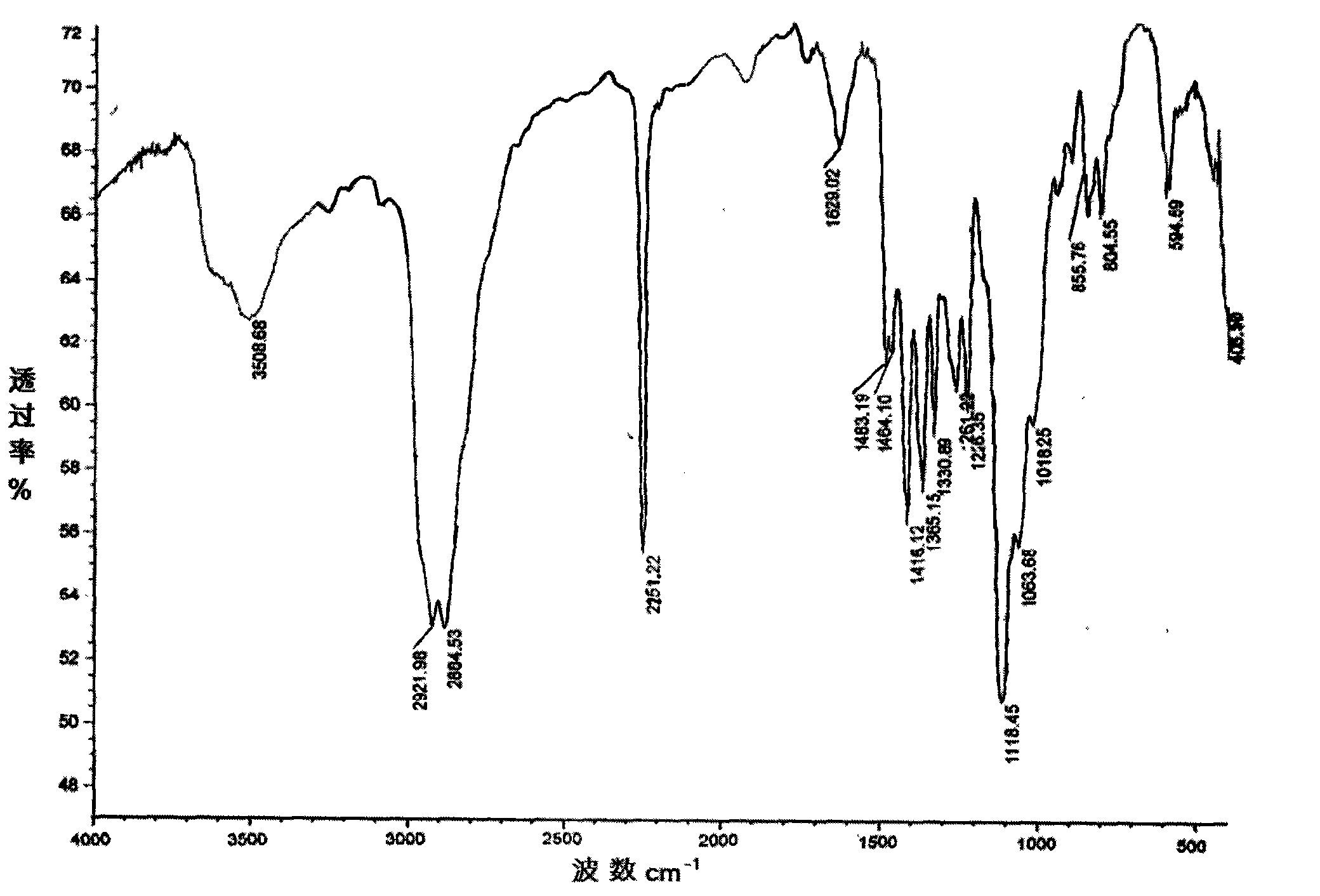

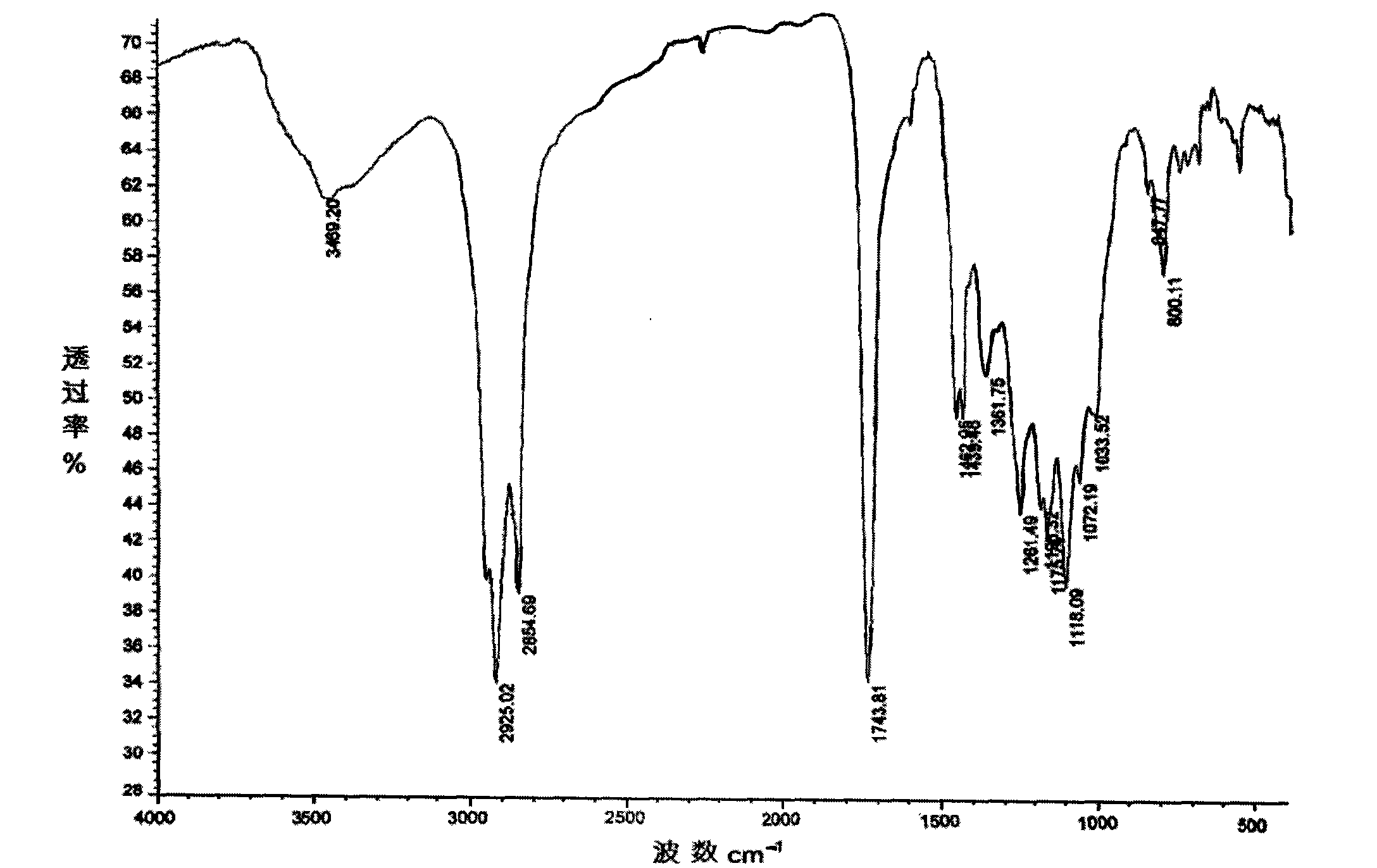

Dibenzoxazine monomer containing ortho-position maleimide groups and preparation method thereof

ActiveCN106366079AShort synthesis reaction timeImprove machinabilityOrganic chemistryOrtho positionMonomer

The invention discloses a dibenzoxazine monomer containing ortho-position maleimide groups and a preparation method thereof. The molecular formula is show in the following picture, wherein R1 is any one of following structures. The introduced ortho-position maleimide groups weaken the rigidity of molecules, effectively shorten the time for synthesis of benzoxazine and improve the machinability of benzoxazine resin. In addition, except for oxazine ring curing cross-linking of dibenzoxazine, the maleimide groups at the two ends of a molecule further can carry out secondary bi-crosslinking, and therefore the thermal stability of the resin is greatly improved. The preparation technology is simple, the comprehensive performance of the resin is excellent, and the dibenzoxazine monomer is suitable for matrix resin of high-performance compound materials.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

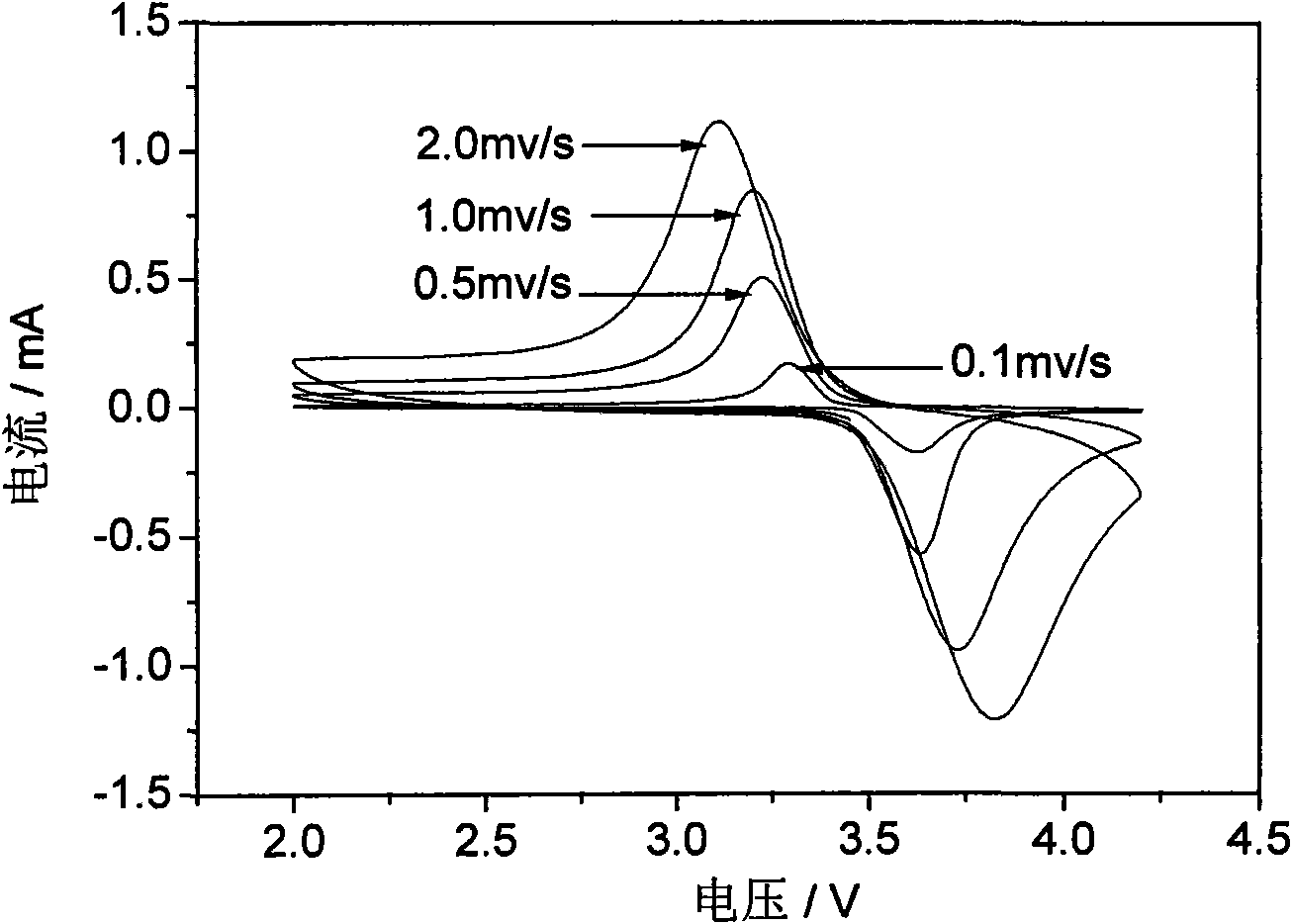

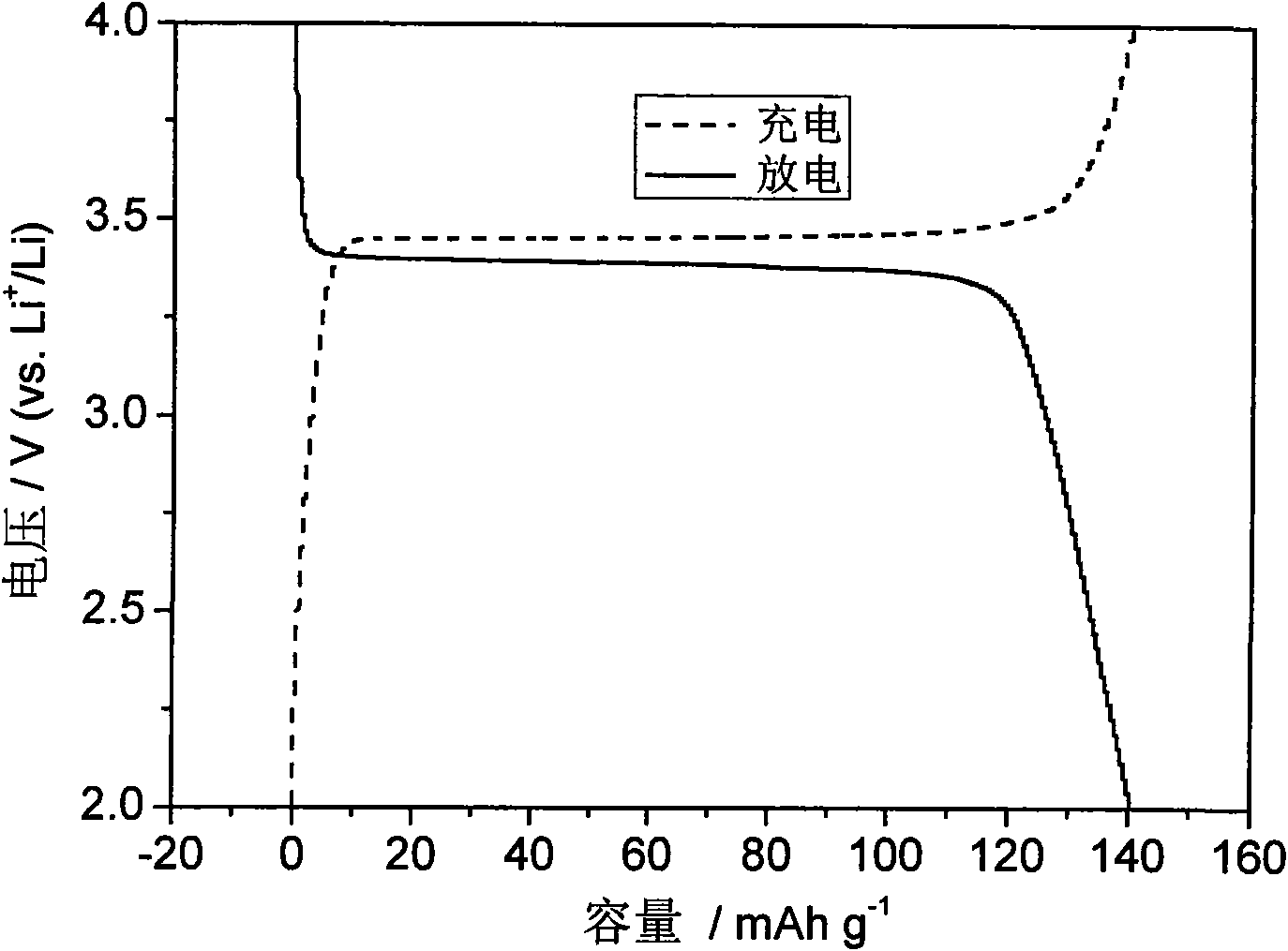

Method for synthesizing nanometer LiFePO4 lithium ion power battery cathode material by ferric iron source

InactiveCN101567439ASimple equipmentShort synthesis reaction timeElectrode manufacturing processesPhosphorus compoundsEmulsionElectrical battery

The invention relates to a method for synthesizing a nanometer LiFePO4 lithium ion power battery cathode material by a ferric iron source. The method comprises the steps of: taking lithium source, ferric iron source and phosphorus source compounds as raw materials, performing material mixing according to the stoichiometric proportion of the materials, then adding a certain amount of combustion improver, and dissolving the mixture into water to form a solution or an emulsion with even dispersion; and carrying out spontaneous combustion on the solution or the emulsion to obtain a precursor of the cathode material, and then roasting the prepared precursor under inert atmosphere in a furnace to obtain the cathode material. The method adopts cheap ferric iron source as the raw material, has simple process and reduced cost, also has even particle size and element distribution, can prepare nanometer-grade particles, obviously reduce energy consumption, meet environmental requirement, is suitable for mass production, and greatly accelerates the industrialization process of the cathode material.

Owner:NANJING ZHONGDA QINGSHAN ELECTRIC VEHICLE

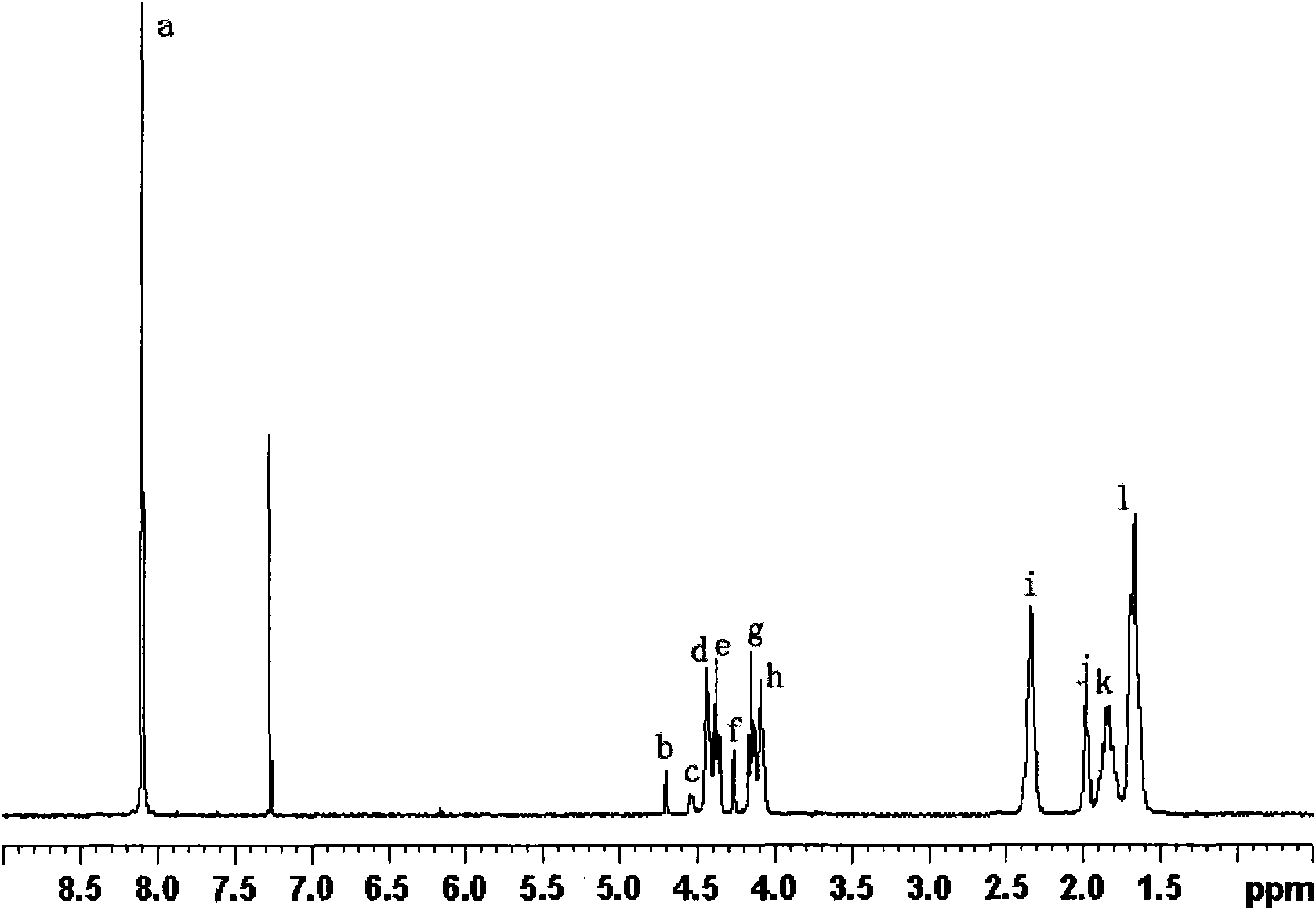

Method for synthesizing three direction dendrimer core by microwave

InactiveCN101580478AShort synthesis reaction timeIncrease radiant energyOrganic compound preparationCarboxylic acid amides preparationPhase-transfer catalystTriethanolamine

The invention relates to a method for synthesizing three direction dendrimer core by microwave, comprising the following steps: synthesizing dinitrile: dissolving trolamine in a reaction vessel with 1,4-dioxane, adding a strong base catalyst and a crown ether phase transfer catalyst; then adding acrylonitrile in the reaction system, placing the solution in a microwave reactor for microwave irradiation to obtain dinitrile; synthesizing triester: dissolving the obtained dinitrile in a reaction vessel with methanol, adding concentrated sulphuric acid; placing the solution in the microwave reactor for microwave irradiation to obtain triester; synthesizing triamine: dissolving the obtained triester in a reaction vessel with methanol, adding ethylene diamine; placing the solution in the microwave reactor for microwave irradiation to obtain three direction dendrimer core. Compared with the existing art, the invention has the following advantages: the radiation energy is large by microwave heating, the synthetic reaction time of dendrimer core is effectively shortened; the productivity can be obviously improved, which is obvious for the alcoholysis of nitrile.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Synthetic silicon oxynitride raw material and preparation method thereof

InactiveCN105253865AHigh purityShort synthesis reaction timeNitrogen and non-metal compoundsPhysical chemistryNitrogen atmosphere

The invention relates to a synthetic silicon oxynitride raw material and a preparation method thereof. A technical scheme adopted in the invention is characterized in that the method comprises the following steps: mixing 50-60wt% of elemental silicon with 40-50wt% of silica, and carrying out ball milling in a ball mill until the granularity is 4.5-6.5[mu]m to obtain a ball milled powder; and putting the ball milled powder in an atmosphere furnace, heating in highly pure nitrogen atmosphere at a heating rate of 10-12DEG C / min to 1000-1100DEG C, heating at a heating rate of 6-8DEG C / min to 1400-1500DEG C, and carrying out heat insulation for 4-9h to obtain the synthetic silicon oxynitride raw material. The method has the advantages simplicity, short production period, low cost, and no need of special synthesis devices or processing technologies; and the prepared synthetic silicon oxynitride raw material has the characteristic of high Si2N2O purity and completeness of grown crystal grains.

Owner:WUHAN UNIV OF SCI & TECH

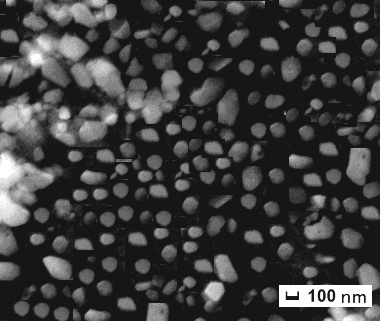

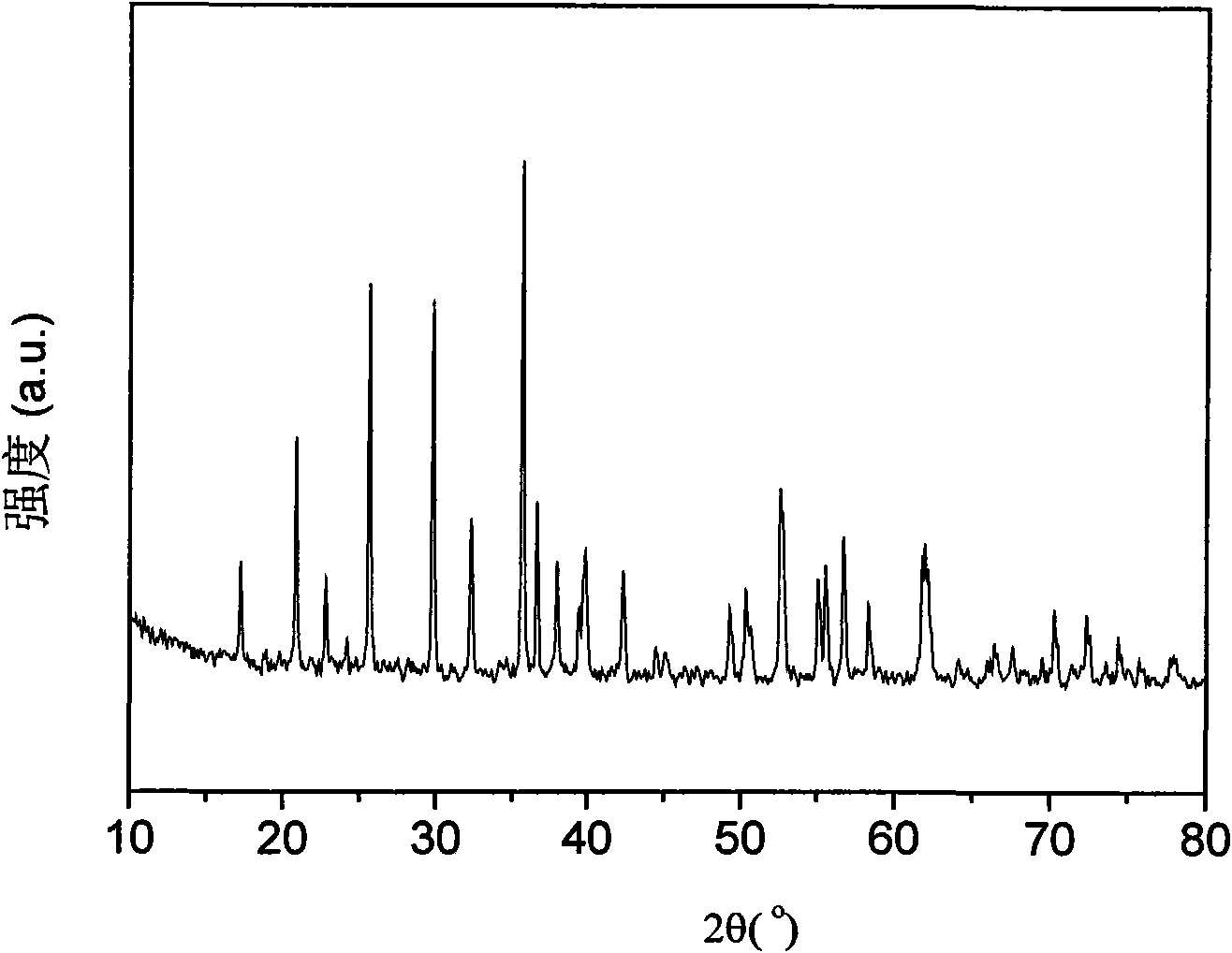

Method for preparing photocatalyst with monatomic Pt embedded into covalent organic framework and application of photocatalyst

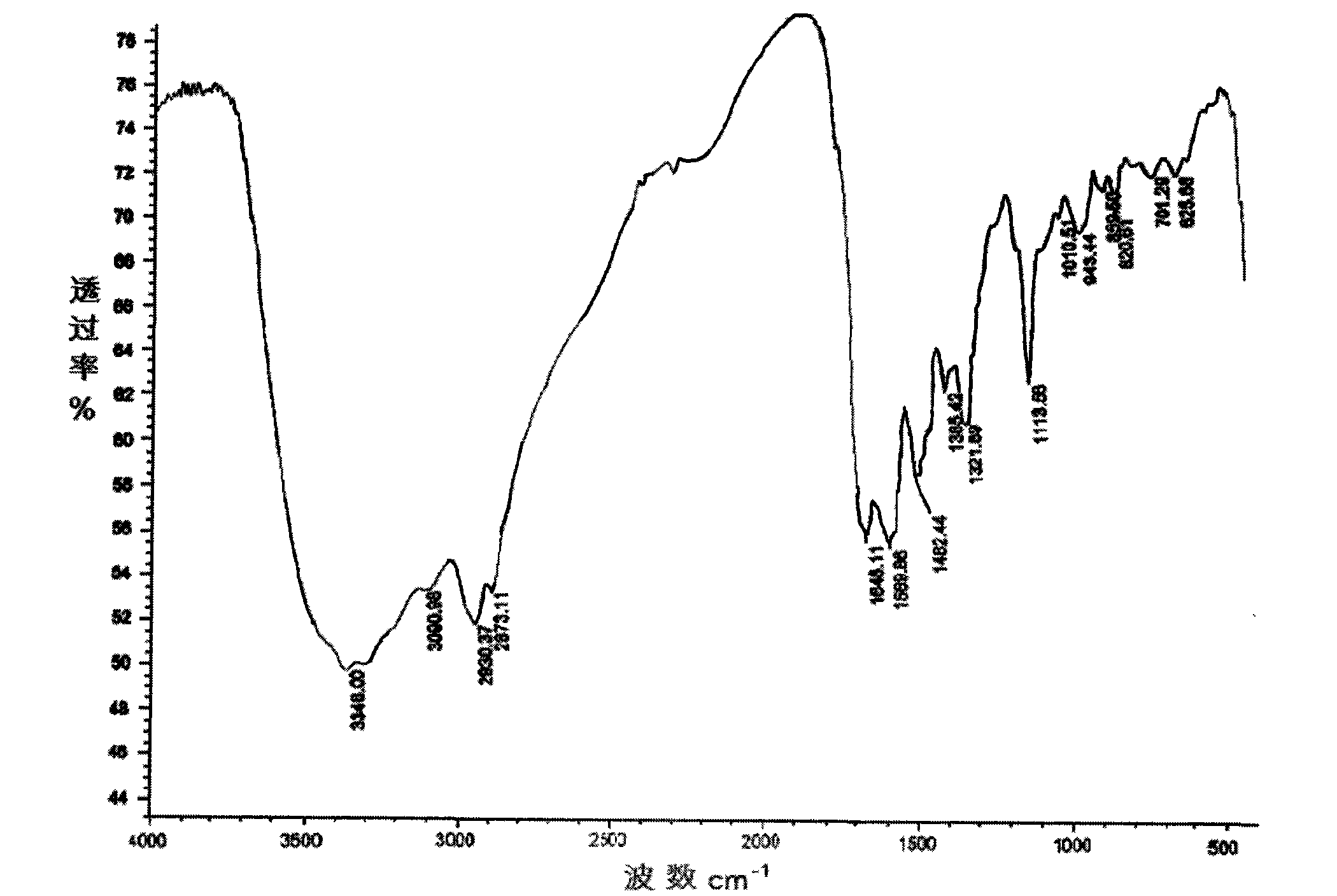

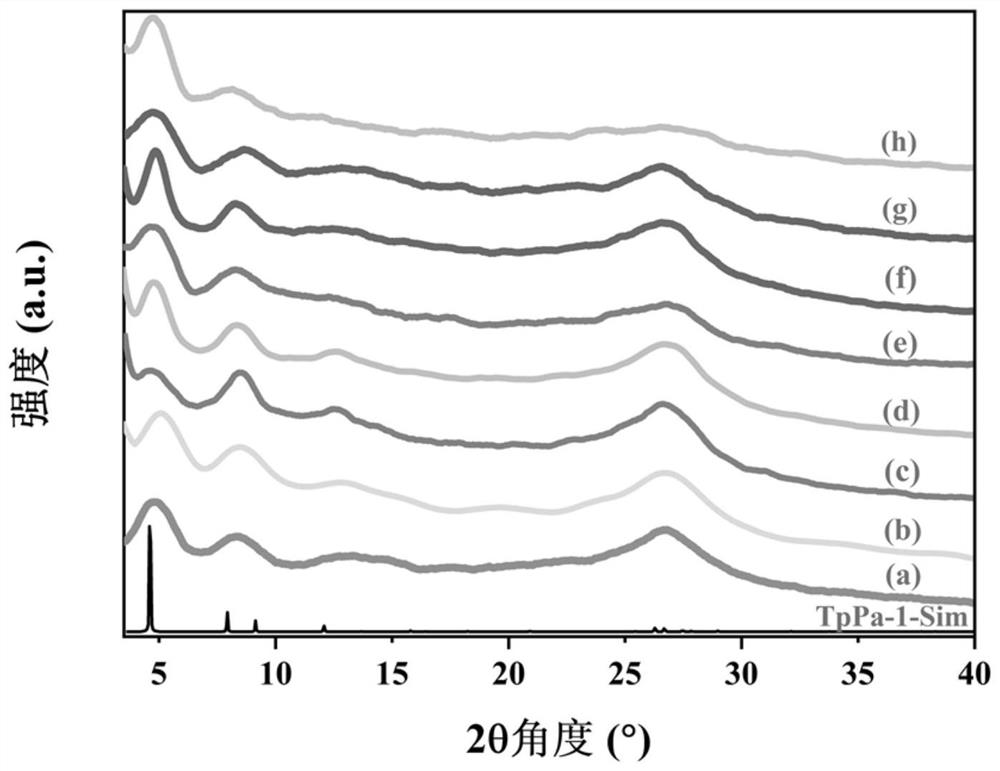

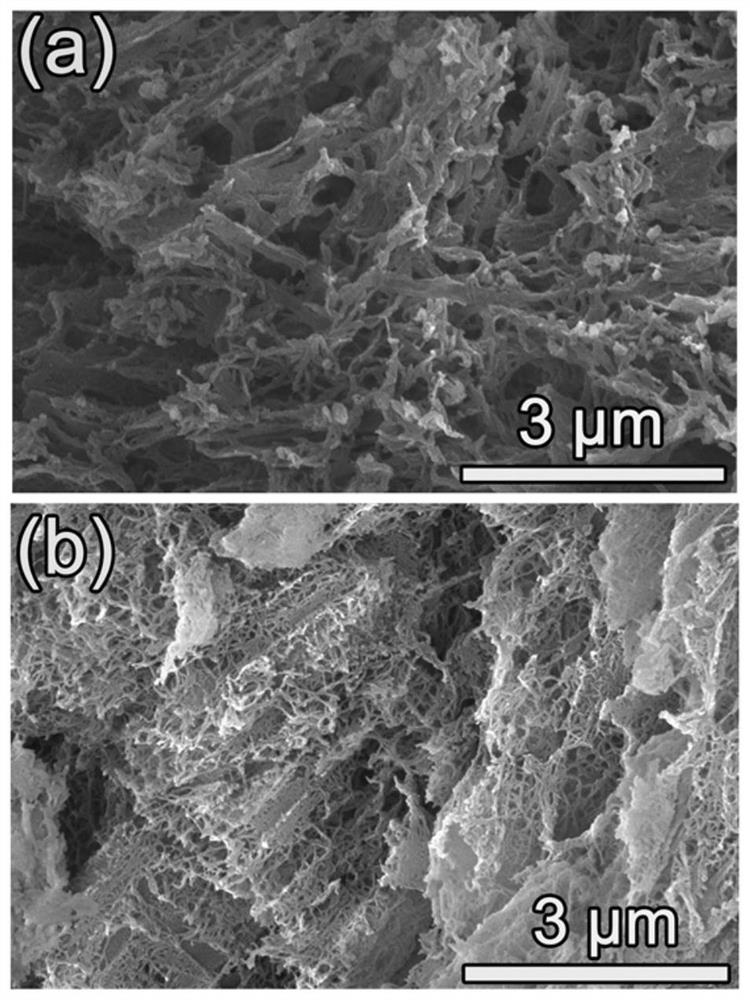

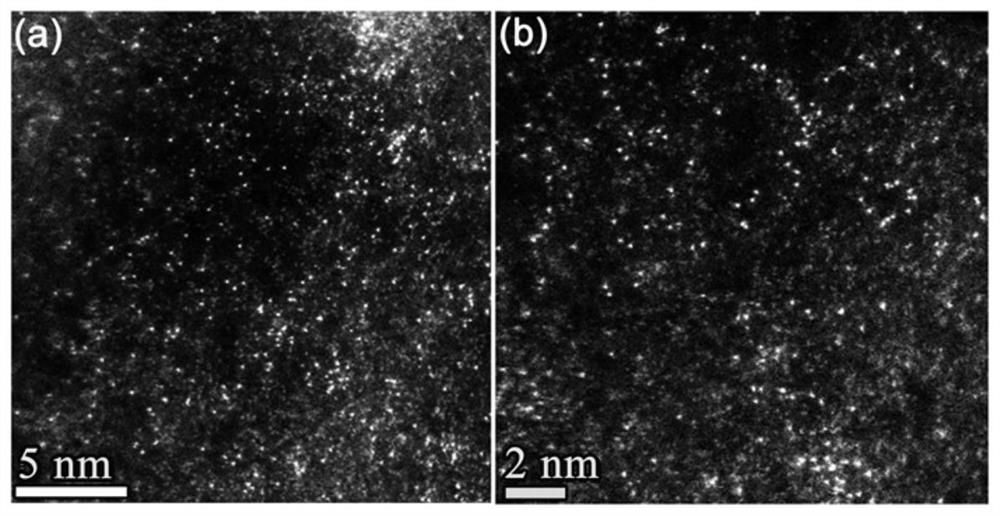

PendingCN114534783AImprove the hydrogen production efficiency of photolysis waterImprove hydrogen production efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsEnergy inputPtru catalystPhysical chemistry

The invention discloses a method for preparing a photocatalyst with monatomic Pt embedded into a covalent organic framework and application of the photocatalyst. A Pt-containing precursor solution is introduced in the process of preparing TpPa-1-COF, the Pt1 at TpPa-1-COF photocatalyst is obtained through low-temperature calcination and reduction, especially 3% of Pt1 at TpPa-1-COF, and the hydrogen production efficiency reaches 719 molg <-1 > h <-1 > and is 48 times that of water photolysis hydrogen production of a pure TpPa-1-COF catalyst. The preparation process is short in reaction time and mild in reaction condition, characterization tests such as XRD (X-Ray Diffraction) and a spherical aberration corrected high-angle annular dark field scanning transmission electron microscope (AC HAADF-STEM) graph show that the TpPa-1-COF material embedded with the monatomic Pt provides a large number of Pt active sites, favorable conditions are provided for catalyzing water to produce hydrogen, and the application prospect is good.

Owner:YANCHENG INST OF TECH

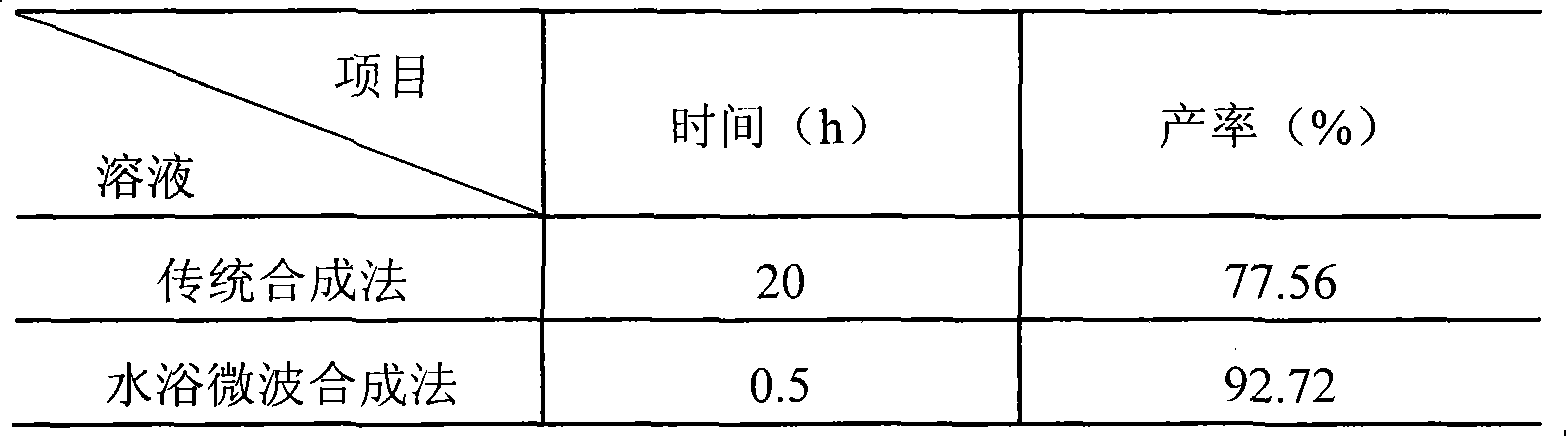

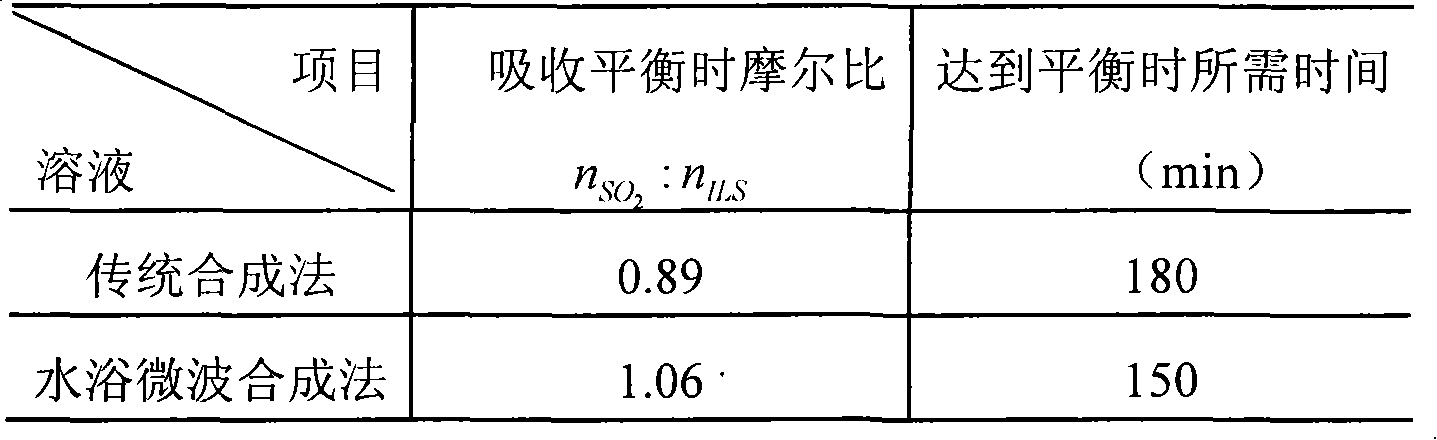

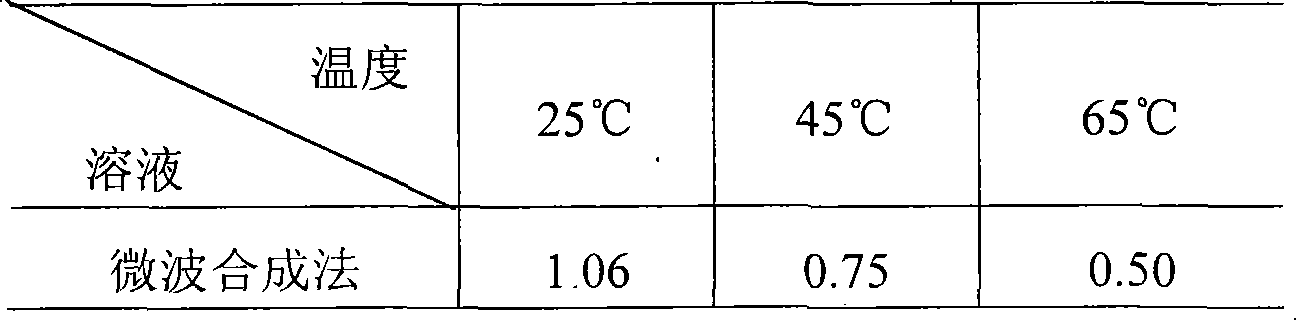

Method for synthesizing ionic liquid of ethanolamine lactate

InactiveCN101628876ASynthesis fastPromote neutralizationOrganic compound preparationAmino-hyroxy compound preparationWater bathsMicrowave method

The invention relates to the field of chemical engineering, in particular to a method for synthesizing an ionic liquid of ethanolamine lactate used for absorbing SO2 gas. The method is characterized in that: the water-bath microwave method is adopted to prepare the ionic liquid; under the microwave action, the target product can be quickly synthesized; and for the exothermic reaction, the water bath can remove excessive heat, weaken the microwave action, and better control the reaction temperature. The synthesis reaction time of the method is greatly shortened, and the synthesis reaction can be completed in 30 minutes. The ionic liquid of ethanolamine lactate prepared by the method has the advantages of high yield, short balance time, high desulfurizing efficiency and the like, and can be widely used as a fume desulfurizer.

Owner:NANJING UNIV OF SCI & TECH

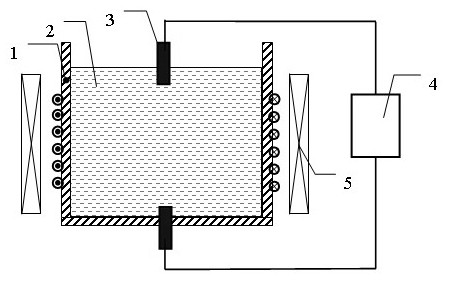

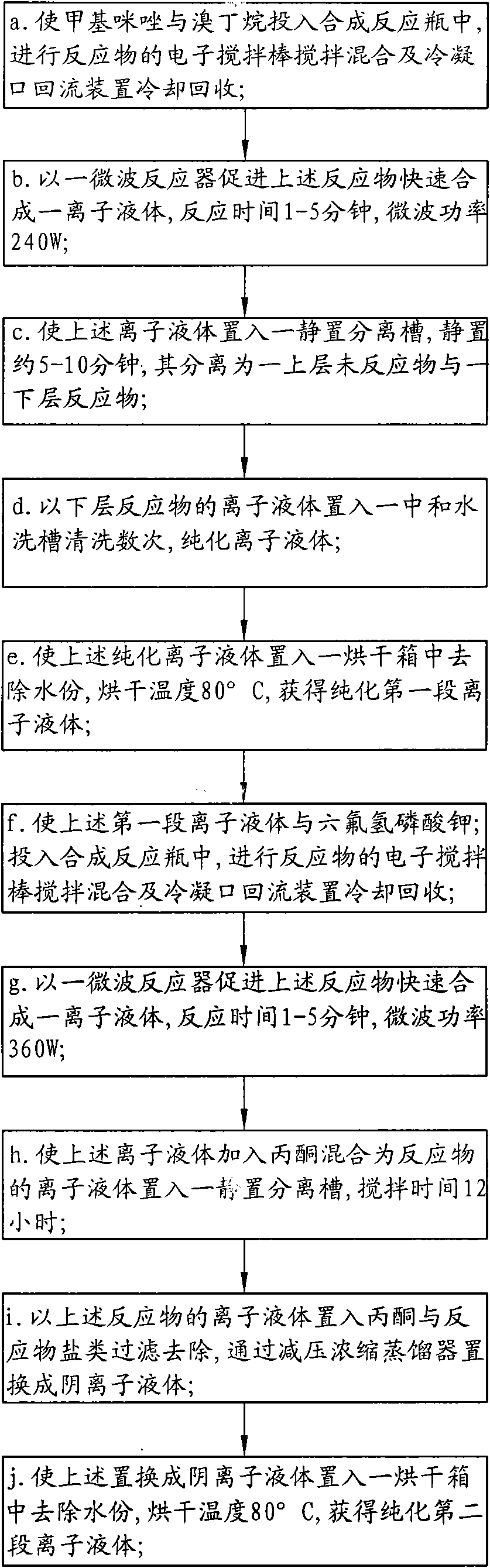

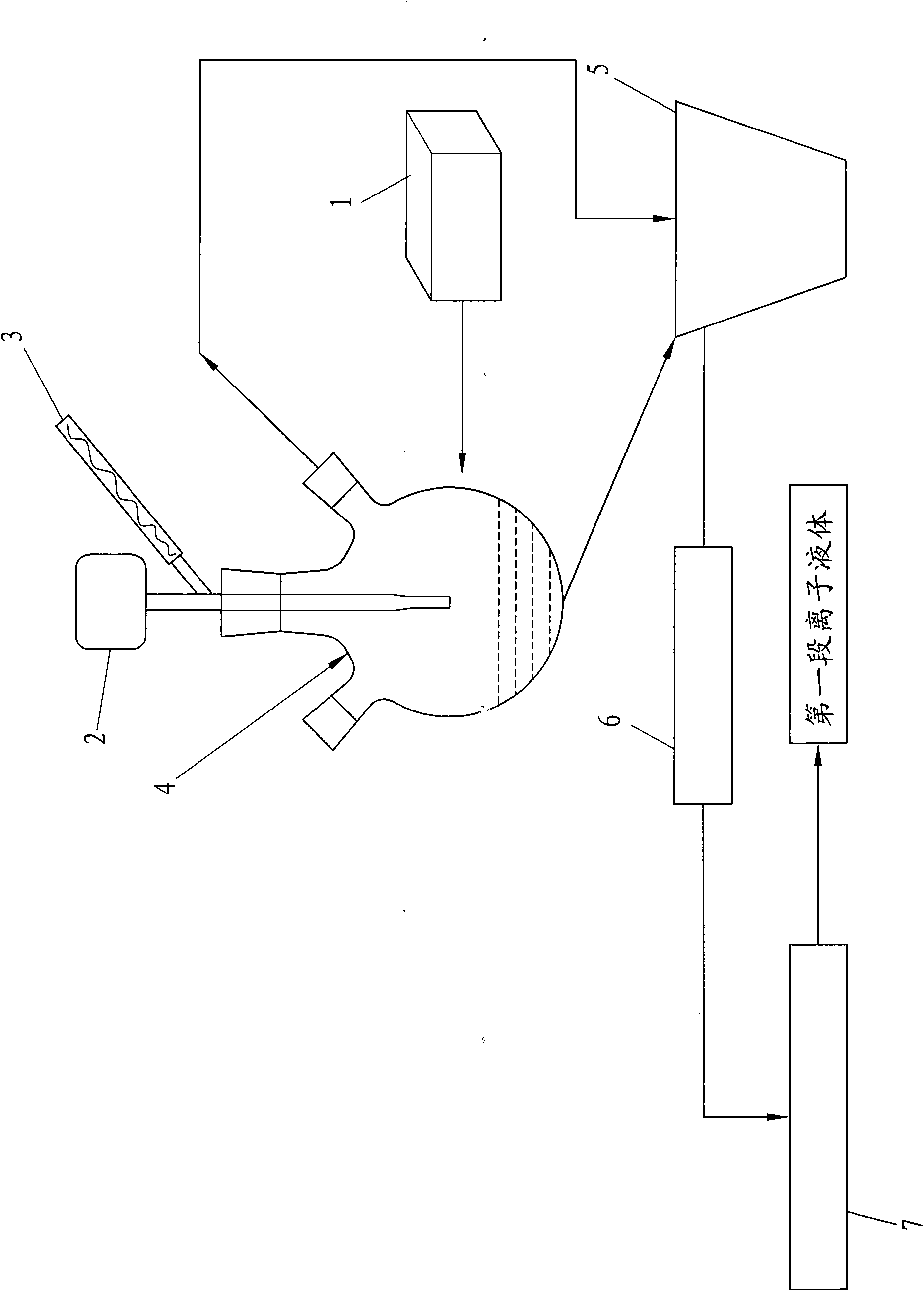

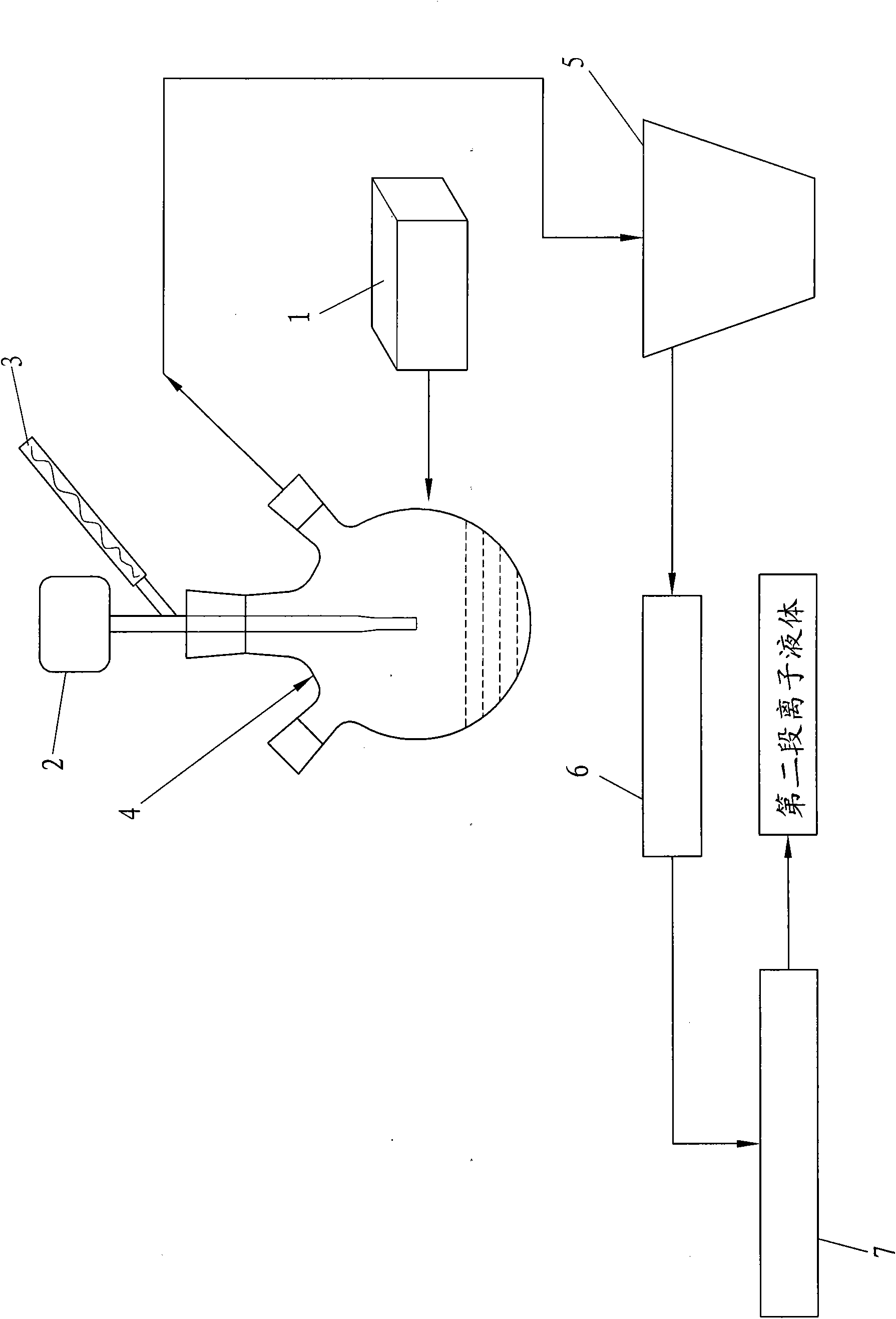

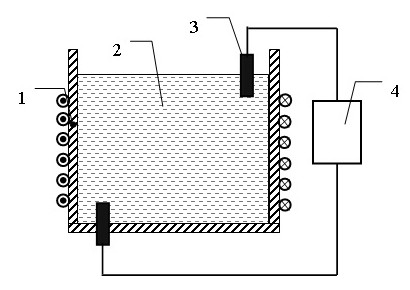

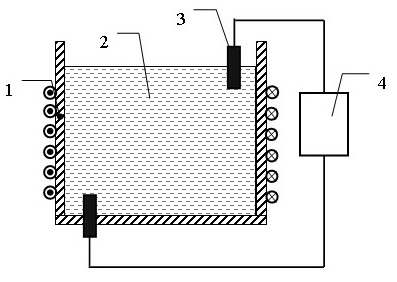

Method and device for rapidly preparing ionic liquid by using microwaves to promote synthesis

InactiveCN102372677AFast preparationLow costOrganic chemistryEnergy based chemical/physical/physico-chemical processesMicrowaveHydrogen phosphate

The invention discloses a method and device for rapidly preparing an ionic liquid by using microwaves to promote synthesis. According to the invention, after mixing methylimidazole and bromobutane, in the first stage, promoting the synthesis of methylimidazole and bromobutane by using microwaves, when the molar ratio of methylimidazole to bromobutane is 1:1, a first stage ionic liquid can be prepared by the synthesis of methylimidazole and bromobutane in only 2 minutes with the yield of 86-99 %, and the time is 1 / 720 of the required time in traditional technology; in the second stage, after mixing the first stage ionic liquid with potassium hexafluoro hydrogen phosphate, an anion-replacement reaction is carried out, a second stage ionic liquid can be prepared in 2.5 minutes with the yield of 90 %, and the time is 1 / 576 of the required time in traditional technology. The use of the invention can rapidly synthesized the first stage ionic liquid, and simultaneously can carry out anion-replacement on the first stage ionic liquid rapidly to obtain the second stage ionic liquid, and after the total reaction time of 4.5 minutes, the yield of the ionic liquid can reach to more than 90 %.

Owner:KUN SHAN UNIVERSITY

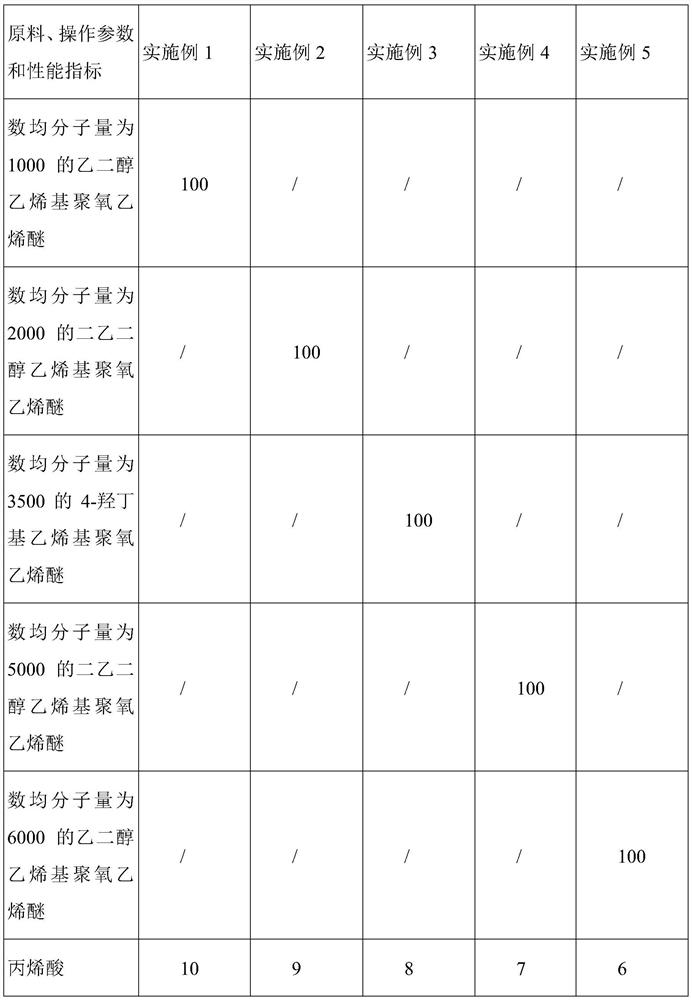

Polycarboxylate-type water reducing agent for gypsum-based self-leveling mortar and preparation method and use method thereof

ActiveCN113527592AReduced molecular weight distribution widthIncrease the length of the main chainVinyl etherPhosphorous acid

The invention discloses a polycarboxylate-type water reducing agent for gypsum-based self-leveling mortar and a preparation method and a use method thereof. The polycarboxylate-type water reducing agent is prepared from the following components in parts by weight: 100 parts of polyether, 6 to 10 parts of acrylic acid, 1 to 2 parts of fumaric acid, 0.2 to 1 part of methyl acrylate, 0.2 to 1 part of butyl acrylate, 0.5 to 2 parts of dimethyl diallyl ammonium chloride, 0.01 to 0.05 part of diethylene glycol divinyl ether, 0.01 to 0.05 part of triethylene glycol divinyl ether, 2 to 5 parts of hydrogen peroxide, 0.02 to 0.1 part of a reducing agent E51, 0.02 to 0.1 part of a reducing agent FF6, 0.001 to 0.005 part of ferrous sulfate, 0.01 to 0.05 part of mercaptopropionic acid, 0.01 to 0.05 part of mercaptoacetic acid, 0.01 to 0.05 part of mercaptoethanol, 0.5 to 2.5 parts of sodium hypophosphite, 12 to 20 parts of sodium hydroxide and 80 to 160 parts of water. The invention provides polycarboxylate-type water reducing agent for the gypsum-based self-leveling mortar and the preparation method and the use method thereof. The polycarboxylate-type water reducing agent is good in adaptability to byproduct gypsum, high in water reducing rate, good in slump retaining effect, fast in coagulation, small in shrinkage and high in strength, and can be widely applied to the field of gypsum-based self-leveling mortar.

Owner:连云港石化有限公司

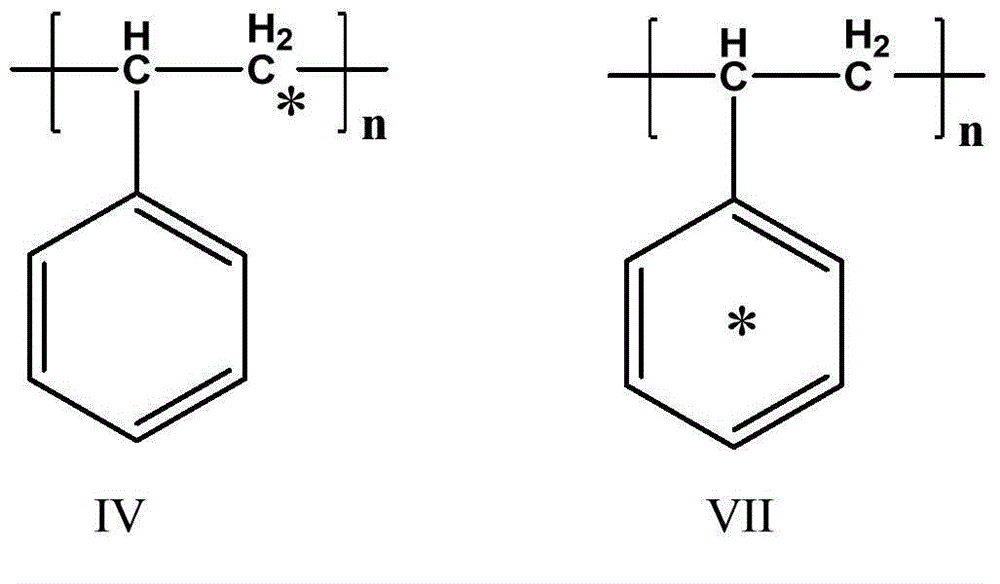

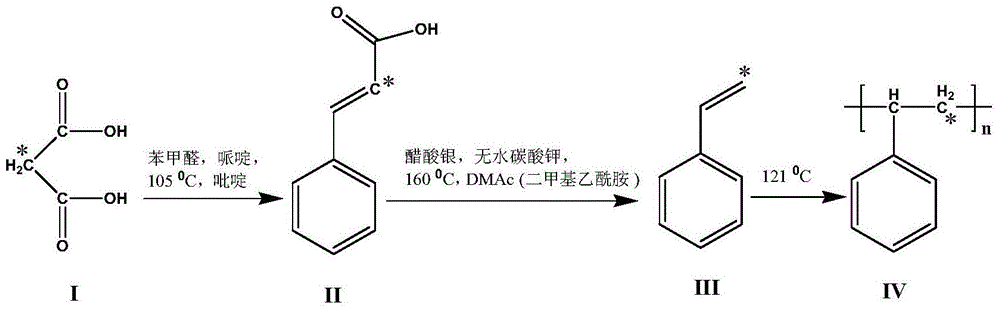

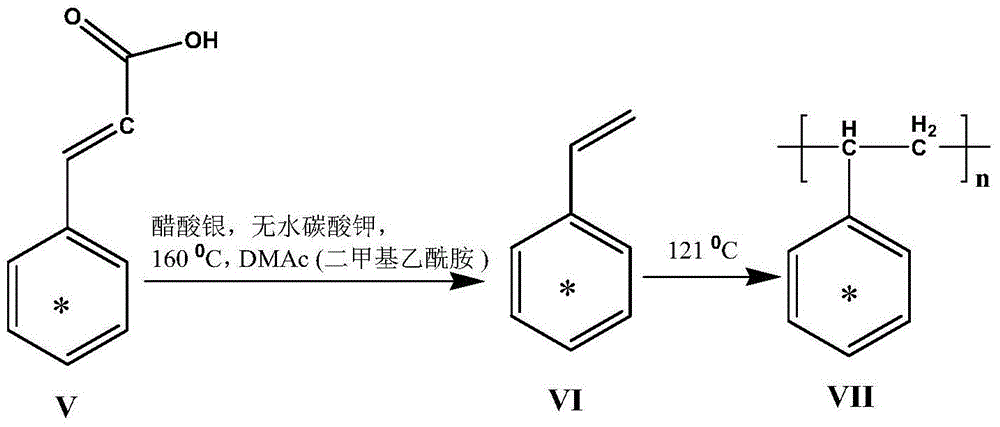

14C-labeled polystyrene (PS) and synthesis method thereof

The invention discloses 14C-labeled polystyrene (PS) and its synthesis method and belongs to the field of radioactive isotope 14C-labeled compounds. According to the invention, 14C radioactive isotope label is introduced into the structure of polystyrene (PS). A 14C-labeled site is on a branched chain or a phenyl ring, and is respectively named [beta-14C]-PS and [U-ring-14C6]-PS. The general structural formula is as shown in the Figure 1, wherein * indicates the 14C-labeled site. The synthesis method comprises the following steps: adding the 14C-labeled styrene into non-labeled styrene for dilution, putting into a high-temperature and high-pressure reactor and reacting at 118-123 DEG C for 8-12 h; dissolving reaction products with chloroform, washing with methanol, depositing and purifying to obtain the 14C-labeled polystyrene. The synthesis method has the following advantages: reaction materials are easily available, unreacted raw materials can be recovered, and synthesis cost is low; reaction time is short and efficiency is high; and reaction conditions are mild, operation technique is safe, and the preparation technology is simple. Radioactive purity of the 14C-labelled polystyrene synthesized by the method reaches more than 99%.

Owner:NANJING UNIV

Method for synthetizing particle reinforced metal matrix composite material in pulsed electric field

InactiveCN102121076AImprove mechanical propertiesIncrease speedMaterials preparationMetal matrix composite

The invention provides a new method for synthetizing a particle reinforced metal matrix composite material in a pulsed electric field, belonging to the technical field of material preparation. The main process of the method is characterized in that the pulsed electric field is applied to a fusant in a synthetic process of the particle reinforced composite material by the traditional fusant directreaction method; and the pulsed current peak value density is 1-10A / cm<2>, the pulse frequency is 0.1-10Hz, and the time of processing the fusant in the pulsed electric field is 2-10minutes. The comprehensive effect of the electric potential oscillation fluctuation, transient force effect and heat effect in the pulsed electric field are utilized by the method provided by the invention, so as to promote the ionic migration and particle nucleation in in-situ reaction, inhibit the growth of the particles and improve the dispersibility of the particles, thus by adopting the method provided by theinvention, the reaction rate and the yield can be improved, the obvious effects of particle shape control and dispersion promotion are achieved, and the method is suitable for preparing high-performance particle reinforced composite material in an industrial scale.

Owner:JIANGSU UNIV

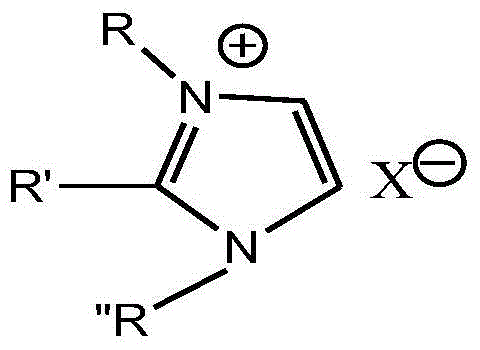

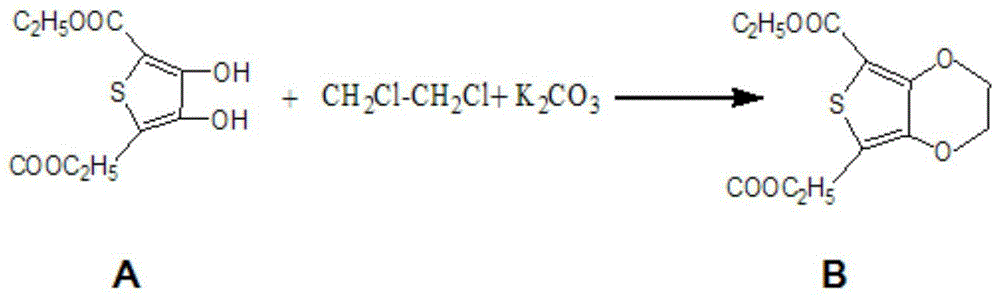

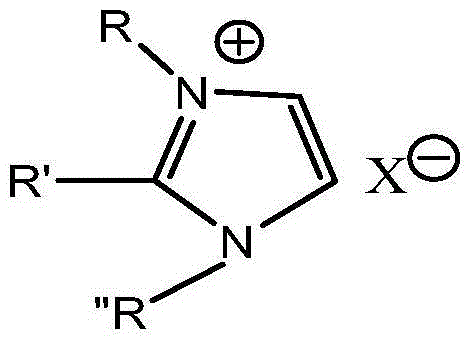

Imidazolium ionic liquid, application thereof and preparation method of 2, 5-azodicarboxylic acid diethyl ester-3, 4-ethylenedioxythiophene

InactiveCN104974093AEffective recycling and reuseImprove solubilityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsIonEthyl ester

The invention belongs to the technical field of chemosynthesis, and particularly relates to an imidazolium ionic liquid, application thereof and a preparation method of 2,5-azodicarboxylic acid diethyl ester-3,4-2 ethylenedioxythiophene. Potassium carbonate is used as a catalyst, the imidazolium ionic liquid is used as a solvent and a catalyst, dichloroethane is used as a cyclic etherreagent, and the dichloroethane and the 2,5-azodicarboxylic acid diethyl ester-3,4-dihydroxy thiophene are cyclized so as to prepare the 2,5-azodicarboxylic acid diethyl ester-3,4- ethylenedioxythiophene. The preparation method is low in cost, is high in yield, and is simple to post-process, and the solvent can be recycled.

Owner:武汉海斯普林科技发展有限公司

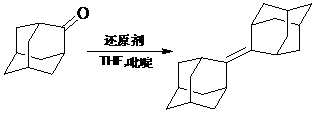

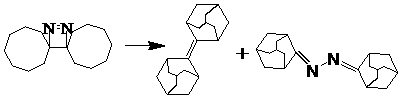

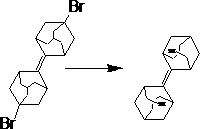

Tetracyclic decene dimer synthesis method

ActiveCN103204758AShort synthesis reaction timeHigh yieldHydrocarbonsHydrocarbon preparationSynthesis methodsCoupling reaction

The invention provides a tetracyclic decene dimer synthesis method. A tetracyclic decylone is used as an initial raw material and undergoes a carbonyl reduction coupling reaction to synthesize a tension ring cage hydrocarbon tetracyclic decene dimer (C20H28). Compared with the prior art, the synthesis method has the advantages of simple synthetic technology, low cost, high synthetic yield and high product purity, and allows the target compound to be synthesized only through a one-step reaction, the yield to reach about 87% and the purity of the product to reach above 98%; and the tetracyclic decene dimer can be used as the fuel or fuel additive of solid rocket engines.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Preparation method of water-in-water type cationic polyacrylamide emulsion

InactiveCN103601848AImprove stabilityOperational securityWater/sewage treatment by flocculation/precipitationSynthesis methodsDouble bond

The invention relates to a preparation method of a polyacrylamide emulsion. The method is characterized by comprising the following steps: taking dimethyl diallyl ammonia chloride (DMDAAC) as the cationic monomer, taking ammonium sulfate and PDMDAAC respectively as the dispersion medium and the dispersion agent for CPAM dispersion polymerization in a saline water medium, and making acrylamide to carry out free radical copolymerization reactions with quaternary ammonium salt organic compounds so as to generate the water-in-water type cationic polyacrylamide emulsion. The appearance of the emulsion is in a milk white color, and the particle size is smaller than 1 [mu]m, which is in the range of emulsion particle size value. The preparation method adopts a novel polymer synthesis method, and overcomes the shortages existing in the prior art that a large amount of organic solvent and surfactant used in the synthesis process generates secondary pollutions to the environment and the product cost is greatly increased. The emulsion can be widely applied to the fields of oil field, industrial or city sewage processing, sludge dehydration, paper making, and personal nursing and cosmetic.

Owner:SHANGHAI WSHINE CHEM

Preparation method of polyethylene terephthalate-1,3-propanediol copolyester

The invention relates to a preparation method of polyethylene terephthalate-1,3-propanediol copolyester. In the preparation method, terephthalic acid or dimethyl terephthalate, 1,3-propanediol and ethylene glycol are used as raw materials, titanate, germanium compound and cobalt compound are used to form composite catalyst, phosphorus compound is added to be used as stabilizer; under the synergistic catalysis and hue-adjusting functions of the materials, the reaction time can be greatly shortened, the polyester chip of which intrinsic viscosity is 0.75-1.05dL / g is prepared through direct polymerization; and the reaction product has good hue, and the copolyester product can be used in the fields of fiber and engineering plastic.

Owner:PETROCHINA CO LTD

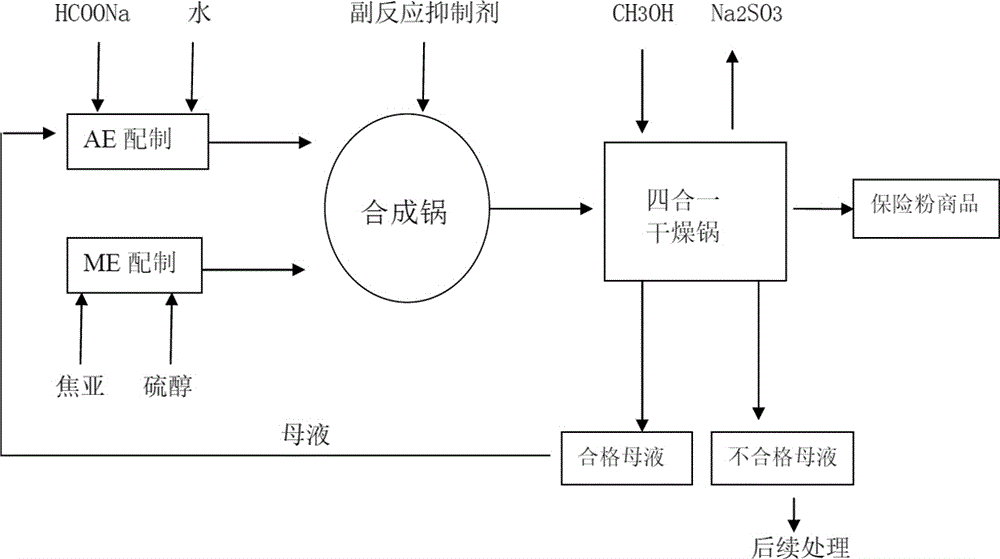

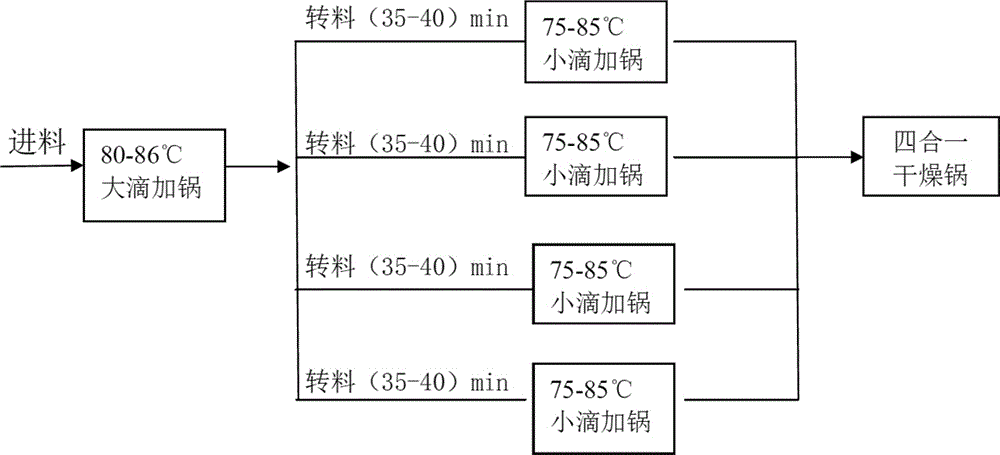

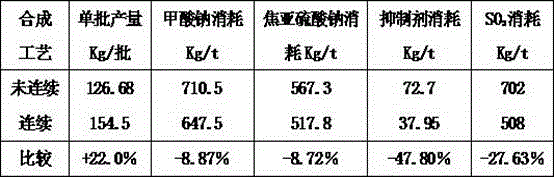

Sodium hydrosulfite synthesizing and continuous producing method

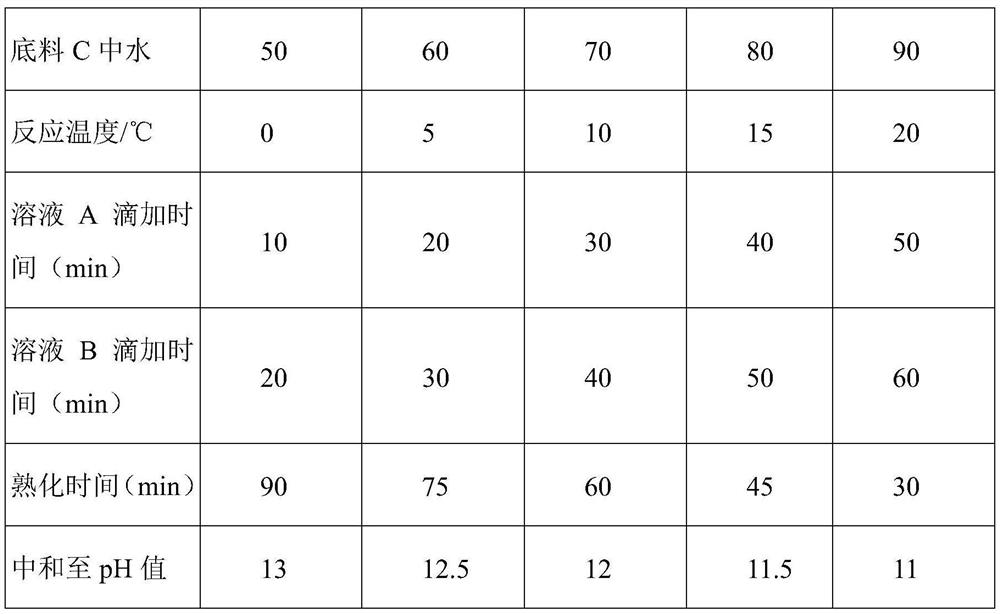

ActiveCN106517103ALess investmentSave overall synthesis timeThiosulfates/dithionites/polythionitesRipeningMaterial transfer

The invention discloses a sodium hydrosulfite synthesizing and continuous producing method. The sodium hydrosulfite synthesizing and continuous producing method comprises the following steps: taking a synthesizing pot as a tubular reactor; after preparing raw materials AE and ME, transferring the raw materials AE and ME into AE and ME storage tanks via inert gas; adding the raw materials AE and ME in a large synthesis dropwise adding pot; opening the pot and inserting a bottom tube into the large synthesis dropwise adding pot to transfer the materials into a small synthesis dropwise adding pot; keeping the liquid level of the materials in the large dropwise adding pot to be stable relatively in a material transferring process; continuing adding the raw materials AE and ME into the large synthesis dropwise adding pot continuously and uniformly; after the small synthesis dropwise adding pot receives a first batch of materials, enabling a second small dropwise adding pot to begin to receive the material from the large synthesis dropwise adding pot, and enabling the rest dropwise adding pot to begin to receive the material from the large synthesis dropwise adding pot in the same way; continuously adding a SO2-CH3OH solution as a raw material at a suitable speed to an end point by the small dropwise adding pots from the time when the small dropwise adding pots begin to receive the material to the time when reaction reaches the end point; and after insulating and ripening are completed, placing the material in a drying process for subsequent use. A repeated operation process of a reaction process is omitted, so that a synthesis process is continuous, and while the efficiency of the device is improved, consumption of sodium formate and sodium pyrosulfite is reduced.

Owner:CHIFENG RUIYANG CHEM

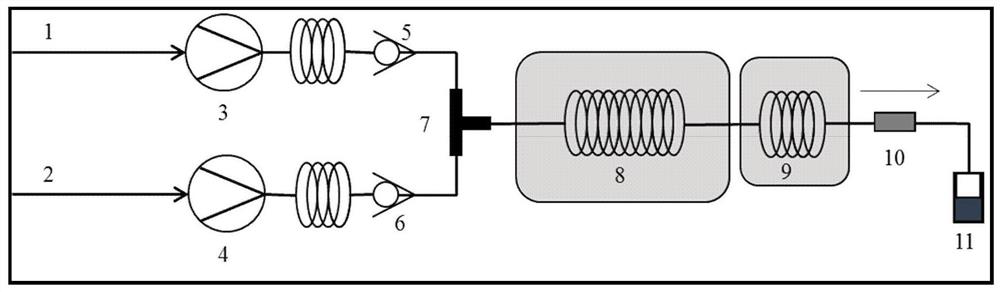

A kind of method for continuously synthesizing n-methylpyrrolidone and n-ethylpyrrolidone

ActiveCN107474003BShort synthesis reaction timeImprove efficiencyOrganic chemistryPyrrolidinonesEthyl group

A method for continuously synthesizing N-methylpyrrolidone and N-ethylpyrrolidone, the method is carried out in a microreactor, and gamma-butyrolactone solution and corresponding alkylamine solution are continuously passed through a microreactor to synthesize N-methylpyrrolidone and N-ethylpyrrolidone. Wherein, the microreactor includes a reaction section and a reaction suppression section, and the reaction mixture is carried out under the condition that the residence time of the reaction mixture is 1 to 30 minutes, and wherein the γ-butyrolactone solution and the corresponding alkylamine solution Both use ethylene glycol as a solvent, the molar ratio of alkylamine and γ-butyrolactone in the reaction mixture is 1.0-1.6, and the concentration of the γ-butyrolactone solution is 0.5-2 mol / L. The invention can shorten the synthesis process time of N-methylpyrrolidone and N-ethylpyrrolidone from several hours to within 30 minutes, and meanwhile, the yield of the product reaches more than 90%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

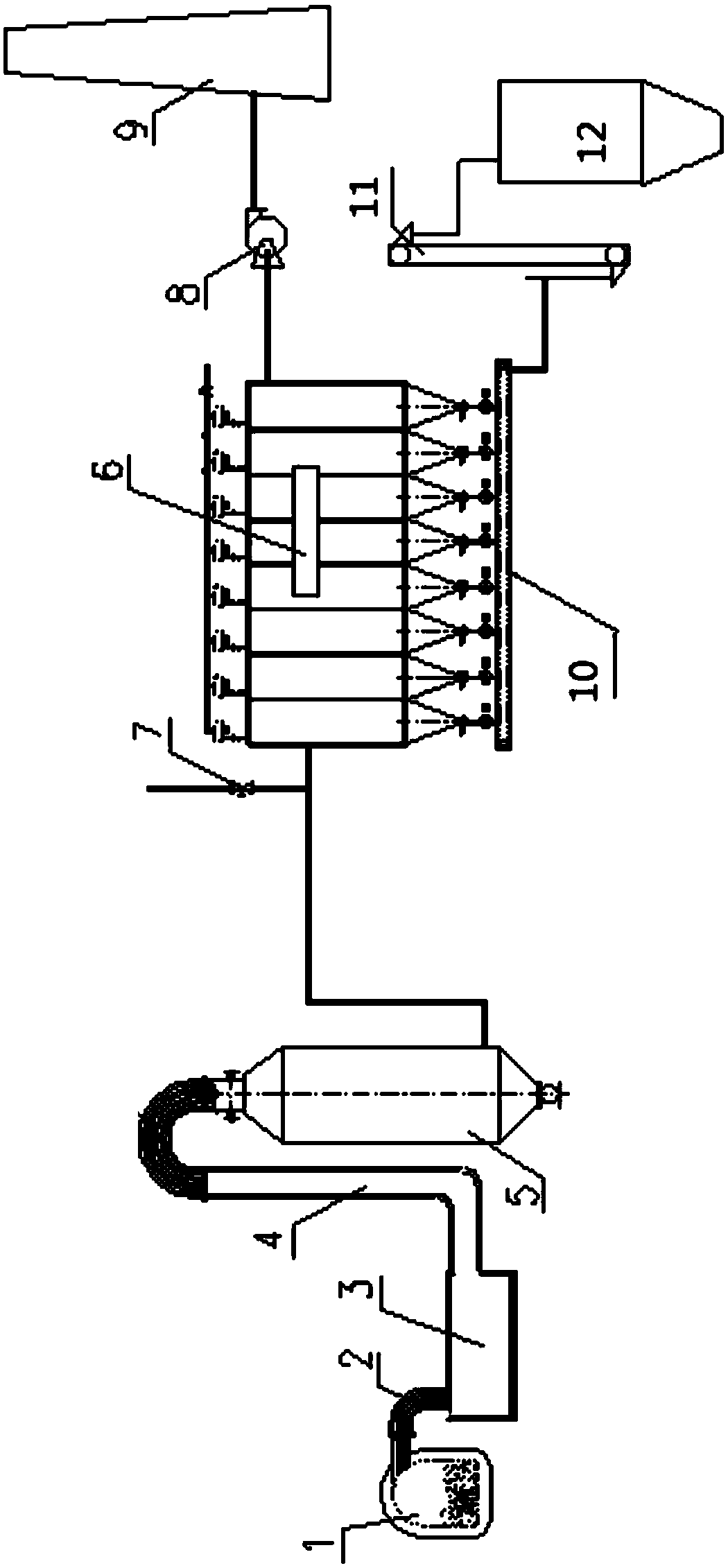

Purification system and method for flue gas in continuous feeding electric-arc furnace

PendingCN108827013AShort synthesis reaction timeReduce the production of toxic and carcinogenic dioxinsIncreasing energy efficiencyWaste heat treatmentVacuum furnaceFlue

The invention relates to a purification system and method for flue gas in a continuous feeding electric-arc furnace. The flue gas purification system comprises a water cooling elbow, a settling chamber, an insulating flue, an evaporative cooling tower, a bag-type dust collector and a discharging device; one end of the water cooling elbow communicates with a smoke outlet of a steel scrap preheatingsection of the electric-arc furnace in a sealing mode; the other end of the water cooling elbow is introduced into the settling chamber in a sealing mode; the insulating flue is provided with a low end and a high end, and the low end of the insulating flue communicates with the upper portion of the settling chamber in a sealing mode; the evaporative cooling tower is provided with a flue gas inletand a flue gas outlet, and the high end of the insulating flue communicates with the flue gas inlet of the evaporative cooling tower in a sealing mode; the bag-type dust collector is provided with aflue gas inlet and a flue gas outlet, and the flue gas inlet of the dust collector communicates with the flue gas outlet of the evaporative cooling tower through a pipeline with a mixer selector valve; and the discharging device communicates with the flue gas outlet of the dust collector. According to the purification system and method for the flue gas in the continuous feeding electric-arc furnace, the content of toxic cancerogenic substances such as dioxin in purified flue gas is greatly decreased, and the cooling water demand quantity is significantly decreased.

Owner:江苏久华环保科技股份有限公司

Preparation method of polybutylene terephthalate/adipate butanediol copolyester

The invention relates to a preparation method of polybutylene terephthalate / adipate butanediol copolyester, which utilizes a titanium compound and an antimony compound as the composite catalyst, the mole ratio of terephthalic acid to adipate is 3:7-8:2, the ratio of the total mole of the terephthalic acid and the adipate to the mole of 1,4-butanediol is 1:1.0-1.8, esterification is carried out atnormal pressure and the temperature of 150-220 DEG C, the pressure is reduced to high vacuum 10-150 Pa for the reaction, the final temperature for the reaction is 265-280 DEG C, and inert gas is utilized to recover the pressure to be normal to obtain the copolyester. The reaction time is shortened, the production amount of tetrahydrofuran is small, the intrinsic viscosity of copolyester chips is 0.90-1.32 dL / g, the hue b value of the product is between 0 and 8, the L value is between 68 and 85, and the product of the polybutylene terephthalate / adipate butanediol copolyester can be used in thefields of various soft package plastic products.

Owner:PETROCHINA CO LTD

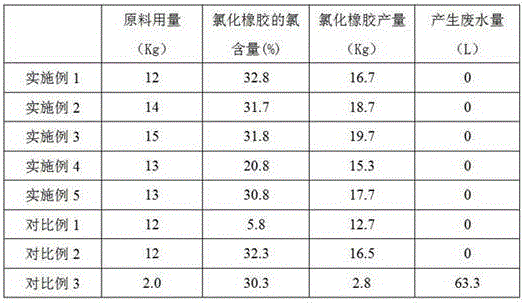

Chlorinated rubber prepared by utilizing recycled tire desulfurized rubber

The invention discloses chlorinated rubber prepared by utilizing recycled tire desulfurized rubber. The chlorinated rubber comprises the following raw materials in parts by weight: 40 to 60 parts of a hydrochloric acid solution with a concentration of 10 to 15wt%, 8.0 to 15.0 parts of the recycled tire desulfuized rubber, 3.0 to 9.0 parts of chlorine, 0.07 to 0.25 part of a dispersant, 0.07 to 0.15 part of an emulsifier and 0.01 to 0.03 part of an initiator. The preparation method comprises the following steps: mixing raw materials, directly introducing liquid chlorine, and carrying out a reaction under heating and pressurizing. The chlorinated rubber prepared by using the method provided by the invention adopts the pollution-free recycled tire rubber obtained by utilizing a novel desulfurization technology as a raw material, and an aqueous acid-phase chlorination method is adopted to prepare the chlorinated rubber and an industrial product--hydrogen chloride contained hydrochloric acid with a concentration of 23 to 26wt%; and the method overcomes the problems of large water consumption and high treatment cost of generated acid-contained wastewater in an aqueous phase method, opens up a novel approach for high-value-added utilization of the recycled tire rubber, and has low cost.

Owner:程贤甦

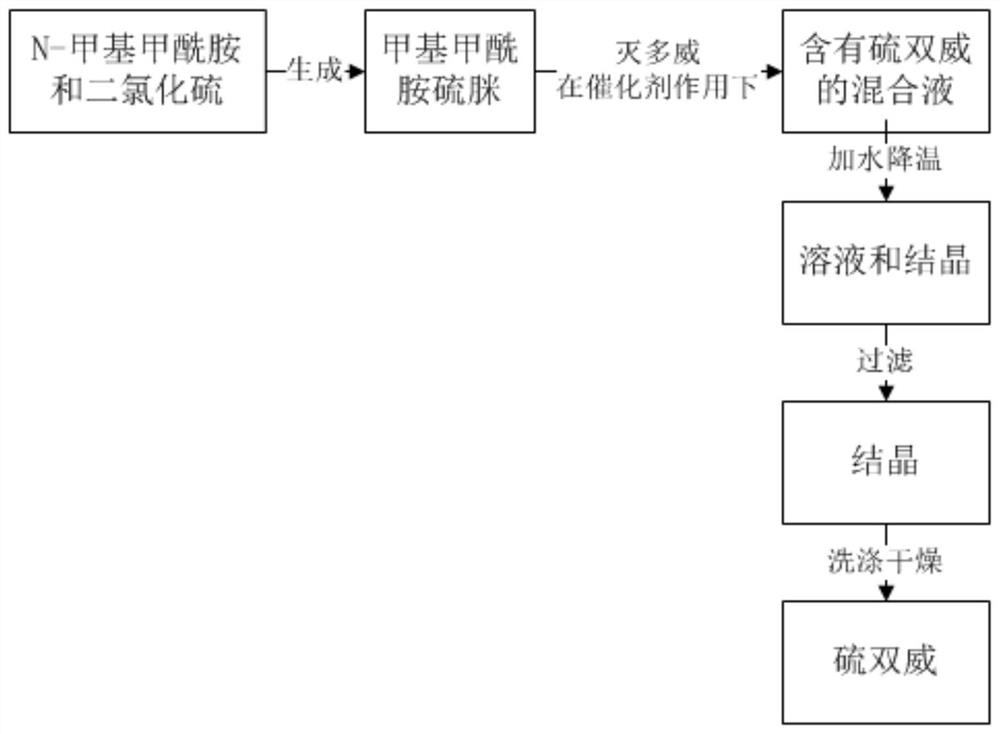

Preparation method of high-content thiodicarb

PendingCN114031533AIncreased toxicityReduce the risk of safety occupational health hazardsBiocideOrganic chemistryChemical synthesisPtru catalyst

The invention discloses a preparation method of high-content thiodicarb, and relates to the technical field of chemical synthesis. The method comprises the following steps: generating methylformamide thiamidine by taking N-methylformamide and sulfur dichloride as raw materials, carrying out condensation reaction on the methylformamide thiamidine and methomyl as raw materials under the action of a catalyst to generate a mixed solution containing thiodicarb, adding water into the mixed solution, conducting cooling to obtain a solution and crystals, filtering the solution and crystals, washing the filtered crystals, centrifugally filtering the crystal and a detergent, and drying the centrifugally filtered crystal to obtain thiodicarb with the content of greater than or equal to 98.0% and the total yield of greater than or equal to 95.0% in terms of methomyl. According to the method provided by the invention, the safety occupational health hazard risk is reduced, the process is safer, the operation is convenient, the use of pyridine is avoided, the foul odor on the production site is avoided, the environmental protection pressure is relieved, the production cost is reduced, the product quality and yield of thiodicarb are remarkably improved, and the thiodicarb reaches the export standard.

Owner:山东华阳农药化工集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com