Method for synthesizing ionic liquid of ethanolamine lactate

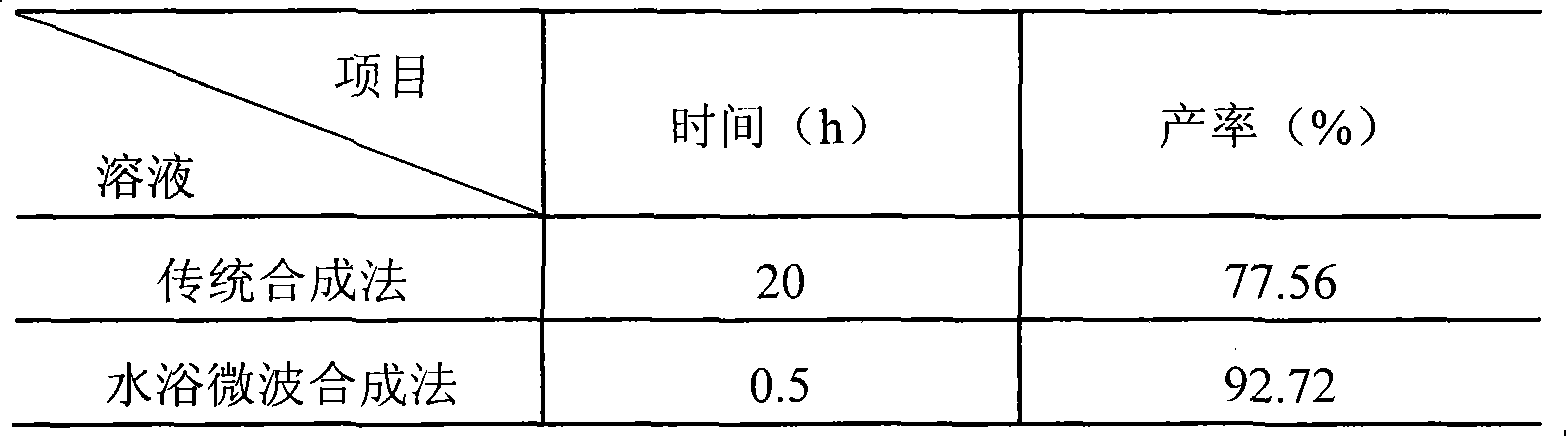

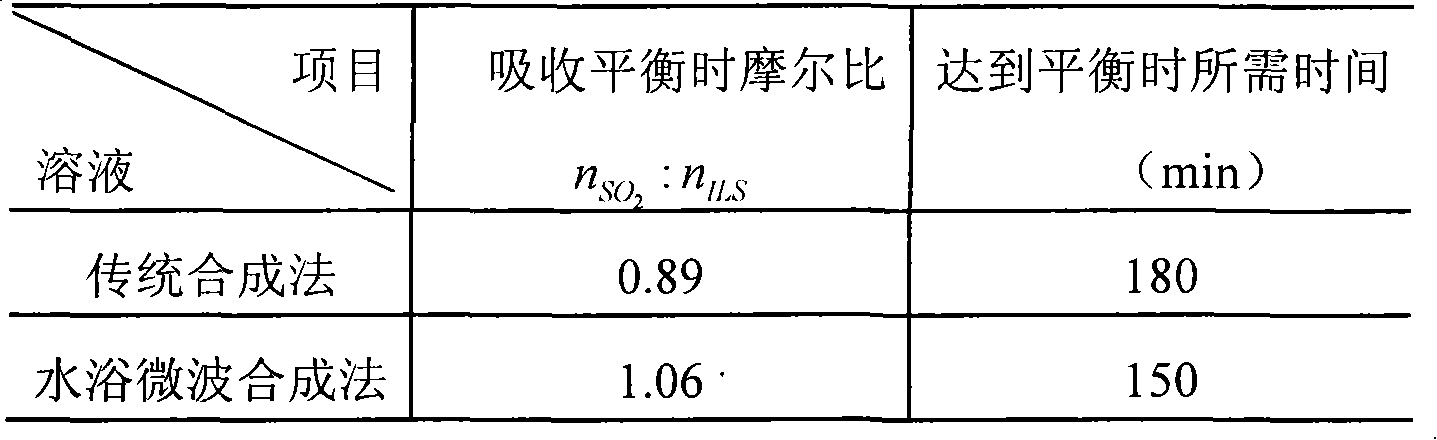

A technology of ethanolamine lactate and ionic liquid, which is applied in the field of synthesis of quaternary ammonium salt ionic liquid, and can solve problems such as cumbersome operation process, unfavorable ionic liquid properties and performance experiments, and long synthesis reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

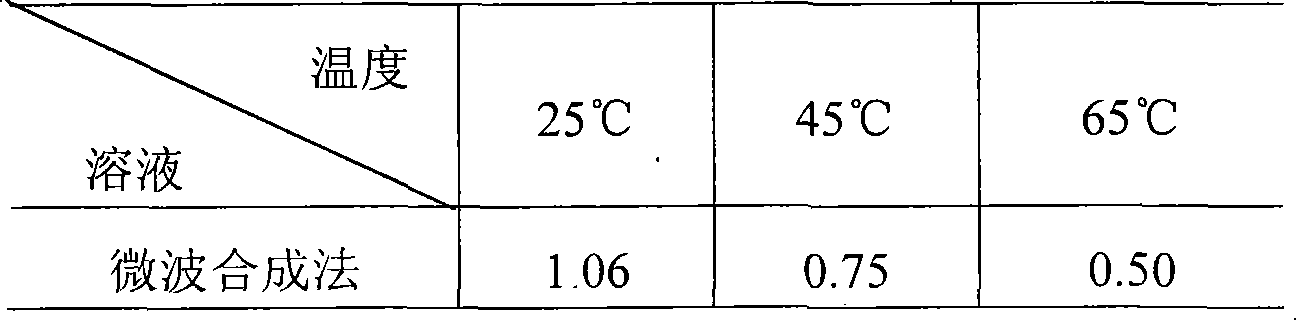

Method used

Image

Examples

Embodiment 1

[0014] 1. Put the rotor in the three-necked microwave special flask, then weigh 0.5mol ethanolamine and 0.55mol lactic acid according to the molar ratio of 1:1.1 and add them to the 100mL microwave special three-necked flask and the balance liquid adder for use;

[0015] 2. Place the three-necked flask containing ethanolamine in a beaker filled with cold water, so that the liquid level of the cold water is slightly higher than the liquid level in the three-necked flask to form a water bath;

[0016] 3. Put the beaker with the three-necked flask into the microwave reactor, and make the three interfaces of the three-necked flask connect with the balance liquid adder and N 2 The air guide tube is connected with a spherical condenser tube;

[0017] 4. Set the microwave power of the microwave reactor to 300w, the reaction temperature to 65°C, and feed N 2 Gas, the flow rate is selected as 0.2L min -1 or 0.3L·min -1 , so that the reactants do not overflow as a limit, and ensure t...

Embodiment 2

[0020] The process steps are the same as in Example 1, except that the molar ratio of ethanolamine and lactic acid added is 0.90:1, the reaction temperature is 25°C, the microwave power and reaction time are 300w and 10min respectively, and the above synthesis steps are repeated. The purified ionic liquid can be obtained, and the calculated yield of this example is 84.37% after weighing.

Embodiment 3

[0022] The process steps are the same as in Example 1, except that the molar ratio of ethanolamine and lactic acid added is 1:1.1, the reaction temperature is 65°C, the microwave power and reaction time are 700w and 10min respectively, and the above synthesis steps are repeated. The purified ionic liquid can be obtained, and the calculated yield of this example is 86.36% after weighing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com