Patents

Literature

32results about How to "Promote neutralization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

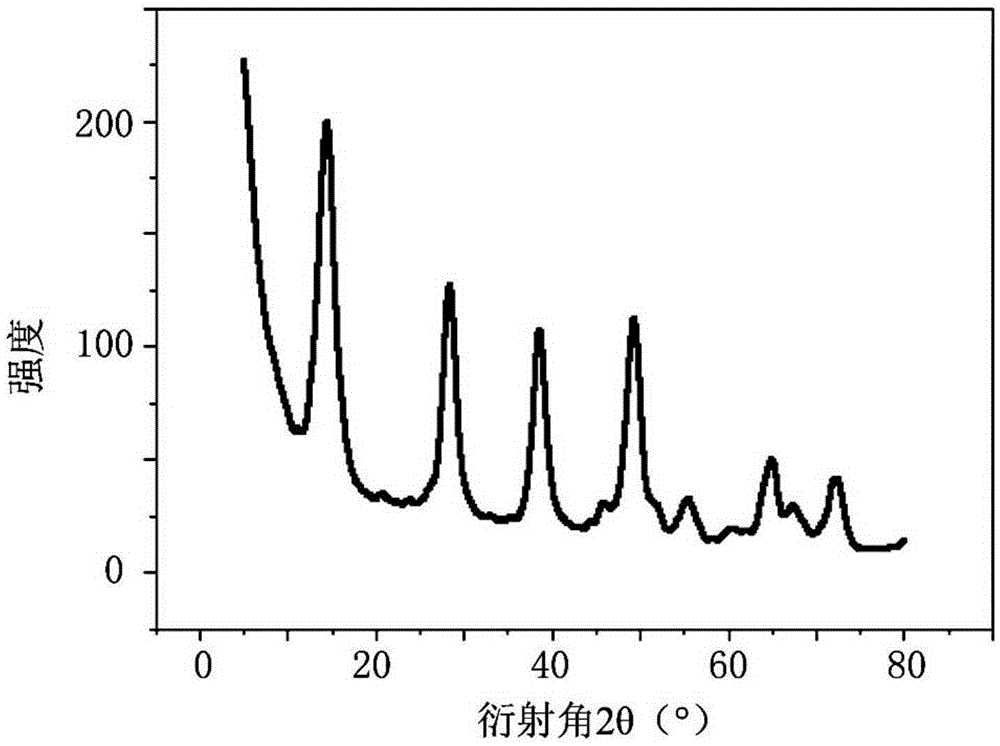

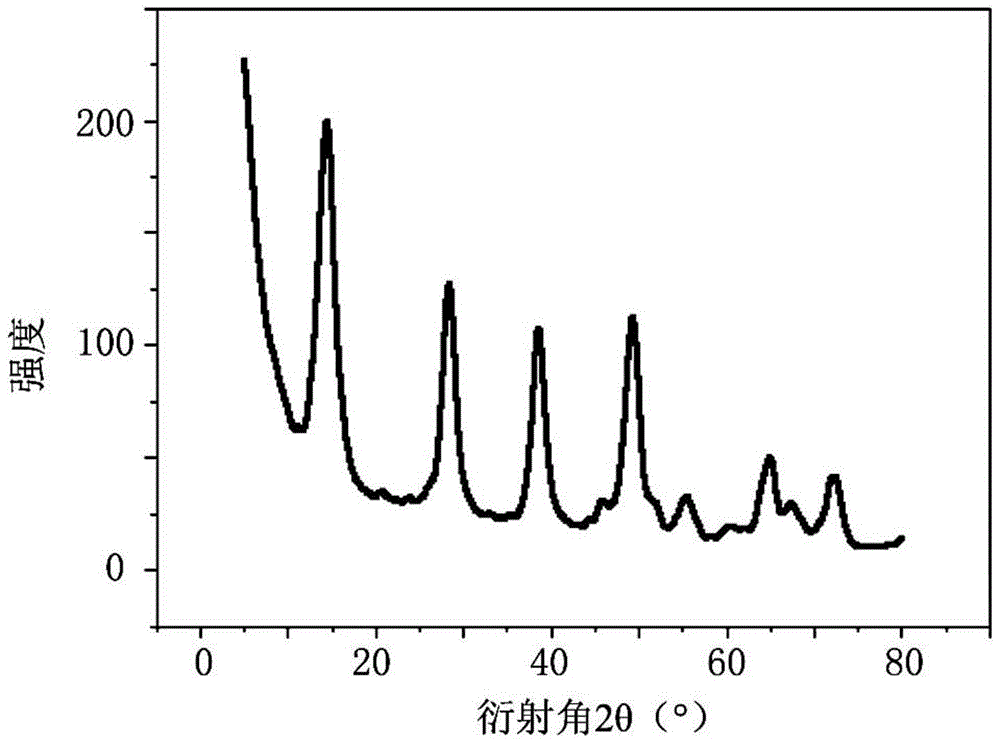

Preparation method of high-activity crystal seed by hydrolysis of titanium sulfate solution

The invention discloses a preparation method of high-activity crystal seed by hydrolysis of a titanium sulfate solution and belongs to the technical field of production of titanium dioxide by a sulfuric acid method. The preparation method comprises the following steps of (A) taking and putting a hydrolytic titanium sulfate solution into a preheating groove to be preheated to 50-65 DEG C, wherein the concentration of TiO2 in the hydrolytic titanium sulfate solution is 195-205g / L, the concentration of Ti<3+> is 1.0-3.0g / L (calculated by TiO2), the concentration ratio F between effective acid andtotal TiO2 is 1.70-1.85, the concentration ratio between Fe and TiO2 is 0.26-0.31, the solid content is less than 30mg / L, and the stability is greater than or equal to 500; (B) preheating alkaline liquid to 50-65 DEG C, and controlling the concentration of the preheated alkaline liquid to 8.0-8.5%; (C) within 1-4 minutes, adding the hydrolytic titanium sulfate solution into the alkaline liquid, and after the reaction is finished, controlling the temperature of the crystal seed titanium sulfate solution to be 40-60 DEG C; (D) diluting and controlling the concentration of TiO2 in the crystal seed titanium sulfate solution to be 30-160g / L. The crystal seed prepared by the method is high in activity, less in added amount in water crystallization and high in hydrolysis rate, and the obtained hydrated titanium dioxide is uniform in particle size distribution.

Owner:HEBEI MILSON TITANIUM DIOXIDE

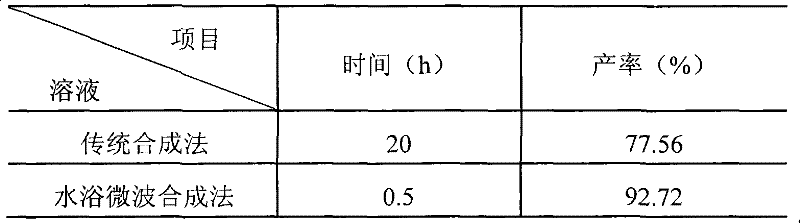

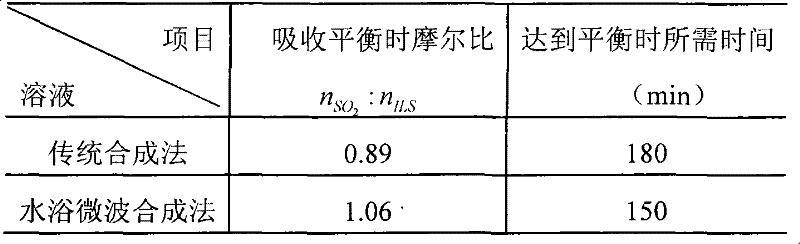

Method for synthesizing ionic liquid of ethanolamine lactate

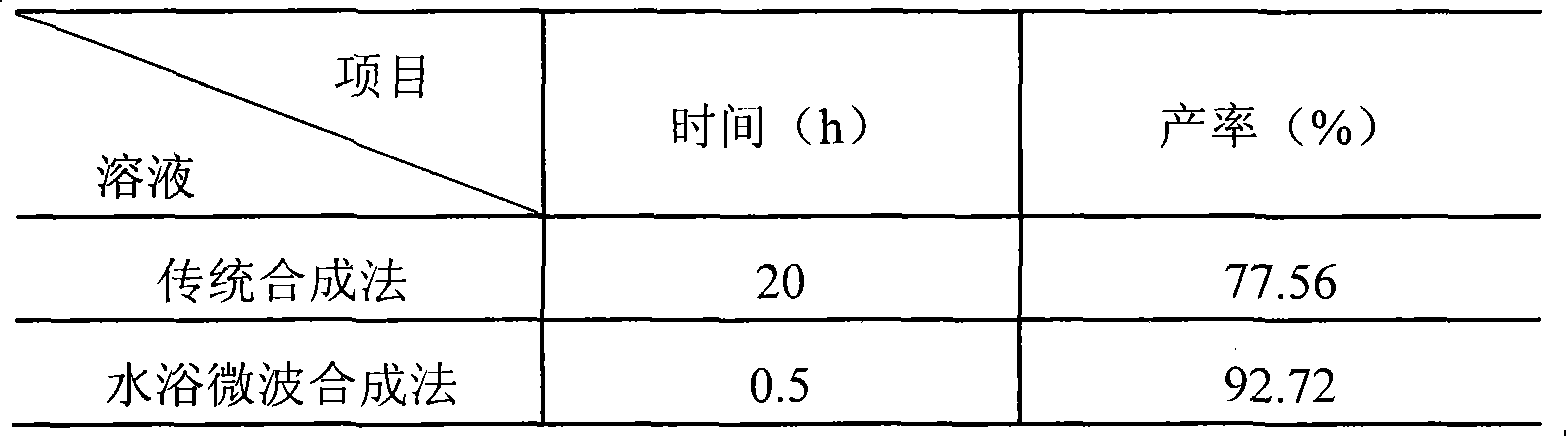

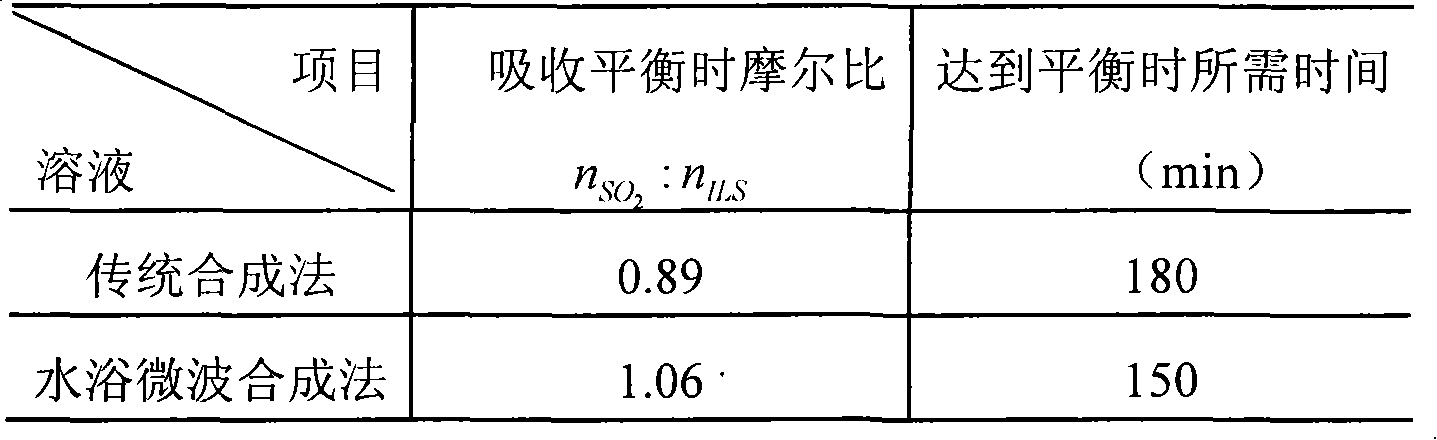

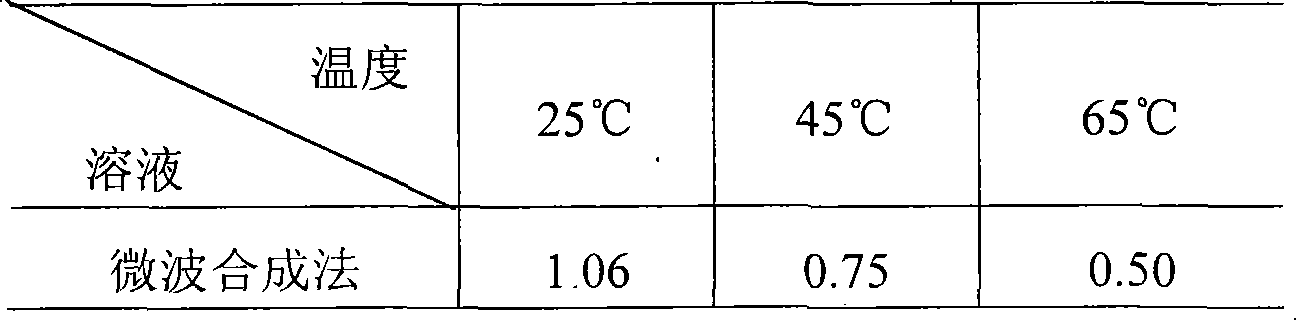

InactiveCN101628876ASynthesis fastPromote neutralizationOrganic compound preparationAmino-hyroxy compound preparationWater bathsMicrowave method

The invention relates to the field of chemical engineering, in particular to a method for synthesizing an ionic liquid of ethanolamine lactate used for absorbing SO2 gas. The method is characterized in that: the water-bath microwave method is adopted to prepare the ionic liquid; under the microwave action, the target product can be quickly synthesized; and for the exothermic reaction, the water bath can remove excessive heat, weaken the microwave action, and better control the reaction temperature. The synthesis reaction time of the method is greatly shortened, and the synthesis reaction can be completed in 30 minutes. The ionic liquid of ethanolamine lactate prepared by the method has the advantages of high yield, short balance time, high desulfurizing efficiency and the like, and can be widely used as a fume desulfurizer.

Owner:NANJING UNIV OF SCI & TECH

Lithium alginate production process

The invention provides a lithium alginate production process.The lithium alginate production process includes steps: (1) performing alkali digestion of brown algae to prepare alginic acid; (2) adding the alginic acid and a certain quantity of a composite lithium salt into a neutralization reactor to react for 50-70min until the alginic acid and the composite lithium salts are completely neutralized to form lithium alginate, wherein neutralization reaction includes solid-phase neutralization reaction and liquid-phase neutralization reaction with ethyl alcohol serving as a medium; consumption of the composite lithium salt is 7-15% of that of the alginic acid; the composite lithium salt is composed of lithium carbonate and lithium acetate, and a ratio of the lithium carbonate to the lithium acetate is 80-90:10-20; (3) performing centrifuging, plunger extruding granulation, drying and grinding to obtain lithium alginate in required meshes.The lithium alginate prepared according to the process is 100-2000mPa.s in viscosity, 40-320 in mesh number, 6.0-8.0 in pH value, smaller than or equal to 15.0% in moisture content and 14-28% in ash content.In addition, the lithium alginate production process can be implemented under the condition of existing sodium alginate solid-phase and liquid-phase neutralization production technology.

Owner:青岛海之林生物科技开发有限公司

Production technology of magnesium alginate

The invention provides production technology of magnesium alginate. The production technology comprises the following steps: (1) preparing alginic acid from brown algae via alkali digestion; (2) adding alginic acid and a certain amount of composite magnesium salt into a reactor, and reacting for 50-75 min till alginic acid and composite magnesium salt are neutralized and are completely converted to magnesium alginate, wherein the neutralization reaction comprises a solid-phase neutralization reaction and a liquid-phase neutralization reaction taking alcohol as a medium; (3) using the composite magnesium salt with the amount being 7-15% of that of alginic acid; (4) taking magnesium chloride and basic magnesium salt, the ratio of which is 10-20:80-90, to prepare the composite magnesium salt, wherein (5) the basic magnesium salt comprises one or more of magnesium bicarbonate, magnesium hydroxide, magnesium carbonate, magnesium oxide, magnesium acetate, and magnesium silicate; and (6) performing centrifugation, plunger extruding granulation, drying, and pulverizing to prepare magnesium alginate with a required mesh size. Magnesium alginate prepared in the invention has the viscosity in a range of 100-2000 mPa.s, the mesh size in a range of 40-320 mesh, the pH value in a range of 6.0-8.0, a water content no more than 15.0%, and an ash content in a range of 14-28%. The production technology can be realized in a condition of conventional solid-phase, and liquid-phase neutralization production technology of algin.

Owner:青岛海之林生物科技开发有限公司

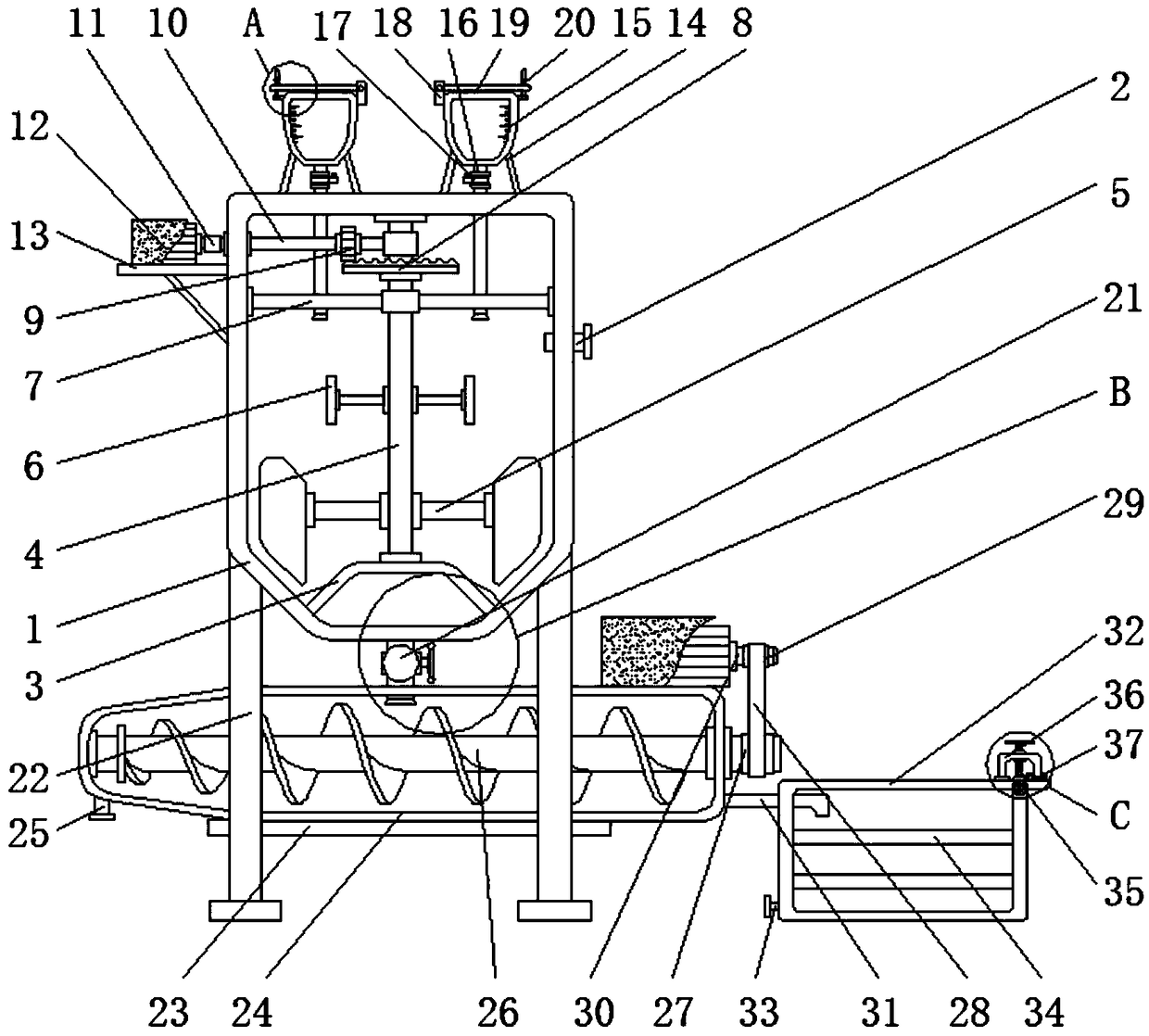

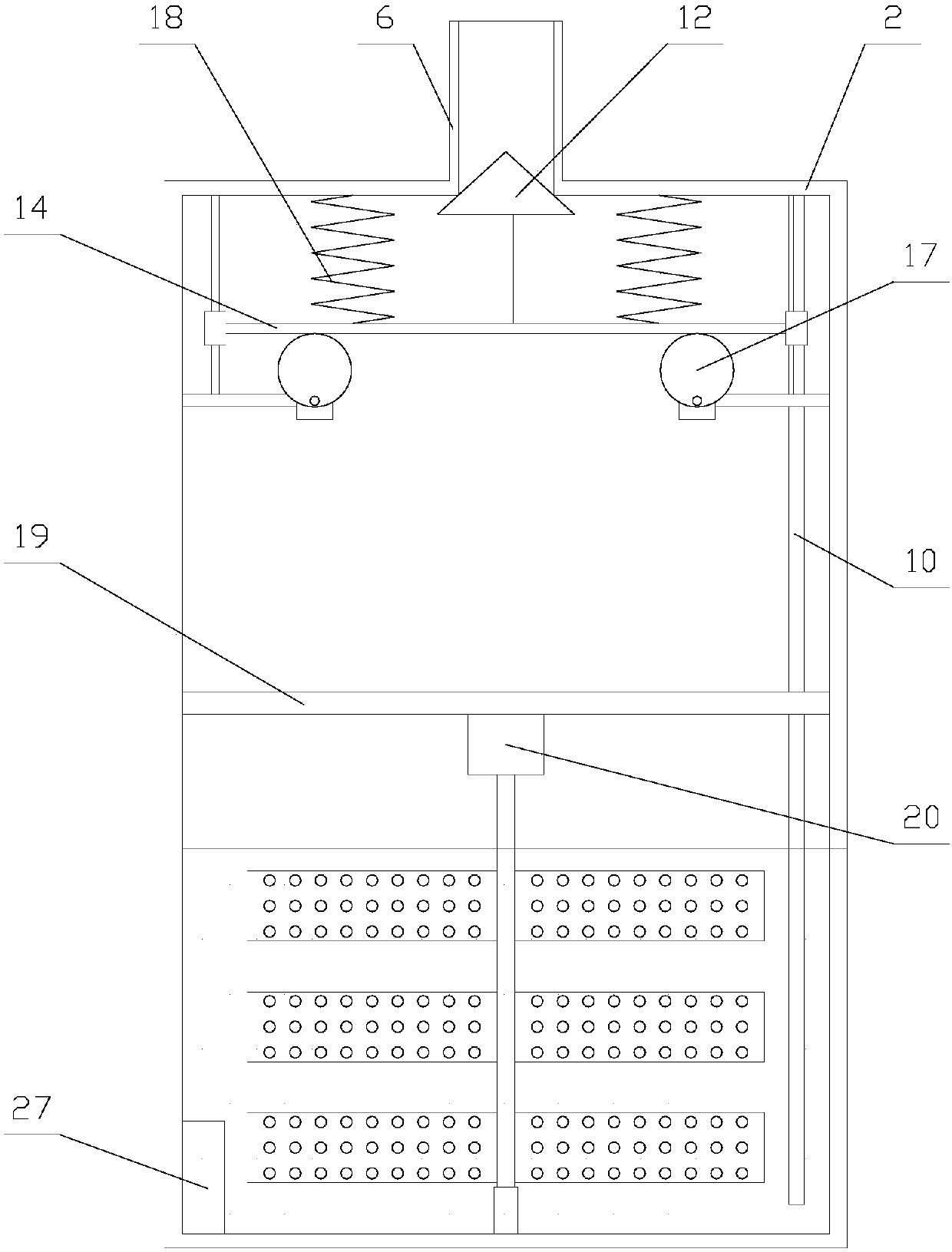

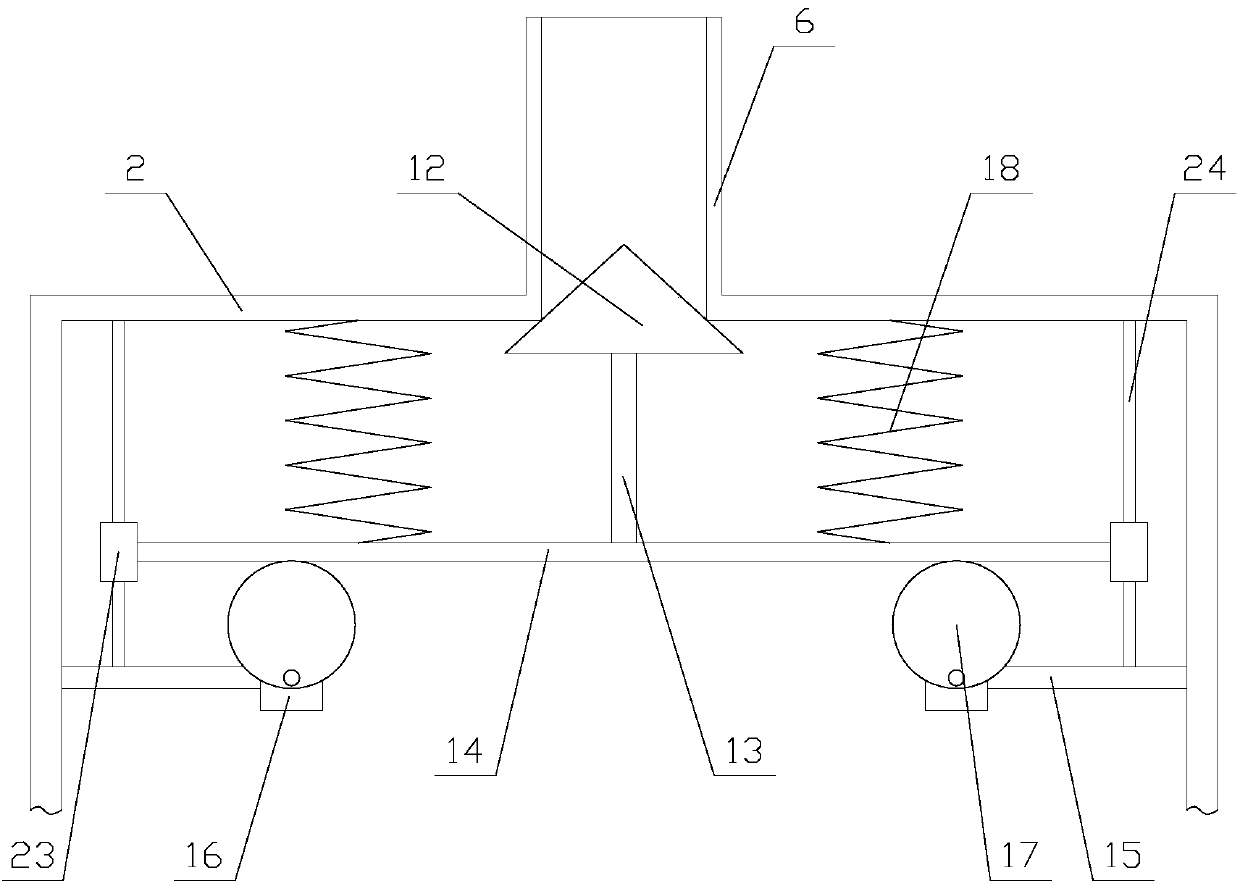

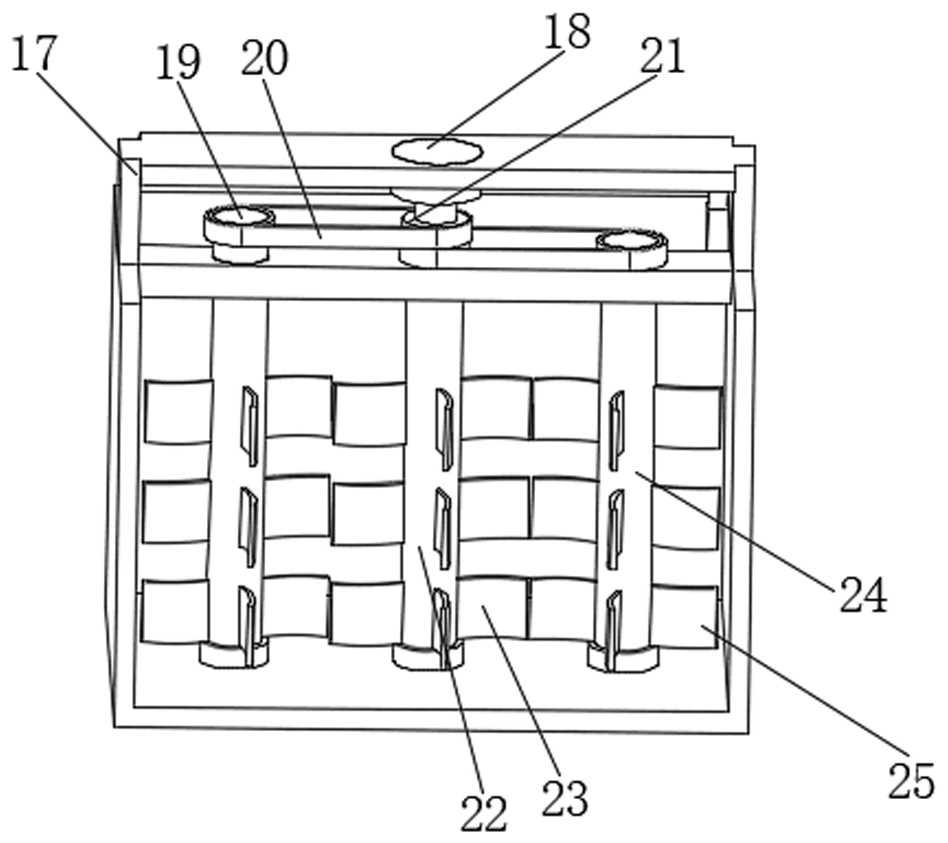

Low-energy-consumption sewage treatment device based on carbon source recovery

InactiveCN108862701AEasy to handleSolve the workloadSpecific water treatment objectivesWater contaminantsSewageTherapeutic effect

The invention relates to the technical field of industrial sewage treatment equipment, and discloses a low-energy-consumption sewage treatment device based on carbon source recovery. The low-energy-consumption sewage treatment device comprises a treatment tank, wherein a water inlet is fixedly formed in the top of one side of the outside of the treatment tank; the bottom of an inner cavity of thetreatment tank is fixedly connected with the bottom end of a support frame; one end of a transmission rod is movably sleeved and connected with the top end of the support frame; the other end of the transmission rod penetrates through the inside of a sealing plate, extends to the top of the inner cavity of the treatment tank, and is movably sleeved and connected with the top of the inner cavity ofthe treatment tank. The low-energy-consumption sewage treatment device based on carbon source recovery has the advantages that through the matching of a chemical addition tank and an electromagneticvalve, chemicals can be conveniently and better added into sewage in an inner cavity of the treatment tank, so that the problems that the workload of workers is increased through the manual chemical addition, and the consumption of chemicals cannot be easily mastered are solved; the investment of the sewage treatment device on the chemical cost is reduced; the treatment effect of the low-energy-consumption sewage treatment device on the sewage is improved.

Owner:陈肖兰

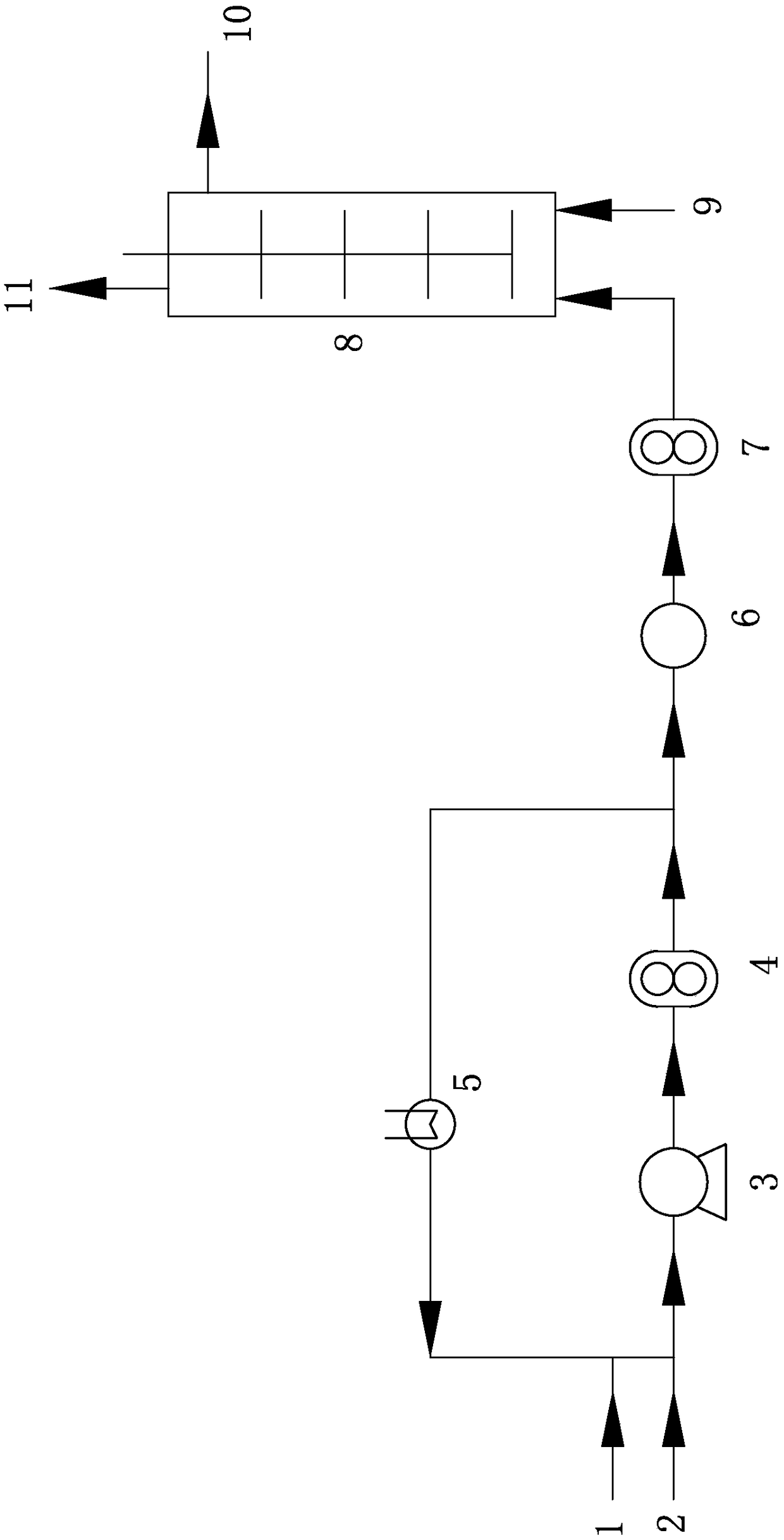

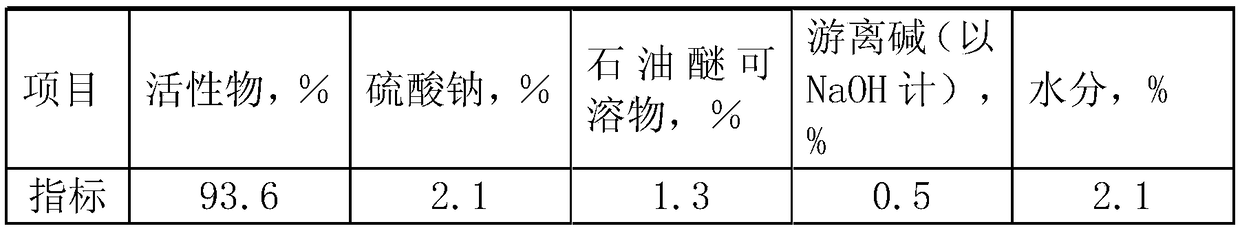

Process and device for continuously producing powdery sodium alpha-olefin sulfonate

InactiveCN109438293APrevent subsidenceLow viscosityChemical industrySulfonic acids salts preparationSulfonateProcess equipment

The invention relates to a manufacturing process of a powdery surfactant, and aims at providing a process and a device for continuously producing powdery sodium alpha-olefin sulfonate. The productionprocess and the preparation device need to have the characteristics of simple process equipment, energy saving, environment protection and high production efficiency; the obtained powdery sodium alpha-lefin sulfonate active substance has high content and low sultone residue. The process is characterized in that the process for continuously producing the powdery sodium alpha-olefin sulfonate comprises the following steps of (1) sulfonated and aged vinyl sulphonate, caustic soda flakes and neutralized recycled materials enter a neutralizer according to a certain flow rate to be neutralized; (2)the neutralized materials are conveyed through a neutralization conveying pump; one part of the materials are used as recycled materials to be used and enter the neutralizer after being heated by a heater; the other part of materials pass through a back pressure valve and are conveyed from the bottom by a hydrolysis conveying pump to enter a hydrolysis column with a stirrer; meanwhile, a path of high-pressure steam is introduced from the bottom of the hydrolysis column.

Owner:ZANYU TECH GRP CO LTD +1

Uses of melanin in water

ActiveUS20180222779A1Reduce acidificationPromote neutralizationElectrolysis componentsWater/sewage treatment by irradiationBicarbonateSeawater

Methods for reducing and regulating the acidification of water are provided. The method for reducing the acidification of water includes contacting at least one melanin material with the water and catalyzing a reaction between the water, CO2 and / or bicarbonate that produces glucose and increases pH of the water. The acidification of water is regulated by removing the at least one melanin material from the water once a desired pH of the water has been attained. The methods for reducing and regulating the acidification of water are particularly suited for the treatment of seawater that has been acidified by naturally occurring or artificially initiated reactions that increase free hydrogen ions in water, for example absorption of atmospheric carbon dioxide.

Owner:SOLIS HERRERA ARTURO

A kind of production technology of magnesium alginate

Owner:青岛海之林生物科技开发有限公司

Intelligent waste gas treatment system for optical fiber preform production equipment

InactiveCN107670438ARealize rational utilizationMaintain Neutral AbsorbencyUsing liquid separation agentSpray towerWater pipe

The invention relates to an intelligent waste gas treatment system for optical fiber preform production equipment. The system comprises a spray tower, a reaction chamber, a pipeline mechanism, a waterpump, a first water pipe, a feeding chamber and a feeding pipe, wherein the reaction chamber is internally provided with a feeding mechanism and a mixing mechanism, the feeding mechanism comprises ablock, a vertical bar, a transverse board and two feeding units, and the mixing mechanism comprises a transverse bar, a second motor, a second driving shaft and two mixing units. According to the intelligent waste gas treatment system for optical fiber preform production equipment, the outer wall of the reaction chamber absorbs the heat of the waste gas through a wound pipe, so that a reaction liquid and the waste gas are neutralized at a faster speed, waste gas heat is used reasonably, and the neutralizing reaction is carried out completely due to the mixing mechanism, further, the feeding mechanism allows an alkaline agent in the feeding chamber to enter the reaction chamber from the feeding pipe, and the alkaline agent is dissolved in the reaction liquid, so that the reaction liquid recovers alkaline so as to keep neutralizing and absorbing acidic waste gas, and the system is more practical.

Owner:SHENZHEN BEIYOUTONG NEW ENERGY TECH DEV CO LTD

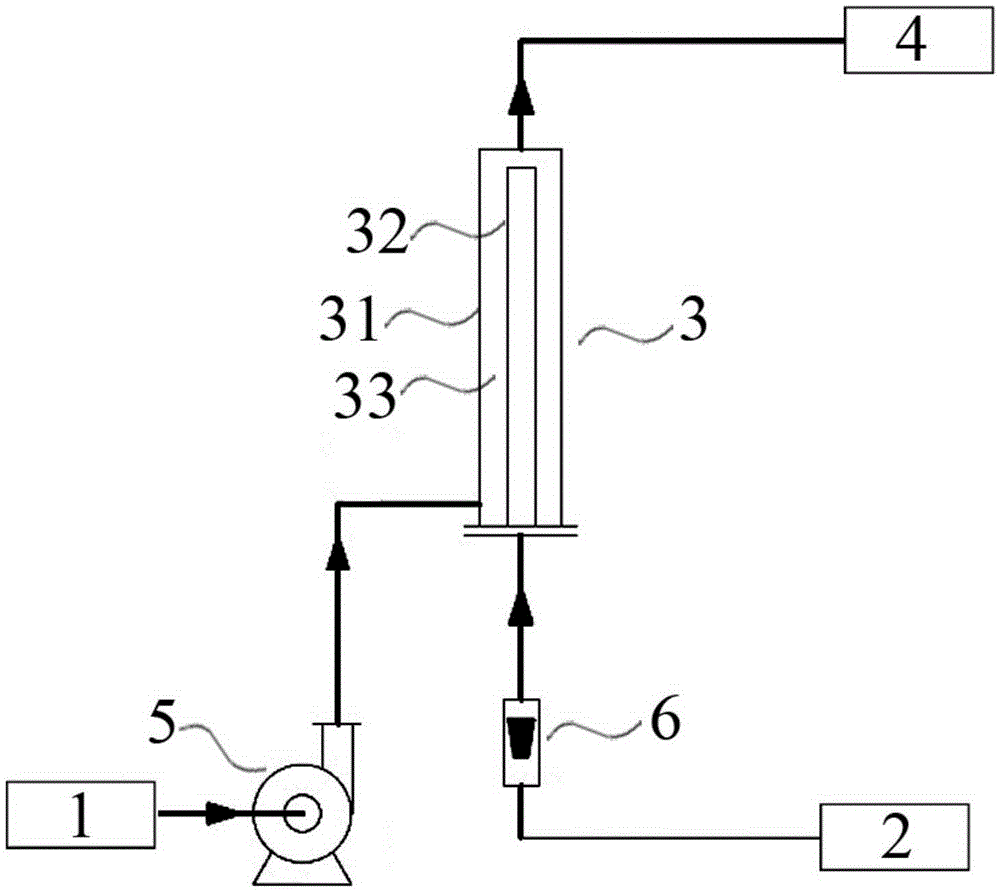

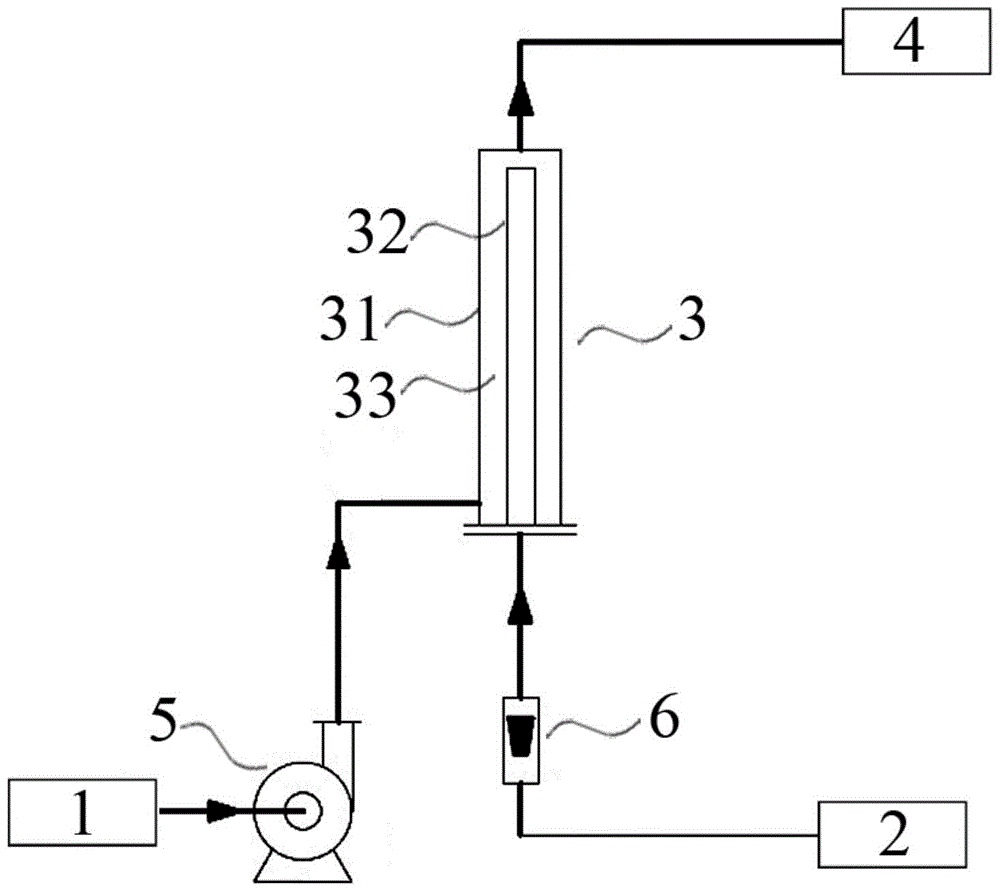

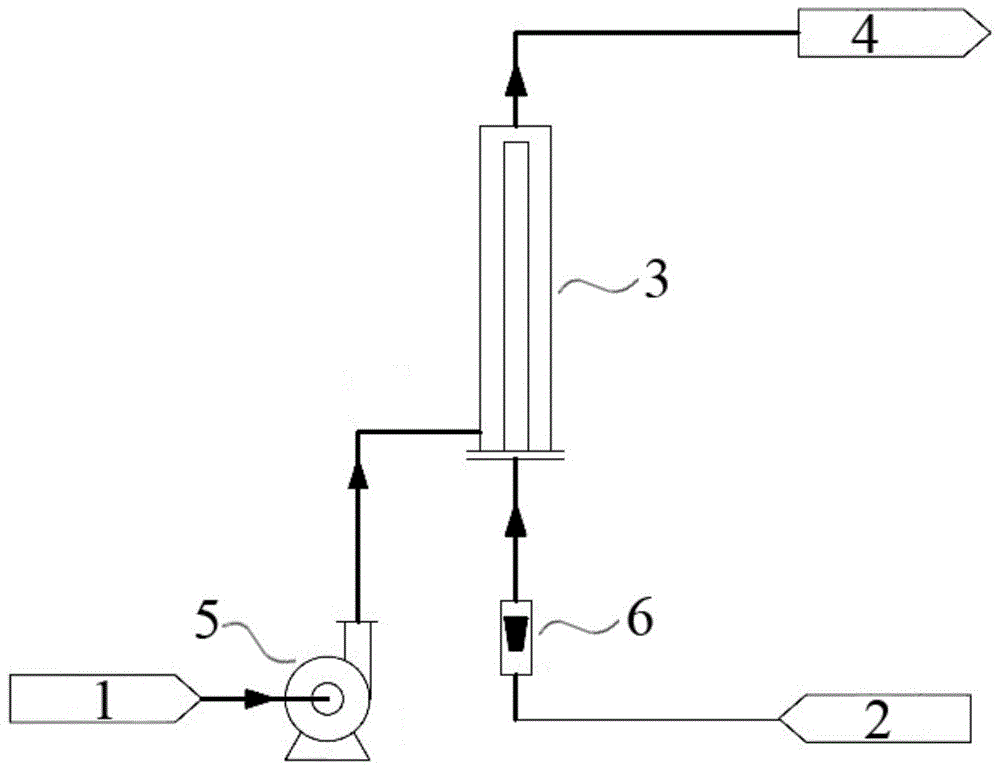

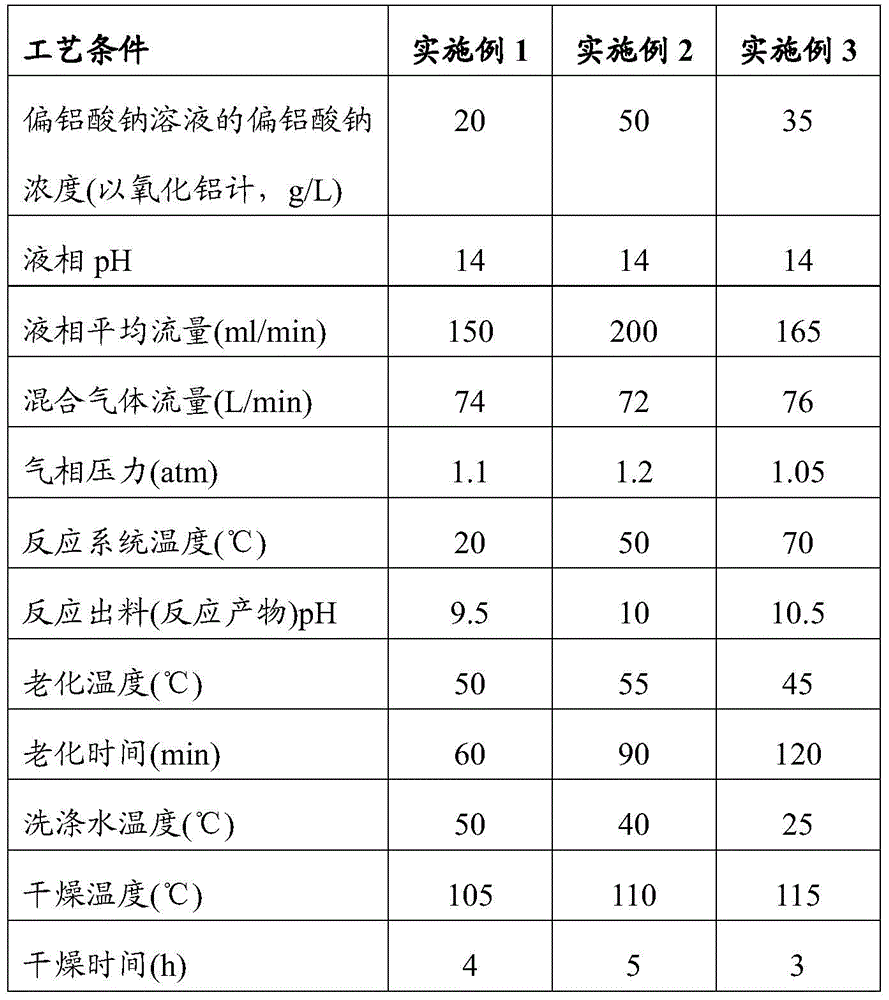

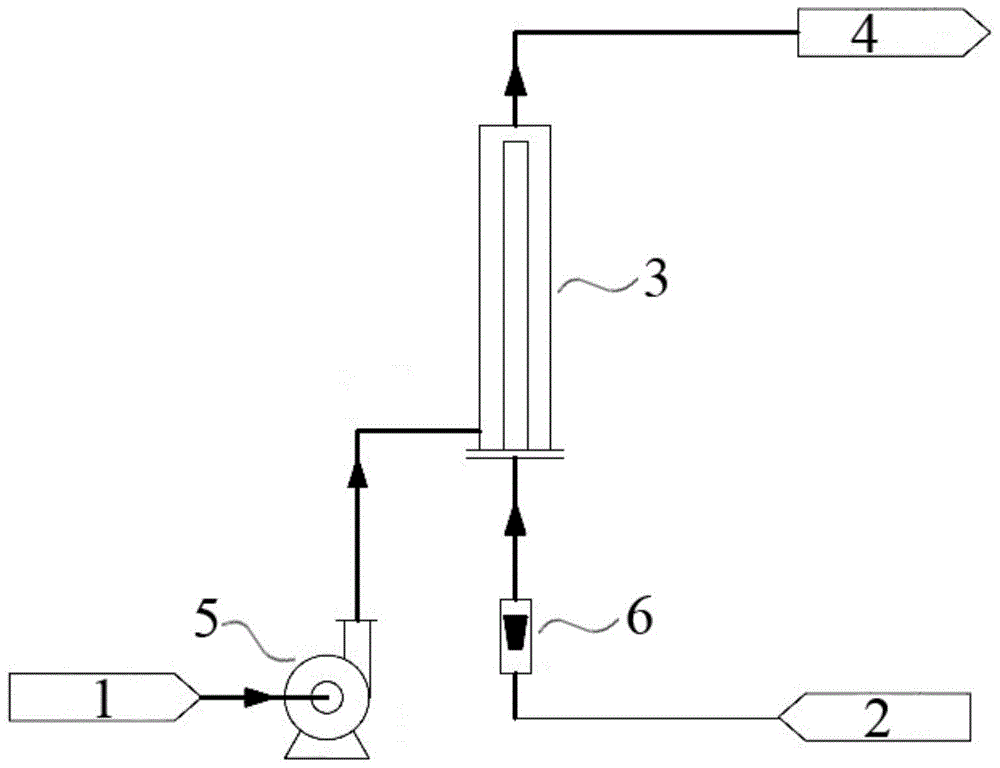

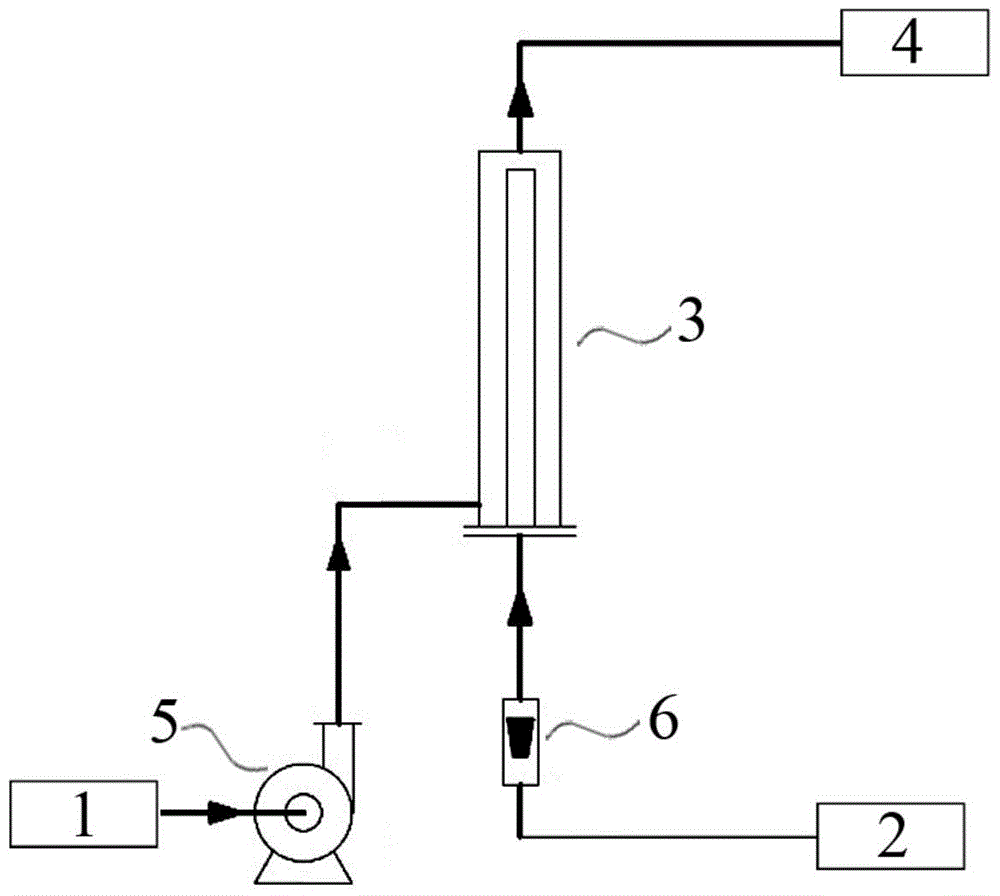

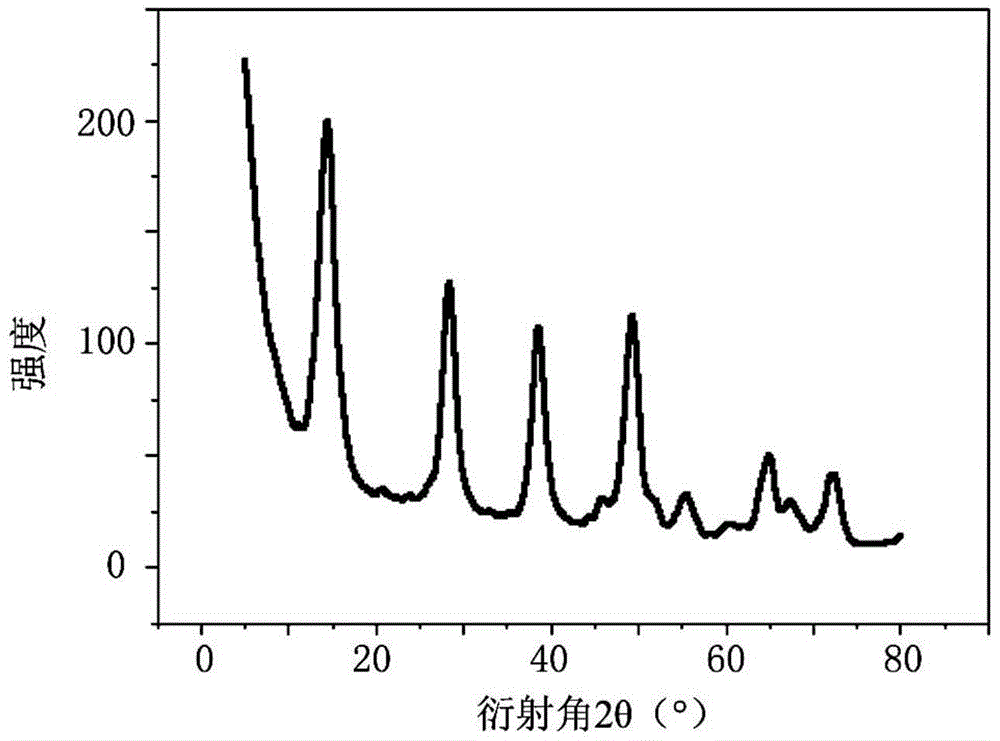

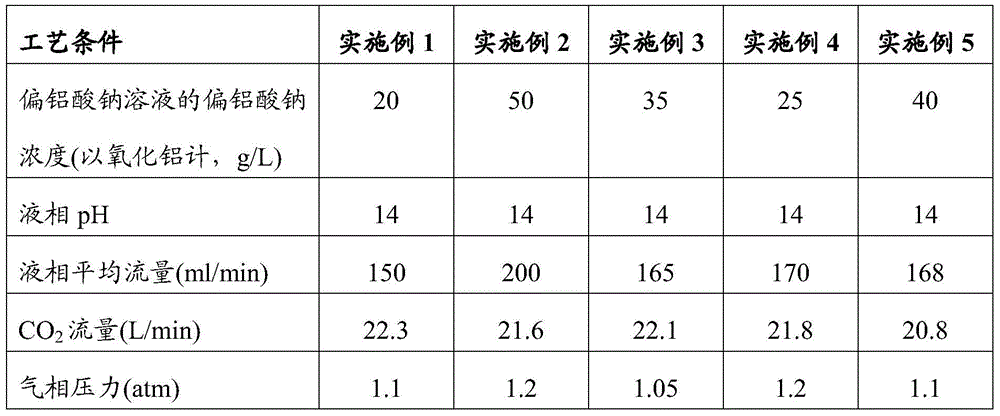

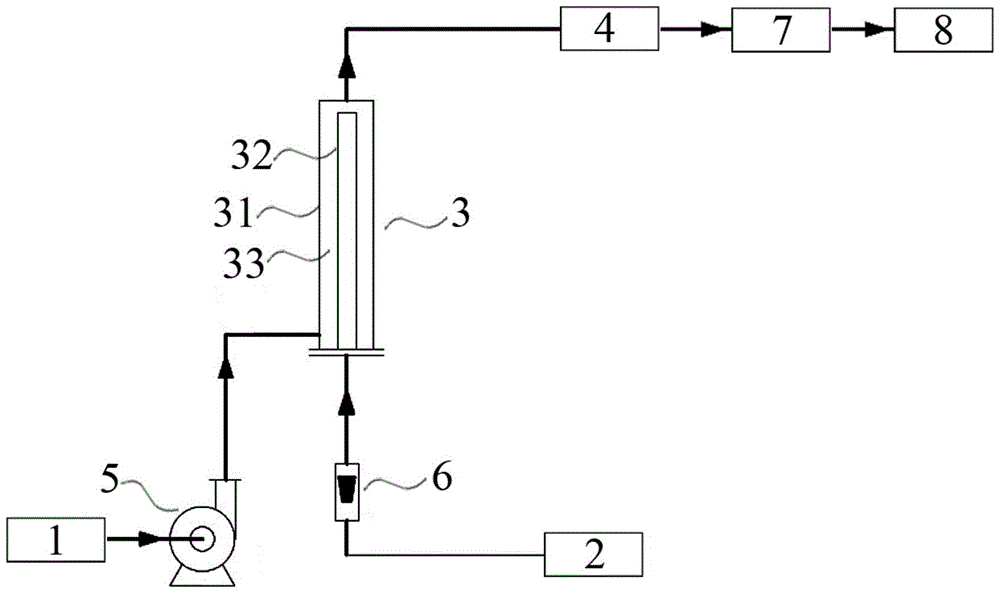

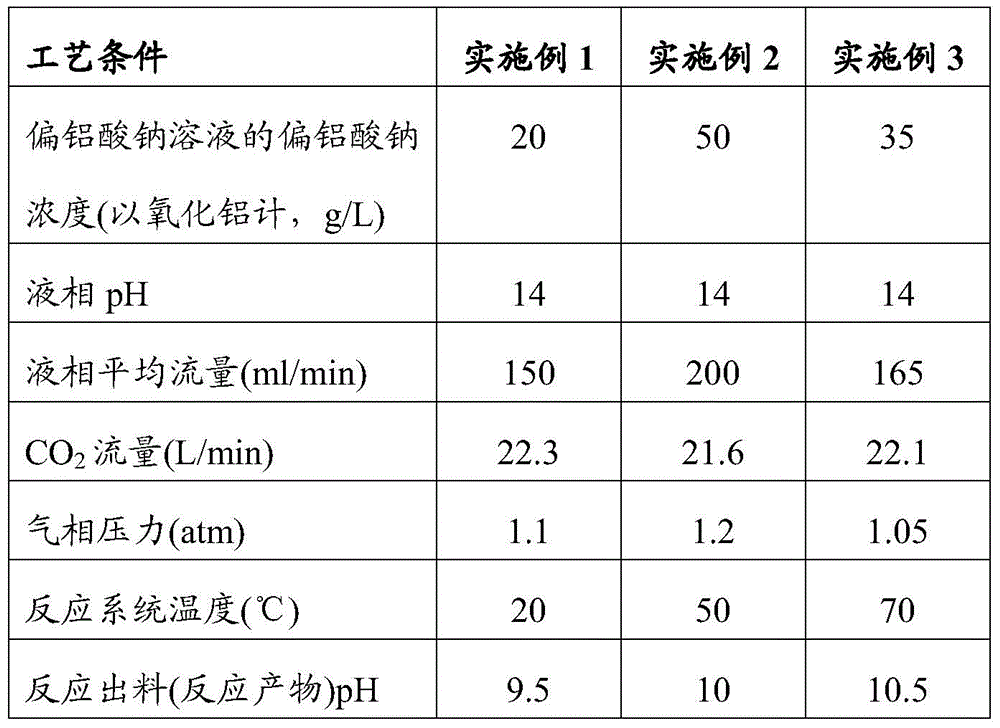

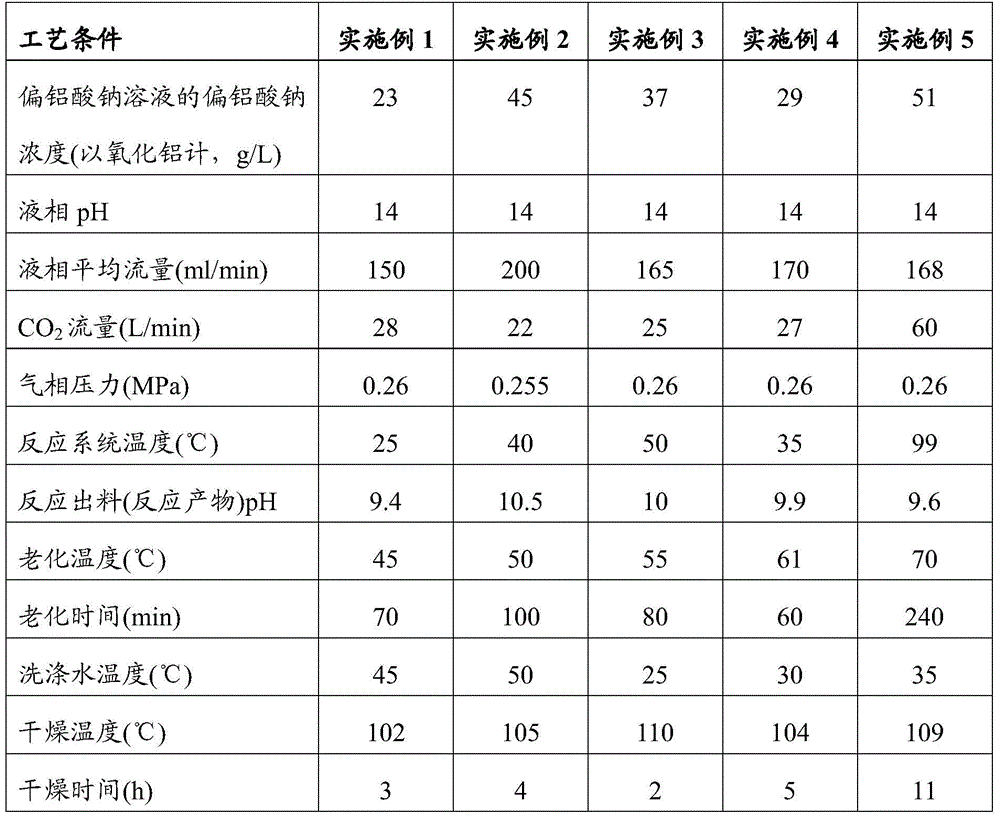

Production device and method of aluminum hydroxide

ActiveCN105417561AInhibition of spontaneous hydrolysis reactionsPromote neutralizationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationBoehmiteCarbon dioxide

The invention discloses a production device and method of aluminum hydroxide. The production device comprises an inorganic membrane reactor, a meta-aluminate supply unit, a carbon dioxide supply unit and a reaction product storage unit. The meta-aluminate supply unit is connected with a liquid-phase inlet of a shell of the inorganic membrane reactor and used for supplying a meta-aluminate solution to a cavity of the inorganic membrane reactor. The carbon dioxide supply unit is connected with a gaseous-phase inlet of an inorganic membrane assembly of the inorganic membrane reactor and used for supplying carbon dioxide to the inorganic membrane assembly of the inorganic membrane reactor. The meta-aluminate solution and the carbon dioxide are reacted in the inorganic membrane reactor to form a reaction product with the aluminum hydroxide. By means of the aluminum hydroxide obtained through the production device and method, pseudo-boehmite stable in quality can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for preparing halogenated polymer

The invention provides a method for preparing a halogenated polymer. The method comprises the following steps: a) a polymer and a halogenation agent are contacted under existence of an organic solvent and an initiator, partial hydrogen atoms in the polymer are substituted by halogen atoms to obtain a halogenation polymer solution containing halogen hydride and the initiator; and b) the halogenation polymer solution obtained in the step a) and alkali lye are fully mixed under supersonic wave effect to remove halogen hydride and the initiator. According to the method, dehalogenation and discoloration of the halogenated polymer product in a subsequent drying process are effectively inhibited; technical condition and process are simple and easy, and the pure halogenated polymer product which is not easy to fad is provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production process of super-low-viscosity magnesium alginate

InactiveCN105754009AShorten the production cycleSolve water consumptionActivated carbonMagnesium salt

The invention discloses a production process of super-low-viscosity magnesium alginate.The production process is characterized by including following steps: (1), cleaning and chopping brown alga, adding water of five times and 15% composite magnesium salt, and disposing in a high-temperature high-pressure reaction kettle for degradation for 50-60 min; (2), roughly filtering to obtain magnesium alginate rough extract; (3), adding activated carbon into the magnesium alginate rough extract for adsorption and decoloring, and filtering to obtain primarily-purified extract; (4), performing further purifying and impurity removing on the primarily-purified extract through ion exchange resin adsorption to obtain purified extract; (5), concentrating the purified extract; (6), spray-drying concentrate to obtain solid powder of magnesium alginate.Rotary viscosity of 1% glue liquid of magnesium alginate prepared by the production process at 20 DEG C is 5-10 mPa.s.

Owner:青岛海之林生物科技开发有限公司

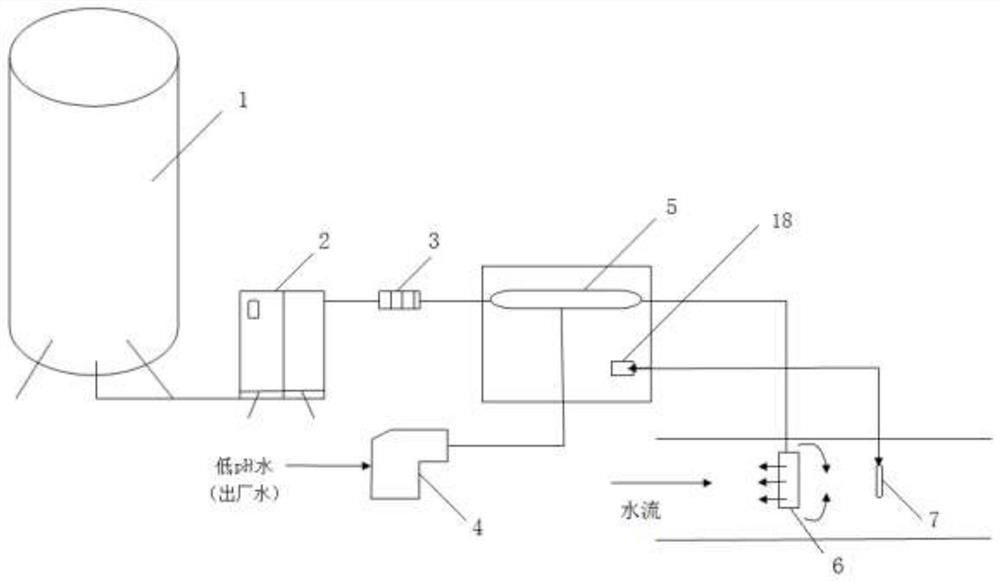

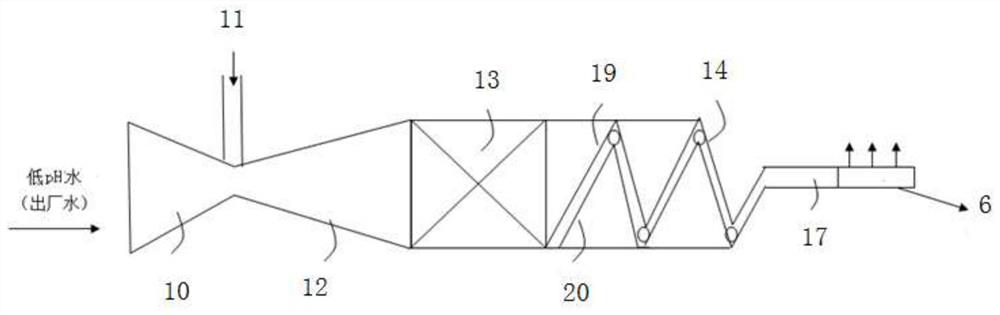

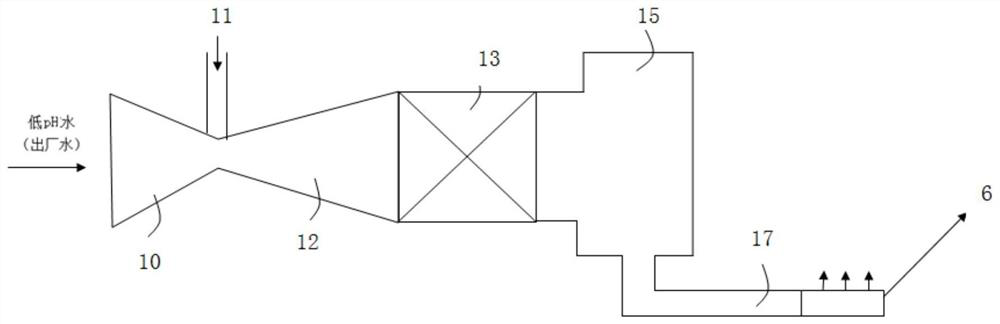

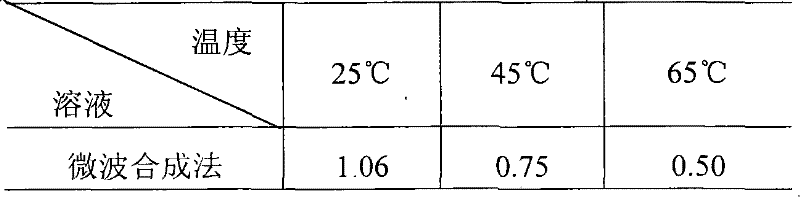

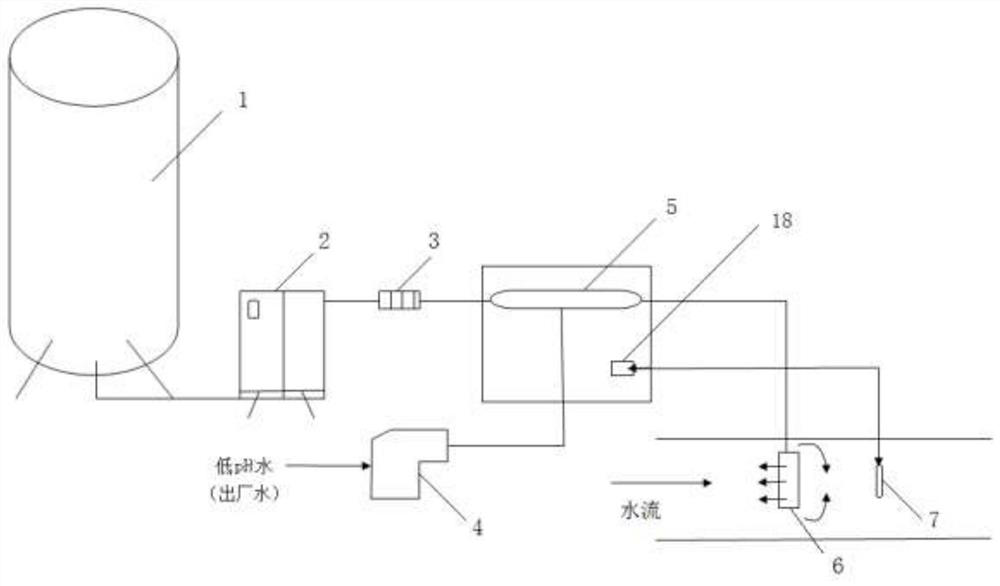

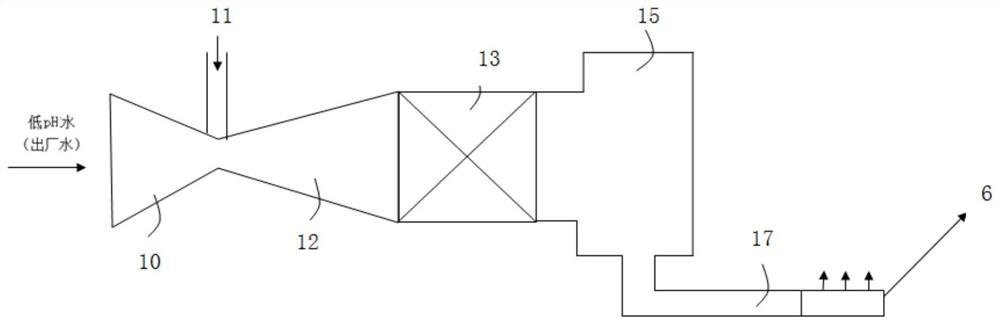

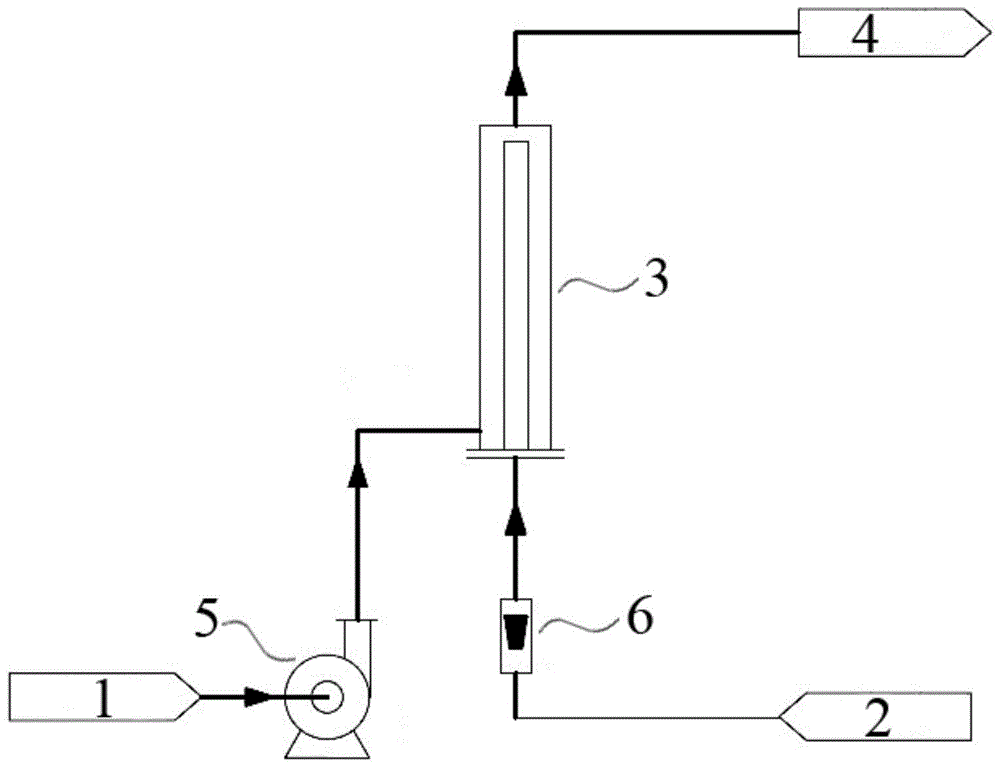

Method for adding carbonic acid by adopting carbonic acid solution adding system

PendingCN113830874AAdjust hardnessAdjust TurbidityWater/sewage treatment by neutralisationLiquid storage tankHigh carbon dioxide

The invention discloses a method for adding carbonic acid by adopting a carbonic acid solution adding system. The method comprises the following steps of 1) establishing a carbonic acid solution adding system which comprises a mixer and a diffuser, arranging an annular coil pipe or a liquid storage tank and a long-distance pipeline between the mixer and the diffuser, arranging the diffuser in water to be treated, enabling the side wall of the diffuser to be provided with a channel for releasing a carbonic acid solution, namely a small hole or a narrow gap or a combination of the small hole and the narrow gap, and enabling the channel to generate a certain back pressure and enabling the supersaturated carbonic acid solution to be sprayed into water to be treated at a certain pressure, 2) heating and regulating the pressure of the carbon dioxide gas to a certain temperature and a certain pressure, and feeding the carbon dioxide gas into the mixer, 3) pressurizing reaction water to a certain pressure through a water pump, and feeding into the mixer, and 4) arranging a water quality on-line detector in the raw water, and controlling the flow of the carbon dioxide gas through the connection of a signal receiver and a PLC. According to the method, the water quality can be accurately adjusted, meanwhile, bubbles can be greatly reduced, and the utilization rate of carbon dioxide gas is greatly increased.

Owner:哈维(上海)环境科技有限公司

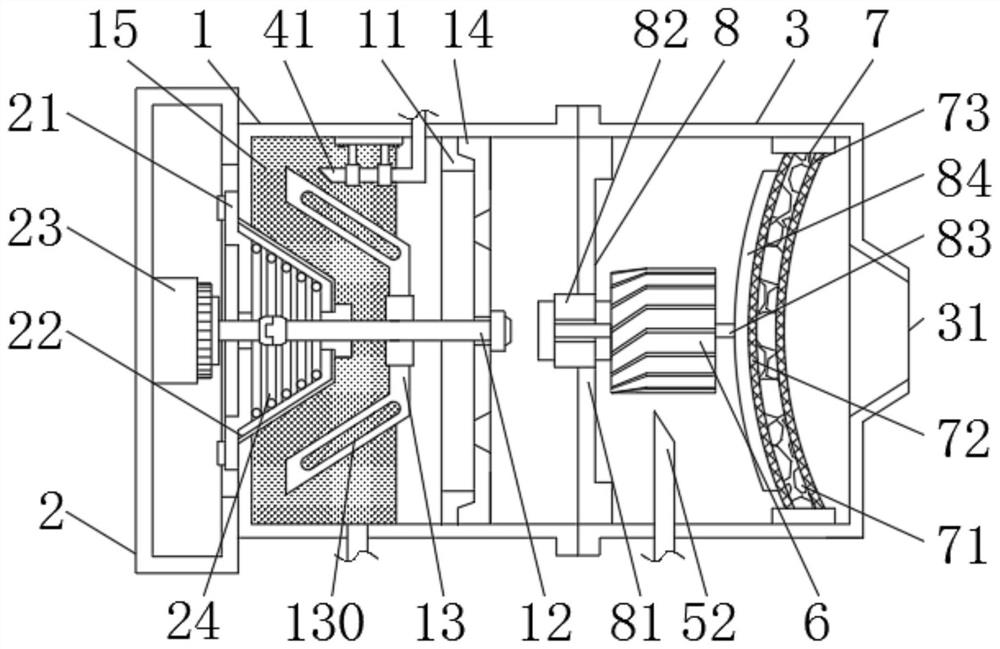

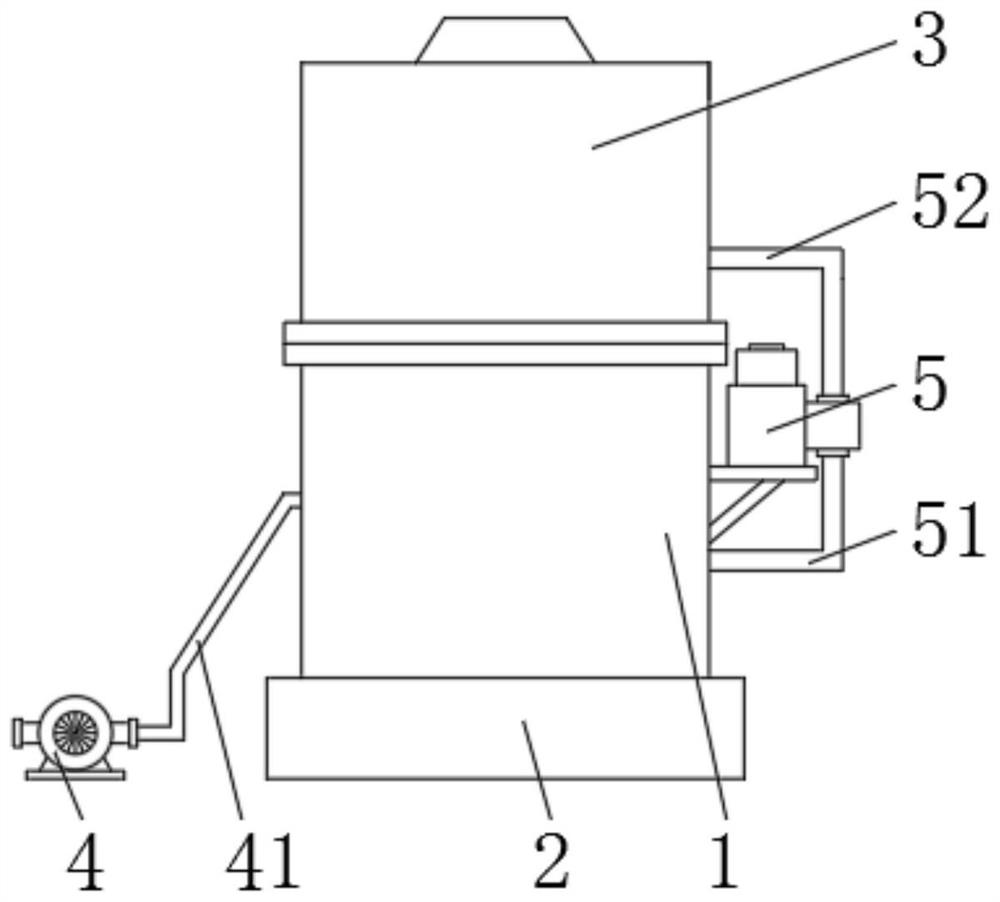

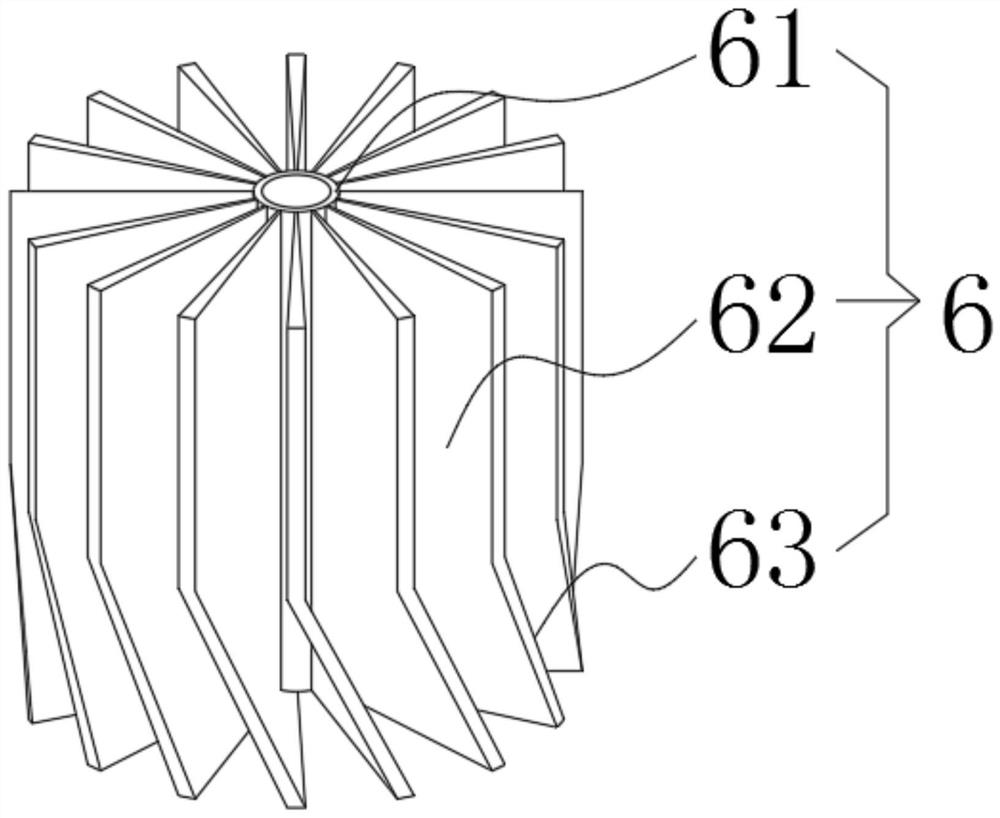

Tail gas treatment device for domestic waste incineration

ActiveCN109647162BEnsure normal dischargePromote neutralizationGas treatmentDispersed particle separationEnvironmental engineeringMechanical engineering

The invention discloses a tail gas treatment device for domestic garbage incineration, which relates to the technical field of environmental protection equipment, and specifically comprises a neutralization chamber, a driving chamber fixedly installed at the bottom of the neutralization chamber, a clean room fixedly connected to the top of the neutralization chamber, and fixedly installed on the purification chamber. The transmission wheel, the purification device and the cleaning device inside the chamber. An axial flow fan is fixedly installed outside the neutralization chamber. Inside the neutralization chamber, a fixing ring is fixedly connected to the inner side wall of the neutralization chamber. The baffle is set to cooperate with the gas outlet to ensure that the exhaust gas can be discharged while effectively reducing the outlet area, so that part of the exhaust gas can flow back into the neutralization liquid again, and prevent part of the tail gas from escaping due to incomplete reaction in the neutralization liquid. It is pointed out that the acidic or alkaline substances cannot be completely neutralized, resulting in the problem that the discharge does not meet the standard.

Owner:湖南美中环境生态科技有限公司

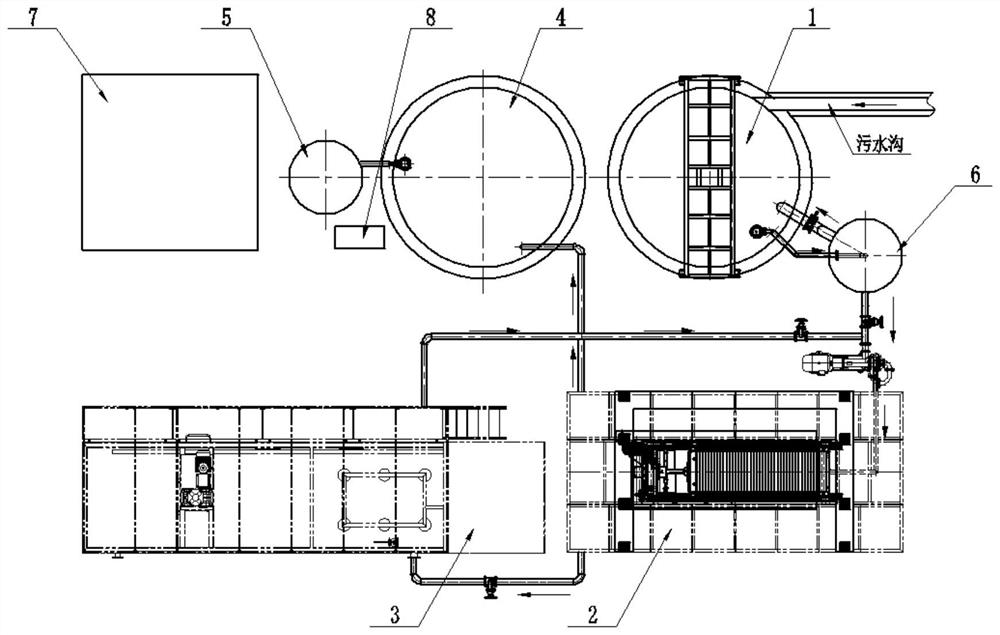

Concrete mixing station production sewage treatment, regeneration and reuse system and method

ActiveCN114873707AStable in natureHazard reductionEnergy based wastewater treatmentWater/sewage treatment by neutralisationWater storageWastewater

The invention discloses a concrete mixing station production sewage treatment, regeneration and reuse system, which comprises a dehydration separation system used for carrying out solid-liquid separation on sewage entering the dehydration separation system, dividing the treated sewage into clear water and neutralized water, inputting the neutralized water into a carbon dioxide neutralization device, and introducing the carbon dioxide neutralization device into the dehydration separation system; inputting the clear water into the clear water storage pool; the carbon dioxide neutralization device is used for receiving the neutralization water input by the dehydration separation system and injecting carbon dioxide into the neutralization water, the neutralization water is neutralized to form mixed water, and the mixed water is input into the dehydration separation system; a closed cycle is formed between the dehydration separation system and the carbon dioxide neutralization device. According to the invention, the alkaline neutralized water is neutralized, and a closed cycle is established between the neutralizing device and the dehydration separation system, so that the discharge of wastewater is avoided, and the regeneration and reuse ratio of sewage is increased.

Owner:SICHUAN RAILWAY CONSTR CO LTD

Production device and method of aluminum hydroxide

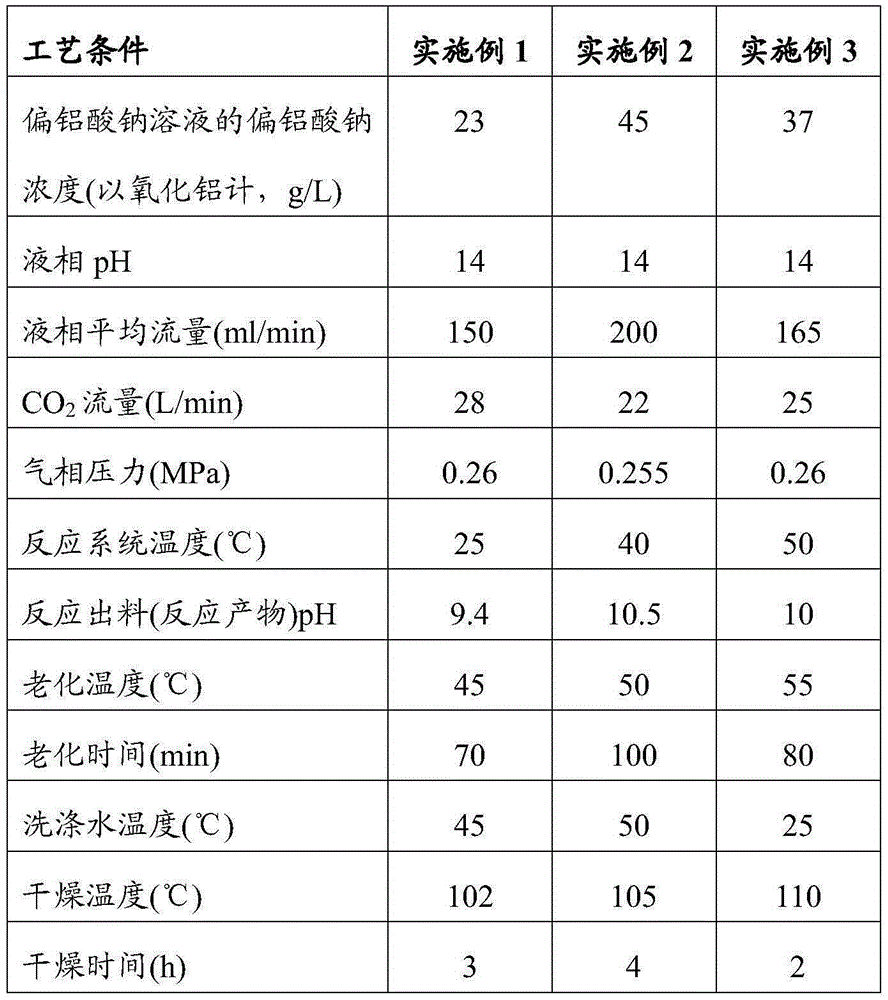

ActiveCN105417561BInhibition of spontaneous hydrolysis reactionsPromote neutralizationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateGas phase

The invention discloses a production device and method of aluminum hydroxide. The production device comprises an inorganic membrane reactor, a meta-aluminate supply unit, a carbon dioxide supply unit and a reaction product storage unit. The meta-aluminate supply unit is connected with a liquid-phase inlet of a shell of the inorganic membrane reactor and used for supplying a meta-aluminate solution to a cavity of the inorganic membrane reactor. The carbon dioxide supply unit is connected with a gaseous-phase inlet of an inorganic membrane assembly of the inorganic membrane reactor and used for supplying carbon dioxide to the inorganic membrane assembly of the inorganic membrane reactor. The meta-aluminate solution and the carbon dioxide are reacted in the inorganic membrane reactor to form a reaction product with the aluminum hydroxide. By means of the aluminum hydroxide obtained through the production device and method, pseudo-boehmite stable in quality can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +2

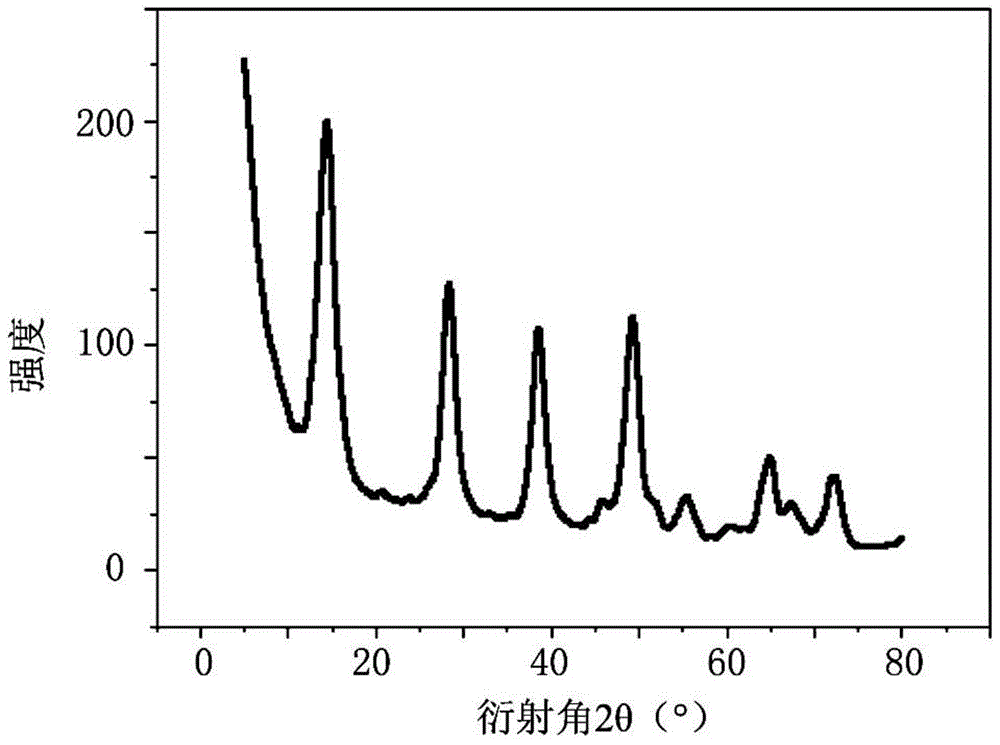

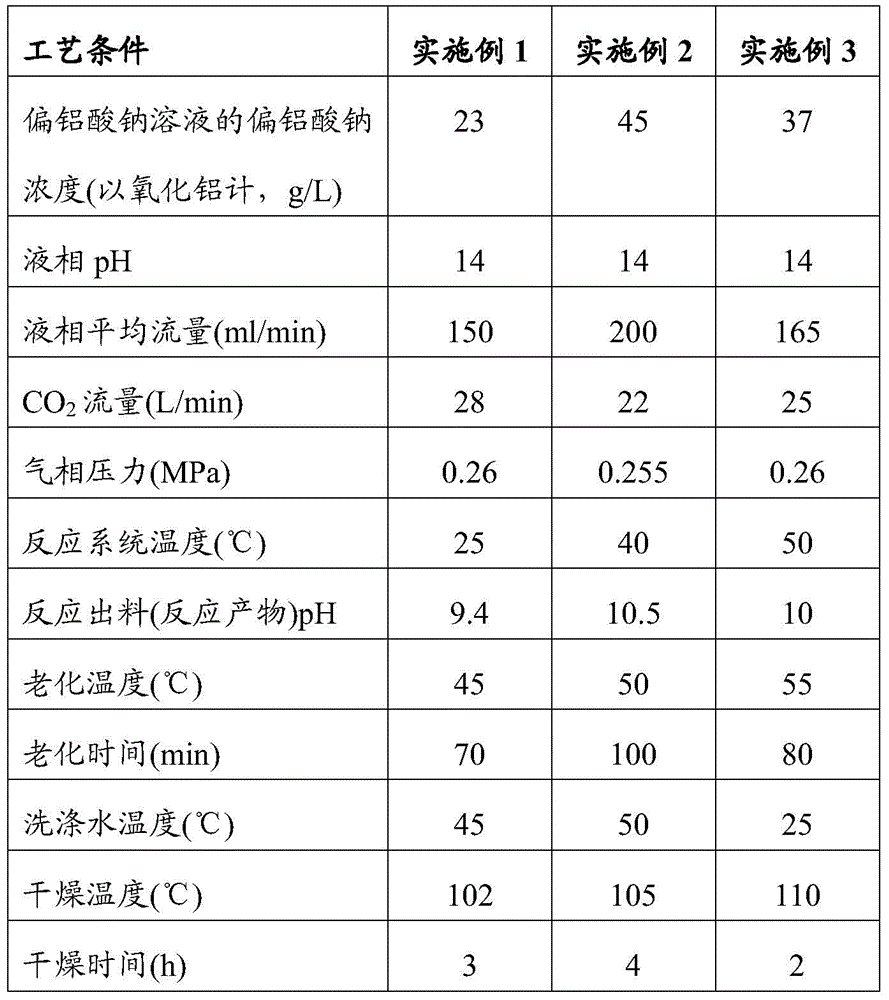

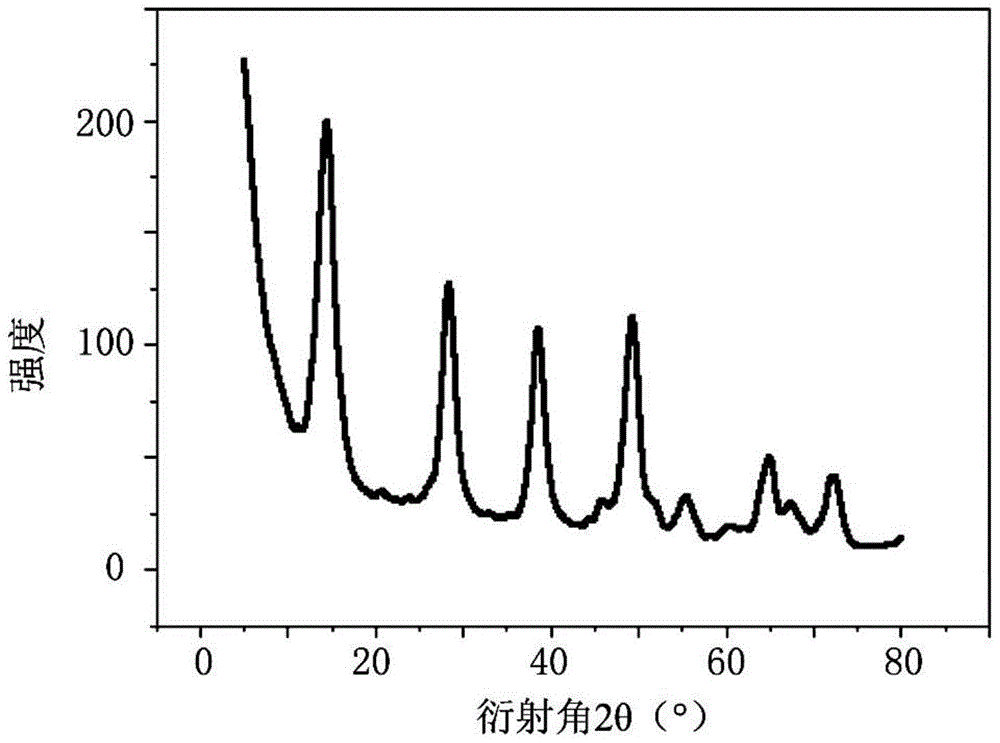

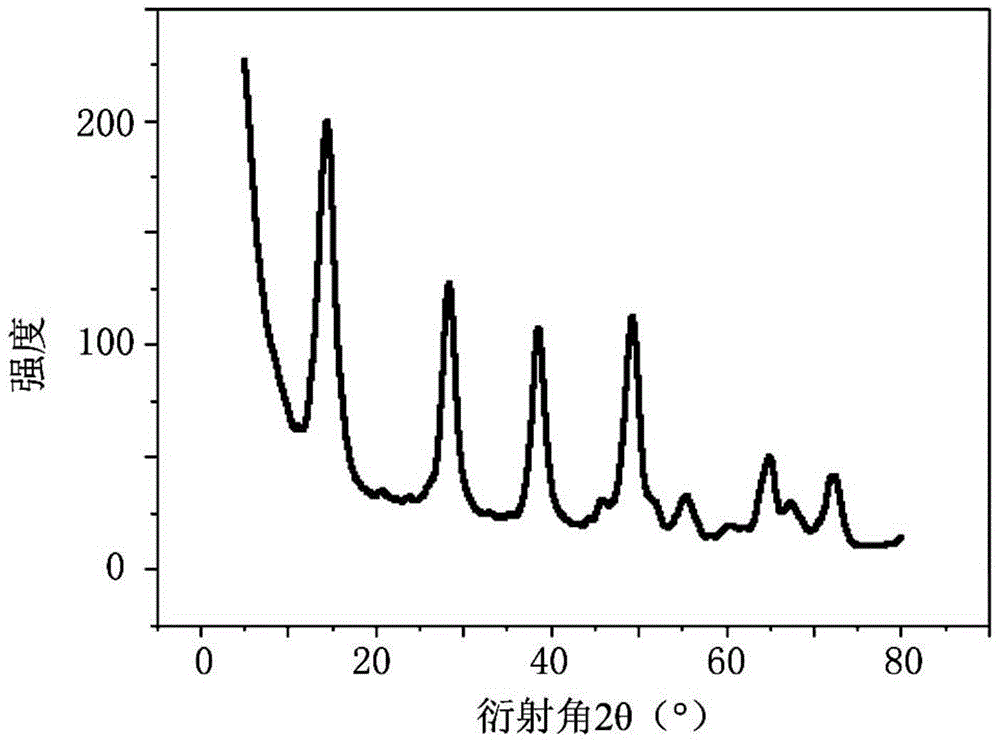

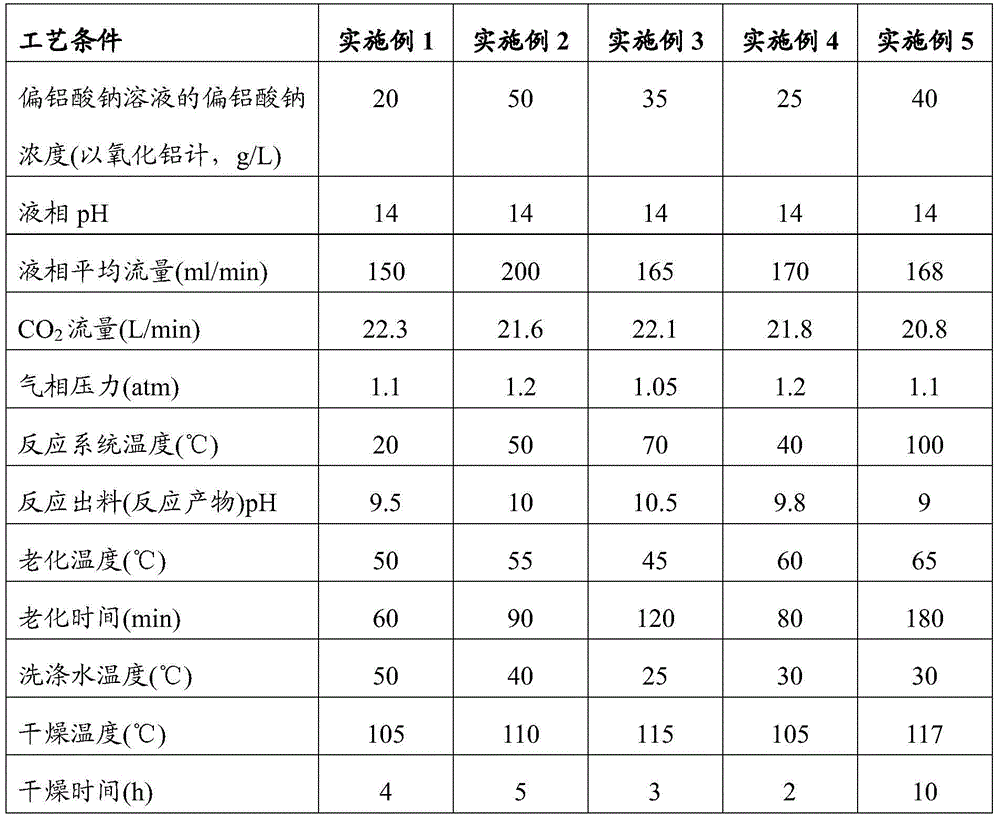

Method for producing pseudo-boehmite using inorganic membrane reactor

ActiveCN105417560BInhibition of spontaneous hydrolysis reactionsControl concentrationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationNitrogenNitrogen gas

The invention discloses a method for producing pseudo-boehmite by adopting an inorganic membrane reactor. The method comprises a gel forming step, an aging step, a separating and washing step and a drying step. According to the method, the gel forming step comprises the step that a meta-aluminate solution makes contact with mixed gas in the inorganic membrane reactor to generate a reaction product, wherein the mixed gas comprises carbon dioxide gas and one or two of air and nitrogen; the pseudo-boehmite with the stable quality can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for synthesizing ionic liquid of ethanolamine lactate

InactiveCN101628876BSynthesis fastPromote neutralizationOrganic compound preparationAmino-hyroxy compound preparationMicrowave - actionPhysical chemistry

The invention relates to the field of chemical engineering, in particular to a method for synthesizing an ionic liquid of ethanolamine lactate used for absorbing SO2 gas. The method is characterized in that: the water-bath microwave method is adopted to prepare the ionic liquid; under the microwave action, the target product can be quickly synthesized; and for the exothermic reaction, the water bath can remove excessive heat, weaken the microwave action, and better control the reaction temperature. The synthesis reaction time of the method is greatly shortened, and the synthesis reaction can be completed in 30 minutes. The ionic liquid of ethanolamine lactate prepared by the method has the advantages of high yield, short balance time, high desulfurizing efficiency and the like, and can be widely used as a fume desulfurizer.

Owner:NANJING UNIV OF SCI & TECH

Carbonic acid solution adding system

PendingCN113772801AQuick responseShort reaction timeWater/sewage treatment by neutralisationLiquid storage tankEnvironmental engineering

The invention discloses a carbonic acid solution adding system. The system comprises a mixer and a diffuser, and further comprises a carbon dioxide gas pipeline and a reaction water pipeline; a water pump is arranged on the reaction water pipeline; the water pump outlet is connected with a mixer inlet; the carbon dioxide gas pipeline is connected with the mixer inlet; an annular coil pipe or a liquid storage tank and a long-distance pipeline are arranged between the mixer and the diffuser; the diffuser is arranged in water to be treated; the side wall of the diffuser is provided with a channel for releasing a carbonic acid solution, and the channel for releasing the carbonic acid solution is a small hole or a narrow gap or a combination of the small hole and the narrow gap; and the channel for releasing the carbonic acid solution can generate certain back pressure and enable the supersaturated carbonic acid solution to be sprayed into water to be treated at certain outlet pressure, and it is guaranteed that the pressure difference between the outlet pressure of the diffuser and the water pressure to be treated is 2 bar or above. The carbonic acid solution adding system can accurately adjust the water quality, greatly reduce the generation of bubbles and greatly improve the utilization rate of carbon dioxide gas.

Owner:哈维(上海)环境科技有限公司

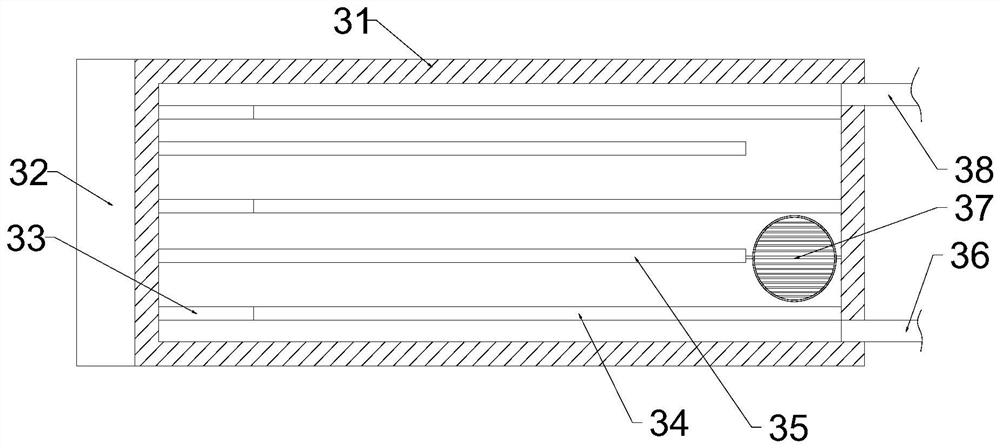

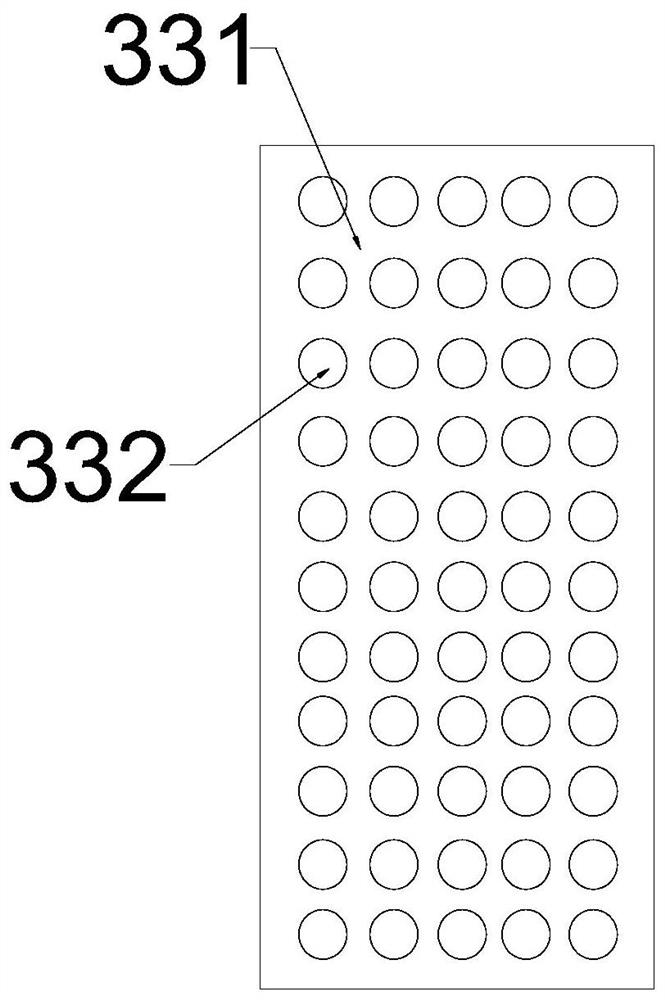

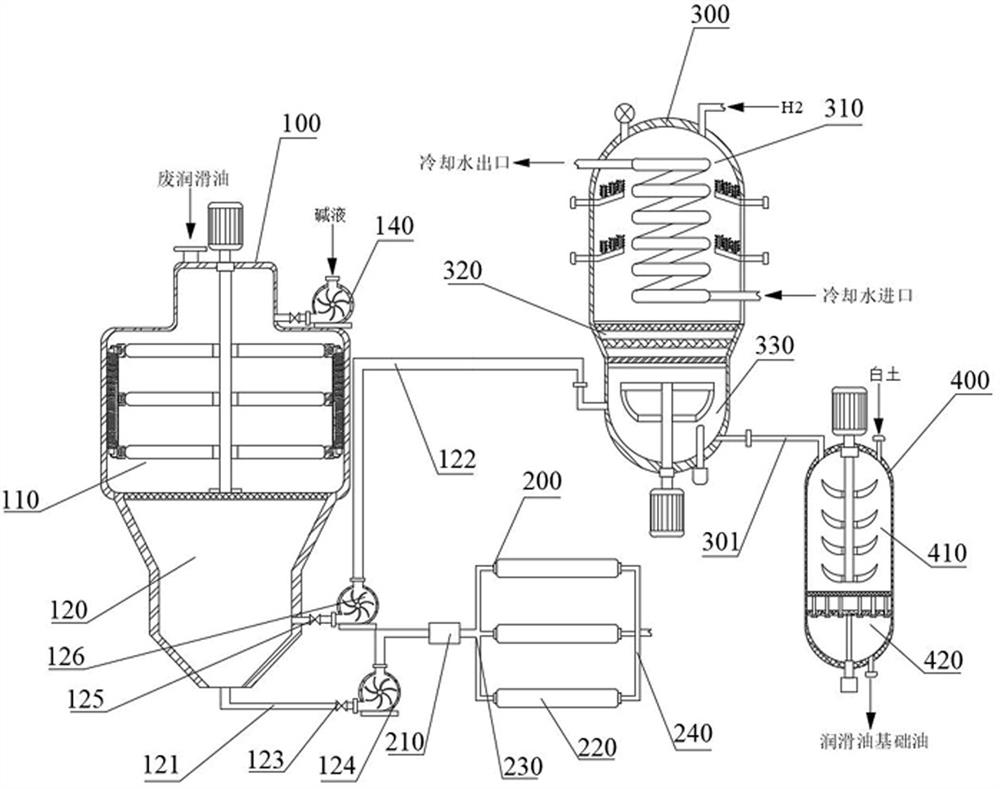

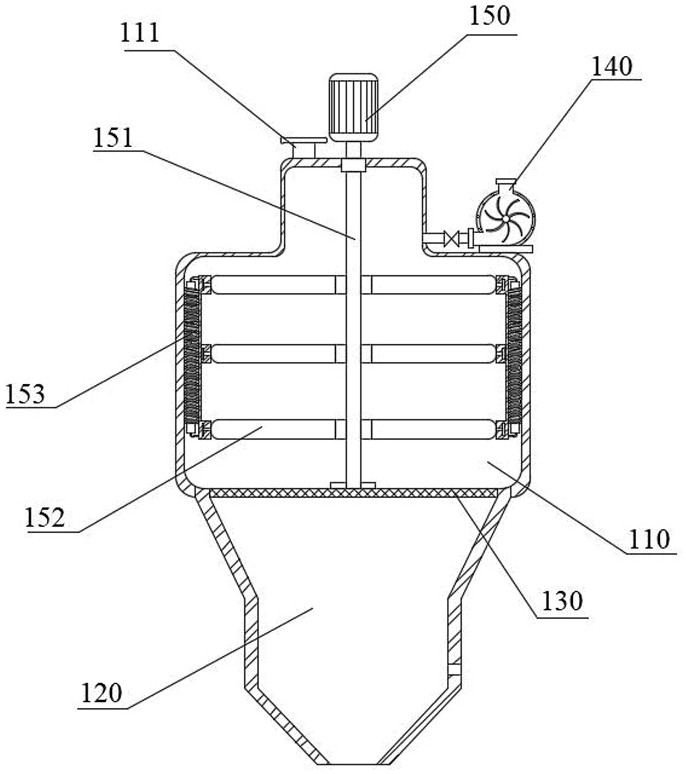

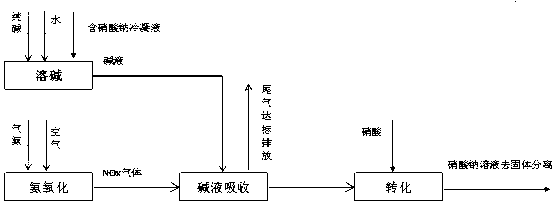

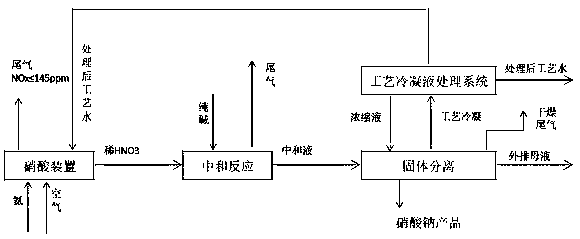

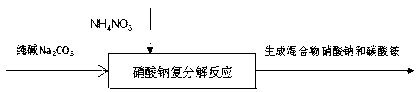

A low-chlorine photothermal molten salt production process and production device

ActiveCN108584991BPromote neutralizationShort reaction residence timeChemical industryAlkali metal nitrate preparationEngineeringSlurry

The invention discloses a low-chloride photothermal molten salt production process and production device. The production process comprises the steps that a, molten salt solution preparation is performed: alkaline liquid and a salpeter solution are used as raw materials to be fed into a neutralizing reactor for neutralization reaction; steam generated through neutralization reaction is subjected toheat recovery; b, a certain concentration of neutralization solution obtained through neutralization reaction is treated by an evaporative crystallization work procedure to obtain molten salt crystals; c, the molten salt crystals are subjected to centrifugal separation and drying to obtain products; centrifugal mother liquid returns to front end work procedures. The alkaline solution is used as raw materials for producing high-quality molten salt; a jet pipe type reactor with a static mixer is used for neutralization reaction; the molten salt solution obtained after the neutralization is usedfor producing solids by evaporation concentration, crystallization or slurry praying drying methods; after the subsequent treatment and package, the solids are used as final molten salt products; thechlorine content can be lower to be 15 to 20 ppm; the corrosion of molten salt products on user equipment can be reduced, so that the service life of equipment is prolonged; the long-period safe operation of a solar photothermal power generation device is ensured.

Owner:CHINA CHENGDA ENG

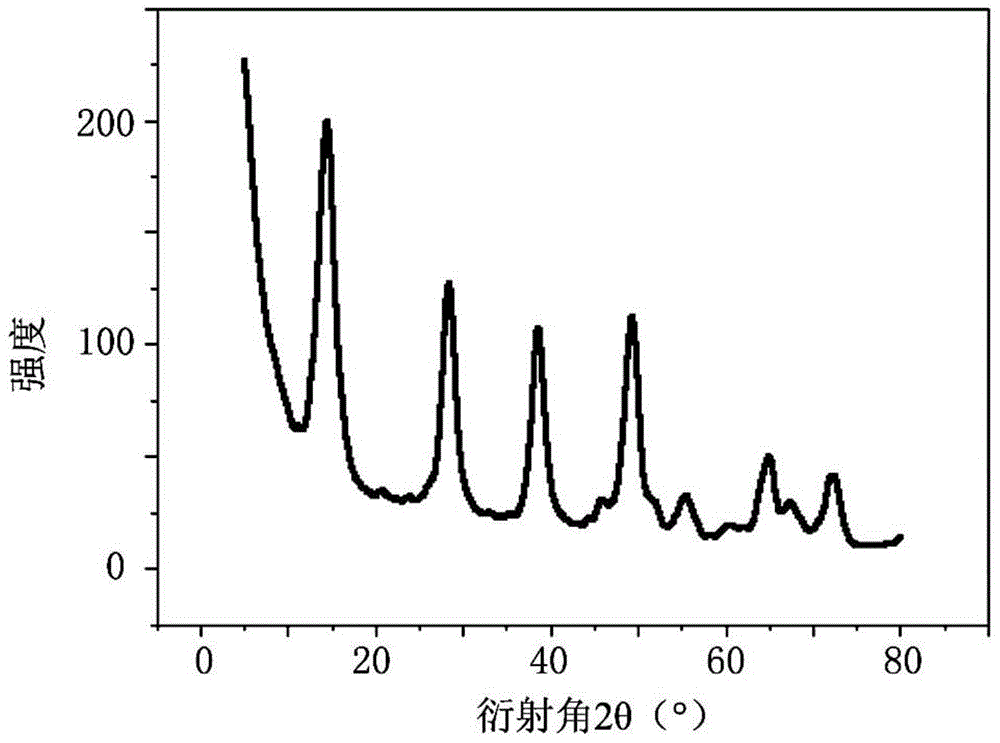

Preparation method of pseudo-boehmite

ActiveCN105347373BInhibition of spontaneous hydrolysis reactionsControl concentrationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationMembrane reactorCarbon dioxide

The invention discloses a preparation method of pseudo-boehmite. The preparation method comprises the following steps: the step of gel-forming, the step of aging, the step of separation and washing and the step of drying. During the step of gel-forming, a meta-aluminate solution and carbon dioxide gas are contacted with each other in an inorganic membrane reactor so as to form a reaction product, wherein pressure of the carbon dioxide gas is greater than or equal to 0.1 MPa. By the method of the invention, pseudo-boehmite of stable quality can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +2

Production method of pseudo-boehmite with large pore volume

ActiveCN105347372BInhibition of spontaneous hydrolysis reactionsPromote neutralizationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium oxides/hydroxidesMembrane reactorCarbon dioxide

The invention discloses a production method of large pore volume pseudo boehmite. The production method comprises the following steps: the step of gel-forming, the step of aging, the step of separation and washing and the step of drying. During the gel-forming step, a meta-aluminate solution containing a pore-enlarging agent and carbon dioxide gas are contacted with each other in an inorganic membrane reactor so as to form a reaction product. By the method of the invention, pseudo boehmite of stable quality can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +2

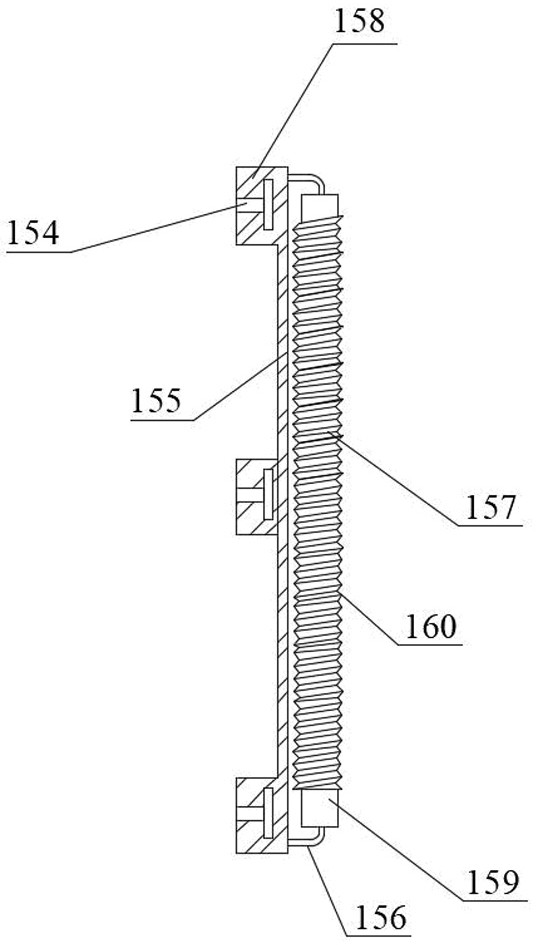

Production device and method of pseudo-boehmite

ActiveCN105347375BInhibition of spontaneous hydrolysis reactionsPromote neutralizationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateMembrane reactor

The invention discloses a production device of pseudo-boehmite and a method thereof. The production device comprises a gel-forming device which comprises a meta-aluminate supply unit, a carbon dioxide supply unit and an inorganic membrane reactor. The inorganic membrane reactor comprises a shell and an inorganic membrane component. The inorganic membrane component is arranged inside the shell and is in seal connection with the shell. The meta-aluminate supply unit is used for supplying a meta-aluminate solution to the inorganic membrane reactor. The carbon dioxide supply unit is used for supplying carbon dioxide gas to the inorganic membrane component. The inorganic membrane component is used for containing carbon dioxide gas and diffusing the carbon dioxide gas into the meta-aluminate solution in the cavity. By the device and the method, pseudo-boehmite of stable quality can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +2

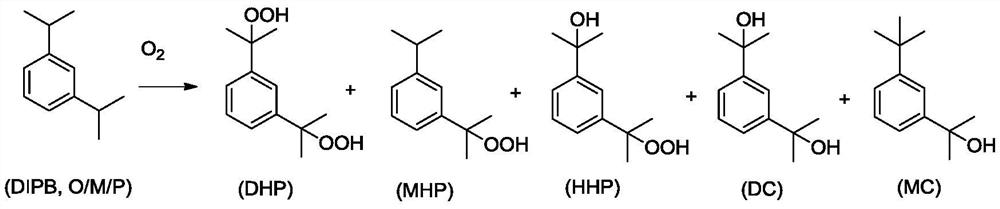

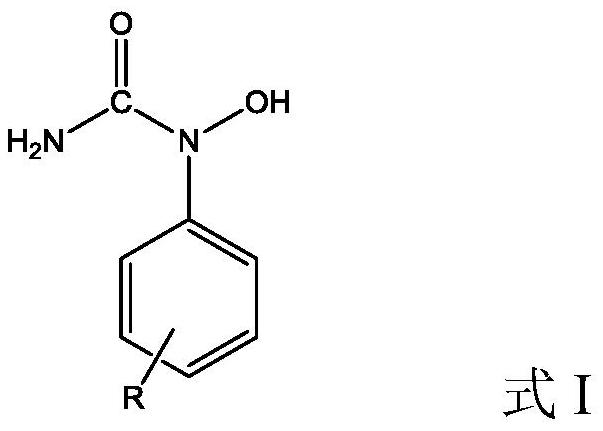

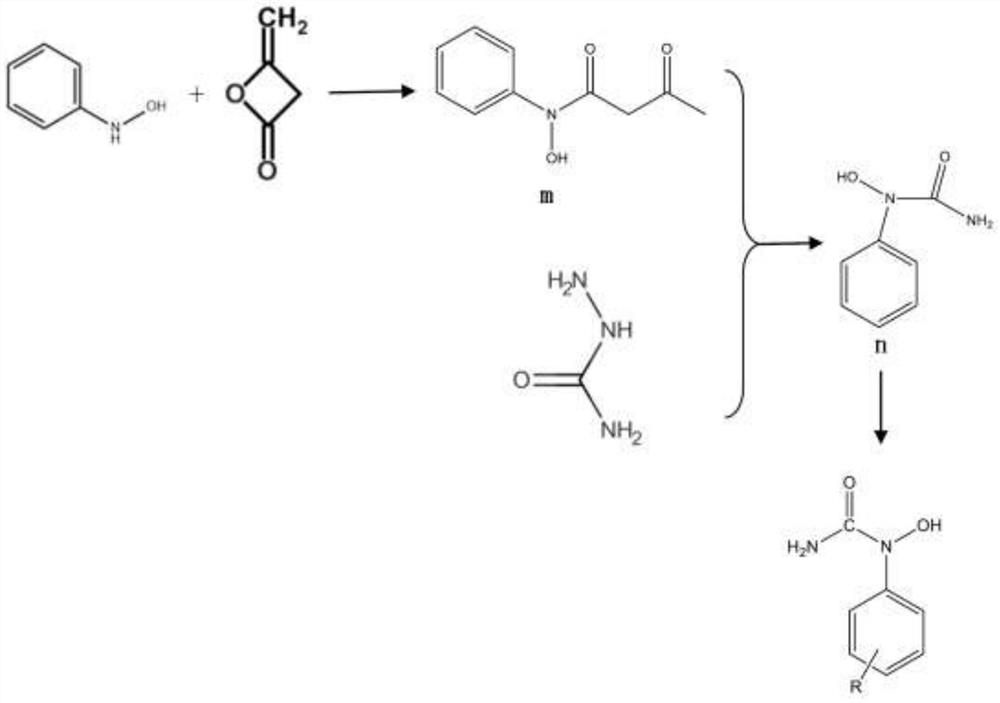

A kind of preparation method of dicumyl hydroperoxide

ActiveCN113620853BIncrease reaction rateGood miscibility in the systemOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystReaction rate

The invention discloses a preparation method of dicumyl benzene hydroperoxide, which comprises the following steps: a structural compound represented by the following formula is used as a catalyst, and dicumyl benzene is contacted and reacted with an oxygen-containing gas to generate dicumyl benzene-containing hydrogen Peroxide reaction solution. The method has the advantages of simple operation, fast reaction rate, high reaction yield, good safety and excellent industrial application prospect.

Owner:WANHUA CHEM GRP CO LTD

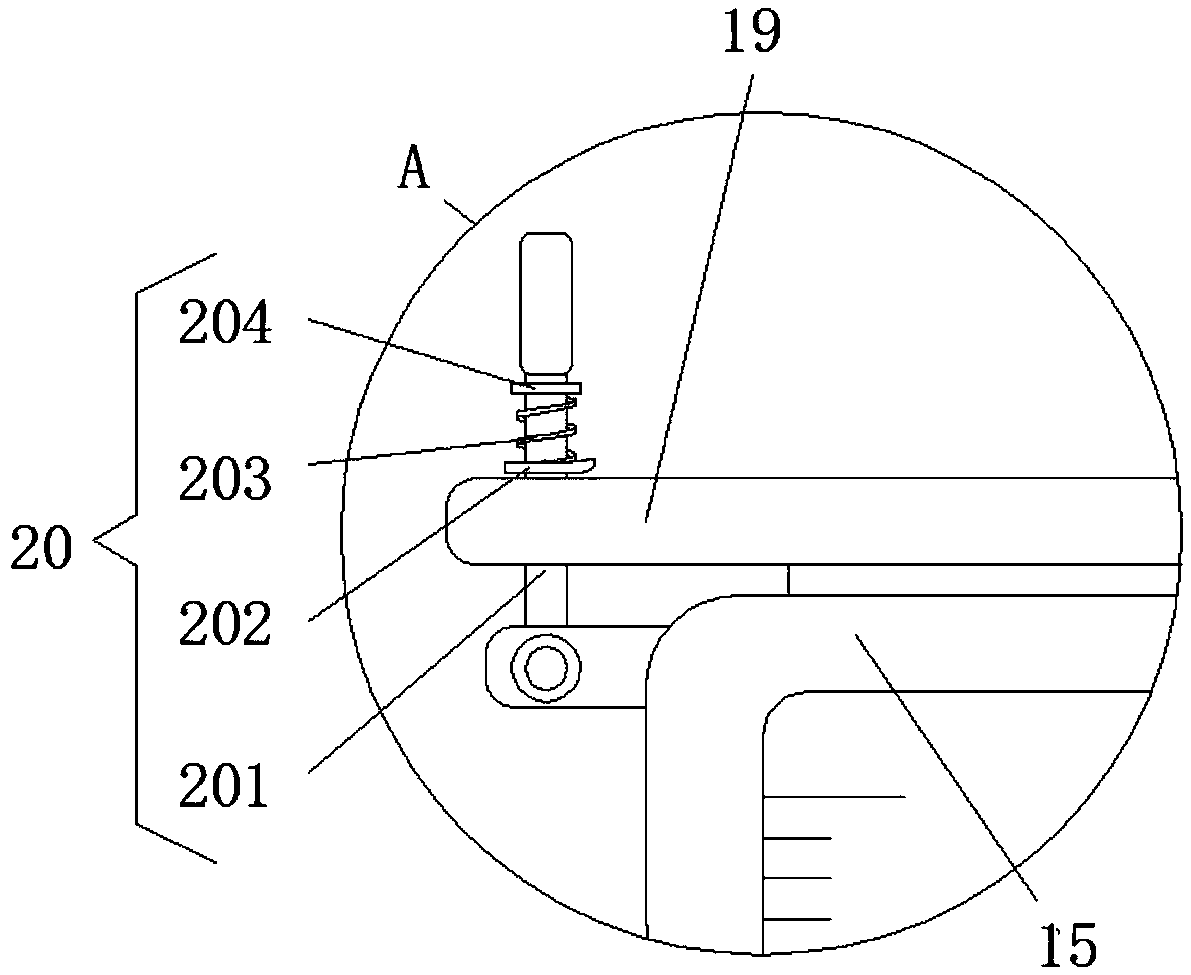

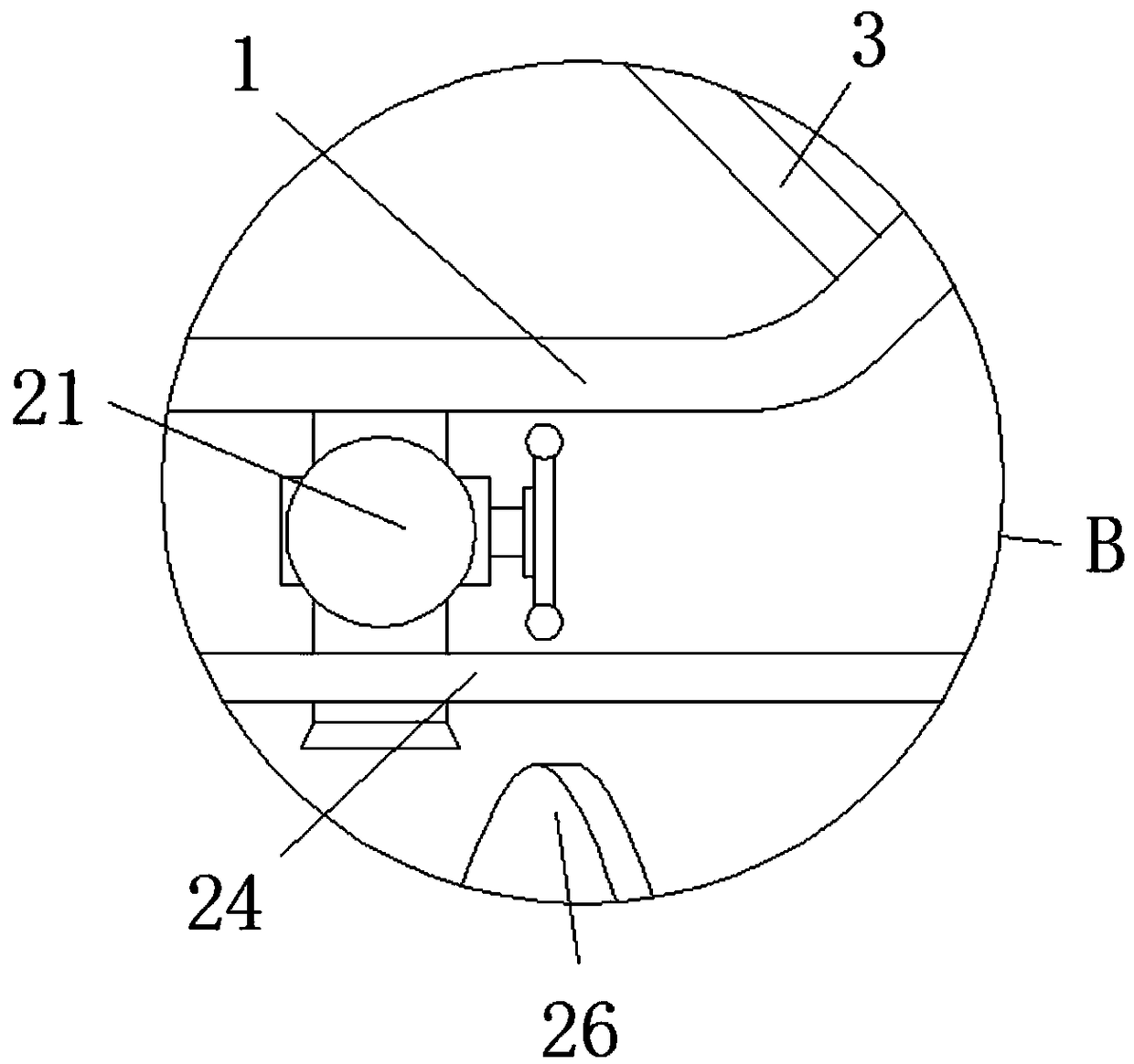

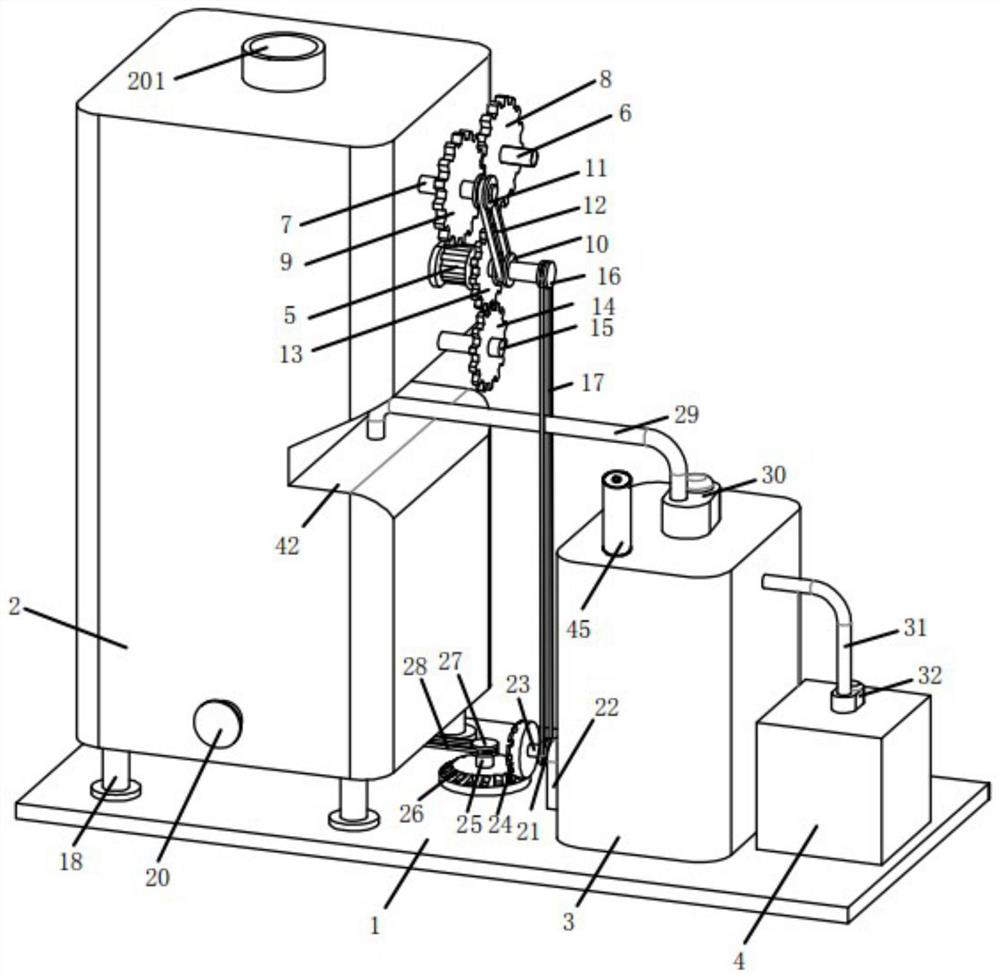

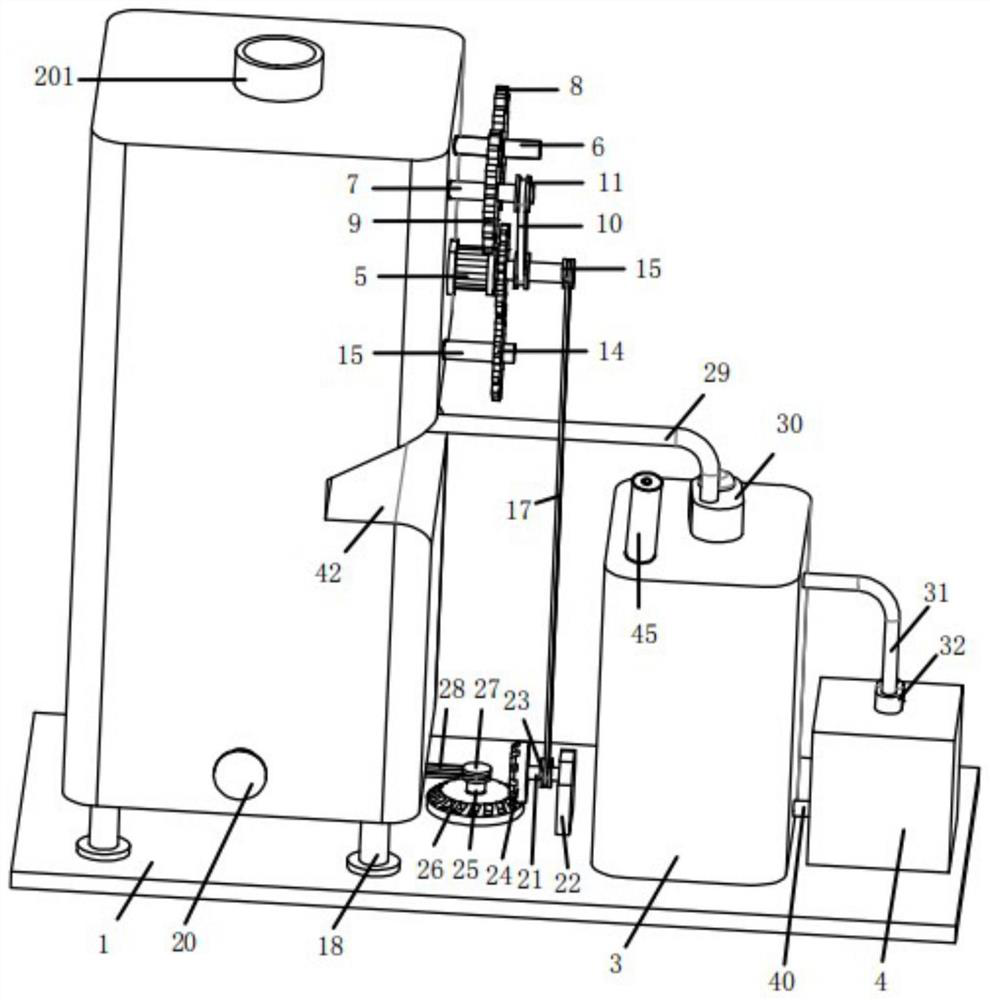

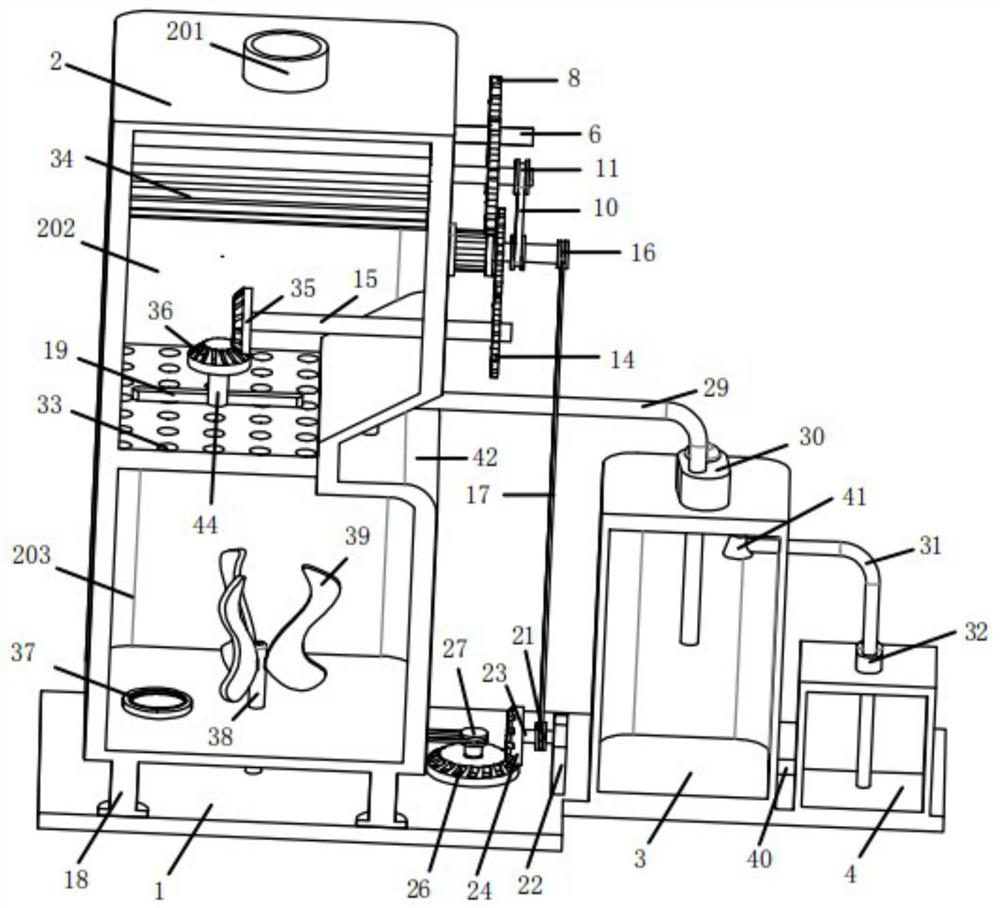

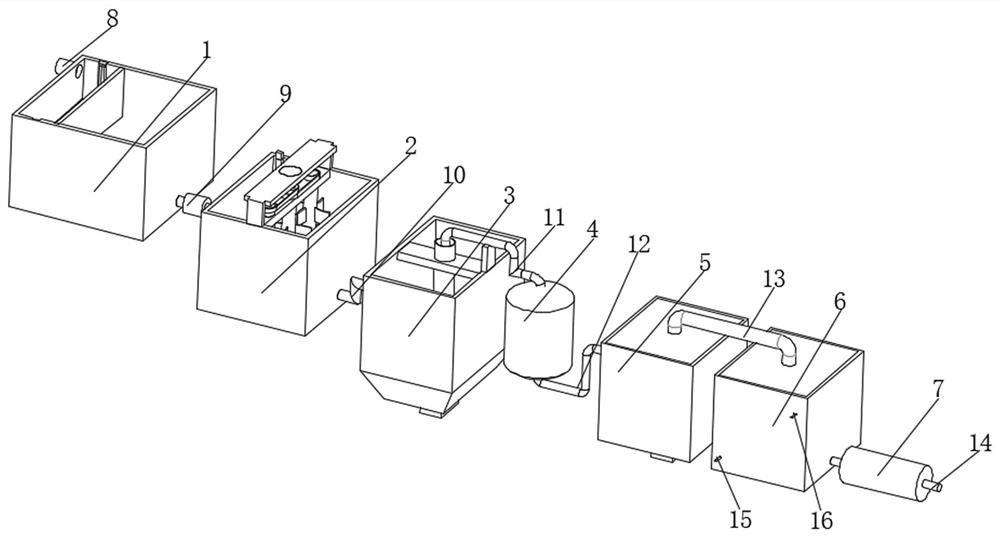

Solid waste digestion environmental protection device

InactiveCN112845497AShorten digestion timeAchieve cleanupSievingRotary stirring mixersElectric machineryDigestion

The invention provides a solid waste digestion environmental protection device, and belongs to the technical field of environmental protection devices. The device comprises a base plate, a processing box, a neutralization box and a circulation box, the processing box, the neutralization box and the circulation box are arranged at the upper side of the base plate in sequence from left to right, the upper side of the processing box is internally provided with a 201, a 202 and a 203 are arranged in the processing box, a plurality of uniformly-distributed leakage holes are arranged between the 202 and the 203, two crushing teeth are arranged in the 202, the right end of the base plate is fixedly connected with a motor, the motor is connected with a first driving mechanism, a second driving mechanism and a third driving mechanism, the first driving mechanism is connected with the crushing teeth to compress and fix waste, and cleaning brushes are arranged on the inner walls, close to each other, of the 202 and the 203. The second driving mechanism is connected with the two cleaning brushes to clean residual waste, the lower inner wall of the 203 is rotatably connected with a sixth rotating shaft, and the sixth rotating shaft movably penetrates through the lower end of the base plate and extends downwards so that toxic gas generated during digestion reaction can be effectively solved, and the digestion rate is increased.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

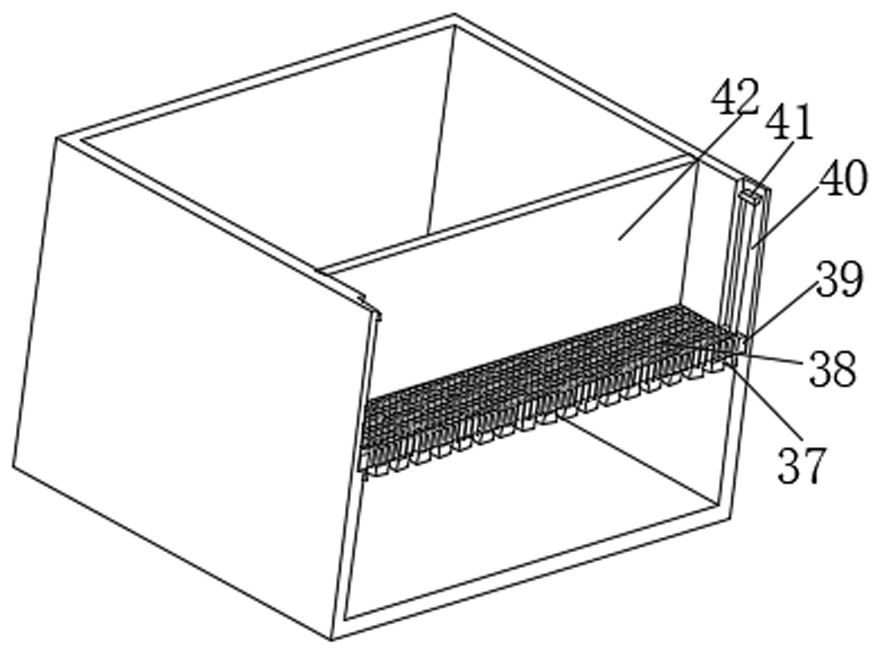

High-salinity industrial wastewater advanced treatment and recycling process

PendingCN113880339AImprove processing efficiencyPromote neutralizationTreatment involving filtrationMultistage water/sewage treatmentIndustrial waste waterElectric machine

The invention relates to the technical field of high-salinity industrial wastewater treatment, and discloses a high-salinity industrial wastewater advanced treatment and recycling process which comprises a filtering box body, a neutralizing box body is arranged on one side of the filtering box body, a settling box body is arranged on the other side of the neutralizing box body, and an ultrafiltration device is arranged on the other side of the settling box body. According to the high-salinity industrial wastewater advanced treatment and recycling process, by arranging the neutralizing box body, when the wastewater enters the neutralizing box body, the neutralizing solution is added into the neutralizing box body for the neutralization reaction, the motor works to drive the first rotating shaft to rotate, and the first rotating shaft drives the first stirring rod to rotate so that the efficiency of the neutralization reaction is accelerated; meanwhile, the driving wheel arranged on the output shaft of the motor rotates, and the driven wheel is driven to rotate under the action of the belt so that the second rotating shafts on the two sides of the first rotating shaft rotate, the second rotating shafts drive the second stirring rods to rotate, and the neutralization reaction is further accelerated.

Owner:福建省环境保护设计院有限公司

Production method of pseudo-boehmite

ActiveCN105347374BInhibition of spontaneous hydrolysis reactionsControl concentrationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationMembrane reactorCarbon dioxide

The invention discloses a production method of pseudo-boehmite. The production method comprises the following steps: the step of gel-forming, the step of aging, the step of separation and washing and the step of drying. During the step of gel-forming, a meta-aluminate solution and carbon dioxide gas are contacted with each other in an inorganic membrane reactor so as to form a reaction product. By the method of the invention, pseudo-boehmite of stable quality can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +2

A kind of preparation method of titanium sulfate liquid hydrolysis highly active crystal seed

ActiveCN107857298BHigh activityImprove stabilityTitanium dioxideHydration reactionPhysical chemistry

The invention discloses a preparation method of high-activity crystal seed by hydrolysis of a titanium sulfate solution and belongs to the technical field of production of titanium dioxide by a sulfuric acid method. The preparation method comprises the following steps of (A) taking and putting a hydrolytic titanium sulfate solution into a preheating groove to be preheated to 50-65 DEG C, wherein the concentration of TiO2 in the hydrolytic titanium sulfate solution is 195-205g / L, the concentration of Ti<3+> is 1.0-3.0g / L (calculated by TiO2), the concentration ratio F between effective acid andtotal TiO2 is 1.70-1.85, the concentration ratio between Fe and TiO2 is 0.26-0.31, the solid content is less than 30mg / L, and the stability is greater than or equal to 500; (B) preheating alkaline liquid to 50-65 DEG C, and controlling the concentration of the preheated alkaline liquid to 8.0-8.5%; (C) within 1-4 minutes, adding the hydrolytic titanium sulfate solution into the alkaline liquid, and after the reaction is finished, controlling the temperature of the crystal seed titanium sulfate solution to be 40-60 DEG C; (D) diluting and controlling the concentration of TiO2 in the crystal seed titanium sulfate solution to be 30-160g / L. The crystal seed prepared by the method is high in activity, less in added amount in water crystallization and high in hydrolysis rate, and the obtained hydrated titanium dioxide is uniform in particle size distribution.

Owner:HEBEI MILSON TITANIUM DIOXIDE

A kind of preparation method of halogenated polymer

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com