Patents

Literature

201results about How to "Improve recycling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

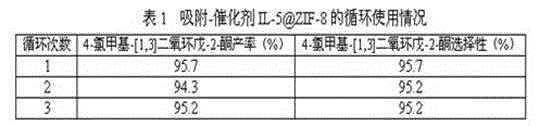

ZIF-8 encapsulated amino ionic liquid type carbon dioxide adsorbing-catalyzing agent

ActiveCN105149002ALarge capacityHigh activityProductsOrganic chemistryMetal-organic frameworkIonic liquid

The invention discloses a ZIF-8 encapsulated amino ionic liquid type carbon dioxide adsorbing-catalyzing agent. The ZIF-8 encapsulated amino ionic liquid type carbon dioxide adsorbing-catalyzing agent is prepared according to the following steps: taking the metal organic framework material ZIF-8 as a carrier; taking the amino-group functionalized ionic liquid 1-(3-aminopropyl)-3-methylimidazole chloride as an active component; immobilizing the amino-group functionalized ionic liquid in the super-cages of the ZIF-8 carrier in an in-situ manner during preparation of ZIF-8, wherein 1.5 to 5 mmol of the amino-group functionalized ionic liquid is immobilized in each gram of the adsorbing-catalyzing agent. The adsorbing-catalyzing agent integrates the functions of selective adsorbing and catalyzing into a whole, and can be used for synchronously adsorbing and converting carbon dioxide, so as to reduce the cost of the CUU technology.

Owner:TAIYUAN UNIV OF TECH

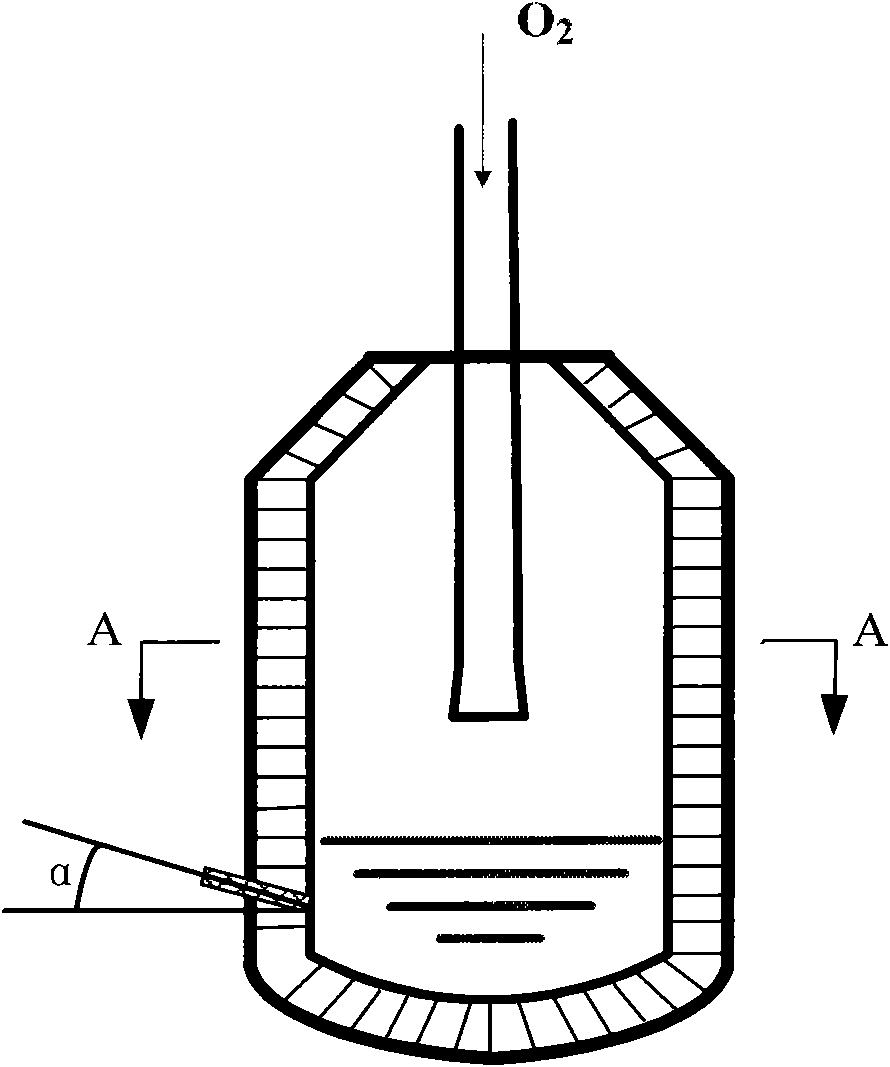

Converter vanadium extraction process adopting top blowing oxygen lance to blow cooling agents

The invention relates to a converter vanadium extraction process adopting a top blowing oxygen lance to blow cooling agents, belongs to the technical field of ferrous metallurgy, and is used for solving the problems that the temperature of a molten pool is difficult to control in the vanadium extraction course, the dynamic condition is poor and the like and increasing the oxidation conversion rate of vanadium and the quality of vanadium slag. The converter vanadium extraction process comprises a powder supply system and an oxygen supply system; and the cooling agents are blown through using a supersonic oxygen jet of the top blowing oxygen lance, and the aims of controlling the temperature of the molten pool in the vanadium extraction course and improving the stirring ability of the molten pool are achieved by utilizing a principle that powder rapidly reacts with hot iron to absorb heat, thereby achieving the technical effect of efficient vanadium extraction. The cooling agents enters the oxygen lance via a powder supply pipe in the powder blowing process; an outlet of the powder supply pipe can be positioned between the upper part of a lance body and an Raoult outlet of a blowing head; and the inner diameter of the powder supply pipeline is in the range of 15 to 180mm, the powder blowing flow rate is in the range of 20 to 800kg / min, the carrier gas flow rate is in the range of 100 to 4000Nm3 / h, and the carrier gas pressure is in the range of 0.5 to 1.6Mpa. The converter vanadium extraction process is suitable for vanadium extraction converters of 200 to 300t; and by adopting the converter vanadium extraction process, the semi-steel vanadium content can be reduced to below 0.03 percent, and the quality of vanadium slag (V2O5) is increased by more than 1 percent, so that the recovery rate of vanadium resources is increased.

Owner:UNIV OF SCI & TECH BEIJING

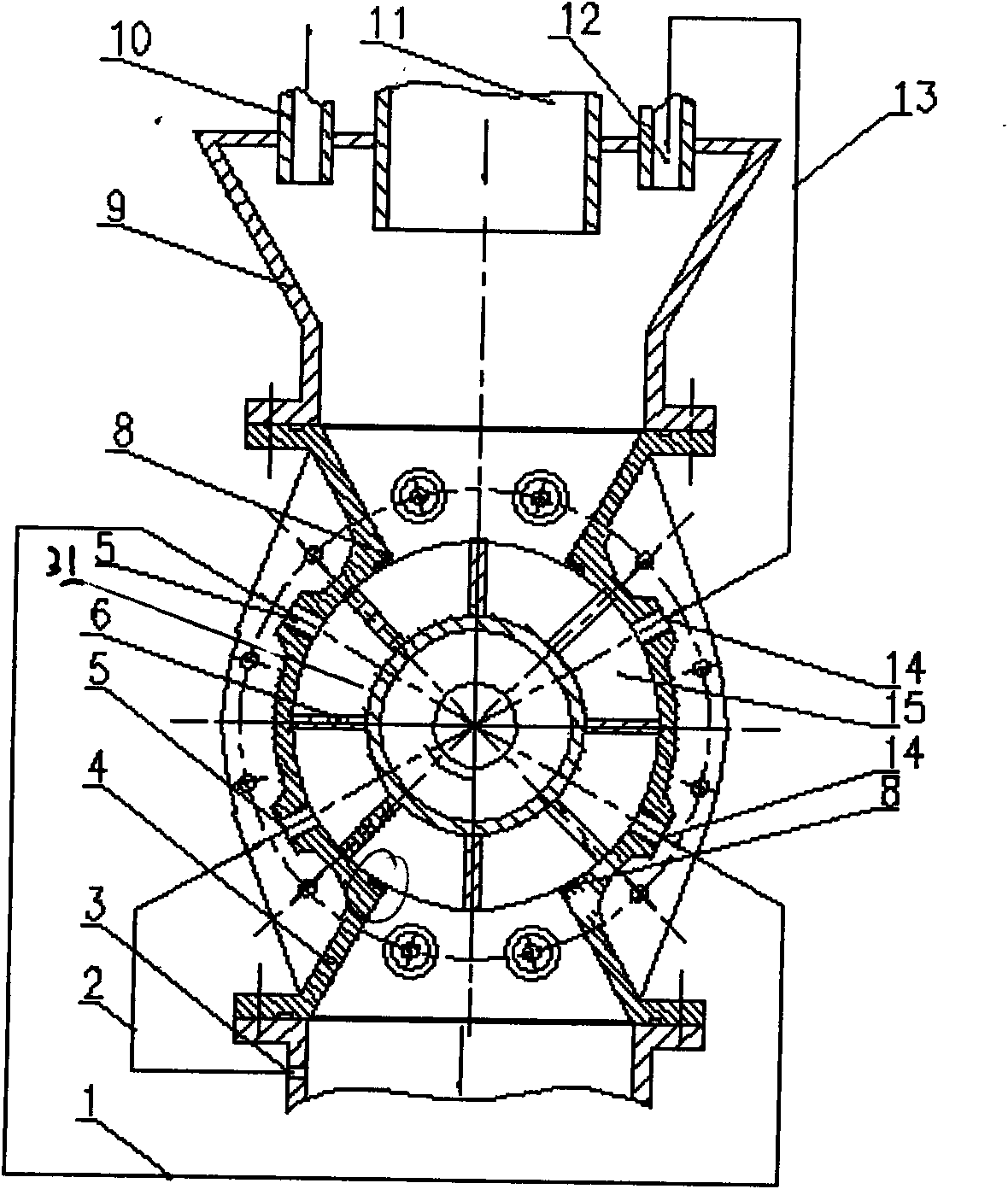

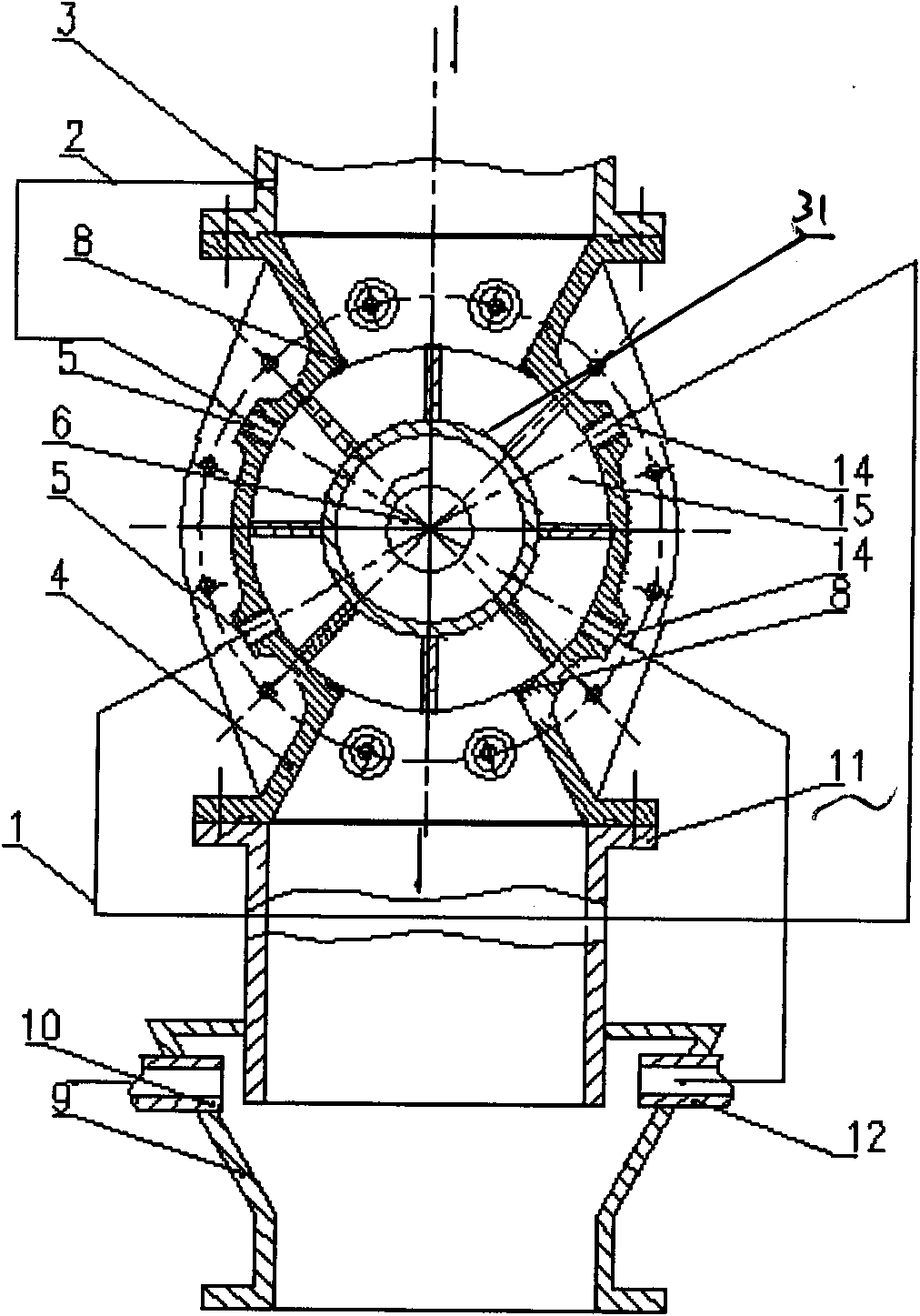

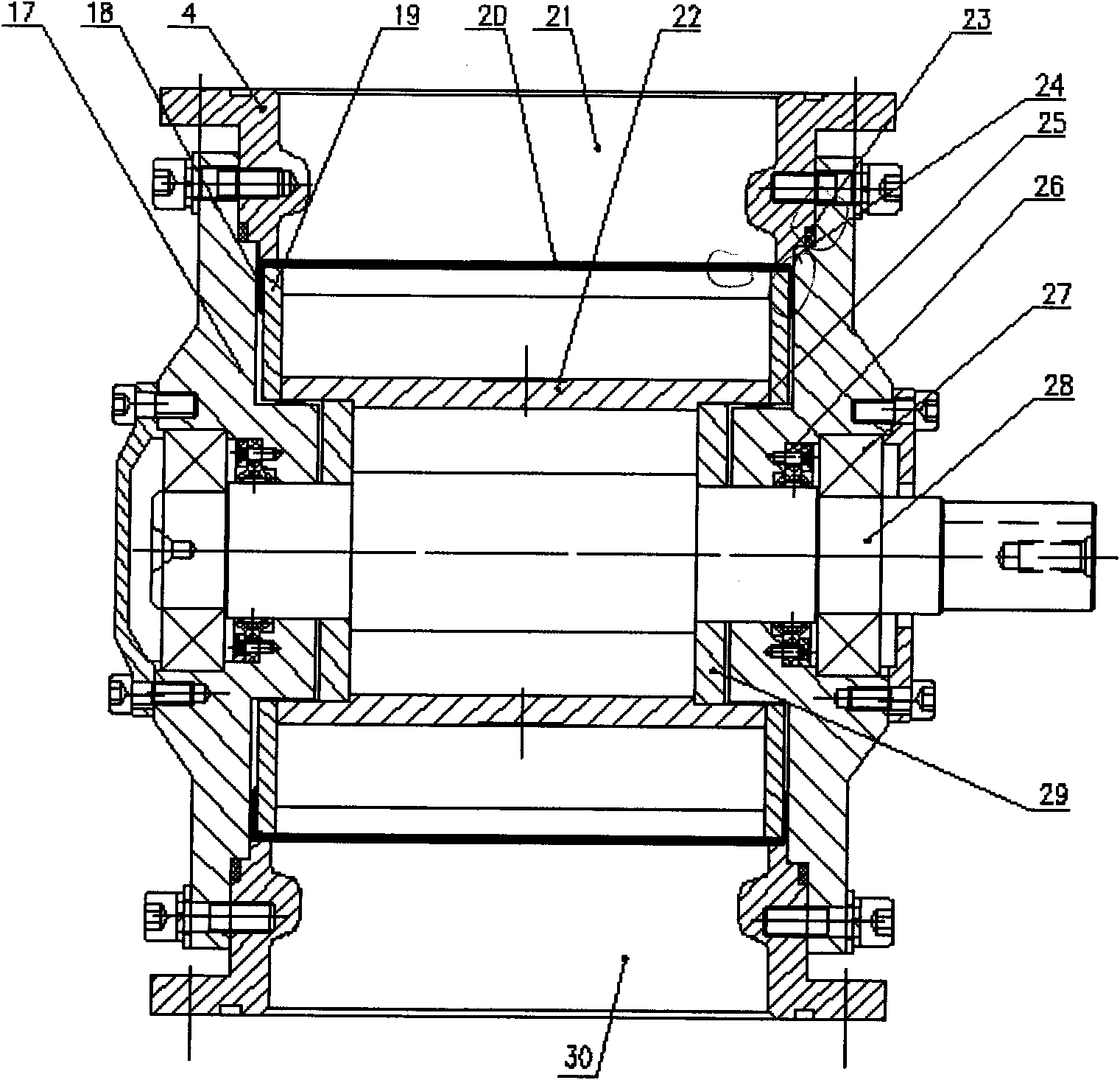

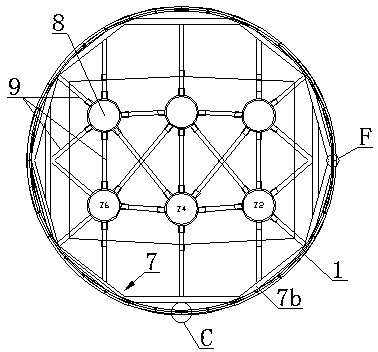

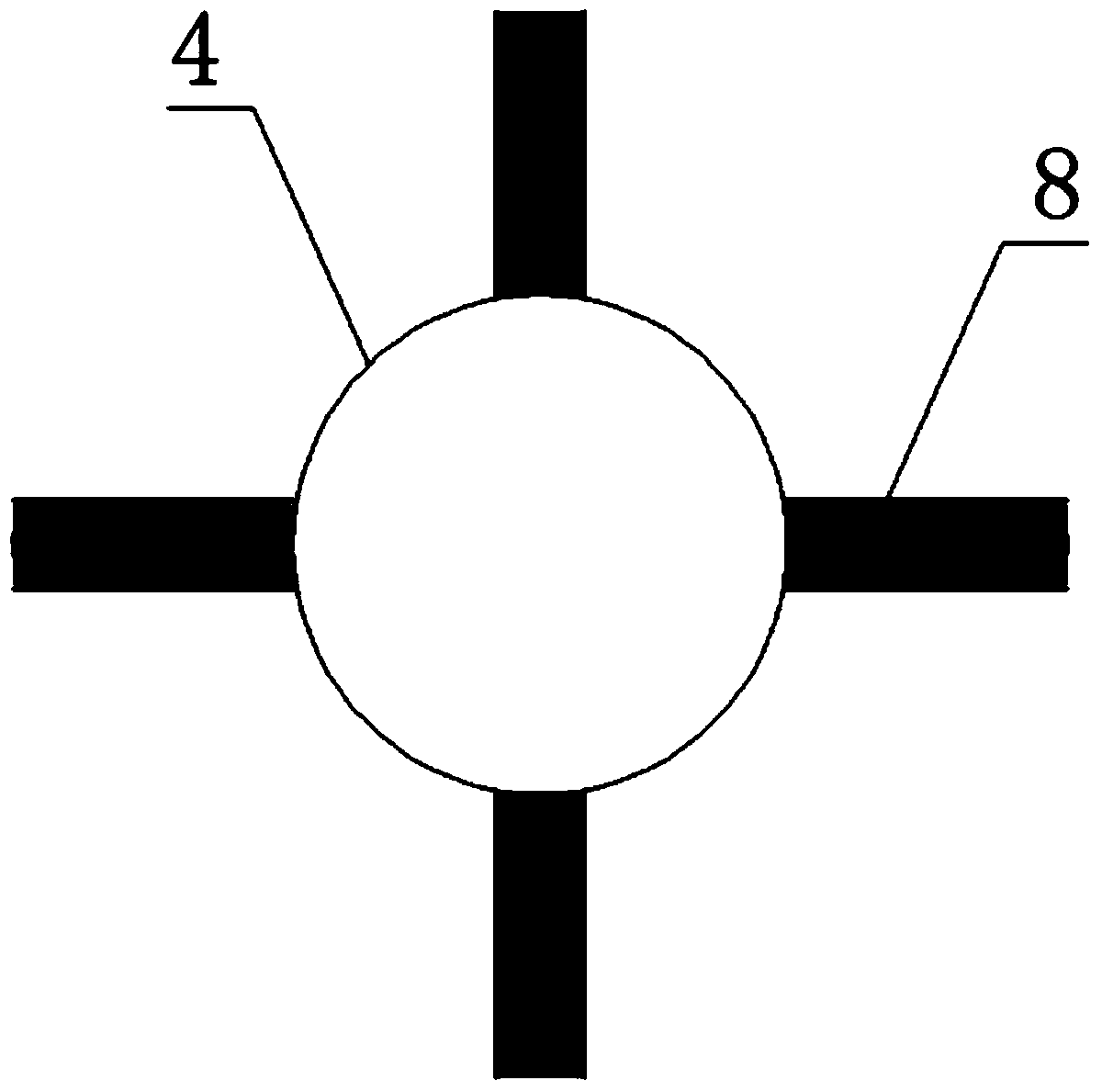

Rotary sealing feeding valve

InactiveCN101676179AImprove recycling rateSmall pressure fluctuationsBulk conveyorsRotary conveyorsRotary valveTemperature difference

The invention relates to a rotary sealing feeding valve which comprises a valve casing, side flanges which are symmetrically arranged and a star-shaped rotor, wherein the side flanges are fixedly installed at the front side and the back side of the valve casing; a main shaft is supported between the side flanges; and the star-shaped rotor is supported between two side flanges in the valve casing. The invention is characterized in that the space between each side flange and the valve casing is divided into a plurality of sealed chambers by the star-shaped rotor; a pressure-reducing balanced opening and a pressure-increasing balanced opening are arranged on the valve casing; and the valve casing also comprises a feeding opening and a discharge opening. The rotary sealing feeding valve is a rotary valve which is suitable for continuous feeding in the environment with pressure difference and temperature difference.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

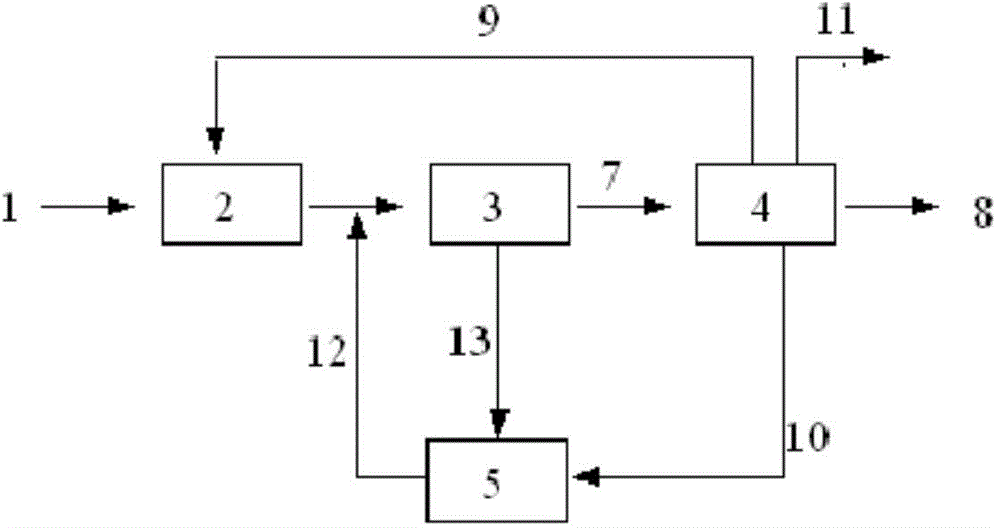

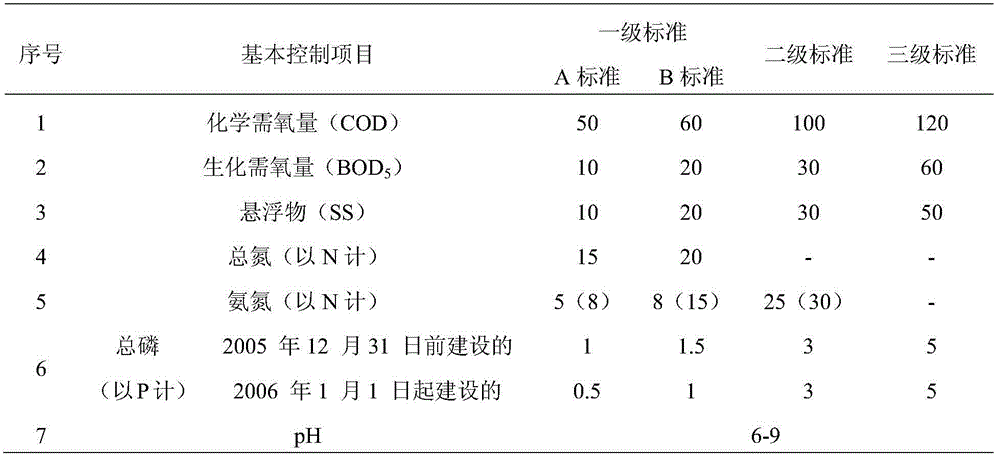

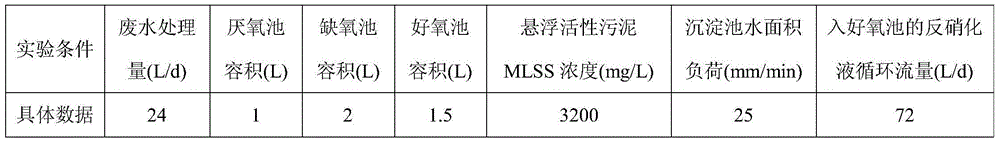

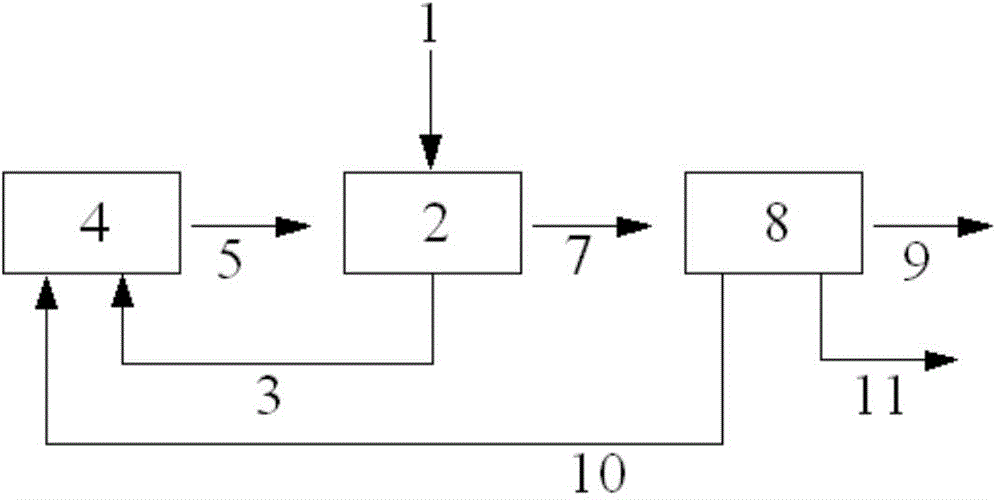

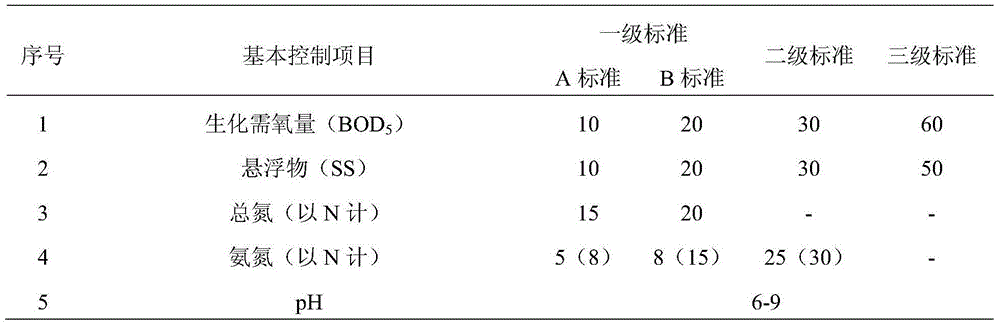

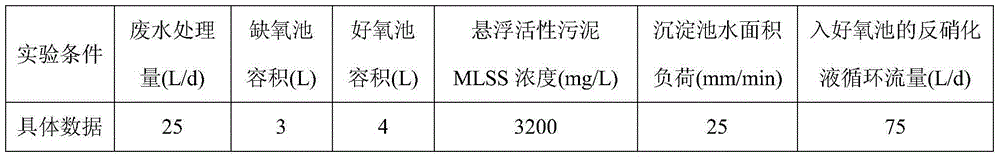

Efficient biochemical nitrogen and phosphorus removal method for waste water

ActiveCN104556572AImprove mud life and recycling rateReduce stepsTreatment using aerobic processesWater contaminantsChemistryIon adsorption

The invention discloses an efficient biochemical nitrogen and phosphorus removal method for waste water. Ammonia nitrogen and phosphorus in waste water are efficiently removed by combining a modified A2 / O biological nitrogen and phosphorus removal technology and a chemical method, namely, zeolite adsorbing ammonia nitrogen method; the denitrification liquid flowing out from an anoxic denitrification tank enters an aerobic nitration tank to form internal circulation; the residual denitrification liquid directly enters a sedimentation tank for solid-liquid separation; phosphorus-accumulating bacteria directly flows back to an anaerobic tank from the sludge of a sedimentation tank, and then enters the anoxic nitration tank. Ion adsorption and biological regeneration treatment are combined; water outlet total nitrogen is less than or equal to 5 mg / L; the removal ratio of total nitrogen and total phosphorus is more than 90%; requirements that water outlet total nitrogen in Taihu basin chemical engineering zone is superior to the primary standard, namely, the A standard, of the urban sewage treatment plant pollutant discharge standard (GB18918-2002) are met stably.

Owner:江苏艾特克环境工程设计研究院有限公司 +1

Production method of earthworm cast-based ecological organic fertilizer

InactiveCN102649652AReduce energy consumptionImprove recycling rateBio-organic fraction processingProductsWater contentChemistry

The invention discloses a production method of an earthworm cast-based ecological organic fertilizer. The production method comprises the following steps of: selecting organic solid waste with carbon-nitrogen ratio of 1:23-28 as a matrix, wherein the water content is 52-68 percent and the pH value is 6-7; inoculating 1-2 kg of Daping No. 2 earthworms into the matrix every square meter at 15-25 DEG C; separating continuously produced earthworm cast to serve as a raw material for producing the organic fertilizer; adding a rotten organic fertilizer which is inoculated with antagonistic bacteria into the earthworm cast; after performing amplification culture on the beneficial microorganisms therein; adding an insect repellent plant material therein according to the amount which is 0.5-4.5 percent of the weight of the materials; uniformly mixing to obtain the ecological organic fertilizer. The production method has the characteristics of rational design, convenience in operation, large-scale application and environmental friendliness; the prepared organic fertilizer has a good application effect and high applicability; and the produced organic fertilizer integrates the characteristics of a microbial fertilizer, an organic fertilizer and an inorganic fertilizer and has the characteristics of multiple functions, multiple effects and full nutrition.

Owner:宋忠俭

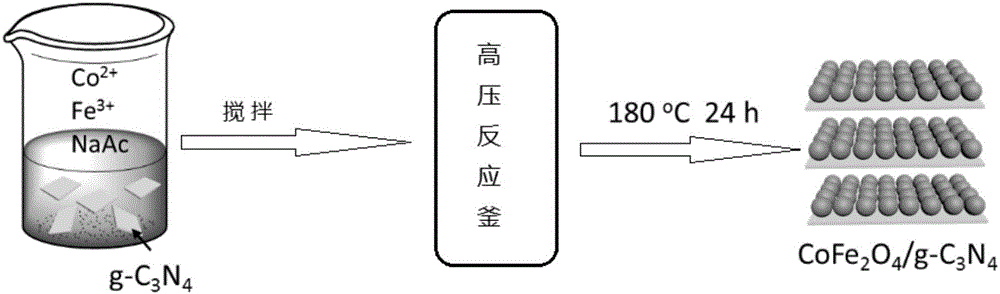

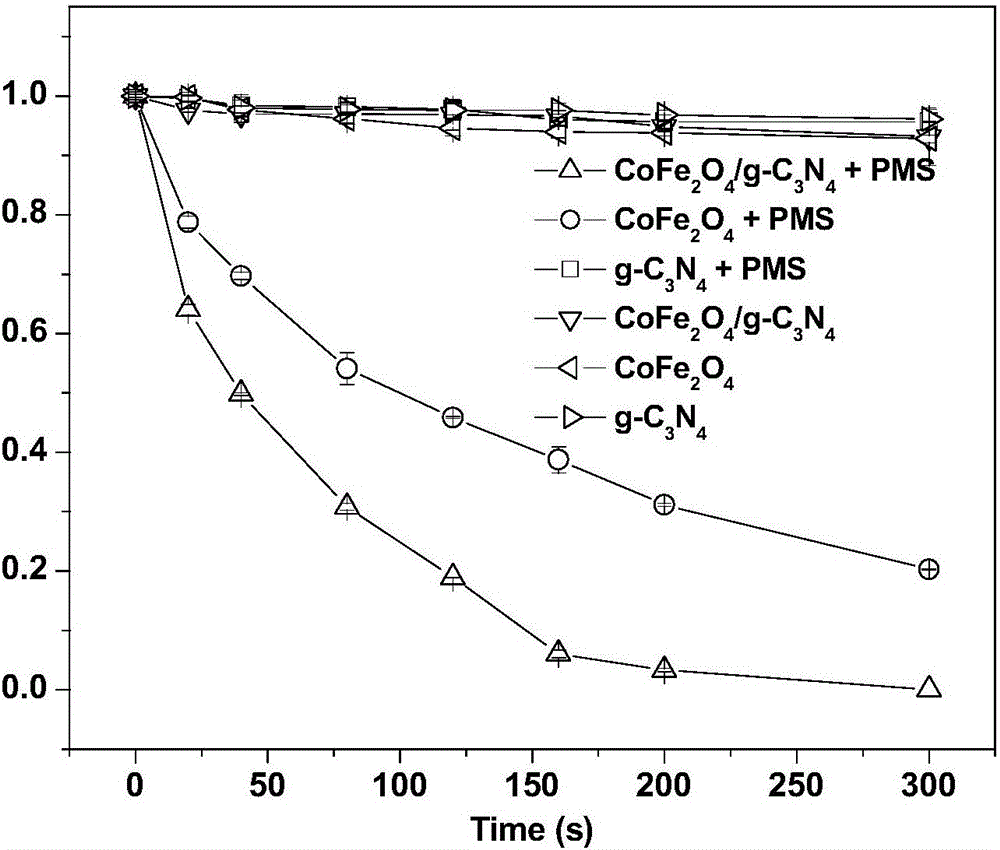

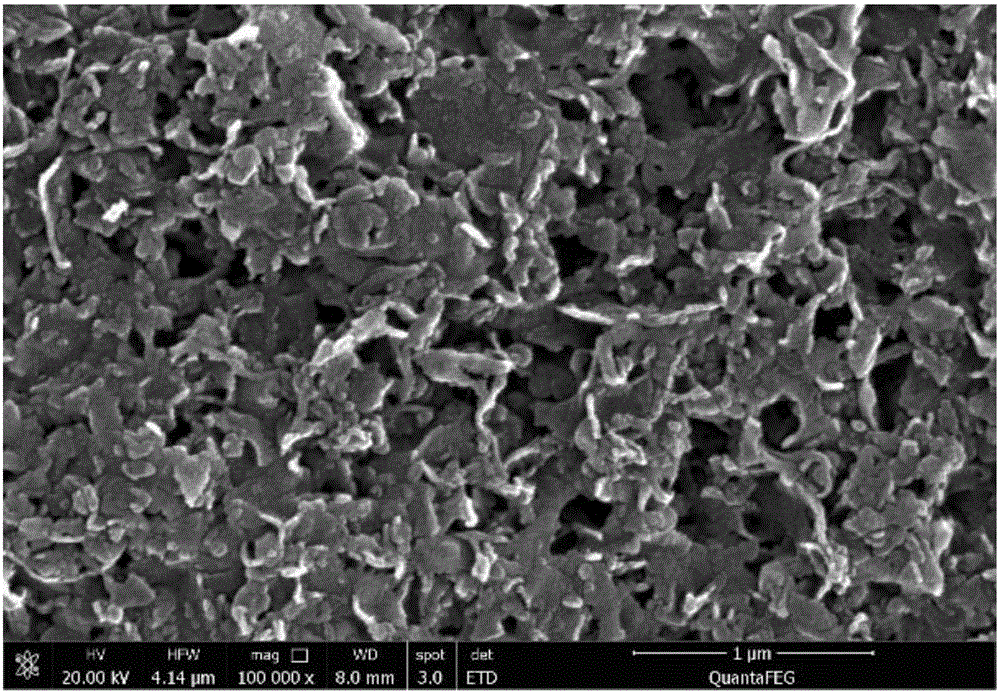

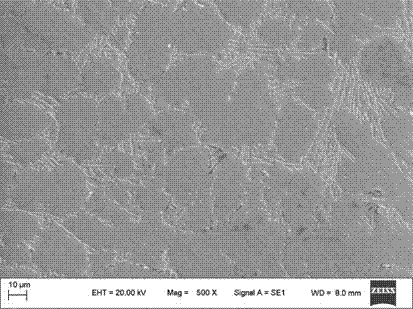

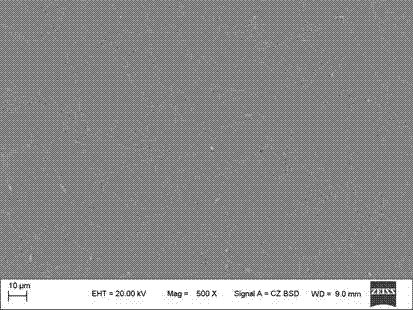

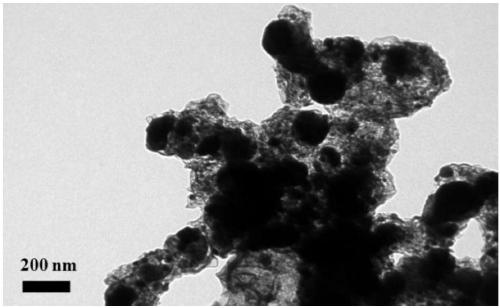

CoFe<2>O<4>/g-C<3>N<4> magnetic nanomaterial and preparation method therefor

ActiveCN106582772ASolve reunionEasy to recyclePhysical/chemical process catalystsDispersed particle separationSodium acetateNanoparticle

The invention relates to the technical field of a material, and discloses a CoFe<2>O<4> / g-C<3>N<4> magnetic nanomaterial and a preparation method therefor. The preparation method comprises the steps of preparing g-C<3>N<4> nanosheets, and dispersing the g-C<3>N<4> nanosheets into ethylene glycol; then adding FeCl<3>.6H<2>O and CoCl<2>.4H<2>O and fully dissolving; and finally adding sodium acetate, stirring and calcining in a drying oven, and finally obtaining black sediments CoFe<2>O<4> / g-C<3>N<4>. According to the CoFe<2>O<4> / g-C<3>N<4> magnetic nanomaterial disclosed by the invention, the CoFe<2>O<4> nanoparticles are uniformly distributed on the g-C<3>N<4> nanosheets, so that CoFe<2>O<4> nanoparticle agglomeration can be prevented, and more active sites are provided to improve catalytic activity; in addition, the CoFe<2>O<4> nanoparticles are magnetic, so that the particles are distributed on the g-C<3>N<4> nanosheets sequentially to form bigger planar nanomaterials; and the planar nanomaterials can be separated more quickly under a magnetic field compared with independent CoFe<2>O<4> nanomaterials.

Owner:SUZHOU INST FOR ADVANCED STUDY USTC

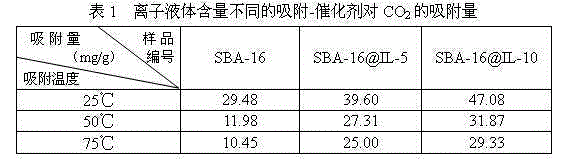

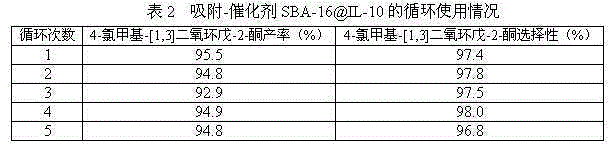

Adsorbing-catalyzing agent based on amino-functionalized ionic liquid and preparation method thereof

ActiveCN105170099ALarge capacityHigh activityProductsOrganic chemistryCatalytic transformationMolecular sieve

The invention discloses an adsorbing-catalyzing agent based on amino-functionalized ionic liquid. The adsorbing-catalyzing agent is prepared by taking a mesoporous moecular sieve SBA-16 as a carrier and amino-functionalized ionic liquid 1-(3-aminopropyl)-3-[3-(triethoxysilyl)propyl]-4,5-dihydroimidazole chloride as an active component and grafting the amino-functionalized ionic liquid to the carrier, wherein 1-10 mmol of the amino-functionalized ionic liquid is loaded in every 1 g of the adsorbing-catalyzing agent. The adsorbing-catalyzing agent integrates an adsorption capturing function and a catalytic conversion function into a whole and can achieve synchronous adsorption and conversion of CO2 and reduce the cost of a CUU technique.

Owner:TAIYUAN UNIV OF TECH

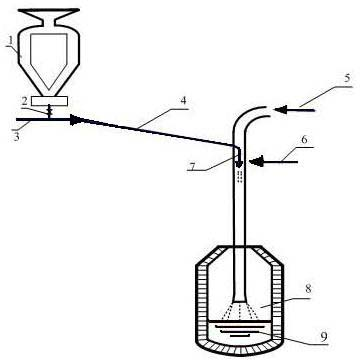

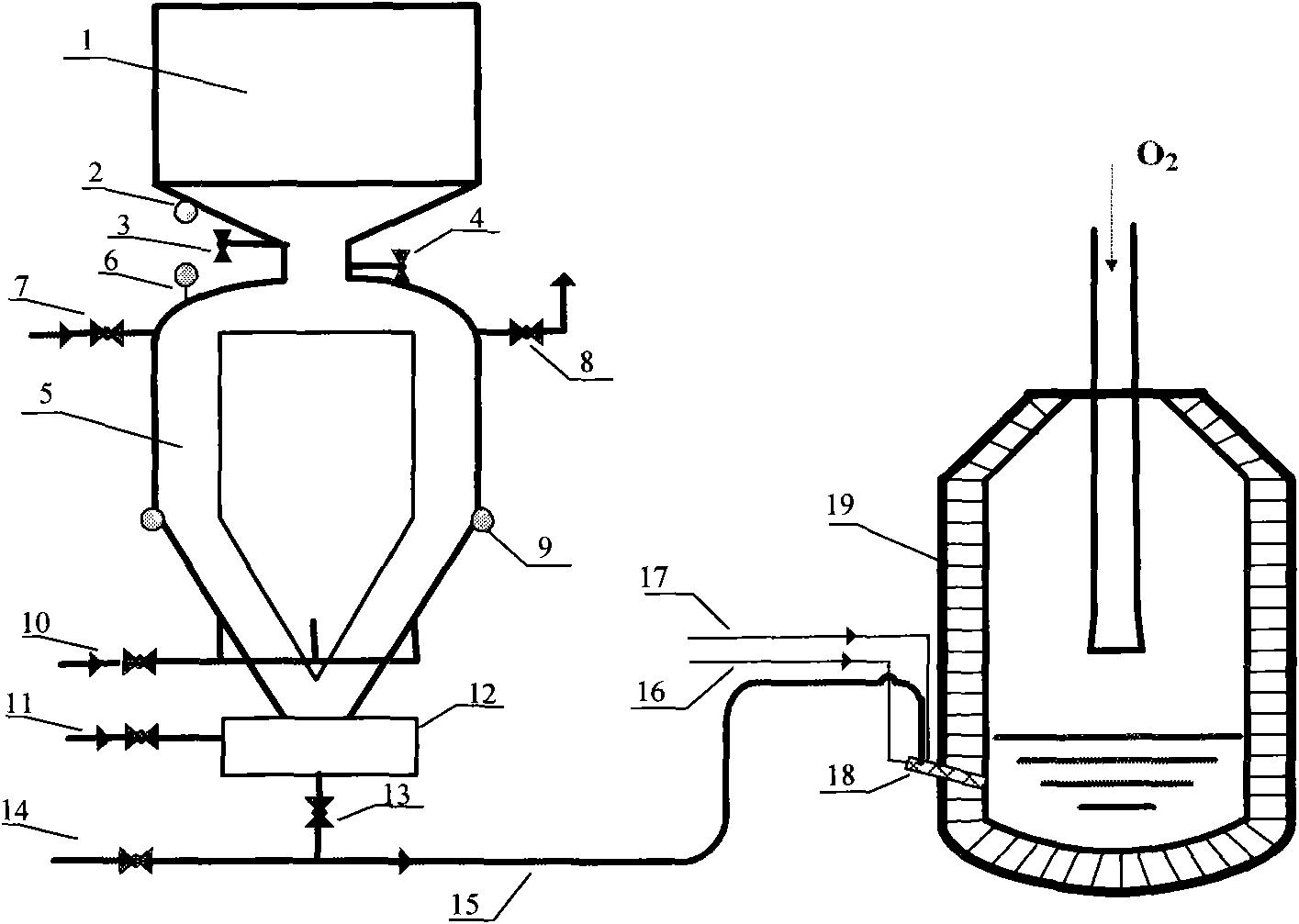

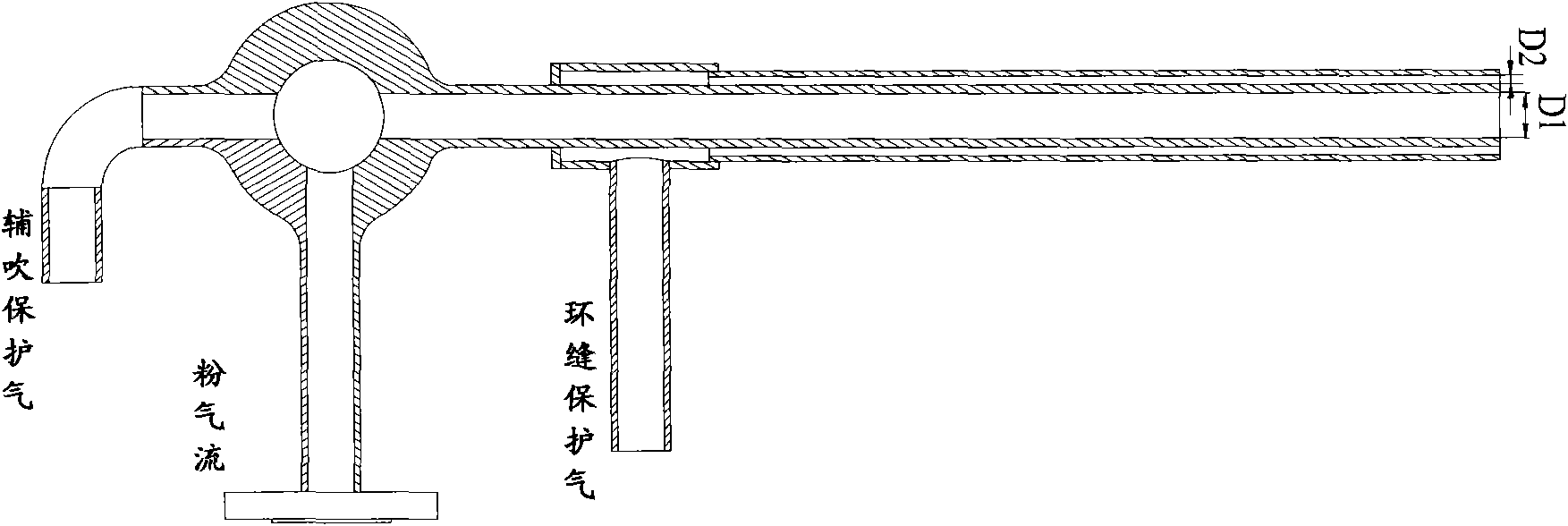

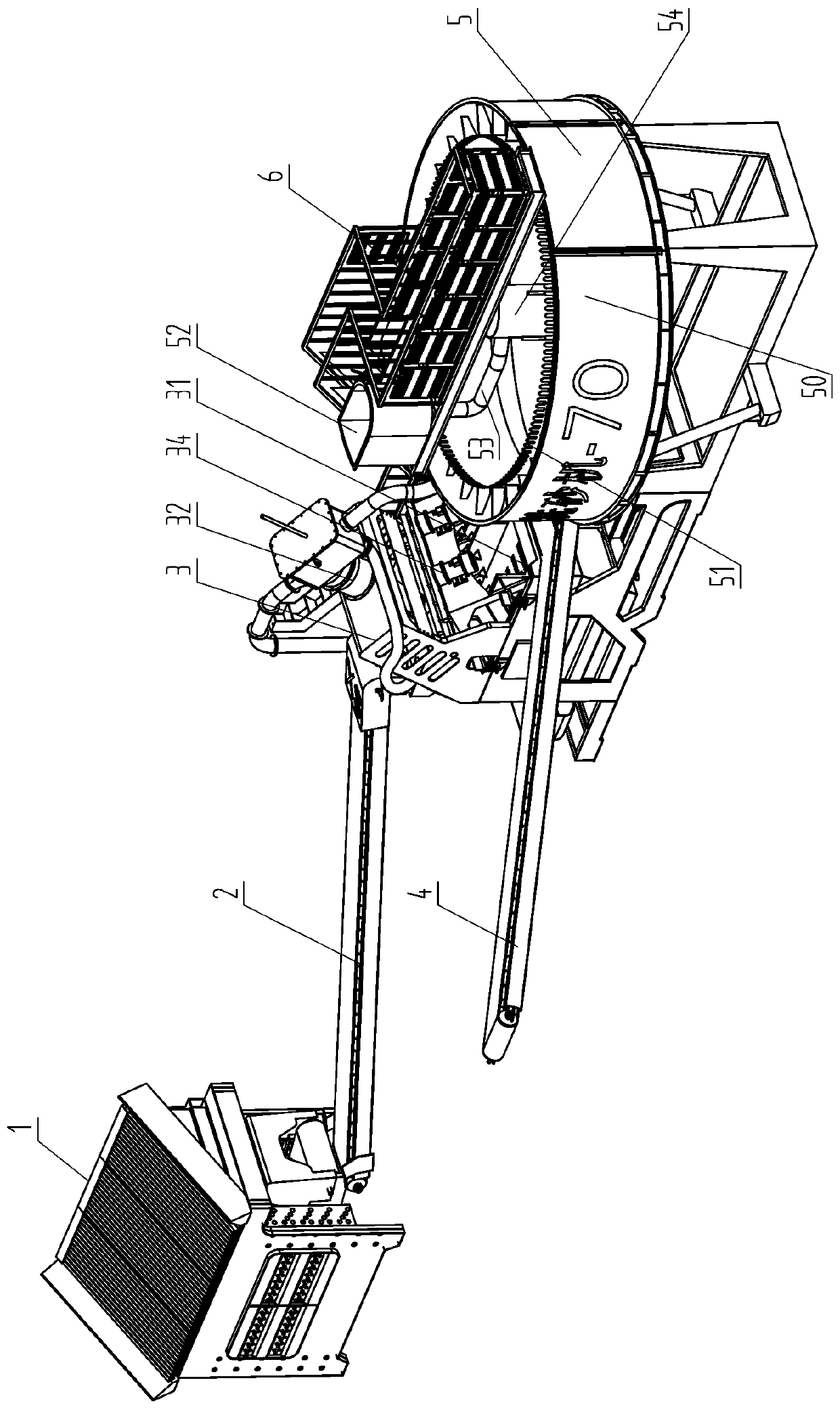

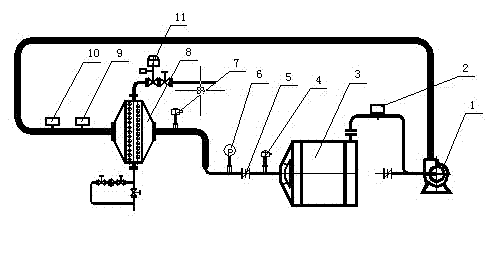

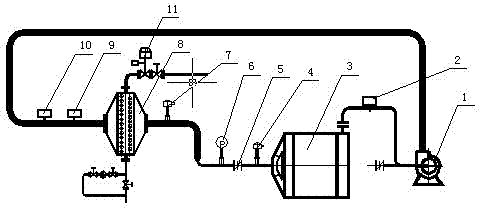

Powder spraying device and method for efficient vanadium extracting process of converter

ActiveCN101967532AImprove mechanical propertiesOptimizationCharge manipulationManufacturing convertersBrickSlag

The invention discloses a powder spraying device and a powder spraying method for an efficient vanadium extracting process of a converter, belongs to the technical field of metallurgy, and aims to solve the technical problems of poor dynamical condition, low oxidation conversion rate of vanadium and the like in the vanadium extracting process of the converter. The device comprises a powder spraying tank system, a PLC (programmable logic controller) control system, a gas adjusting valve set and a powder spraying gun. The powder spraying rate is accurately and continuously controlled by adjusting the frequency of a rotary feeding tray motor, the powder spraying gun has a double-sleeve structure, carrier gas powder spraying is adopted in a central pipe, meanwhile, auxiliary blowing gas ensures continuous operation of the powder spraying process, and circular seam blowing protective gas protects the powder spraying gun. The powder spraying gun is arranged on the side or the bottom of the vanadium extracting converter, and protective sleeve bricks are embedded around the powder spraying gun. The device is suitable for the vanadium extracting converter of 10 to 200 tons, can spray 50 to 200kg / min iron concentrate powder in the vanadium extracting process of the converter, improve the dynamical and thermodynamic conditions of vanadium extraction of the converter, reduce the content of half steel vanadium to be less than 0.03 percent and improve the content of vanadium slag (V2O5) by 2 to 5 percent, meanwhile, is favorable for shortening the vanadium extracting smelting period of the converter, and realizes efficient vanadium extraction of the converter.

Owner:HEBEI IRON AND STEEL +1

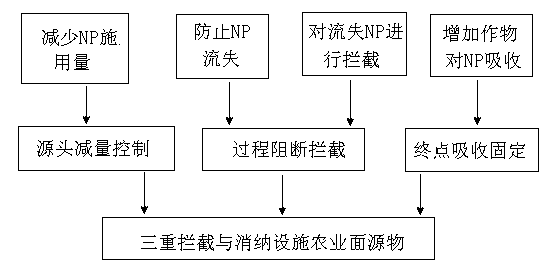

Facility agricultural non-point source pollutant on-site intercepting and absorptive method

InactiveCN103190268AImprove recycling rateShort processing cycleHorticultureSoil-working methodsNitrogen fertilizerPesticide

The invention belongs to the technical field of environment protection, and relates to a facility agricultural non-point source pollutant on-site intercepting and absorptive method. By the aid of a triple intercepting and absorptive method of source control, process blocking and intercepting and destination absorption and fixation of facility agricultural pollutants, non-point source pollution sources-flow-convergence processes and water-fertilizer key factors determining forming of non-point source pollution are subjected to process key point control, and on-site reduction of facility agricultural non-point source pollution is achieved by means of reducing consumption of nitrogen and phosphorus, increasing nitrogen and phosphorus absorption, preventing nitrogen and phosphorus loss and recycling nitrogen and phosphorus. By the method, nitrogenous fertilizer input of facility farmlands is decreased by 35%, phosphate fertilizer input is decreased by 22%, chemical pesticide input is decreased by 41.4%, agricultural waste recycling and harmless treatment utilization rate reaches 91.7%, treatment cycle is shorted by 46.2%, nitrogen is reduced on site by 38.45%, and phosphorus is reduced by 25.42%. The method can be widely applied to interception and control of facility agricultural non-point source pollutants.

Owner:INST OF AGRI ENVIRONMENT & RESOURCES YUNNAN ACAD OF AGRI SCI

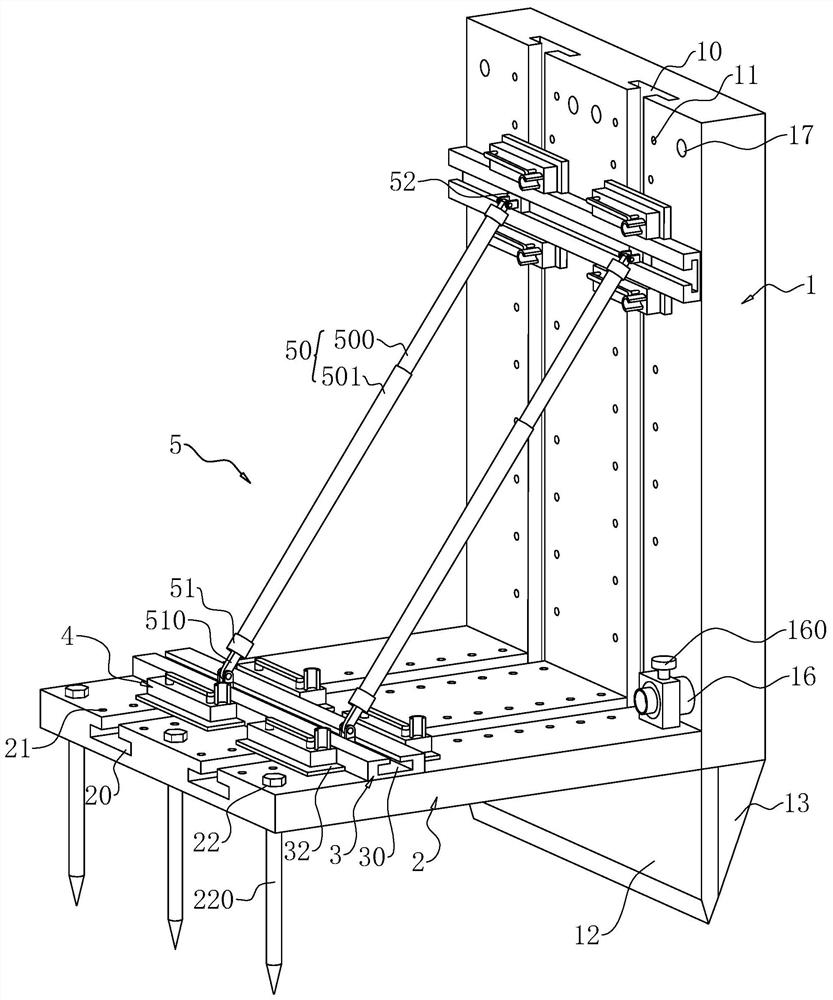

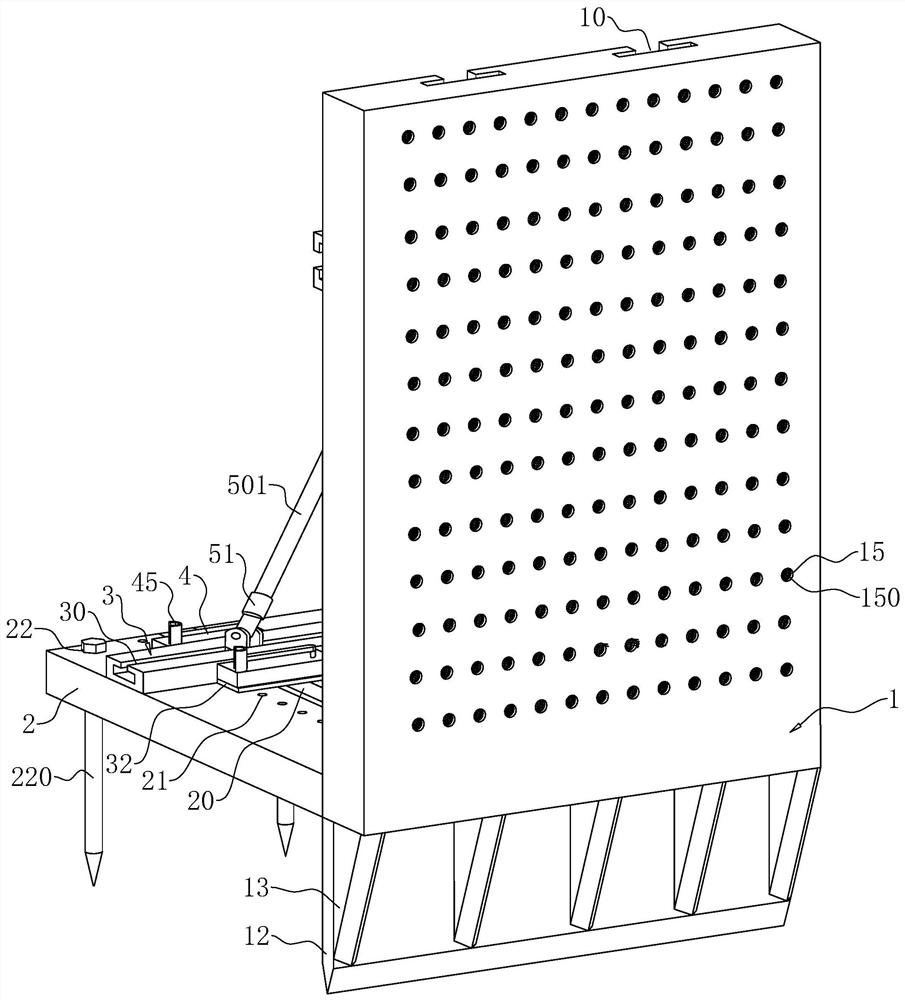

Foundation pit supporting structure and construction method thereof

ActiveCN111827299AEasy to installImprove recycling rateExcavationsArchitectural engineeringUltimate tensile strength

The invention relates to a foundation pit supporting structure and a construction method thereof. The foundation pit supporting structure comprises a first supporting plate, a second supporting plate,sliding rods, a limiting assembly and supporting assemblies. The moving direction of the sliding rod located on the first supporting plate is perpendicular to the second supporting plate. The movingdirection of the sliding rod located on the second supporting plate is perpendicular to the first supporting plate. Multiple first limiting grooves are formed in the first supporting plate. Multiple second limiting grooves are formed in the second supporting plate. Limiting plates are mounted on the sliding rods, and limiting holes are formed in the limiting plates. Limiting assemblies comprise limiting rods. Each supporting assembly comprises a supporting part and second sliding blocks, wherein one second sliding block is in sliding connection with the sliding rod located on the first supporting plate, and the other second sliding block is in sliding connection with the sliding rod located on the second supporting plate. The foundation pit supporting structure has the effect that the selfsupporting strength can be changed according to design requirements conveniently.

Owner:北京住总第一开发建设有限公司

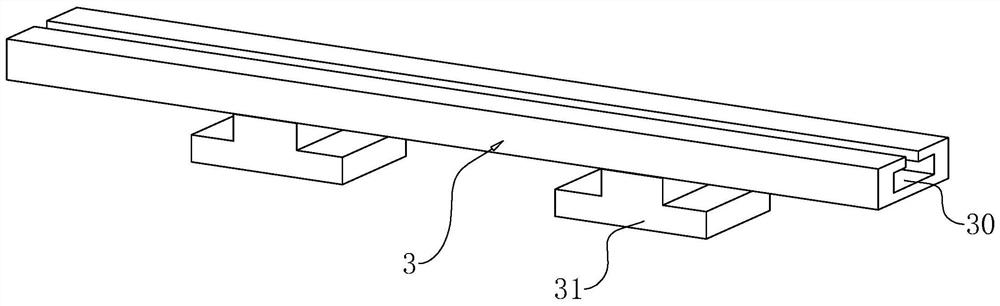

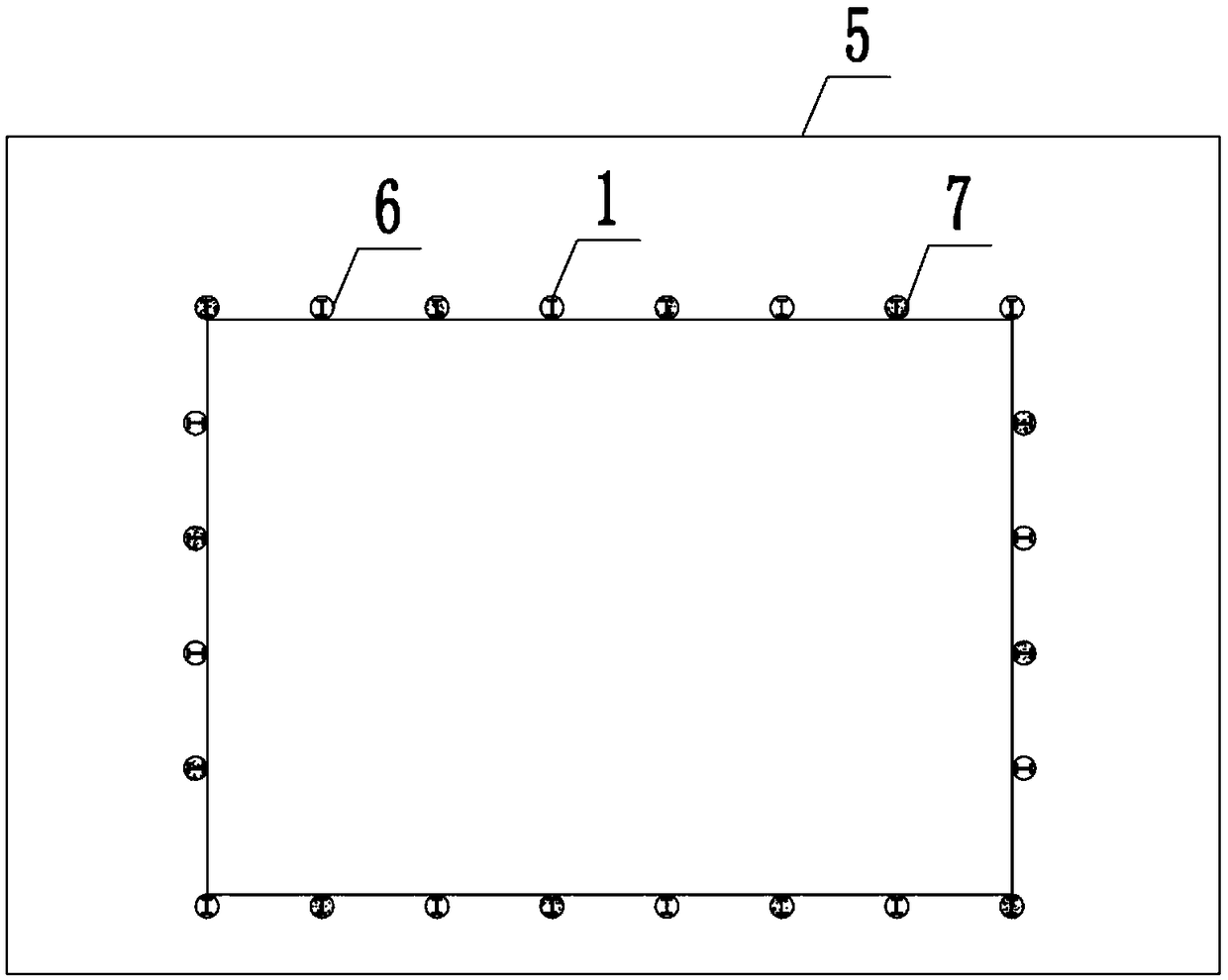

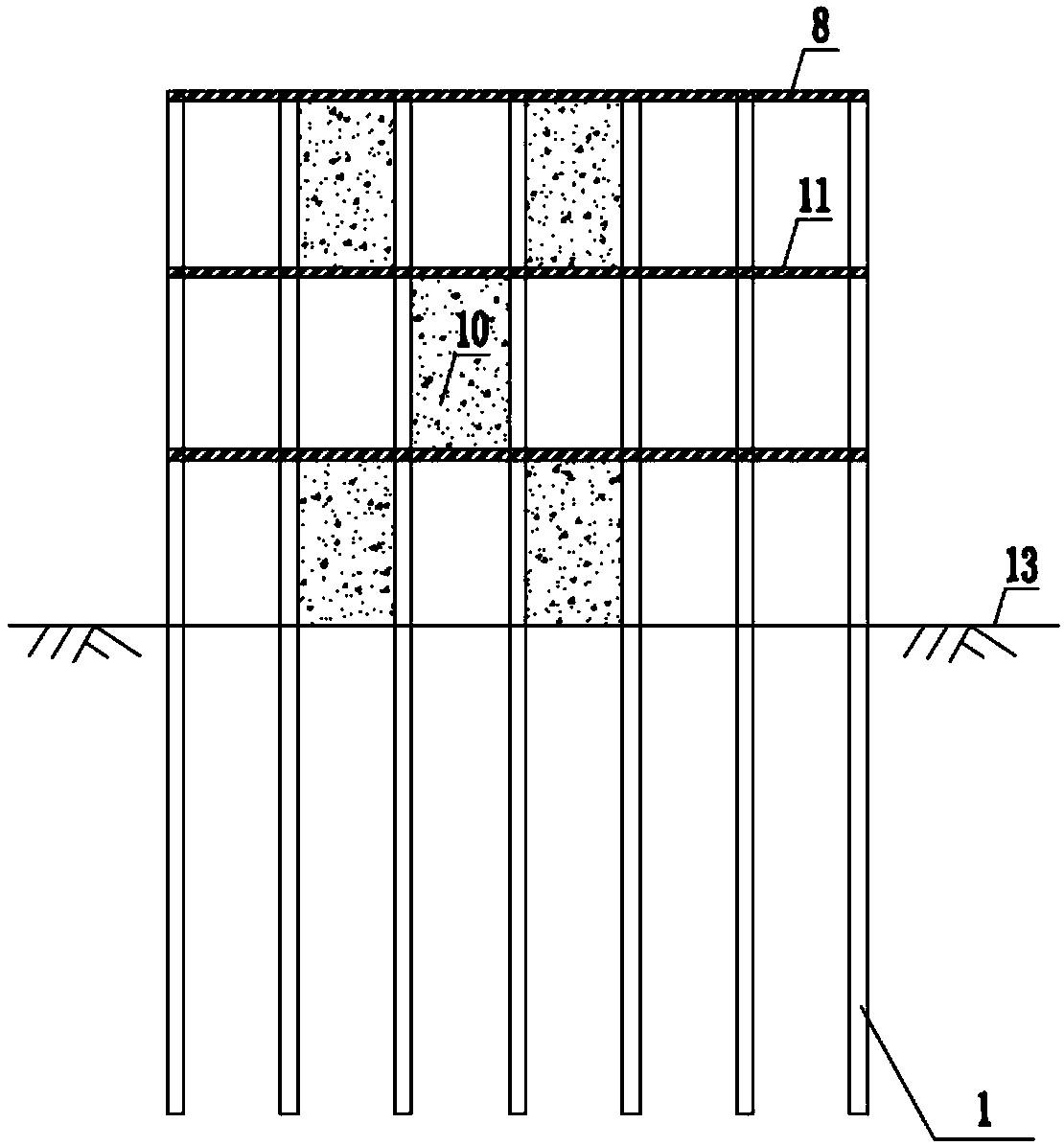

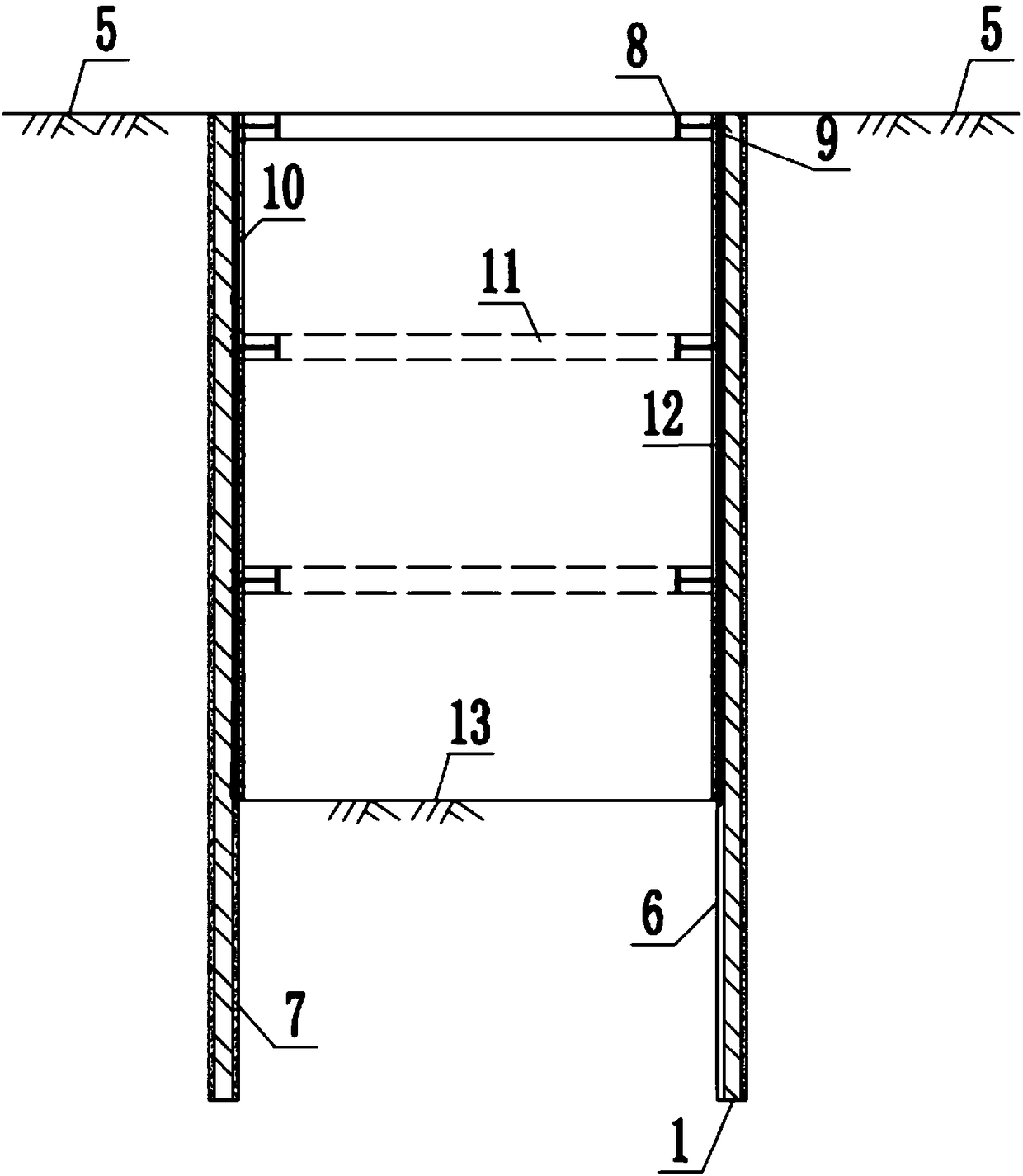

Design construction method of flexible compound fabricated recoverable rectangular working well supporting structure

InactiveCN109056746AMeet the positioning and installation accuracy requirementsAdvanced technologyExcavationsStructure systemHigh polymer

The invention relates to a standardized design construction method of a flexible compound fabricated recoverable rectangular working well supporting structure. The method comprises the following stepsthat (1) construction of minisize supporting piles is carried out; (2) construction of pile top crown beams; (3) a rectangular working well is excavated, panels and waist beams are installed, and high polymers are poured to side walls for sealing; (4) excavation is carried out layer by layer sequentially in the vertical direction, and the step (3) is carried out repeatedly till the design depth is met, that is, construction of the rectangular working well supporting structure is completed accordingly; and (5) after the supporting structure fulfills the usage function, the supporting structurerecovery work can be carried out as the backfilling work is started. Through standardized design construction of the established supporting structure system, one supporting structure can meet the construction requirement of most rectangular working wells in a region, the advantages of safety, reliability, quick and convenient construction, advanced technologies, high recoverability, superior economic indicators and the like are achieved, and the application and development prospects are considerable.

Owner:南方工程检测修复技术研究院

Cooling liquid recovery device of numerical control machine tool

ActiveCN109483315AImprove recycling rateAvoid accidental injuryMaintainance and safety accessoriesScrapEngineering

The invention relates to the technical field of machine tools, in particular to a cooling liquid recovery device of a numerical control machine tool. A cooling liquid filtering box is fixedly connected to a base through two supporting bases, a filtering plate sliding base is connected to the upper end of the cooling liquid filtering box in a sliding mode, a first-stage filtering assembly is slidably connected in the filter plate sliding base, a control assembly is rotationally connected to the upper end of the cooling liquid filtering box, and the control assembly is in meshed transmission connection with the filter plate sliding base; and a secondary filtering assembly is slidably connected to the middle end of the cooling liquid filtering tank, and a scrap iron cooling box is fixedly connected to the cooling liquid filtering tank. According to the device, a cooling liquid can be subjected to double filtration, the filtering effect is good, the cooling liquid can be discharged out forrecycling after cooling, so that an circulation use rate of the cooling liquid is improved, and a certain economic benefit is achieved; the first-stage filtering assembly can filtered out cutting scraps and solid particles in the cooling liquid and discharged into the scrap iron cooling box for cooling, and the high-temperature cutting scraps can be prevented from accidentally injuring workers.

Owner:广州通发智能装备股份有限公司

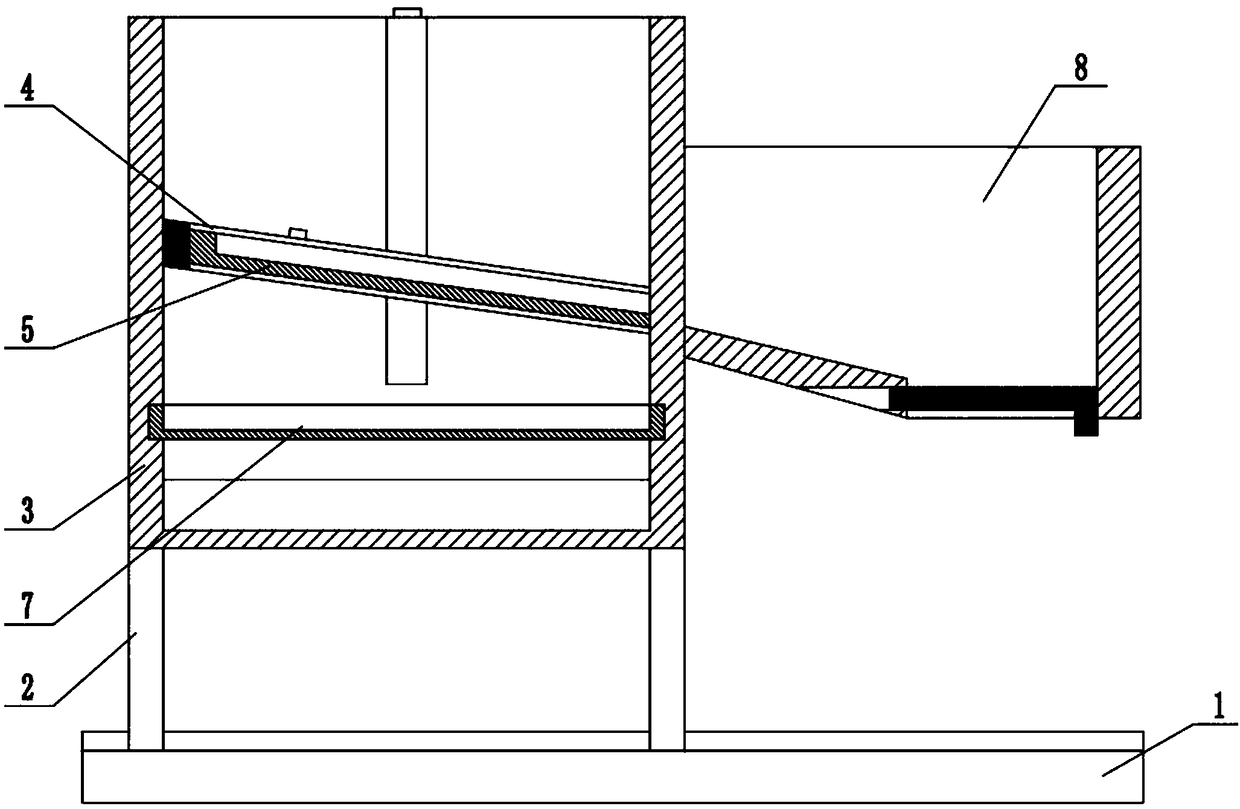

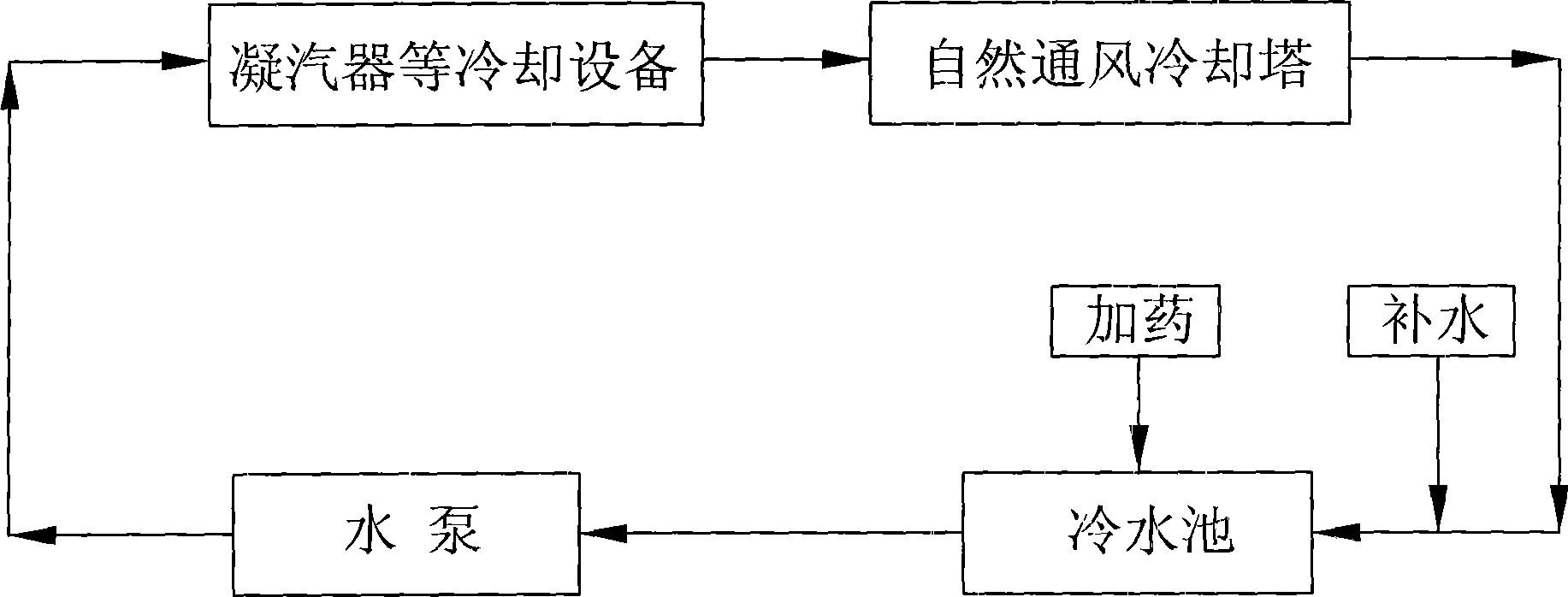

Scale and corrosion inhibitor formula for high concentration multiple operation of recirculated cooling water system and method of use thereof

InactiveCN101417838AImprove recycling rateReduce external drainage and make-up waterScale removal and water softening2-Methyl propaneChemistry

The invention relates to a scale and corrosion inhibiter formulation used for the high concentration multiple operation of a circulating cooling water system, which comprises the raw materials with the following weight percent contents: 14.0-16.0 percent of 2-phosphonate butane-1, 2, 4-tricarboxylic acid, 7.0-9.0 percent of hydroxyl ethylidene diphosphonic acid, 11.0-13.0 percent of ZnSO4.7H2O, 1.0-2.0 percent of benzotriazole, 2.0-4.0 percent of calgon (NaPO3) 6, 1.0-3.0 H2SO4, 29.0-31.0 percent of acrylic acid / 2- acrylamide-2-methyl propane sulfonic acid polymer and water as the rest. The inhibiter has the advantages of solving the problems of corrosion and scale formation of the pipeline and equipment in the operating process of the circulating cooling water system of the electric power plant, improving the cyclic utilization rate of the circulating cooling water system, reducing the external water discharge and supplementary water, and avoiding the hazards of low-hardness and low-alkalinity water on the system under the condition of high concentration multiple operation.

Owner:韶关市雅鲁环保实业有限公司

Large-scale steel cylinder cofferdam structure

The invention discloses a large-scale steel cylinder cofferdam structure, belonging to the technical field of cofferdam structures. The large-scale steel cylinder cofferdam structure is characterized by comprising a steel-structure cylinder body, wherein a plurality of vertical reinforcing ribs are distributed along the circumferential direction of the inner wall of the cylinder body at intervals; a plurality of transverse reinforcing structures are arranged on the inner wall of the exposed part of the cylinder body along the axial direction at intervals; the inner diameter of the cylinder is 15-30 meters. The large-scale steel cylinder cofferdam structure is reasonable in structure and high in construction efficiency, can be circularly used and is used for constructing offshore engineering structures such as bridge bearing platforms.

Owner:CCCC FHDI ENG

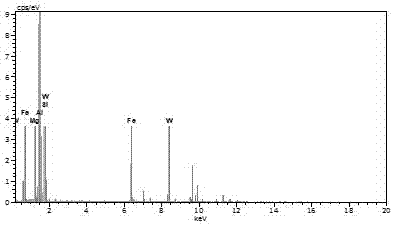

Method for renewable aluminum alloy iron-rich phase metamorphism

The invention discloses a method for renewable aluminum alloy iron-rich phase metamorphism. The invention adopts the technical scheme that the method comprises the steps of melting renewable aluminum alloy furnace burdens, and rising temperature to 740 to 800 DEG C; pressing W-containing intermediate alloy into a melt body, and then carrying out intensively stirring for 10 to 30 min, wherein the amount of W added into the melt body accounts for 0.05 to 0.3 weight percent of the mass of the melt body; after stirring, adding a refining agent at 730 to 760 DEG C, and then carrying out stirring, degassing, refining and slagging off; and carrying out stilling for 5 to 10 min with the temperature kept, and then carrying out discharging and casting. By utilizing the method, a form of an iron-rich phase can be improved, a needle-shaped iron-rich phase is eliminated, and a bone-shaped or Chinese script type iron-rich phase is refined, so that a renewable aluminum alloy structure is improved, a mechanical property and a processing property of the renewable aluminum alloy are improved, and the recovery rate of the aluminum alloy is remarkably improved.

Owner:ZHONGBEI UNIV

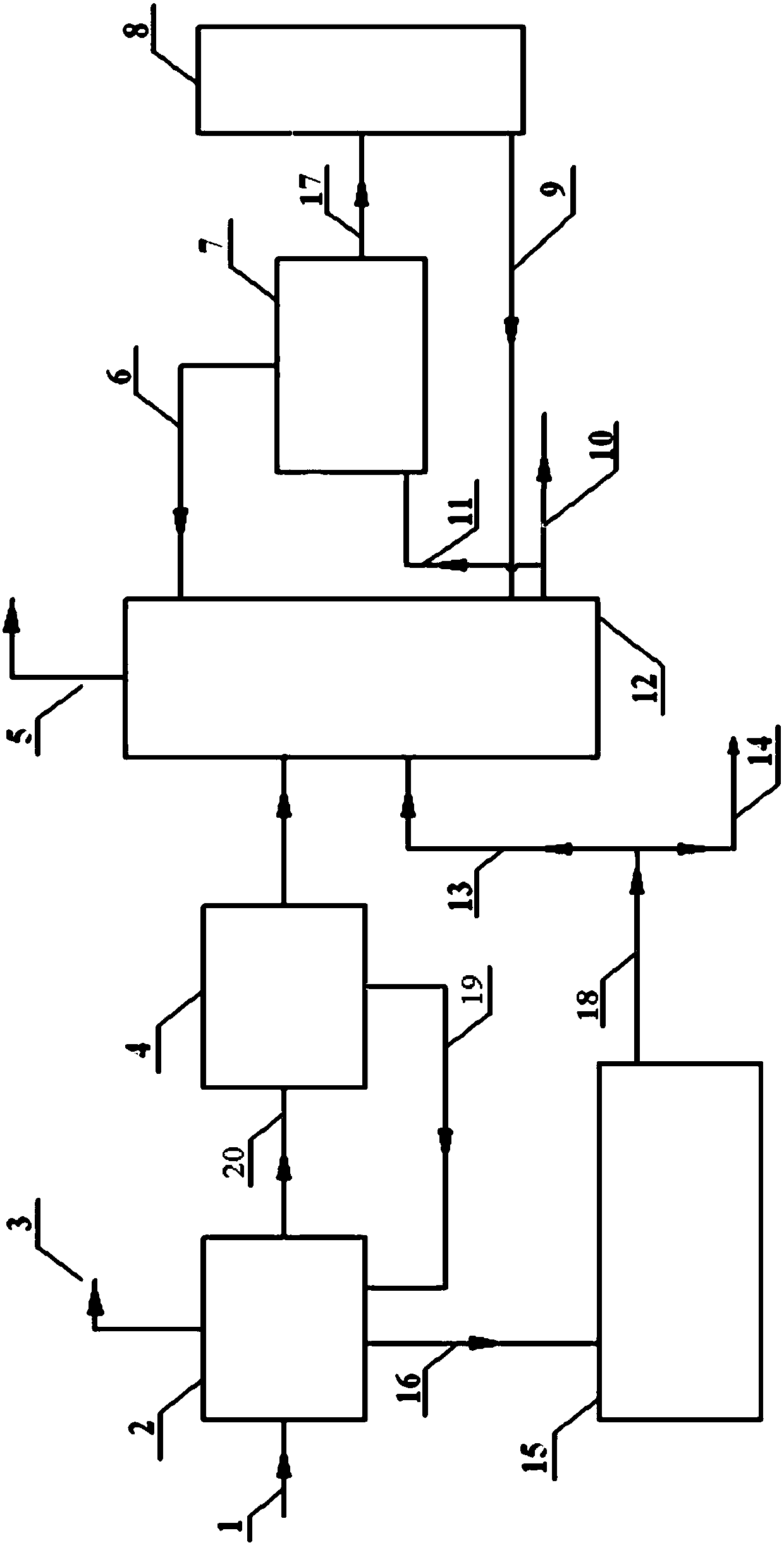

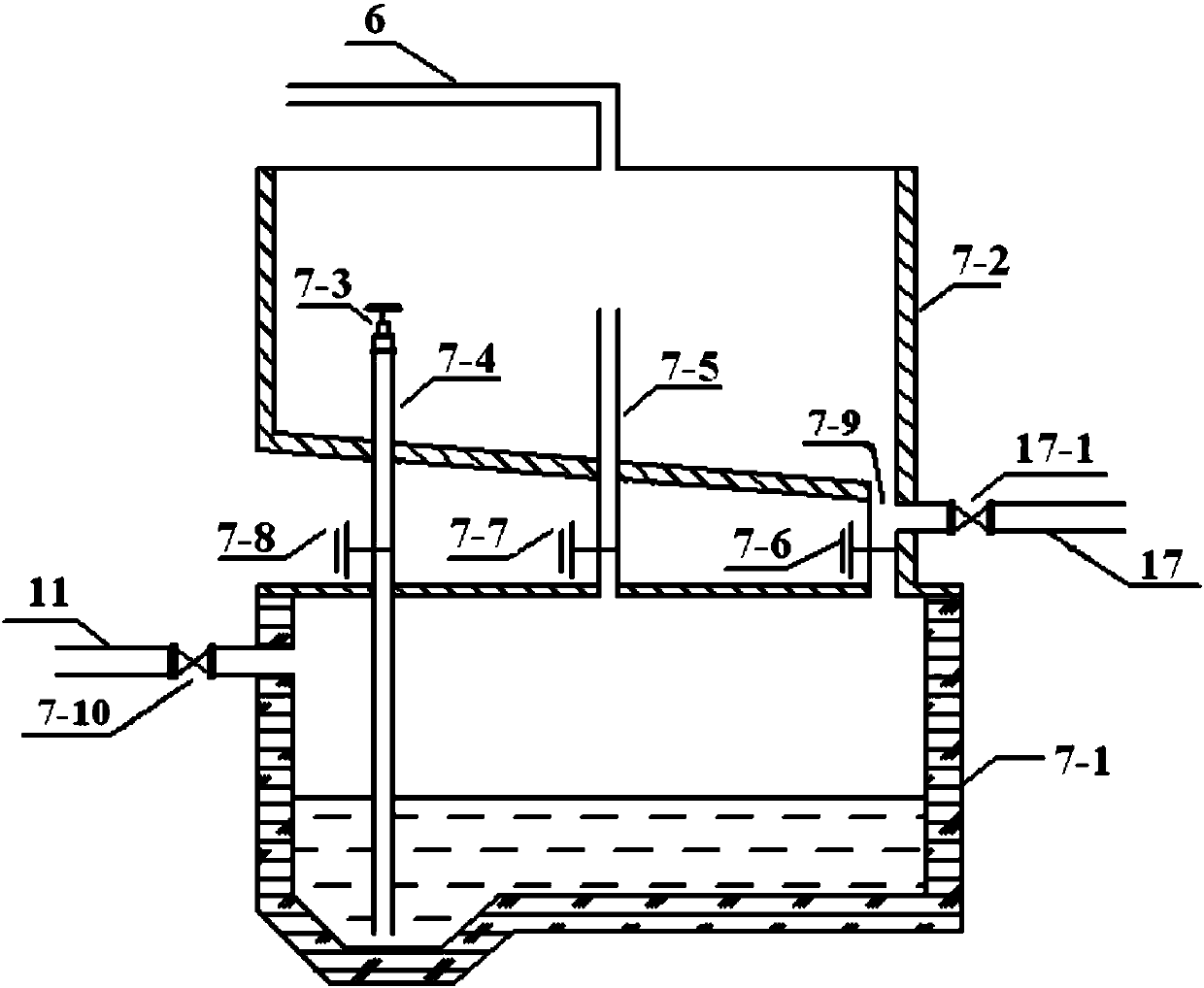

Device for treating biurea condensation sewage generated from preparation of ADC (Azodicarbonamide) foaming agent with urea method and use method of device

ActiveCN106698561AImprove recycling rateWater contaminantsDispersed particle separationBiureaChemical oxygen demand

The invention discloses a device for treating biurea condensation sewage generated from preparation of an ADC (Azodicarbonamide) foaming agent with a urea method and a use method of the device, relates to a sewage treatment device and a use method thereof, and aims to solve the problem that COD (Chemical Oxygen Demand) in effluent of the biurea condensation sewage generated when the ADC foaming agent is prepared by using the urea method is hard to meet standards. The device consists of an evaporation crystallizer, a high-temperature salt bath decomposition and gas absorption system and a pressure hydrolysis-flash evaporation system. The use method disclosed by the invention comprises the following steps: feeding sewage into the evaporation crystallizer, performing cooling crystallization on concentrated liquid, feeding into an ammonia distillation tower for ammonia distillation, discharging the bottom liquid of the ammonia distillation tower into the pressure hydrolysis-flash evaporation system for decomposition treatment, and feeding salt generated from evaporation crystallization into the high-temperature salt bath decomposition and gas absorption system for purification treatment. By adopting the device and the use method, urea and hydrazine hydrate of the ADC condensation sewage can be recycled, sodium chloride can be purified, the water circulation utilization rate can be increased, and standards of indexes such as COD in the effluent can be met.

Owner:HARBIN ENG UNIV

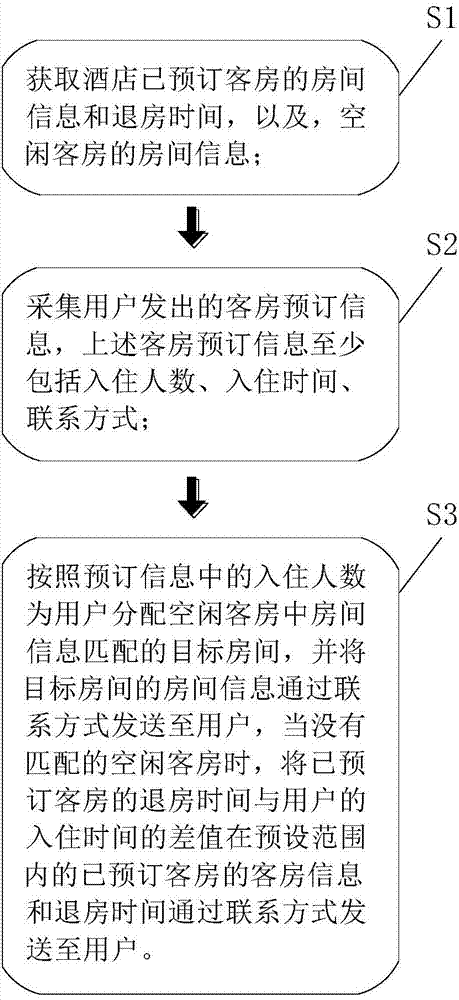

Intelligent reservation method of hotel rooms

The invention discloses a method for intelligently booking a hotel room, comprising the following steps: S1, acquiring room information and check-out time of reserved rooms in the hotel, and room information of vacant guest rooms; S2, collecting room reservation information sent by users, The above room reservation information includes at least the number of occupants, check-in time, and contact information; S3. Allocate vacant rooms to the user according to the reservation information, and send the room information of the target room to the user. When there is no matching vacant room, the reserved room will be The room information and check-out time of the reserved rooms for which the difference between the check-out time and the check-in time of the user is within a preset range are sent to the user. The present invention proposes an intelligent reservation method for hotel guest rooms. The method comprehensively collects room reservation information sent by users, and selects target rooms for users according to the room reservation information sent by users, which improves the pertinence of the selection of target rooms and improves the User satisfaction with booking results.

Owner:合肥昊思云科科技有限公司

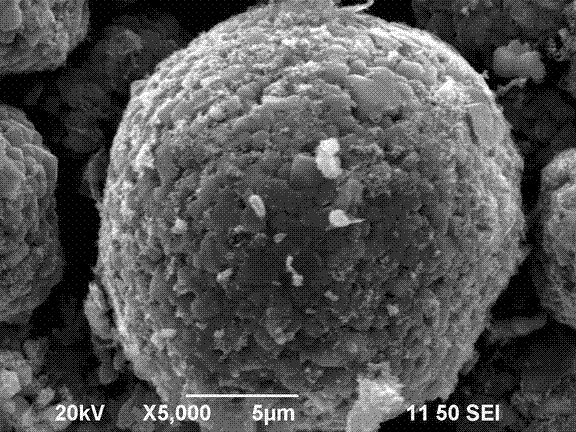

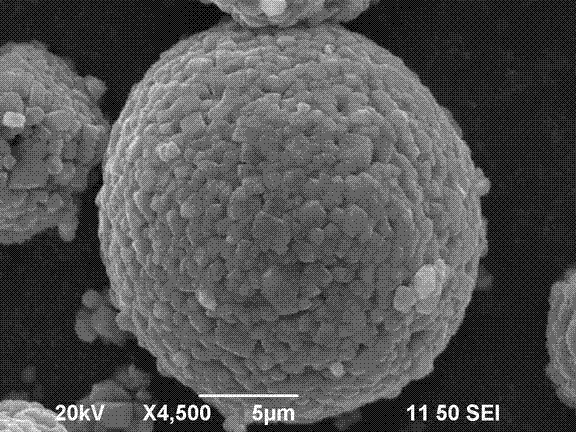

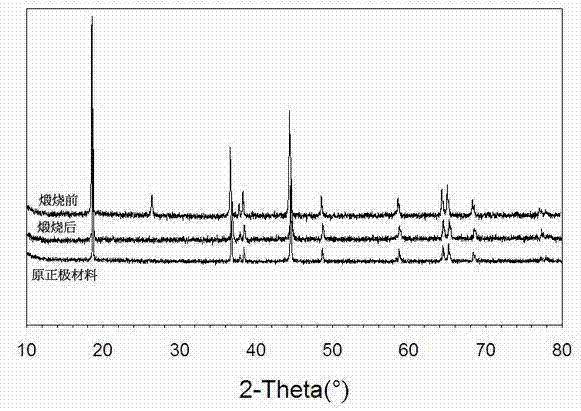

Method for recycling active substances from waste pieces of positive poles of lithium ion batteries

InactiveCN103618119AReduce crushing processHigh viscosityWaste accumulators reclaimingBattery recyclingPhysical chemistryLithium-ion battery

The invention discloses a method for recycling active substances from waste pieces of positive poles of lithium ion batteries. The method comprises the steps of (1) putting the waste pieces of the positive poles of the lithium ion batteries into a swelling agent, wherein the waste pieces of the positive poles is in complete contact with the swelling agent at 19-189 DEG C for 0.1-36 hours; (2) screening or sorting out aluminum foil sheets, filtering, settling, and screening or centrifuging the swelling agent mixture containing active substances, and washing to separate solid active substances and a liquid swelling agent out; (3) drying the solid active substances obtained in step (2) at 40-250 DEG C, adding a lithium source into the dried solid active substances, mixing uniformly, and then calcining by three steps; and (4) after calcining, naturally cooling down a furnace, and then collecting solid substances, namely regenerated positive pole active substances. The regenerated positive pole material recycled by the method has the structure, appearance and component same as that of a material for manufacturing the positive pole of a lithium ion battery, and has stable electrochemical performance.

Owner:HENAN NORMAL UNIV +1

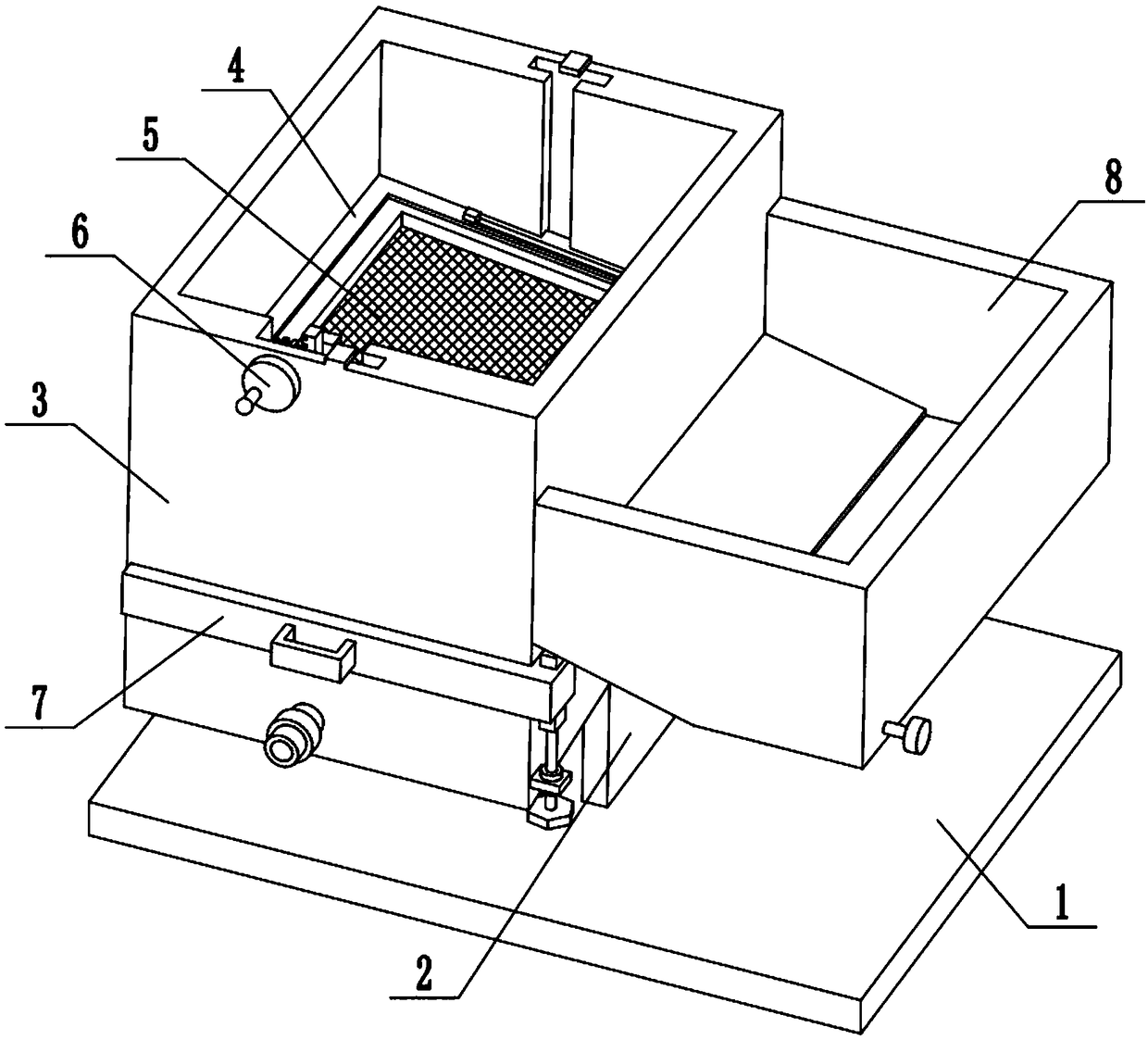

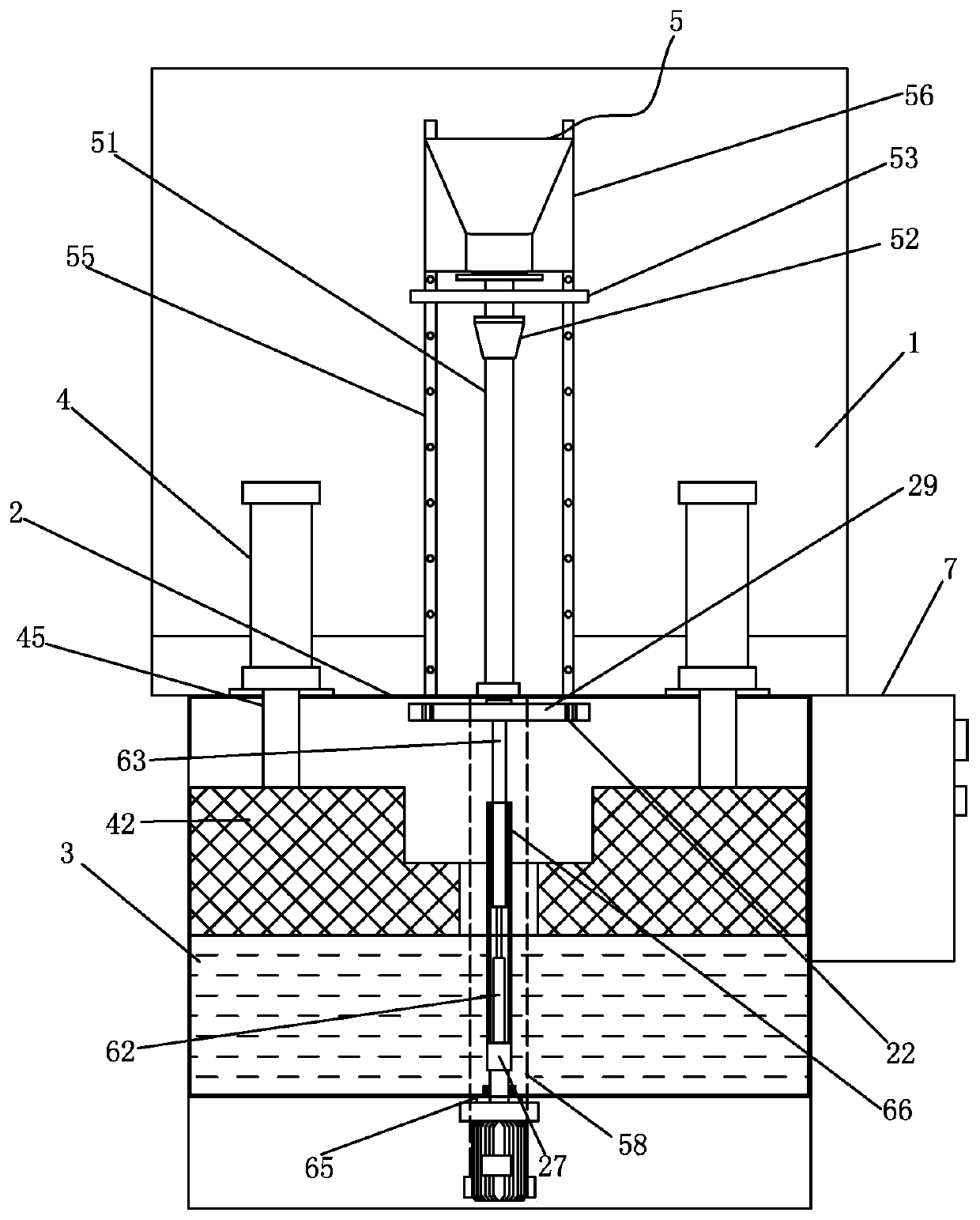

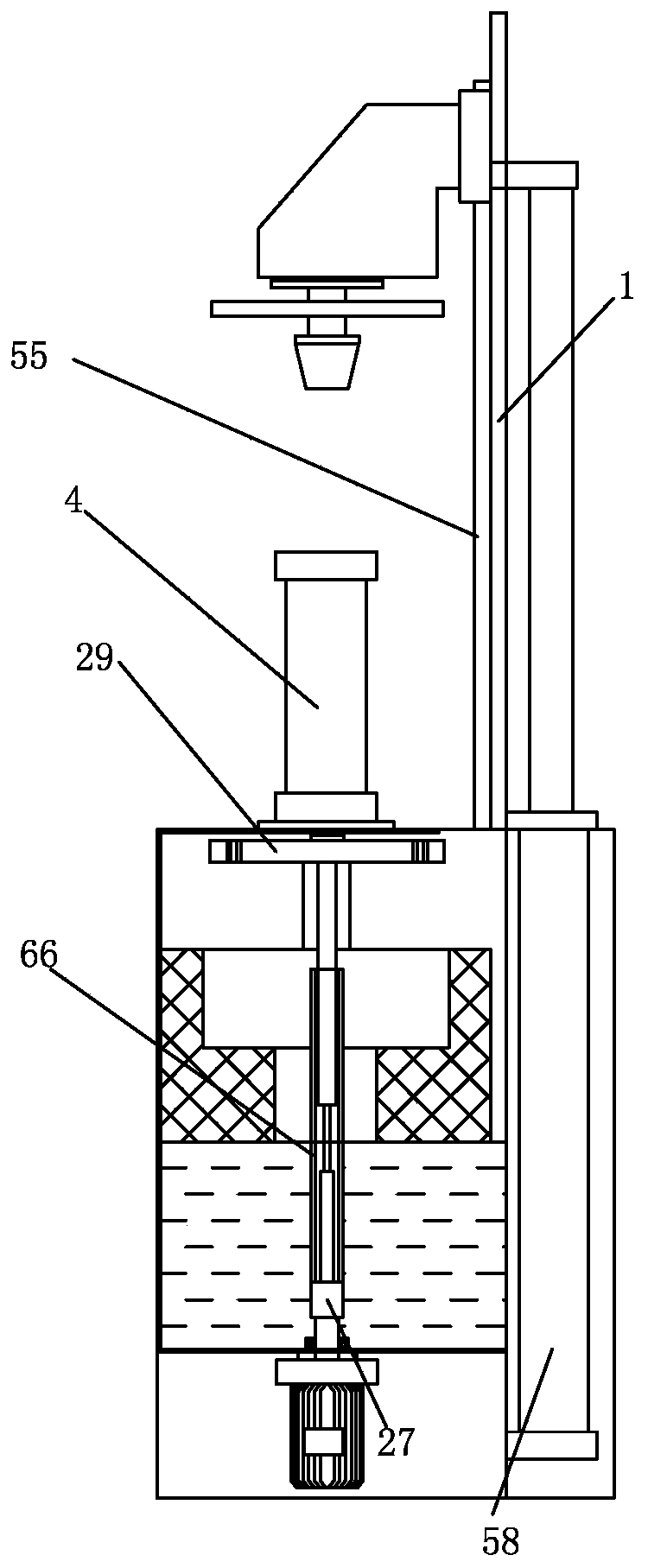

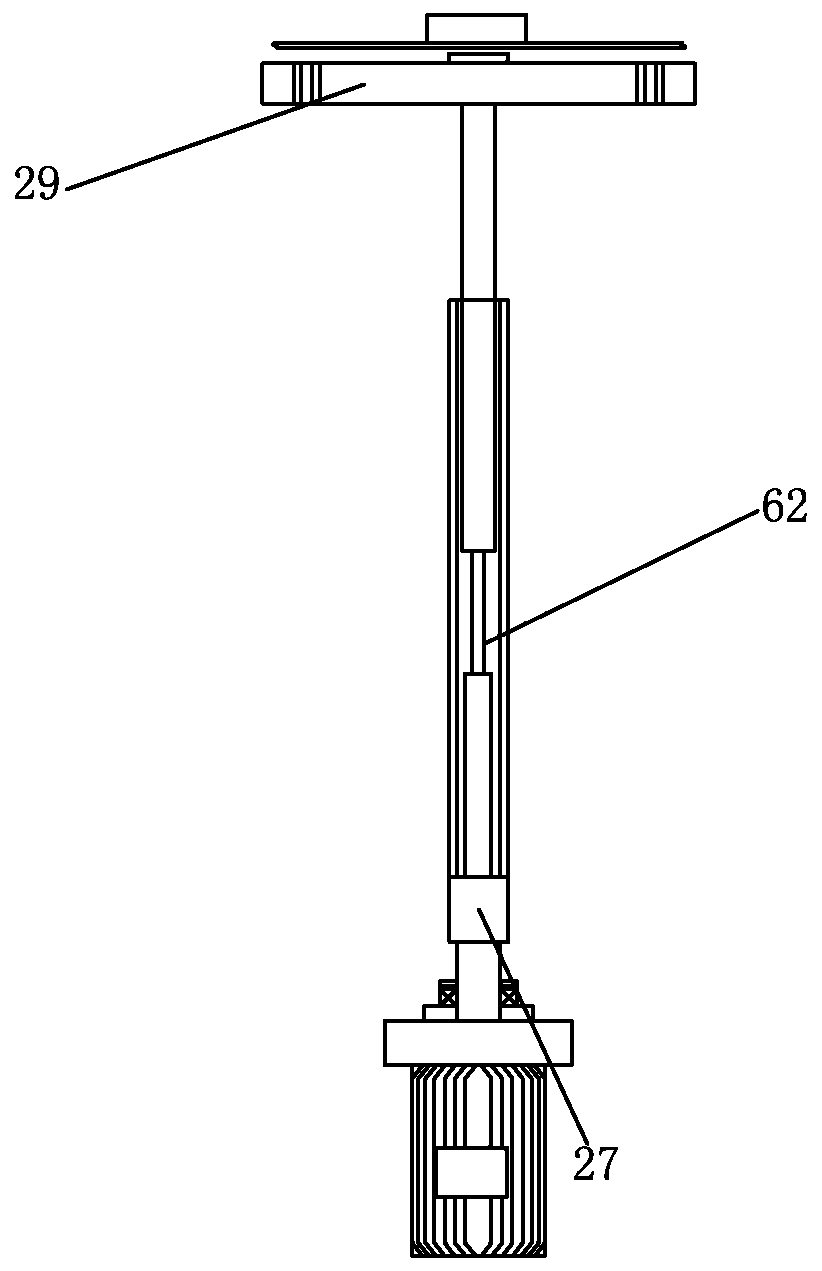

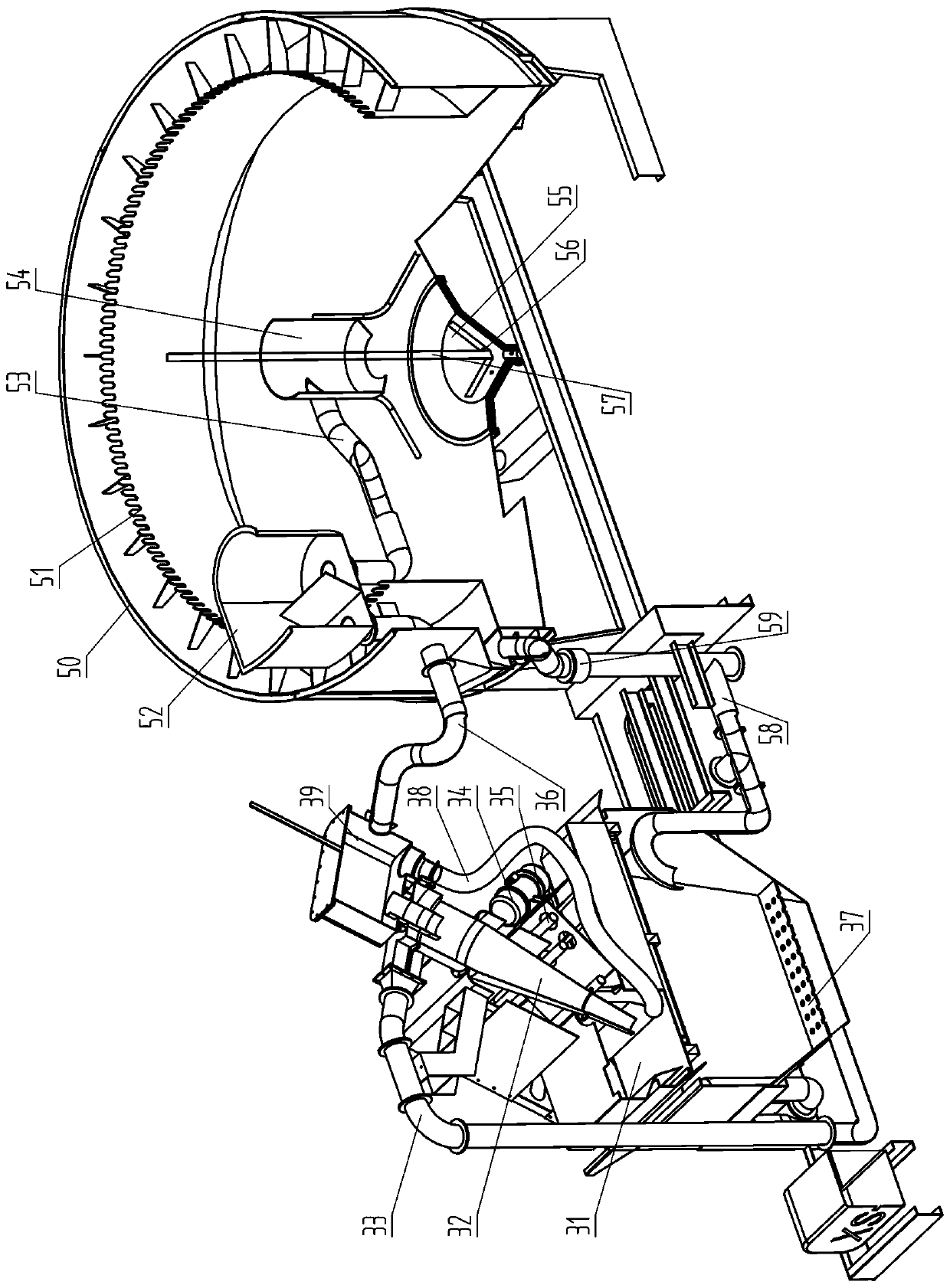

Mechanical component oil dipping and spinning-dry device

ActiveCN109876995AEffective anti-rustImprove recycling rateLiquid surface applicatorsCoatingsHydraulic cylinderMechanical components

A mechanical component oil dipping and spinning-dry device comprises a frame. The frame is provided with a work panel, an oil tank and compression air cylinders or hydraulic cylinders or electric pushrods. The work panel is arranged on the top of the oil tank. The frame is arranged on the rear side portion of the oil tank. A workpiece hole is formed in the center of the work panel of the oil tank. A rotation disc is arranged below the workpiece hole. A motor is arranged at the bottom of the oil tank. The bottom of the rotation disc is connected with the top end of a rotation shaft. The bottomend of the rotation shaft is connected with a motor output shaft. The mechanical component oil dipping and spinning-dry device is reasonable in structure and low in cost, the rotation shaft of the mechanical component oil dipping and spinning-dry device can rotate and spin surplus oil on the workpiece dry, the cyclic utilization rate of the oil is increased, and cost is saved; and the phenomenonof uneven oil coating is avoided, and rust prevention can be effectively conducted on the workpiece.

Owner:刘忠义

Environment-friendly preparation method of plastic color master batch

InactiveCN107746466AImprove recycling rateImprove diffusivityBulk chemical productionHazardous substanceWater resources

The invention discloses an environment-friendly preparation method of a plastic color master batch. The preparation method is characterized in that an inorganic pigment is dissolved in a supercriticalfluid; then the supercritical mixed solution is mixed with a resin carrier; the supercritical mixed solution permeates into a plurality of hole structures of the resin carrier; the inorganic pigmentparticles are gradually deposited in the carrier through reduced pressure expansion; and finally, separating and drying are performed for obtaining the master batch. The preparation method provided bythe invention has the following advantages that no solvent is involved in the whole preparation process, and no harmful substance is discharged, so that the problem that industrial three wastes (waste gas, waste water and industrial residue) are difficult to treat is fundamentally solved, and the atmosphere and water resources are effectively protected; the natural utilization rate is high, and the recycling rate of carbon dioxide can reach 90% or more; surfactants such a dispersing agent, a detergent and the like are not needed in the preparation process; and the dyeing production efficiencyis high, the supercritical carbon dioxide fluid is low in viscosity, large in diffusion coefficient, and small in diffusion boundary layer, so that the dissolved monomolecular inorganic pigment can rapidly permeate into gaps of the carrier resin, the coloring rate is far larger than coloring rates of traditional systems, the production period is greatly shortened, and the production efficiency isimproved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

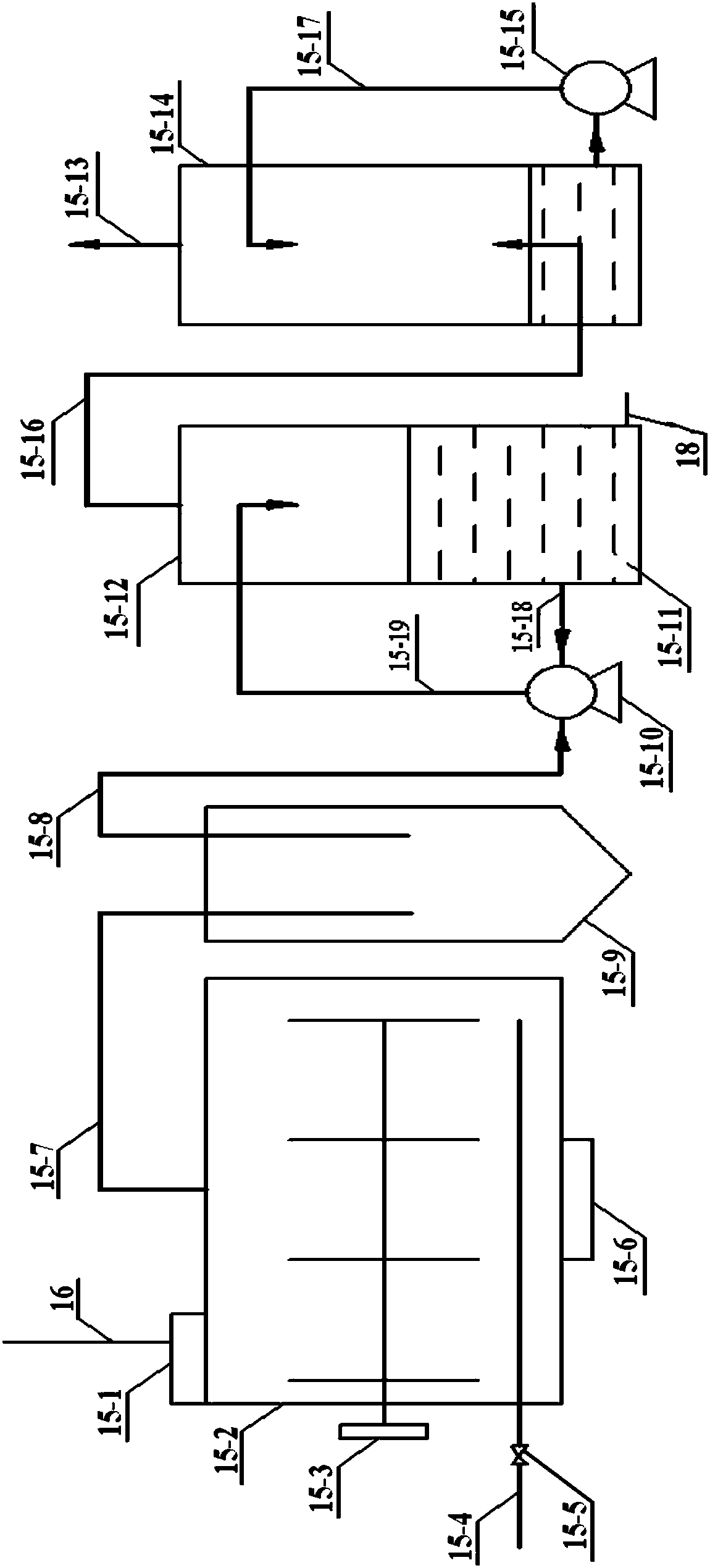

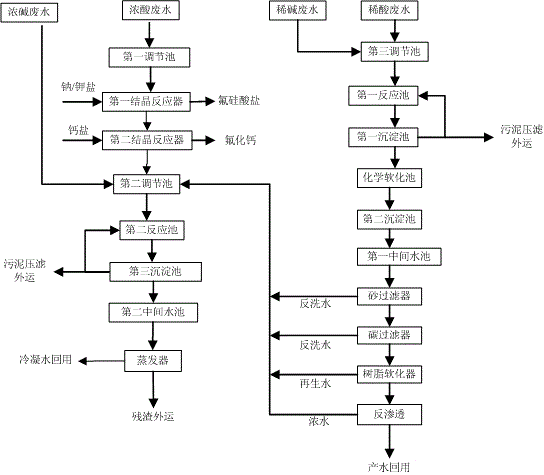

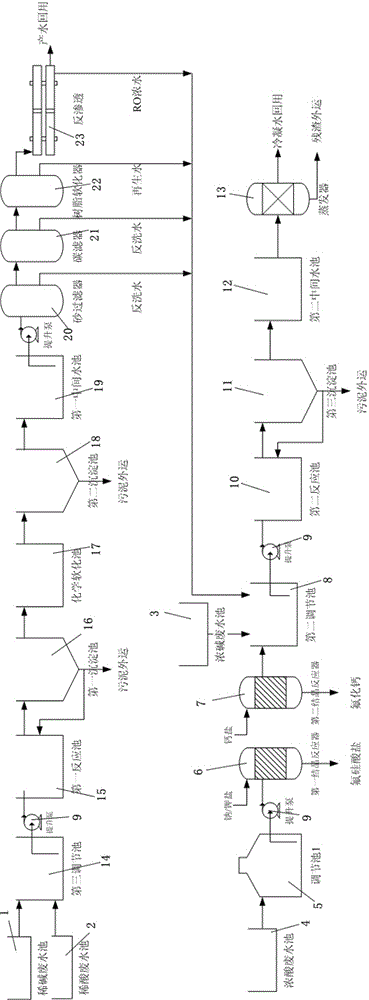

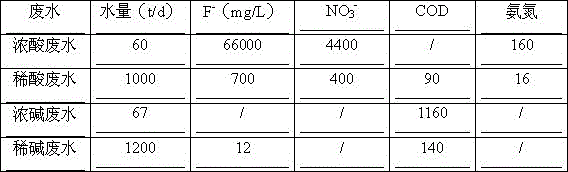

Process and system for resourcing and recycling fluorine-containing wastewater in photovoltaic industry

ActiveCN106746113AThe process is highly targetedReduce processing difficultyCalcium/strontium/barium fluoridesScale removal and water softeningPhotovoltaic industryActivated carbon filtration

The invention provides a process for resourcing and recycling fluorine-containing wastewater in the photovoltaic industry. The process comprises the following steps: sorting and collecting concentrated acid wastewater, concentrated alkali wastewater, diluted acid wastewater and diluted alkali wastewater; adding sodium salt or potassium salt into the concentrated acid wastewater according to the concentration of fluorosilicate ions of the concentrated acid wastewater to perform crystallizing reaction to obtain fluosilicate, and adding calcium salt into the concentrated acid wastewater according to the fluorinion concentration of the concentrated acid wastewater to perform crystallizing reaction to obtain calcium fluoride; removing fluorine from the diluted alkali wastewater and diluted acid wastewater, feeding into a precipitation tank for precipitating treatment, performing chemical softening treatment, sequentially passing through a sand filter, an activated carbon filter, a resin softener and a reverse osmosis device to obtain produced water; crystallizing the concentrated acid wastewater, feeding system effluent and concentrated alkali wastewater into a reaction tank for fluorine removal treatment, feeding into the precipitation tank for precipitating treatment, and producing condensed water through an evaporator. Furthermore, the invention provides a system for resourcing and recycling the fluorine-containing wastewater in the photovoltaic industry.

Owner:CHINA ELECTRONICS INNOVATION ENVIRONMENTAL TECH CO LTD +1

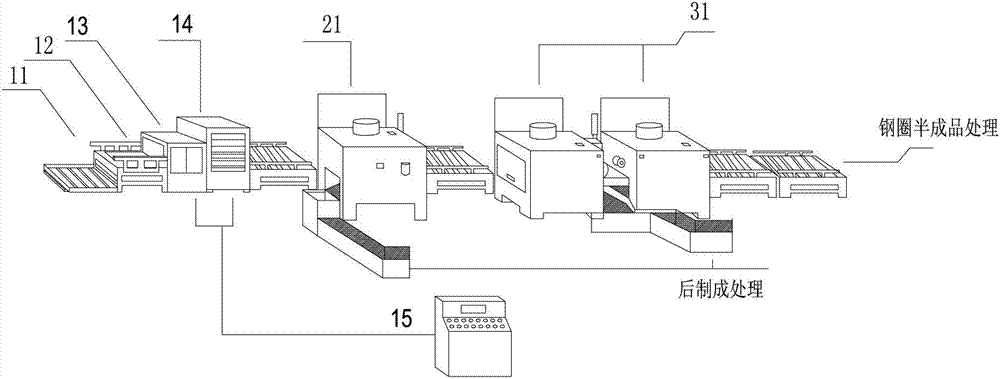

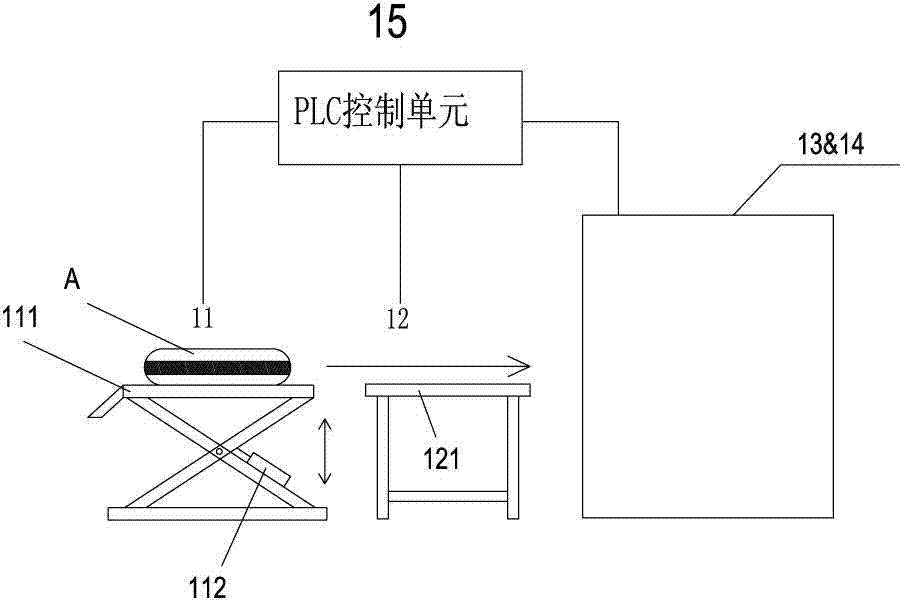

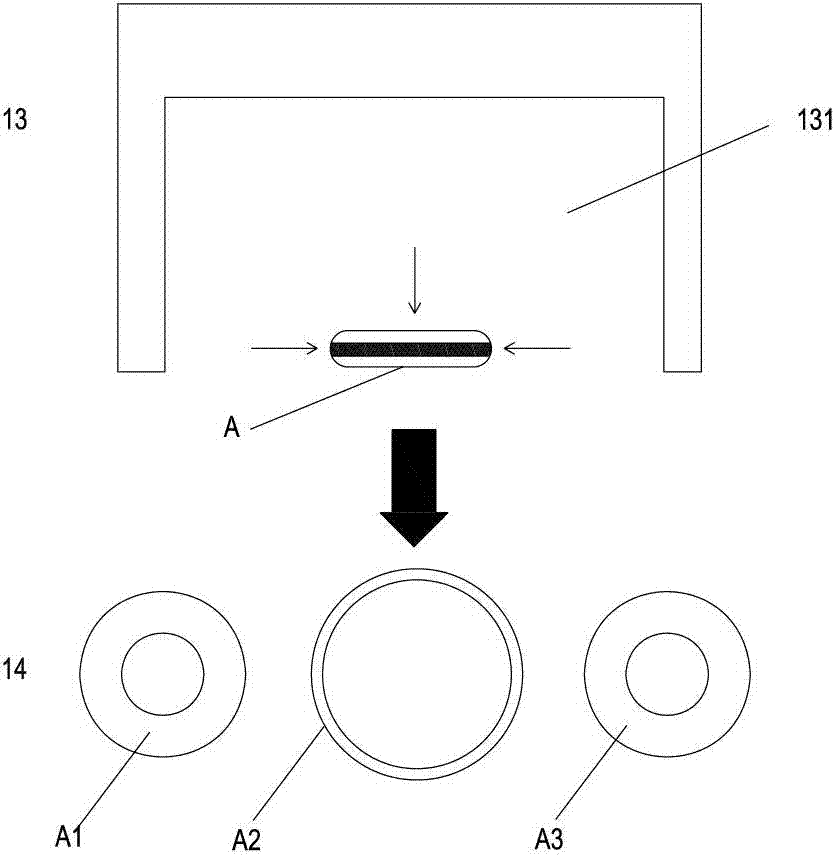

Clearer production process and preparation system for junked tire

ActiveCN102765146ASolve recycling problemsFull stripping operation time shortenedPlastic recyclingAfter treatmentEngineering

The invention discloses a clearer production process and a preparation system for junked tire. The process mainly comprises the following steps: (1) collecting junked tires as raw materials; (2) weighing the raw materials, and automatically recording weight and dimension; (3) cleaning the raw materials by treating each tire by a low-pressure multi-direction water curtain; (4) cutting raw material: after treatment by the low-pressure multi-direction water curtain, selecting a processing efficiency mode, aligning with a set center line and sending the tires one by one into a semi-closed three unit cutting and processing intelligent system; and after the intelligent positioning, cutting each tire into three independent units through a PLC model; (5) pulverizing the raw materials; and (6) treating semi-finished products. According to the invention, each junked tire is directly cut into a ring tire and two sidewalls to form three units. The process has no requirement on tires, simplifies the key process steps and reduces machines; the process is different from prior art, in which a cover tire surface is first peeled off, and then an inner tube is treated; therefore, the process provided by the invention greatly improves the processing capacity and efficiency.

Owner:YATEFEI XIAMEN RUBBER SCI & TECH

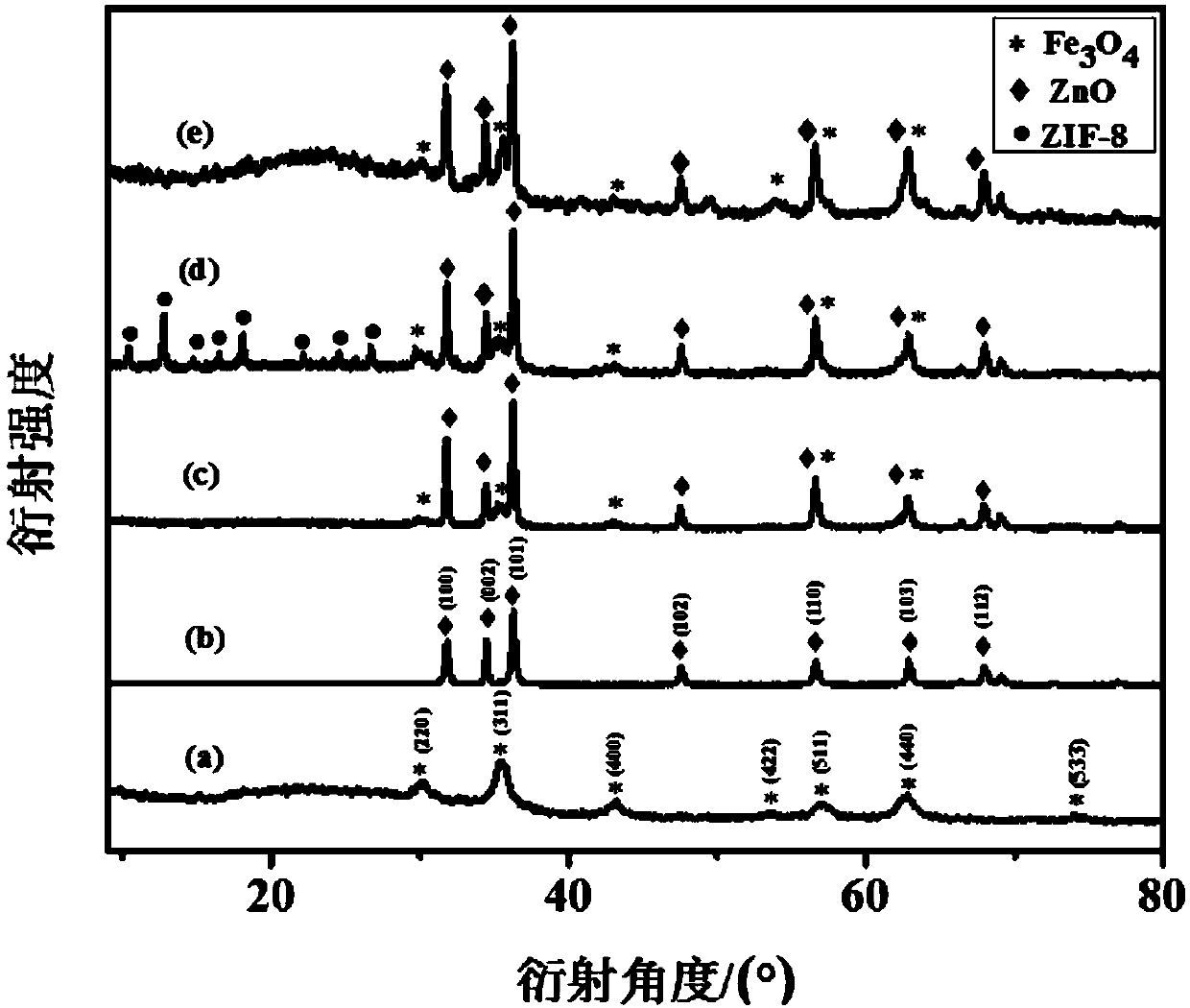

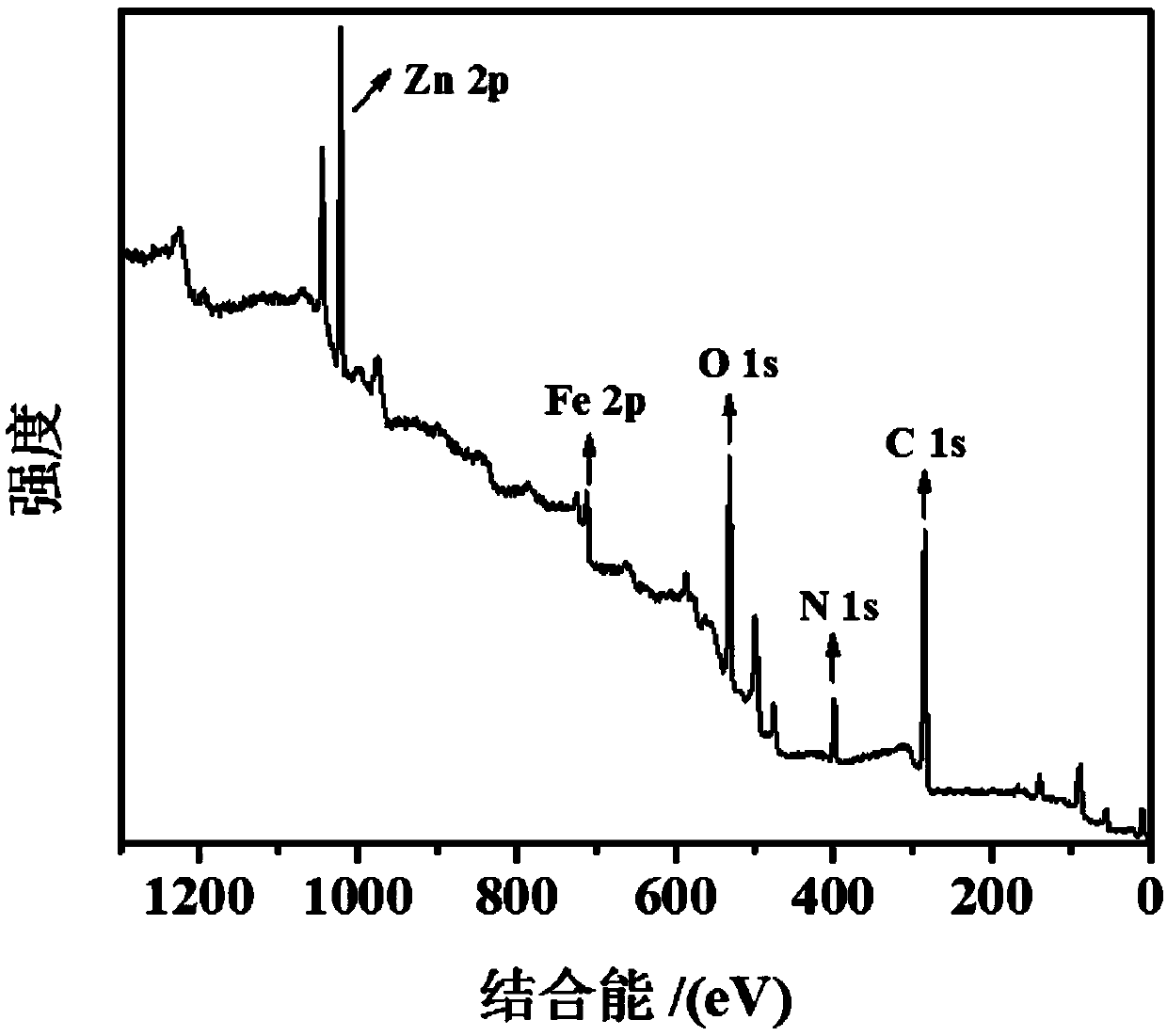

Preparation method of Fe3O4@ZnO@N-C composite photocatalysis material

InactiveCN109675607AImprove photocatalytic degradation performanceEasy to usePhysical/chemical process catalystsWater/sewage treatment by irradiationMetal-organic frameworkSewage

The invention discloses a preparation method of a Fe3O4@ZnO@N-C composite photocatalysis material. The preparation method comprises the steps of taking Fe3O4 magnetic nanoparticle in a controllable submicron size as a carrier, preparing a Fe3O4@ZnO composite catalyst, depositing a metal organic framework material ZIF-8 on an outer layer of Fe3O4@ZnO by a complexing effect between Zn2+ and di-methylimidazole to prepare a Fe3O4@ZnO@ZIF-8 composite with a multiple core-shell structure, and converting ZIF-8 into ZnO and nitrogen doped carbon through a heat treatment technology. The prepared composite has good photocatalytic degradation performance and stable recycling performance; a recovery rate is increased; and the composition of a photo-induced electron-hole pair is reduced. The prepared composite can be used for degrading organic pollutants in sewage and increasing photocatalytic degradation efficiency and a recycling rate.

Owner:SHANGHAI UNIV

Biochemical denitrifying method for wastewater

ActiveCN104445833AImprove denitrification efficiencyImprove mud ageWater treatment compoundsSpecific water treatment objectivesTotal nitrogenOxygen

The invention dislcoses a biochemical denitrifying method for wastewater. According to the biochemical denitrifying method, an improved A / O biochemical denitrifying process is combined with a chemical method (namely a zeolite adsorption ammonia nitrogen method) to efficiently remove ammonia nitrogen in wastewater, denitrification liquid flowing from an anoxic denitrification tank enters an aerobic nitrification tank to form internal circulation, and residual denitrification liquid directly enters a sedimentation tank to be subjected to solid-liquid separation; by combining ionic adsorption with biologic regeneration, total nitrogen in effluent water is less than or equal to 5mg / L, the removal rate of total nitrogen is higher than 90%, and thus the requirement that total nitrogen in effluent water of a chemical industrial park of a Tai Lake area is superior to the standard A of 'discharge standard of pollutants for municipal wastewater treatment plant' (GB18918-2002) is stably met.

Owner:江苏艾特克环境工程设计研究院有限公司

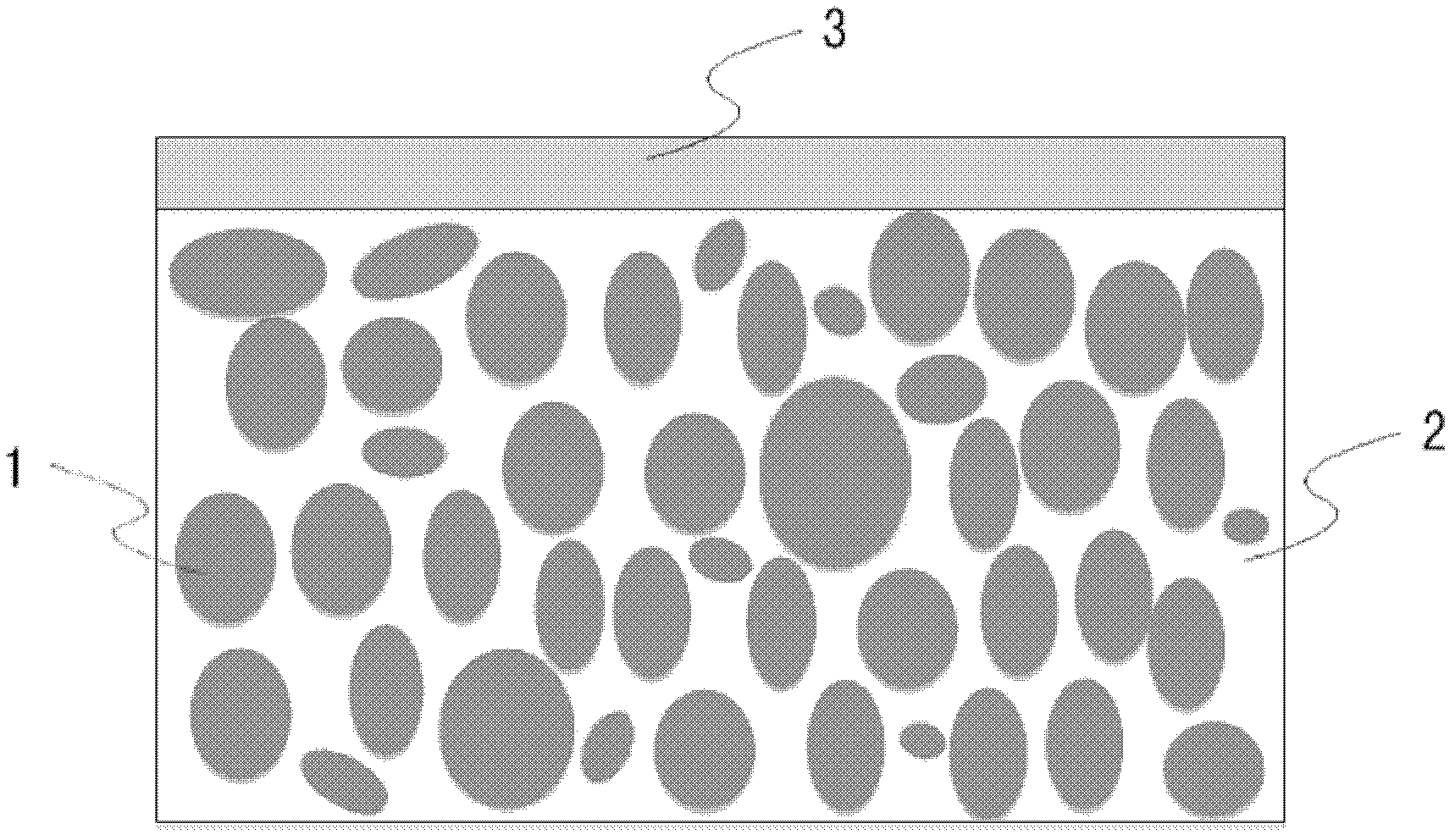

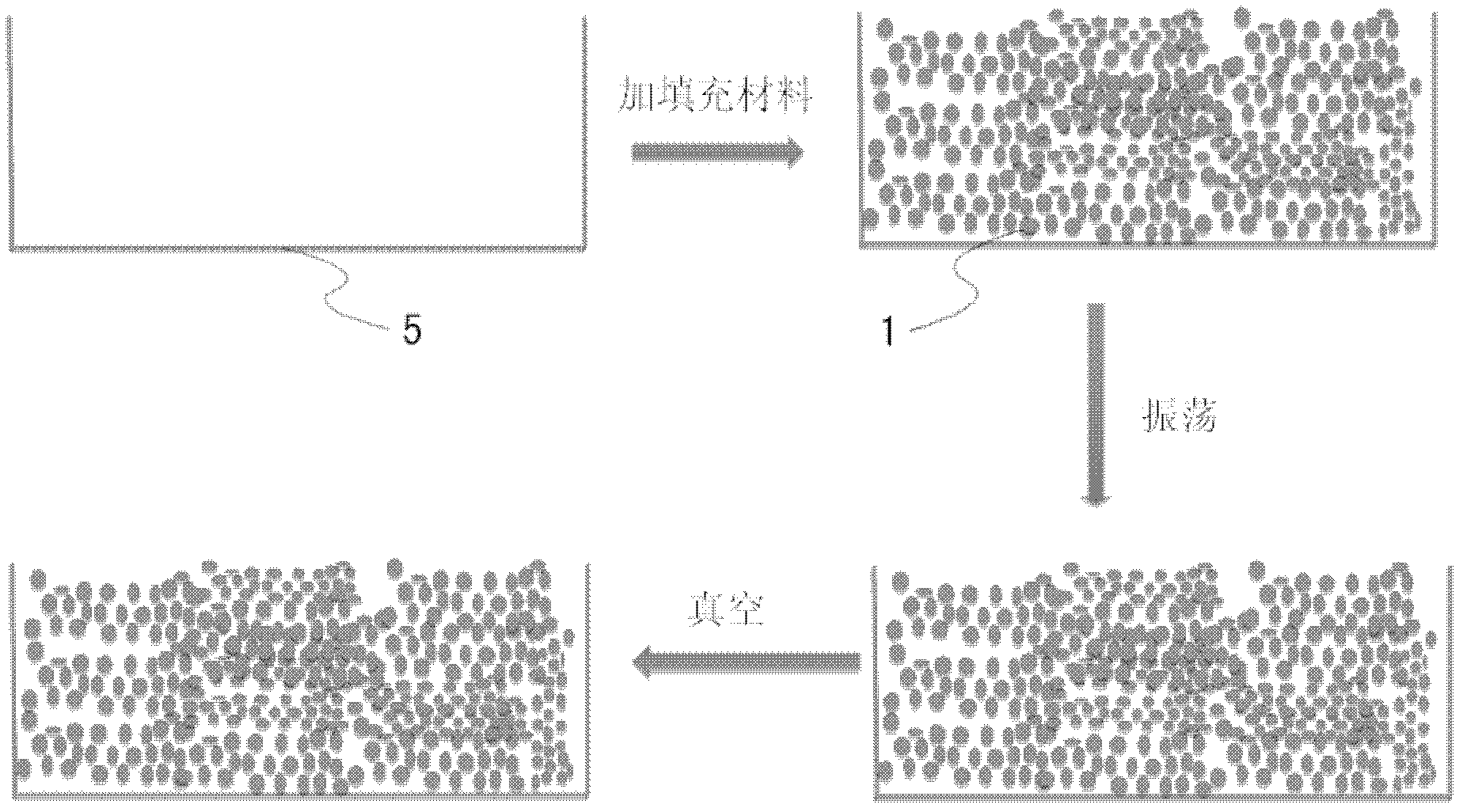

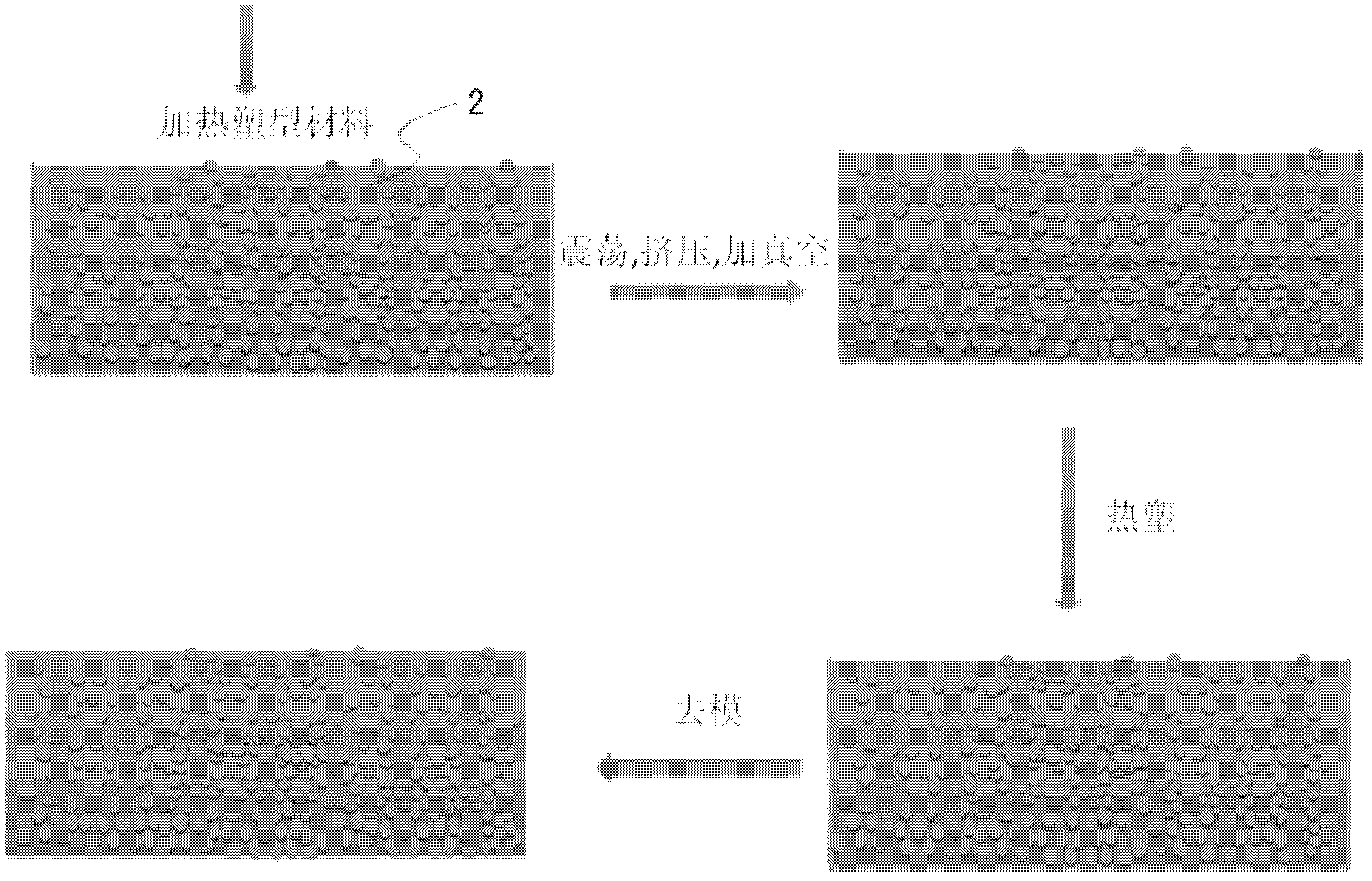

Novel artificial marble

InactiveCN102935738AWith self-cleaning functionWith cleanLayered productsCeramic shaping apparatusDecompositionFilling materials

The invention provides a novel artificial marble and manufacturing method thereof. The novel artificial marble comprises a body layer composed of a filling material and a resin adhesive material, a coating layer containing titanium dioxide or a mixed coating comprising titanium dioxide. The surface of the novel artificial marble has a titanium dioxide coating film or a coating containing titanium dioxide or the mixed coating comprising titanium dioxide, so that the artificial marble has a self-cleaning function, and can greatly reduce cost for maintaining clean when the artificial marble is used as a building material. Due to the excellent ultraviolet absorption function of titanium dioxide, decomposition of the component materials of the artificial marble can be effectively prevented; mechanical performance of the artificial marble can be maintained; and fractures / cracks can be prevented from appearance. The particles or powder of the main raw materials of the artificial marble are inorganic waste materials of buildings and livings and even waste materials of the artificial marble, thereby reducing cost, decreasing resource waste and protecting the environment.

Owner:张磊

Sand washing device

The application discloses a sand washing device, and belongs to the sand washing device field. The sand washing device is used for washing sand gravels, and comprises a sand washing machine and a cycle water pool used for processing wastewater generated by the sand washing machine, wherein the sand washing machine at least comprises a vibrating screen driven by a vibration generator, a mixing box is arranged at the bottom of the vibrating screen, the mixing box is connected with an entrance of a spiral separator through a sand pump and a pumping pipe, an exit of the spiral separator comprises a water outlet and a sand exit, the water outlet is connected with the cycle water pool through a sewage pipe, the sand exit of the spiral separator is located above the vibration screen, a high pressure clear water pipe is further arranged above the vibrating screen, the high pressure clear water pipe is connected with a water source through a high pressure water pump, the cycle water pool at least comprises an outer pool body, and a cleaning agent box is arranged on the outer pool body. Based on the above technical scheme, the sand washing device can improve cyclic utilization rate for the wastewater generated in the sand washing process, reduce water consumption and improve environmental protection effects on the premise of improving sand washing efficiency.

Owner:山东诚邦重工有限公司

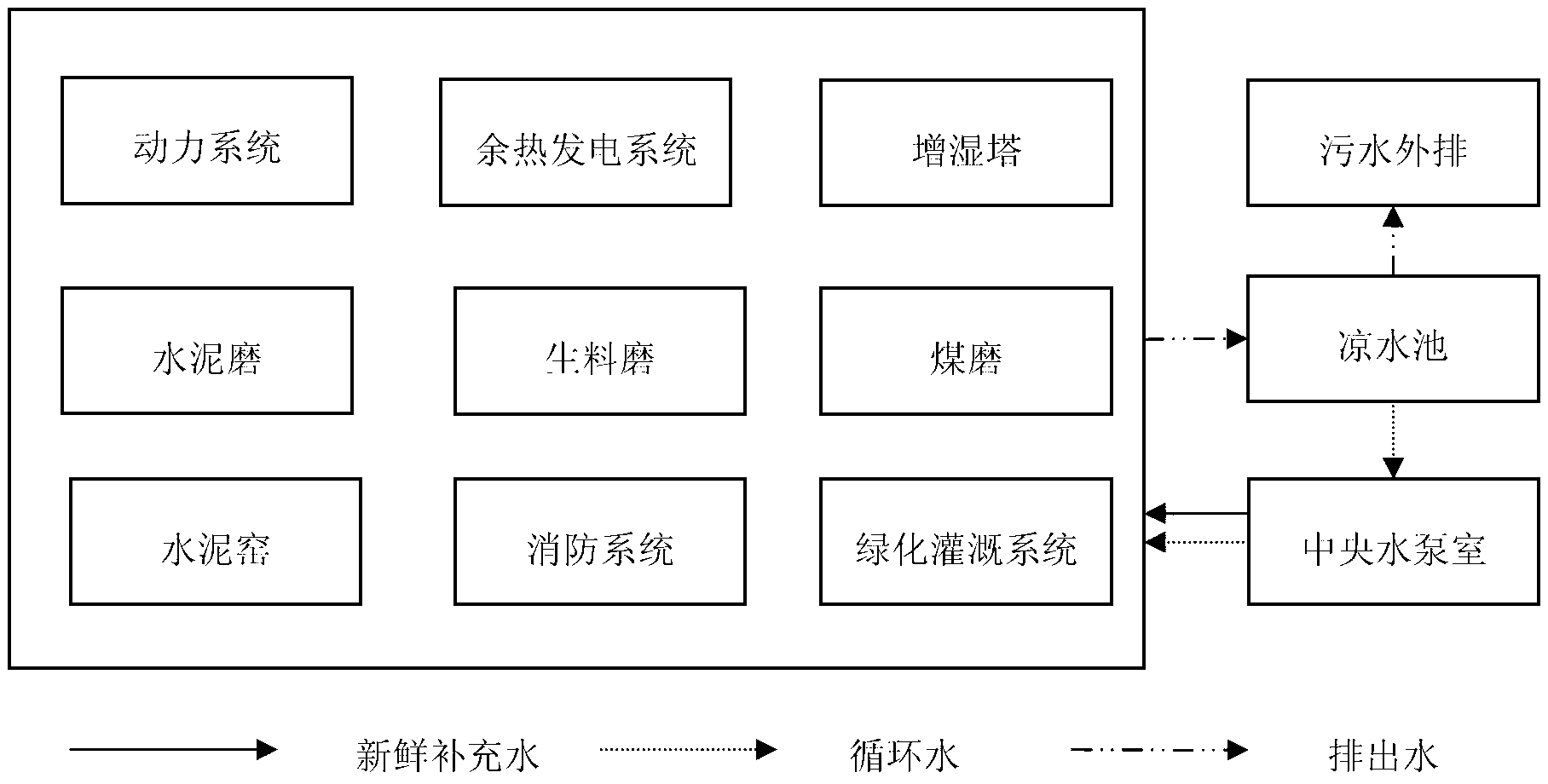

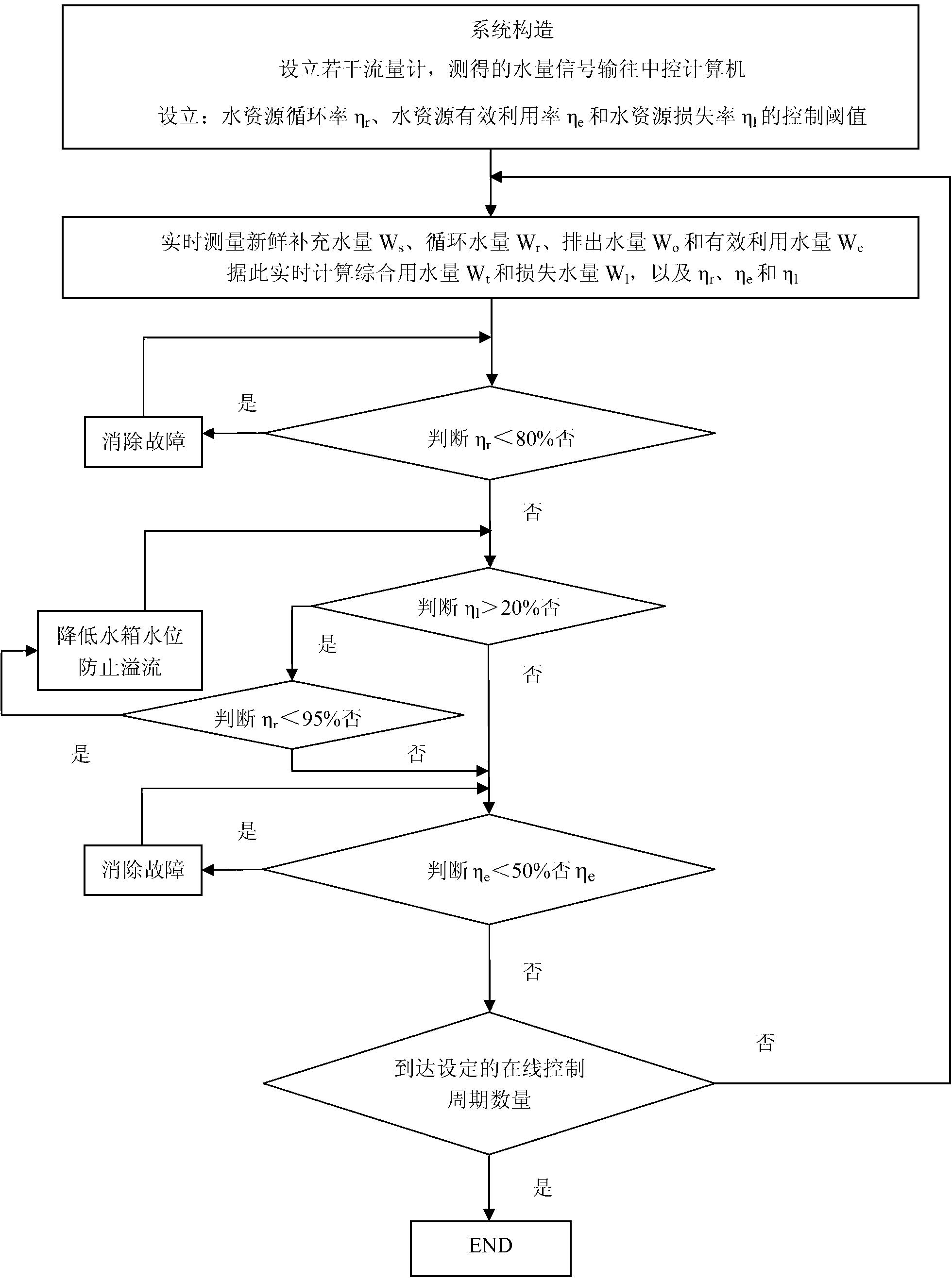

Metering and on-line control method of cement production water footprint

ActiveCN103226350AImprove recycling rateSave resourcesTotal factory controlProgramme total factory controlWater useEngineering

The invention relates to a metering and on-line control method of a cement production water footprint and belongs to the field of water resource management of cement production. The metering and on-line control method is characterized in that the method is accomplished in a cement production water footprint metering and on-line control system controlled by a central control computer, and comprises the steps of measuring fresh water supplement quantity, circulating water quantity, discharged water quantity and effective water utilization quantity in real time under the control of the central control computer, accordingly working out comprehensive water consumption, water loss, and a circulating rate, an effective utilization rate and a loss rate of a water resource, sequentially judging whether the circulating rate of the water resource reaches a standard, whether the loss rate and the circulating rate of the water resource meet a set threshold simultaneously, and whether the effective utilization rate of the water resource is higher than 50%, and adopting failure removal measures corresponding to different stages till meeting a set object. The method facilitates boosting the green progress of the cement industry under the condition of saving the water resource, and facilitates saving the initial investment and operating cost.

Owner:BEIJING UNIV OF TECH

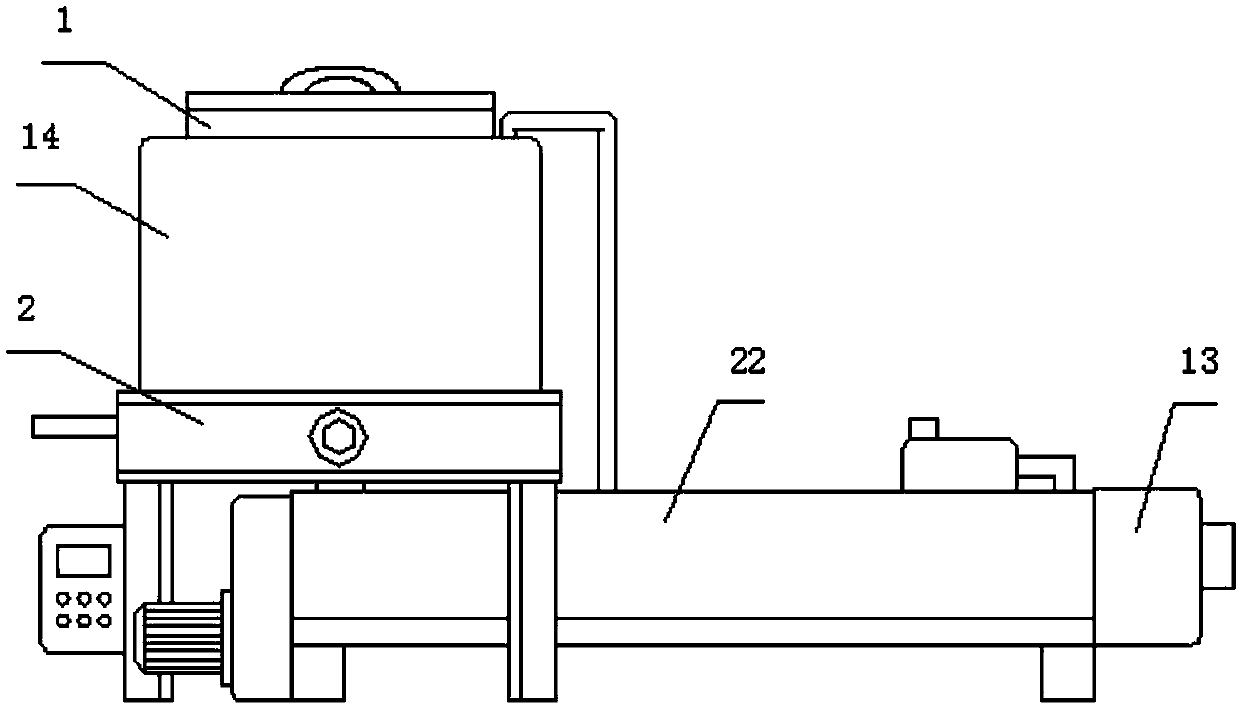

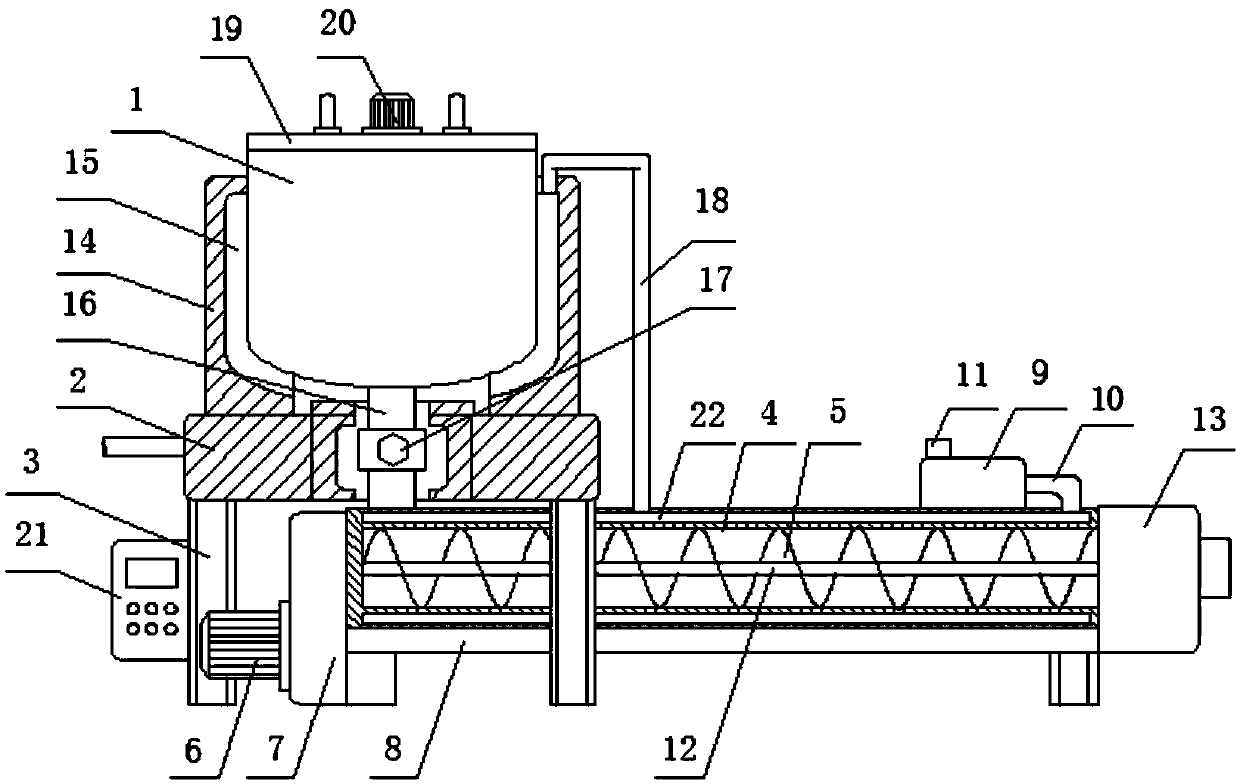

Single screw extruding production line

The invention discloses a single screw extruding production line, which comprises a hot melting furnace, a screw conveying housing, and a conveying heating cavity, a burning furnace frame is installedon the lower side of the hot melting furnace, first supporting feet are welded to the lower side of the burning furnace frame, a feeding pipe is installed in the middle of the lower side of the hot melting furnace, the lower end of the feeding pipe communicates with the upper part of one end of the screw conveying housing, the screw conveying housing is transversely installed on the lower side ofthe lower side of the burning furnace frame through a second supporting foot, one end of the screw conveying housing is connected with a conveying motor in a transmission mode, an extruding die is installed at one end of the screw conveying housing, an insulating layer is installed on the outer side of the lower part of the hot melting furnace, an insulating cavity is formed in the insulating layer, and a smoke conveying pipe is installed on one side of the upper end of the insulating layer. According to the single screw extruding production line, waste heat produced by burning of the hot melting furnace can be heated, the screw conveying housing prevents solidification of conveying materials, the energy utilization recovery rate is high, and the material extruding conveying effect is good.

Owner:GUANGZHOU POTOP EXPERIMENTAL ANALYSIS INSTR

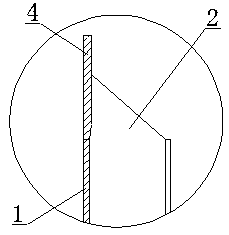

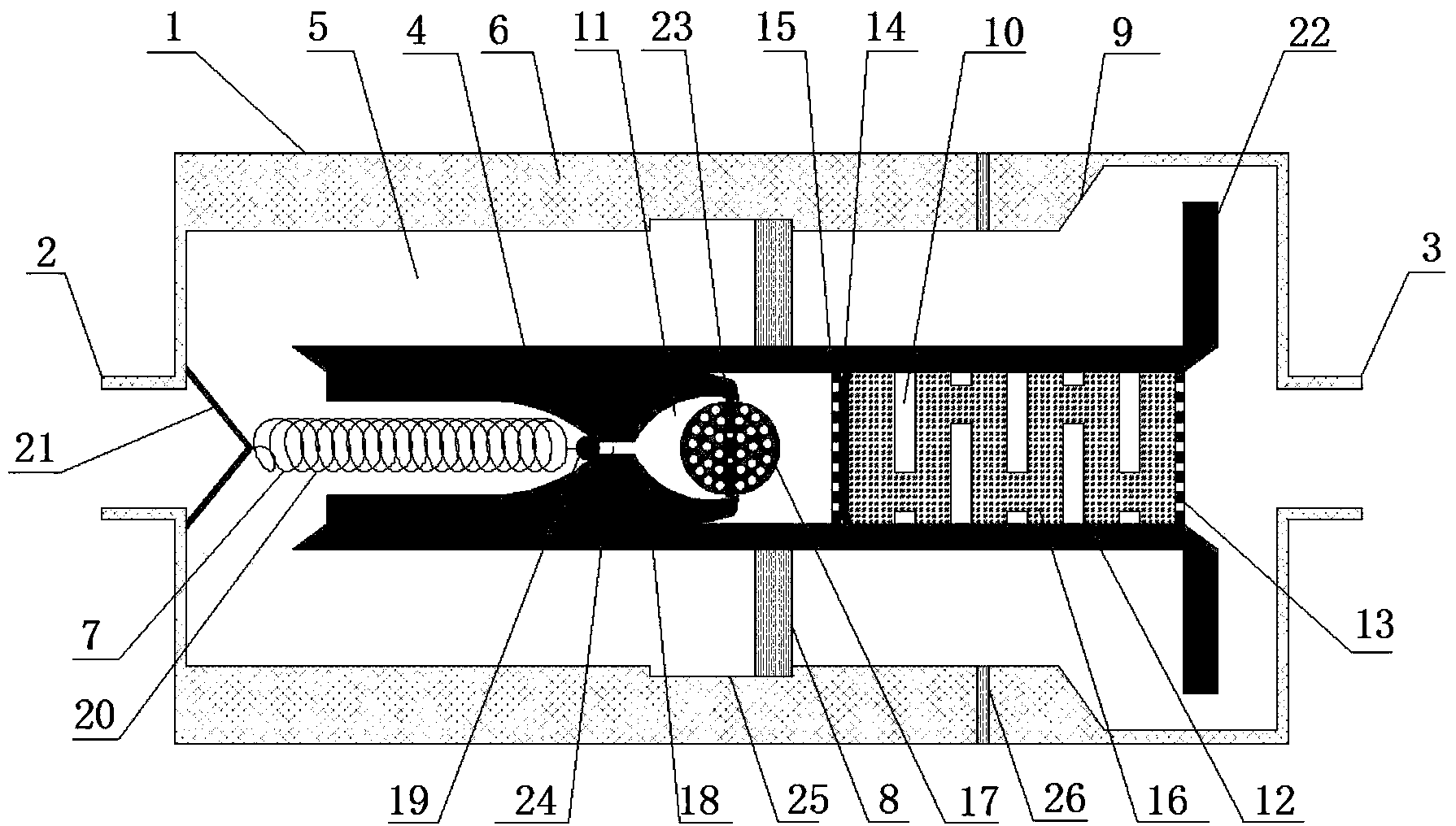

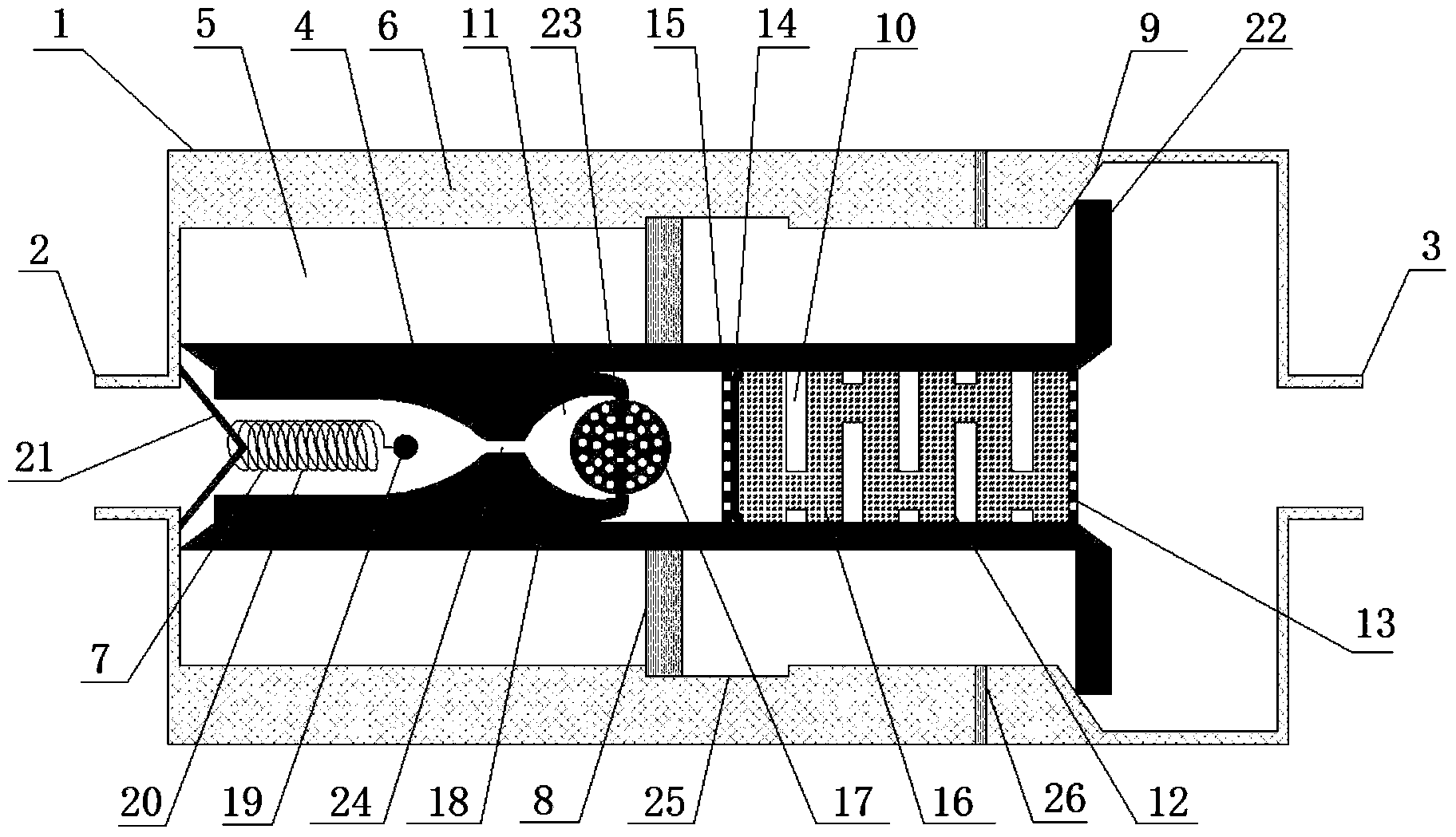

Switching control valve for state of aircraft cargo compartment fire extinguishing system

ActiveCN103968107AChange flow pathGuarantee fire safetyFire rescueMultiple way valvesLow speedSolid particle

The invention relates to a switching control valve for the state of an aircraft cargo compartment fire extinguishing system, and the switching control valve is particularly suitable for serving as a diversion element of extinguishing agents in an aircraft cargo compartment fire extinguishing pipeline. A flow control device comprises a valve body (1), a high-speed inlet (2) and a low-speed inlet (3), wherein a sliding type valve element (4), a valve cavity (5), a valve base (6) and an elastic force control switch (7) are arranged in the valve body, a slider (8) is arranged on the periphery of the sliding type valve element (4), a conical-angle face (9) is arranged at one end, close to the low-speed inlet (3), of the valve base (6), and a drying filtering cavity (10) and a throttling cavity (11) are formed in the valve cavity (5). The switching control valve meets different flow speed requirements and different requirements for extinguishing agents when fire happens to an aircraft, the using number of pipelines in the aircraft is reduced, the stability and the high efficiency of the fire extinguishing system of the aircraft are guaranteed, water, solid particles and other impurities in the extinguishing agents can be removed, and icing and blocking are avoided.

Owner:UNIV OF SCI & TECH OF CHINA

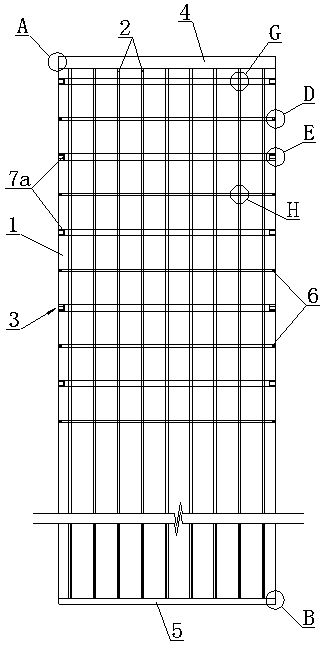

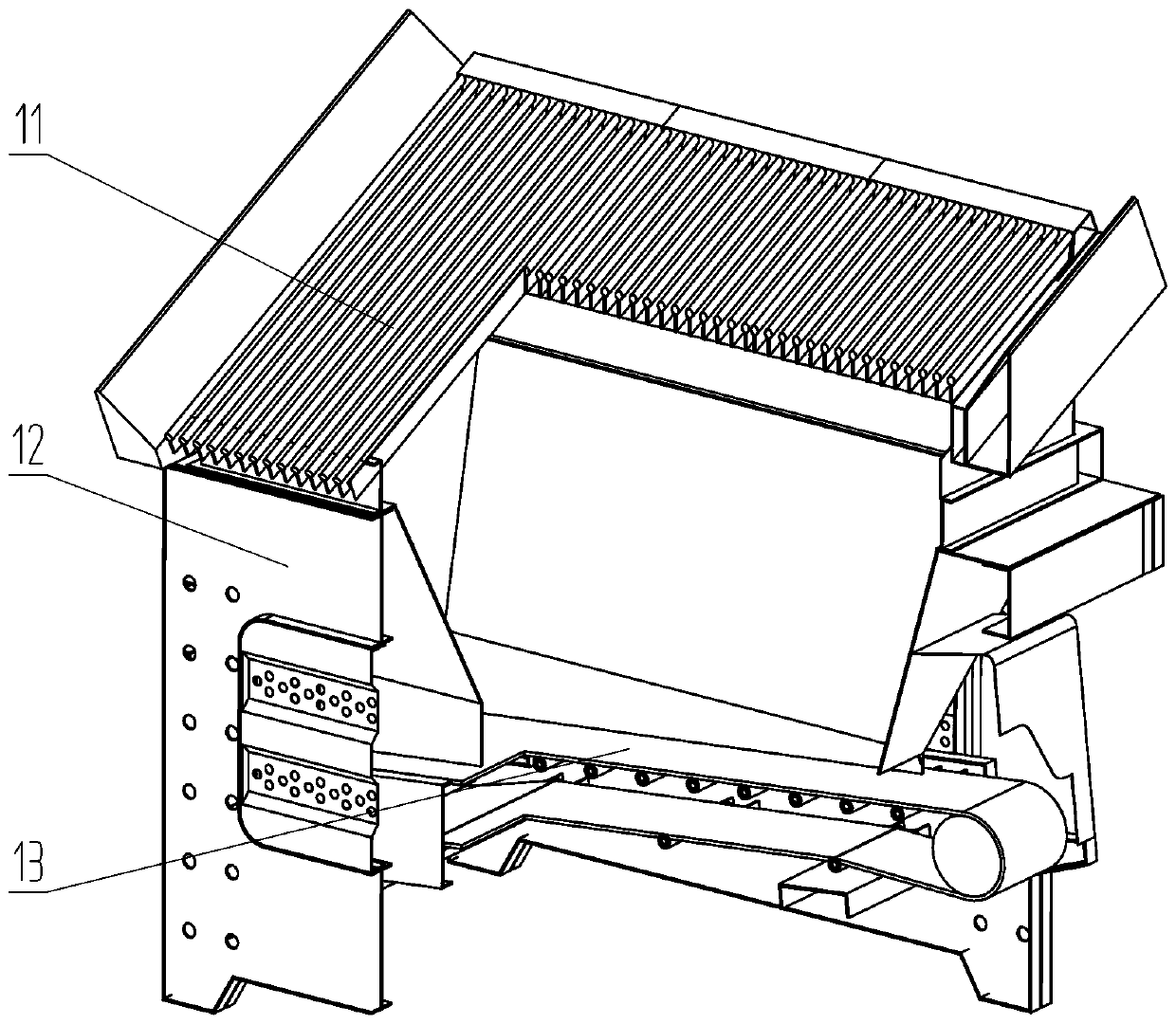

Denitration catalyst drying apparatus

InactiveCN102345970AImprove recycling rateReduce manufacturing costDrying gas arrangementsDrying machines with local agitationProcess engineeringTuyere

The invention relates to a denitration catalyst drying apparatus, comprising a drying oven, a heat exchanger and a connection pipeline. An air inlet of the drying oven is connected with an air blower while an air outlet thereof is connected with the heat exchanger; the heat exchanger is connected with a hot steam pipeline; and the output port of the pipeline is connected with the air blower. The denitration catalyst drying apparatus has the following advantages that: 1) in the denitration catalyst drying apparatus, the hot air is recycled through pipelines, so that circulatory utilization rate of the hot air is improved, production cost of enterprises is reduced and economic benefits of enterprises are improved; 2) temperature devices, pressure detection devices, humidity detection devices and air door adjusting devices are arranged everywhere on the pipelines, thus, the temperature, the pressure and the humidity can be regulated according to practical situation, and the catalyst can be dried optimally.

Owner:江苏万德环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com