Efficient biochemical nitrogen and phosphorus removal method for waste water

A technology for denitrification, dephosphorization, and wastewater, applied in the field of environmental engineering, can solve the problems that anaerobic tanks cannot guarantee an absolute anaerobic environment, the dephosphorization effect is difficult to be further improved, and the sludge fully absorbs phosphorus. and recycling rate, low operating cost, stable phosphorus removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

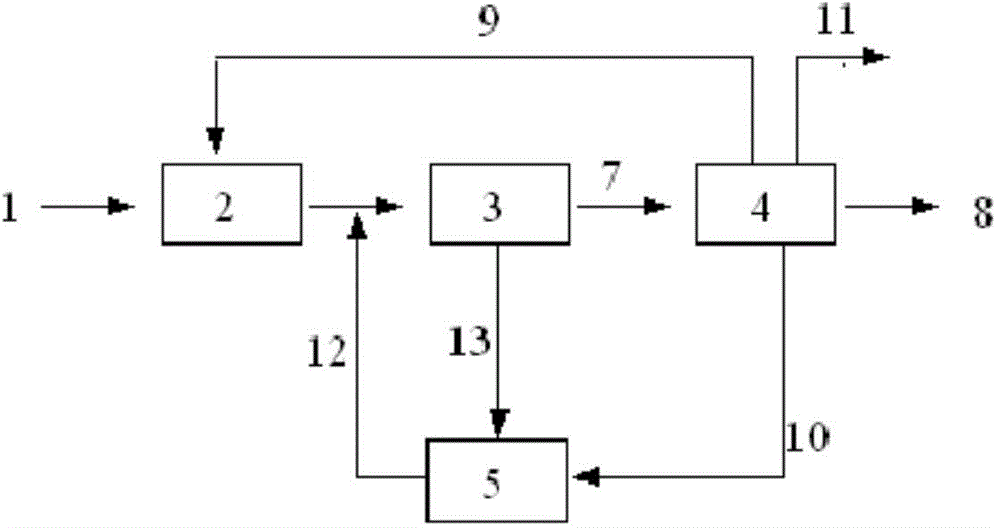

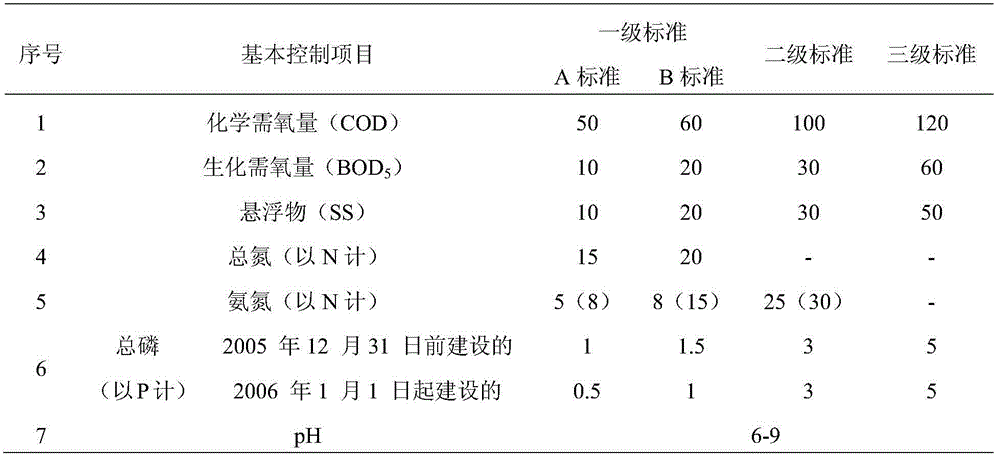

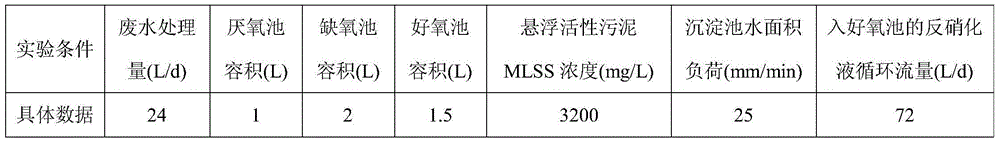

[0039] An enterprise in the chemical industry park in the Taihu Lake Basin selected the improved A 2 The / O denitrification and phosphorus removal process is used to remove nitrogen and phosphorus from the wastewater entering the municipal sewage pipe network. The quality of the influent wastewater is shown in Table 2, and all indicators are seriously inconsistent with the "Urban Wastewater Treatment Plant Pollutant Discharge Standards" "(GB18918-2002 Class I standard A standard discharge requirements. The specific experimental conditions are shown in Table 3. After 2 months of operation, the treated water obtained from the effluent of the sedimentation tank was tested again.

[0040] Table 2 Influent wastewater quality

[0041] water quality index

pH

SS(mg / L)

BOD(mg / L)

TP (mg / L)

TN (mg / L)

NH 3 -N (mg / L)

content

24

7.6

115

132

7.3

38

28

[0042] Table 3 Experimental conditio...

Embodiment 2

[0051] The same influent waste water quality and specific experimental conditions as in Example 1 were tested again with the treated water obtained from the effluent of the sedimentation tank after 2 months of operation.

[0052] The specific process steps are as follows:

[0053] 1), anaerobic reaction section: mainly release phosphorus in the anaerobic reaction tank 2, the wastewater 1 containing nitrogen and phosphorus enters the anaerobic reaction tank 2, and also enters the return activated sludge 9 from the sedimentation tank 4 at the same time, The phosphorus accumulating bacteria in the refluxing activated sludge 9 release phosphorus in an anaerobic environment, and at the same time, the zeolite in the anaerobic reaction tank 2 enriches the ammonia nitrogen in the wastewater 1 through adsorption; in the absence of nitrate nitrogen and oxygen, the accumulation Phosphorus bacteria can fully release phosphorus, store a large amount of energy substances in the body, so tha...

Embodiment 3

[0059] The same influent waste water quality and specific experimental conditions as in Example 1 were tested again with the treated water obtained from the effluent of the sedimentation tank after 2 months of operation.

[0060] The specific process steps are as follows:

[0061] 1), anaerobic reaction section: mainly release phosphorus in the anaerobic reaction tank 2, the wastewater 1 containing nitrogen and phosphorus enters the anaerobic reaction tank 2, and also enters the return activated sludge 9 from the sedimentation tank 4 at the same time, The phosphorus accumulating bacteria in the refluxing activated sludge 9 release phosphorus in an anaerobic environment, and at the same time, the zeolite in the anaerobic reaction tank 2 enriches the ammonia nitrogen in the wastewater 1 through adsorption; in the absence of nitrate nitrogen and oxygen, the accumulation Phosphorus bacteria can fully release phosphorus, store a large amount of energy substances in the body, so tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com