Patents

Literature

49results about How to "Reduce crushing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of high molecular weight instant cation polyacrylamide

The invention relates to a preparation method for instant cation polyacrylamide with a high molecular weight. The monomer of acrylamide and a cation type monomer are used as the main materials, firstly, the acrylamide and a comonomer are dissolved into deionized water; then a photoinitiator and / or a photosensitizer additive and a redox initiator are added in the solution to form a compound initiating system; the materials of the components are uniformly mixed in a viscous state, poured on a plane and paved into a sheet shape, introduced with high purity nitrogen, then ultraviolet light illumination is carried out to the materials paved into the sheet shape; after the materials of the viscous state are in a gel block, the materials are dried, broken, granulated and cracked to obtain a product of a dry powder shape. In the invention, the heat release and temperature rising of bulk adiabatic polymerization are avoided, while the polymerization and drying are carried out under a lower temperature; therefore, the reaction process is stable; the product has the advantages of higher molecular weight, better solubility, faster dissolving speed, simple technique and low cost; in addition, the processing after polymerization reduces the working procedure of breaking of bulk gel.

Owner:朱定洋

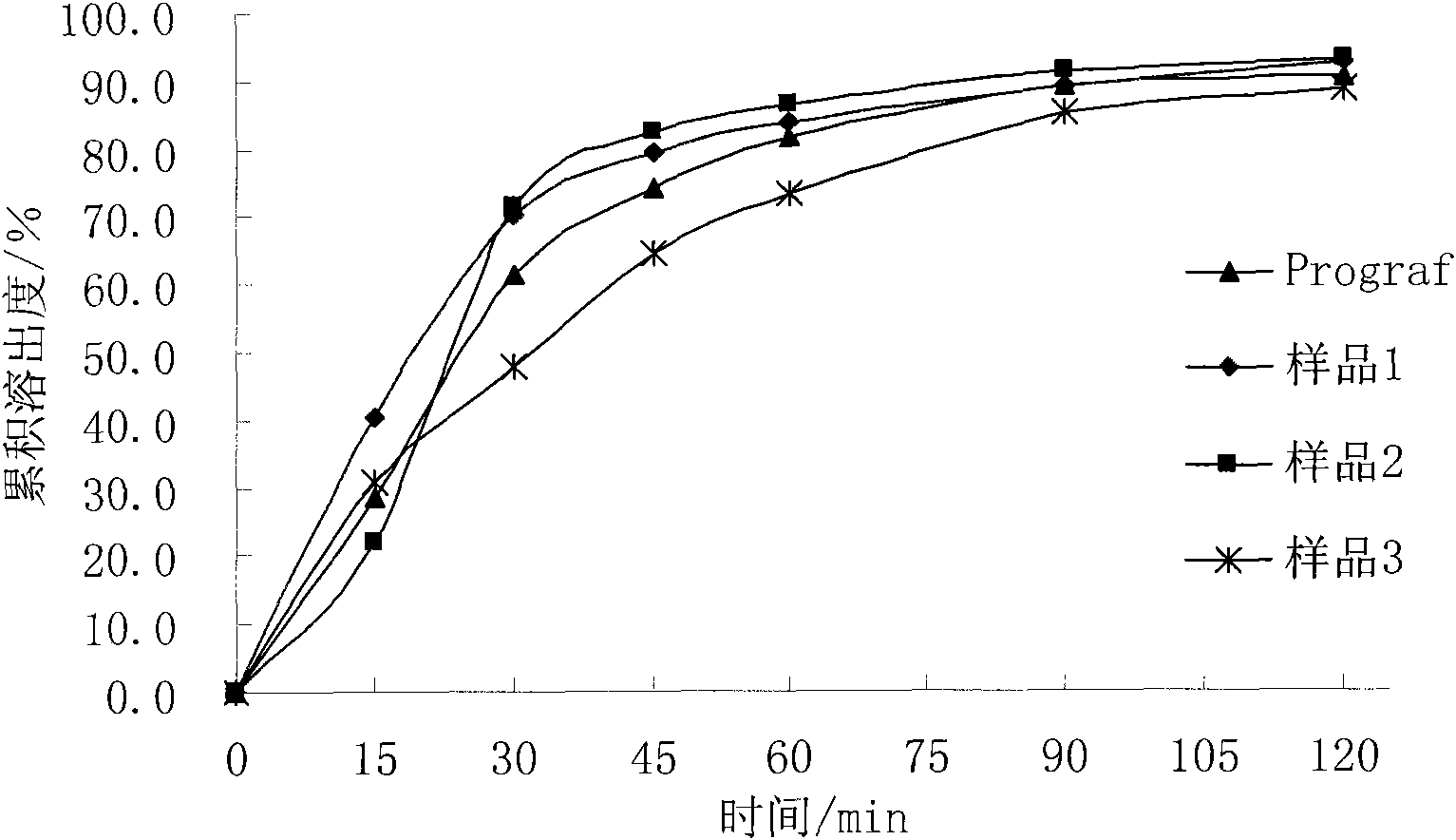

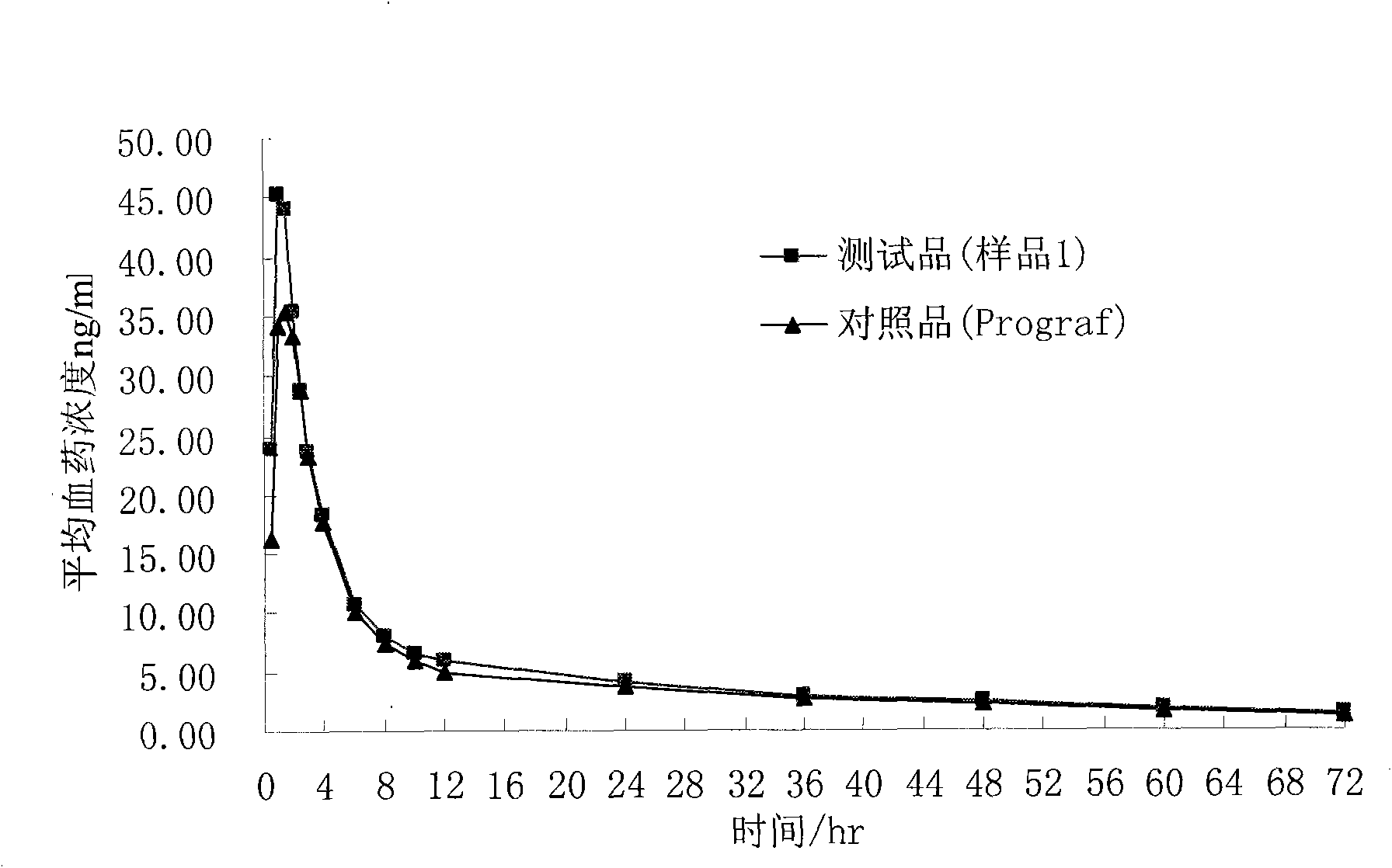

Composition containing water-insoluble high-activity drug and preparation method thereof

ActiveCN101537184ASolving DissolutionSolve the two major problems of dustOrganic active ingredientsPowder deliveryOrganic solventWater insoluble

The invention discloses a composition containing a water-insoluble high-activity drug and a preparation method thereof. The water-insoluble high-activity drug is dissolved in an organic solvent containing a solid dispersion carrier, evenly sprayed on the surface of filler or blank pellets by adopting a fluidized bed and dried. The invention realizes the one-step completion of preparing the solid dispersion of the water-insoluble high-activity drug, pelleting and drying, has simple and convenient process, and no dust pollution, and effectively avoids the adverse influence of the high-activity drug on the health of production staff. The granules prepared by the method has even granularity, and good liquidity and compression formability, and can be further prepared into oral solid preparation. The composition prepared by the method has good drug dissolvability, and high oral absorption and bioavailability.

Owner:HANGZHOU ZHONGMEI HUADONG PHARMA +1

A kind of tobacco matrix composite biopesticide and its manufacturing method

InactiveCN102265908AHas double insecticidal effectImprove resource utilizationBiocideAnimal repellantsBiotechnologySocial benefits

The invention provides a tobacco matrix composite biopesticide and a preparation method thereof. The composite biopesticide which comprises at least a tobacco botanical insecticidal component and at least a microbial insecticidal component is prepared through fermenting insecticidal microbes with selecting a tobacco waste as a raw material. The preparation method comprises the following operationsteps: preparation of a medium, amplification culturing of spawns, fermentation of the biopesticide, and extraction. A fermentation technology can adopt liquid state fermentation or solid state fermentation. The tobacco matrix composite biopesticide of the invention which not only contains the insecticidal microbes and metabolites thereof, but also contains tobacco insecticidal components (nicotine and the like for example) has dual insecticidal effects. The method of the invention which allows resources of the tobacco waste which is not reasonably utilized at present to be fully utilized allows grain resources to be saved, and good economic benefits, ecological benefits and social benefits to be generated.

Owner:ZHENGZHOU UNIV

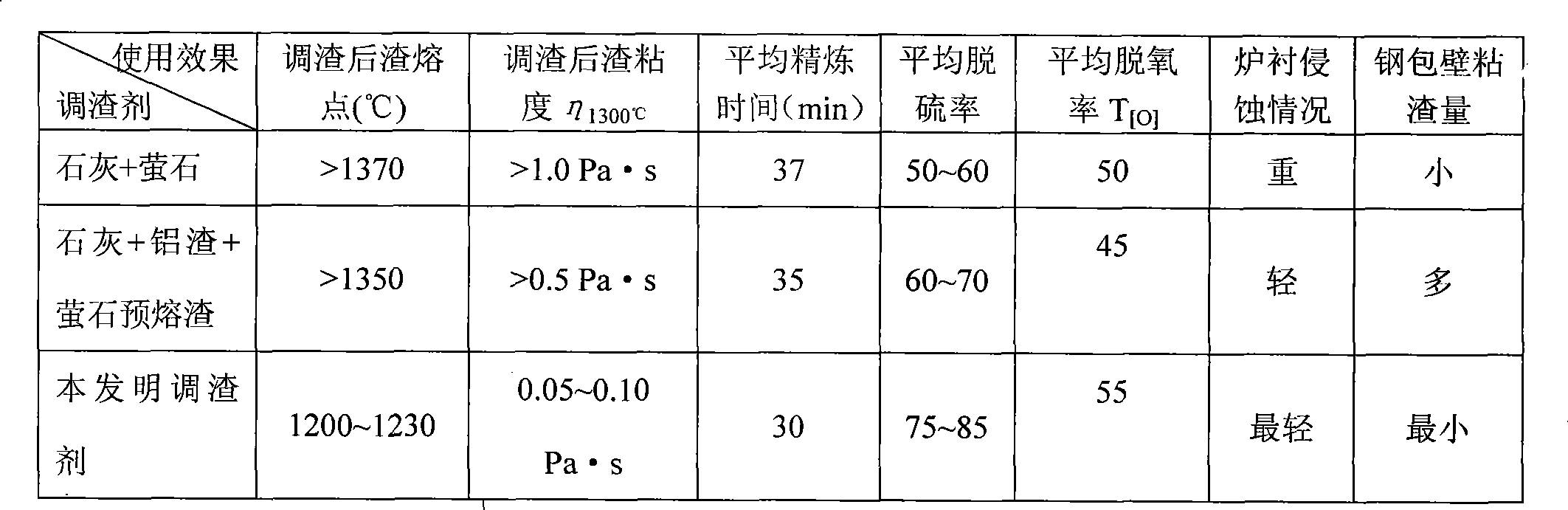

Ladle refining slag modifier, preparation method and slag modifying method

InactiveCN101519712AStrong fluxing effectImprove flux effectProcess efficiency improvementSteelmakingImpurity

The invention belongs to the technical field of steelmaking and refining, and discloses a ladle refining slag modifier, a preparation method and a slag modifying method. The slag modifier comprises the following chemical components in percentage by mass: 30 to 60 percent of CaO, 30 to 60 percent of Al2O3, 2 to 10 percent of MgO2, 2 to 10 percent of B2O3, and less than 8 percent of impurities. The slag modifying method using the slag modifier comprises that: the slag modifier is hoisted to the front of a refining furnace after a steelmaking furnace discharges steels, and then is directly fed into ladles, or the slag modifier can also be fed into the furnace along with other slags at a refining station; the components of modifying slag are determined according to the ladle residue amount and components, desulfuration amount and steel deoxidation product amount; and the modifying slag for controlling the ladle slag comprises the following components according to the adding amount: 48 to 54 percent of CaO, 26 to 32 percent of Al2O3, 6 to 8 percent of MgO, 2 to 4 percent of B2O3, and 0 to 8 percent of SiO2, wherein the modifying slag is better if the content of the SiO2 is lower. The slag modifier has the capabilities of quickly manufacturing the slag, improving desulfuration and deoxidation of the refining slag and accommodating and absorbing deoxidation products, and is simple to prepare and convenient to store, transport and use.

Owner:JIANGSU UNIV

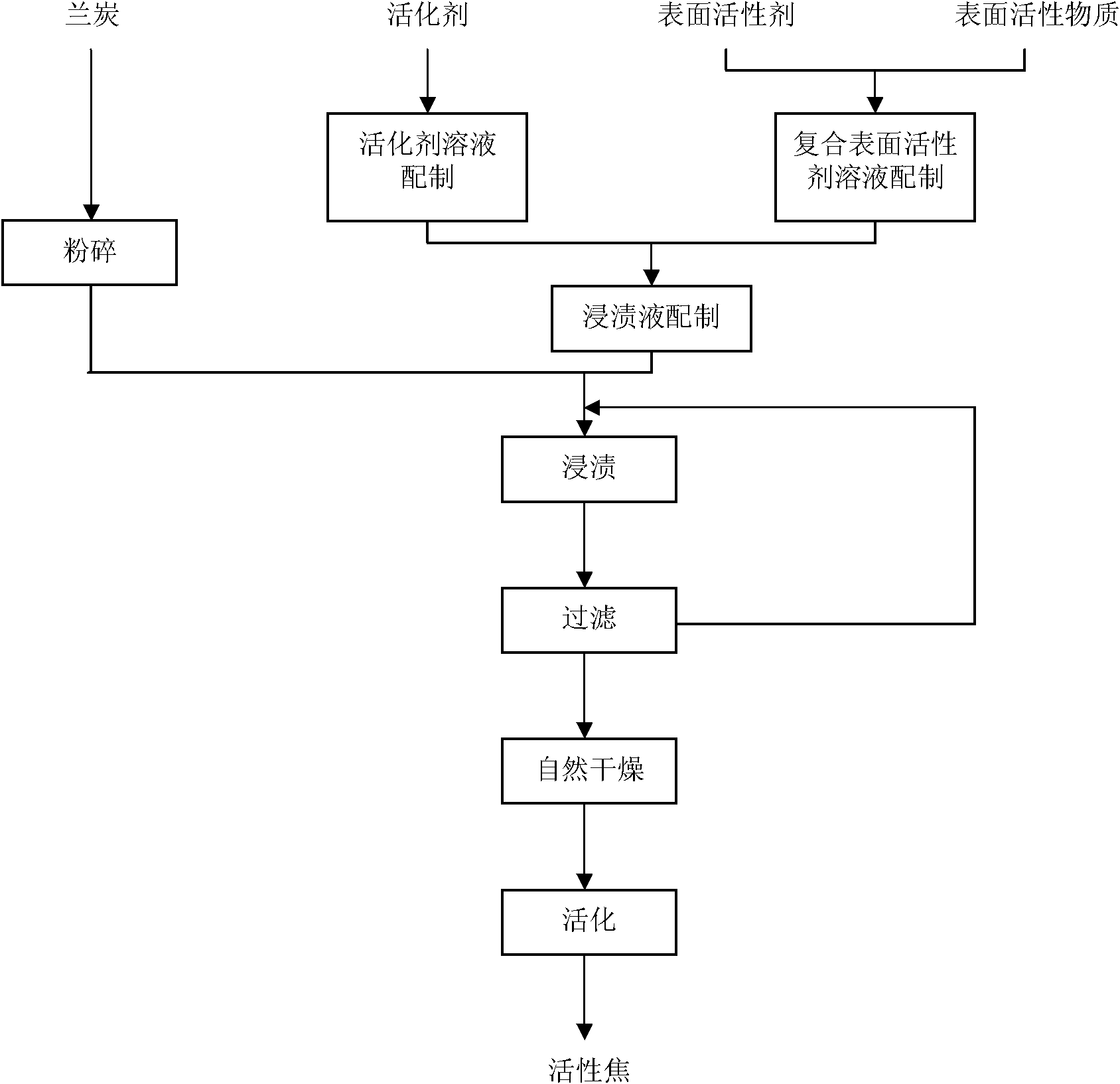

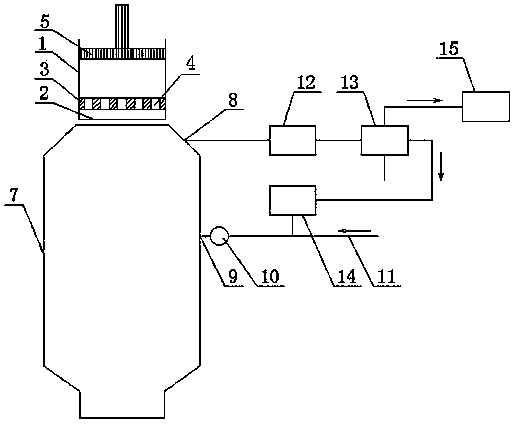

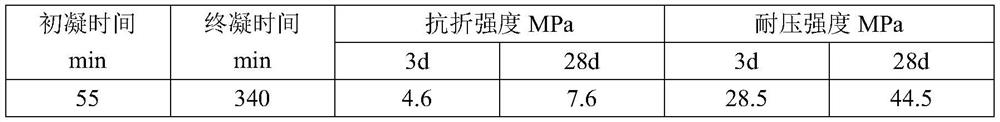

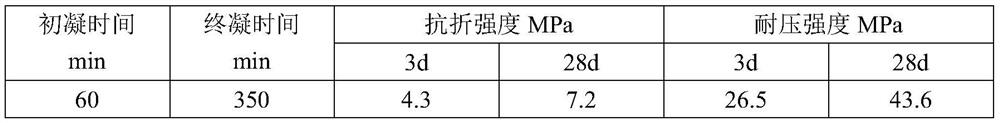

Activated coke for absorbing dioxin in flue gas and preparation method thereof

ActiveCN102728322ASolve spontaneous combustionAvoid disposition problemsOther chemical processesDispersed particle separationSorbentFlue gas

The present invention relates to an activated coke for absorbing persistent organic pollutant like dioxin in flue gas and a preparation method thereof by using coal quality semi coke as a raw material. The preparation method is as follows: crushing the coal quality semi coke; impregnating the coal quality semi coke with an impregnating solution containing metal hydroxide or alkali metal carbonate activator and compound surfactant, and naturally drying; and finally activating the impregnated and dried semi coke at 800-950 DEG C to prepare the activated coke for absorbing dioxin in flue gas. The activated coke has characteristics of developed porous structure, low manufacturing cost and good adsorption effect, etc.

Owner:BAOSHAN IRON & STEEL CO LTD +1

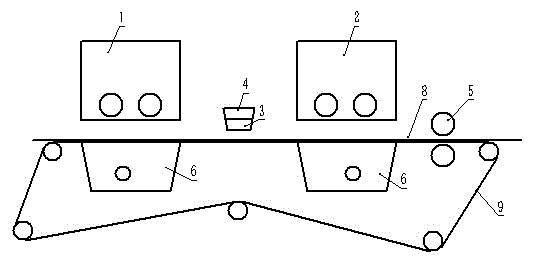

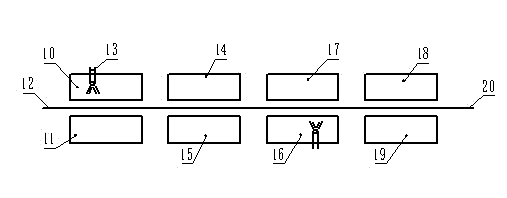

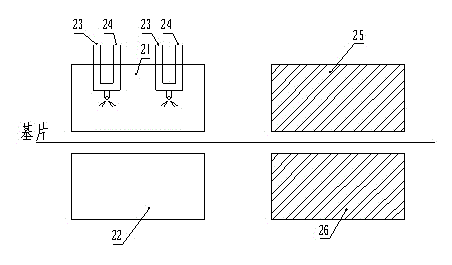

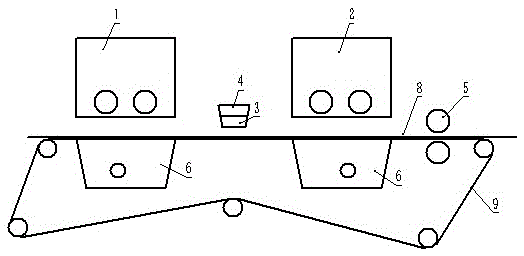

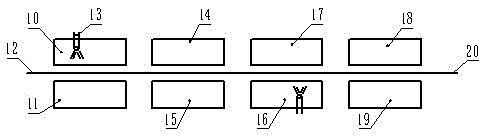

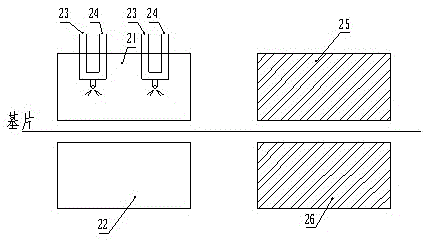

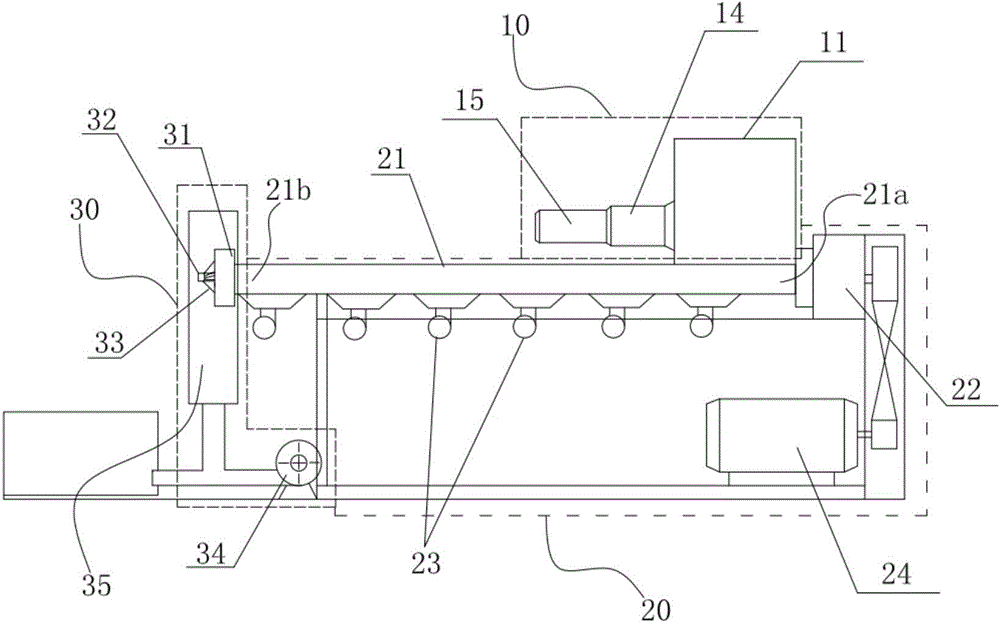

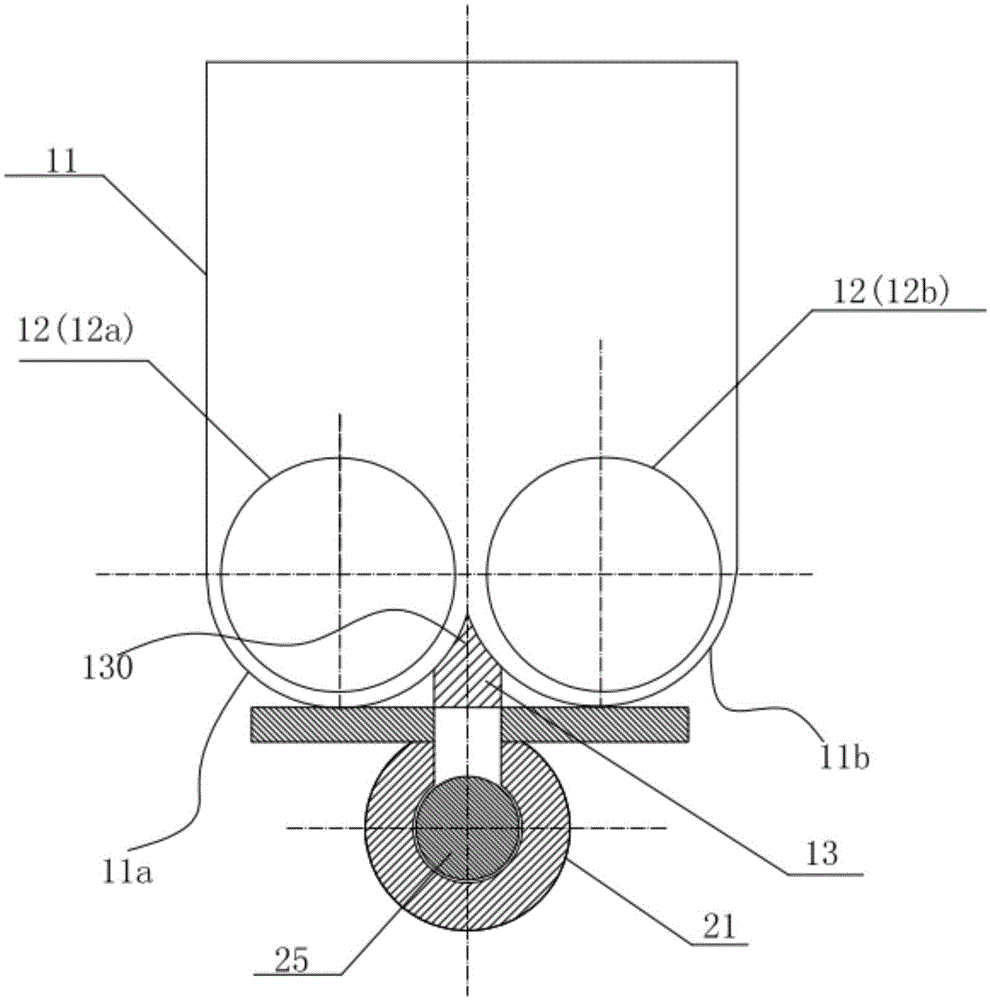

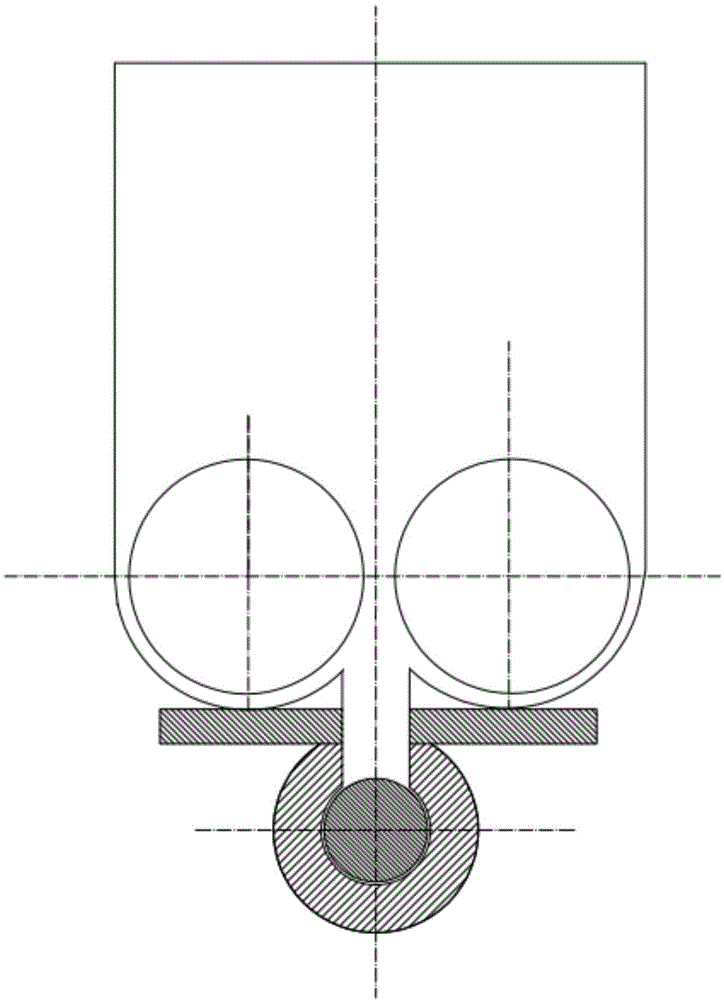

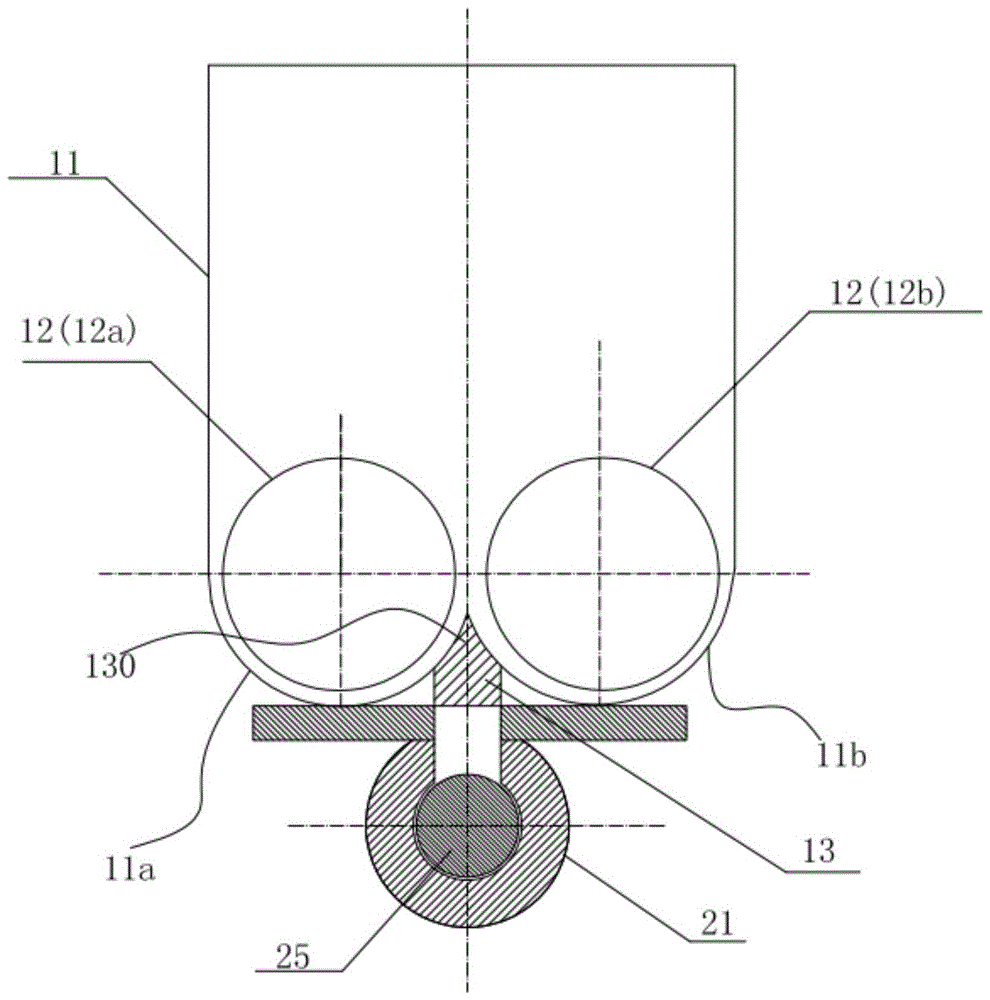

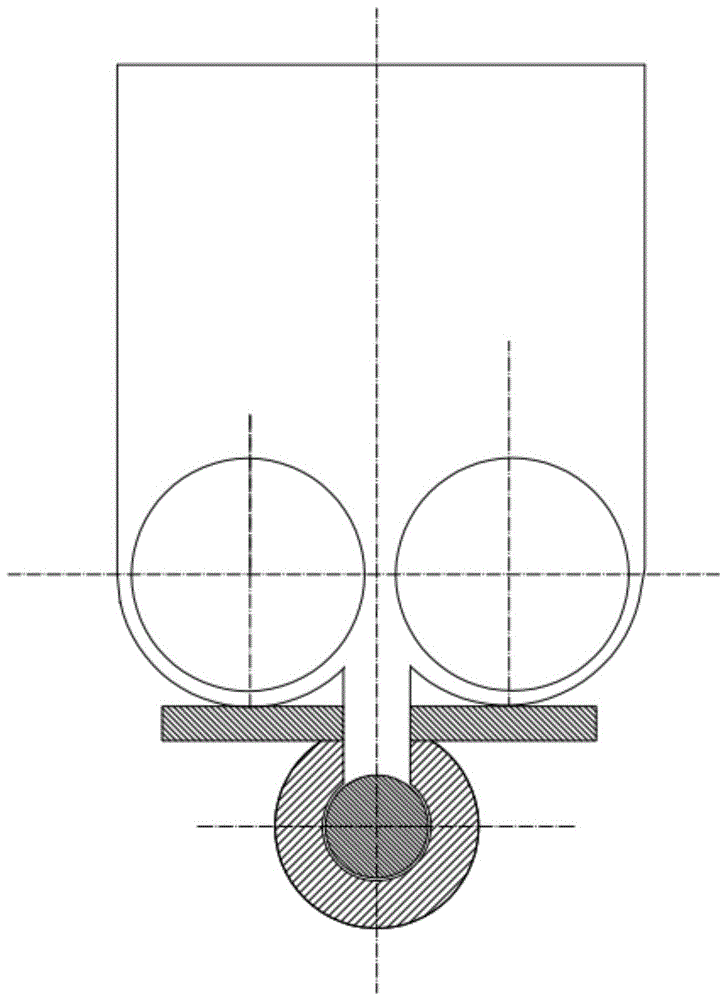

Method for regenerating tobacco leaves by loaded tobacco fragments manufactured by dry papermaking technology

ActiveCN104824824AImprove smoking qualityOvercoming the deficiencies of manufactured reconstituted tobacco leavesTobacco preparationAdhesiveSingle fiber

The present invention provides a method for regenerating tobacco leaves by loaded tobacco fragments manufactured by a dry papermaking technology, and belongs to the field of a tobacco product machining method. The method comprises the following two steps: step 1, sorting the tobacco fragments and adding the tobacco fragments in a substrate forming process, conveying fibers into a first forming device (1) after plant fibers are deliberated into single fiber shapes, and forming a fiber layer (7) by using an airflow net forming method; and step 2, spraying paste prepared from the tobacco fragments, tobacco powder and an adhesive on the formed substrate, i.e. spraying the paste made of the tobacco fragments, the tobacco powder and the adhesive on one surface of the substrate, drying, then spraying the paste made of the tobacco fragments, the tobacco powder and the adhesive on the other surface of the substrate and drying to obtain the tobacco leaves regenerated by the loaded tobacco fragments manufactured by the dry papermaking technology. By virtue of the method, not only can procedures be reduced, but also powder-falling and dust-raising phenomena caused by excessive tobacco powder are reduced, the use amount of the adhesive is also reduced and the smoking quality is improved.

Owner:SHANXI LIGONG MECHANICAL & ELECTRICAL TECH

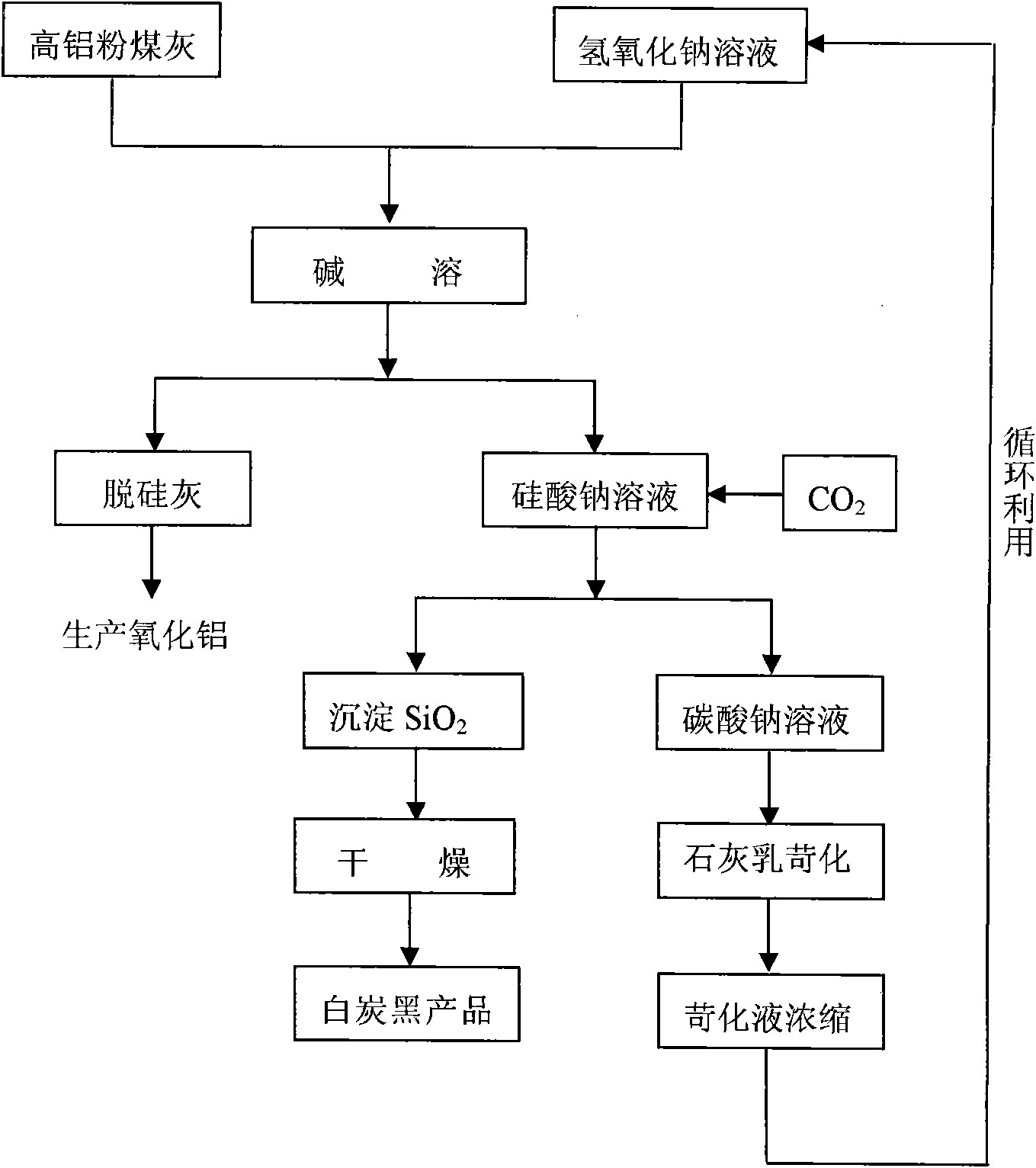

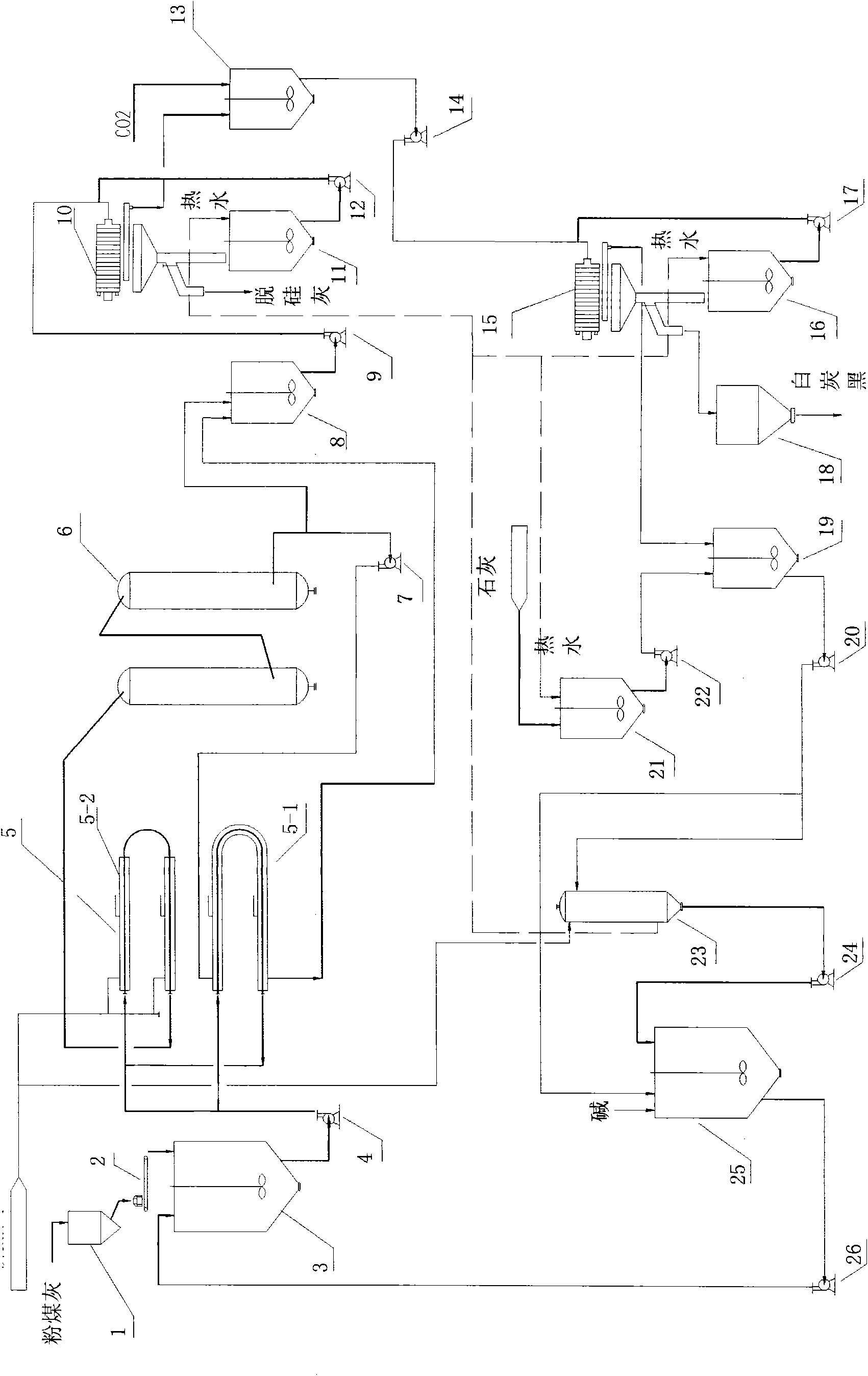

Method for producing white carbon black by using high alumina fly ash and system thereof

The invention discloses a method for producing white carbon black by using high alumina fly ash and a system thereof, relating to the technical field of material and chemistry. The invention comprises a fly ash slurry blending system, a fly ash pre-desiliconization system, a white carbon black preparation system and a caustification system. the structure is characterized in that the sleeve heater is divided into two sections; the outlet passage at the lower part of a heat preservation stay pot is divided into two paths; the solution outlet of a tube type falling film evaporator is connected with one inlet of a circulating mother liquor preparation tank through an evaporating solution pump, and one of the other two inlets of the circulating mother liquor preparation tank is alkali supplementing passage and the other thereof is connected with the outlet of a caustification tank through a caustification solution pump; the outlet passage of the circulating mother liquor preparation tank is connected with the inlet of a fly ash slurry preparation tank through a circulating mother liquor pump, so that the whole system forms a closed circulation. The invention is simple in process, low in production cost, low in energy consumption, and stable in performance of the products, meanwhile the fly ash of which white carbon black is extracted out can be used for preparing aluminium oxide as an important aluminium resource.

Owner:TONGFANG ENVIRONMENT

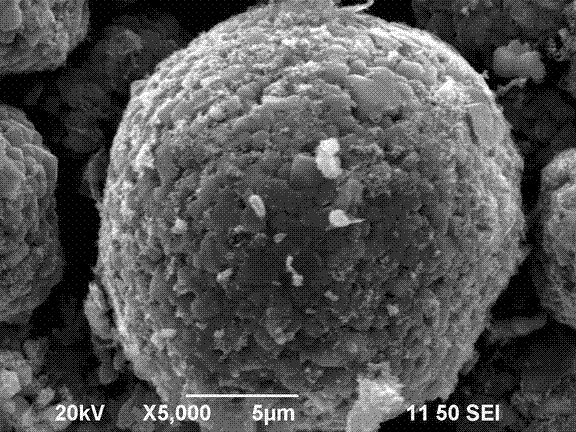

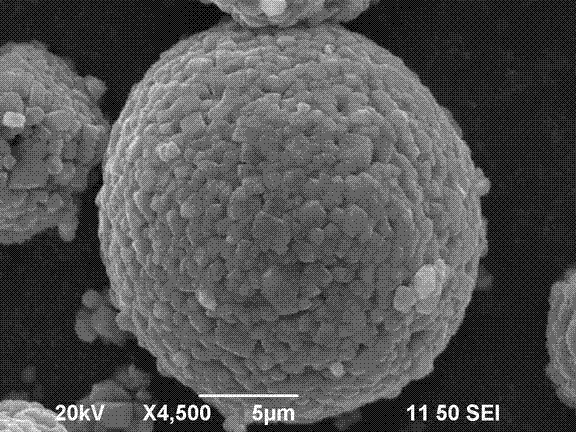

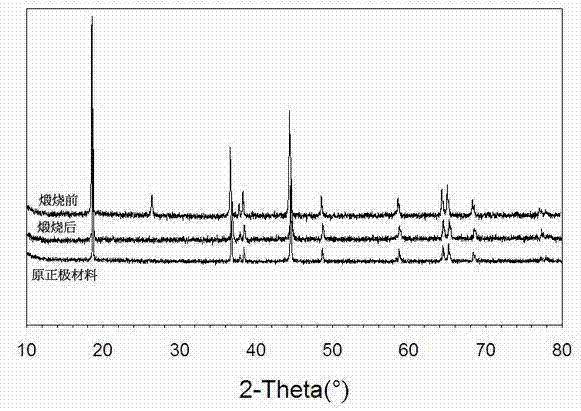

Method for recycling active substances from waste pieces of positive poles of lithium ion batteries

InactiveCN103618119AReduce crushing processHigh viscosityWaste accumulators reclaimingBattery recyclingPhysical chemistryLithium-ion battery

The invention discloses a method for recycling active substances from waste pieces of positive poles of lithium ion batteries. The method comprises the steps of (1) putting the waste pieces of the positive poles of the lithium ion batteries into a swelling agent, wherein the waste pieces of the positive poles is in complete contact with the swelling agent at 19-189 DEG C for 0.1-36 hours; (2) screening or sorting out aluminum foil sheets, filtering, settling, and screening or centrifuging the swelling agent mixture containing active substances, and washing to separate solid active substances and a liquid swelling agent out; (3) drying the solid active substances obtained in step (2) at 40-250 DEG C, adding a lithium source into the dried solid active substances, mixing uniformly, and then calcining by three steps; and (4) after calcining, naturally cooling down a furnace, and then collecting solid substances, namely regenerated positive pole active substances. The regenerated positive pole material recycled by the method has the structure, appearance and component same as that of a material for manufacturing the positive pole of a lithium ion battery, and has stable electrochemical performance.

Owner:HENAN NORMAL UNIV +1

Method for reconstituted tobacco leaves loaded with tobacco fragments manufactured by dry-laid papermaking technology

ActiveCN104824824BImprove smoking qualityOvercoming the deficiencies of manufactured reconstituted tobacco leavesTobacco preparationAdhesiveSingle fiber

The present invention provides a method for regenerating tobacco leaves by loaded tobacco fragments manufactured by a dry papermaking technology, and belongs to the field of a tobacco product machining method. The method comprises the following two steps: step 1, sorting the tobacco fragments and adding the tobacco fragments in a substrate forming process, conveying fibers into a first forming device (1) after plant fibers are deliberated into single fiber shapes, and forming a fiber layer (7) by using an airflow net forming method; and step 2, spraying paste prepared from the tobacco fragments, tobacco powder and an adhesive on the formed substrate, i.e. spraying the paste made of the tobacco fragments, the tobacco powder and the adhesive on one surface of the substrate, drying, then spraying the paste made of the tobacco fragments, the tobacco powder and the adhesive on the other surface of the substrate and drying to obtain the tobacco leaves regenerated by the loaded tobacco fragments manufactured by the dry papermaking technology. By virtue of the method, not only can procedures be reduced, but also powder-falling and dust-raising phenomena caused by excessive tobacco powder are reduced, the use amount of the adhesive is also reduced and the smoking quality is improved.

Owner:SHANXI LIGONG MECHANICAL & ELECTRICAL TECH

A kind of vermiculite oxygen shoveling agent and its rapid composting fermentation method for treating sludge

InactiveCN102276318AImprove permeabilityImprove loosenessBio-organic fraction processingOrganic fertiliser preparationMicroorganismSludge compost

A vermiculite oxygen scavenger and a rapid composting fermentation method for treating sludge by using the same. The sludge composting fermentation oxygen scavenger is a mixture of plant particles and vermiculite, and its weight ratio is 1:1-1.3. Its advantages are: increase the permeability and looseness of the compost; make the compost fermentation process uniform; after composting, the obtained clinker is loose, the vermiculite and the material are easy to separate, and the dominant microorganisms attached to the micropores on the surface can be separated with time. They are used together as recycled materials; due to the low loss of vermiculite particles during use, they can be recycled and reused, and the loss rate of each compost is less than 5%; the operating cost is low, and the crushing process of sawdust or straw is reduced, greatly reducing Labor intensity and obvious economic benefits; the early heating speed of composting is fast, and the dehydration and cooling of the compost body are more rapid at the end of composting; the time required for composting to decompose can be shortened by 5-7 days, which is about 1 / 2 shorter than the composting cycle of similar industrial composting technologies at home and abroad 3. It improves the composting efficiency and is more suitable for the automatic control of the composting process.

Owner:武汉正清和环保科技开发有限公司

Granular folacin production method and product

InactiveCN1633991AThe method is simpleEasy to operateOrganic active ingredientsOrganic chemistryFolic acidChemistry

The invention relates to the forming process of folic acid after the synthesizing procedure, which consists of charging deionized water, preparing paste with 28-45% of solid content, loading into screw pump, using a pressure type spray and granulation drier to squeeze the paste out of the screw pump at the air intake temperature of 210-320 deg. C and air-out temperature of 90-150 deg. C, simultaneously carrying out atomizing and granulating, drying and compacting, and finally obtaining 20-120 mesh of granular folic acid product through sieving.

Owner:CHANGZHOU NIUTANG CHEM PLANT CO LTD

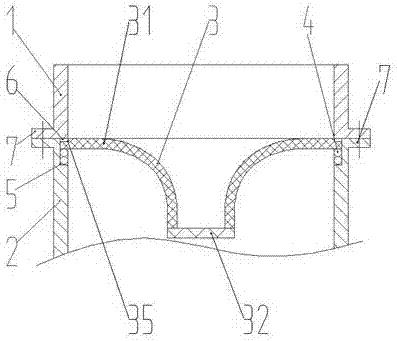

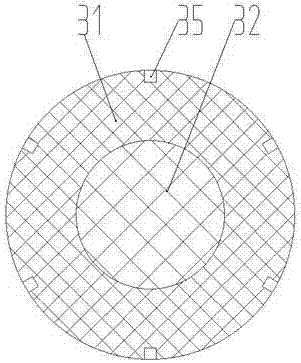

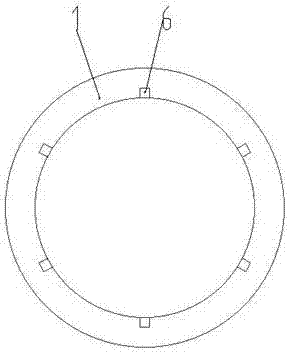

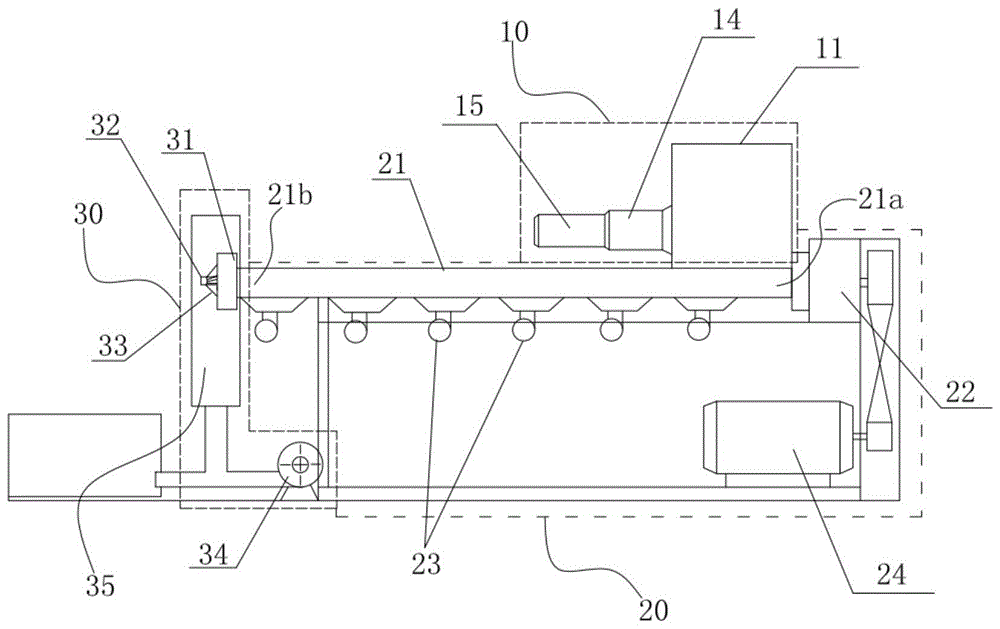

Calcium carbide cooling molding device

ActiveCN104108716ASimple production processReduce crushing processChemical industryCalcium carbideCooling towerAir blower

The invention relates to a calcium carbide cooling molding device. The calcium carbide cooling molding device is provided with a cooling tower, an extruding mechanism and a container with an upper opening. The container comprises a horizontal sieve plate and cylindrical side walls wrapping four outer sides of the sieve plate. The sieve plate is provided with several through sieve apertures, and the sieve apertures in the sieve plate close to the four edges have equivalent diameters greater than those of the sieve apertures close to the center of the sieve plate. The extruding mechanism is in a sliding fit relationship with the inner side wall of the container. The top and the bottom of the cooling tower are respectively provided with a calcium carbide feeding inlet and a calcium carbide discharging outlet. The side wall of the cooling tower is provided with an air outlet and an air inlet. A blower is arranged at the air inlet. The top of the cooling tower is provided with a station for receiving the container. The air outlet is connected to a heat release medium inlet of the heat exchanger by a dust remover. The calcium carbide cooling molding device can directly cure small calcium carbide blocks in calcium carbide transformation from a melt state to a solid state, is free of large-block calcium carbide fragmentation, reduces calcium carbide powder or calcium carbide dust produced by calcium carbide fragmentation, and realizes full resource utilization and recovery of heat released in calcium carbide curing.

Owner:重庆鸿庆达产业有限公司

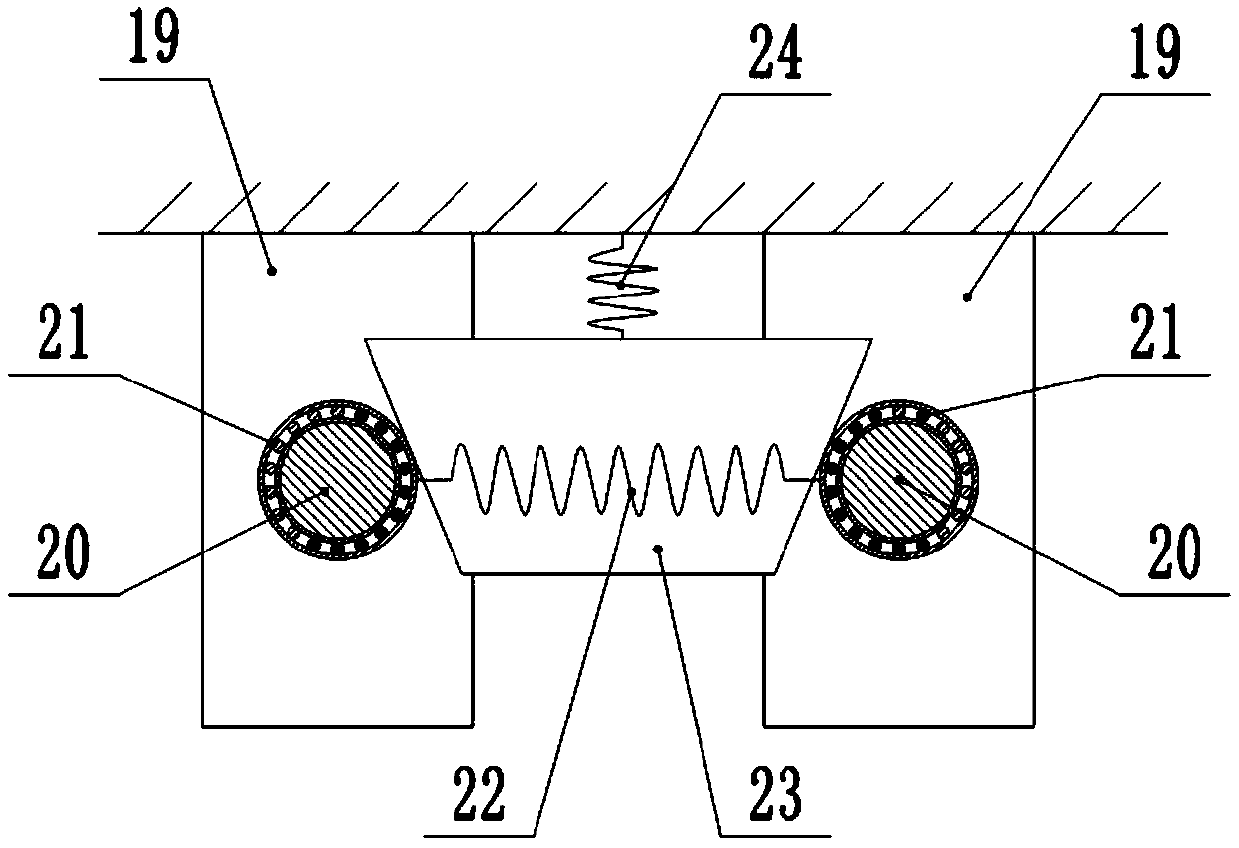

Multifunctional feeding device for vertical sieving and vibrating sand making machine

PendingCN107282276AAvoid easy cloggingBroken evenly and fullySievingScreeningBreaking strengthEffective solution

The invention discloses a multifunctional feeding device for a vertical screen vibrating sand making machine, which comprises a feeding box body, a material distribution plate and elastic parts; the upper end of the feeding box body is an incompletely closed feeding The lower end surface is a fully-opened discharge port; in the feed box, a distribution plate is arranged transversely relative to its axis; an elastic member is axially arranged between the distribution plate and the feed box; The feed box is located on the square of the impeller of the sand making machine, and the material distribution plate, the impeller, the feed pipe of the sand making machine, and the vibrating mechanism of the sand making machine are arranged correspondingly on the same axis from top to bottom; The material distributing mechanism and the vibrating mechanism on the vertical vibrating vibrating machine work together to make the material make full use of the collision force, and the crushing strength is greater. The above structure can effectively solve the problem of unsmooth discharge of materials in the vibrating vibrating vertical vibrating mechanism and sand making. The problem of low crushing efficiency and insufficient crushing of materials has greatly improved the crushing efficiency and quality of materials, and reduced the energy consumption of crushing.

Owner:尹国祥

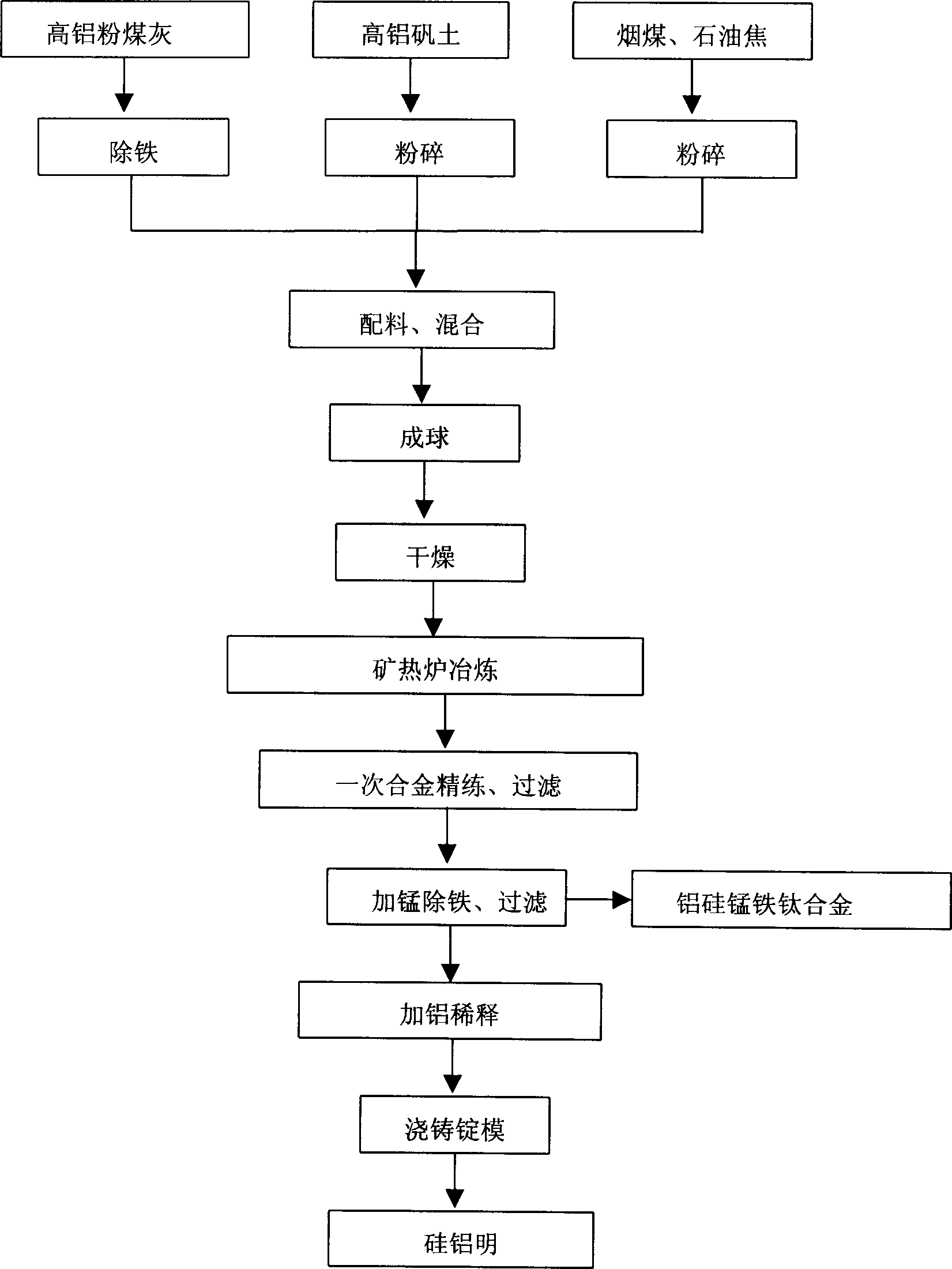

Method for preparing silumin and Al-Si-Mn-Fe-Ti alloy by using high-aluminum fly ash

ActiveCN1690235ARealize resource utilizationReduce manufacturing costProcess efficiency improvementSiluminAdhesive

Preparing silumin and Al-Si-Mn-Fe-Ti alloy with coal ash of high-alumina powder, relates to the technical sphere of non-ferro metals smelting. The steps of the invented process are: 1) deironing from coal ash of high-alumina powder, and breaking separately the bauxite chamotte and reducer boghead coal and oil coke; 2) batching and mixing them; 3) adding adhesive and water to the mixture, globularzing and drying; 4) sending the dried pellet to the stove and smelting in a high temperature to prepare primary alloy; 5) cleaning up of inclusion and gas in the primary alloy by refining and filtering it; 6) adding manganese to the refined alloy and deironing and filtering to prepare the Al-Si-Mn-Fe-Ti allay; 7) adding Al to the deironed and filtered alloy, diluting and casting ingot, to prepare silumin. The invention is characterized in that the investment is a little, the productive cycle is short, the energy consumption is low, and the quality of the alloy is nice.

Owner:TSINGHUA UNIV +1

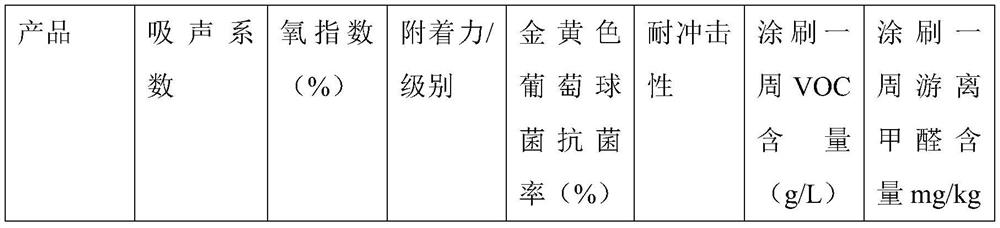

Sound-insulation shock-absorption antibacterial coating and preparation method thereof

The invention discloses a sound-insulation shock-absorption antibacterial coating and a preparation method thereof. The formula comprises the following raw materials in parts by weight: 150-200 partsof cement, 100-150 parts of heavy calcium carbonate powder, 130-180 parts of wood fiber, 50-80 parts of sepiolite fiber, 30-60 parts of basalt fibers, 20-40 parts of micronized glass beads, 3-5 partsof hydroxypropyl methyl cellulose, 8-15 parts of redispersible latex powder, 10-20 parts of shells, 10-20 parts of medical stone, 5-10 parts of nano titanium dioxide, 1-3 parts of Octakis(trimethylsiloxy)silsesquioxane, 3-5 parts of a dispersing agent and 2-4 parts of toner. The coating provided by the invention not only has the advantages of good shock absorption, sound insulation, antibiosis, flame retardance, adhesive property, dispersibility, lower cost and the like, but also is excellent in environmental protection performance and harmless to human bodies, can purify the air and remove harmful substances such as formaldehyde in the air, and can be widely applied to the building fields such as residences, schools, hospitals, hotels and office buildings.

Owner:广西绿桂装饰材料有限公司

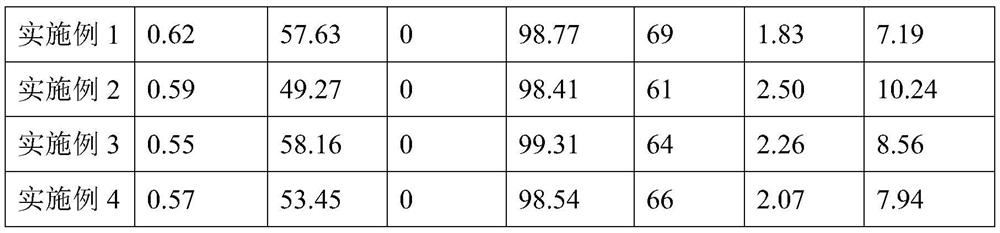

Method for extracting radix scrophulariae saponin from radix scrophulariae leftovers

InactiveCN105287885AImprove qualityMaintain biological activity and medicinal effectPlant ingredientsReflux extractionSaponin

The invention belongs to the field of extraction of effective ingredients of plants, and discloses a method for extracting radix scrophulariae saponin from radix scrophulariae leftovers. The method comprises the steps that the radix scrophulariae leftovers are dried and smashed; 75% ethyl alcohol is used for soaking the radix scrophulariae leftovers, then 75% ethyl alcohol is used for reflux extraction of radix scrophulariae saponin in the radix scrophulariae leftovers three times, and three times of extraction are combined to obtain a filtrate; a 3 g / mL loading solution is prepared and loaded to HPD100 type macroporous resin for adsorption, water with the volume 10 times that of the loading solution is used for elution, and 50-70% ethyl alcohol with the volume 12 times that of the loading solution is used for elution; a second-time elution solution is collected, and concentration and drying are carried out to obtain the radix scrophulariae saponin powder. The method enables the purification rate of the radix scrophulariae saponin in the radix scrophulariae leftovers to reach more than 90% and has the practical significance in production of radix scrophulariae saponin, leftovers produced in radix scrophulariae production are sufficiently utilized, and the method has the advantages of saving resources, reducing waste, reducing pollution, and achieving environmental production.

Owner:GUIZHOU BOFENG BIOLOGICAL TECH IND DEV

High-titanium blast furnace slag pervious concrete and using method thereof

ActiveCN112390599AImprove grindabilityReduce crushing processSolid waste managementCement productionSlagSuperplasticizer

The invention discloses high-titanium blast furnace slag pervious concrete and a using method thereof. The high-titanium blast furnace slag pervious concrete is prepared from, by mass, 1330-1360 partsof high-titanium blast furnace slag particles, 120-150 parts of high-titanium blast furnace water-quenched slag, 210-240 parts of cement, 9-11 parts of superplasticizer, 12-13 parts of enhancer, 13-15 parts of pigment and 90-95 parts of water. The preparation method comprises the following steps: uniformly mixing and stirring the raw materials, conducting paving and rolling on the ground, and naturally conducting curing for 12-15 days. According to the method, the utilization amount of waste resource blast furnace slag in the metallurgical process is effectively increased, and the productioncost is reduced.

Owner:PANZHIHUA HUANYE METALLURGICAL SLAG DEV CO LTD

Activated coke for absorbing dioxin in flue gas and preparation method thereof

ActiveCN102728322BReduce dosageUniform adsorptionOther chemical processesDispersed particle separationSorbentFlue gas

The present invention relates to an activated coke for absorbing persistent organic pollutant like dioxin in flue gas and a preparation method thereof by using coal quality semi coke as a raw material. The preparation method is as follows: crushing the coal quality semi coke; impregnating the coal quality semi coke with an impregnating solution containing metal hydroxide or alkali metal carbonate activator and compound surfactant, and naturally drying; and finally activating the impregnated and dried semi coke at 800-950 DEG C to prepare the activated coke for absorbing dioxin in flue gas. The activated coke has characteristics of developed porous structure, low manufacturing cost and good adsorption effect, etc.

Owner:BAOSHAN IRON & STEEL CO LTD +1

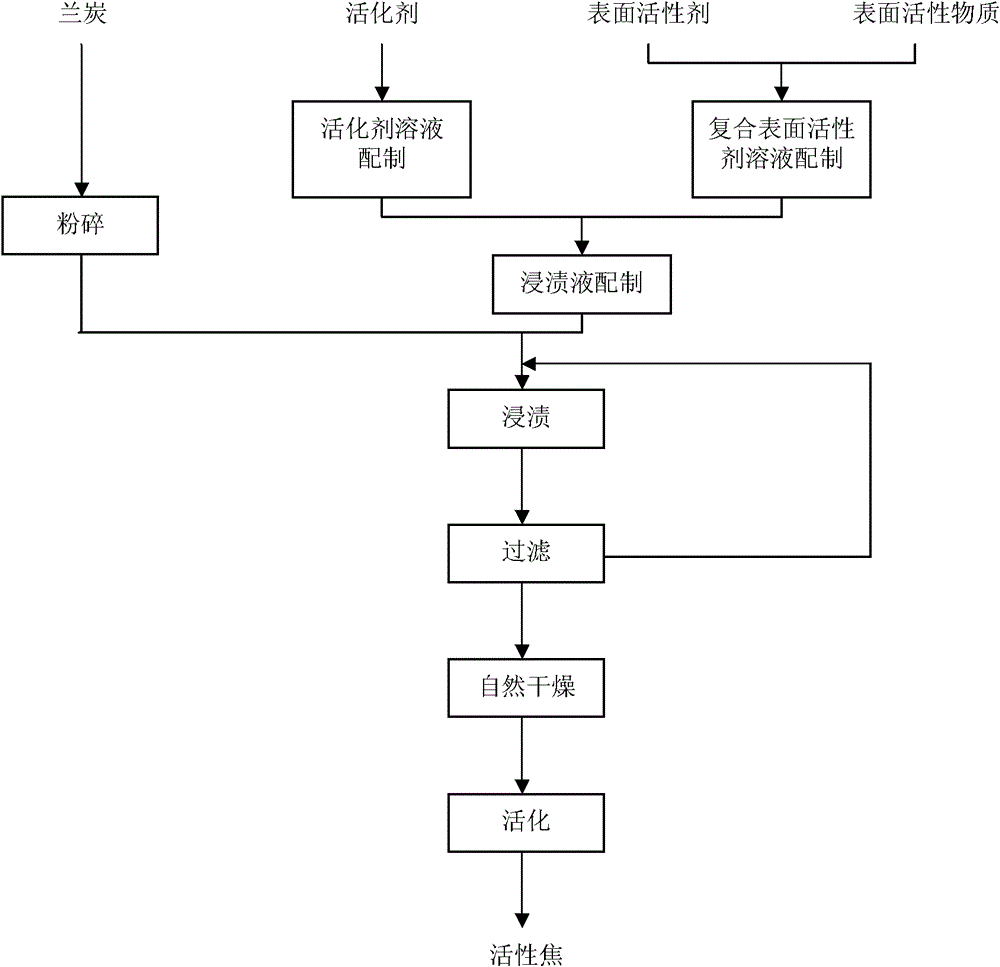

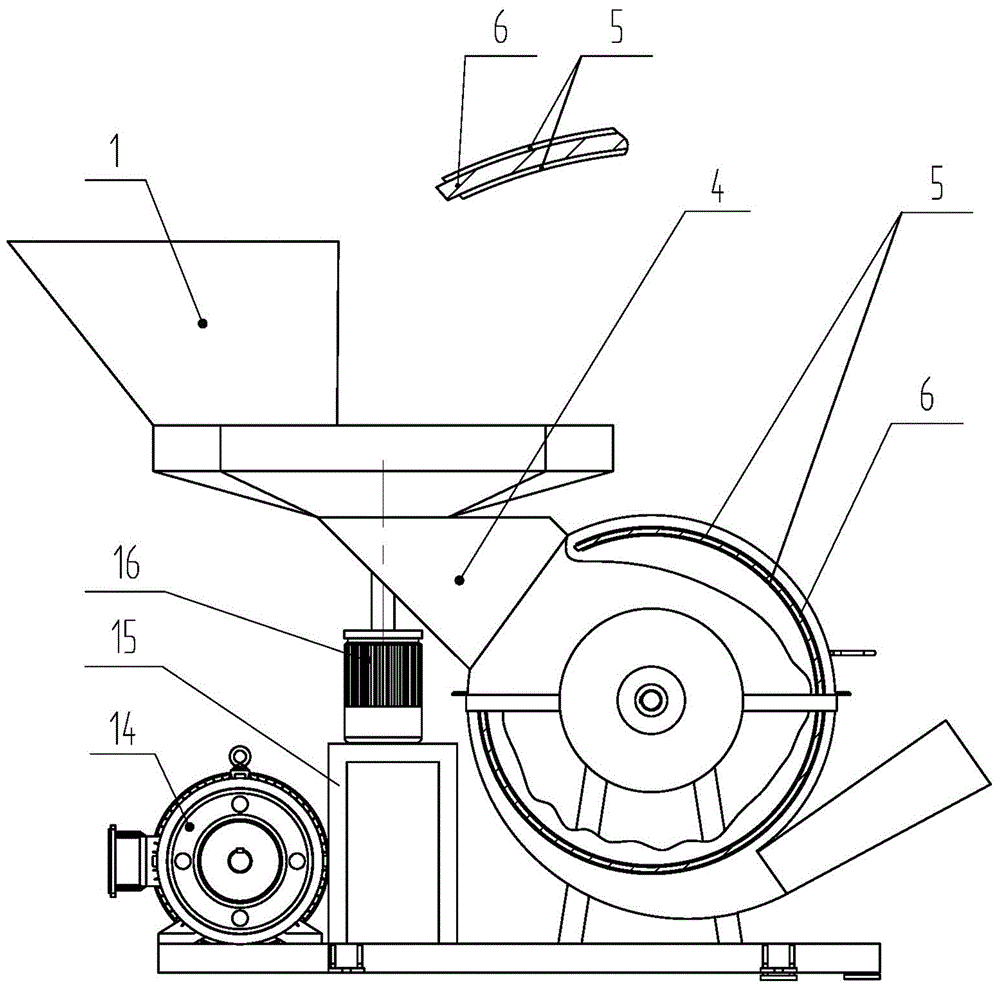

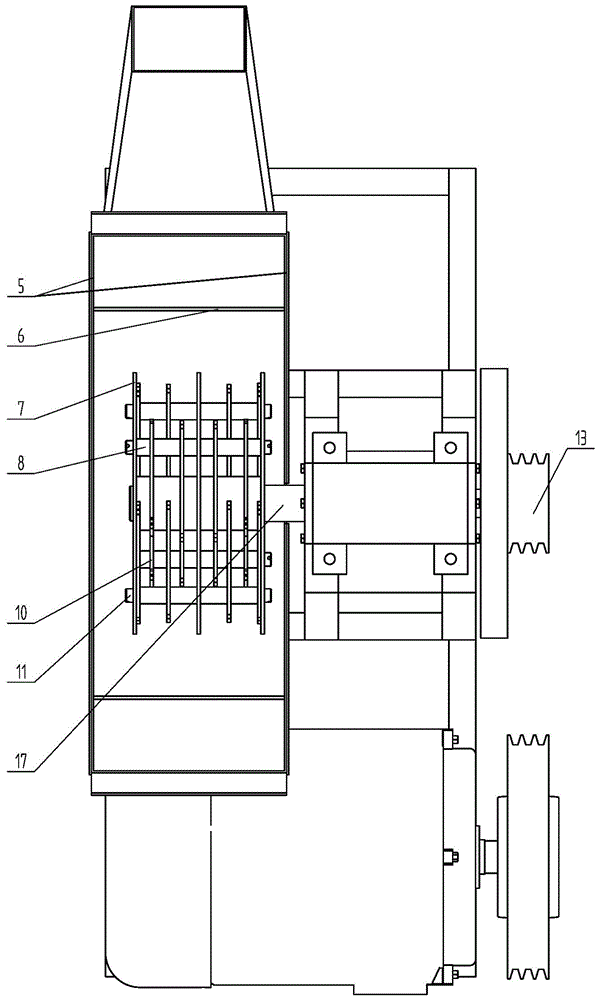

Upcut hammer mill

The invention provides an upcut hammer mill. The upcut hammer mill comprises a milling chamber, motors, belt pulleys and a rack and further comprises an upcut chamber. The upcut chamber comprises a feed port, upcut knives and an upcut knife shaft. The milling chamber comprises arc-shaped rails, a rubbing plate, knife rests, spacer bushes, a stationary knife, hammer knives, hammer knife shafts and a knife rest spindle. The upcut knife shaft penetrates the upcut chamber to be in transmission connection with the second motor at the bottom. An upper cavity and a lower cavity of the milling chamber are connected through a bolt. The whole cavity is fixedly arranged on a milling chamber rack through the knife rest spindle. The arc-shaped rails and the rubbing plate are fixedly arranged in the upper cavity and the lower cavity. The four hammer knife shafts are evenly distributed on the knife rests. The hammer knives are spaced by the spacer bushes, two sets of hammer knives are distributed alternately, every two adjacent sets of hammer knives are symmetrically arranged in a staggered manner, and materials of different particle sizes can be obtained by replacing rubbing plates with meshes of different sizes. Procedures are reduced to the maximum degree, the upcut chamber is creatively designed to be separated from the milling chamber, and traditional hammer milling is ingeniously benefited; and energy consumption is reduced, operation is convenient, and labor intensity is reduced.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

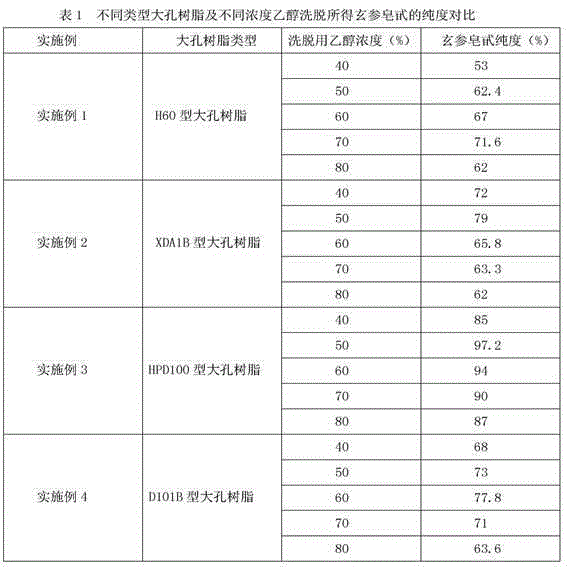

Manufacturing method of phosphogypsum ball

The present invention relates to a preparation method of phosphogypsum sphere which can be substituted for natural gypsum in cement industrial. Said method includes the following steps: (1), raw material selection: selecting naturally dried rejected material of phosphate fertilizer plant, screening, removing impurity, its grain size is less than 10mm; (2), adding modifying agent alkaline substance, uniformly mixing them, drying in drying kiln, in the drying process making the impurities of water, water-soluble phosphorus pentoxide, sulfate radical and phosphate radical be volatilized; and (3), pressing sphere and forming.

Owner:朱成书

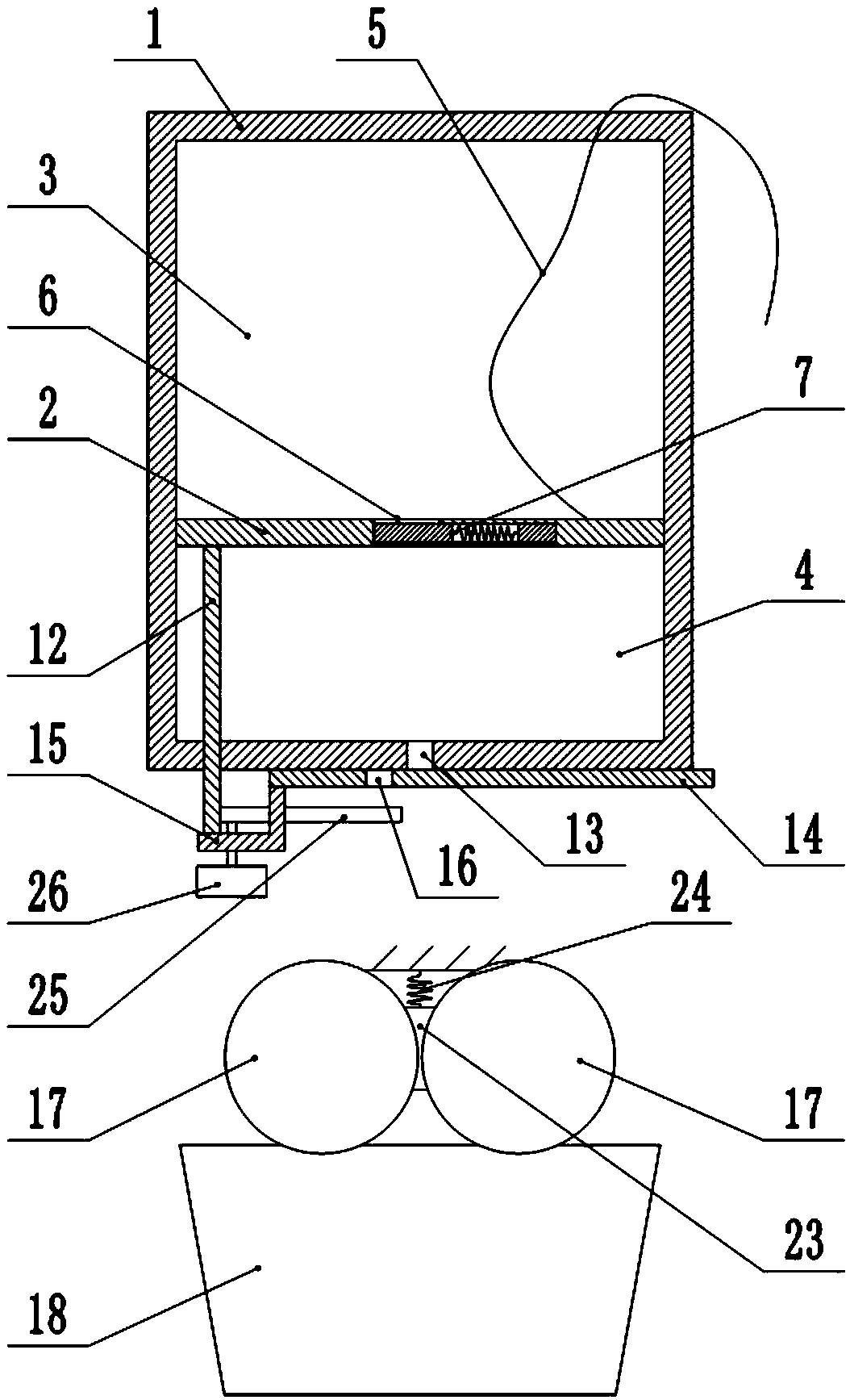

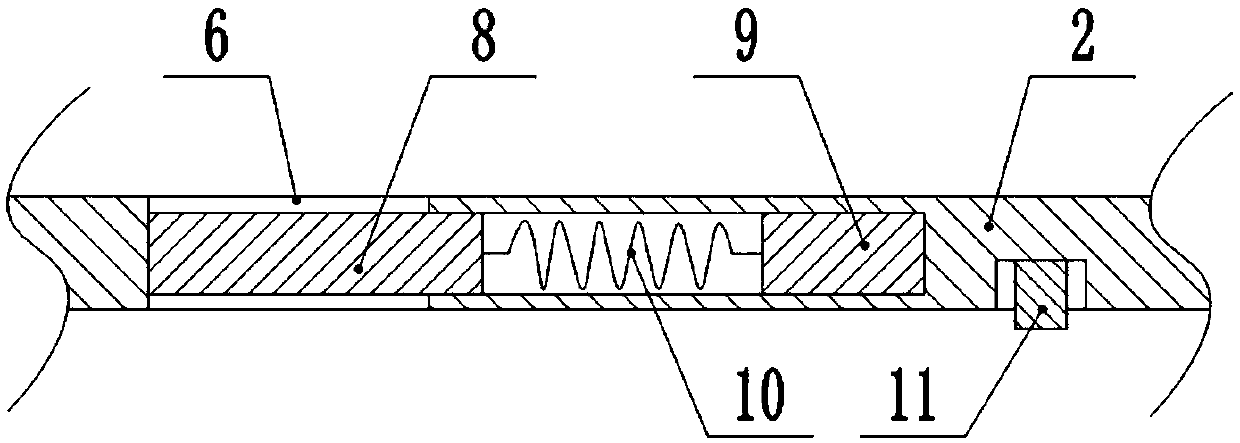

Wine-making raw material treatment equipment

The invention relates to the technical field of wine-making equipment and particularly discloses wine-making raw material treatment equipment. The wine-making raw material treatment equipment comprises a material storage tank, the material storage tank is internally and slidably connected with a sliding plate, the sliding plate separates the material storage tank into an upper cavity and a lower cavity with the volume ratio being 7:3 and is provided with a through slot, a plugging mechanism is arranged at the through slot, the sliding plate is connected with a support rod, the bottom wall of the lower cavity is provided with a material outlet and a through hole for the support rod passing through and is slidably connected with a baffle used for sheltering the material outlet, the baffle isconnected with a position-limiting plate used for supporting the support rod, a rack and two crushing rollers are arranged below the material outlet, the crushing rollers are coaxially connected withrotating shafts, the rotating shafts are provided with bearings, a first spring is connected between the two bearings, a wedge block is clamped between the two bearings and is connected with a secondspring, the second spring is connected to the rack, and the support rod is connected with an L-shaped pushing rod used for pushing the wedge block. By means of the wine-making raw material treatmentequipment, sorghum rice reaching the wine-making raw material crushing requirements can be crushed out at a time, and improvement of the wine-making efficiency is facilitated.

Owner:钟伟光

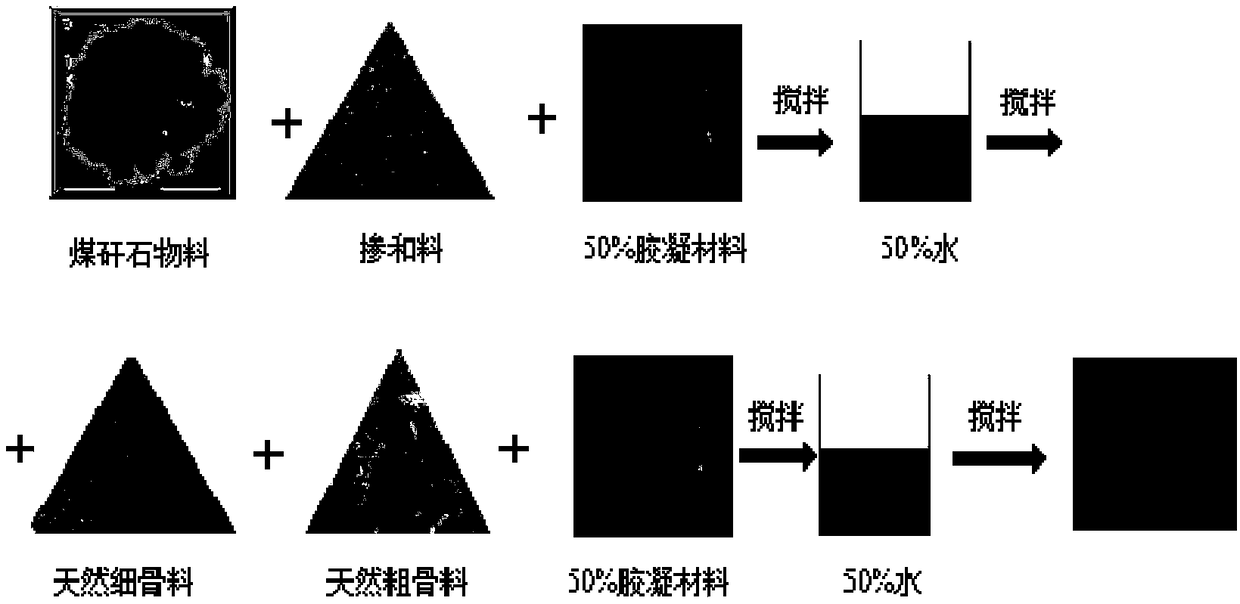

Coal gangue concrete as well as preparation method and application thereof

InactiveCN109053062AReduce crushing processImprove work efficiencySolid waste managementCement mixing apparatusMechanical propertySediment

The invention discloses coal gangue concrete as well as a preparation method and the application thereof. The coal gangue concrete comprises components of a coal gangue raw material and a concrete material, and particularly discloses the coal gangue concrete specifically prepared from the following components according to certain proportions: coal gangue aggregate, an admixture, a cementing material, water for mixing, natural coarse aggregate and natural fine aggregate; the adding weight of the coal gangue raw material is smaller than or equal to 30 percent of total weight of the coal gangue concrete. The preparation method comprises the following steps: crushing, flushing and drying coal gangue to obtain sediment and the coal gangue aggregate and treating the sediment to prepare the admixture; mixing part of raw materials according to mixture ratio and carrying out primary stirring to form a primary stirring material; adding corresponding materials into the primary stirring material and carrying out secondary stirring to obtain the coal gangue concrete. The coal gangue does not need to be broken for multiple times, so that the preparation method has the advantages of environment friendliness, high efficiency, facilitation for industrial production and capability of saving a large amount of energy; the prepared coal gangue concrete has better mechanical properties and improvedworkability; in addition, the coal gangue concrete can be applied to the technical field of preparation of concrete-filled steel tubular members.

Owner:SHENYANG JIANZHU UNIVERSITY

Tobacco matrix composite biopesticide and preparation method thereof

InactiveCN102265908BHas double insecticidal effectImprove resource utilizationBiocideAnimal repellantsSocial benefitsMetabolite

The invention provides a tobacco matrix composite biopesticide and a preparation method thereof. The composite biopesticide which comprises at least a tobacco botanical insecticidal component and at least a microbial insecticidal component is prepared through fermenting insecticidal microbes with selecting a tobacco waste as a raw material. The preparation method comprises the following operationsteps: preparation of a medium, amplification culturing of spawns, fermentation of the biopesticide, and extraction. A fermentation technology can adopt liquid state fermentation or solid state fermentation. The tobacco matrix composite biopesticide of the invention which not only contains the insecticidal microbes and metabolites thereof, but also contains tobacco insecticidal components (nicotine and the like for example) has dual insecticidal effects. The method of the invention which allows resources of the tobacco waste which is not reasonably utilized at present to be fully utilized allows grain resources to be saved, and good economic benefits, ecological benefits and social benefits to be generated.

Owner:ZHENGZHOU UNIV

Disposable environment-friendly tableware and manufacturing process thereof

Disposable environment-friendly tableware and a manufacturing process thereof belong to the technical field of tableware manufacture. The disposable tableware product produced by a traditional manufacturing process by adopting a master method has the defects of high brittleness, low starch content and high evaporated residual slag content. The manufacturing process disclosed by the invention comprises three steps, namely master preparation, film preparation by extrusion and plastics sucking moulding. The manufacturing process is characterized in that during master preparation, maleic anhydride E resin, starch and a lubricating agent are fused and mixed to from granular materials; the materials are directly input into an extrusion granulator for extruding to form a strip shape; strip materials enter a dicing cutter for dicing; breaking work procedures are reduced, the process flow is shortened and the addition amount of the starch is promoted; in the second step, assistants such as master, polypropylene and TMC-300 nucleating agent are sequentially added into a high mixer; the mixer is input into an extruder for stretching and extruding; and the extruded component is subjected to three-roll crushing, cooling and setting by using circulating water to form a film. Due to the addition of the TMC-300 nucleating agent as the assistant, the physical and mechanical performances of the product are improved and the thermal deformation temperature, strong modulus and the impact resistant strength of the product are improved.

Owner:浙江天禾生态科技有限公司

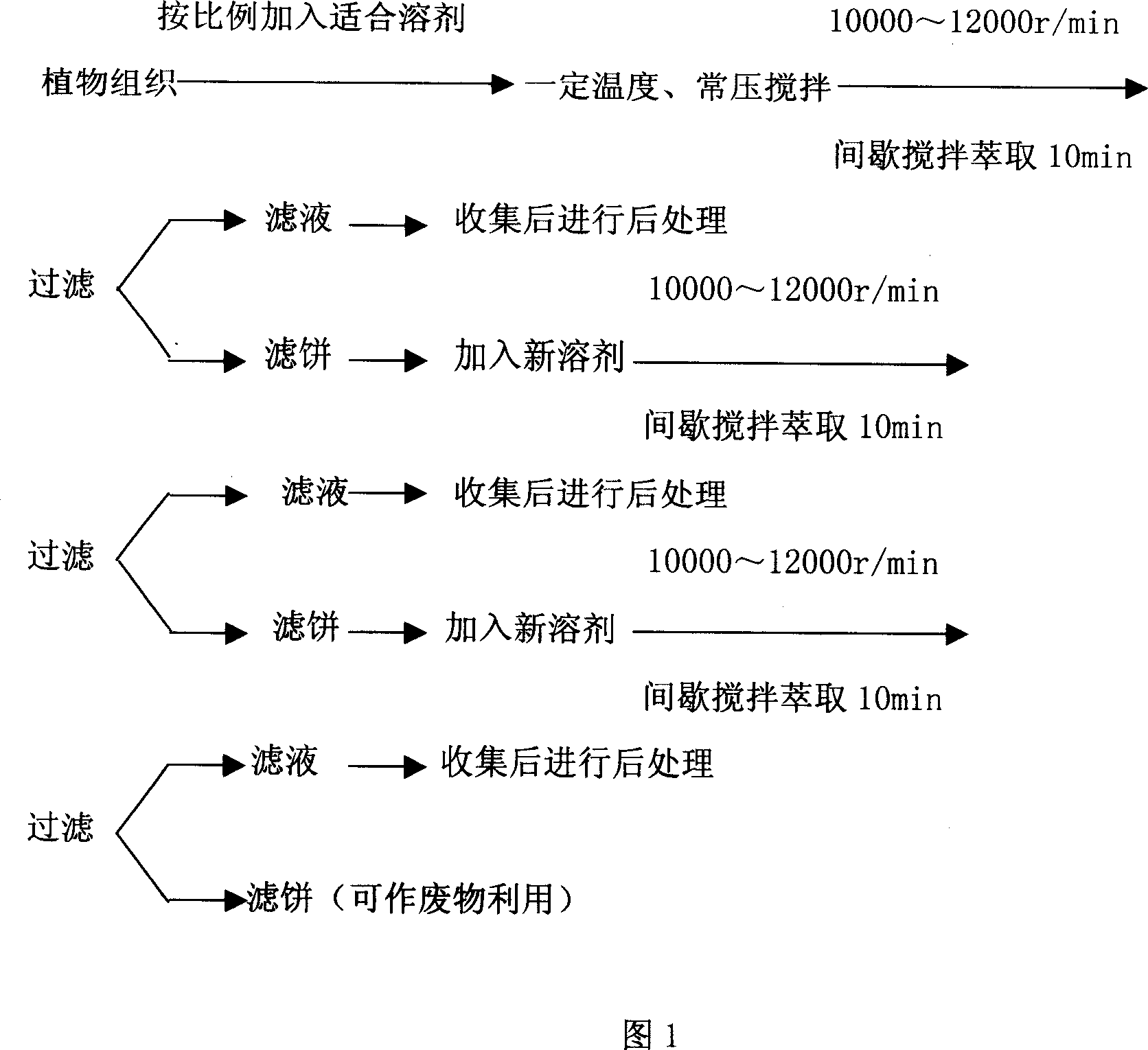

Fast extraction of plant chemical ingredient

InactiveCN101028569ASolving Hard-to-Smash ProblemsAvoid lostSolid solvent extractionPhytochemicalChemical composition

Owner:THE RES INST OF RESOURCES INSECTS RIRI OF THE CHINESE ACADEMY OF FORESTRY

Preparation of high molecular weight instant cation polyacrylamide

The invention relates to a preparation method for instant cation polyacrylamide with a high molecular weight. The monomer of acrylamide and a cation type monomer are used as the main materials, firstly, the acrylamide and a comonomer are dissolved into deionized water; then a photoinitiator and / or a photosensitizer additive and a redox initiator are added in the solution to form a compound initiating system; the materials of the components are uniformly mixed in a viscous state, poured on a plane and paved into a sheet shape, introduced with high purity nitrogen, then ultraviolet light illumination is carried out to the materials paved into the sheet shape; after the materials of the viscous state are in a gel block, the materials are dried, broken, granulated and cracked to obtain a product of a dry powder shape. In the invention, the heat release and temperature rising of bulk adiabatic polymerization are avoided, while the polymerization and drying are carried out under a lower temperature; therefore, the reaction process is stable; the product has the advantages of higher molecular weight, better solubility, faster dissolving speed, simple technique and low cost; in addition, the processing after polymerization reduces the working procedure of breaking of bulk gel.

Owner:朱定洋

Powder injection molding feeding manufacturing equipment

ActiveCN104148638AAvoid intercooling and solidificationAvoid it happening againHigh volume manufacturingEngineering

The invention discloses powder injection molding feeding manufacturing equipment which comprises a kneading device, an extruding device and a grain cutting device. A discharge outlet of the kneading device is communicated with a barrel inlet end of the extruding device, the grain cutting device is connected to a barrel outlet end of the extruding device, and powder materials are kneaded by the kneading device, then are directly fed into the extruding device, pass the extruding device and then are directly fed into the grain cutting device to be subjected to hot-cutting air-cooled granulation. The powder injection molding feeding manufacturing equipment for realizing powder injection molding feeding manufacturing effects has the advantages that large-scale continuous operation with high production efficiency can be carried out; the hot-state materials can be directly fed into follow-up machining links, accordingly, reheating temperature rise required by granulation procedures can be reduced, and energy consumption can be greatly decreased; labor can be saved, the efficacy of the equipment can be improved, the productivity can be enhanced, and the production cost can be reduced; crushing procedures which are carried out after intermediate cooling and solidifying can be reduced, dust can be prevented in material crushing procedures, and accordingly operation environments can be improved.

Owner:DONGGUAN HUAJING POWDER METALLURGY

Preparation method of quaternary ammonium group contained (methyl) acrylate copolymer water dispersion

ActiveCN109627458ASolve the problem of adding fat-soluble plasticizersAvoid pollutionPharmaceutical non-active ingredientsDistillationPlasticizer

The invention relates to a preparation method of a quaternary ammonium group contained (methyl) acrylate copolymer water dispersion. The method comprises the steps that stirring continues to be performed in hot water with the temperature being 50-100 DEG C, a quaternary ammonium group contained (methyl) acrylate copolymer and a small amount of plasticizer combined with the solvent are added, the stirring time is 2-24 h, and the water dispersion is generated; then, according to application of the follow-up preparation, whether or not a distillation recycling solvent is needed and other additives suitable for medicine applications are added is selected according to the follow-up preparation; after cooling is performed to room temperature, a fine screen is used for filtering away possibly existing solids which are not dispersed completely. The method is applicable to water soluble and fat soluble plasticizers, no unexpected surface active agent with the hole forming effect for affecting medicine release is adopted, and the quaternary ammonium group contained (methyl) acrylate copolymer water dispersion is more efficient to prepare and wider to apply.

Owner:英德茂丰药业有限公司 +1

Sound insulation wallpaper

InactiveCN105755893AImprove adhesionGood sound insulationWaste product additionSpecial paperAluminiumHeavy metals

The invention discloses sound-insulation wallpaper, which relates to the technical field of a decoration material. The sound insulation wallpaper comprises a decoration surface layer and a basic layer disposed below the decoration surface layer, and is characterized in that a sound absorption layer is arranged between the decoration surface layer and the basic layer, wherein the sound absorption layer adopts a composite material prepared by adopting one or a mixture of two of sugarcane fibers and rubber or resin as a basic layer and adopts one powder or mixed powder of iron, copper and aluminum as a filling agent. By adopting the sound insulation wallpaper, the problems that the body health is influenced by the environmental pollution caused by the dropping of heavy metals of the existing sound absorption wallpaper and the production cost is high are solved.

Owner:柳州市够旺贸易有限公司

A preparation equipment for powder injection molding feed

ActiveCN104148638BAvoid intercooling and solidificationAvoid it happening againHigh volume manufacturingEngineering

Owner:DONGGUAN HUAJING POWDER METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com