Method for regenerating tobacco leaves by loaded tobacco fragments manufactured by dry papermaking technology

A technology of reconstituted tobacco leaves and dry-laid paper, which is applied in the field of tobacco product processing, can solve the problems affecting the smoking quality and quality of reconstituted tobacco leaves, affect product quality and production environment, and easily drop powder on the edge end surface, etc., and achieve the goal of technological innovation Remarkable effect, improvement of dust phenomenon, and reduction of crushing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

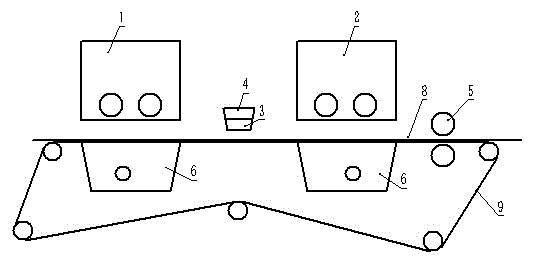

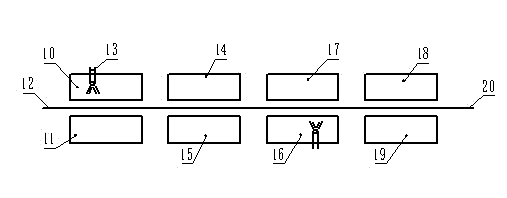

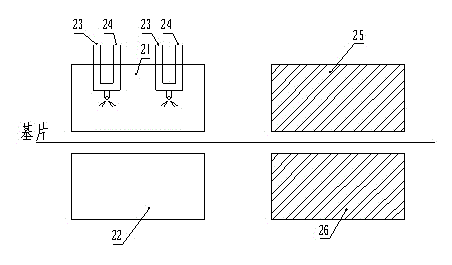

Embodiment 1

[0029] The plant fibers are defibrated into single fibers and sent to the first shaper (1) by air, and under the protection of the negative pressure box (6), a fiber layer (7) of 10g / m2 is formed, and the tobacco chips are passed through the spreader ( 3) Measuring and spreading on the first former (1), and laying a layer of tobacco fragments on the formed fiber thin layer, the quantity of tobacco fragments is 10g / m2. Then on the fiber layer covered with tobacco chips, under the negative pressure protection of the negative pressure box (6) by the second shaper (2), a layer of fiber is laid on it, and the amount of fiber laying is 10g / m2, like this Just formed a combined composite fiber layer (8) that is sandwiched with tobacco fragments in the middle of the upper and lower fiber layers. After the pre-pressing by the pre-pressing hot roller (5), the substrate prototype is formed. At this time, the substrate has not been sprayed with adhesive, and its strength is low. On the fo...

Embodiment 2

[0031] After the plant fiber is defibrated, it is sent to the first former (1) by air, and under the protection of the negative pressure of the negative pressure box (6), a fiber layer (7) with a weight of 10g / m2 is formed, and then formed by the second Under the negative pressure protection of the negative pressure box (6), the device (2) lays another layer of fiber layer on the fiber layer (7), the weight of the newly laid fiber layer is 8g / m2, thus forming a fiber layer of 18g / m2 (8), pre-pressed by the pre-pressing hot roller (5) to form a substrate prototype composed of fiber layers. At this time, the formed substrate has no strength. On the formed substrate, a certain amount of adhesive is sprayed on the upper and lower sides , under the protection of the negative pressure of the negative pressure box (11) and the negative pressure box (17), the adhesive is attached to the substrate, and has a certain penetration, and is dried by the drying box (14, 15, 18, 19) Then ther...

Embodiment 3

[0033] The plant fibers are defibrated into single fibers and sent to the first shaper (1) by air. Under the protection of the negative pressure of the negative pressure box (6), a fiber layer (7) of 10g / m2 is formed. The spreader (3) measures and spreads on the fiber layer (7) formed by the first former (1), spreads a layer of tobacco chips, the tobacco chips are quantitatively 10g / m2, and then spreads on the fiber layer covered with tobacco chips , under the protection of the negative pressure of the negative pressure box (6) by the second shaper (2), a layer of fiber is laid on it, and the amount of fiber laying is 10g / m2, thus forming a sandwich between the upper and lower fiber layers The combined fiber layer (8) with tobacco fragments has just formed the base sheet prototype after pre-pressing with the pre-pressing hot roller (5). At this time, the substrate is not sprayed with adhesive, and its strength is low. On the formed substrate, the upper and lower sides are spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com