Patents

Literature

35results about How to "Increase smoke production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of cooling and aroma-enhancing particles for HNB cigarettes and cooling and aroma-enhancing particles for HNB cigarettes

ActiveCN112656024AImprove distribution uniformityGood compatibilityTobacco preparationTobacco treatmentHigh humidityPlant fibre

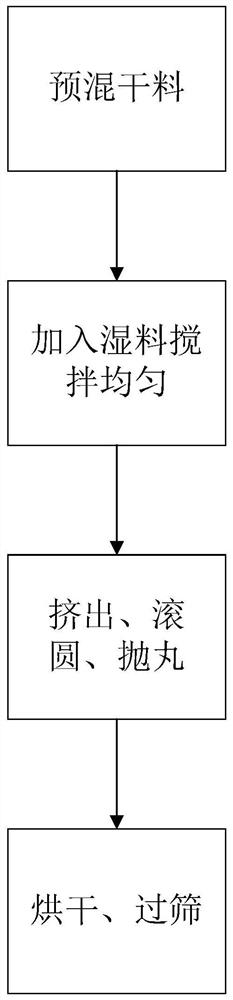

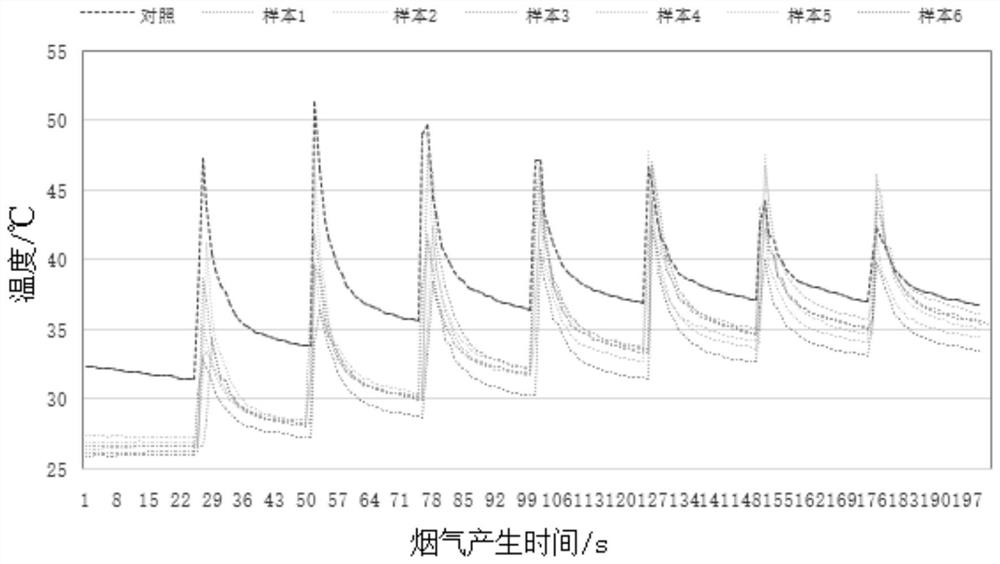

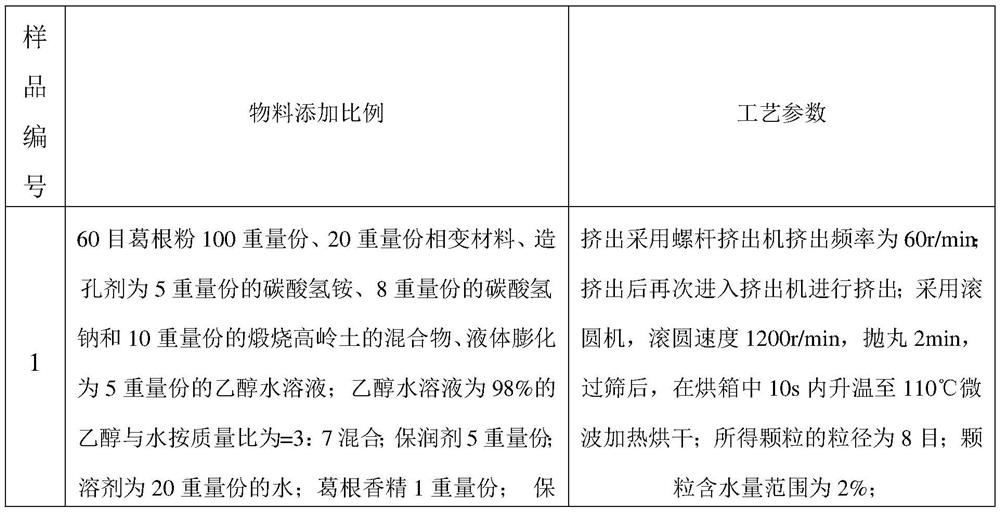

The invention discloses a preparation method of cooling and aroma-enhancing particles for HNB cigarettes and a cooling and aroma-enhancing particles for HNB cigarettes. The preparation method comprises the following steps of: premixing plant fiber-containing powder, a phase-change material and a pore-forming agent uniformly; adding a humectant, a solvent, essence and a liquid swelling agent, performing uniform mixing; carrying out screw extrusion for at least two times; and performing rounding, shot blasting, drying and sieving to obtain particles. According to the preparation method, the liquid swelling agent and the pore forming agent are added in the mixing stage, and the powder containing the plant fibers is used as the raw material, so that in the extrusion process of the interior of each particle, the connection performance of the material is enhanced by utilizing the bridging effect of the plant fibers; the high-humidity quick-drying (quick drying and swelling of high-humidity objects) of the particle components and the pore-forming effect of the pore-forming agent and the swelling agent increase the porosity of the particles, enhance the connection tightness of the plant fibers to powder material in the particles, reduce the breakage rate of the particles during filling, enhance the quality of filled tobaccos and improve product quality.

Owner:YUNNAN YANGRUI TECH GRP

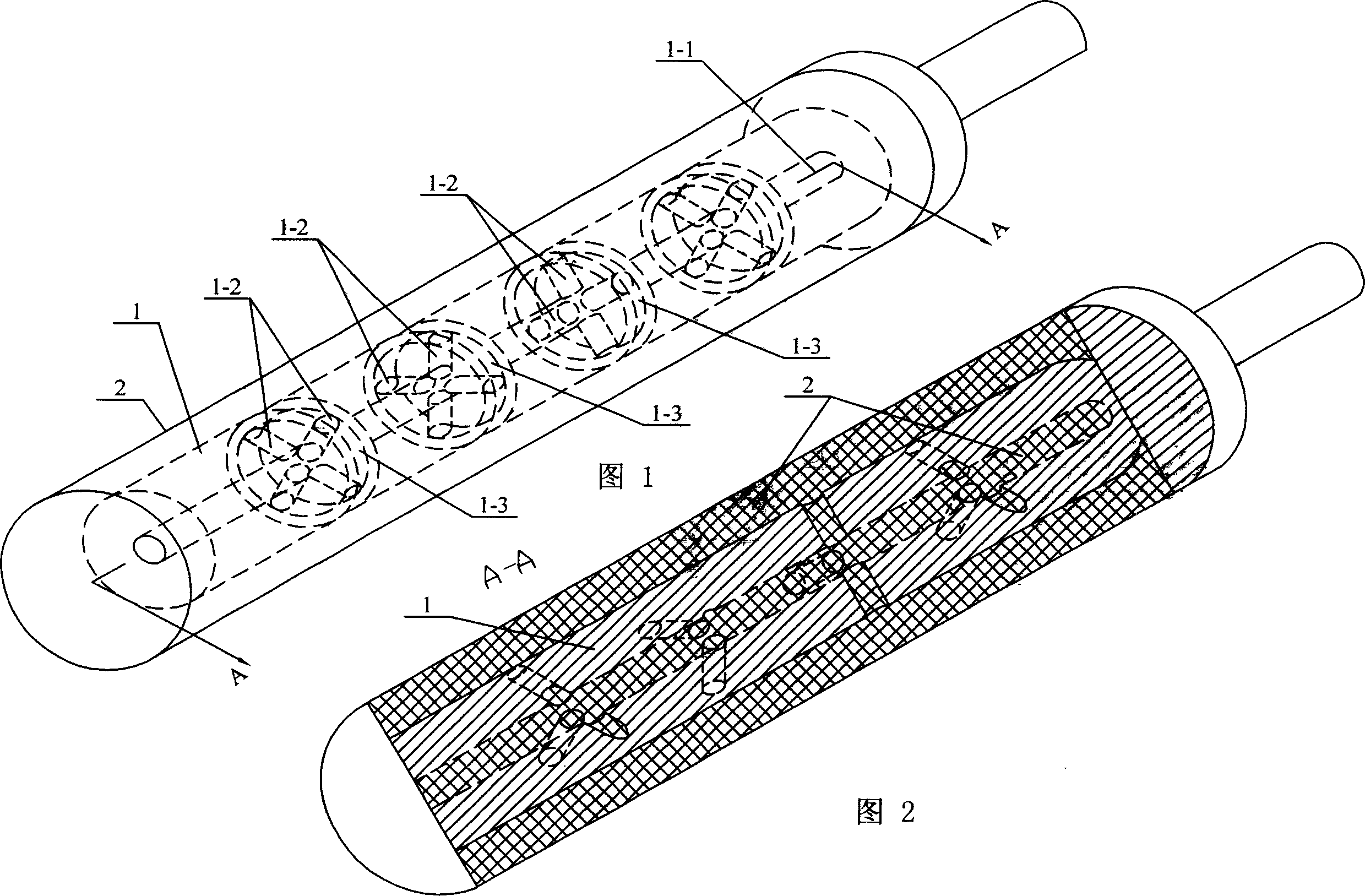

Heat non-burning cigarette body and manufacturing method thereof

InactiveCN109938398AIncrease heat transfer and smoke effectImprove the smoke effectTobacco treatmentBiochemical engineeringProduction effect

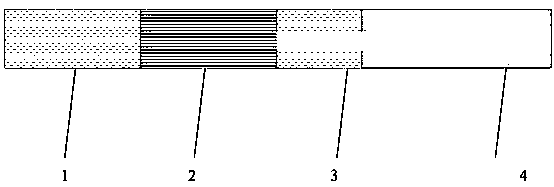

The invention relates to a heat non-burning cigarette body and a manufacturing method thereof, and belongs to the field of heat non-burning cigarettes. The heat non-burning cigarette body comprises anauxiliary unit and a smoke production unit, wherein the auxiliary unit comprises a filter section, a cooling section and a hollow section; one end of the hollow section is connected with the smoke production unit, and the other end of the hollow section is connected with the cooling section; the cooling section is connected with the filter section; the smoke production unit is of a compact hollowtubular structure; the inner diameter of the hollow is 1 to 8 mm; the outer diameter of the column is 5 to 10 mm; the length is 10 to 60 mm. According to the heat non-burning cigarette body and the manufacturing method thereof, a paste smoke production material is made into the compact hollow tubular structure to further enhance the heat transfer and smoke production effect of the smoke production material and increase the suction number and the smoke concentration; furthermore, compared with a smoke production unit such as cut tobaccos and a sheet, the smoke production unit of the heat non-burning cigarette body cannot be covered by cigarette paper, so that a layer of cigarette paper is reduced, and the heat transfer effect between a heating tube and a smoke production material can be further enhanced.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD +1

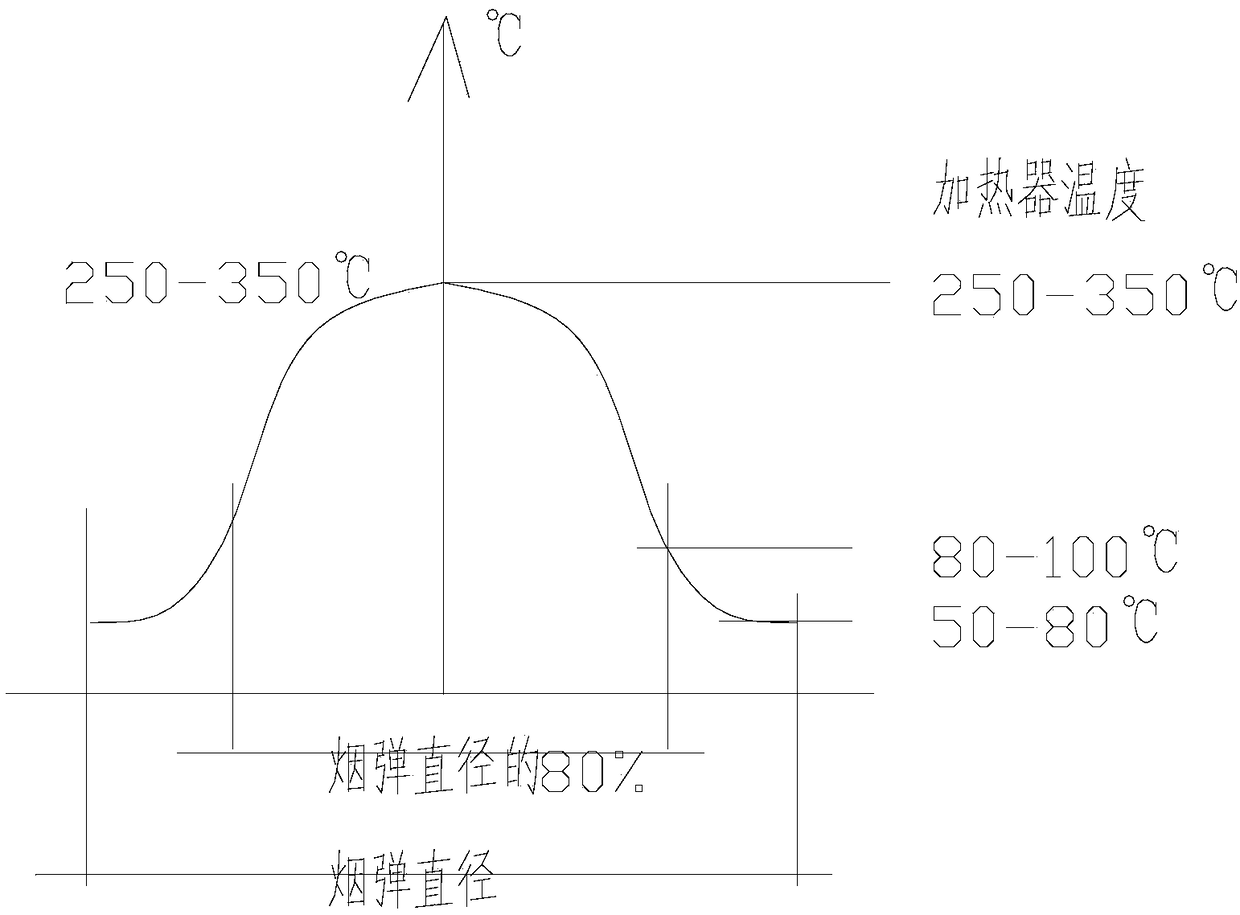

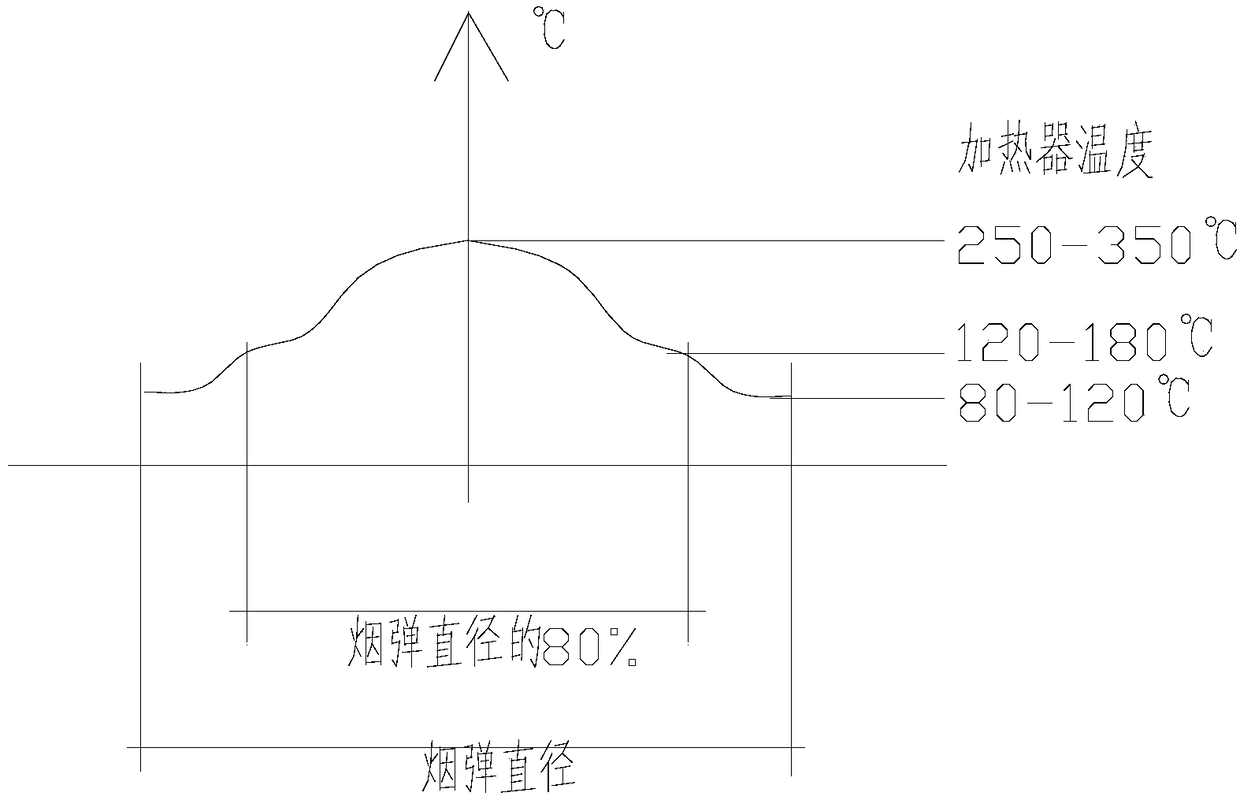

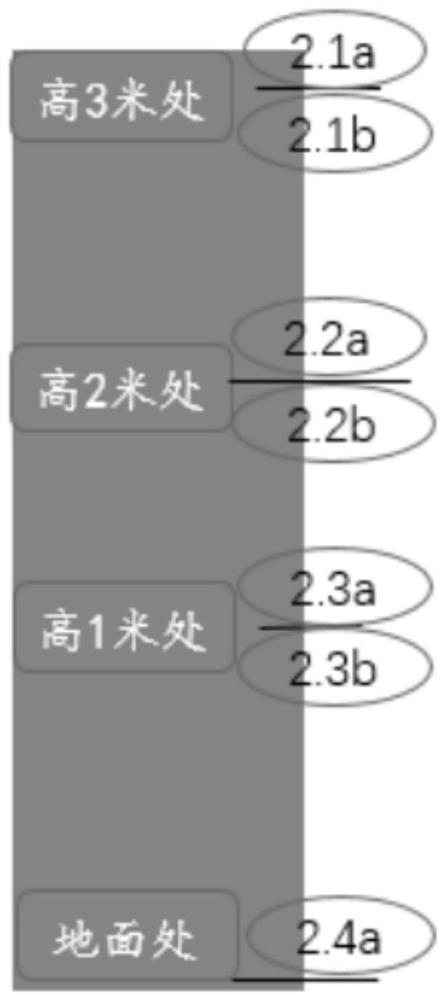

A substrate capable of raising heating temperature and increasing smoke emission amount and a preparation method thereof

The invention relates to a substrate capable of raising heating temperature and increasing smoke emission amount, which is prepared by pulverizing tobacco raw material and pulping plant fibers throughthick pulp method or other similar papermaking method. A metal product and an adhesive are added to that tobacco substrate during the preparation process, and the substrate is finally formed into a smoky rod by cutting or slicing through roll, and is a filler material for heating a smoky bomb, wherein a smoky substance (propylene glycol, for example) contained therein is heated and evaporated toform smoke.

Owner:江苏瑞驰机电科技有限公司

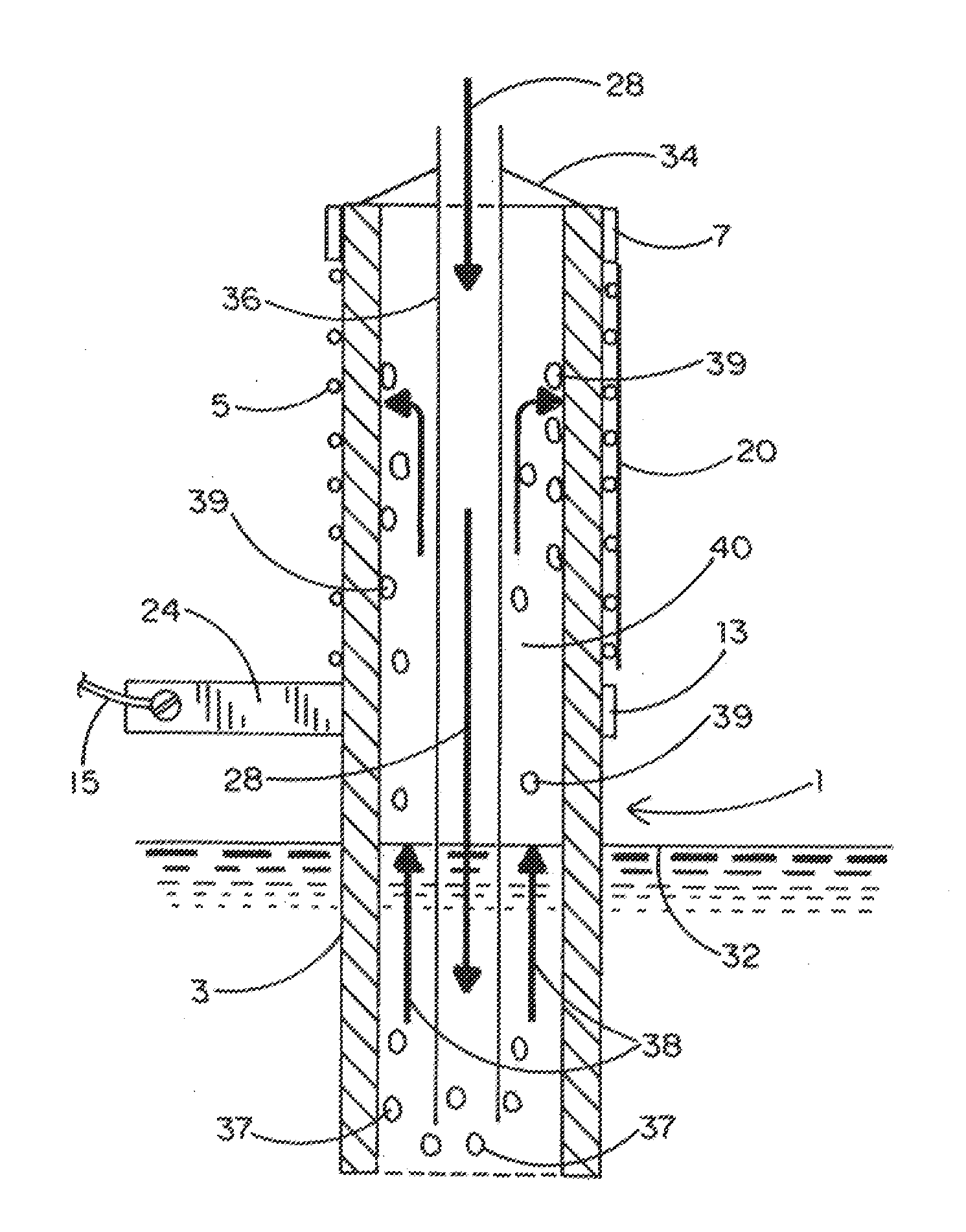

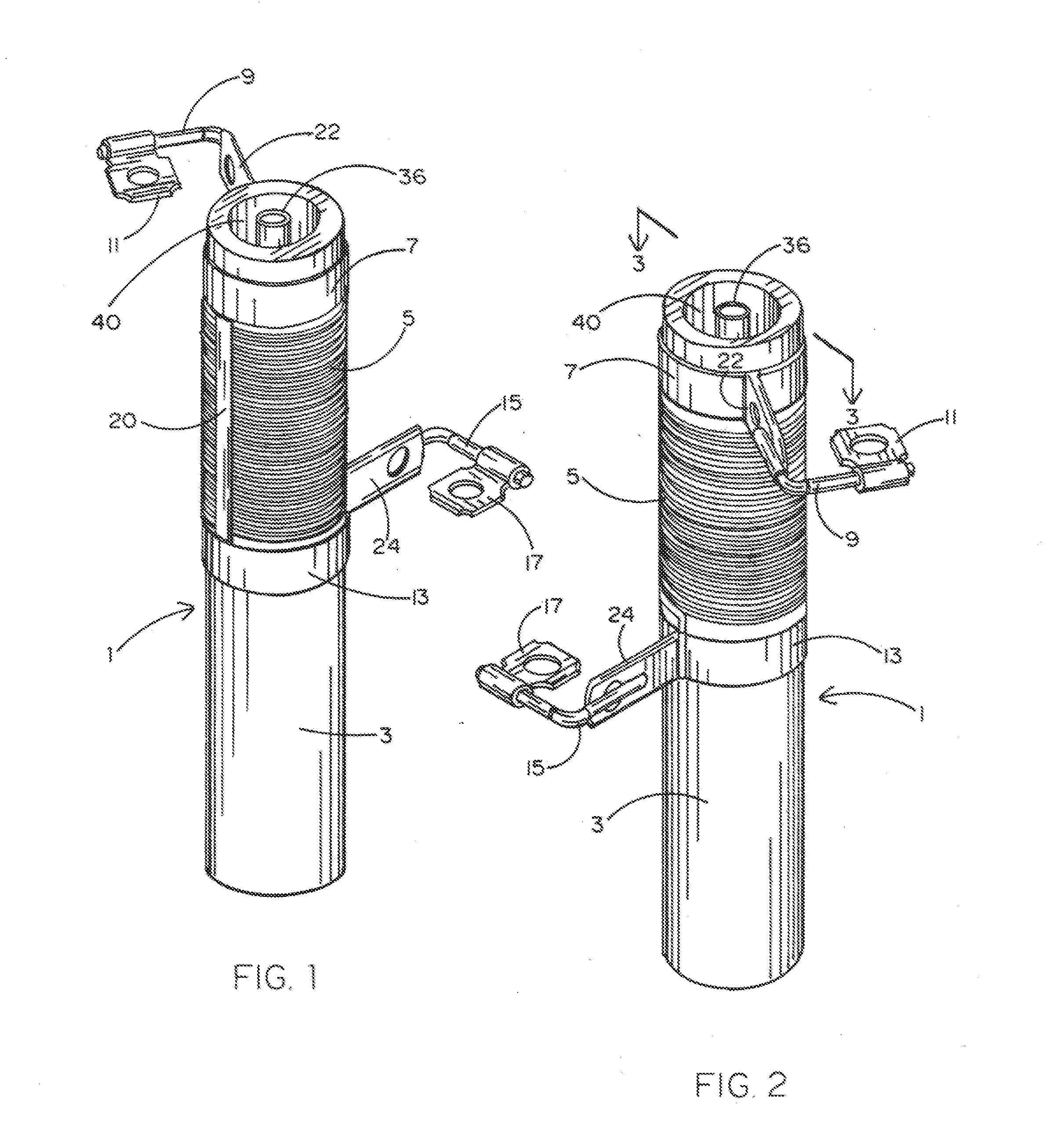

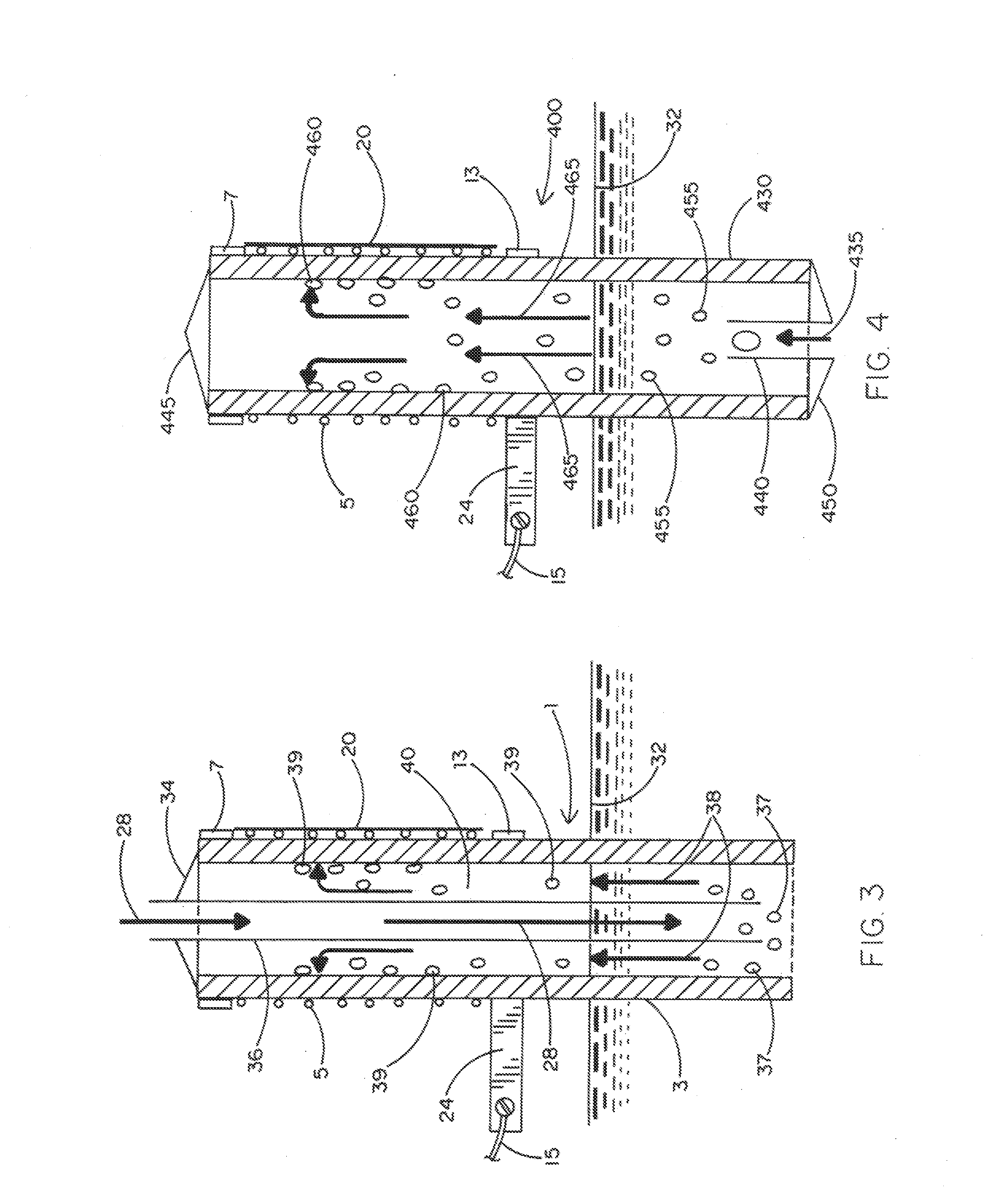

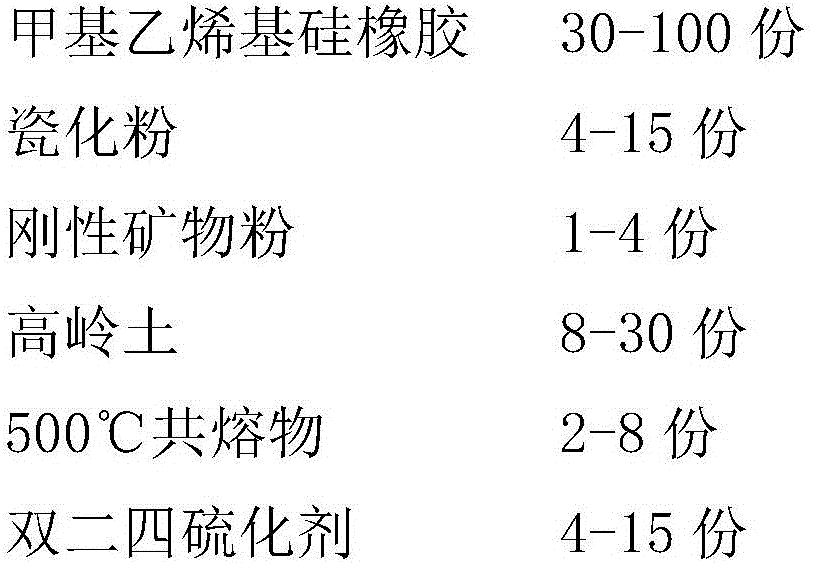

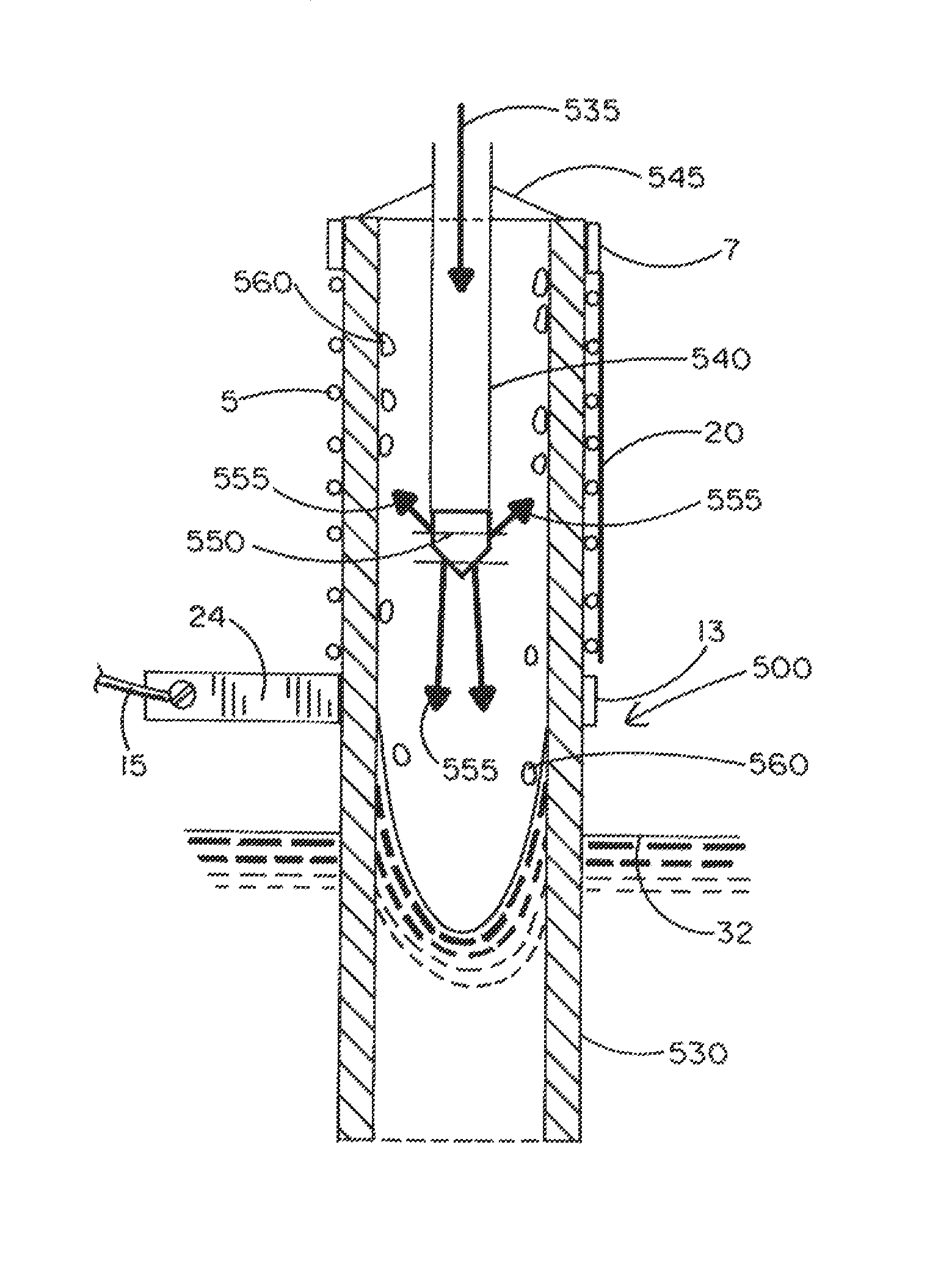

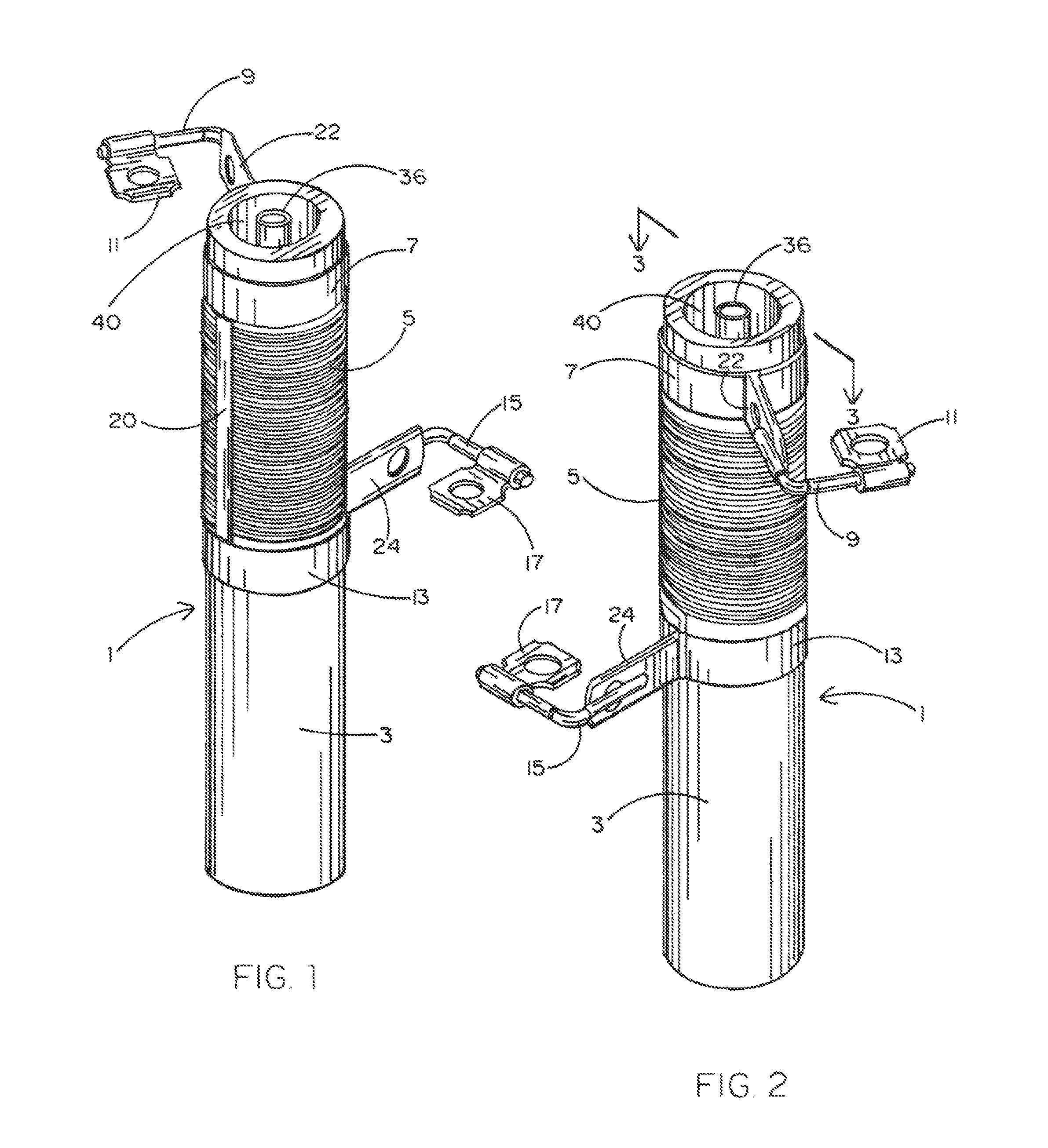

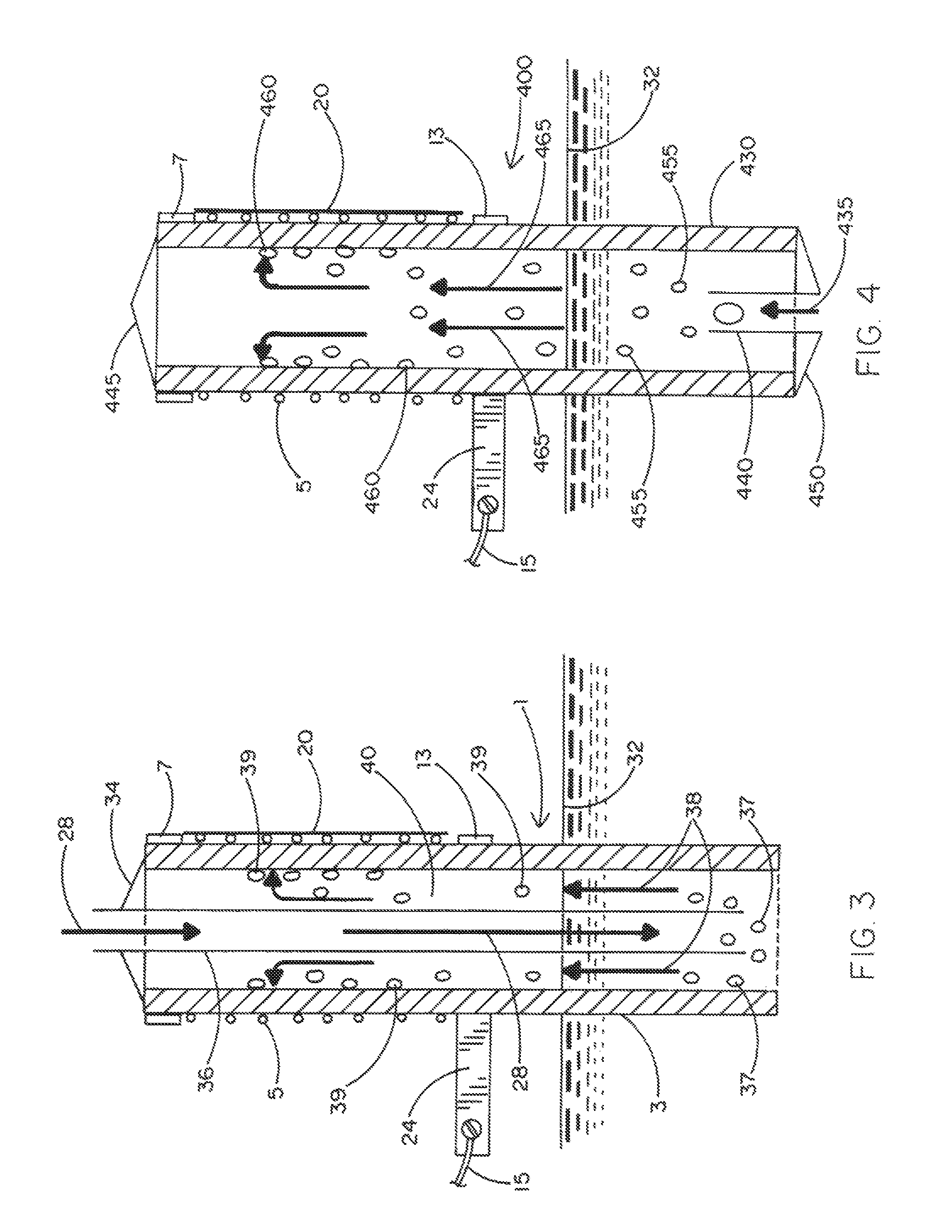

Oil transporting vaporizer for a smoke generating apparatus to detect leaks in a fluid system

ActiveUS20140069174A1Increase smoke productionEnhance oil bubble contactDetection of fluid at leakage pointSteam generation heating methodsPorosityHot Temperature

An oil transporting vaporizer for a smoke generating apparatus to generate smoke to be supplied to a closed system to be tested for leaks. In a preferred embodiment, the vaporizer includes a hollow tube that is manufactured from a high temperature, fire resistant, porous material (e.g., ceramic). The vaporizer stands in a reservoir of oil such that some of the porous tube is filled with oil from the reservoir. A heater wire surrounds the outside of the porous tube above the oil within the tube. A gas (e.g., air) is blown into the porous tube and towards the oil to cause a mixture of air and gas to move through the tube. Because of its porosity, the air / oil mixture permeates the tube in the vicinity of the heater wire so as to be vaporized into smoke when the heater wire is energized.

Owner:CPS PRODS

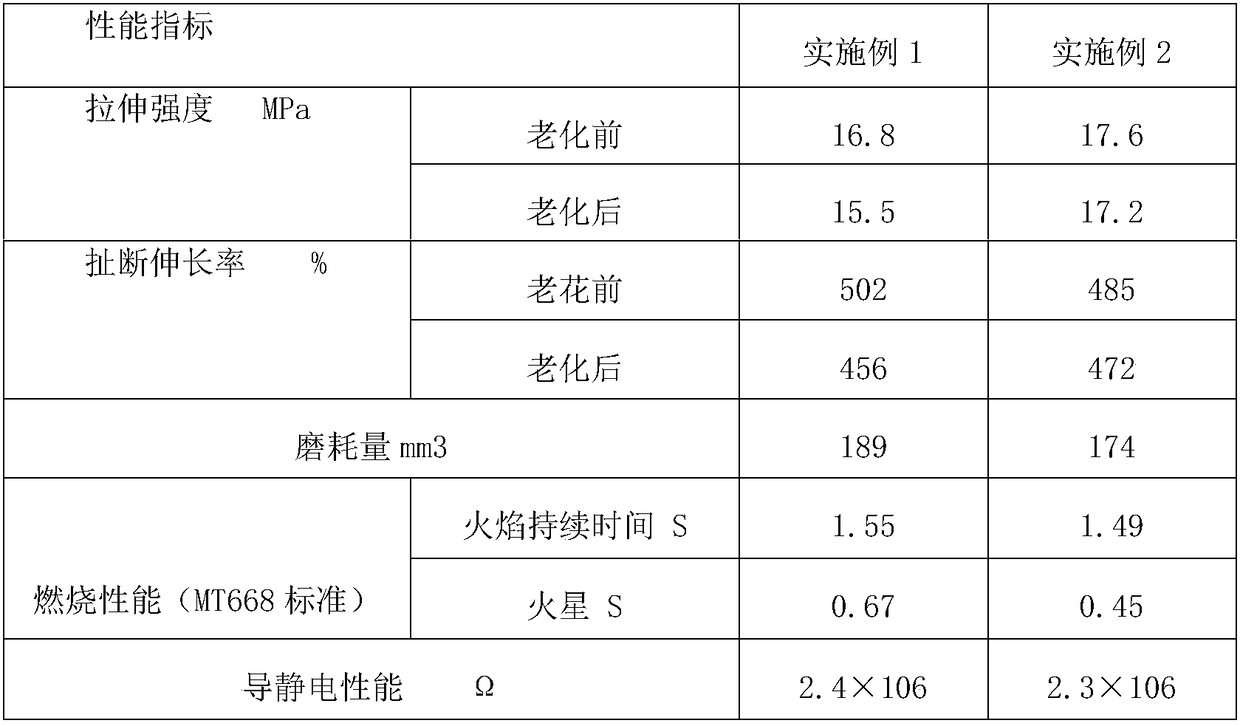

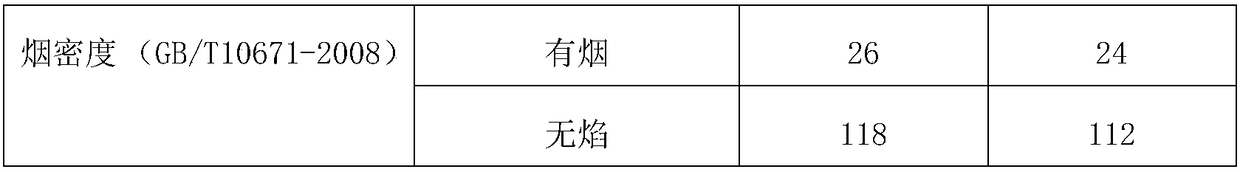

Low-smoke low-halogen flame-retardant conveyor belt covering glue for coal mine and preparation process thereof

InactiveCN108659285AHigh bromine contentImprove thermal stabilityConveyorsComposite ceramicEngineering

The invention discloses low-smoke low-halogen flame-retardant conveyor belt covering glue for a coal mine, and relates to the technical field of conveyor belt covering glue. The covering glue comprises the following chemical components: natural standard rubber, styrene-butadiene rubber SBR1502, cis-butyl BR9000 rubber, polyisobutylene PB1300, an anti-aging agent, zinc oxide, magnesium oxide, stearic acid, a flow release agent, N234 carbon black, nano-aluminum hydroxide, antimony trioxide, decabromodiphenylethane, composite ceramic powder, expanded halogen-free flame-retardant IFR, a multi-purpose synergistic halogen-free flame retardant PNA220, molybdenum salt used as a smoke suppressant, an accelerator and sulfur. The low-smoke low-halogen flame-retardant conveyor belt covering glue disclosed by the invention is used under a coal mine well to meet flame-retardant performance of the conveyor belt, has excellent wear resistance and flame retardancy, and is low in smoke amount and smoketoxicity.

Owner:江苏凯嘉橡胶科技股份有限公司

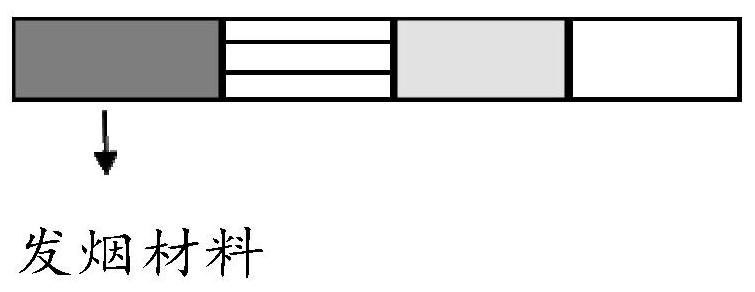

Smoke generating product and electronic cigarette

The invention relates to the technical field of heat-not-burn cigarettes, in particular to a smoke generating product and an electronic cigarette. The smoke generating product comprises a smoke generating section, an isolating section, a flavor blending and cooling section and a cellulose acetate fiber section, wherein the smoke generating section, the isolating section and the flavor blending andcooling section all contain tobacco components; the sum of the tobacco components in the smoke generating section, the isolating section and the flavor blending and cooling section accounts for 30% or above of the total raw material mass of the smoke generating product; the smoke generating section is connected with the isolating section, the isolating section is connected with the flavor blending and cooling section, and the flavor blending and cooling section is connected with the cellulose acetate fiber section; a plurality of gas flowing channels are formed in the flavor blending and cooling section. According to the smoke generating product, the number of smoking can be increased, the user experience is improved, and meanwhile the utilization rate of tobacco raw materials is increased.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD +1

Aroma-producing material for heat-not-burn tobacco and preparation method thereof

ActiveCN107594612ARich aromaGood aroma textureCigar manufactureEssential-oils/perfumesHeat not burnCotton material

The invention relates to an aroma-producing material for heat-not-burn tobacco and a preparation method thereof. The preparation method comprises the steps of preparing coating medium and coating. Aroma quality of the aroma-producing material prepared by the natural extracts-based coating medium is closer to that of traditional tobacco. The aroma-producing material is applied to the heat-not-burntobacco, heat conduction uniformity and smoke amount of the tobacco can be increased, the whole smoking quality of the tobacco can be improved, and the aroma-producing material can be effectively usedwhen the heat-not-burn tobacco is smoked.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD +1

Fragrance generating material used in interlayer of nonflammable heating cigarette and preparation method of material

ActiveCN107752122AModerate concentrationReduce stimulationTobacco treatmentTobacco devicesAdditive ingredientMaterials science

The invention relates to a fragrance generating material used in an interlayer of a nonflammable heating cigarette and a preparation method of the material. The preparation method includes the steps of preparing a coating material and conducting coating and the like. The fragrance generating material is prepared by the coating materials in which natural extracts serve as main ingredients, and thefragrance quality is more similar to that of a traditional cigarette. Meanwhile, the fragrance generating material is applied to the nonflammable heating cigarette, and can improve the heat conductionuniformity of the cigarette and increase the smoke generating amount of the cigarette, and the effect of improving the smoking quality of the overall cigarette is achieved; the fragrance material canbe effectively utilized when the nonflammable heating cigarette is smoked.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD +1

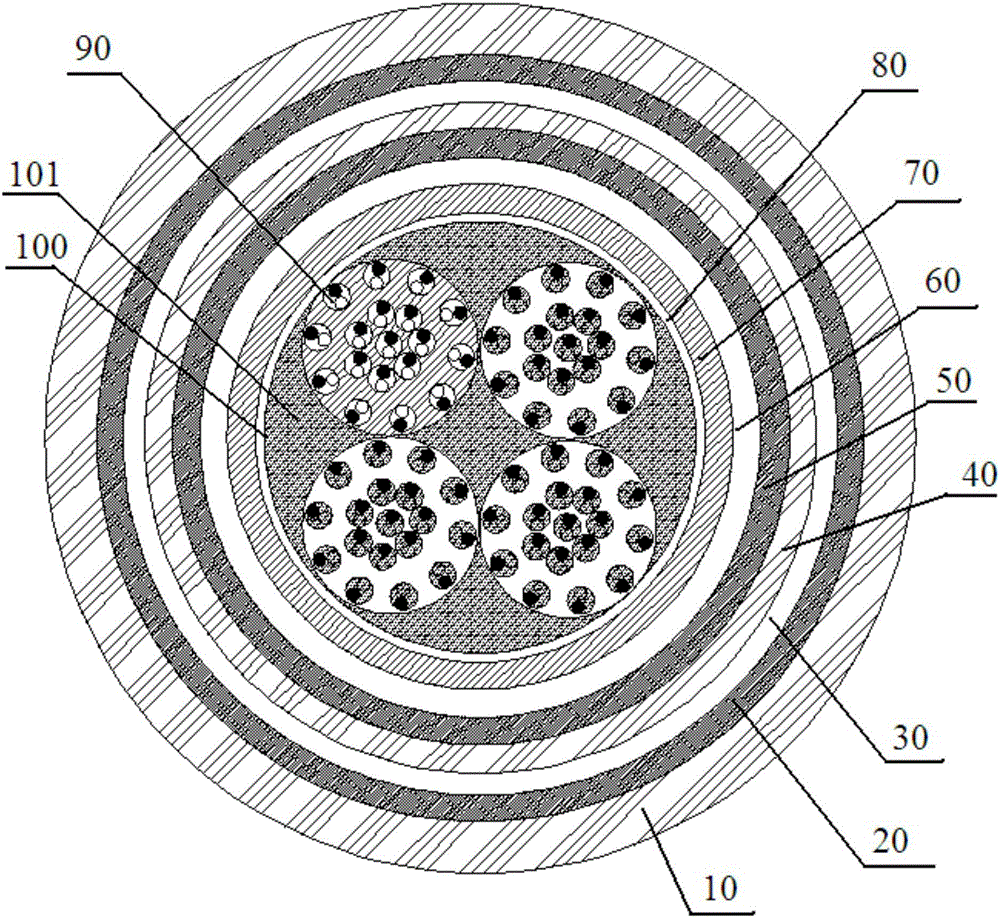

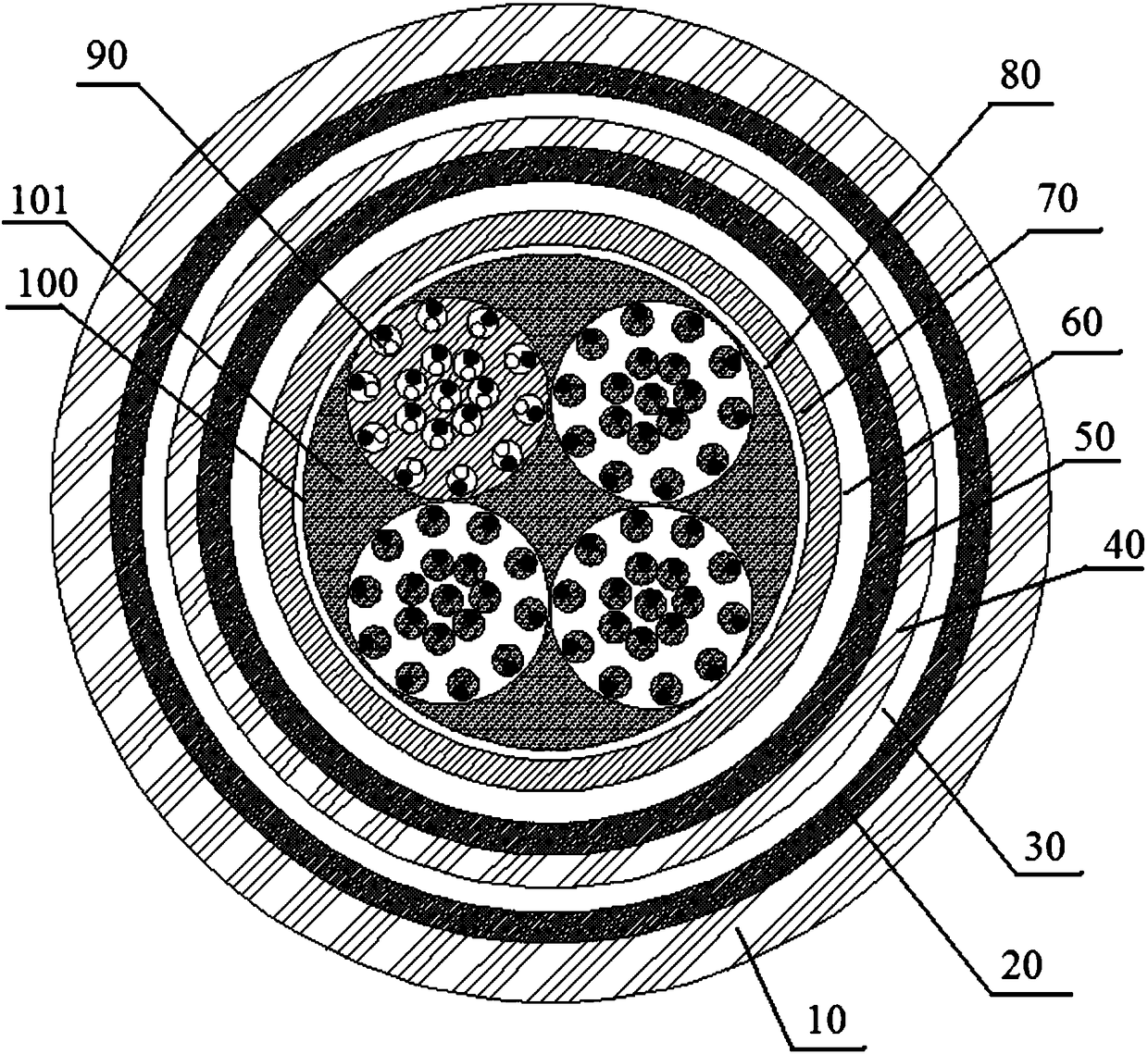

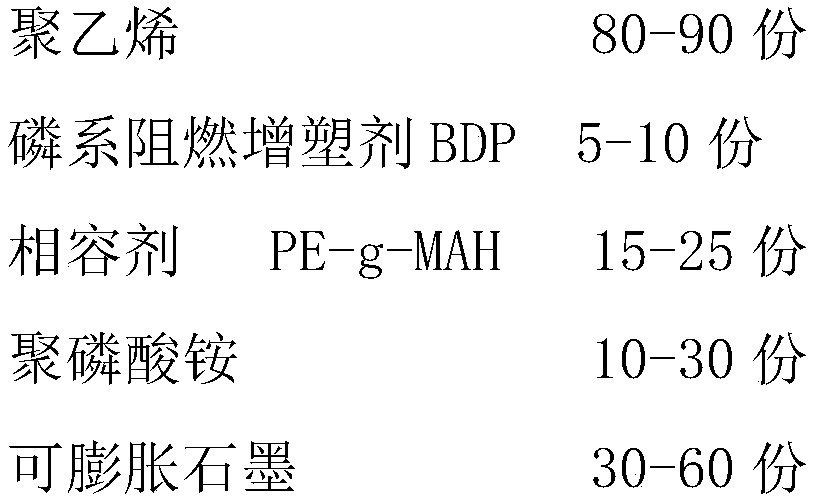

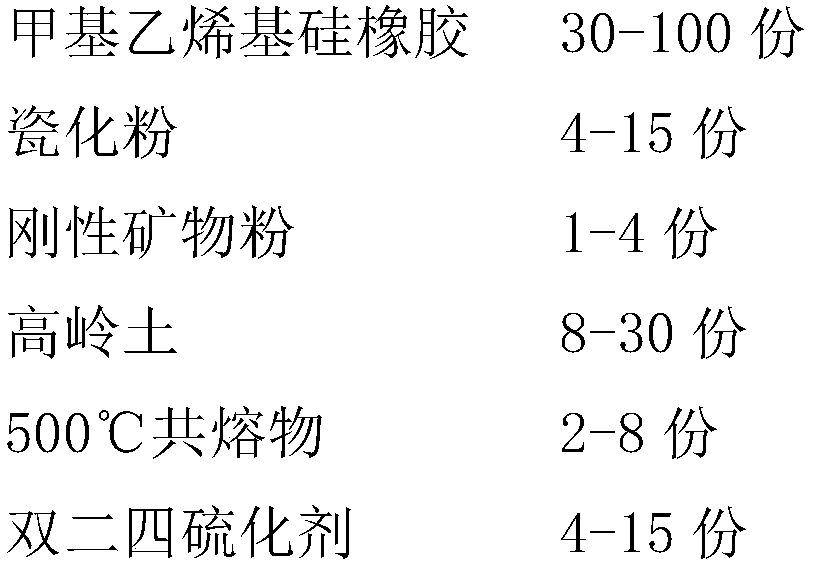

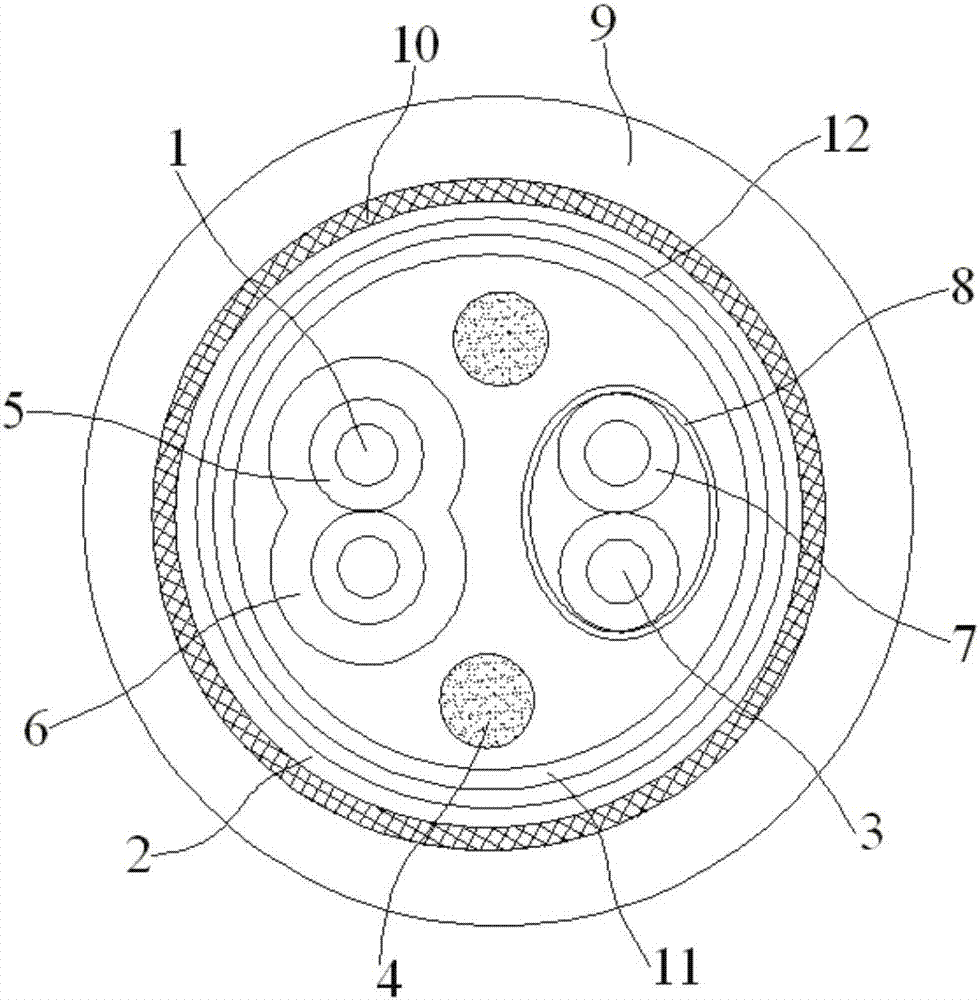

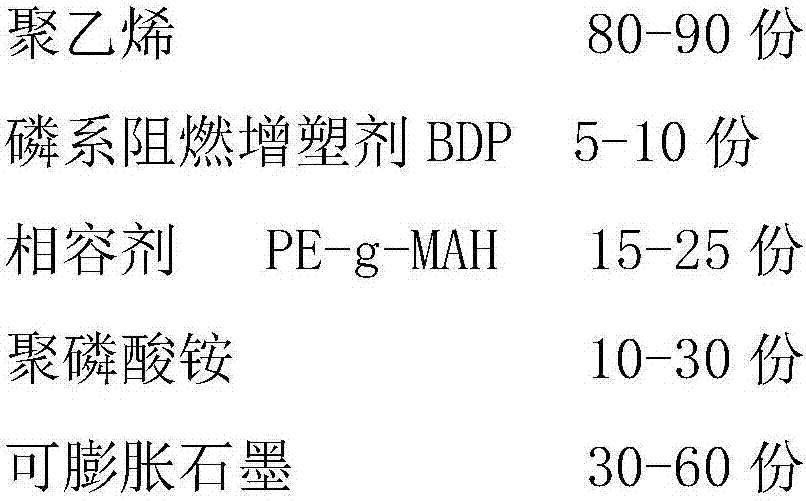

Fireproof flame-retardant rail transit communication cable

ActiveCN106084427AReduce heat exposureKeep the lightingCommunication cablesInsulated cablesEngineeringRail transit

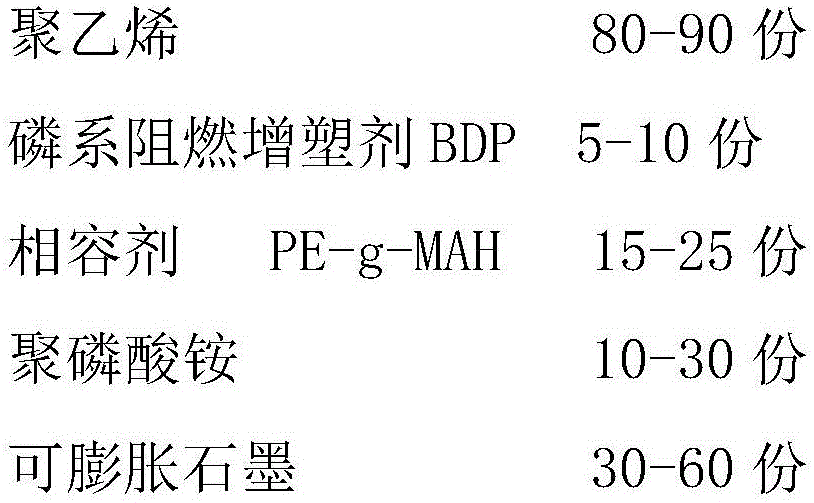

The invention discloses a fireproof flame-retardant rail transit communication cable. The fireproof flame-retardant rail transit communication cable comprises a low-smoke zero-halogen outer sheath, a first fireproof layer, a high-magnetic-conductive steel tape armoring layer, a low-smoke zero-halogen inner sheath, a second fireproof layer, an aluminum sheath, a PE heat insulating layer, a waterproof layer and multiple strands of stranded insulating core wires. A low-smoke zero-halogen polyethylene material is prepared from 80-90 parts of polyethylene, 5-10 parts of phosphorus flame-retardant plasticizer BDP, 15-25 parts of PE-g-MAH, 10-30 parts of ammonium polyphosphate and 30-60 parts of expansible graphite. The second fireproof layer is made of a fireproof silicone rubber material. The fireproof silicone rubber material is prepared from 30-100 parts of methyl vinyl silicone rubber, 4-15 parts of vitrified powder, 1-4 parts of rigid mineral powder, 8-30 parts of kaolin, 2-8 parts of 500DEG C eutectic and 4-15 parts of DCBP. All the layers are retardant to flames, most of heat can be absorbed, and optical fibers can keep optical connectivity for a long time.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Oil transporting vaporizer for a smoke generating apparatus to detect leaks in a fluid system

ActiveUS9482590B2Increase smoke productionEnhance oil bubble contactDetection of fluid at leakage pointSteam generation using steam absorptionPorosityHot Temperature

Owner:CPS PRODS

Electronic cigarette preventing e-liquid leakage and scorching

The invention discloses an electronic cigarette preventing e-liquid leakage and scorching. The electronic cigarette comprises a power supply assembly and an e-liquid cup assembly; the e-liquid cup assembly comprises a cavity body, an e-liquid extractor, a heating plate and a colloidal silica body; the cavity body is provided with a middle annular part, a cavity and an air passage; the air passagepenetrates to the top end of the e-liquid cup assembly; the heating plate flatly fits under the e-liquid extractor, and the colloidal silica body wraps outside the e-liquid extractor and heating plate; one end of the colloidal silica body is connected to the outer side wall of the middle annular part through a first sealing part, and the other end is connected to the inner side wall of the cavitybody through a second sealing part; a transition cavity is formed above the e-liquid extractor and between the e-liquid extractor and the colloidal silica body, and the transition cavity is communicated with the air passage; a plurality of air inlet holes are formed in the circumferential direction at intervals between the power supply assembly and the e-liquid cup assembly, an air inlet cavity isenclosed between the power supply assembly and the e-liquid cup assembly, and the air inlet holes are all communicated with the air inlet cavity; therefore the situations of e-liquid leakage and scorching are effectively avoided, the heating area is increased, the smoke amount is increased, the heat waste is reduced, the electricity consumption is reduced, and the service life is prolonged.

Owner:肖鑫

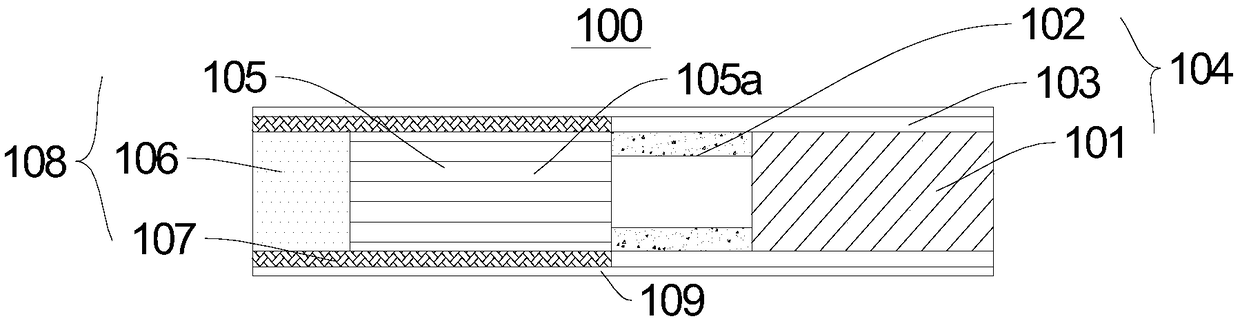

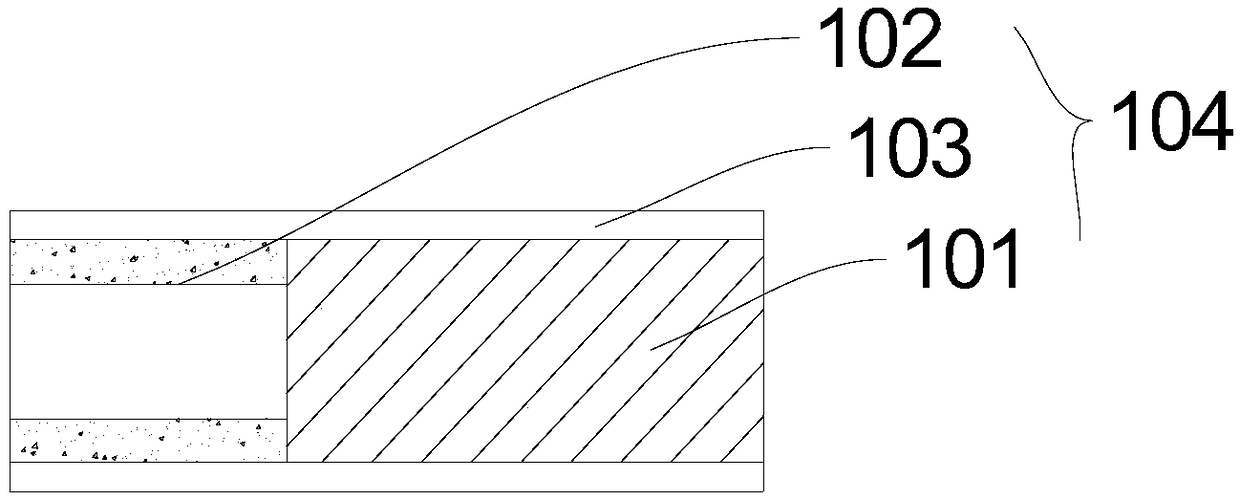

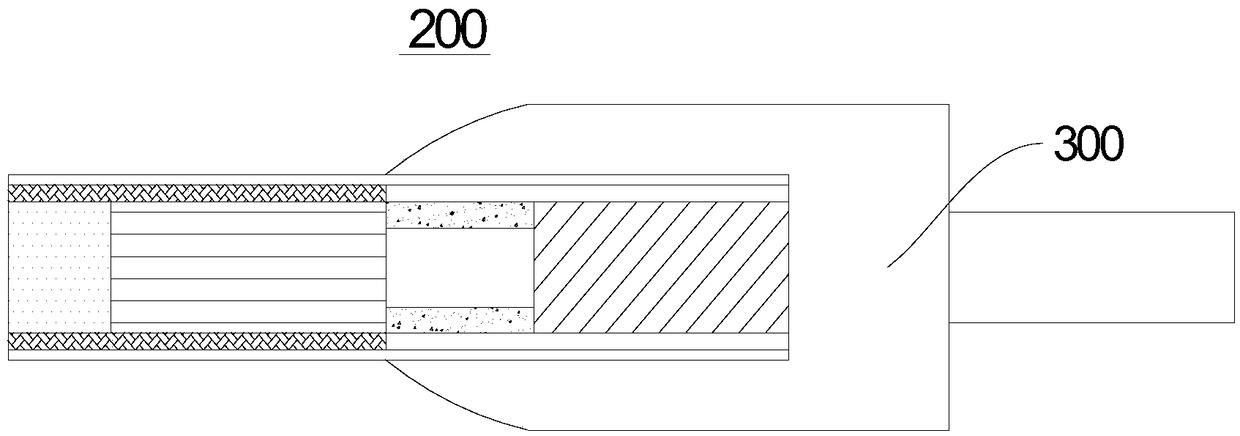

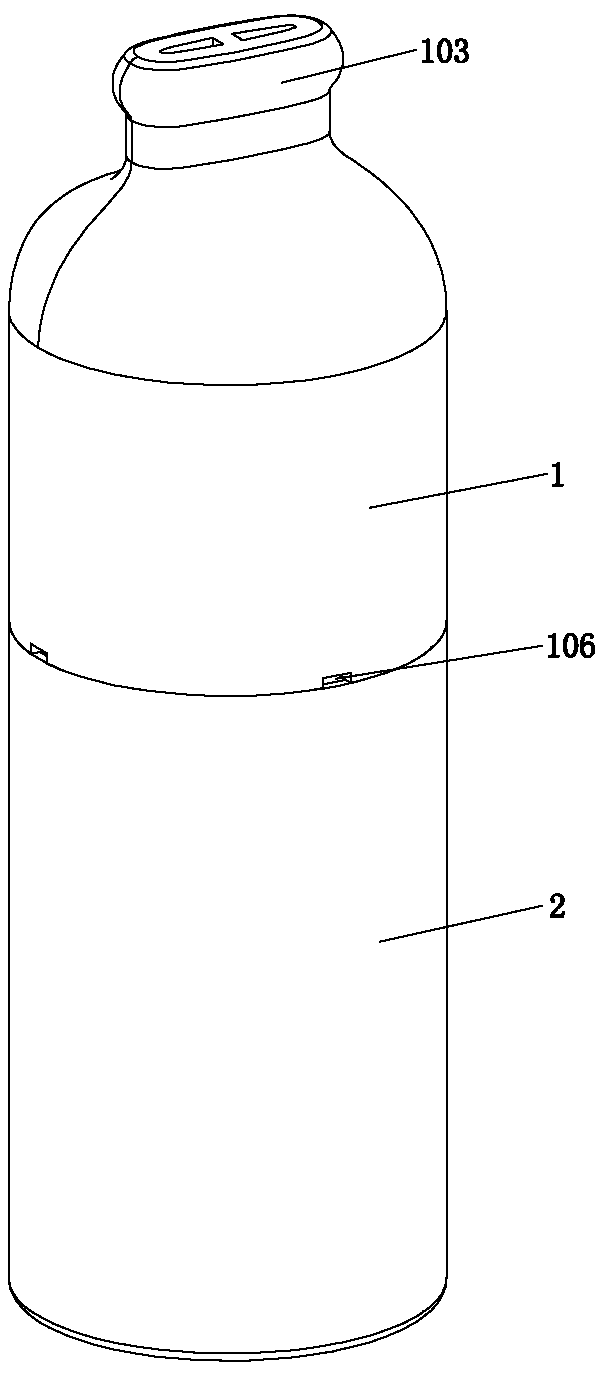

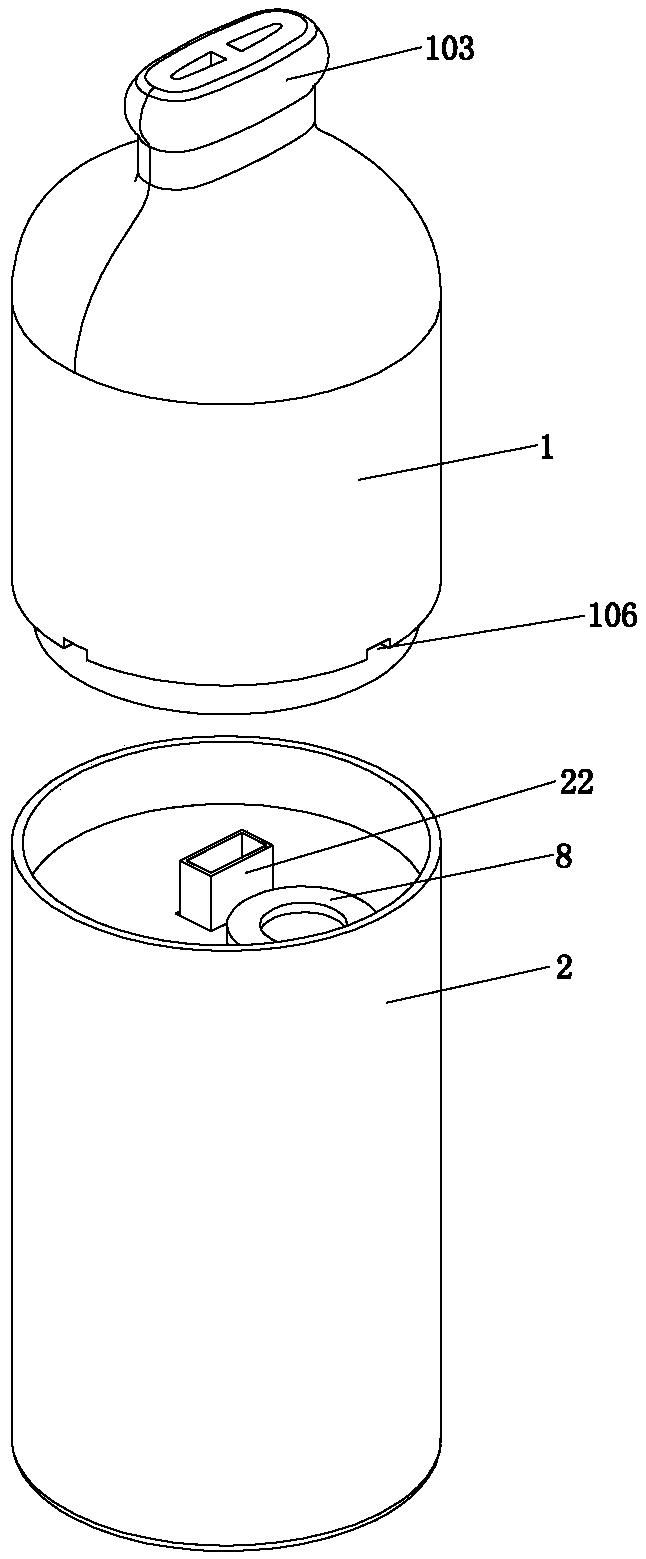

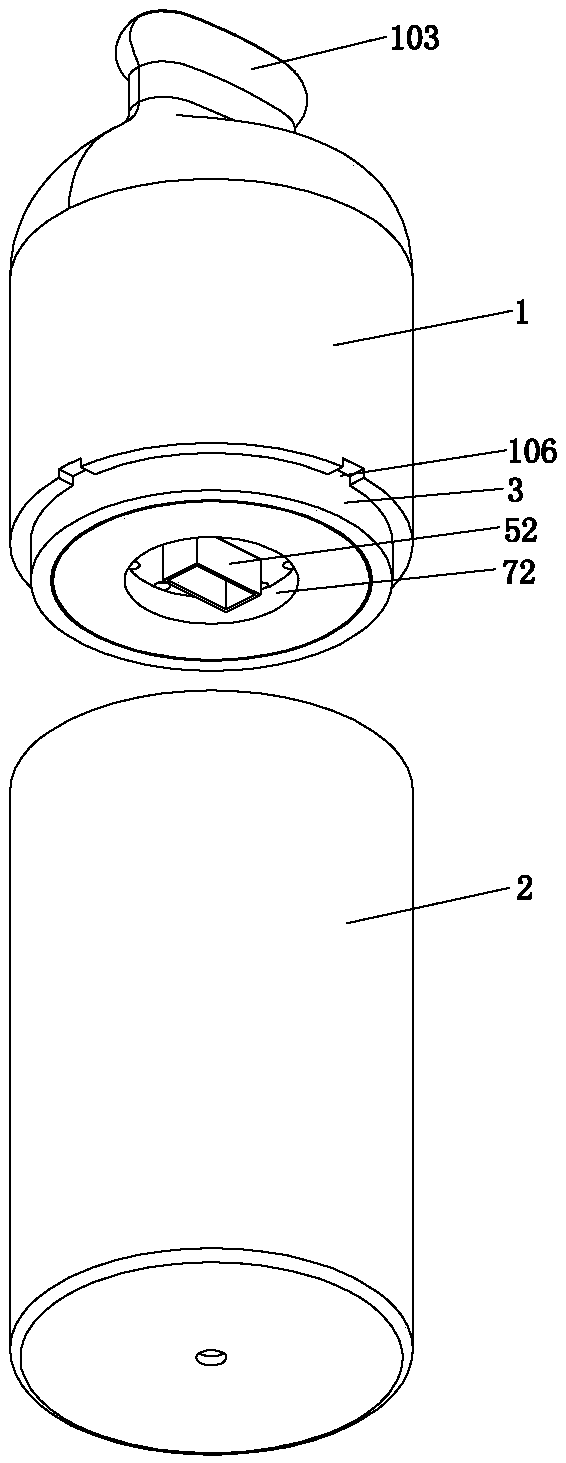

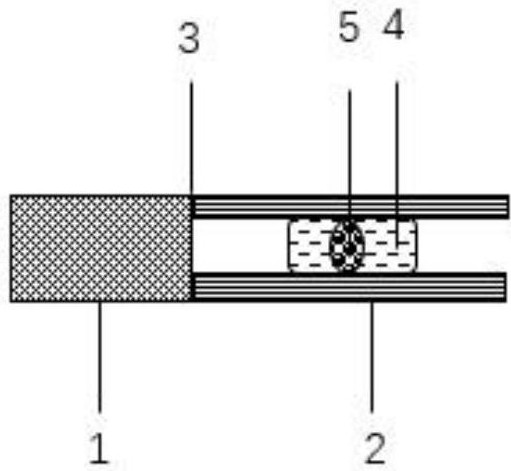

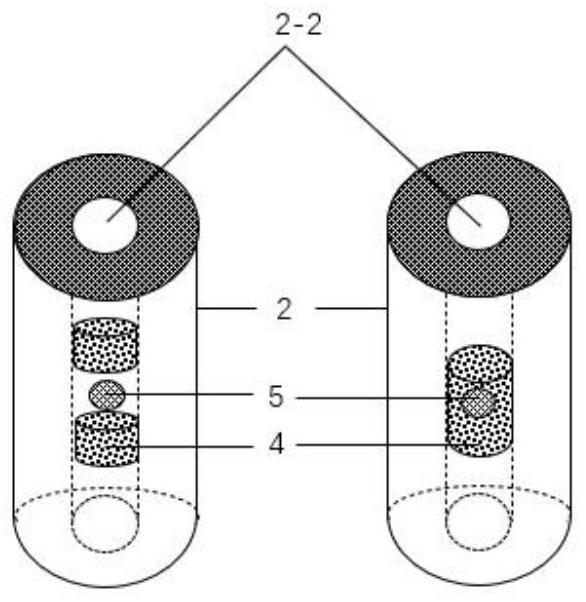

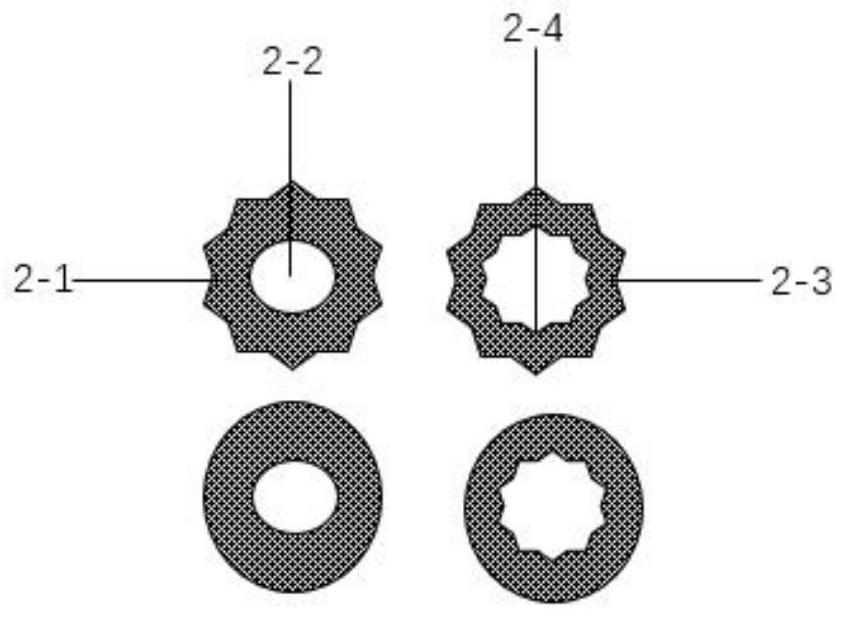

Binary structure heat-not-burn smoke cartridge containing fragrance release carrier

PendingCN112263018ASimple structureIncrease smoke productionTobacco treatmentCigar manufactureEngineeringMechanical engineering

The invention relates to a binary structure heat-not-burn smoke cartridge containing a fragrance release carrier, which is formed by sequentially wrapping and connecting a smoke generating section anda smoke constraining section through outer-layer wrapping paper.In the smoking process of the binary structure heat-not-burn smoke cartridge, the fragrance of the fragrance release carrier is released by external force or the fragrance of the smoke constraint section is eluted by smoke flow, so that the effects of reducing the smoke temperature, guiding the smoke and supplementing the fragrance are achieved, and the cooled high-concentration smoke rich in fragrance is conveyed into the oral cavity of a consumer. The heat-not-burn smoke cartridge has the advantages of high aroma, high smoke generation amount, low smoke temperature and the like, is simple in structure and easy to industrialize, and has a very good industrial application prospect.

Owner:云南纯旭生物科技有限公司

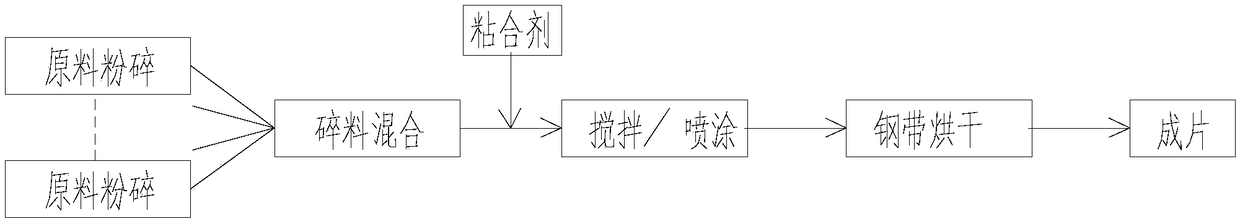

Heating cigarette core material and preparation method thereof

ActiveCN114098134AHigh spreading rateThe characteristics are obviously durableTobacco preparationTobacco treatmentFiberMechanical engineering

The invention provides a heating cigarette core material and a preparation method thereof. According to the preparation method of the heating cigarette core material, the fiber papermaking sheet base is adopted as a carrier, the two-stage transfer coating and six-section tunnel type continuous low-temperature drying technology is applied, and the prepared heating cigarette core material has the advantages of being large in tensile strength, good in on-machine performance, high in coating rate, large in loading capacity, large in fuming amount, obvious in characteristic fragrance, good in stability and the like; the prepared heating cigarette core material can remarkably improve the smoking thickness and satisfaction and improve the smoking sensory quality. The tensile strength of the prepared heating cigarette core material can reach 400 N / m or above, the on-machine adaptability is good, and the requirement for quantitative production is met.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

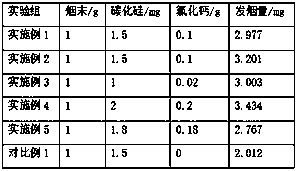

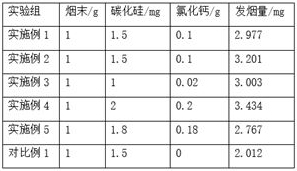

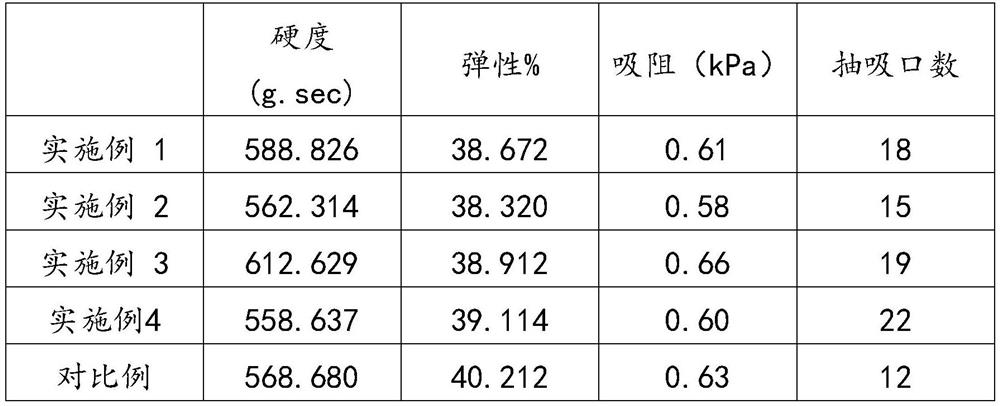

Method for treating tobacco powder of heating cigarette

ActiveCN111329104AHigh thermal conductivityNo loss of active ingredientsTobacco preparationTobacco treatmentCarbide siliconPhysical chemistry

The invention relates to the technical field of heat-not-burn cigarettes, in particular to a method for treating tobacco powder of a heating cigarette. The method comprises the following steps: addingtobacco powder into an ethanol solution, and carrying out heating reflux to obtain filter residues and an ethanol leaching solution; mixing the filter residues with silicon carbide and pectin, and adding the mixture into water to obtain a system a; dropwise adding a calcium chloride solution into the system a, stirring for 50-70 minutes, and removing water to obtain modified filter residues; andapplying the ethanol leach liquor to the modified filter residues, and drying to obtain the treated tobacco powder. On one hand, calcium chloride and pectin are cross-linked to form gel, so that the mechanical strength of silicon carbide combined on tobacco powder is improved; on the other hand, calcium chloride occupies a silicon carbide network, and calcium chloride is removed by utilizing an ethanol leaching solution to form micropores, so that not only is the bonding strength of tobacco active ingredients backfilled into tobacco powder improved, but also the smoke circulation performance can be improved through the micropores, and the smoke generation amount and the smoke generation fragrance are improved.

Owner:CHINA TOBACCO JIANGSU INDAL

An annular heat-not-burn cigarette paper

ActiveCN109440538BAvoid fireChange styleSurface covering paperNon-fibrous pulp additionBurn cigaretteEngineering

The invention relates to an annular heat-not-burn cigarette paper, which is composed of a cigarette paper layer, an adhesive layer and a tinfoil paper layer sequentially from outside to inside. The heat-not-burn cigarette paper of the present invention has high heat transfer efficiency, the carbonization degree of the aroma-producing material in the aroma-producing section is significantly improved, and the amount of smoke is also significantly increased. The specific structure of the heat-not-burn cigarette paper of the invention can prevent the cigarette paper from igniting and eliminate potential safety hazards.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD +2

A kind of preparation method and application of tobacco smoking core material smoking agent

ActiveCN109602069BIncrease smoke productionImprove moisture resistanceTobacco preparationTobacco treatmentCelluloseCarboxymethyl cellulose

The invention discloses a smoking agent for a novel tobacco smoking core material, which comprises the following steps: firstly preparing a cross-linked carboxymethyl cellulose-lotus root starch composite film and a lotus root starch superabsorbent resin; Methylcellulose-lotus root starch composite film and the lotus root starch superabsorbent resin are mixed with a cross-linking agent and an antioxidant, heated and stirred to carry out emulsification and cross-linking reaction, and the novel tobacco smoking core material smoking agent is obtained after standing and aging . The invention also discloses a cigarette containing the smoking agent. After adding the smoking agent, the amount of smoke generated by the core material increases significantly. At the same time, the addition of the smoking agent can also improve the moisture-proof performance of the smoke core material. . The smoke-generating agent of the present invention is in the form of emulsion, and the emulsion system is stable. The smoke-generating agent has good compatibility with the material liquid of the cigarette core material, and the system is stable, and the process is easy to realize.

Owner:CHINA TOBACCO YUNNAN IND

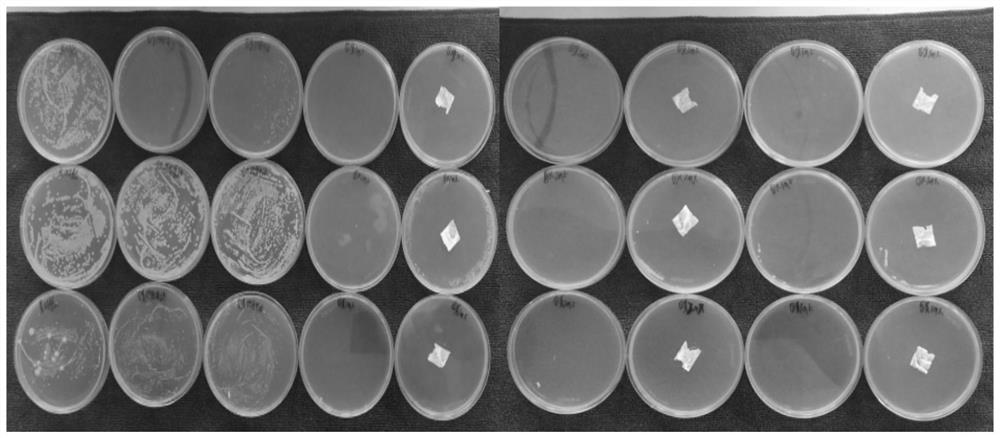

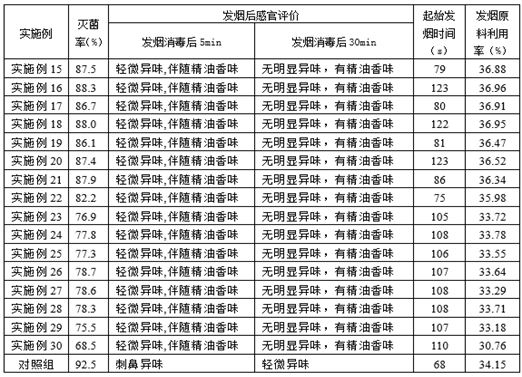

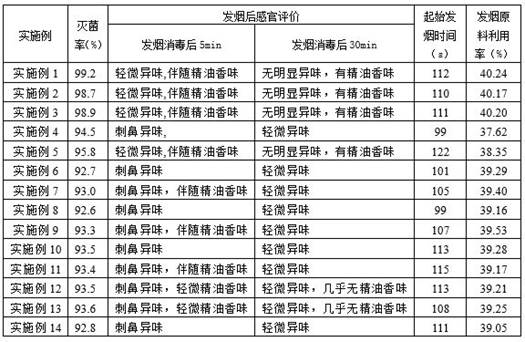

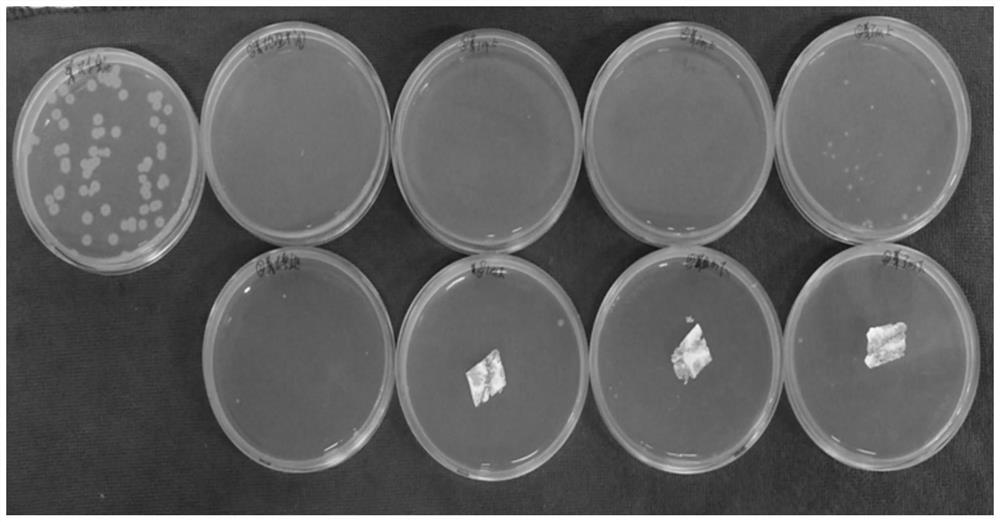

Disinfectant suitable for high-temperature and high-pressure spray disinfection pipeline and disinfection composition containing disinfectant

InactiveCN112586502AGood dispersionLess prone to cloggingBiocideDisinfectantsCrop livestockDisinfectant

The invention discloses a disinfectant suitable for a high-temperature and high-pressure spray disinfection pipeline and a disinfection composition containing the disinfectant. The disinfectant is 1,3-dihydroxymethyl-5,5-dimethyl hydantoin. According to the scheme, the disinfectant can well resist abrasion to a high-temperature and high-pressure spray disinfection pipeline, can be well gasified athigh temperature to form atomized particles with moderate particle sizes, can be well carbonized to form smoke-shaped particles to be sprayed out from an opening of the high-temperature and high-pressure spray disinfection pipeline, and is not prone to pipeline blockage. The composition also comprises a synergist. The disinfectant provided by the scheme of the invention is compounded with the synergist to form molecular nano spray, so that the smoke yield is increased, and the dissolution condition of the disinfectant is indicated; the disinfection composition can be more uniformly diffused to any corner in a disinfection space, and can be permanently suspended in the air for disinfection for several hours; meanwhile, various viruses and pathogenic microorganisms (such as escherichia coli, bacillus subtilis and staphylococcus aureus) can be killed; and the disinfection composition is especially suitable for killing microorganisms in livestock breeding places.

Owner:湖南幻影三陆零科技有限公司

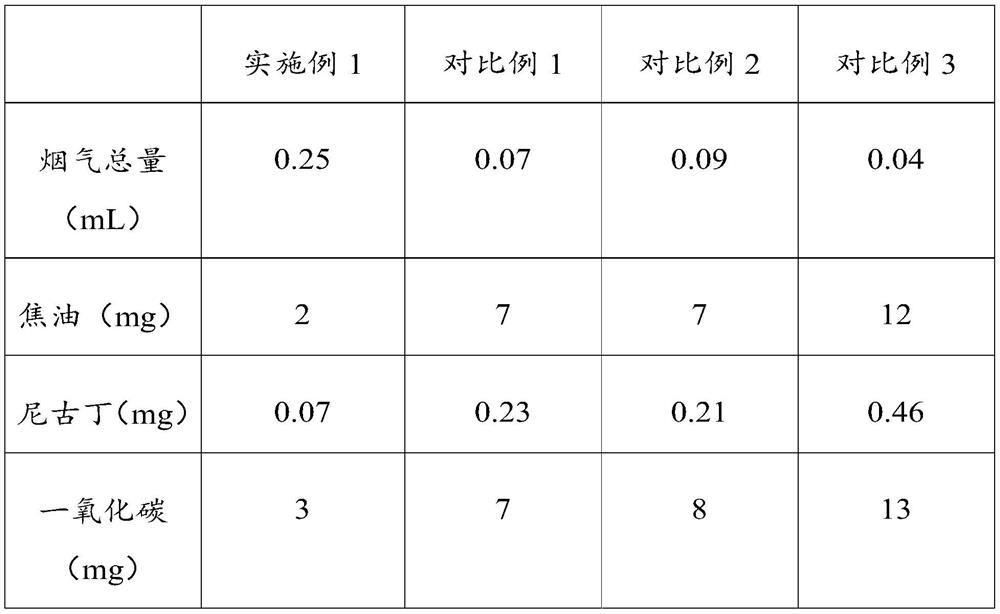

Smoke material and preparation method thereof

The invention relates to the technical field of cigarette smoking materials, and in particular to a smoking material and a preparation method thereof. The smoking material includes a carrier material, a smoking module and a hole-forming material forming holes on the carrier material and the smoking module. The pore-forming material is arranged on the surface of the carrier material to form a first pore-forming material layer, and the smoke-generating module is arranged on a side of the pore-forming material relatively far away from the carrier material to form a smoke-generating layer, and the smoke-generating layer is relatively far away from the side of the first pore-forming material layer A porogen is provided to form a second porogen layer. The pore-forming material can quickly dissipate the smoke to the surface of the cigarette, increase the speed of smoke release and the amount of smoke produced, and improve the user's sense of use. At the same time, the pore-forming material prevents smoke from accumulating in the cigarette and reduces the harmful gas produced by the cigarette. At the same time, the pore-forming material can absorb the harmful gas produced by the cigarette, further reducing the release of harmful gas, and protecting the health of smokers.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD

Mixed fuming disinfectant and use method thereof

PendingCN114041469ABacteriostaticGood dispersionBiocideDisinfectantsProcess engineeringIsocyanuric acid

The invention provides a mixed fuming disinfectant and a use method thereof. The mixed fuming disinfectant comprises the following raw materials in parts by weight: 45-95 parts of an agent A, 10-50 parts of an agent B and 4-10 parts of an agent C. The agent A comprises chlorinated isocyanuric acid, chlorinated isocyanuric acid alkali metal salt and starch in a mass ratio of (2-8): (3-7): 1. The agent B comprises an aldehyde disinfectant, water and a disinfection synergist in a mass ratio of (5-50): (5-19): 1. The agent C comprises a purifying component, a stabilizing component and a dispersing component in a mass ratio of (5-15): (4-12): (3-9). As a functional auxiliary agent C is introduced on the basis of a traditional agent A and agent B mixed fuming disinfectant, a series of negative problems of raw material residues and incomplete fuming reaction due to explosive boiling caused by too high heating rate after raw materials of a traditional mixed fuming disinfectant are mixed, poor indoor air quality caused by strong pungent smell generated after fuming, and the like are solved. The agent C can be used as a functional additive of the mixed fuming disinfectant, and can also be independently used as an air deodorant.

Owner:肖隆 +1

Disinfectant and disinfection composition containing same

InactiveCN112450217AGood dispersionLess prone to cloggingBiocideFungicidesCrop livestockDisinfectant

The invention discloses a disinfectant and a disinfection composition containing the disinfectant. The disinfectant is dibromocyanopropionamide. The disinfectant of the invention can be well dispersedin a high-temperature and high-pressure spray disinfection pipeline, can be well gasified at high temperature to form atomized particles with moderate particle sizes, can be well carbonized to form smoke-like particles to be sprayed out from an opening of the high-temperature and high-pressure spray disinfection pipeline, and is unlikely to block the pipeline . The composition also comprises a synergist. The disinfectant provided by the scheme of the invention is compounded with the synergist to form molecular nano spray, so that the spray yield is increased, and the dissolution condition ofthe disinfectant can be indicated; the disinfection composition can be more uniformly diffused to any corner in a disinfection space, and can be permanently suspended in the air for disinfection for several hours; meanwhile, the disinfection composition can kill various viruses and pathogenic microorganisms (such as escherichia coli, bacillus subtilis and staphylococcus aureus); the disinfection composition is especially suitable for killing microorganisms in livestock breeding places.

Owner:湖南幻影三陆零科技有限公司

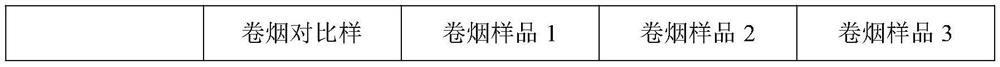

A kind of interlayer aroma-producing material for heat-not-burn cigarettes and its preparation method

The invention relates to a fragrance generating material used in an interlayer of a nonflammable heating cigarette and a preparation method of the material. The preparation method includes the steps of preparing a coating material and conducting coating and the like. The fragrance generating material is prepared by the coating materials in which natural extracts serve as main ingredients, and thefragrance quality is more similar to that of a traditional cigarette. Meanwhile, the fragrance generating material is applied to the nonflammable heating cigarette, and can improve the heat conductionuniformity of the cigarette and increase the smoke generating amount of the cigarette, and the effect of improving the smoking quality of the overall cigarette is achieved; the fragrance material canbe effectively utilized when the nonflammable heating cigarette is smoked.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD +1

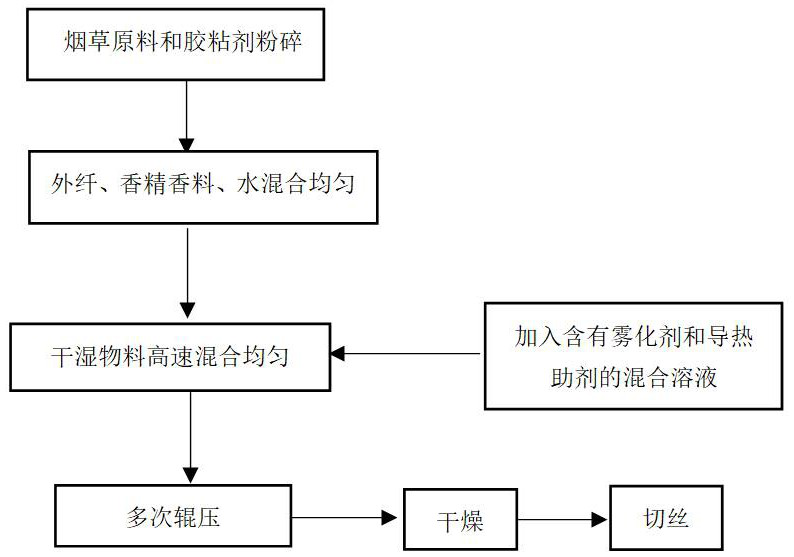

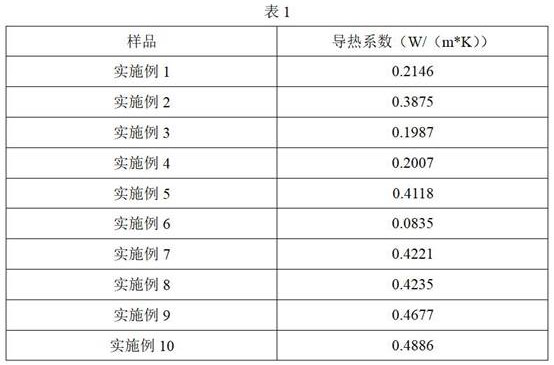

A preparation method of heat-not-burn tobacco products by optimized rolling method

ActiveCN112352997BImprove thermal conductivityReduce viscosityTobacco preparationTobacco treatmentProcess engineeringSmoke Emission

The invention provides a method for preparing heat-not-burn tobacco products by optimized rolling method, which comprises the following steps: blending tobacco raw materials and adhesives and then pulverizing them to obtain the first mixed material; The second mixed material; add the first mixed material to the second mixed material and stir evenly to obtain the third mixed material; prepare the mixed solution of atomizing agent and thermal conductivity additive at 80~85 °C; add the mixed solution evenly to The surface of the third mixed material is subjected to multiple roll forming, drying, and shredding to make heat-not-burn tobacco products. A method for preparing heat-not-burn tobacco products with an optimized rolling method of the present invention can improve the thermal conductivity of heat-not-burn tobacco products, so that the heating heat can be quickly and evenly transferred to the inside of the heat-not-burn tobacco, so that the amount of smoke and flavor components The fast and even release further enhances the sensory quality of the draw.

Owner:HUBEI CHINA TOBACCO IND +1

Filling pump shaft

InactiveCN1280547CHigh impact strengthEvenly distributedSpecific fluid pumpsPump componentsLow noiseMetallic materials

Owner:于志伟

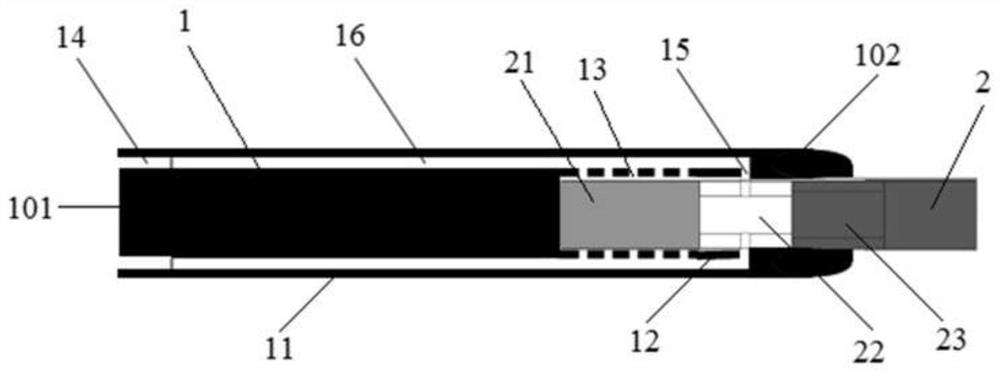

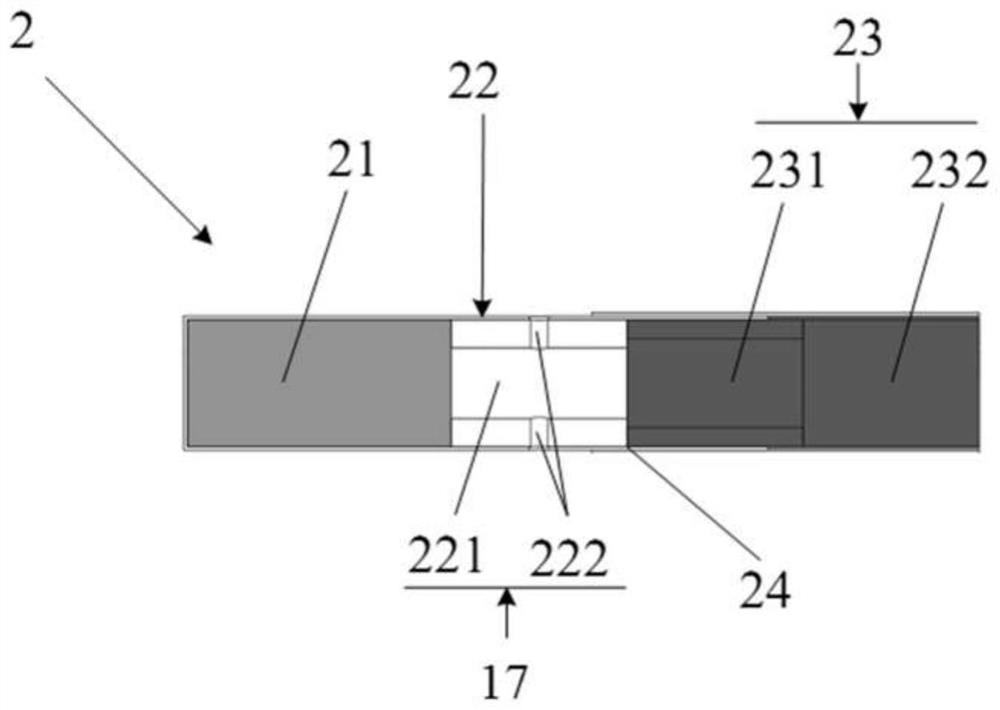

Aerosol generating device with flow guide structure

The invention provides an aerosol generating device with a flow guide structure, which comprises an aerosol generating element and an aerosol generating product , the aerosol generating element is provided with a far end part and a near end part which is opposite to the far end part and is provided with an opening in the axial direction, and the aerosol generating element comprises a shell, an internal working part accommodated in the shell and a receiving sleeve, wherein the aerosol generating element is provided with a hollow containing cavity in a part close to the near end part so as to accommodate the receiving sleeve; one end of the aerosol generating product is inserted into the containing cavity through the opening, and the aerosol generating device is provided with a flow guide structure communicated with the outside, so that air can sweep over the periphery of the aerosol generating substrate and enter the aerosol generating product through the flow guide structure. According to the aerosol generating device, under the action of the flow guide structure, air does not directly flow through the aerosol generating substrate, but sweeps through the periphery of the aerosol generating substrate to enter the aerosol generating product.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +1

A kind of processing method of heating cigarette powder

ActiveCN111329104BImprove thermal conductivityNo loss of active ingredientsTobacco preparationTobacco treatmentCarbide siliconMetallurgy

The invention relates to the technical field of heat-not-burn cigarettes, in particular to a method for processing heated cigarette smoke powder. It comprises the following steps: adding tobacco powder into ethanol solution, heating and refluxing to obtain filter residue and ethanol extract; mixing the filter residue with silicon carbide and pectin into water to obtain system a; adding calcium chloride dropwise to system a After stirring the solution for 50-70min, remove the water to obtain a modified filter residue; apply the ethanol extract to the modified filter residue, and dry to obtain treated tobacco powder. On the one hand, the present invention forms a gel by cross-linking calcium chloride and pectin to improve the mechanical strength of silicon carbide bonded to tobacco dust; Calcium forms micropores, which not only improve the binding strength of tobacco active ingredients backfilled into tobacco powder, but also improve the circulation performance of smoke through the micropores, thereby increasing the amount of smoke and the aroma of smoke.

Owner:CHINA TOBACCO JIANGSU INDAL

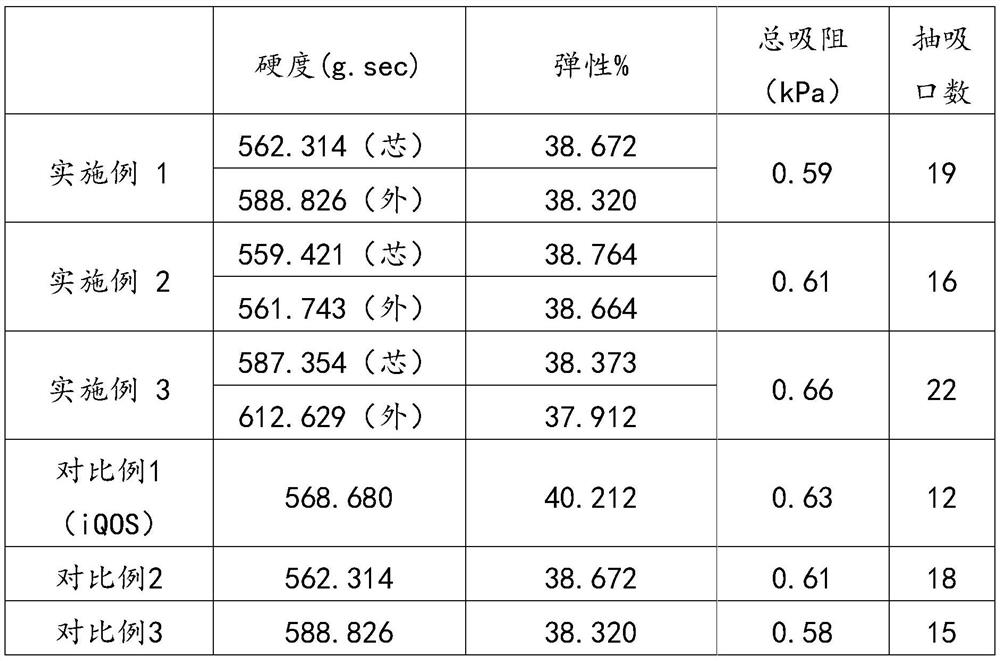

Heat-not-burn solid smoke cartridge

PendingCN113475757AMeet the requirements of cost reduction and efficiency increaseHighly corporatedTobaccoGellan gumHeater Rod

The invention relates to a heat-not-burn solid smoke cartridge, which comprises a smoke cartridge body, the smoke cartridge body is provided with an axially-through insertion hole of a smoking set heating rod, and the hole diameter of the insertion hole is smaller than the outer diameter of the smoking set heating rod; the cigarette cartridge body is composed of a cigarette cartridge main material and a cigarette cartridge auxiliary material, wherein the cigarette cartridge main material is composed of tobacco particles with two mesh numbers; the smoke cartridge auxiliary material is prepared by blending a smoke agent and a binder; and the binder is prepared from low-acyl gellan gum and high-acyl gellan gum. According to the technical scheme, two kinds of tobacco particles with different particle sizes and corresponding mesh numbers are selected, so that the air permeability of the cigarette cartridge is determined, the smoking resistance value during smoking is influenced, and meanwhile, the physical characteristics such as elasticity, hardness, toughness and density of the cigarette cartridge are influenced. Compared with common sheet type smoke cartridges, the solid smoke cartridge is prepared through extrusion forming equipment, the preparation technology is simple, the production process is low in consumption and efficient, and the requirements of enterprises for cost reduction and efficiency improvement are met.

Owner:CHINA TOBACCO HENAN IND

A fire-resistant and flame-retardant rail transit communication cable

ActiveCN106084427BReduce heat exposureKeep the lightingCommunication cablesInsulated cablesEngineeringRail transit

The invention discloses a fire-resistant and flame-retardant rail transit communication cable, which includes: a low-smoke halogen-free outer sheath, a first fire-resistant layer, a high-magnetic conductive steel tape armor layer, a low-smoke halogen-free inner sheath, a second fire-resistant layer, aluminum sheath, PE insulation layer, water-blocking layer, and several strands of twisted insulated core wires. The formula of the low-smoke halogen-free polyethylene material includes: 80-90 parts of polyethylene, phosphorus-based flame retardant plasticizer BDP 5-10 parts, PE-g-MAH 15-25 parts, ammonium polyphosphate 10-30 parts, expandable graphite, 30-60 parts; the second refractory layer is a refractory silicone rubber material, and the formula of the refractory silicone rubber material includes : 30-100 parts of methyl vinyl silicone rubber, 4-15 parts of porcelain powder, 1-4 parts of rigid mineral powder, 8-30 parts of kaolin, 2-8 parts of 500°C eutectic, 4 dioxin vulcanizing agents ‑15 servings. The layers are flame retardant and can absorb most of the heat, and the optical fiber can maintain light transmission for a long time.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Solid smoke cartridge and preparation method thereof

PendingCN113197370AImprove the heating effectIncrease smoke productionTobaccoProcess engineeringEngineering

The invention relates to a solid smoke cartridge and a preparation method thereof, the solid smoke cartridge is composed of a smoke cartridge core material and a smoke cartridge outer layer, the dosage of high-acyl gellan gum in the smoke cartridge core material is larger than that of low-acyl gellan gum, so that the hardness of the smoke cartridge core material is smaller than that of the smoke cartridge outer layer, insertion of a heating needle of a smoking set is facilitated, and the heating effect is improved; the smoke cartridge main material and the smoke cartridge auxiliary material are fully mixed, so that the tobacco particles in the smoke cartridge main material absorb sufficient smoke agent, the finally prepared solid smoke cartridge product has higher smoke amount, and a smoker can obtain more smoking times during smoking; two kinds of tobacco particles with different particle sizes and corresponding mesh numbers are selected, so that the air permeability of the cigarette cartridge is determined, the smoking resistance value during smoking is influenced, and meanwhile, the physical characteristics of the cigarette cartridge are influenced. According to the technical scheme, compared with common sheet type smoke cartridges, the solid smoke cartridge is prepared through extrusion forming equipment, the preparation technology is simple, the production process is low in consumption and efficient, and the requirements of enterprises for cost reduction and efficiency improvement are met.

Owner:CHINA TOBACCO HENAN IND

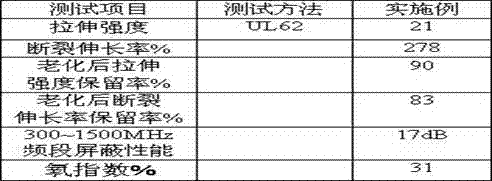

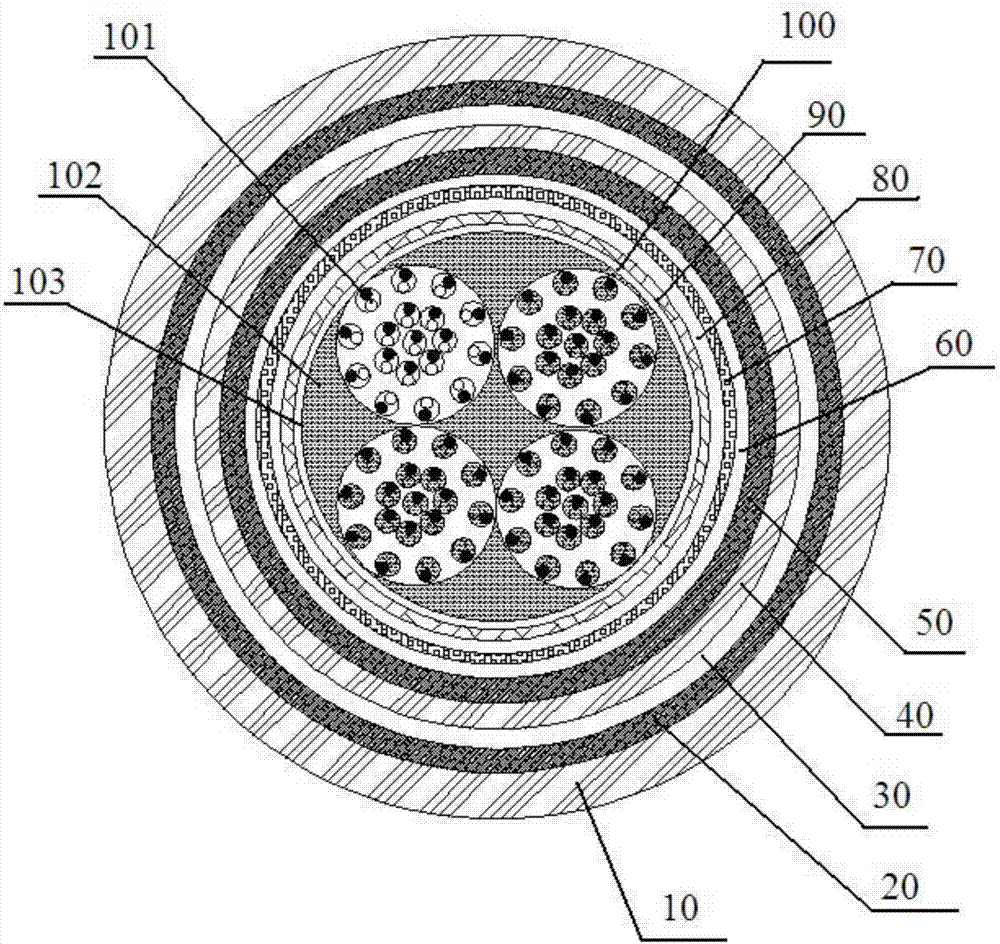

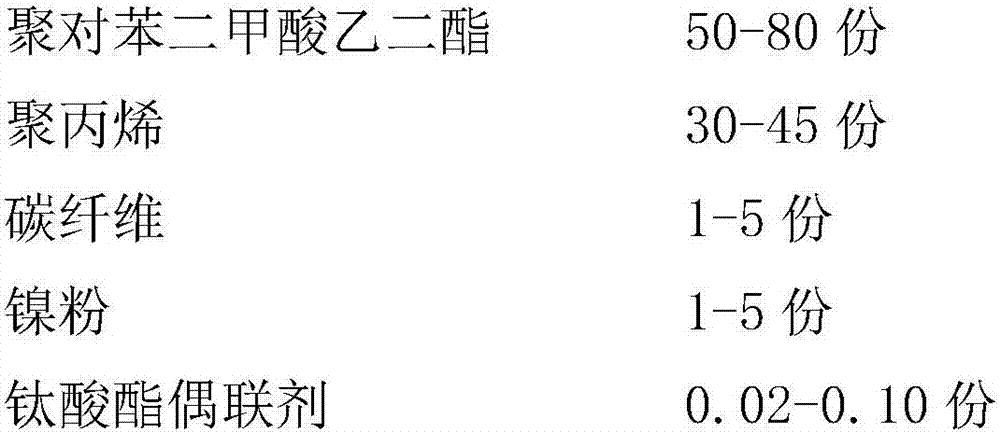

Low-smoke-amount and flame-retardant type composite data transmission cable

InactiveCN107025959AReduce reflectionReduce absorptionPower cables including communication wiresPower cables with screens/conductive layersPolyesterCopper conductor

The invention discloses a low-smoke-amount and flame-retardant type composite data transmission cable. The composite data transmission cable comprises two electric power copper conductors, two data copper conductors and filling ropes, wherein each of the two electric power copper conductors is coated with an insulating layer separately; the two insulating layers are arranged in parallel with a transverse 8 shape; the surfaces of the two insulating layers are covered with an inner sheath layer externally; the surfaces of a one-sided aluminum foil layer, the inner sheath layer and the filling ropes are coated with a polyester band layer; the outer surface of a flame-retardant layer is coated with an outer sheath layer; and the shielding insulating layers are prepared from the following components in parts by weight: PVC resin, ethylene-vinyl acetate copolymer, didecyl phthalate, polythiophene, siloxane, fumed silica, cerium sesquioxide, and antimony trioxide. By virtue of the low-smoke-amount and flame-retardant type composite data transmission cable, reflection and absorption on low-frequency electromagnetic wave are improved while crosstalk and signal attenuation are reduced; and in addition, the composite data transmission cable has relatively high stretching and tearing strength and physical and mechanical properties.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Electromagnetic shielded communication cables for rail transit

ActiveCN106298001BImprove mechanical propertiesImprove shielding effectCommunication cablesInsulated cablesFiberPolyester

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com