Mixed fuming disinfectant and use method thereof

A disinfectant and hybrid technology, which is applied in the direction of disinfectant, disinfection, botany equipment and methods, etc., can solve the problems of incomplete reaction of raw materials, short smoke generation time, affecting disinfection effect, etc., and achieve improved dispersibility and storage , Improve the effect of deodorization, strengthen the effect of sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

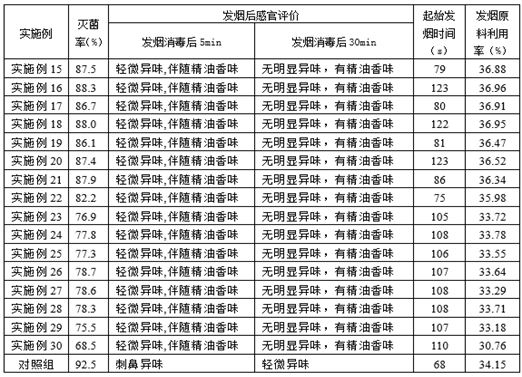

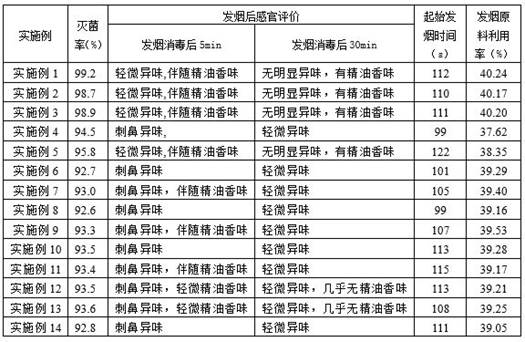

Examples

Embodiment 1

[0030] A mixed type fuming disinfectant is obtained through the following technical solutions:

[0031] The mixture of dichloroisocyanuric acid and trichloroisocyanuric acid with a mass ratio of 1:1, the mixture of sodium dichloroisocyanurate and sodium trichloroisocyanurate with a mass ratio of 1:2, and cornstarch by mass A agent is prepared by mixing at a ratio of 5:5:1; the aldehyde disinfectant of glutaraldehyde and o-phthalaldehyde with a mass ratio of 1:4, water, and the disinfection of propylene glycol and glycerol with a mass ratio of 1:2 The synergist is mixed according to the mass ratio of 27:12:1 to prepare B agent.

[0032]Mix saturated samarium chloride solution, rosin pentaerythritol ester, palm wax, and acetone in a mass ratio of 3:4:6:10 to obtain 30 parts of treatment liquid, and then mix 65 parts of activated carbon powder with 80 parts in a mass ratio of 1 : 1:1:1 blend of plant essential oils of neroli essential oil, tuberose essential oil, claret essentia...

Embodiment 2

[0037] A mixed type fuming disinfectant is obtained through the following technical solutions:

[0038] The mixture of dichloroisocyanuric acid and trichloroisocyanuric acid with a mass ratio of 1:1, the mixture of sodium dichloroisocyanurate and sodium trichloroisocyanurate with a mass ratio of 1:3, and tapioca starch by mass A agent is prepared by mixing at a ratio of 8:7:1; the aldehyde disinfectant of glutaraldehyde and o-phthalaldehyde with a mass ratio of 1:5, water, and the disinfection of propylene glycol and glycerol with a mass ratio of 1:3 The synergist is mixed at a mass ratio of 50:5:1 to prepare Agent B.

[0039] Mix saturated samarium chloride solution, rosin pentaerythritol ester, palm wax, and acetone in a mass ratio of 1:2:8:10 to obtain 40 parts of treatment liquid, and then mix 50 parts of activated carbon powder with 65 parts in a mass ratio of 1 : 1:1:1 blend of plant essential oils of neroli essential oil, tuberose essential oil, claret essential oil an...

Embodiment 3

[0044] A mixed type fuming disinfectant is obtained through the following technical solutions:

[0045] The mixture of dichloroisocyanuric acid and trichloroisocyanuric acid with a mass ratio of 1:1, the mixture of sodium dichloroisocyanurate and sodium trichloroisocyanurate with a mass ratio of 1:1, and wheat starch by mass A agent is prepared by mixing at a ratio of 2:3:1; the aldehyde disinfectant of glutaraldehyde and o-phthalaldehyde with a mass ratio of 1:3, water, and the disinfection of propylene glycol and glycerol with a mass ratio of 1:1 The synergist is mixed at a mass ratio of 5:19:1 to prepare Agent B.

[0046] Mix saturated samarium chloride solution, rosin pentaerythritol ester, palm wax, and acetone in a mass ratio of 5:6:2:10 to obtain 20 parts of treatment liquid, and then mix 80 parts of activated carbon powder with 95 parts in a mass ratio of 1 : 1:1:1 blend of neroli essential oil, tuberose essential oil, claret essential oil and rosin essential oil with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com