Heat non-burning cigarette body and manufacturing method thereof

A heat-not-burn and cigarette technology, which is applied in the fields of tobacco, tobacco processing, application, etc., can solve problems such as insufficient smoke generation, poor heat transfer effect, and loose smoking materials, so as to increase the amount of smoke-generating substances and increase transmission Thermal effect, effect of density improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

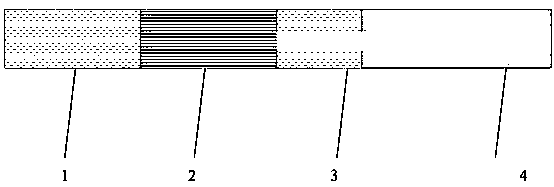

[0018] According to the weight ratio of 60% tobacco powder, 20% glycerol, 10% white wine, 5% tobacco extract, and 5% starch, the materials are mixed evenly, and extruded into a hollow tubular smoking unit with a hollow inner diameter of 1.5 mm, the outer diameter of the cylinder is 6.5mm, the length is 23mm, and the paste density is controlled at 1.2g / cm 3 , with a moisture content of 14%, such as figure 1 As shown, one end of the hollow section is connected to the smoking unit, the other end is connected to the cooling section, and the cooling section is connected to the filtering section. The filtering section, the cooling section, the hollow section and the smoking unit are rolled into a heat-not-burn cigarette by rolling cigarette paper. bomb.

Embodiment 2

[0020] According to the weight ratio of 55% tobacco powder, 25% glycerin, 5% white wine, 10% tobacco extract, and 5% starch, the materials are mixed evenly, and extruded into a hollow tubular smoking unit with a hollow inner diameter of 1.0mm. The outer diameter of the cylinder is 6mm, the length is 24mm, and the paste density is controlled at 1.4g / cm 3 , with a moisture content of 15%, one end of the hollow section is connected to the smoking unit, the other end is connected to the cooling section, and the cooling section is connected to the filtering section. The filtering section, cooling section and hollow section are rolled with hard cigarette paper, and the hard cigarette paper is extended The hollow section extends 5-10mm in the direction to form a cavity, and the hollow tubular smoking unit is socketed in the cavity to form a heat-not-burn pod.

[0021] Compared with the current IQOS heat-not-burn cigarette cartridges with the best indicators in various aspects, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com