Flame-retardant spray polyurea elastomer coating and preparation method thereof

A polyurea elastomer and flame-retardant technology, which is applied in the field of polyurea elastomer coating and its preparation, can solve the problems of poor flame-retardant effect and poor physical properties of materials, and achieve flame-retardant durability and migration resistance Good, the effect of improving the flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

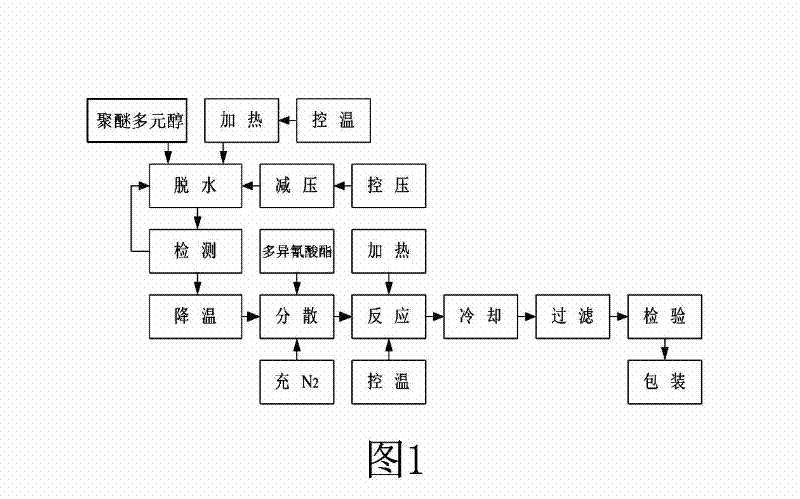

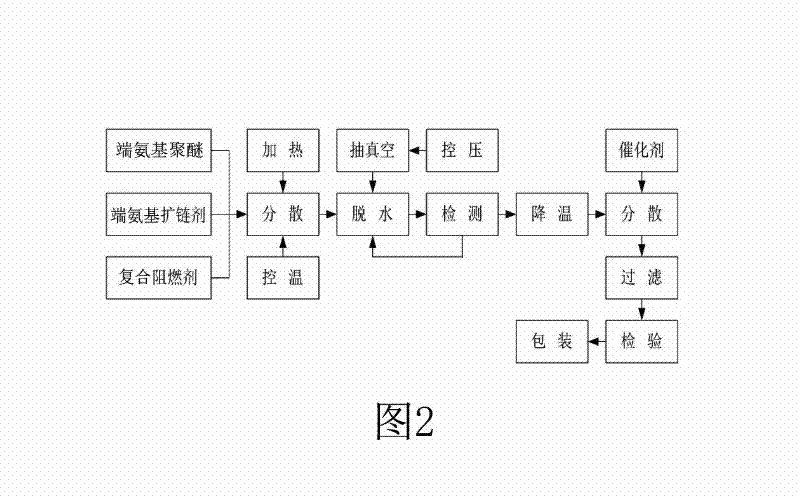

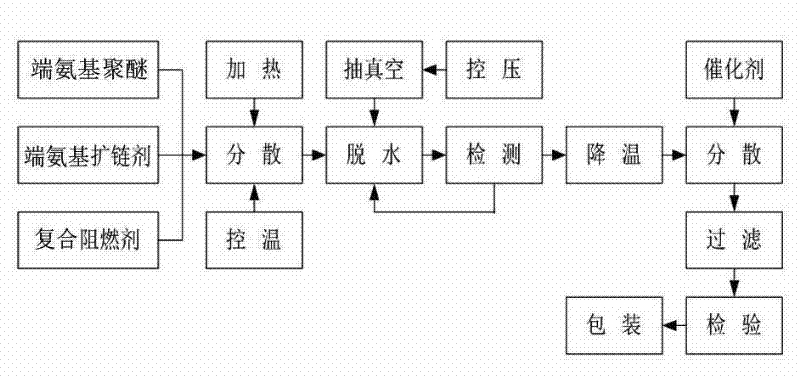

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, this flame-retardant spray polyurea elastomer coating is composed of A component and B component,

[0045] The raw materials of the A component are proportioned as follows by weight percentage:

[0046] Polyether polyol 50%,

[0047] Polyisocyanate 50%;

[0048] The raw materials of the B component are proportioned as follows by weight percentage:

[0049] Amino-terminated polyether 44.20%,

[0050] Amino-terminated chain extender 25.20%,

[0051] Composite flame retardant 30.55%,

[0052] Catalyst 0.05%;

[0053] Described composite flame retardant proportioning by weight percentage is as follows:

[0054] Tetrabromophthalic anhydride diol PHT4-DIOL 50%;

[0055] Tris(2-chloropropyl)phosphate TCPP 10%;

[0056] Chlorinated paraffin 30%;

Embodiment 2

[0058] Embodiment 2, this flame-retardant spray polyurea elastomer coating is composed of A component and B component,

[0059] The raw materials of the A component are proportioned as follows by weight percentage:

[0060] Polyether polyol 40%,

[0061] Polyisocyanate 60%;

[0062] The raw materials of the B component are proportioned as follows by weight percentage:

[0063] Amino terminated polyether 55.0%,

[0064] Amino-terminated chain extender 24.5%,

[0065] Composite flame retardant 20.4%,

[0066] Catalyst 0.1%;

[0067] The raw materials of the composite flame retardant in the B component are proportioned as follows by weight percentage:

[0068] Tetrabromophthalic anhydride diol PHT4-DIOL 58%;

[0069] Tris(2-chloropropyl)phosphate TCPP 12%;

[0070] Chlorinated paraffin 20%;

Embodiment 3

[0072] Embodiment three, this flame-retardant spray polyurea elastomer coating is composed of A component and B component,

[0073] The raw materials of the A component are proportioned as follows by weight percentage:

[0074] Polyether polyol 60%,

[0075] Polyisocyanate 40%;

[0076] The raw materials of the B component are proportioned as follows by weight percentage:

[0077] Amino-terminated polyether 35.0%,

[0078] Amino-terminated chain extender 35.0%,

[0079] Composite flame retardant 29.9%,

[0080] Catalyst 0.1%;

[0081] Described composite flame retardant proportioning by weight percentage is as follows:

[0082] Tetrabromophthalic anhydride diol PHT4-DIOL 30%;

[0083] Tris(2-chloropropyl)phosphate TCPP 6%;

[0084] Chlorinated paraffin 40%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com