Patents

Literature

71 results about "Tetrabromophthalic anhydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

3,4,5,6-Tetrabromophthalic anhydride can be prepared by reacting phthalic anhydride and bromine in a mixture of concentrated sulfuric acid and 70% hydrogen peroxide in the presence of catalytic amounts of iodine or in chlorosulfonic acid containing a small amount of sulfur.

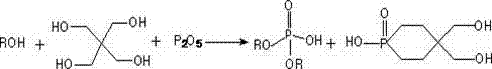

Preparation method and application of multivariate cooperation flame-retardant polyol

The invention relates to a preparation method and application of multivariate cooperation flame-retardant polyol and belongs to the technical field of chemical, energy saving and protection and environmental-friendly new processes. The preparation method comprises the steps of heating pentaerythritol, other alcohols and phosphorus pentoxide to obtain phosphorus cycle flame-retardant intermediate; continuously adding epoxy compound and tetrabromophthalic anhydride, and heating to perform catalytic reaction to obtain multivariate cooperation flame-retardant polyol. The preparation process is simple, the cost of raw materials is low, the operation is easy to perform and the prepared product is can be used for preparing polyurethane heat insulating materials.

Owner:UNIV OF JINAN

High-temperature-resistant matrix resin for high-Tg copper-clad plate and preparation method of high-temperature-resistant matrix resin

InactiveCN104559059AConvenient sourceSimple preparation processSynthetic resin layered productsMetal layered productsEpoxyOrganic solvent

The invention relates to high-temperature-resistant matrix resin for a high-Tg copper-clad plate and a preparation method of the high-temperature-resistant matrix resin. The matrix resin comprises epoxy resin, a polyimide resin liquid, tetrabromophthalic anhydride, DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide), a curing agent and an organic solvent whose mass ratio is 100:50:150: (12-25) : (5-30) : (50-100). The preparation method is as follows: after epoxy resin, DOPO and tetrabromophthalic anhydride are mixed and react, a component A is obtained; after aromatic diamine, aromatic quaternary amine, aromatic dianhydride and maleic anhydride completely react in a strong-polarity nonprotic organic solvent, an azeotropic dehydrating agent and a catalyst are added, and the polyimide resin liquid, namely, a component B is obtained after an azeotropic dehydration imidization reaction; the component A and the component B are mixed, and the curing agent and the organic solvent are added, and the mixture is uniformly mixed to obtain the high-temperature-resistant matrix resin. The product has excellent overall performance, is suitable for manufacturing an advanced composite material, is particularly suitable for manufacturing the high-Tg copper-clad plate and has a good market prospect.

Owner:DONGHUA UNIV +2

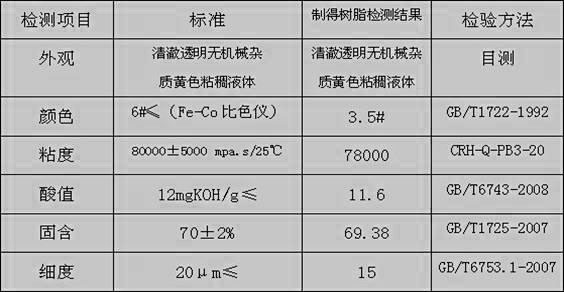

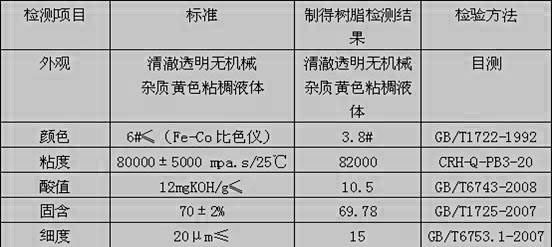

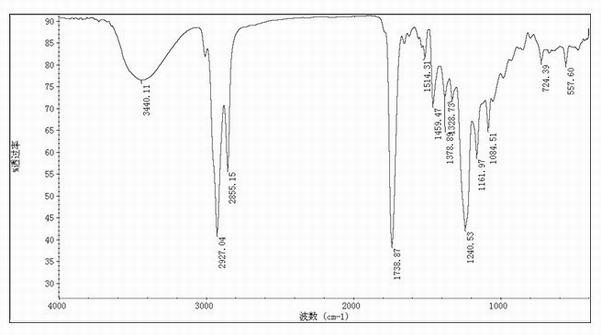

Flame-retardant alkyd resin and preparation method thereof

ActiveCN102627757AWith transparent decorative effectFlame retardantFireproof paintsPolyester coatingsXylylenePolymer science

The invention belongs to the technical field of chemical engineering and especially discloses a flame-retardant alkyd resin. The flame-retardant alkyd resin comprises: by weight, 19.0 to 22.0% of soya fatty acid, 8.2 to 12.2% of pentaerythritol, 4.5 to 8.5% of tetrabromobisphenol A, 0.2 to 0.8% of maleic anhydride, 28.5 to 34.5% of tetrabromophthalic anhydride, 0.05 to 0.2 of at least one color subtraction agent, 0.05 to 0.2% of an antioxidant, 2.00 to 5% of refluxing xylene, and 24 to 28% of at least one dilute solvent. The flame-retardant alkyd resin has strong flame resistance. The preparation method of the flame-retardant alkyd resin is simple.

Owner:HUIZHOU CHANGRUNFA PAINT

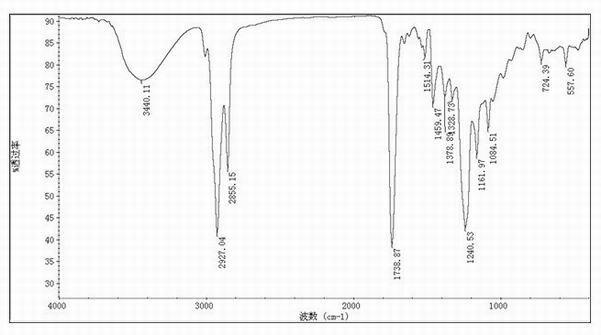

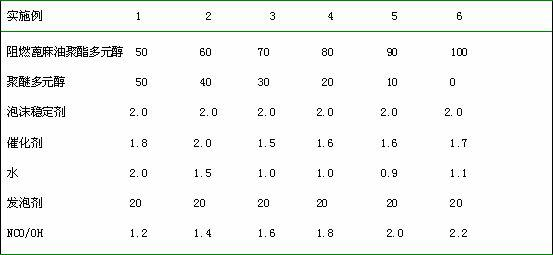

Method for preparing structure type flame-retardant castor-oil-based polyester polyol and applications thereof

InactiveCN102432850AImproved flame retardant performance of rigid foamImprove flame retardant performancePolyesterPolymer science

The invention relates to a method for preparing structure type flame-retardant castor-oil-based polyester polyol and applications thereof. The method comprises the following steps: castor oil and small-molecular alcohol generate alcoholysis reaction under the existence of an alkali catalyst, and then generate esterification reaction with tetrabromophthalic anhydride under the existence of an esterification catalyst, and the flame-retardant castor-oil-based polyester polyol is obtained, wherein the hydroxyl value is 100-450mg / gKOH, the acid value is less than or equal to 1.5mg / gKOH and the content of bromine is 5-30wt%. In the method, the middle process does not need to be separated, the cost is low and the process is simple, and the flame retardance of the prepared polyurethane foam is obviously improved. The prepared polyurethane foam has the advantages of no liquid drop of a product in burning, shape maintenance, less smoke density and the like and can be used for buildings, insulation and certain special fields.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

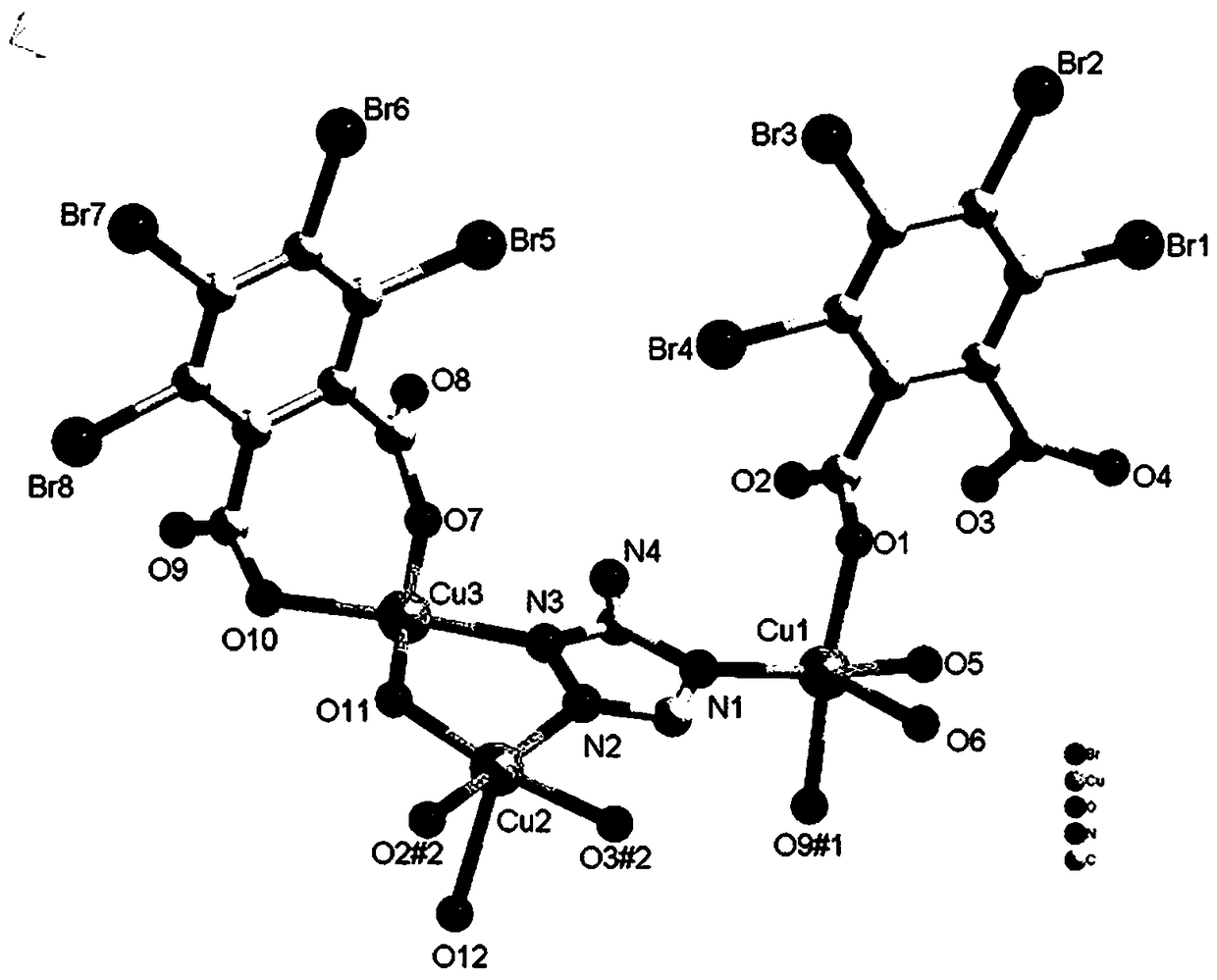

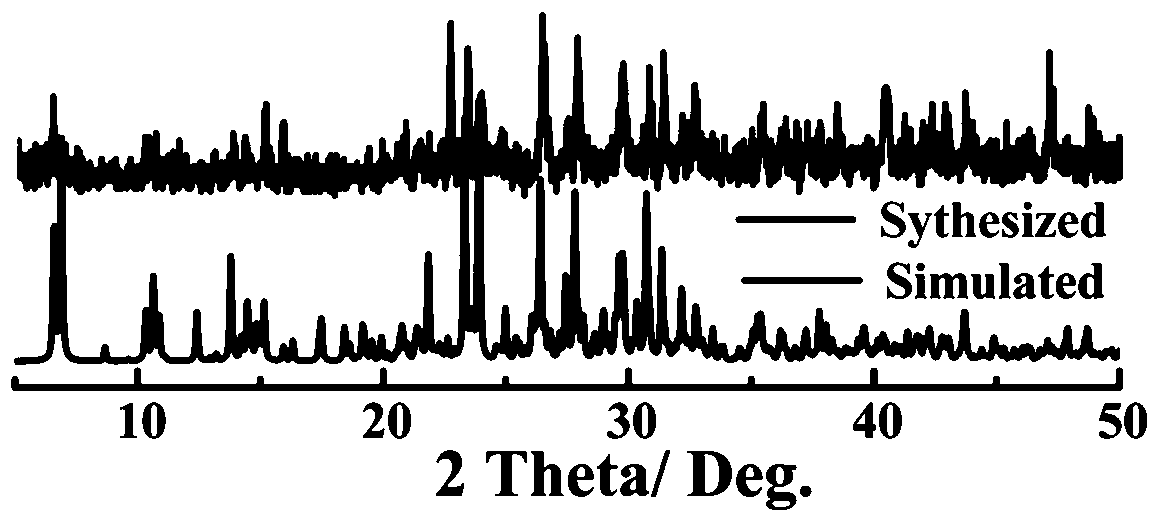

Trinuclear copper cluster-based coordination polymer as well as preparation method and application thereof

The invention discloses preparation of a trinuclear copper cluster-based coordination polymer and application of the trinuclear copper cluster-based coordination polymer in electrocatalytic hydrogen evolution. The chemical molecular formula of the coordination polymer is [Cu3(L)2(ATA)OH(H2O)3.2H2O]n (L=C8H4Br4O4<2->, ATA=Triazol-3-amine);the coordination polymer belongs to a triclinic system and has a space group of Pi. The synthesis method concretely comprises the following steps: enabling tetrabromophthalic anhydride organic ligand, copper salt and a nitrogen-containing auxiliary ligand, i.e., triazol-3-amine (ATA) to be subjected to a reaction under the hydrothermal condition so as to obtain green strip-shaped crystals, and grinding and refining the obtained green strip-shaped crystalsto obtain the needed electrocatalytic material. The coordination polymer shows good catalytic activity in an electrocatalytic hydrogen evolution reaction (HER), and can be applied to the new energy fields such as electrocatalytic decomposition of water for hydrogen production.

Owner:CHINA THREE GORGES UNIV

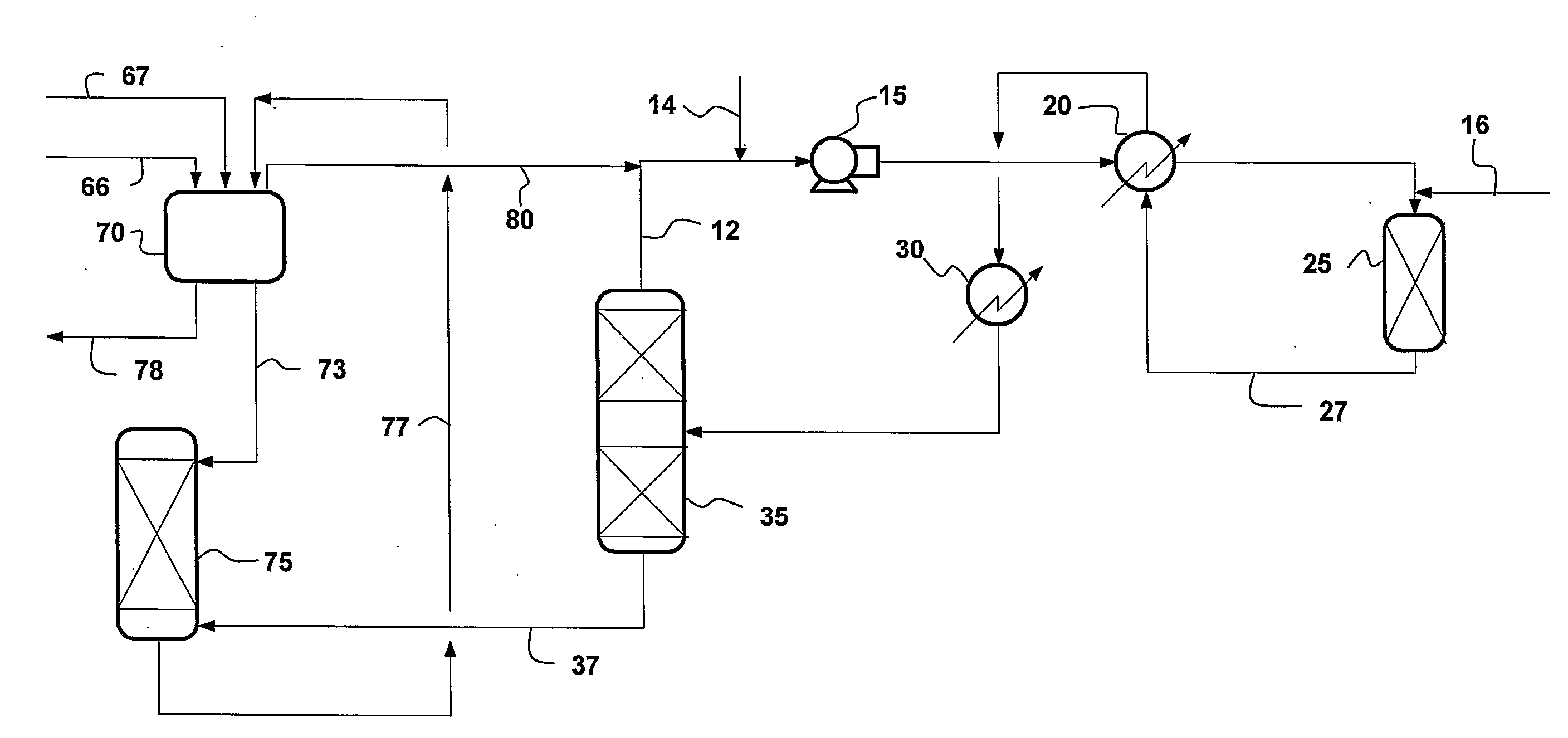

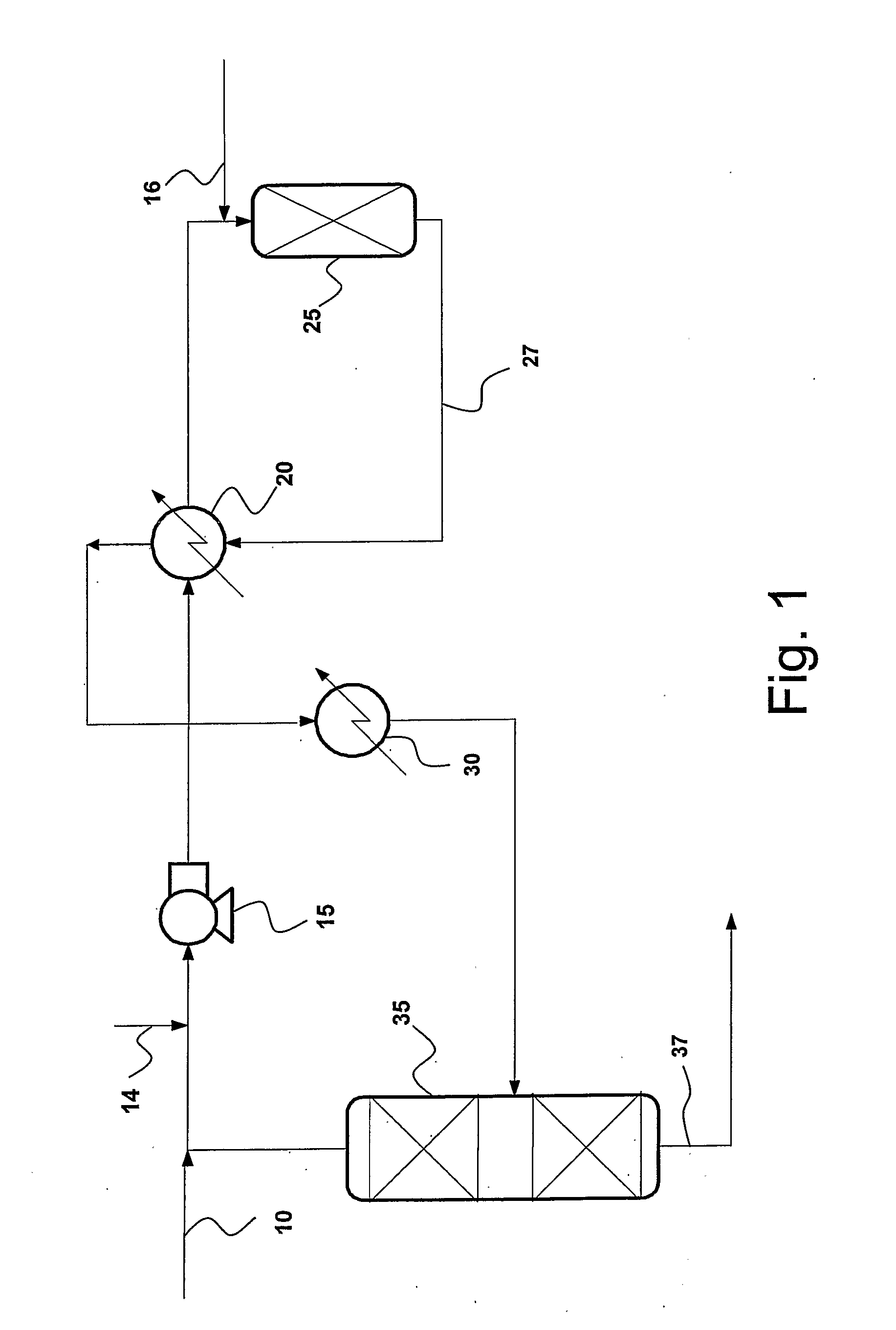

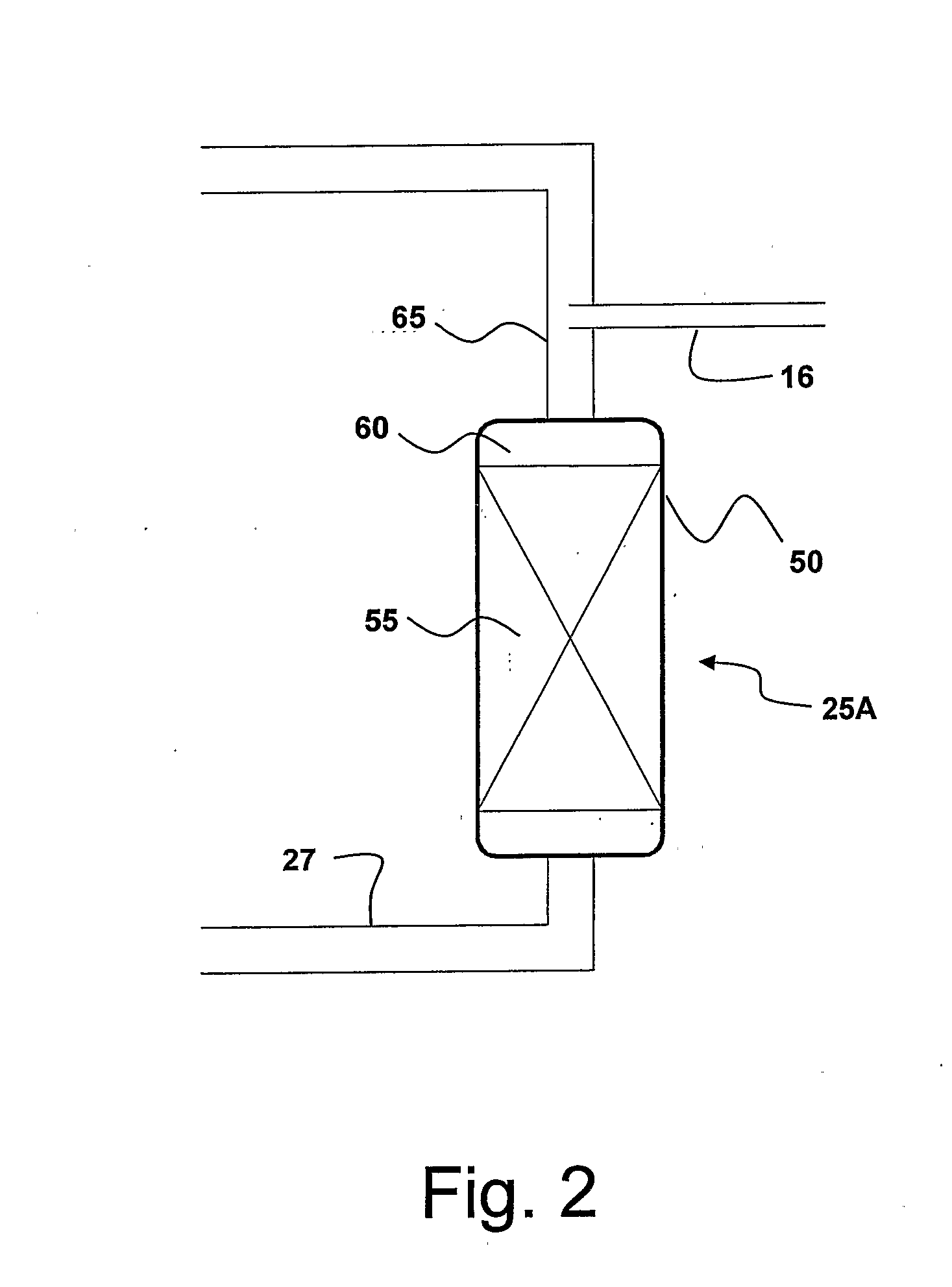

Concurrent Sulfur Dioxide Oxidation Process and its Use in Manufacture of Tetrabromophthalic Anhydride

InactiveUS20070260072A1Efficient use ofOrganic compound preparationSulfur compoundsPtru catalystPhysical chemistry

Sulfur trioxide is formed by a process wherein a first gaseous stream comprised of SO2, SO3, and oxygen and / or air is passed into a bed of a vanadium-containing catalyst that oxidizes S02 to SO3and that releases therefrom a second gaseous stream comprised of sulfur trioxide. This process is improved in a first case by providing vaporized sulfur in the first gaseous stream so that the resultant mixture passes through a substantial portion of the catalyst bed, and maintaining the catalyst bed at one or more temperatures in the range of about 450 to about 700° C. The sulfur is oxidized to S02. As a result, the second gaseous stream released from the downstream end portion of the catalyst bed has an enriched content of sulfur trioxide, which can be used for production of compounds such as tetrabromophthalic anhydride. In a second case, a stream of sulfur dioxide is generated from sulfur and an oxidant, and this stream is introduced into the first gaseous stream referred to above. In this second case, the feed of sulfur dioxide replaces the vaporized sulfur used in the first case. As in the first case, an enriched stream of sulfur trioxide is released from the downstream end of the catalyst and can be used for producing compounds such as tetrabromophthalic anhydride.

Owner:ALBEMARLE CORP

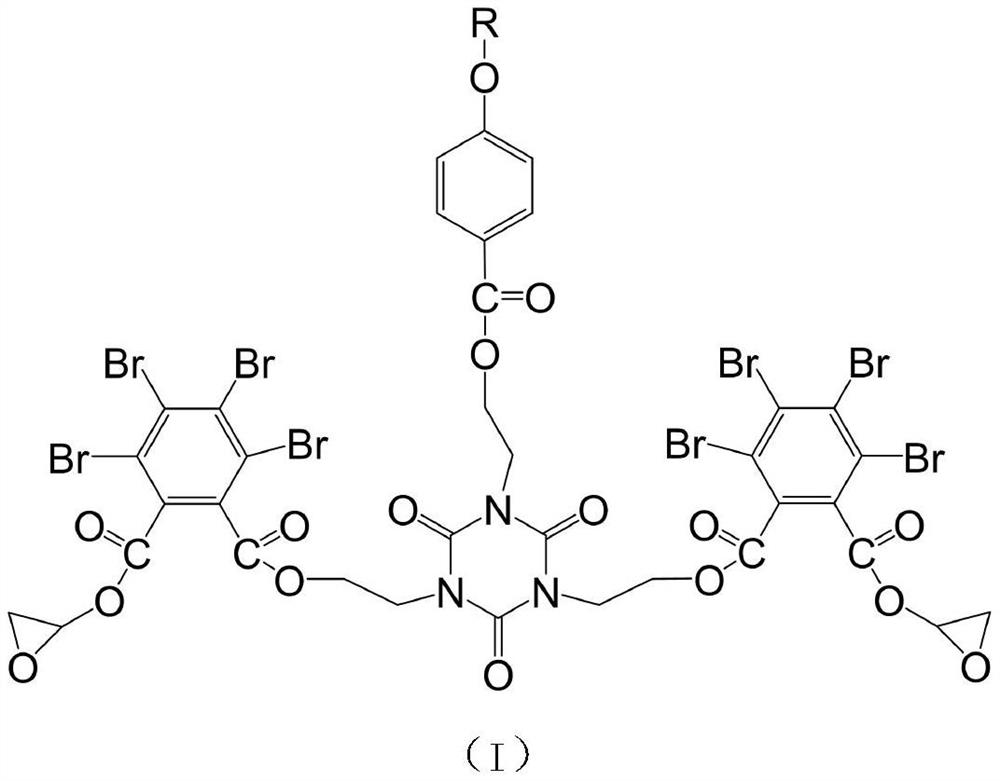

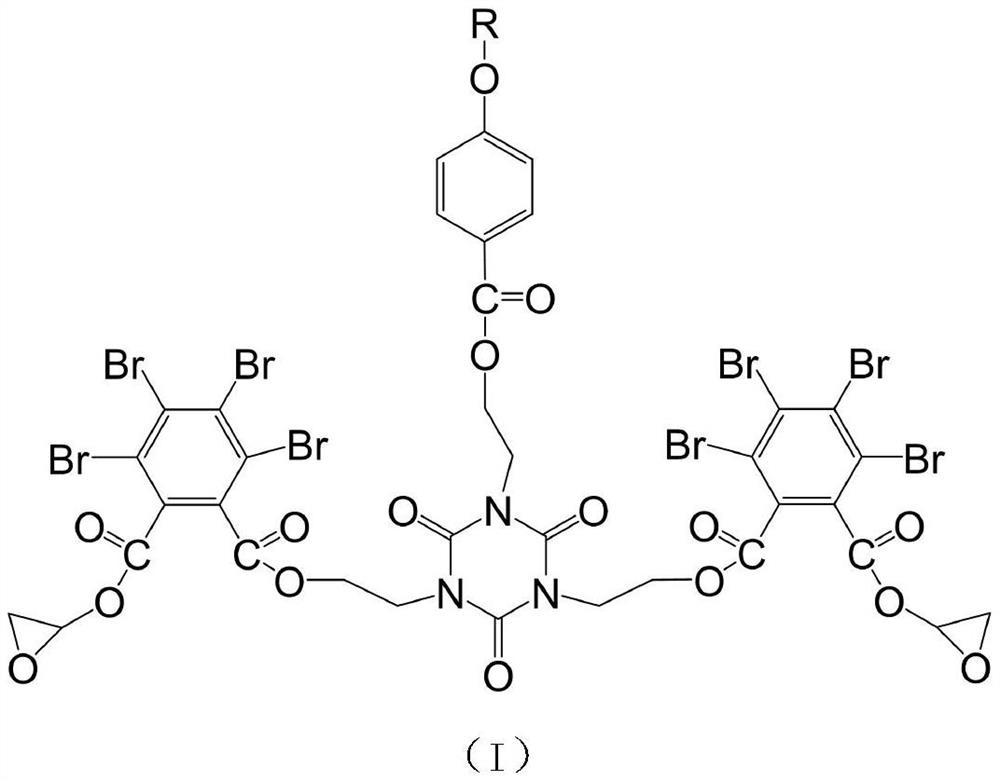

Flame-retardant fireproof epoxy coating and preparation method thereof

InactiveCN111647335AHigh flame retardant and heat resistance performanceHigh purityFireproof paintsEpoxy resin coatingsEpoxyPolymer science

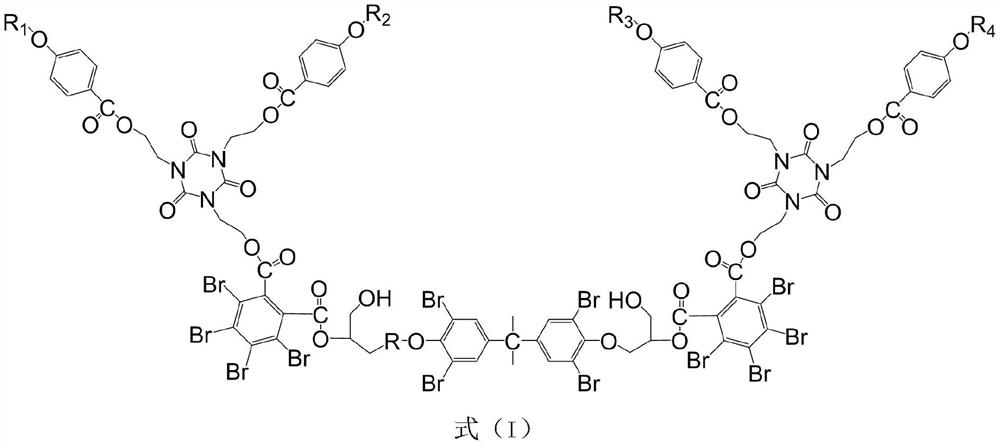

The invention discloses an epoxy coating with flame-retardant and fireproof functions. The epoxy coating comprises epoxy resin with a flame-retardant function. The preparation method of the epoxy resin comprises the following steps: reacting chlorinated paraffin with p-hydroxybenzoic acid to prepare carboxyl-containing chlorinated paraffin; carrying out acylation on the carboxyl-containing chlorinated paraffin, and carrying out esterification reaction on the acylated carboxyl-containing chlorinated paraffin and tris(2-hydroxyethyl)isocyanurate to prepare hydroxyl-containing isocyanurate modified chlorinated paraffin; then, performing a reaction on chlorinated paraffin containing hydroxyl with tetrabromophthalic anhydride to prepare chlorinated paraffin diacid. The preparation method has the advantages that the operation is simple, the raw material source is wide, the reaction condition is mild, the industrial production is met, and the prepared epoxy resin has good flame-retardant andheat-resistant properties and wide application prospects.

Owner:徐松波

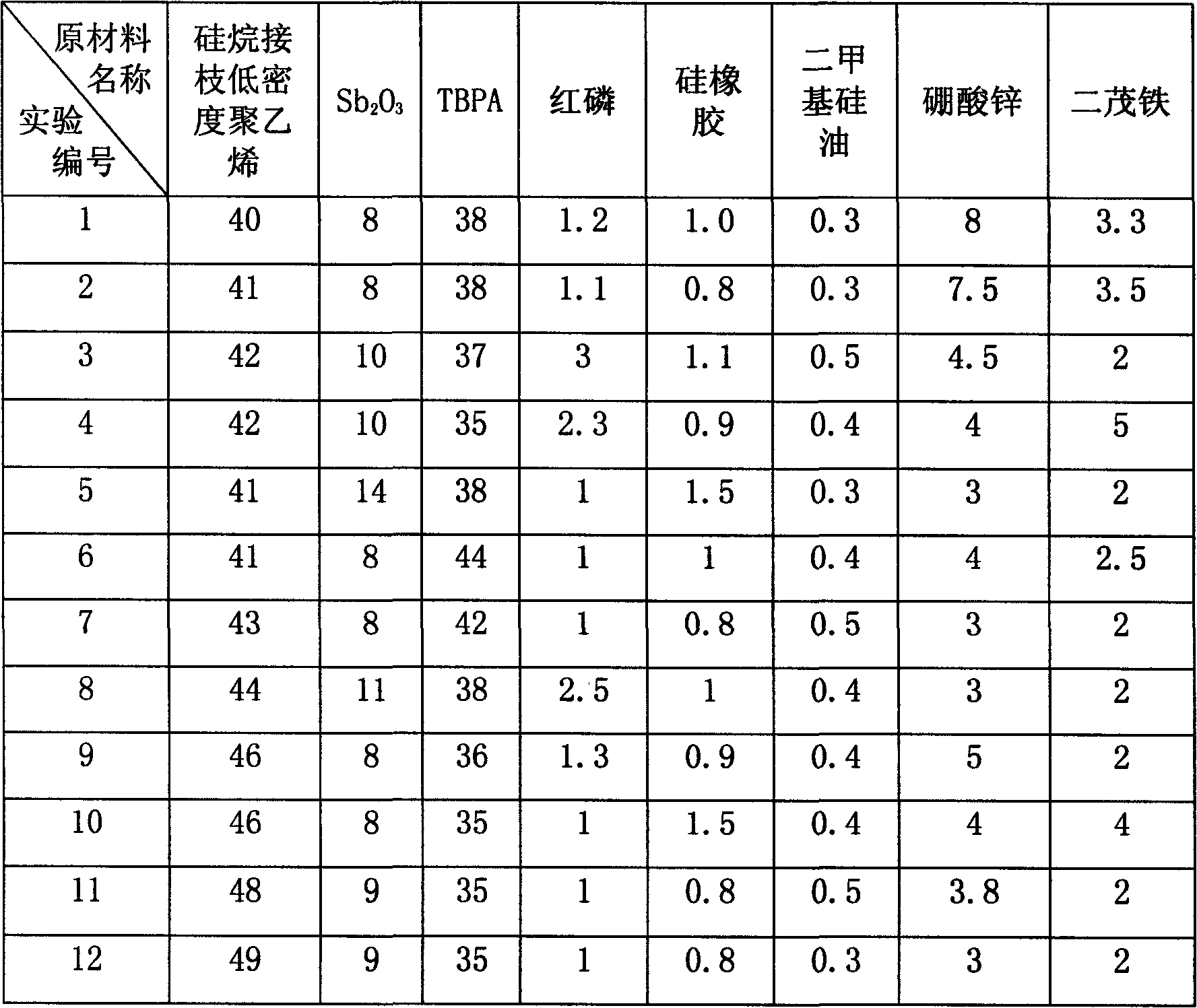

Low-smoke halogen free flame retardant, preparation method and method thereof for preparing flame-resistant materials

ActiveCN101659870AReduce generationImprove flame retardant performanceFireproof paintsPolymer sciencePolyolefin

The invention belongs to the field of flame-resistant wires and cables, and particularly relates to a low-smoke halogen free fire retardant, a preparation method and a method for preparing flame-resistant materials. The low-smoke halogen free fire retardant comprises the following components with weight portions: 40 to 50 portions of polyolefin, 8 to 15 portions of antimonous oxide, 35 to 45 portions of tetrabromoph and 2 to 5 portions of ferrocene. The preparation method comprises the following steps of: firstly mixing the needed components according to the weight portions, stirring evenly and obtaining premix; and then extruding and pelleting to the premix under the condition of 130 to 180 DEG C by an extruder, namely obtaining the flame resistant. The following component according to the following proportion: flame resistant: polyolefin: dibutyltin dilaurate=30:65:5, and then the mixture is extruded on the extruder in an insulating manner. The flame-resistant material has better flame-resistant effect and can realize the low-smoke halogen-free purpose.

Owner:于贵良 +1

Polyurethane hard foam flame-retardant polyether polyol and preparation method thereof

ActiveCN103626985AImprove flame retardant performancePermanent Flame RetardancyPolyolPolymer science

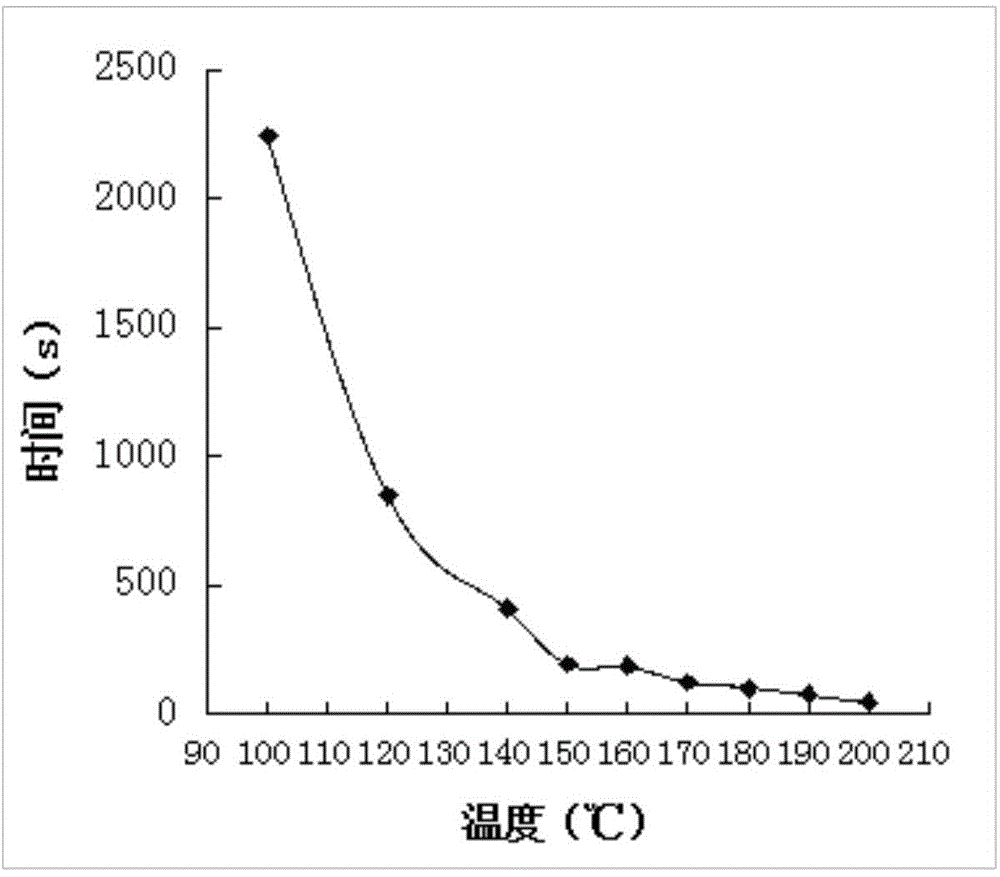

The invention belongs to the field of synthesis of a polyurethane foam material, and particularly relates to polyurethane hard foam flame-retardant polyether polyol. The polyurethane hard foam flame-retardant polyether polyol is prepared from the following raw materials in parts by weight: 20-50 parts of water, 25-30 parts of starch, 8-10 parts of phosphoric acid, 20-40 parts of tetrabromophthalic anhydride, 0.5-1.5 parts of concentrated sulfuric acid and 30-80 parts of epoxypropane. By adopting the polyurethane hard foam flame-retardant polyether polyol, the flame retardant property of the polyurethane hard foam is effectively improved, and the polyurethane hard foam flame-retardant polyether polyol has excellent performances such as permanent flame retardant ability, high strength and low-heat conductivity coefficient. The invention also provides a preparation method of the polyurethane hard foam flame-retardant polyether polyol. The method comprises the following steps: heating water, concentrated sulfuric acid, starch and tetrabromophthalic anhydride until the mixture is transparent after evenly being mixed; adding phosphoric acid; slowly adding epoxypropane after fully mixing under the condition of 120-150 DEG C; vacuumizing for 20-40 minutes at the temperature of 100-120 DEG C after reaction is finished, so as to obtain the polyurethane hard foam flame-retardant polyether polyol. Therefore, the polyurethane hard foam flame-retardant polyether polyol is low in cost, and the preparation method is simple and easy to implement.

Owner:淄博正华发泡材料有限公司 +1

Synthetic method for N,N-Ethylene-Bis(bromophthalimide)

InactiveCN102924361AHigh yieldBromination reaction temperature is lowOrganic chemistryEthylenediamineReaction temperature

The invention discloses a synthetic method for N,N-Ethylene-Bis(bromophthalimide). The synthetic method includes the following steps: (1) throwing phthalic anhydride and catalyst into fuming sulphuric acid, dripping bromine in the fuming sulphuric acid at normal temperature to carry out brominating reaction to obtain crude product tetrabromophthalic anhydride, a reaction molar ratio between the phthalic anhydride and the bromine is 1:3.8-4.1; (2) subjecting the crude product tetrabromophthalic anhydride to scouring and complexation, second neutralization and then second water scrubbing to obtain tetrabromophthalic anhydride; (3) Throwing the tetrabromophthalic anhydride into organic solution, dropwise adding ethanediamine diamine on the basis that the molar ratio between the tetrabromophthalic anhydride and the ethidene diamine is 1:1.9-2.1; and obtaining the crude product of N,N-Ethylene-Bis(bromophthalimide) after condensation reaction at the temperature of 50 DEG C to 150 DEGC. (4) Water scrubbing crude product ethylene double bromine phthalates formyl imine to obtain the ethylene double bromine phthalates formyl imine after high-temperature dewatering. The synthetic method is low in temperature of bromination reaction, temperate in reaction condition, easy to control, low in production energy consumption, high in product yield rate, and good in product quality.

Owner:SHANDONG RUNKE CHEM

Preparation method and application of PET-based multi-component synergetic polyol

InactiveCN105175701AImprove flame retardant performanceLow costPolyethylene terephthalate glycolPolymer science

The invention discloses a preparation method and application of PET-based multi-component synergetic polyol and belongs to the technical field of high-molecular materials, reactive flame retardants, energy saving and protection, environmental-friendly new processes and building thermal insulation materials. The PET-based multi-component synergetic polyol is prepared through catalytic reaction by using recovered polyethylene terephthalate, mixed alcohol, tetrabromophthalic anhydride, isocyanuric acid and alkylene oxide. The raw materials for preparation are cheap and easy to obtain, the reaction conditions are mild, the process is simple, the operation is easy and the industrialized production is facilitated. The product is used for preparing flame-retardant polyurethane foam materials.

Owner:UNIV OF JINAN

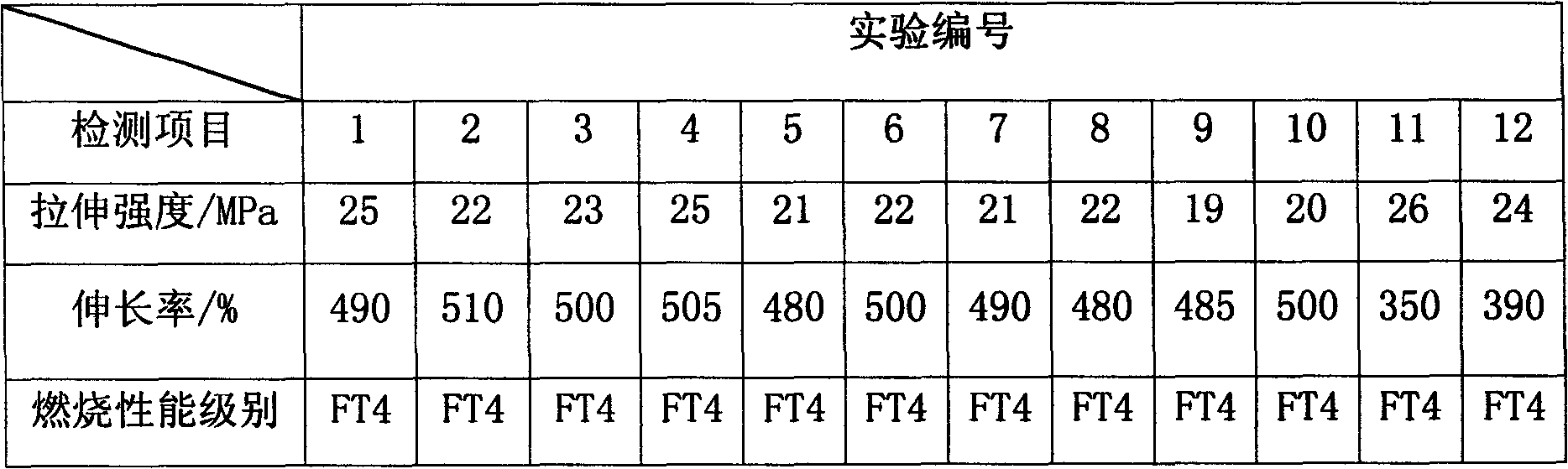

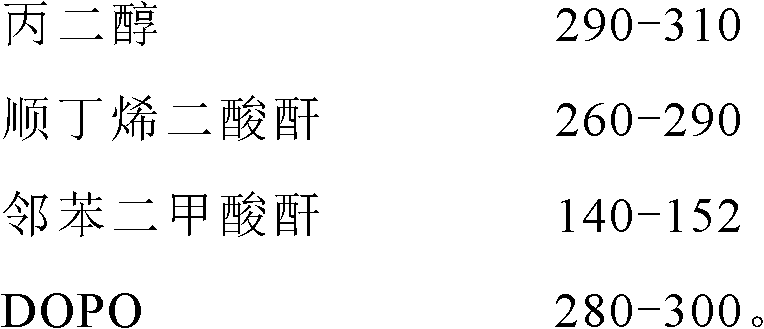

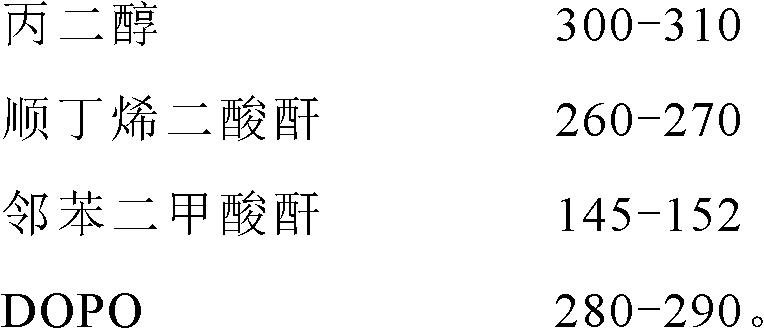

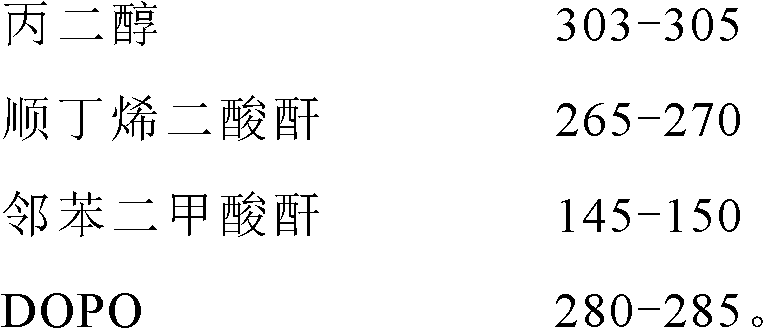

Flame-retardant resin comprising phosphaphenanthrene compound, and synthesizing process and application thereof

The invention comprises a flame-retardant resin comprising phosphaphenanthrene compound. The resin comprises unsaturated polyester synthesized by using the components of, by weight, 290-310 parts of propylene glycol, 260-290 parts of maleic anhydride, 140-152 parts of phthalic anhydride, 280-300 of DOPO, and 600-630 parts of styrene. According to the unsaturated polyester resin, DOPO is used for replacing tetrabromophthalic anhydride, such that a finally obtained resin is a non-halogen flame-retardant reactive resin, and resin application range is widened. In the resin components, maleic anhydride with a relatively large proportion is applied, such that the change of maleic anhydride from unsaturated acid to saturated acid caused by the introduction of DOPO is supplemented. Therefore, the reduction of resin activity and composite material mechanical performances are avoided.

Owner:CHANGZHOU HUARUN COMPOSITE MATERIALS +1

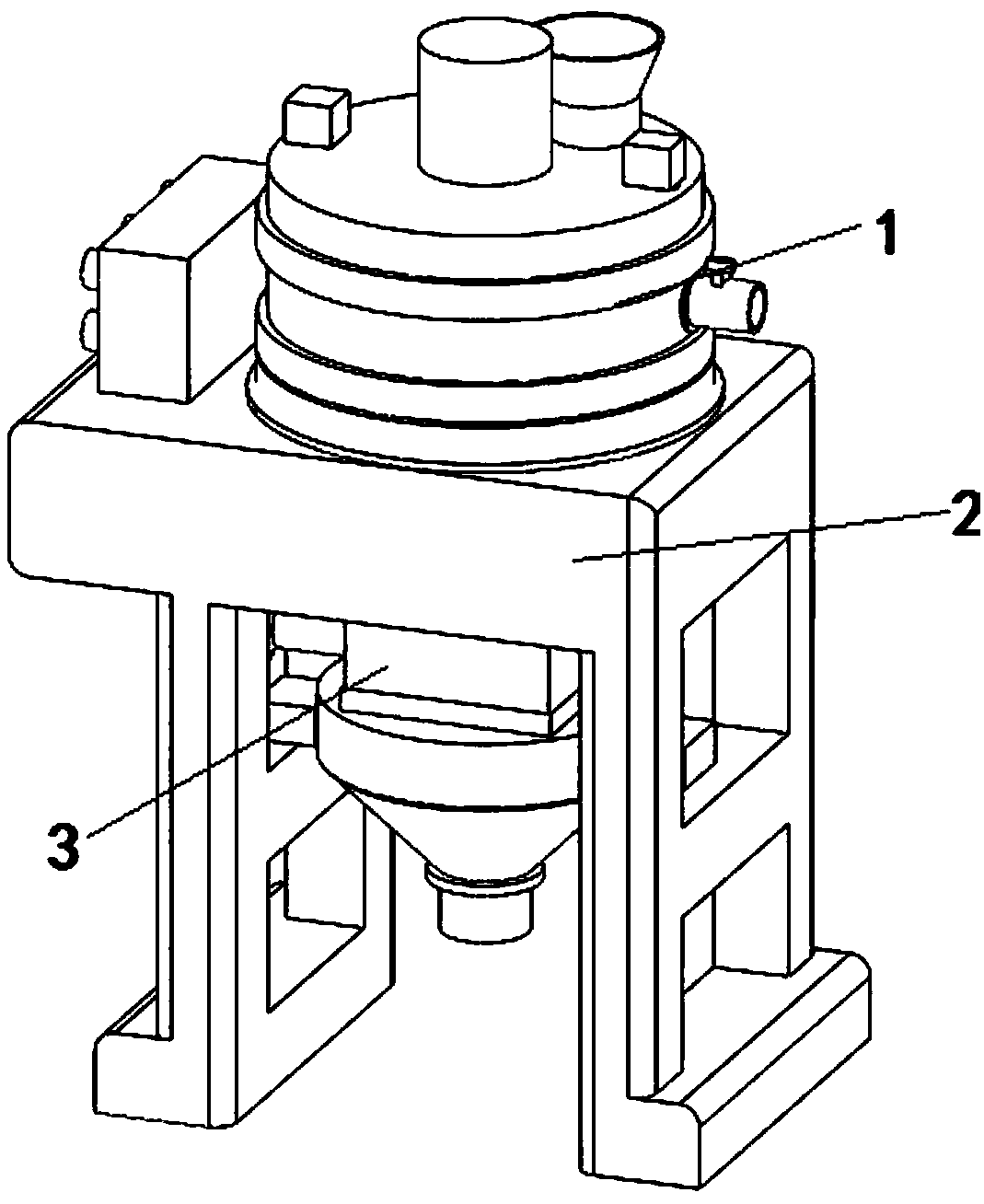

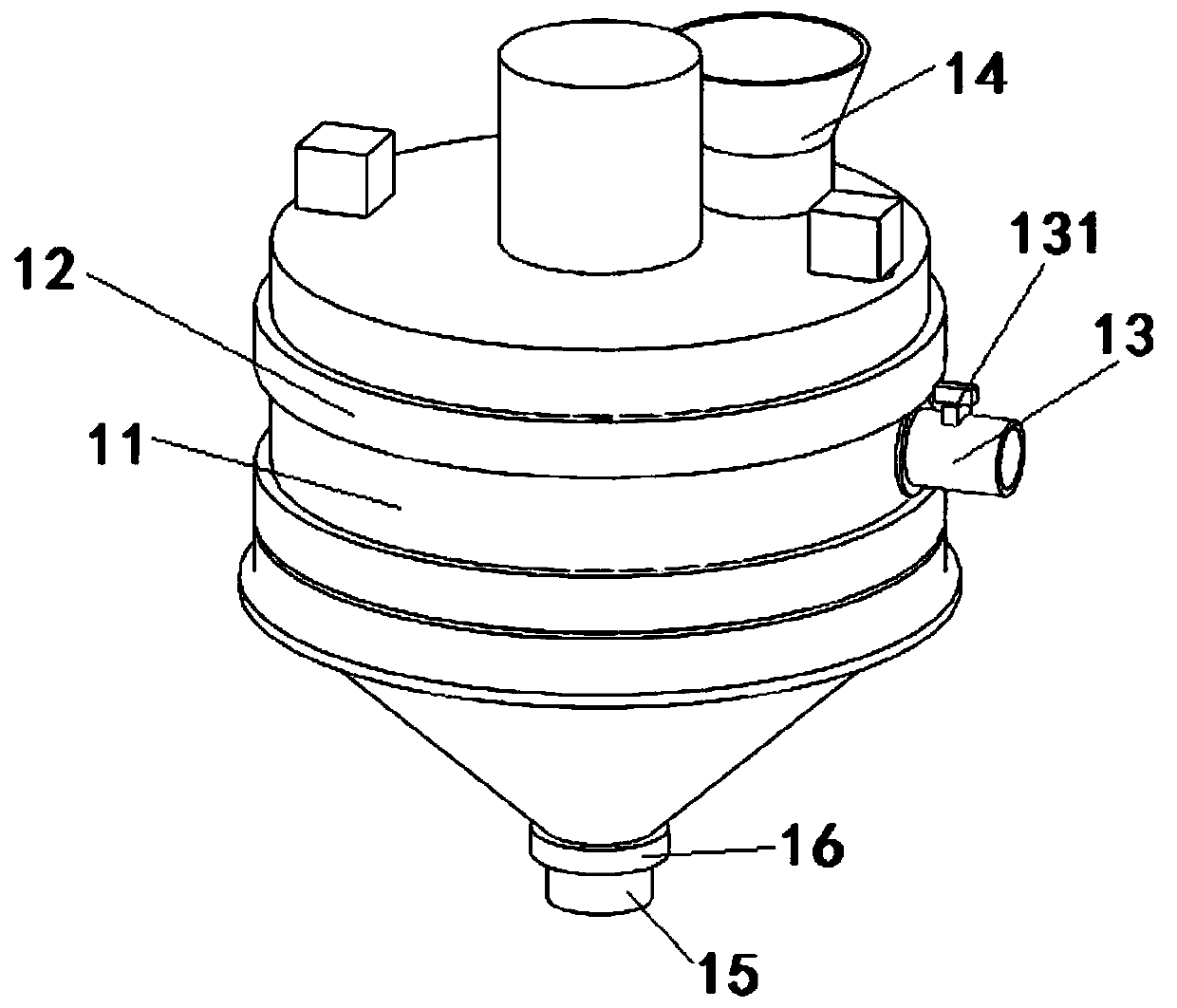

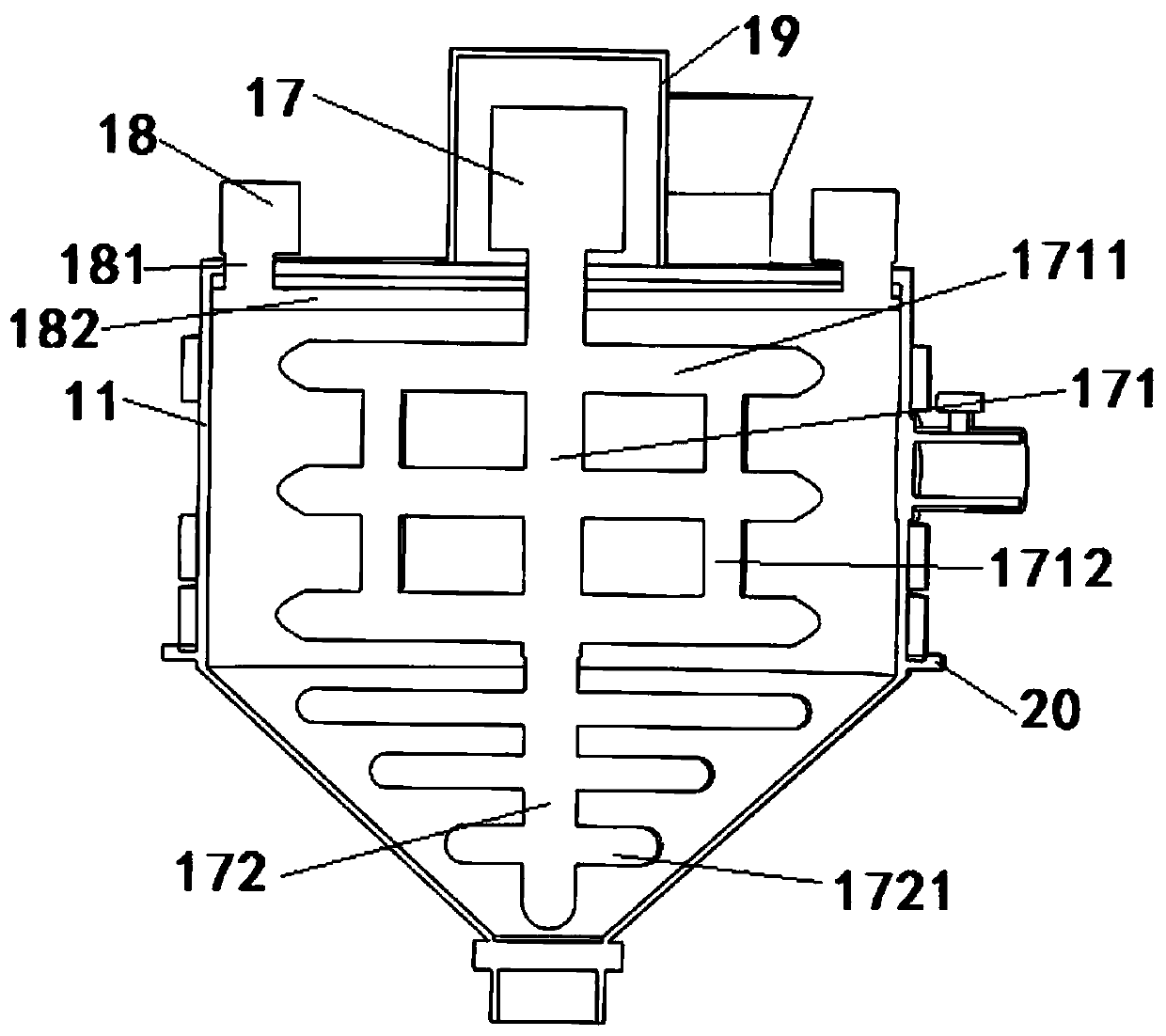

Polyester resin as well as stirring reactor and application thereof

ActiveCN108676154AGood weather resistanceImprove flame retardant performanceChemical/physical/physico-chemical stationary reactorsPolyester coatingsWater basedCross-link

The invention provides a polyester resin as well as a stirring reactor and application thereof. The polyester resin is prepared from the following raw materials: tetrabromophthalic anhydride, chlorendic anhydride, tetrachlorophthalic anhydride, neopentyl glycol, polycarbonate diol, a tin catalyst, a cross-linking monomer, acetone, triethylamine and deionized water. A water-based coating is prepared from the polyester resin, a pigment, a filler, a film formation additive, a wetting dispersant, a polyether defoaming agent, a flatting agent, a cobalt salt dryer, an antibacterial agent and deionized water. The polyester resin has excellent water resistance, abrasion resistance, weather resistance and flame resistance. A polyester resin stirring reactor is capable of more uniformly stirring theraw materials of the polyester resin, directly filtering the mixed polyester resin and improving the quality of the polyester resin. When the polyester resin is applied to a water-based coating, thewater resistance, the abrasion resistance, the weather resistance and the flame resistance of the water-based coating can be improved; and the comprehensive properties of the water-based coating can be improved.

Owner:安徽恒隆新材料有限公司

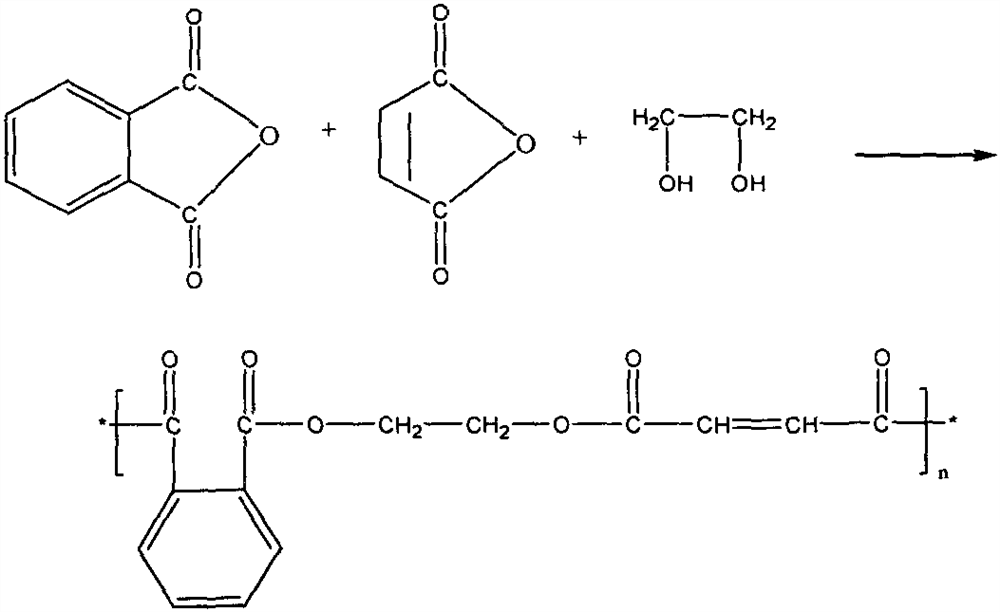

Production method of flame-retardant unsaturated polyester

The invention relates to a production method of a flame-retardant unsaturated polyester. The production process comprises the following steps: mixing maleic anhydride, phthalic anhydride and ethyleneglycol according to a ratio ranging from (30-40):(40-60):(40-50); and adding tetrabromophthalic anhydride, which accounts for 1%-10% of the obtained mixture, into the mixture, elevating the temperature to 80 DEG C in 15 minutes, then elevating the temperature to 160 DEG C in 45 minutes, then elevating the temperature to 190-200 DEG C in one hour, maintaining a reaction for 10-30 minutes at 190-200DEG C, then conducting natural cooling to reduce the temperature to 100-110 DEG C, adding styrene which accounts for 20%-30%, conducting stirring for one hour, and then conducting natural cooling toreduce the temperature to 50 DEG C. A product is the flame-retardant unsaturated polyester.

Owner:TIANJIN UNIV OF SCI & TECH

Preparation method for dihydric alcohol used for preparing polyurethane and application of dihydric alcohol

InactiveCN105175702AHigh molecular weightThe acid value of the system is reducedPolyethylene terephthalate glycolPolyethylene terephthalate

The invention provides a preparation method for dihydric alcohol used for preparing polyurethane and application of the dihydric alcohol, and belongs to the technical field of high molecular materials, reactive flame retardants, energy conservation and protection, environmentally friendly technology and building thermal insulation materials. The dihydric alcohol used for preparing polyurethane is prepared by catalytic reaction among recycled polyethylene terephthalate, dihydric alcohol, alkylene oxide and tetrabromophthalic anhydride. The raw materials are low in cost and easy to get, the reaction is mild, the process is simple, the operation is easy, and industrial production is easy; the product is used for preparing flame retardant polyurethane foam materials.

Owner:UNIV OF JINAN

Preparation method and applications of synergic oligomeric phosphate ester polyol

InactiveCN105254868AGuaranteed physical and mechanical propertiesImprove flame retardant performancePhosphateMolecular materials

The invention discloses a preparation method and applications of synergic oligomeric phosphate ester polyol, and belongs to the high-molecular material, reaction-type flame retardant, energy saving and protection, environment friendly new technology and building insulation material technology fields. The synergic oligomeric phosphate ester polyol is prepared from phosphorus pentoxide, water, alkylene oxide and tetrabromophthalic anhydride as raw materials through a catalytic reaction. The raw materials are cheap and easily available, the reaction is mild, the technology is simple, operation is easy, and industrial production is easy. The product is used for preparation of flame retardation polyurethane foam materials.

Owner:UNIV OF JINAN

Low-temperature-resistant halogen-free flame-retardant polyvinyl chloride cable material used for automobiles and preparation method of low-temperature-resistant halogen-free flame-retardant polyvinyl chloride cable material

InactiveCN104945780AImprove flame retardant performanceMaximize the positive effectInsulated cablesInsulatorsPolyvinyl chlorideAntimony trioxide

The invention discloses a low-temperature-resistant halogen-free flame-retardant polyvinyl chloride cable material used for automobiles and a preparation method of the low-temperature-resistant halogen-free flame-retardant polyvinyl chloride cable material. The low-temperature-resistant halogen-free flame-retardant polyvinyl chloride cable material is prepared from, by weight, 80 parts to 100 parts of polyvinyl chloride resin, 10 parts to 14 parts of polyolefin resin, 7 parts to 9 parts of ethylene vinyl acetate copolymer, 2 parts to 3 parts of 2,2,4-Trimethyl-1,3-pentanediolmono(2-methylpropanoate), 8 parts to 10 parts of dioctyl sebacate, 3 parts to 5 parts of nanometer kaolin, 5 parts to 10 parts of antimonous oxide, 10 parts to 15 parts of aluminium hydroxide, 5 parts to 8 parts of butyl stearate, 7 parts to 9 parts of microcrystalline graphite powder, 8 parts to 12 parts of mica powder, 10 parts to 15 parts of wollastonite, 2 parts to 3 parts of antioxidant TPP, 1 part to 2 parts of insoluble sulfur, 40 parts to 50 parts of dimethyl terephthalate, 5 parts to 7 parts of triethoxyisobutylsilane, 6 parts to 8 parts of rare earth carboxylate stabilizers, 20 parts to 30 parts of nanometer calcium carbonate, 1 part to 2 parts of antioxidant 616, 12 parts to 14 parts of tetrabromophthalic anhydride, 7 parts to 9 parts of silicone emulsion and 7 parts to 8 parts of isophorone. By means of the synergistic effect of added antimonous oxide and chlorine elements in the added polyvinyl chloride resin, the flame-retardant property of polyvinyl chloride is enhanced; by means of compound plasticizers such as the added dioctyl sebacate, flexibility of cables is improved while the cold-resistant performance of products is improved.

Owner:CHANGZHOU CITY WUJIN DISTRICT KAILIDA ELECTRONICS

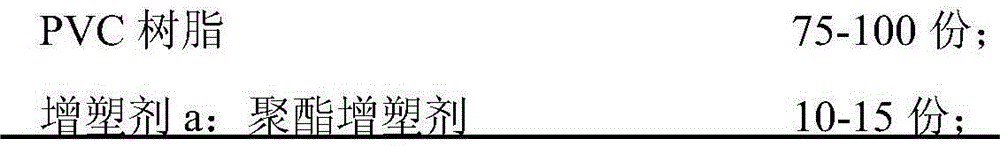

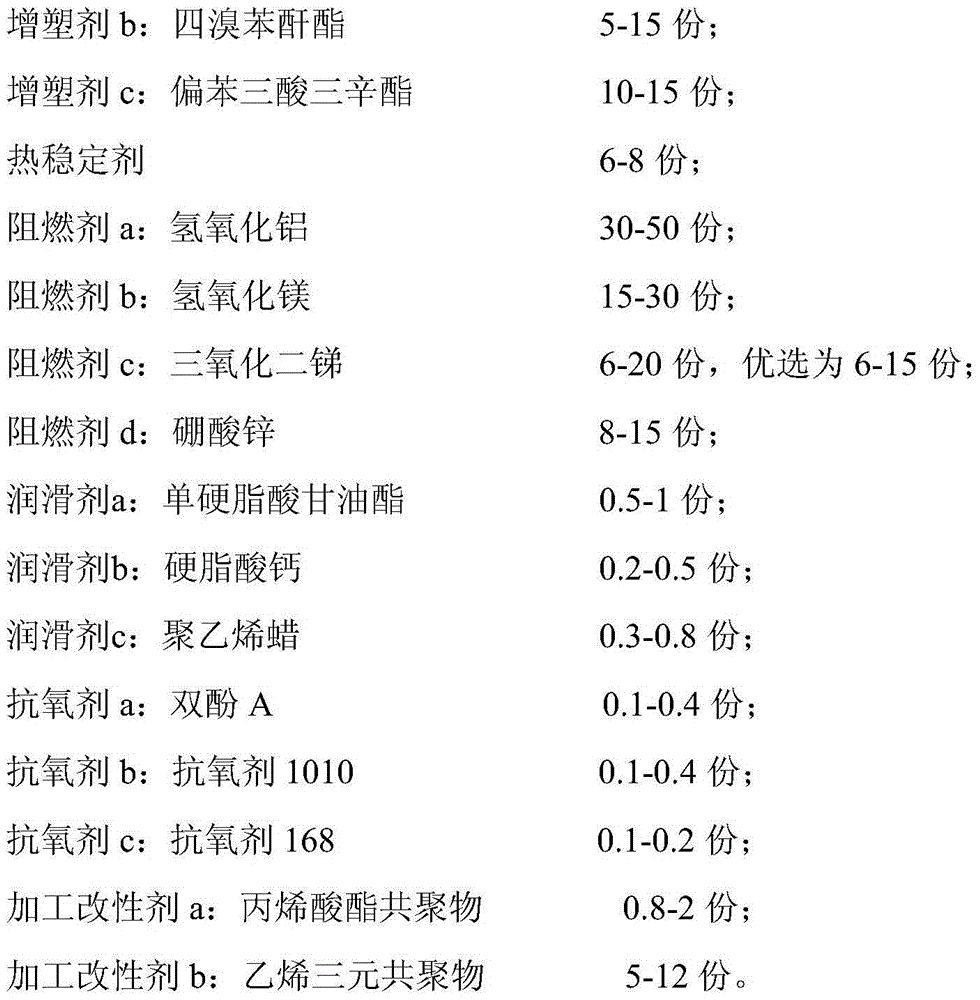

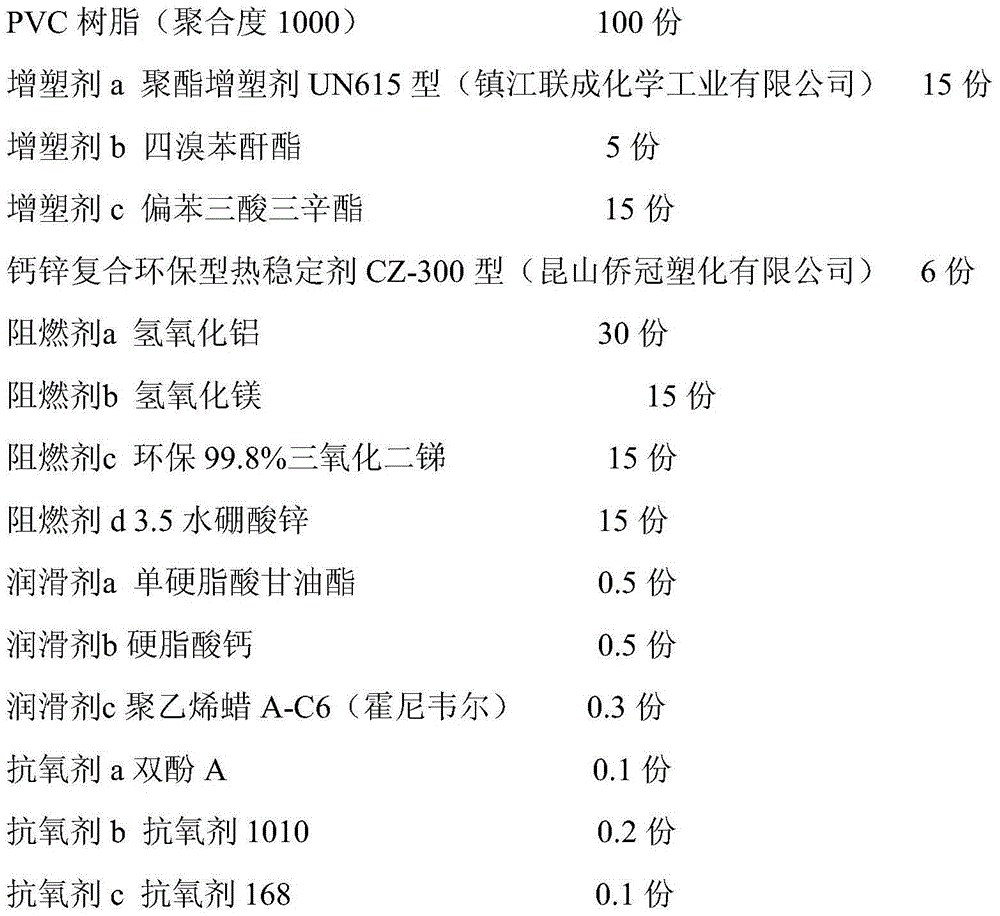

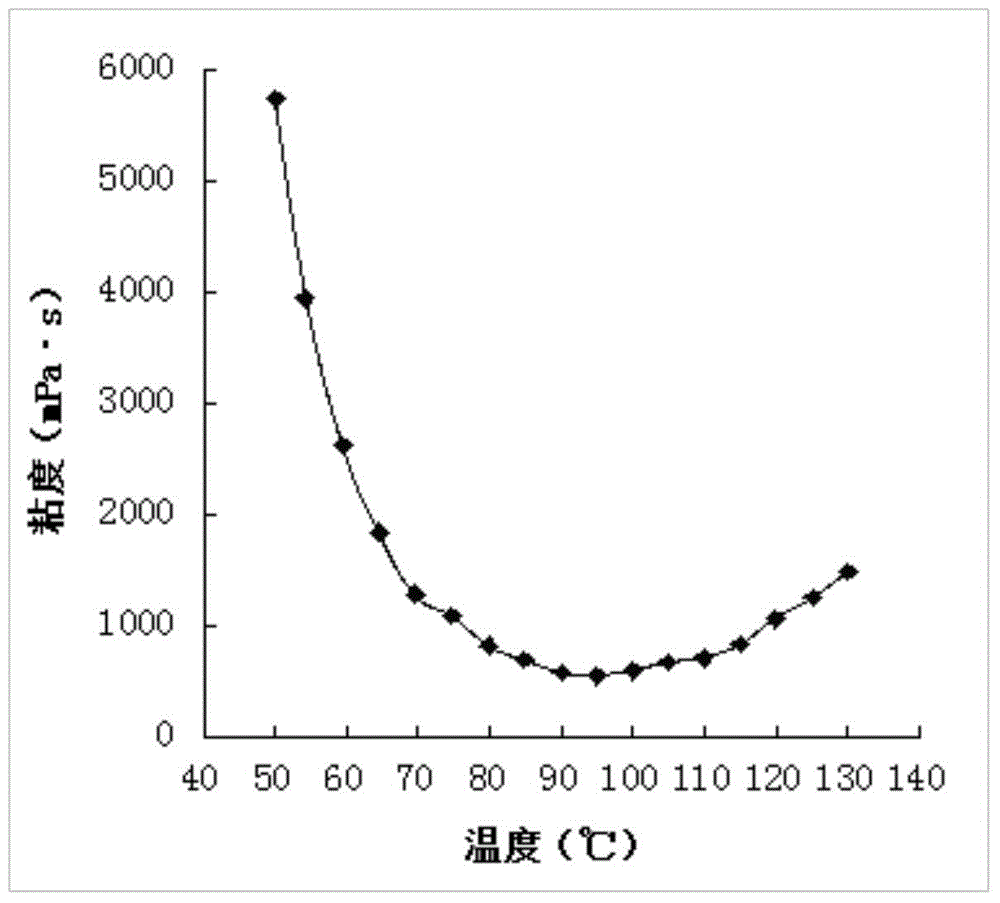

Environment-friendly, CMR-grade and high-flame-retardance PVC (Polyvinyl Chloride) sheath material, and preparation method and use of sheath material

InactiveCN105778327AGood extrusion processing performanceThe surface of the product is smooth and delicatePlastic/resin/waxes insulatorsInsulated cablesPolyesterAntimony trioxide

The invention relates to the field of flame-retardant cable sheath materials and particularly relates to an environment-friendly, CMR-grade and high-flame-retardance PVC (Polyvinyl Chloride) sheath material, and a preparation method and use of the sheath material. The environment-friendly, CMR-grade and high-flame-retardance PVC sheath material provided by the invention is prepared from the following ingredients in parts by weight: PVC resin, a polyester plasticizer, tetrabromophthalic anhydride, trioctyl trimellitate, a thermal stabilizer, aluminum hydroxide, magnesium hydroxide, antimony trioxide, zinc borate, glyceryl monostearate, calcium stearate, polyethylene wax, bisphenol A, an antioxidant 1010, an antioxidant 168, an acrylate copolymer and an ethylene terpolymer. The sheath material provided by the invention is in line with related technical indicators and requirements of UL1581 and UL1666, has environment-friendly performance, is in line with standards RoHS and REACH, also has good extrusion processability and excellent flame retardance and can pass a UL1666 intensive-flame test.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Waste glass powder sintered bricks and production method thereof

The invention discloses waste glass powder sintered bricks and a production method thereof. The waste glass powder sintered bricks comprise, by weight, 20-25 parts of waste glass powder and other raw materials. According to the sintered bricks, by adopting the waste glass powder as the main raw material, clay resources are saved, the production cost is lowered, and the purpose of disposing the waste glass powder and preventing the waste glass powder from polluting the environment is achieved; under the synergistic effect of added antimonous oxide and chlorine in polyvinyl chloride resin, the flame retardancy of polyvinyl chloride is improved; through cooperation of a compound plasticizer composed of added dioctyl sebacate, dimethyl terephthalate, an antioxidant 616 and tetrabromophthalic anhydride and the polyvinyl chloride resin, the forward effect of the plasticizers is maximized, the usage quantity of the plasticizers is reduced while the low temperature resistance of the sintered bricks is improved, and flexibility is improved.

Owner:CHANGZHOU CITY WUJIN DISTRICT KAILIDA ELECTRONICS

High-temperature resisting phosphorus-bromines type solvent-free epoxy matrix resin for carbon fiber cable core and preparation method of epoxy matrix resin

InactiveCN104479299ANo solvent requiredSolvent-free epoxy base resin with good solventTetrabromobisphenol ACarbon fibers

The invention relates to high-temperature resisting phosphorus-bromines type solvent-free epoxy matrix resin for a carbon fiber cable core and a preparation method of the epoxy matrix resin. The matrix resin is composed of ES216 epoxy resin, tetrabromo-bisphenol-A epoxy resin, DOPO, tetrabromophthalic anhydride, four-maleimide resin, a curing agent, a promoter and a reactive diluent. The preparation method comprises the following steps: (1), the ES216 epoxy resin is mixed the four-maleimide resin, heating is performed to rise temperature, stirring for reaction is performed, the reactive diluents is added, and a component A is obtained after stirring; (2), the tetrabromo-bisphenol-A epoxy resin is mixed with the DOPO and the tetrabromophthalic anhydride, heating is performed to rise temperature, stirring for reaction is performed, the reactive diluents is added, and a component B is obtained after stirring; (3), components C are the curing agent and the promoter; the components A, B and C are stirred and mixed evenly. The high-temperature resisting phosphorus-bromines type solvent-free epoxy matrix resin provided by the invention is suitable for manufacturing fiber-reinforced advance composite materials including carbon fiber, glass fiber, aramid fiber and the like, particularly to pultrusion formation of carbon fiber cable cores.

Owner:DONGHUA UNIV +1

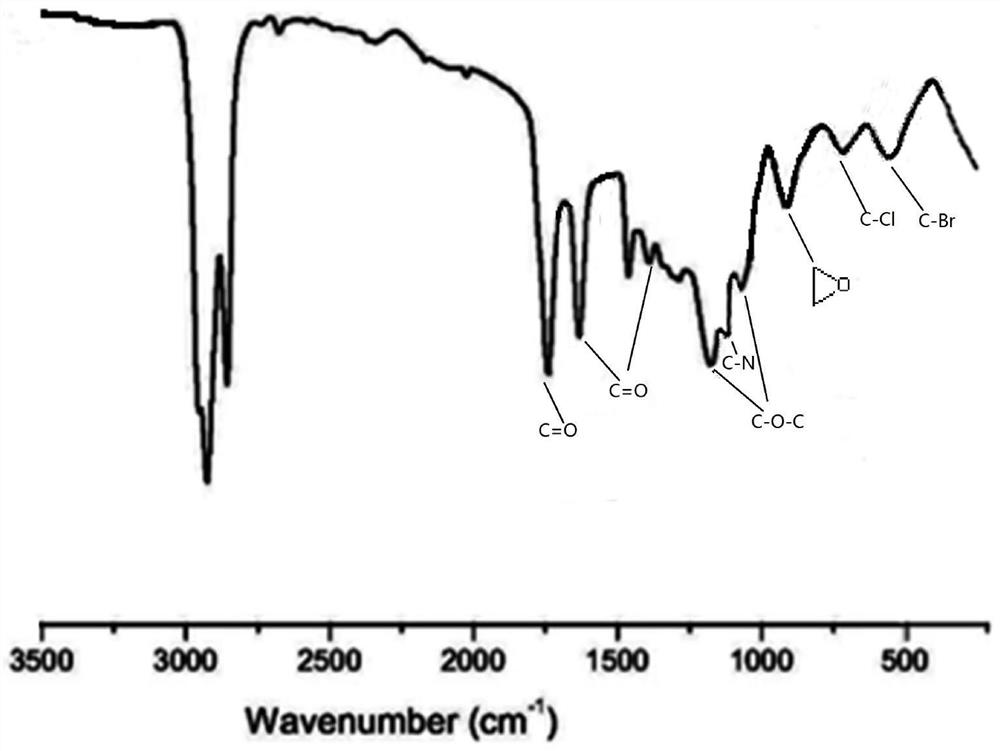

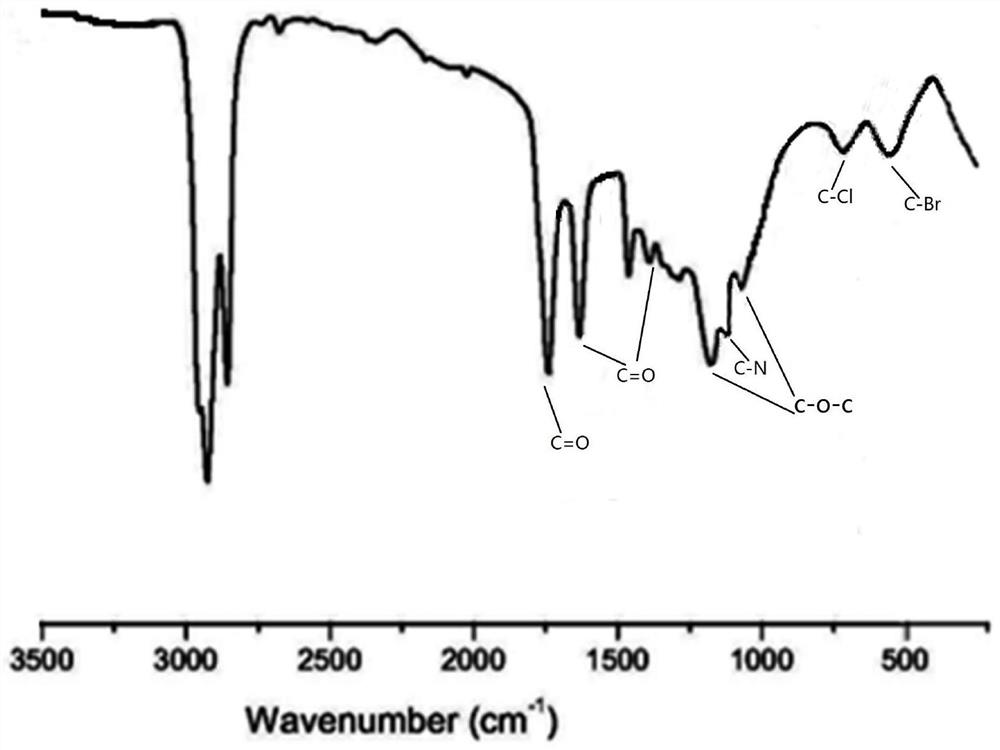

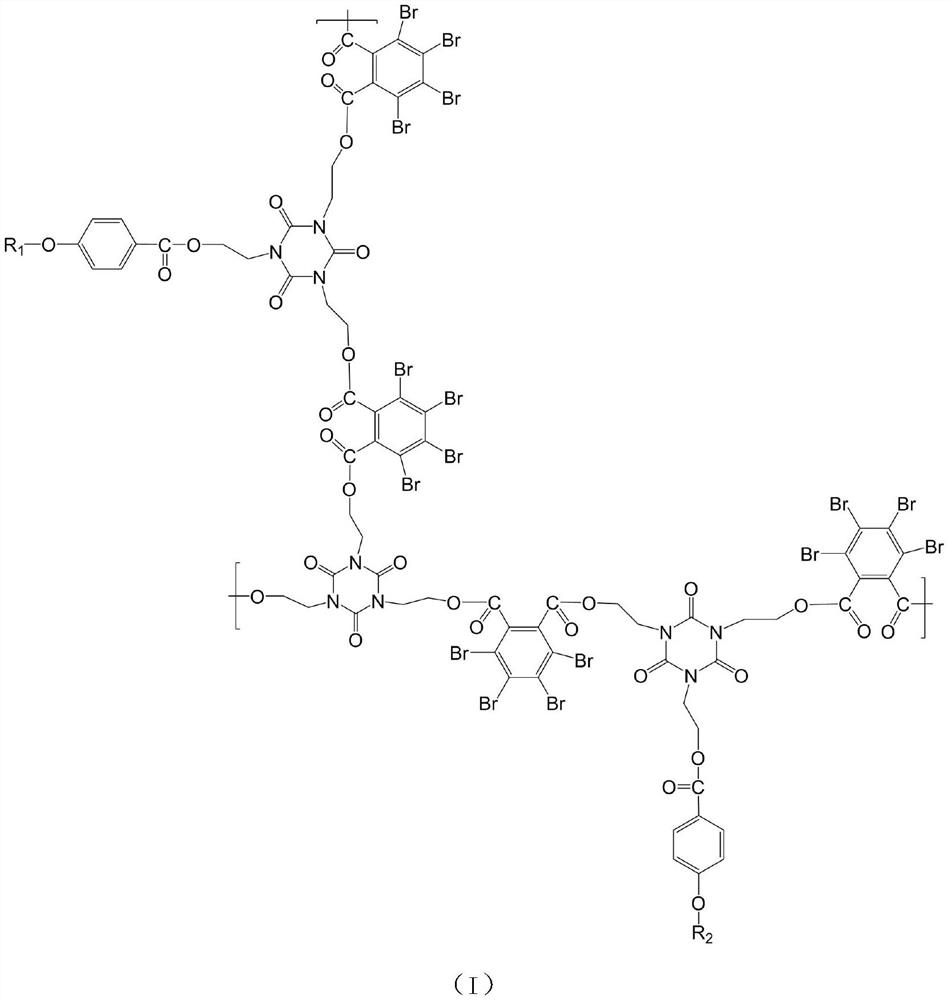

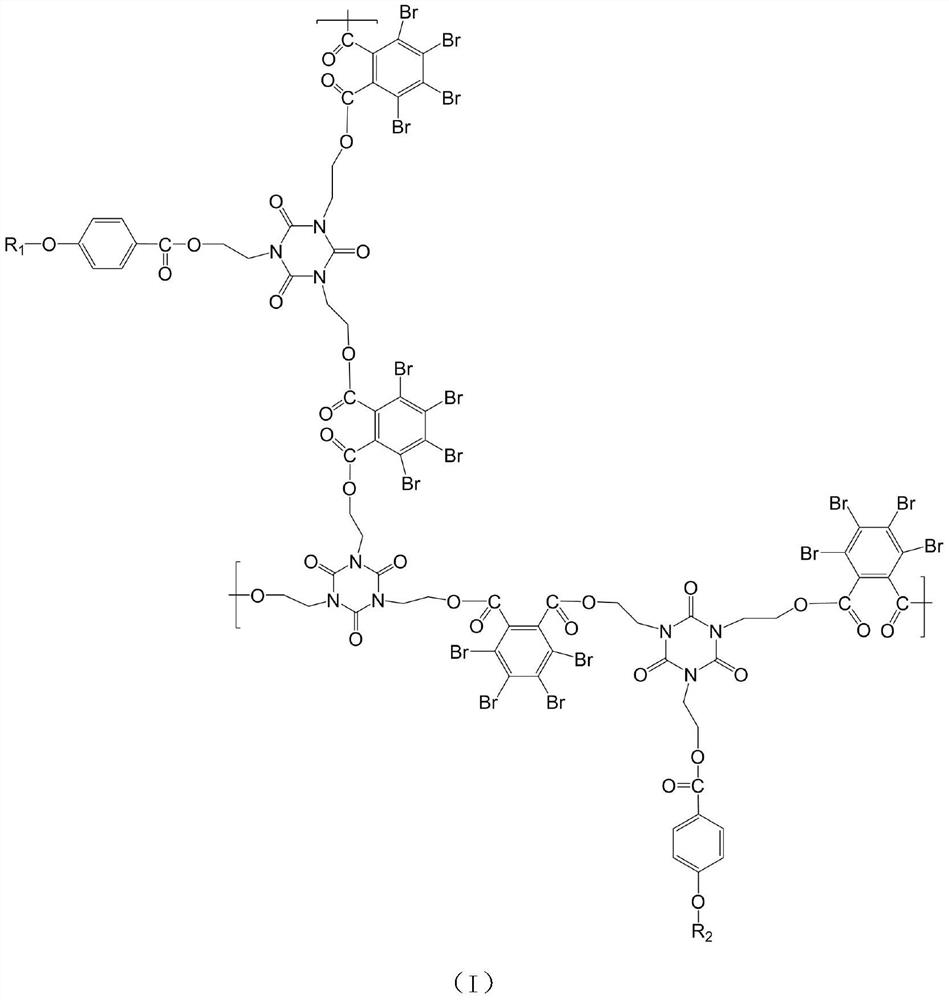

Cross-linked polymer flame retardant and preparation method thereof

InactiveCN111635511AImprove flame retardant performanceHigh purityFireproof paintsBenzoic acidPolymer science

The invention discloses a cross-linked polymer flame retardant and a preparation method thereof. The preparation method of the flame retardant comprises the following steps: reacting chlorinated paraffin with p-hydroxybenzoic acid to prepare carboxyl-containing chlorinated paraffin, acylating the carboxyl-containing chlorinated paraffin to obtain acyl chloride-containing chlorinated paraffin, then, carrying out esterification reaction with tris(2-hydroxyethyl)isocyanurate to obtain hydroxyl-containing isocyanurate modified chlorinated paraffin, then reacting with tetrabromophthalic anhydride to form novel binary acid and performing polycondensation with tris(2-hydroxyethyl)isocyanurate to form macromolecular flame retardant. The preparation method has the advantages that the operation is simple, the raw material source is wide, the reaction condition is mild, the industrial production is met, and the prepared macromolecular flame retardant has excellent flame-retardant performance dueto the synergistic effect of flame-retardant elements of chlorine, bromine and nitrogen and has good migration resistance.

Owner:马海社

High-temperature-resistant, phosphorus-bromine-type and solvent-free epoxy adhesive and preparation method thereof

InactiveCN104559889AConvenient sourceSimple preparation processEpoxy resin adhesivesSolvent freeOxygen

The invention relates to a high-temperature-resistant, phosphorus-bromine-type and solvent-free epoxy adhesive and a preparation method thereof. The adhesive consists of ES216 epoxy resin, tetrabromophthalic anhydride, DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide), bismaleimide resin, organic silicone resin, a curing agent, an accelerator and an active diluent. The preparation method comprises steps as follows: (1) placing the ES216 epoxy resin, the DOPO and the tetrabromophthalic anhydride into a reaction kettle, adding a reactive diluent after the reaction, and evenly mixing the mixture to obtain a component A; (2) placing the bismaleimide resin and the organic silicone resin into the reaction kettle, adding the active diluent after the reaction, and evenly mixing the mixture to obtain a component B; (3) placing the component A, the component B, the curing agent and the accelerator into the reaction kettle, and evenly mixing the mixture to obtain the adhesive. The adhesive can be applied to adhesion of metal, ceramic, glass and composite materials, can also be applied to technologies of RTM, VARTM, pultrusion and the like to manufacture fiber-reinforced advanced composite materials and has a bright application prospect.

Owner:DONGHUA UNIV +1

Fireproof flame-retardant organic glass

InactiveCN105001575AImprove heat resistanceImprove fire and flame retardant performanceHeat resistanceP-tert-butyl catechol

The invention discloses fireproof flame-retardant organic glass which consists of organic glass, a heat-resistant agent, a flame-retardant agent, a molecular weight regulator, a dispersion agent and a polymerization inhibitor. The heat-resistant agent is polyphenylene sulfide, the flame-retardant agent is tetrabromo phthalic anhydride, the molecular weight regulator is zinc dialkyl dithiophosphate, the dispersion agent is chlorinated polyethylene, and the polymerization inhibitor is p-tert-butyl catechol. The fireproof flame-retardant organic glass has the advantages of good heat resistance, good flame resistance, stable quality and high strength by adding the organic glass, the heat-resistant agent, the flame-retardant agent, the molecular weight regulator, the dispersion agent and the polymerization inhibitor.

Owner:ZHANGJIAGANG DELITE NEW MATERIAL

Marine cable material which is resistant to high temperature and excellent in flame retardant performance and preparing method thereof

InactiveCN107057202AGood mechanical propertiesImprove flame retardant performanceRubber insulatorsPolymer sciencePhosphate

The invention discloses a marine cable material which is resistant to high temperature and excellent in flame retardant performance. The marine cable material is prepared from, ethylene propylene diene monomer rubber, polyisoprene rubber, benzoyl peroxide, dicumyl peroxide, ethylene glycol dimethacrylate, calcium lignosulphonate, monoalkoxy unsaturated fatty acid titanate, wollastonite powder, nano aluminum hydroxide, molybdenum trioxide, tetrabromophthalic anhydride, white carbon black, 1,3,5-triazine-2,4,6-triamine phosphate, antioxidant and an anti-aging agent RD. The invention further discloses a preparing method of the marine cable material which is resistant to high temperature and excellent in flame retardant performance. The prepared cable material has good mechanical performance, is excellent in flame retardation and high-temperature resistance, can meet the higher and higher performance requirement of the market for marine cables, and has a wide market prospect.

Owner:JIANGXI JIEN HEAVY IND

Polyurethane foam with flame-retardant function and preparation method thereof

The invention discloses polyurethane foam with a flame retardant function. The polyurethane foam material is formed by curing polyol with a flame-retardant function. The preparation method of the polyol comprises the following steps: reacting chlorinated paraffin with p-hydroxybenzoic acid to prepare carboxyl-containing chlorinated paraffin; acylating the carboxyl-containing chlorinated paraffin to obtain acyl chloride-containing chlorinated paraffin; then carrying out esterification reaction with tris (2-hydroxyethyl) isocyanurate to obtain isocyanurate modified hydroxyl-containing chlorinated paraffin and then reacting with tetrabromophthalic anhydride to obtain monobasic acid; and carrying out esterification reaction on the monobasic acid and tetrabromobisphenol A epoxy resin to preparethe polyol with the flame-retardant function; the preparation method has the advantages that the operation is simple, the raw material source is wide, the reaction condition is mild, the industrial production is met, and the preparation method can be used for preparing the flame-retardant polyurethane foam material.

Owner:徐毓敏

Fire extinguishing coating

The invention discloses a fire extinguishing coating, which comprises the following components in parts by weight: 15.5 to 16.5 parts of vinyl chloride-vinylidene chloride copolymer resin, 25 to 33 parts of tung oil rosin phenolic solution, 11 to 13 parts of methylisobutylketone, 34 to 35 parts of butyl acetate, 40 to 42 parts of paraxylene, 44 to 48 parts of tetrabromophthalic anhydride, 20 to 24 parts of titanium dioxide, 20 to 24 parts of talc powder and 20 to 24 parts of barium sulfate. When high temperature is generated in a fire, the fire extinguishing coating is heated and decomposed to generate fire extinguishing gases and incombustible gases, so that the oxygen content of a firing zone, and flame is automatically extinguished without the supply of a combustion improver oxygen.

Owner:EURONAVY NANTONG HEAVY ANTICORROSION COATINGS

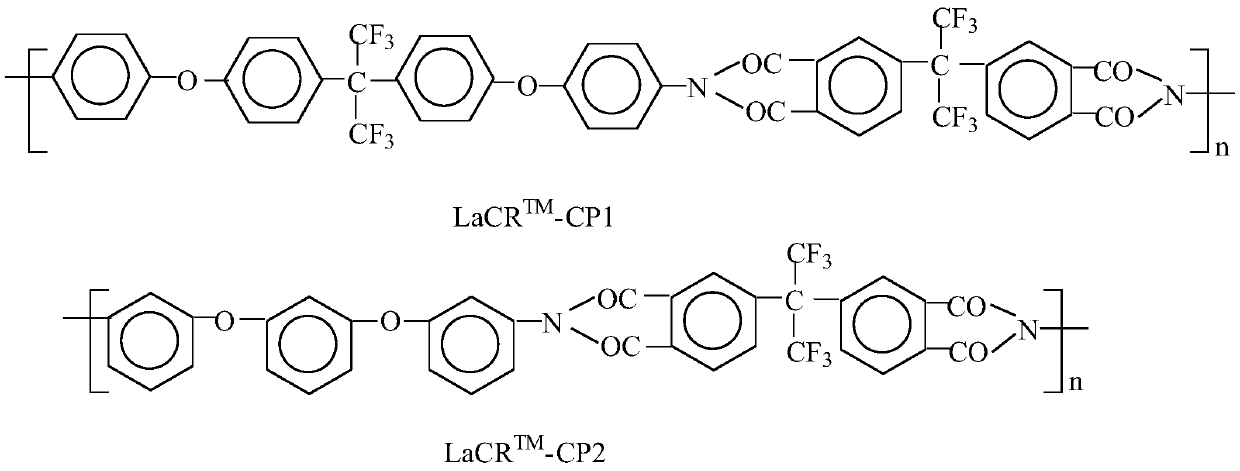

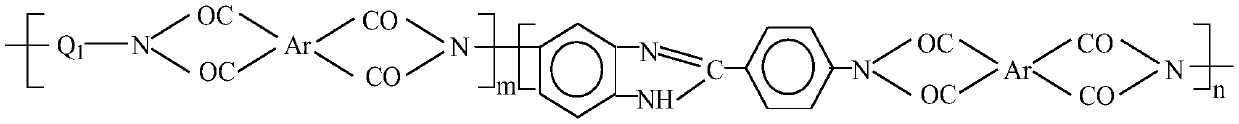

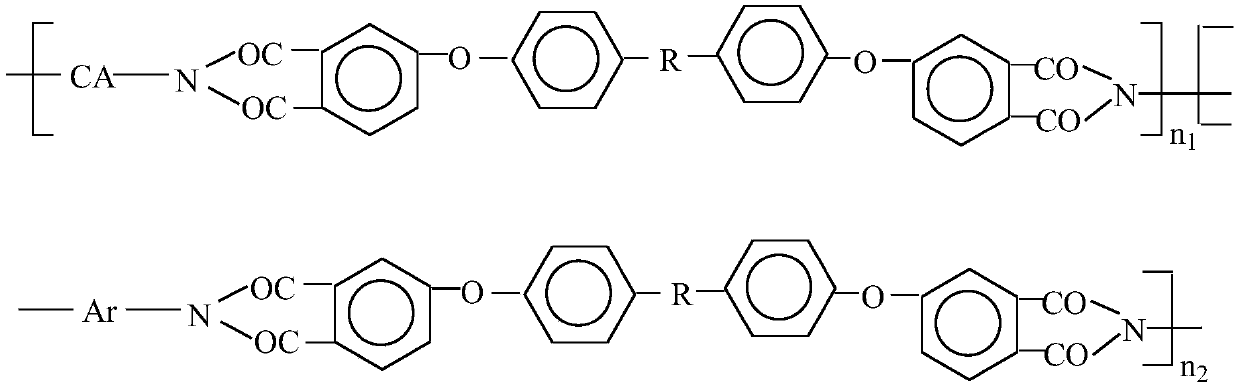

High-flame-retardance resin thin film and preparing method thereof

InactiveCN110066407AImprove flame retardant performanceImprove heat resistancePlastic/resin/waxes insulatorsHeat resistanceCopper

The invention relates to a high-flame-retardance resin thin film and a preparing method thereof. The thin film is a reaction production of aromatic quaternary amine, tetrabromophthalic anhydride, aromatic binary amine and aromatic binary anhydride. The thin film has quite high flame retardance, heat resistance, electrical insulativity, excellent mechanical performance and the like; the preparing method of the thin film is high in universality, mild in reaction condition, simple in operation, low in cost, friendly to the environment and beneficial for industrial large-scale production and can be applied to the high-tech fields of large motor main insulation materials, electromagnetic wire covering electrical insulation materials, flexible copper-clad plates (FCCL) and the like.

Owner:DONGHUA UNIV +2

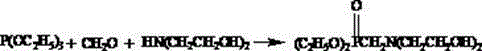

Preparation method and application of functional dihydric alcohol

The invention discloses a preparation method and an application of functional dihydric alcohol, which belong to the technical field of macro-molecular chemistry, a reaction-type flame retardant and a construction heat preservation material. The functional dihydric alcohol is prepared by virtue of the catalytic reaction of diethanol amine, paraformaldehyde, triethyl phosphate, tetrabromophthalic anhydride and alkylene oxide. The prepared functional dihydric alcohol is used for preparing a flame-retardant polyurethane foam material.

Owner:UNIV OF JINAN

Composited nano sintered calcium silicate brick and production method of same

InactiveCN105130395AImprove pressure bearing capacityLow densityCeramic materials productionClaywaresCalcium silicateBrick

The invention discloses a composited nano sintered calcium silicate brick and a production method of same. The composited nano sintered calcium silicate brick is prepared from following raw materials, by weight, precipitated barium sulphate, ultrafine barium sulfate, modified nano titanium dioxide, fly ash, hydrated lime, silicone lime, antimonous oxide, polyvinyl chloride resin, dioctyl sebate, dimethyl terephthalate, an anti-oxidant 616, tetrabromophthalic anhydride and polyvinyl chloride resin and the like. In the invention, by means of a synergistic effect between the added antimonous oxide and chlorine in the polyvinyl chloride resin, the polyvinyl chloride is enhanced in flame retarding performance. The dioctyl sebate, the dimethyl terephthalate, the anti-oxidant 616 and the tetrabromophthalic anhydride form a compounded plasticizer is matched with the polyvinyl chloride resin, so that positive effect of the plasticizer achieved maximum value. The brick is improved in low temperature resistance and meanwhile is reduced in usage quantity of the plasticizer, thereby enhancing flexibility.

Owner:CHANGZHOU WUJIN GOLDEN SUNSHINE ELECTRONICS

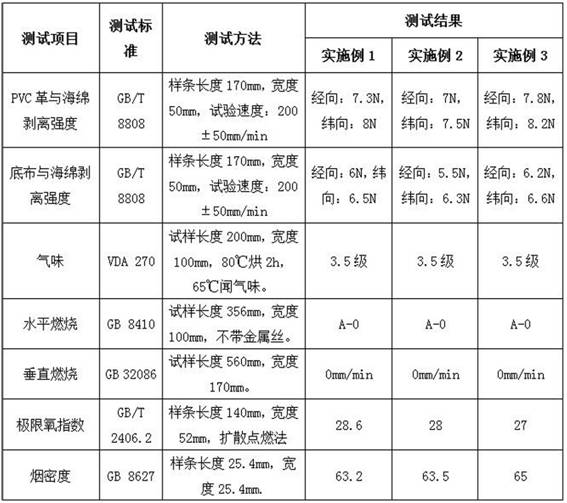

High-oxygen-index automotive trim PVC (polyvinyl chloride) composite fabric prepared by blade-coating method and preparation method thereof

InactiveCN113249977ALight weightImprove flame retardant performanceSynthetic resin layered productsLaminationPhosphoric Acid EstersAdhesive

The invention discloses a high-oxygen-index automotive trim PVC (polyvinyl chloride) composite fabric prepared by a blade-coating method and a preparation method thereof. The composite fabric comprises PVC leather, flame-retardant sponge and flame-retardant base cloth, wherein the PVC leather is attached to the flame-retardant sponge and the flame-retardant base cloth through a flame-retardant water-based adhesive; the PVC leather comprises a surface treatment layer, a surface layer, a foaming layer, a bonding layer and a base cloth layer; the surface layer is prepared from the following raw materials of PVC paste resin, a plasticizer, phosphate, tetrabromophthalic anhydride ester, antimony trioxide, magnesium hydroxide, aluminum hydroxide, organic silicon, a heat stabilizer and color paste; the foaming layer is prepared from the following raw materials of PVC paste resin, a plasticizer, phosphate, tetrabromophthalic anhydride ester, antimony trioxide, magnesium hydroxide, aluminum hydroxide, organic silicon, a heat stabilizer, color paste and a foaming agent; and the phosphate ester is a mixture of a plurality of phosphate ester compounds which do not include tricresyl phosphate. The PVC composite fabric prepared by the invention not only has soft hand feeling, but also can meet the flame-retardant requirements of automotive trim, especially a passenger car seat fabric.

Owner:广西鑫深科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com