Environment-friendly, CMR-grade and high-flame-retardance PVC (Polyvinyl Chloride) sheath material, and preparation method and use of sheath material

An environment-friendly, highly flame-retardant technology, applied in the direction of plastic/resin/wax insulators, organic insulators, conductors, etc., can solve the problems of high cable cost pressure and high price, and achieve low production cost, smooth and delicate surface, and good extrusion The effect of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

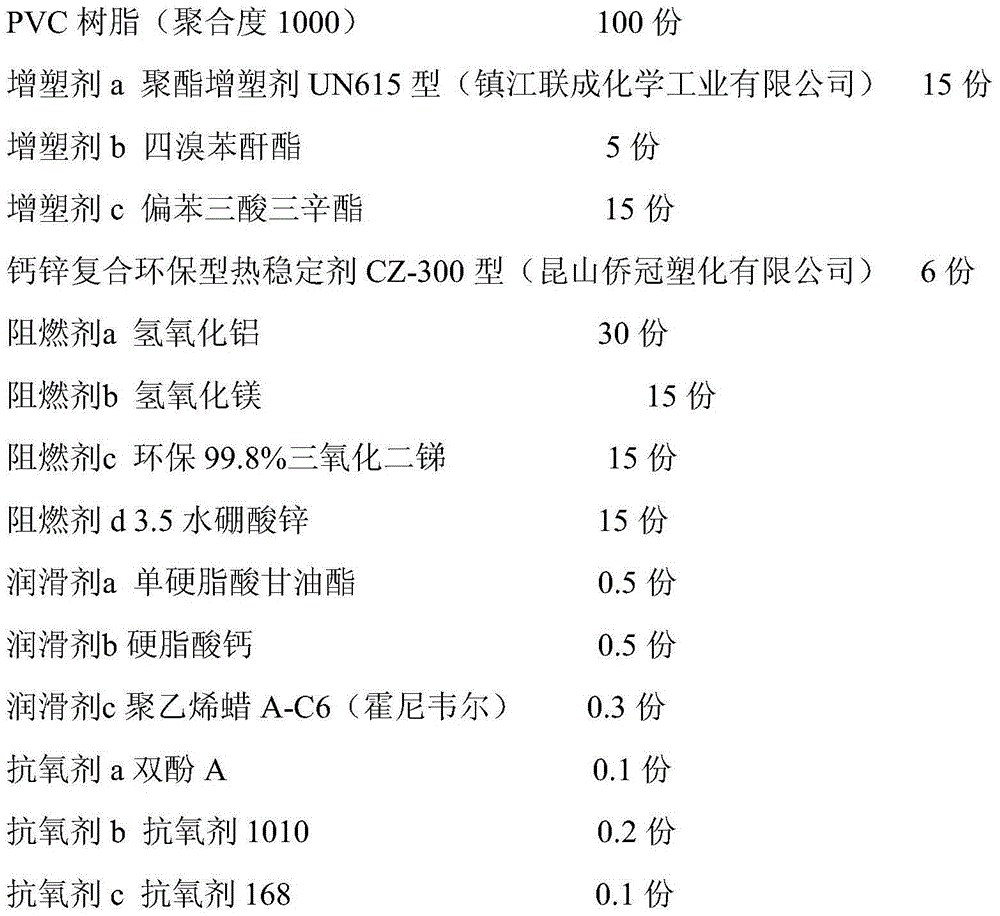

Method used

Image

Examples

Embodiment 1

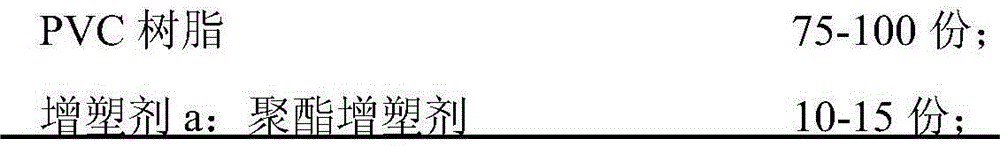

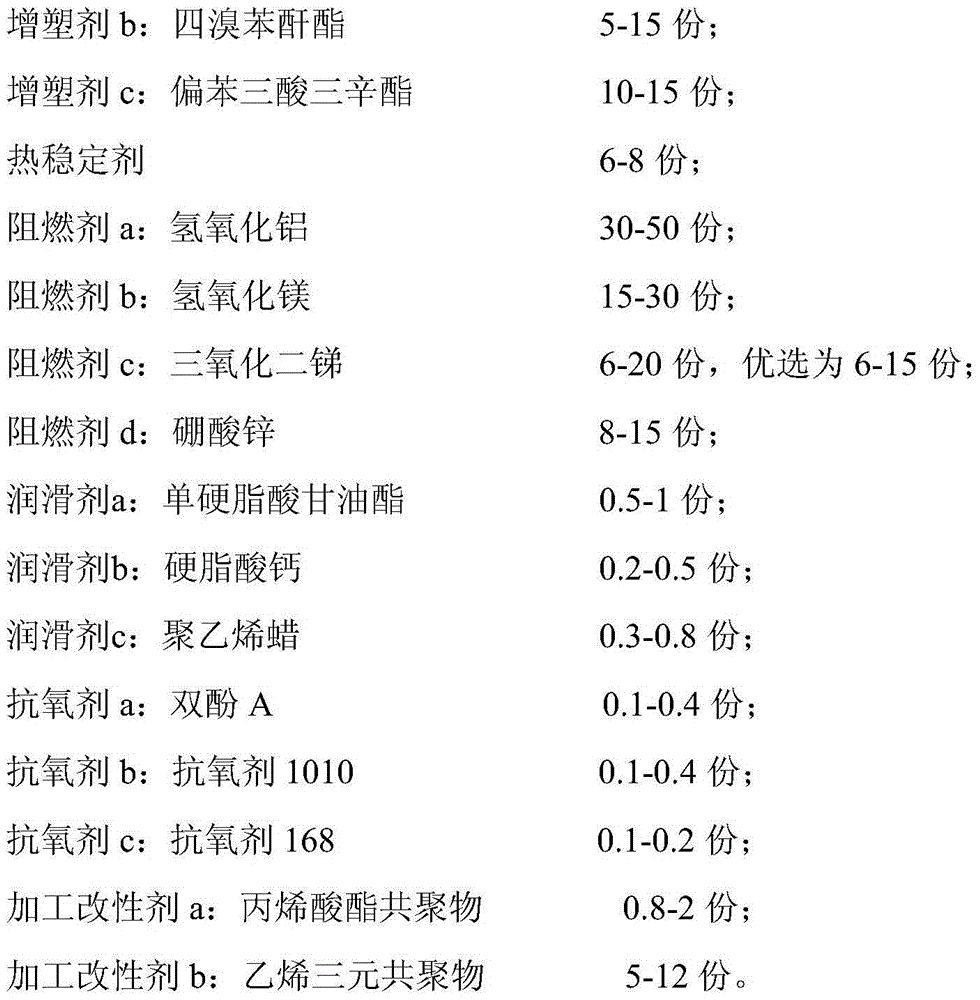

[0041] 1. Experimental materials

[0042]

[0043]

[0044] 2. Preparation method:

[0045] a, with 100 kilograms of PVC resin, 15 kilograms of polyester plasticizers, 5 kilograms of tetrabromophthalic anhydride esters, 15 kilograms of trioctyl trimellitate, 6 kilograms of composite calcium-zinc environment-friendly heat stabilizers, 30 kilograms of aluminum hydroxide, Magnesium hydroxide 15 kg, environmental protection 99.8% antimony trioxide 15 kg, zinc borate 3.5 kg 15 kg, glyceryl monostearate 0.5 kg, calcium stearate 0.5 kg, polyethylene wax 0.3 kg, antioxidant bisphenol A0.1 kg, antioxidant 10100.2 kg, antioxidant 1680.1 kg, ACR4011 kg, 10 kg of ethylene terpolymer, placed in a high-speed kneader and heated for high-speed stirring, the temperature of the high-speed kneader is controlled at 100-120 °C, knead The time is 5-10 minutes;

[0046] b. Put the uniformly stirred raw materials directly into the twin-screw extruder for extrusion and plasticization. The heat...

Embodiment 2

[0049] 1. Experimental materials

[0050]

[0051]

[0052] 2. Preparation method

[0053] Using the raw materials of this example, the method for preparing an environment-friendly CMR grade high flame-retardant PVC sheathing material is the same as Example 1.

Embodiment 3

[0055] 1. Experimental materials

[0056]

[0057] 2. Preparation method

[0058] Using the raw materials of this example, the method for preparing an environment-friendly CMR grade high flame-retardant PVC sheathing material is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com