Patents

Literature

331results about How to "Extrusion stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic polyurethane elastomer and manufacturing method thereof

The invention relates to the manufacturing field of a special extrusion grade T-die thermoplastic elastomer, in particular to a manufacturing formula and a manufacturing method thereof. The formula comprises the following components: 20-40% of 4,4'-diphenylmethane-diisocyanate, 15-70% of polybutylene adipate the molecular weight of which is 1000 or 2000, 0-50% of poly butylene glycol adipate the molecular weight of which is 2000, 5-15% of 1,4-butanediol, 0-5% of glycol, 0.1-1.0% of antioxidant, 0.1-1.0% of lubricant, 0.001-0.1% of environment-friendly catalyst, 0.1-1.0% of ultraviolet absorbent, 0.1-1.0% of light stabilizer and 0.1-1.0% of hydrolysis resistant agent. Continuous production processes are used for synthesizing TPU (thermoplastic polyurethane). The product of the invention has the advantages of stable quality, excellent performance, few T-die extrusion crystal points, good transparency (more than 4mm), stable extrusion, no occurrence of separation of additives, high hydrolysis resistance and high UV (ultraviolet) resistance, and the indexes and the performance of the product can reach the indexes of international like products. The invention provides a thermoplastic polyurethane elastomer and a manufacturing method thereof.

Owner:SHANGHAI LIANJING MATERIAL ASSETAB

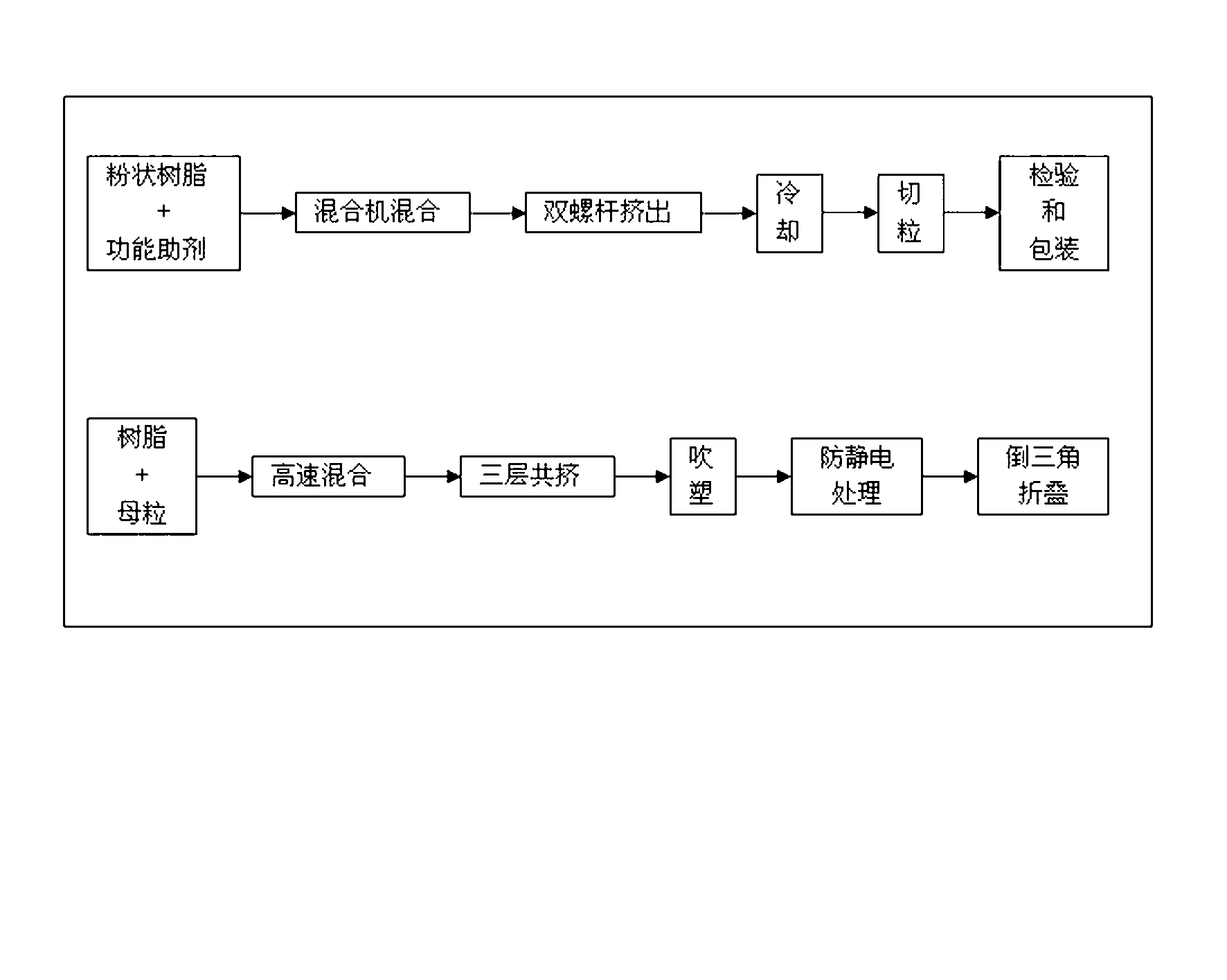

Three-layer co-extruded EVA (ethylene-vinyl acetate copolymer) long-life fog-dissipation environment-friendly multifunctional greenhouse film

ActiveCN103264563AGood colorEasy to processClimate change adaptationSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a nano fog-dissipation multifunctional greenhouse agricultural film, and in particular relates to a three-layer co-extruded EVA (ethylene-vinyl acetate copolymer) long-life fog-dissipation environment-friendly multifunctional greenhouse film, belonging to the field of agricultural mulching films. The raw material formula of an outer layer comprises the following components in percentage by weight: 20-50% of linear low-density polyethylene (LLDPE), 20-50% of low-density polyethylene (LDPE), 10-20% of metallocene polyethylene (mPE) and 5-10% of double-prevention masterbatch; the raw material formula of a middle layer comprises the following components in percentage by weight: 30-40% of ethylene-vinyl acetate copolymer (EVA), 20-40% of linear low-density polyethylene (LLDPE), 20-40% of low-density polyethylene (LDPE) and 5-10% of three-prevention masterbatch; the raw material formula of an inner layer comprises the following components in percentage by weight: 30-40% of ethylene-vinyl acetate copolymer (EVA), 10-20% of linear low-density polyethylene (LLDPE), 20-50% of low-density polyethylene (LDPE) and 5-10% of three-prevention masterbatch; and the formulas of the outer layer, the middle layer and the inner layer are uniformly mixed respectively, master batches are prepared by using a double-head thread screw double-screw extruding machine, a three-layer film is formed through a co-extrusion die head and is extruded out to prepare the multifunctional agricultural greenhouse film. Every quality technical index of the film reaches or exceeds a national standard, and a small part of the indexes is more than 2 times better than the national standard, so that the film is excellent in antiaging performance and cannot generate fog drops, and the service life of the film reaches more than 3 years.

Owner:HENAN YINFENG PLASTIC

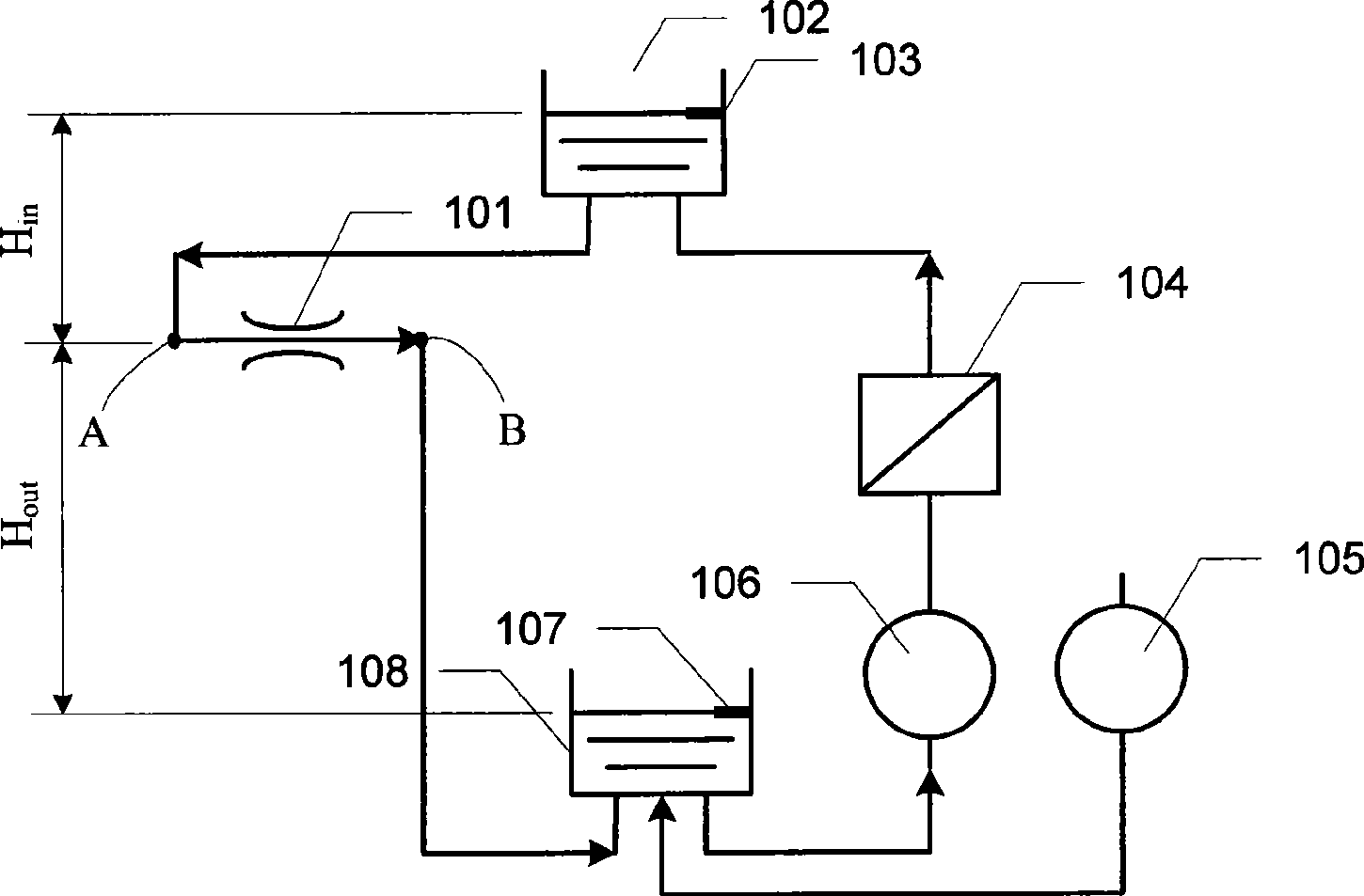

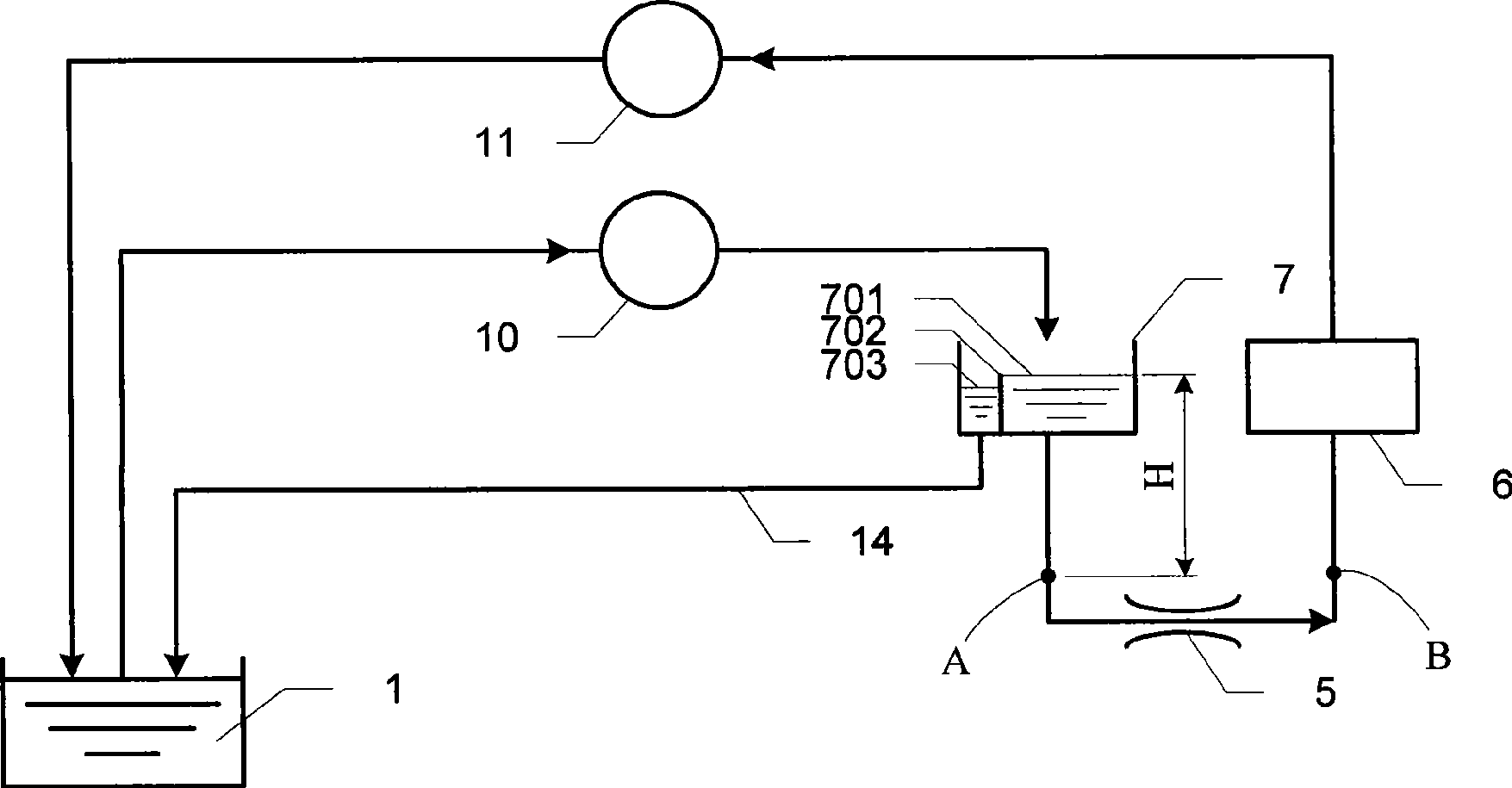

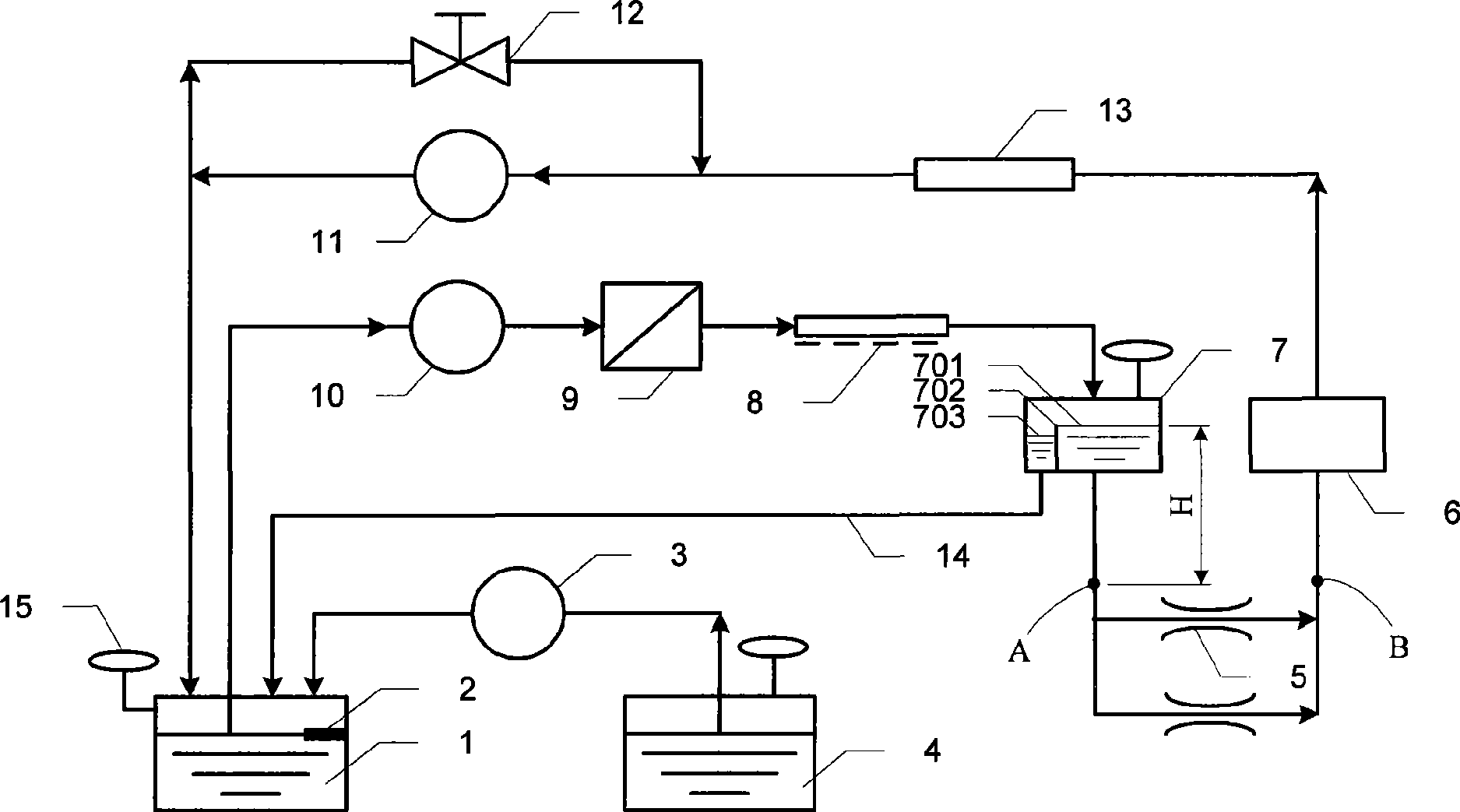

Cyclic ink supply method and cyclic ink supply system

InactiveCN101391530AGuaranteed print qualityReduce system complexityPrintingNozzlePulp and paper industry

The invention discloses a circulation ink supply method and a circulation ink supply system, relating to the ink supply technique. The method and the system can ensure the printing quality, simultaneously, the system complexity can be reduced and the system cost is saved. The circulation ink supply system provided by the embodiment comprises an ink box, an ink inlet pool which is provided with an overflow beam, a discharging trough and an ink supply trough, and an ink inlet pump; the ink inlet end of the ink inlet pump is connected with the ink box; the ink outlet end of the ink inlet pump is connected with the inlet of the ink supply trough of the ink supply pool; the discharging trough outlet of the ink inlet pool is connected with the ink box, wherein, the ink supply trough outlet of the ink inlet pool is connected with the nozzle inlet which is arranged below the ink supply trough of the ink inlet pool; the nozzle inlet is connected with the ink inlet end of at least one nozzle; the ink outlet end of at least a nozzle is connected with the nozzle outlet; the nozzle outlet is connected with the ink inlet end of a returning ink pump; the ink outlet end of the returning ink pump is connected with the ink box.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

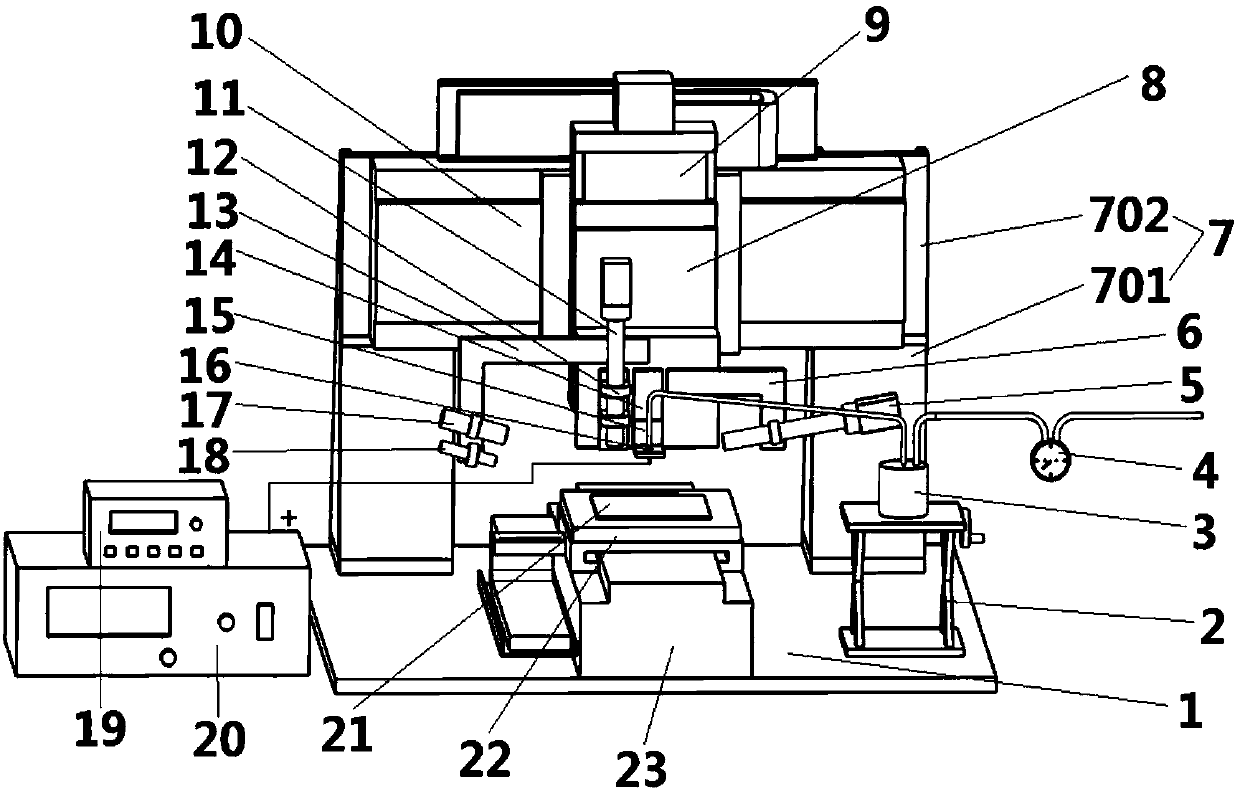

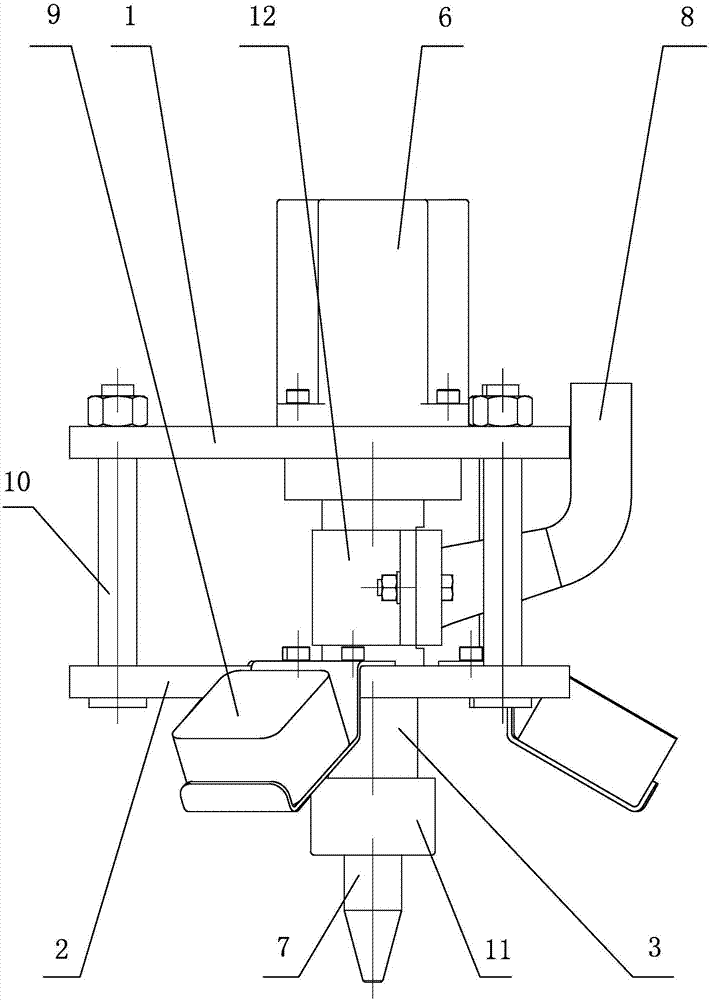

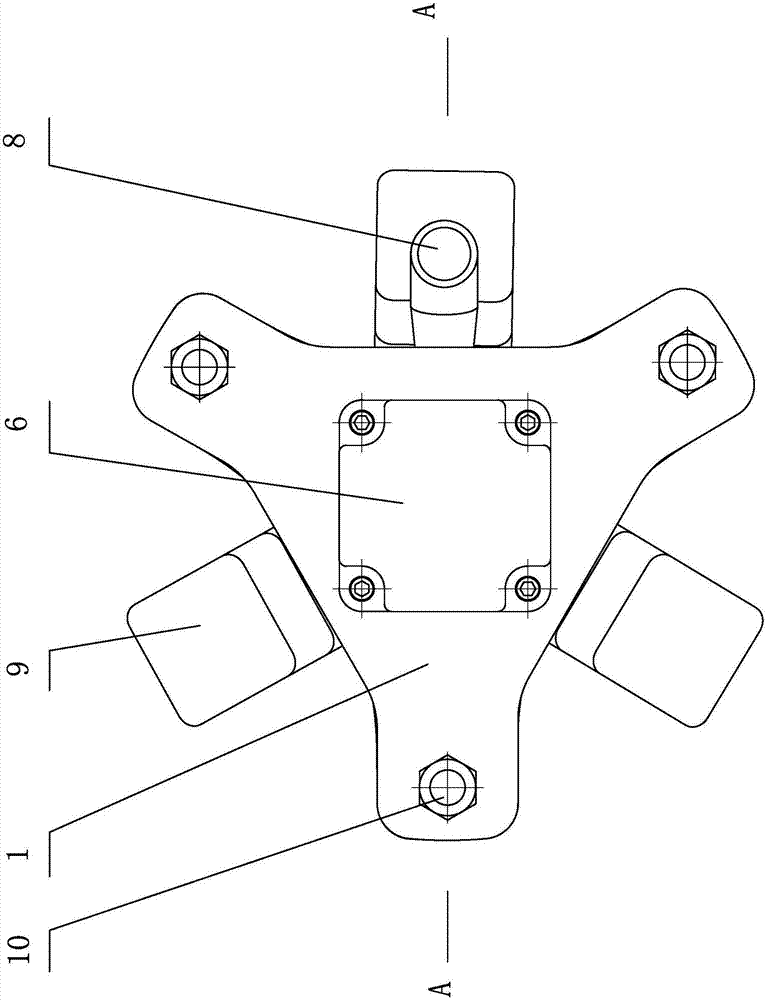

High-precision electric field driven spray deposition 3D printer and working method thereof

PendingCN107932894AHigh frequencyContinuous and stable feedingAdditive manufacturing apparatus3D object support structuresComputer printingImage resolution

The invention discloses a high-precision electric field driven spray deposition 3D printer and a working method thereof, and solves the problems of a traditional 3D printer on multiple aspects of resolution, stability and controllability; high-precision printing of multilayer structures can be realized; the printing process is observed and monitored in real time; and high-precision pattern printing is performed on insulation substrates through electric conducting materials. The high-precision electric field driven spray deposition 3D printer comprises a mounting baseplate; a Y-axle worktable is arranged on the mounting baseplate; a vacuum absorption platform is fixed on the Y-axle worktable; a printing substrate is absorbed on the vacuum absorption platform; a printing nozzle and a vertical observation camera are correspondingly arranged above the printing substrate, and are connected to a Z-axle worktable; the Z-axle worktable is fixed on an X-axle worktable; a squint observation camera is correspondingly arranged on one side of the printing nozzle; an LED light source and a far infrared curing light source are correspondingly arranged on the other side of the printing nozzle; theprinting nozzle communicates with a storage bottle; and the storage bottle is arranged on a lifting table.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

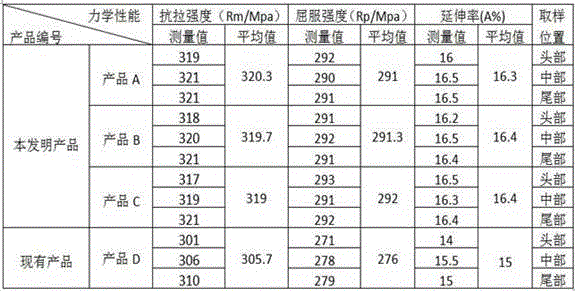

Al-Mg-Si aluminum alloy and extrusion method for sectional bar of Al-Mg-Si aluminum alloy

The invention discloses an Al-Mg-Si aluminum alloy and an extrusion method for a sectional bar of the Al-Mg-Si aluminum alloy. The Al-Mg-Si aluminum alloy comprises, by weight percent, 0.9%-1.25% of Mg, 0.5%-0.9% of Si, 0.2%-0.42% of Cu, smaller than or equal to 0.6% of Fe and 0.07%-0.35% of Cr and further comprises one or more elements of smaller than or equal to 0.15% of Mn, smaller than or equal to 0.22% of Zn, smaller than or equal to 0.15% of Ti, smaller than or equal to 0.05% of V, smaller than or equal to 0.5% of Hf, smaller than or equal to 0.25% of Sc, smaller than or equal to 1.0% of Ag and the balance Al. The aluminum alloy with the high mechanical performance is obtained by optimizing alloy components, the content of the alloy components and the sectional bar extrusion technology, and the production efficiency is effectively improved. The problems that in the prior art, conventional aluminum for transportation is low in strength and poor in ductility, the control range of the sectional bar extrusion technology link is wide, stability is poor, online quenching control difficulty is large, quenching uniformity is poor, and the production efficiency is low are solved.

Owner:广西南南铝加工有限公司

High-gloss extrusion-grade glass-fiber-reinforced nylon 66 composite material and preparation method thereof

The invention belongs to the technical field of high-molecular material, and relates to a nylon 66 composite material and a preparation method thereof. The material is composed of the following components by weight parts: 100 parts of nylon 66, 10-80 parts of glass fibre, 0-40 parts of inorganic filling materials, 0-30 parts of a compatilizer, 0.5-5 parts of a coupling agent, 0.3-5 parts of a chain extender, 0.2-1 part of an anti-oxidant and 0-3 parts of a lubricant. The composite material effectively overcomes disadvantages of poor quality of exposed surfaces of fiberglass and difficult extrusion moulding of glass fiber reinforced nylon 66 materials, and the nylon material which has a high gloss and can be consistently and stably extruded is prepared on a basis of guaranteeing original characteristics of the glass fiber reinforced materials, thereby greatly expanding application range of the nylon materials.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

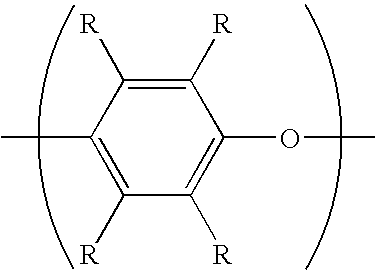

Two step preparation of random polyoxadiazole copolymer and articles resulting therefrom

InactiveUS7582721B2High viscosityExtrusion stabilityMonocomponent synthetic polymer artificial filamentTwo stepCopolymer

In a preparation of random polyoxadiazole copolymer by reaction of a mixture of oleum, hydrazine sulfate, terephthalic acid, and isophthalic acid, the improvement requires the addition of oleum in more than one step.

Owner:DUPONT SAFETY & CONSTR INC

Flange producing technique

The invention discloses a flange producing technique. The flange producing technique comprises a flange stock forging and a blank cutting and shaping; the flange stock forging comprises an electric stove heating, forging and shaping after cooling, extruding and shaping, and solution heat treatment; the blank cutting and shaping includes punching hole, acid washing, rough and fine turning, outer hole drilling, and processing and shaping. A crystal grain of the forging stock is uniform in organization ,low in hardness, good in toughness, high in yield degree, strong in tensile strength, and standard elongation rate; the flange stock forging efficiency is improved by 300%, and materials can reach zero loss; the produced flange disk is accurate in dimension and good in surface finishing degree.

Owner:ANHUI HONGJIE PIPELINE MFG

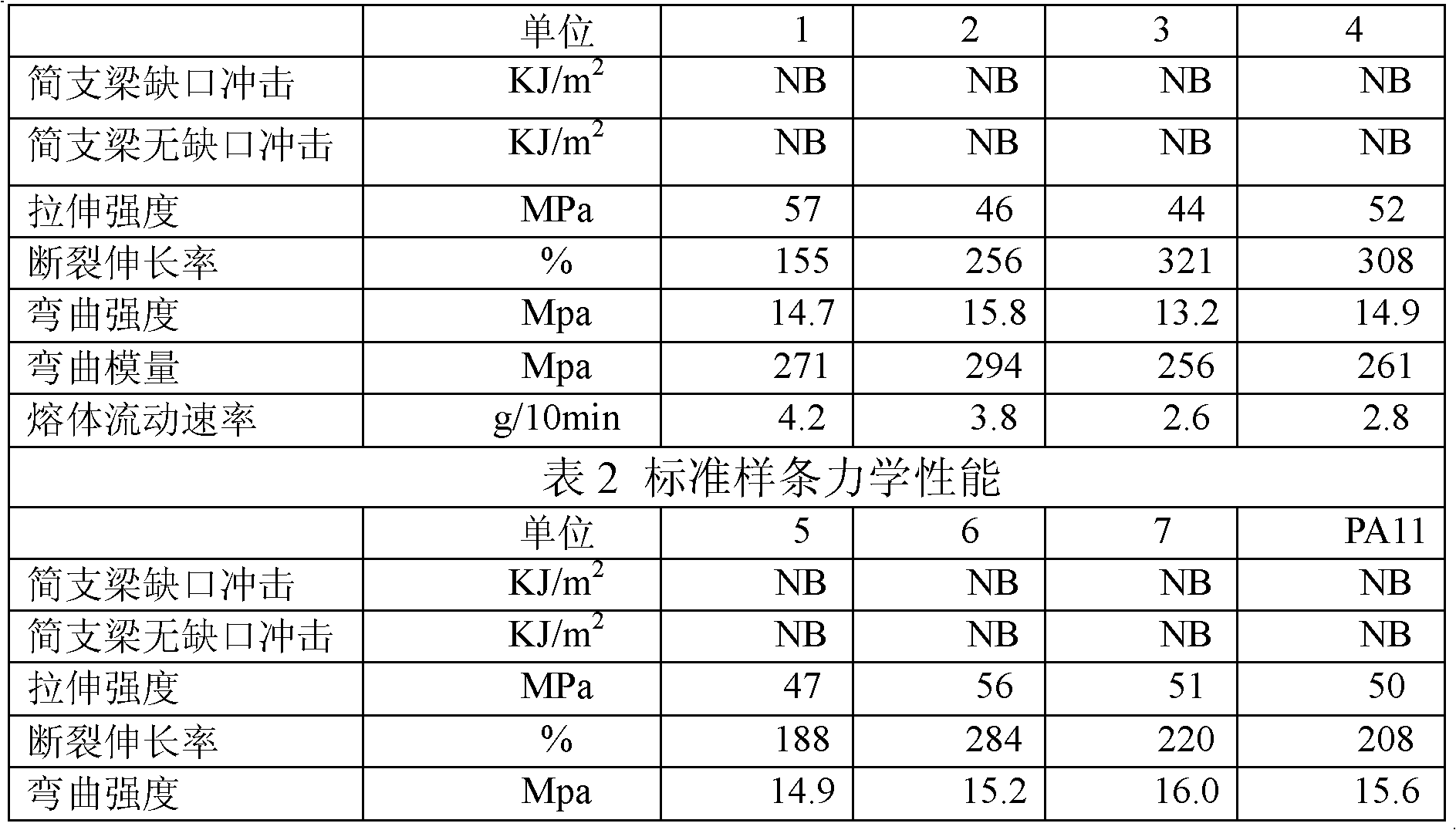

Formula of nylon hose

InactiveCN102604373AHigh strengthGood flexibility at low temperatureFlexible pipesPlasticizerLong chain

The invention relates to a formula of a nylon hose. The nylon hose prepared according to the formula provided by the invention is mainly applied to oil hoses and brake hoses of cars. The formula proportion of the nylon hose in parts by weight is as follows: 100 of long-chain nylon, 1-30 of polyamide elastomer, 0-30 of a plasticizer, 0.1-3.0 of an antioxidant, and 0.1-3.0 of a lubricant. The nylon hose prepared by the formula provided by the invention has the characteristics of high strength, good low-temperature flexibility, oil resistance, good dimensional stability, stable extrusion molding and the like; and after the nylon hose is processed into tubing, the tubing completely accords with the requirements of the standard of DIN73378:1996-02, and completely meets the requirements of replacing the imported tubing PA11 and PA12.

Owner:WUXI YINDA NYLON

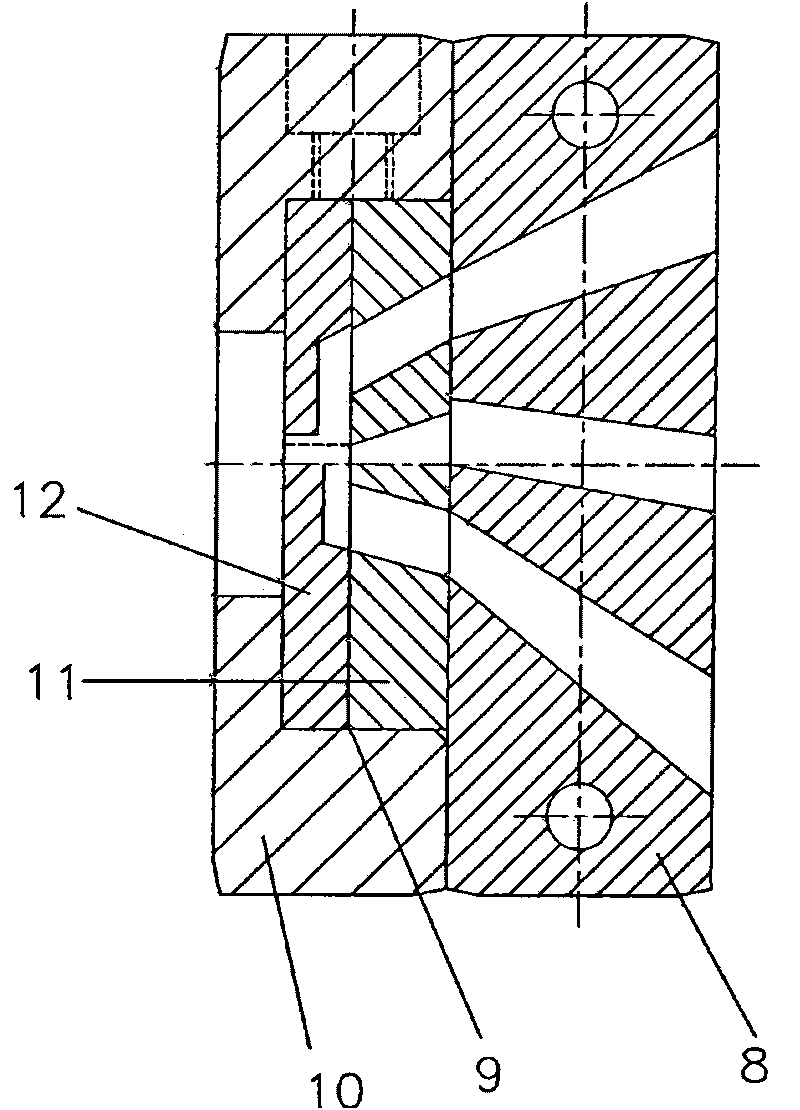

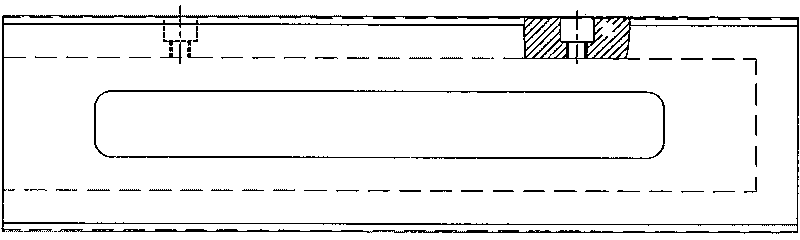

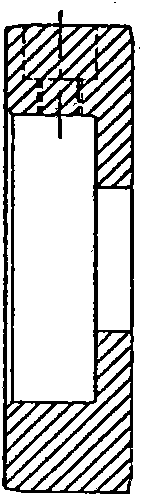

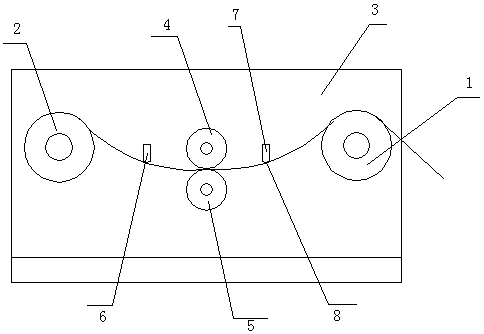

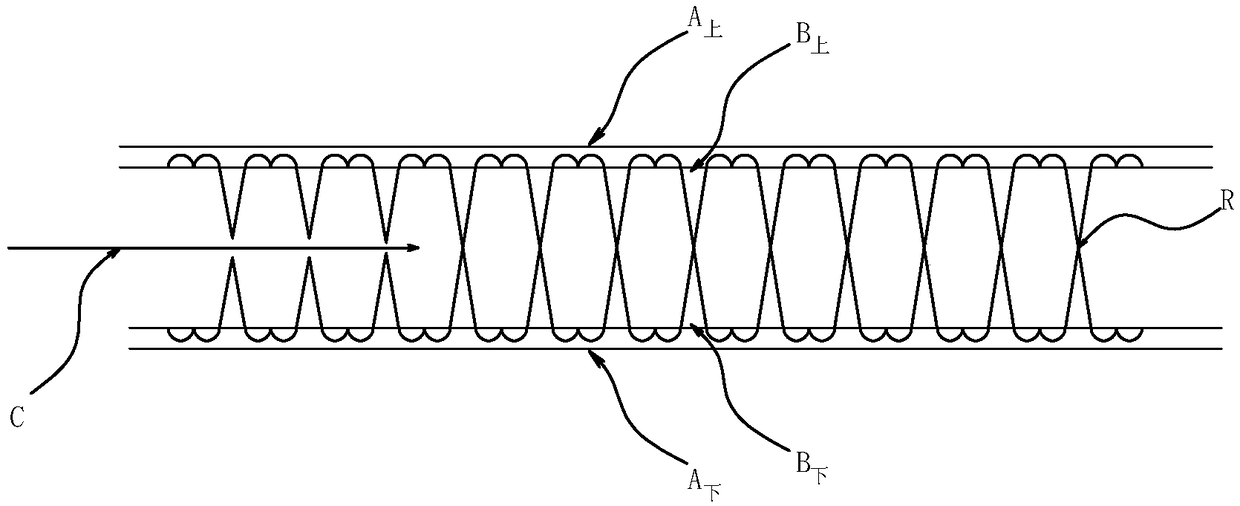

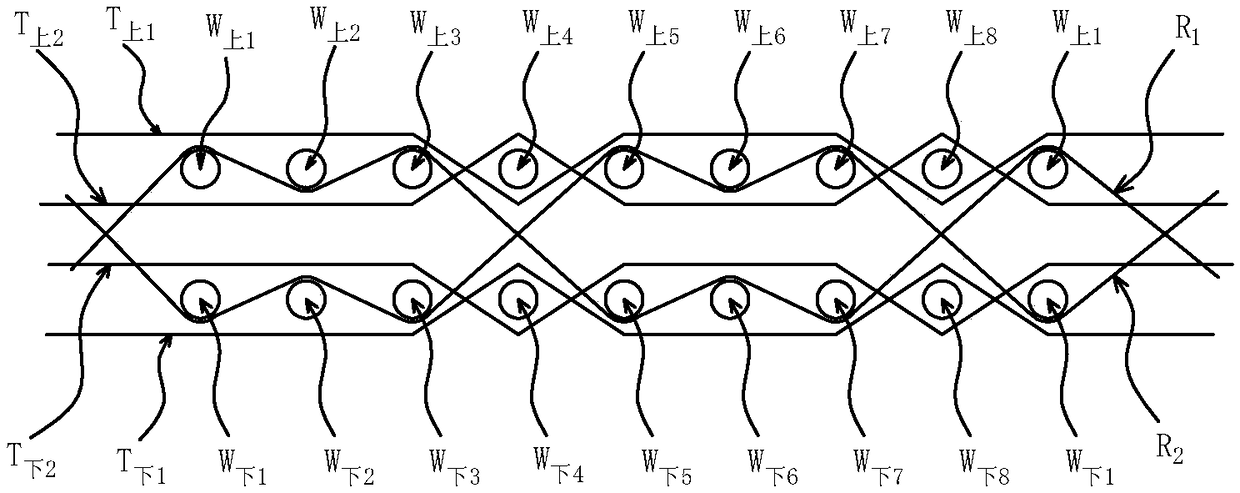

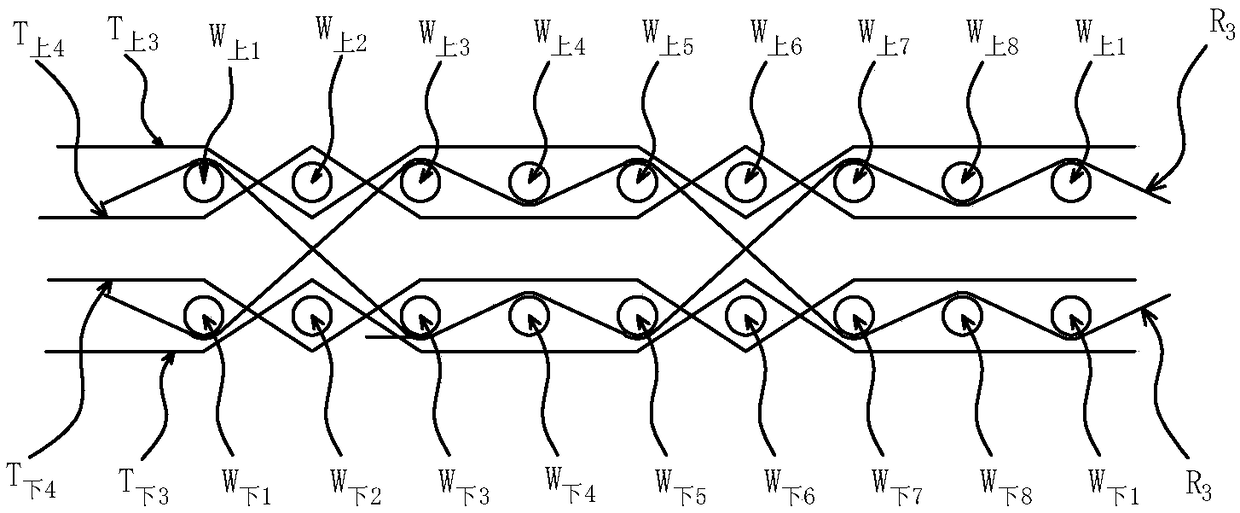

Compound extrusion unit for producing tubeless bicycles and mouth device thereof

The invention provides a compound extrusion unit for producing tubeless bicycles and a mouth device thereof. According to flow direction of a sizing material, the mouth device comprises a performed mouth board, a mouth board and a mouth box, which are sequentially connected; and the mouth board is embedded in the mouth box. The performed mouth board has an integral structure; the mouth board comprises an upper mouth board and a lower mouth board, which are matched with each other; the extrusion unit comprises an extrusion system and a temperature-control system, which are connected with each other; the extrusion system comprises three compound heads and three extrusion machines which are connected with the three compound heads respectively; and three extrusion machines are arranged pickaback, and the mouth device in the three compound heads is the mouth device. The mouth device can avoid streaming and burning of the sizing material in the process of inner compounding and guarantee stable extrusion of the products; and meanwhile, the volume of the device is small and maintenance of equipment is convenient because the extrusion machines are assigned pickaback; and mold components are locked by utilizing a lock, so that locking effect is good and shaping effect of tires is also good.

Owner:东莞市力拓橡塑设备有限公司

Gumming machine for producing decorative paper

InactiveCN108031609AGlue evenlyWill not block glueLiquid surface applicatorsCoatingsPulp and paper industryRejection rate

The invention relates to a gumming machine for producing decorative paper. The gumming machine comprises a rack, and a rotating roller, a traction roller, a gumming roller and a pressure-bearing roller which are rotatably fixed on the rack, wherein the gumming roller is located above the pressure-bearing roller; the rotating roller and the traction roller are located at two sides of the gumming roller respectively; the rack is provided with a first limiting rod and a second limiting rod; the first limiting rod is located between the rotating roller and the gumming roller; the second limiting rod is located between the gumming roller and the traction roller; the gumming roller comprises an inner roller body, an outer roller body and a motor; the inner roller body is of a hollow cylindricalstructure and a glue storage cavity is formed in the inner roller body. By adopting the gumming machine provided by the invention, the production quality of the decorative paper can be ensured, the rejection rate is reduced and the cost is reduced.

Owner:邵美红

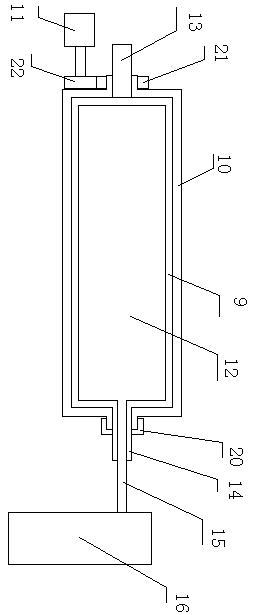

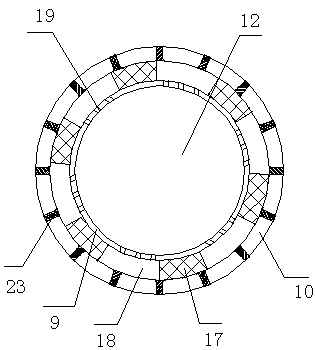

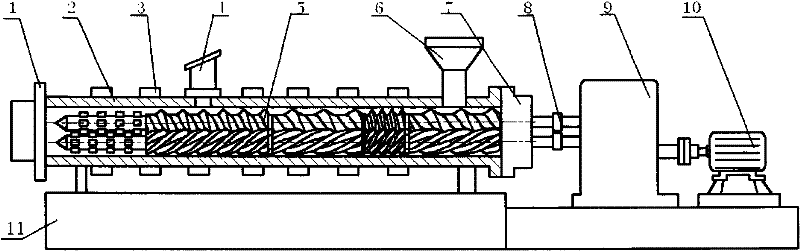

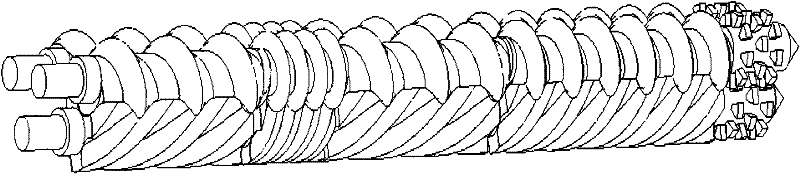

Exhaust-type differential double-screw extruder

The invention relates to an exhaust-type differential double-screw extruder, mainly comprising a feeder, a cylinder, screws, a machine head, a heating and cooling device, an exhaust outlet, a motor and a driving device, wherein one screw is a male rotor, and the other screw is a female rotor; at least one screw thread engaging region is arranged when the screws are combined, the screw socket number of the female rotor in the region is integral multiples of that of the male rotor, the rotating speeds of the female rotor and the male rotor are in inverse proportion to the screw socket number, and differential rotation and no interference during movement can be realized for the female rotor and the male rotor. At least one exhaust outlet is arranged on a material cylinder so as to remove moisture and other volatile components, and the screw configuration distribution meets the exhausting requirement. According to material processing requirements, screw thread sections or other forms with different leads and section shaped lines can be arranged on different sections of a charging section, a fusion section, an exhausting section and a metering section of the screws; when the screws are installed, besides at least one screw thread engaging region with differential rotation is ensured, the screws in different sections can be engaged and can be also unengaged so as to reinforce mixing or other functions. The extruder has favorable mixing, plasticizing and conveying capabilities and is suitable for processing and forming various granules, powder materials or even block materials, such as plastics, rubbers, food, explosives and the like.

Owner:BEIJING UNIV OF CHEM TECH

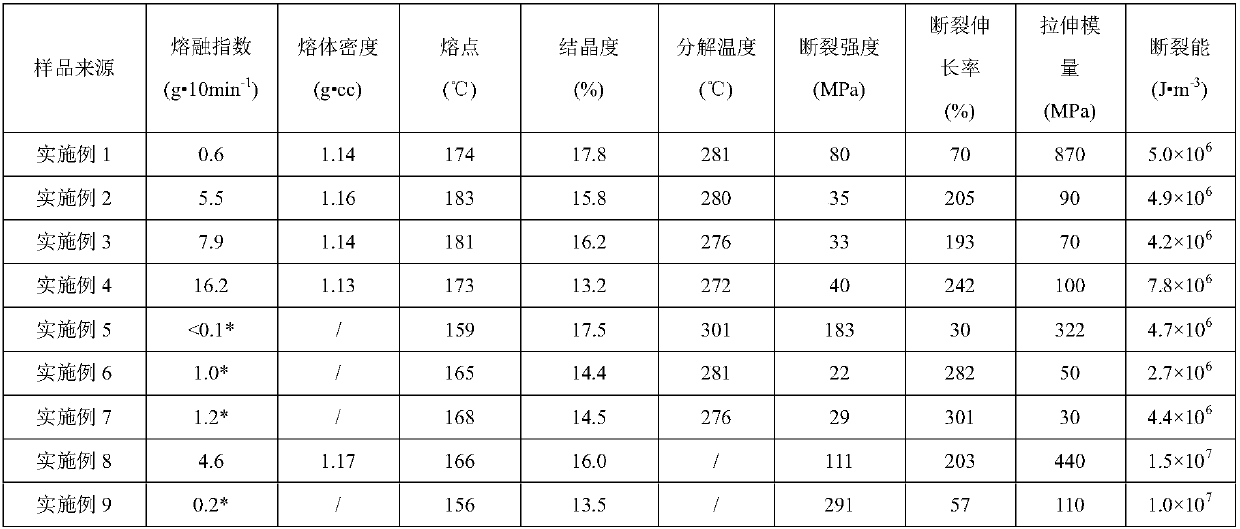

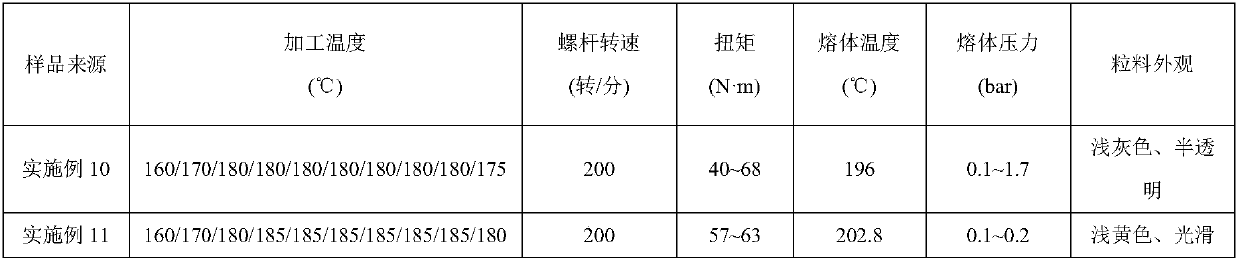

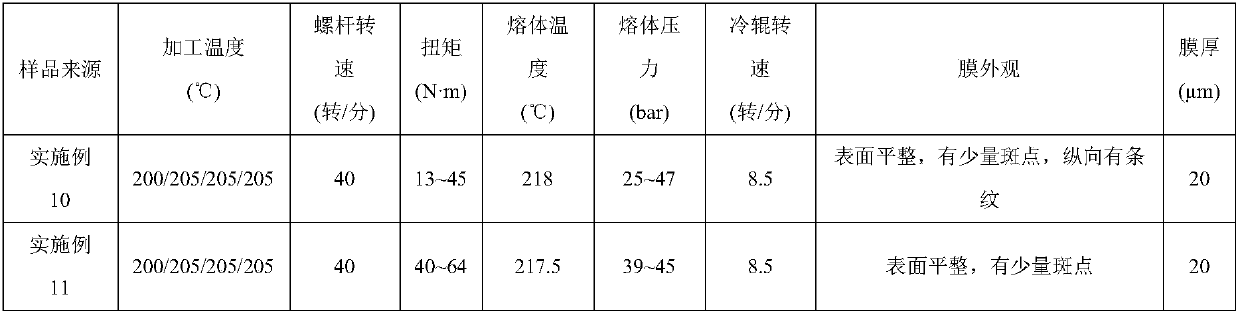

Thermoplastically modified high-fluidity polyvinyl alcohol, and thermoplastically modified high-fluidity polyvinyl alcohol casting film material and preparation method thereof

InactiveCN107936430AExpanded processing windowGood thermoplastic processabilityFlat articlesPolymer sciencePlasticizer

The invention relates to a thermoplastically modified high-fluidity polyvinyl alcohol casting film material and a preparation method thereof. A purpose of the present invention is mainly to solve theproblems of poor thermoplasticity, difficult processing, poor melt fluidity, easy thermal-oxidation degradation, difficult casting film preparation and poor mechanical property of polyvinyl alcohol inthe prior art. The technical scheme comprises that the thermoplastically modified high-fluidity polyvinyl alcohol is used, and comprises, by mass, 1) 70-99.9 parts f polyvinyl alcohol, and 2) 0.1-30parts of a plasticizer, the polyvinyl alcohol and the plasticizer are respectively introduced into a twin-screw extruder, and melt extrusion and granulation are performed through a screw rod extrusionprocessing technology to obtain the thermoplastically modified high-fluidity polyvinyl alcohol. With the technical scheme, the problems in the prior art are well solved. The method of the present invention can be used for industrial production of polyvinyl alcohol casting film materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

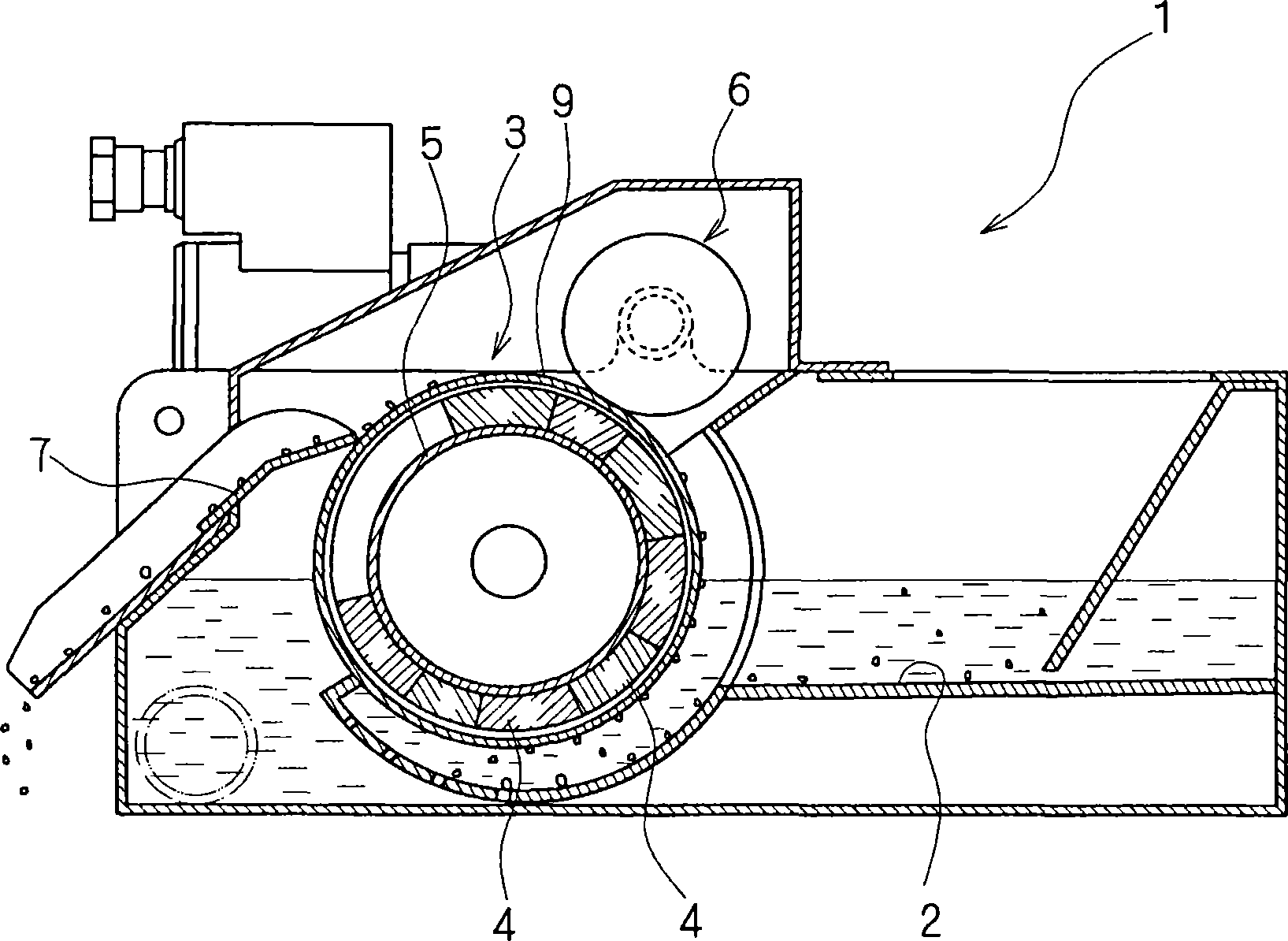

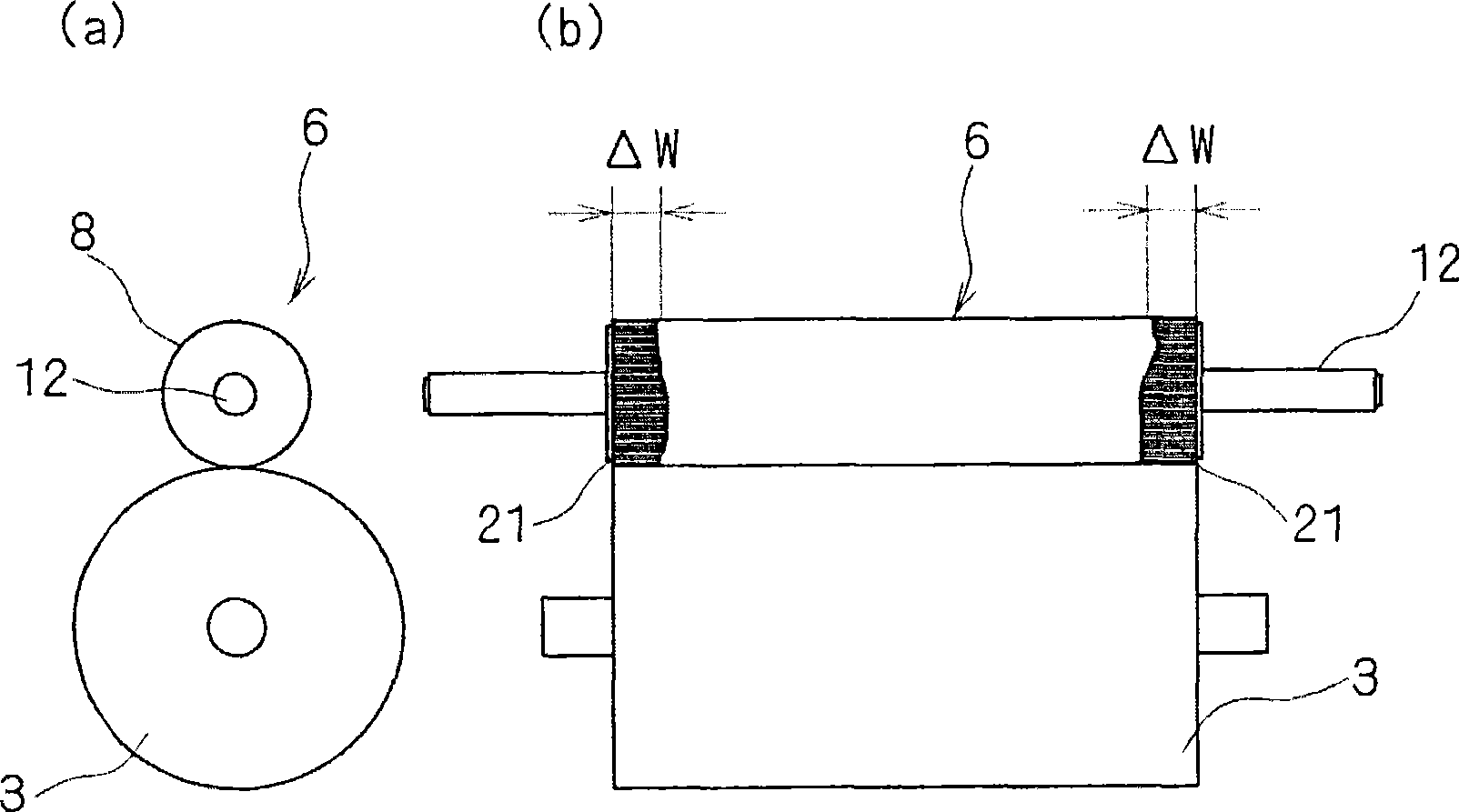

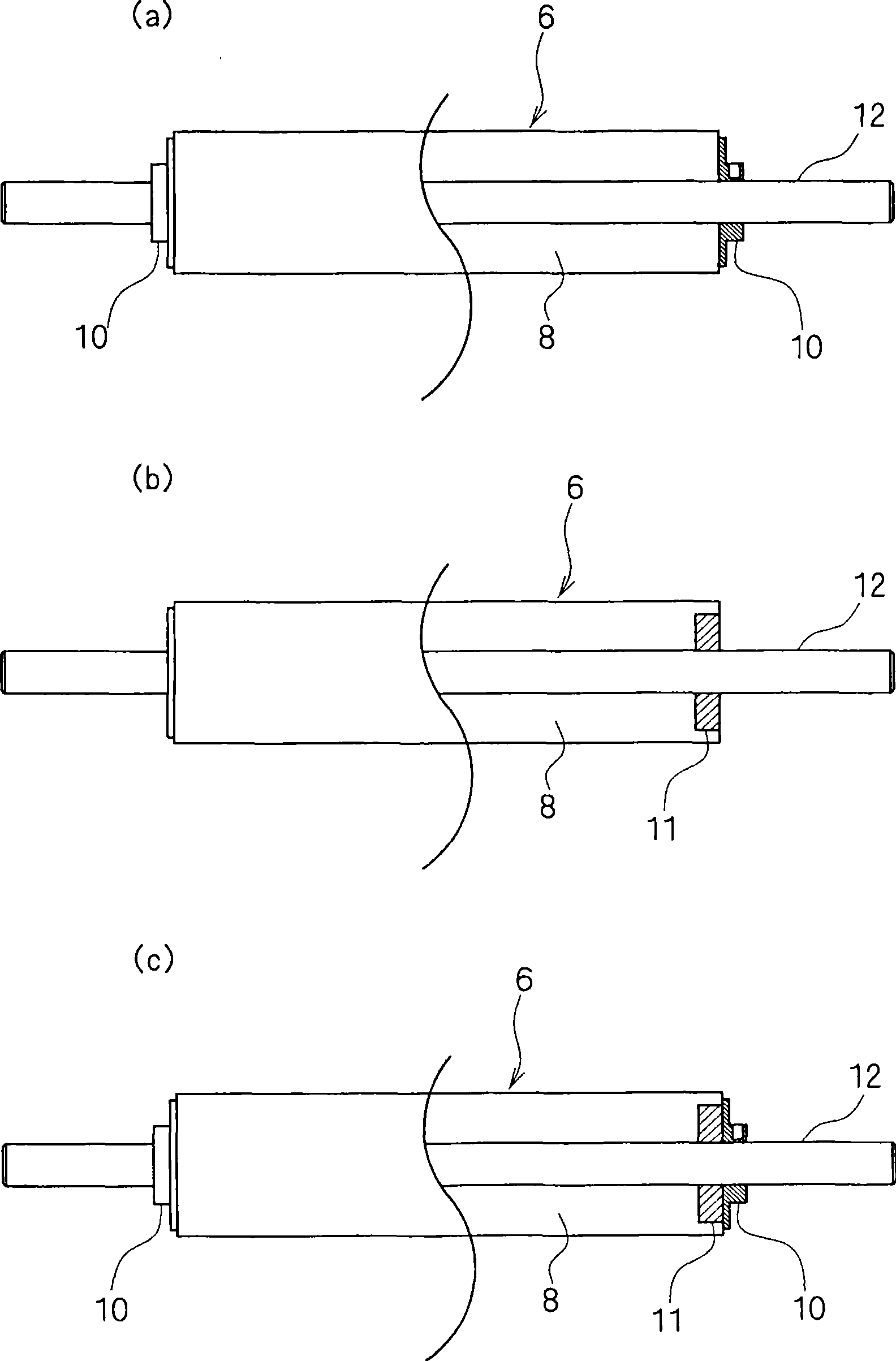

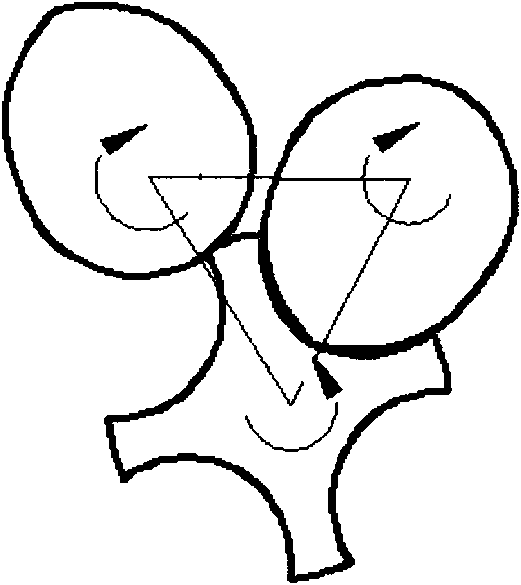

Squeezing roller and rotary drum-type magnetic separator

ActiveCN101448574AHigh hardnessEntry inhibitionShaft and bearingsMagnetic separationPolyesterElastomer

This invention provides a rotary drum-type magnetic separator, which can satisfactorily squeeze a liquid contained in sludge without striking the sludge into the squeezing roller even when the sludge has such a shape that is likely to be striken into the squeezing roller, and a squeezing roller for use in the separator. The separator comprises a squeezing roller (6) which is abutted against a rotary drum (3) and is rotated about a shaft substantially parallel to the rotating shaft of the rotary drum (3). The rotary drum (3) has a built-in and fixed internal cylinder (5) on which a plurality of magnets (4), (4), are disposed. An external cylinder (9) formed of a nonmagnetic material is rotated on the circumference of the internal cylinder (5). An elastic body is disposed on the squeezing roller (6) in its face abutted against the rotary drum (3). The elastic body is formed of an uncrosslinked polyurethane material composed mainly of a polyester polyol. A suppressing member for suppressing the deformation of the elastic body is provided on both ends of the squeezing roller (6).

Owner:SUMITOMO HEAVY IND FINETECH

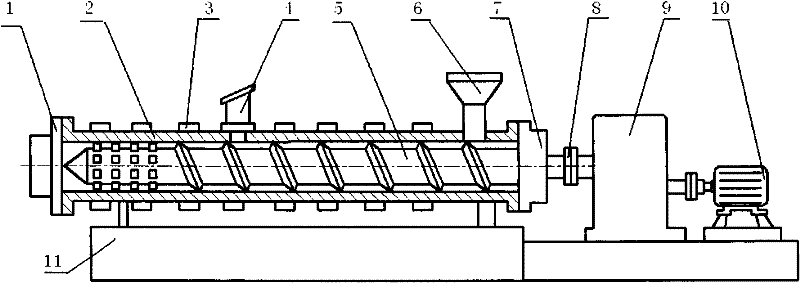

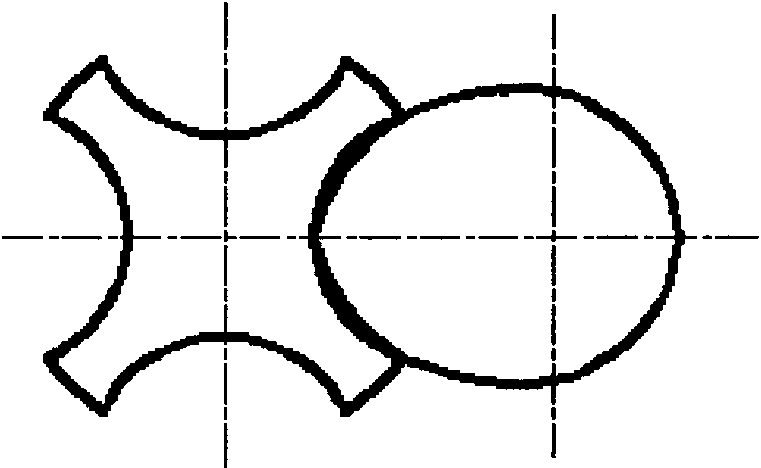

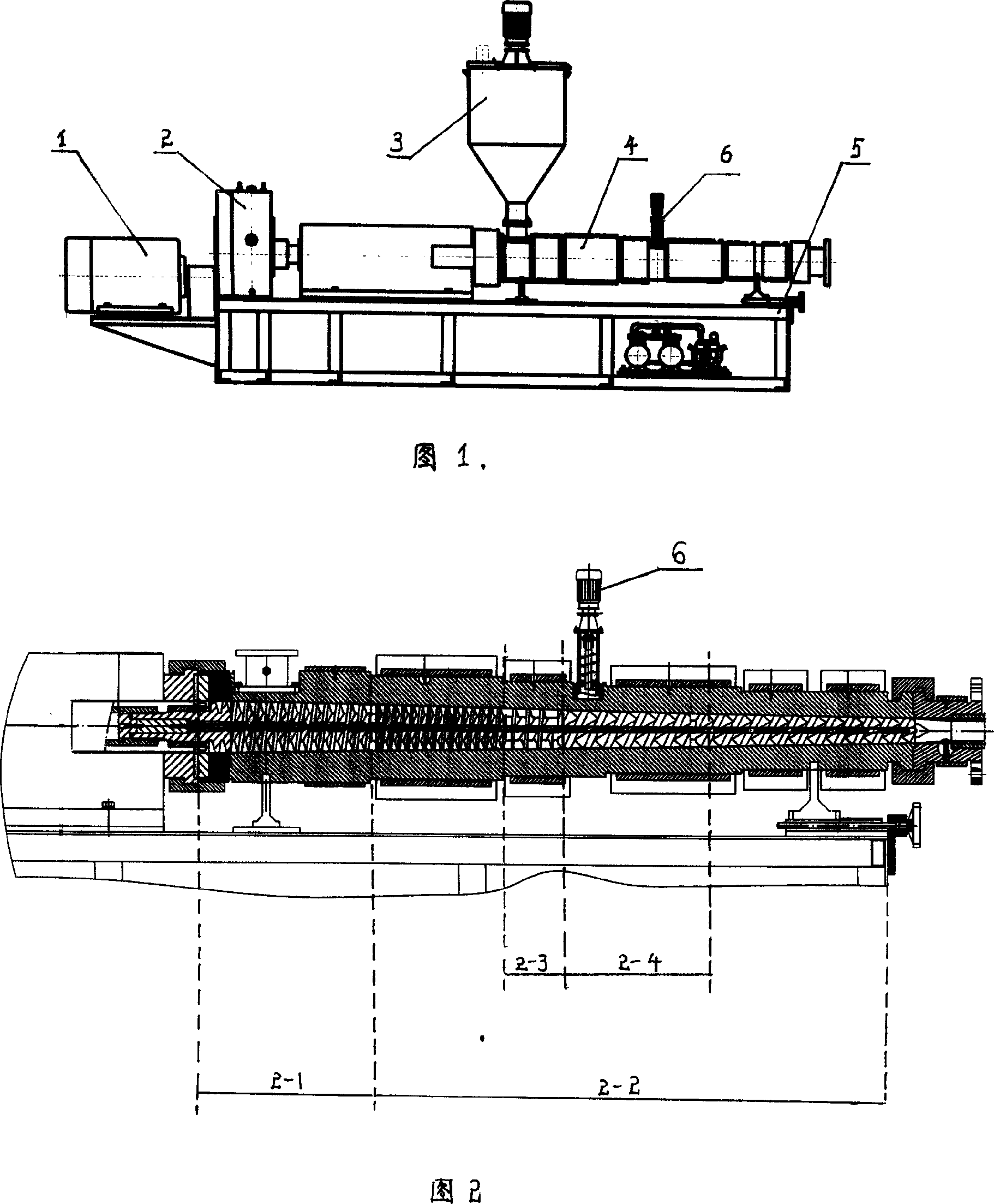

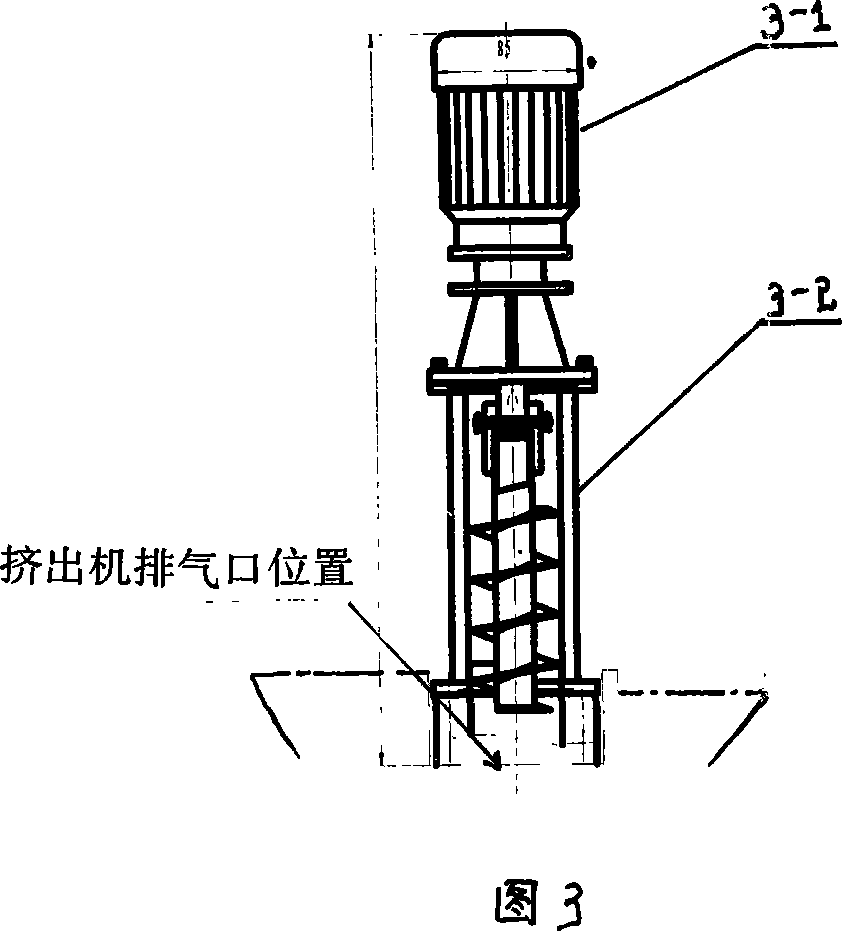

Conical double screw extruder special for wood plastic composite material

The present invention belongs to a special cone-shaped double-screw extruding machine for a wood-plastic composite material of the plastic processing machine, including a power source, a reduction gear box, a screw-machine barrel accessory, a machine frame and a feeding bucket. The power source is connected with a screw inside the screw-machine barrel accessory through the reduction gear box. The feeding bucket communicates with a machine barrel inside the screw-machine barrel accessory. The screw is installed inside the machine barrel. Cooling and temperature-reducing device are installed at the lower part of a feeding opening of the machine barrel and at a closely adjacent section to make the two sections as cooling sections, the sections after which are provided with heating devices which make the rest sections as the heating sections. Only one vent is arranged at the machine barrel. The screw, which is installed inside the machine barrel, is the cone-shaped screw and is provided with a mixing section, and the same time the length-diameter ratio of the machine barrel and the screw is more than 30. Before the vent, the present invention can convey, compress, heat and plastify the wood-plastic composite material under the quite low temperature; after being completely plastified, the plastic can complete enwrap the heated wooden powder before the vent and mix with the wooden powder uniformly; a double-screw vacuum exhausting and flash-preventing device which continuously rotates downwards can exhaust as well as never flash.

Owner:BAOJI QINCHUAN FUTURE PLASTIC MECHINE

Production process of home textile velvet

ActiveCN109023664AExtrusion stabilityExtruded and consolidated firmlyMulti-ply fabricsNatural fiberFineness

The invention discloses a production process of home textile velvet. The home textile velvet is formed by subjecting a double cloth comprising an upper base fabric, a lower base fabric and a pile warpto velvet pile and arrangement. The pile warp is connected with the upper base fabric and the lower base fabric, and is W consolidated through the upper base fabric and the lower base fabric. The pile warp is a natural fiber yarn. An upper base fabric weft yarn and a lower base fabric weft yarn are both functional yarns. An upper base fabric warp yarn and a lower base fabric warp yarn use naturalfiber yarns and functional yarns. The fineness of the ground warp is not restricted by the fineness of the pile warp. The fineness of the ground warp can be less than that of the pile warp, or can begreater than the fineness of the pile warp. The home textile velvet is very suitable for mass production. The production process can reduce the fineness of the pile warp to achieve a light and elegant purpose while ensuring the density of pile is not exposed to the ground. The home textile velvet comprises all natural fibers contacted by the human body, and functional yarns that are imparted by modern technology and cannot be contacted by the human body, which satisfies people's needs.

Owner:ZHEJIANG INNOVATION TEXTILE CO LTD

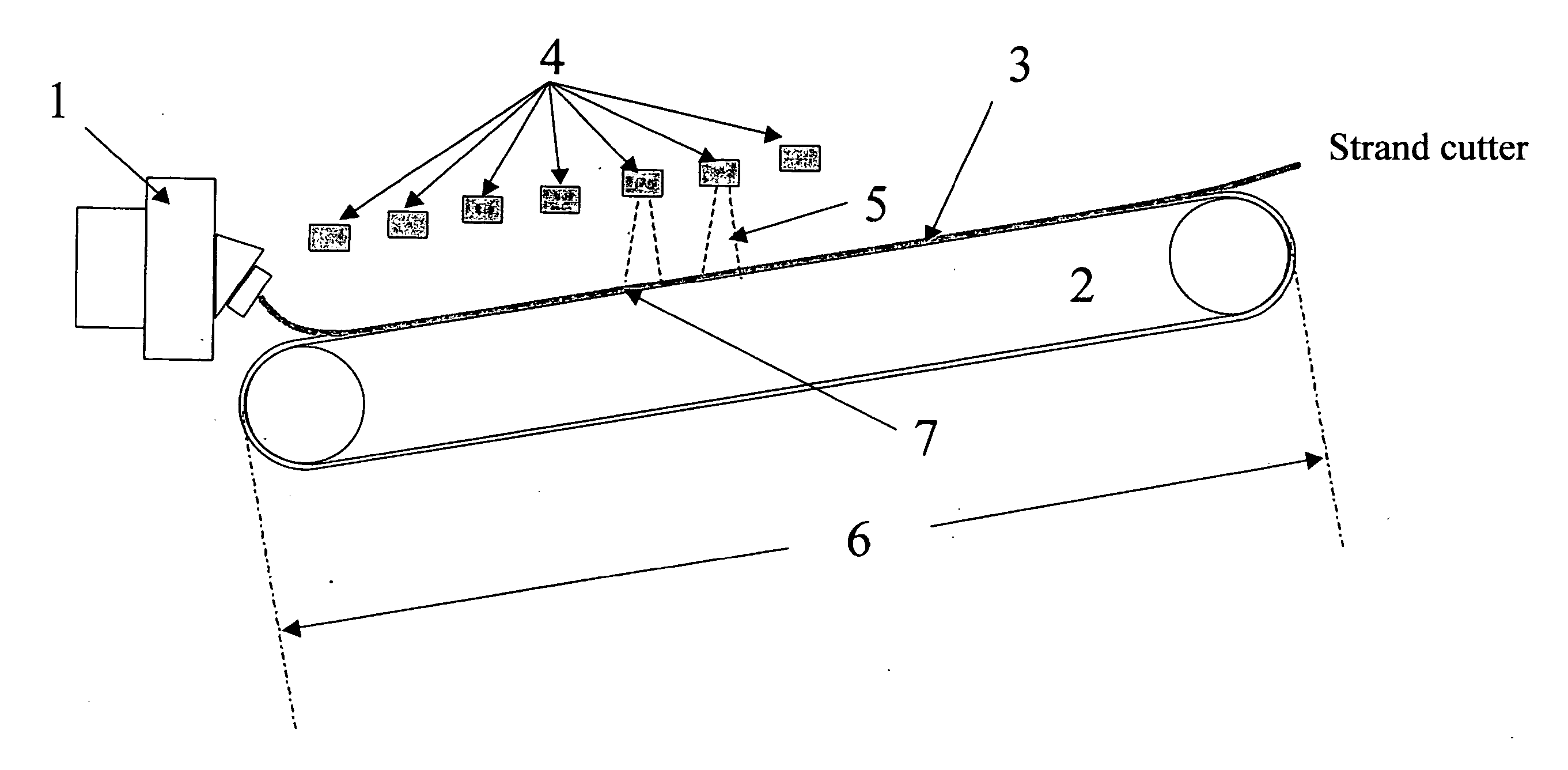

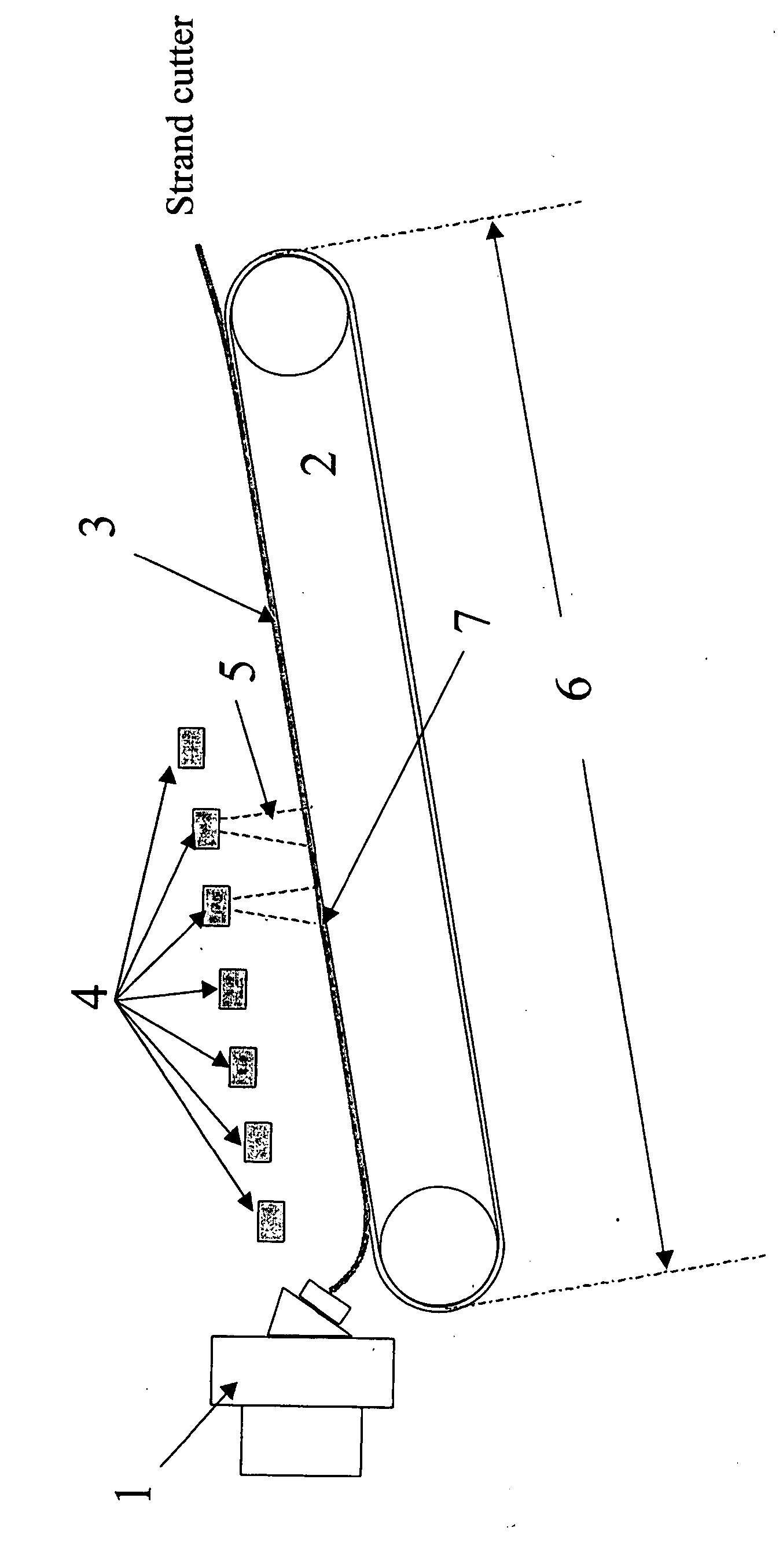

Method for producing resin strand

InactiveUS20070235893A1Increase productionInhibition formationElectroconductive/antistatic filament manufactureFilament/thread formingWire rodMoisture

The present invention can eliminate a breakage of strands on the way to increase yield, significantly suppress formation of adhered consecutive pellets, and obtain pellets having a low moisture content by a method for producing a resin strand comprising melt-kneading a resin composition in an extruder, extruding a strand-shaped molten resin onto a conveyor, and cooling the resin strand with cooling water, wherein the conveyed strand-shaped molten resin is brought into initial contact with the cooling water at a position downstream ranging from 20% to 70% of the total length of the conveying part of the conveyor.

Owner:ASAHI KASEI CHEM CORP

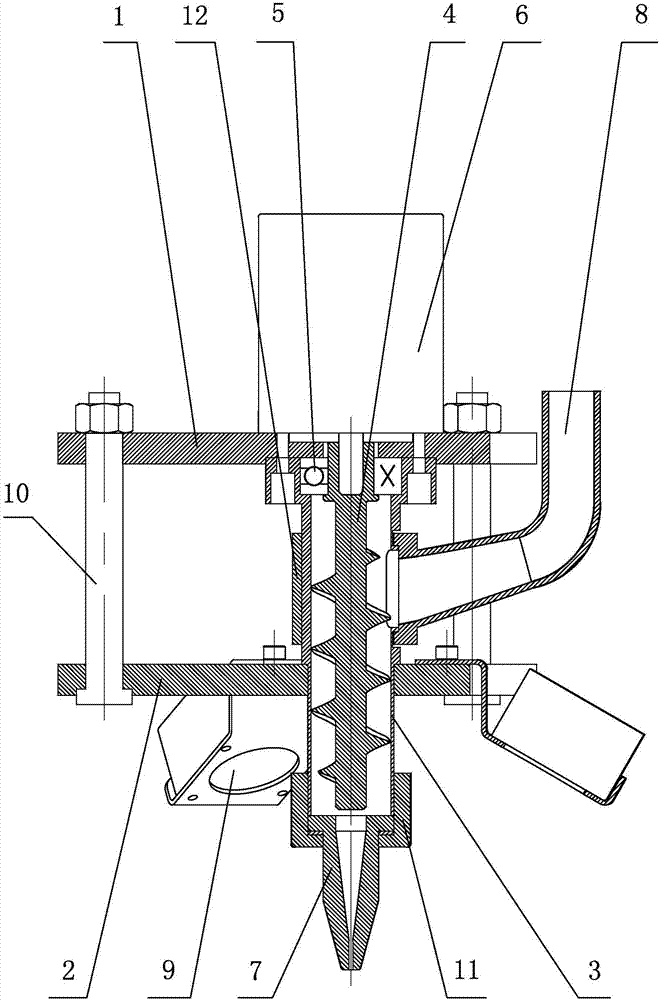

3D printing spray head device

PendingCN107415220ANo cloggingHelp with cleanupManufacturing heating elementsCeramic shaping apparatus3d printRolling-element bearing

The invention discloses a 3D printing spray head device. The 3D printing spray head device comprises an extruding mechanism, a feeding mechanism and a heating mechanism. The extruding mechanism comprises a material guide cylinder which is positioned and mounted through an upper fixing plate and a lower fixing plate. A feeding screw mounted through a rolling bearing is arranged in the material guide cylinder. The upper end of the feeding screw extends out of an upper cylinder opening of the material guide cylinder and is connected with a motor output shaft mounted on the upper fixing plate. A detachable spray head is mounted on a lower cylinder opening of the material guide cylinder. The feeding mechanism comprises a feeding pipe. The feeding pipe communicates with a feeding opening in a material guide cylinder body. The heating mechanism comprises air heaters arranged on the lower fixing plate. Air blowing openings of the air heaters all face a spray nozzle of the spray head. The 3D printing spray head device is simple in structure, good in extrusion effect, uniform to heat and capable of quickly curing a model, and the spray head is not likely to be blocked.

Owner:桂林市新众科技有限公司

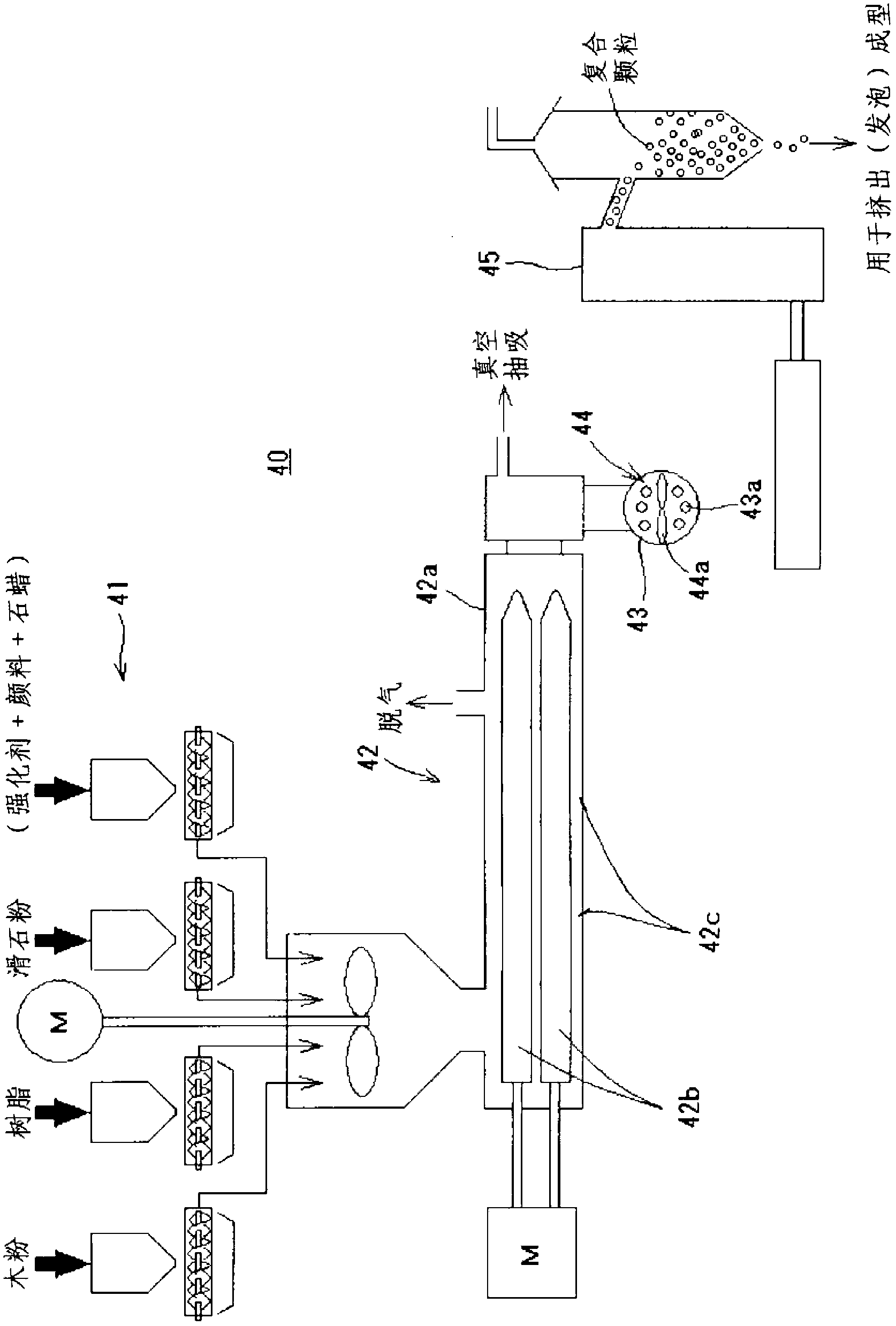

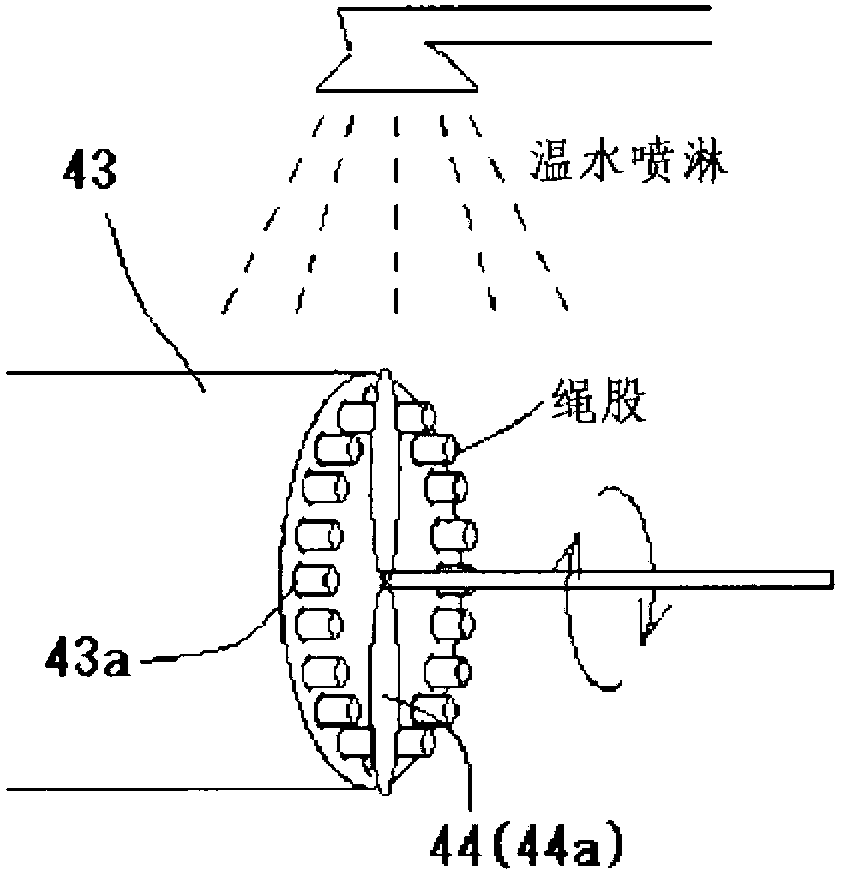

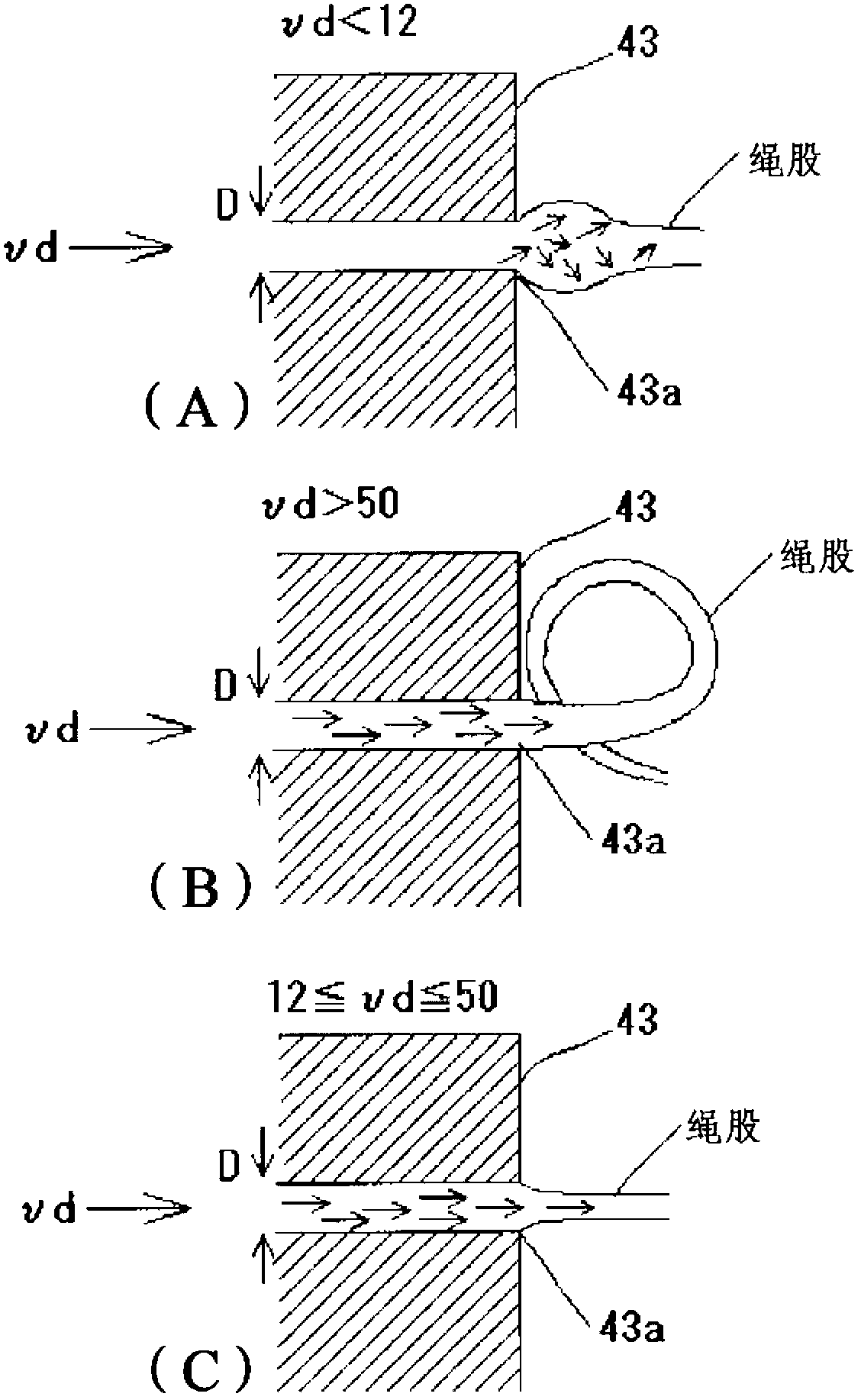

Method for producing composite pellet for extrusion molding, and composite pellet for extrusion molding produced by the method

InactiveCN102869484AInhibit swellingAvoid contactFlat articlesDomestic articlesHydroxystearic AcidVolumetric Mass Density

Disclosed are composite pellets for extrusion molding wherein fusion does not occur between the pellets, and there is no variation in size and density. A molten material obtained by an extruder for a raw material containing a thermoplastic resin and wood powder is extruded into a strand shape through a die nozzle of the extruder, and cut into a predetermined length to form a pellet. At this time, the extrusion amount, the diameter of each nozzle hole, and the number of nozzle holes are adjusted so that the linear velocity (vd) of the molten material in each nozzle hole of the die nozzle is in the range of 12 to 50 cm / sec. Further, regardless of the variations in particle diameter, etc., a stable amount of the composite pellets are supplied to the extruder, and smoothly introduced to a screw of the extruder. The composite pellets and 12-hydroxystearic acid containing a metal of Ca, Mg, or Zn are agitated together, and 0.03 to 0.4 mass% of the 12-hydroxystearic acid is attached to the periphery of 100 mass% of the composite pellet, and the pellets are used for extrusion molding.

Owner:WPC CORP

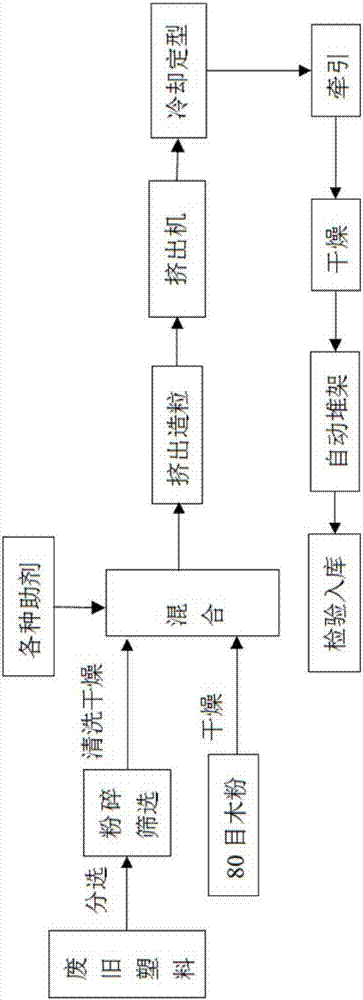

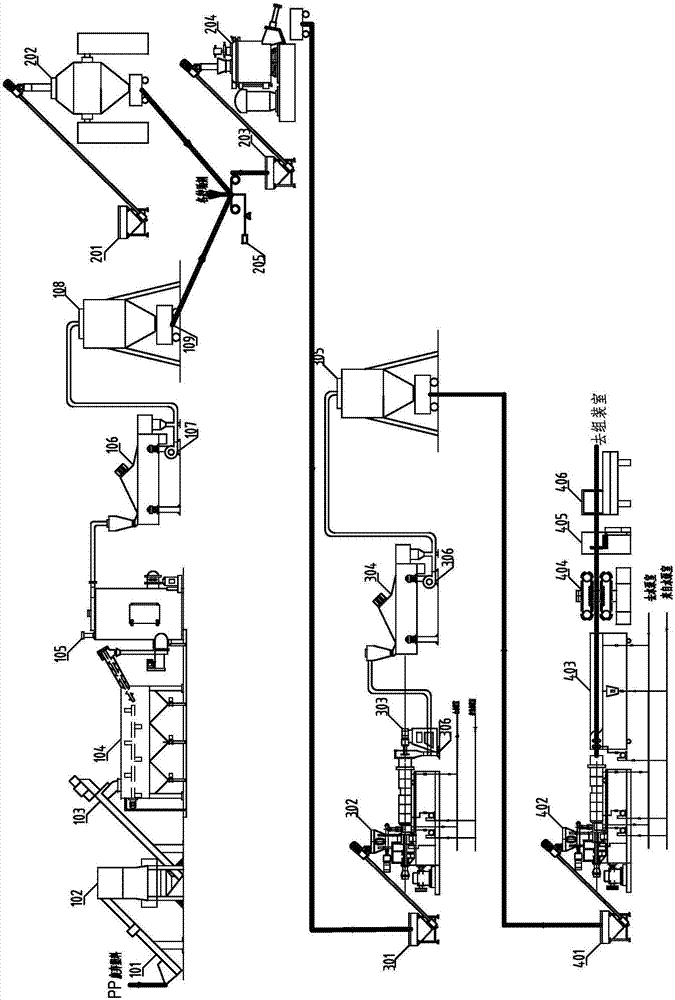

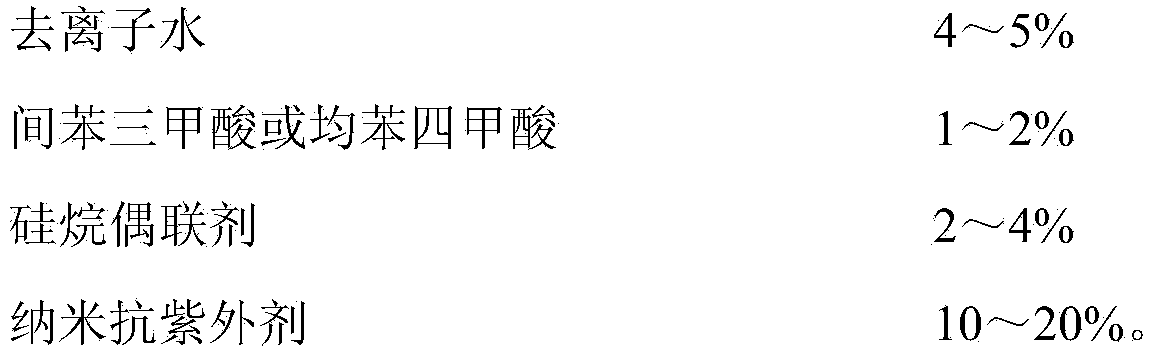

Formulation of wood-plastic profile as well as preparation method and manufacturing device thereof

InactiveCN107189216AImprove impact performance at room temperatureHigh low temperature impact resistanceHeat resistanceAntioxidant

The invention particularly relates to a formulation of wood-plastic profile as well as a preparation method and a manufacturing device thereof. The formula is characterized by being prepared from the following raw materials in parts: 100 parts of PP waste plastic with good mobility, 20 to 75 parts of wood powder, 5 to 15 parts of flexibilizer; 2 to 10 parts of compatibilizer; 1 to 10 parts of lubricant; 0.1 to 1 part of main antioxidant; 0.1 to 0.5 part of auxiliary antioxidant; 0.02 to 0.5 part of light stabilizer and 0.1 to 4 parts of antibacterial agents; the preparation method is characterized by comprising the following steps:(1) recycling the PP waste plastic with good mobility; (2) cleaning, crushing and drying; 3) drying the wood powder; 4) extruding and granulating; and 5) extruding and molding; and the manufacturing device is characterized by comprising a plastic cleaning device, a wood powder drying device, a weighing device, a mixing device, an extrusion granulation device and an extrusion molding device. The invention has the advantages of low cost, durability, long life, good heat resistance, good resistance to ultraviolet rays, high hardness and high load capacity.

Owner:YANTAI UNIV

Special material for waste ABS (acrylonitrile butadiene styrene) plastic regenerated and modified automobile and preparation method of special material

The invention discloses a special material for a waste ABS plastic regenerated and modified automobile and a preparation method of the special material, and solves the problem that the recovery rate of a waste ABS plastic is lower, and resources are wasted in the prior art. The special material comprises the components in parts by weight as follows: 100 parts of a waste ABS broken material, 1-8 parts of ABS, 0.1-0.3 parts of EBS (ethylene bis stearamide), 0.1-0.2 parts of zinc stearate, 0.1-0.2 parts of calcium stearate, 0.1-0.2 parts of antioxidant 10100, 0.2-0.6 parts of antioxidant 168 and 0.1-0.4 parts of montan wax, wherein the waste ABS broken material is obtained by picking, breaking, cleaning, dehydrating, absorbing and drying the waste ABS plastic. The preparation method of the special material for the waste ABS plastic regenerated and modified automobile is further provided. The special material for the waste ABS plastic regenerated and modified automobile and the preparation method of the special material have the advantages that the waste ABS plastic can be recycled, resources are saved, the environment is protected, the cost is reduced, the preparation process is simplified, and the like.

Owner:四川塑金科技有限公司

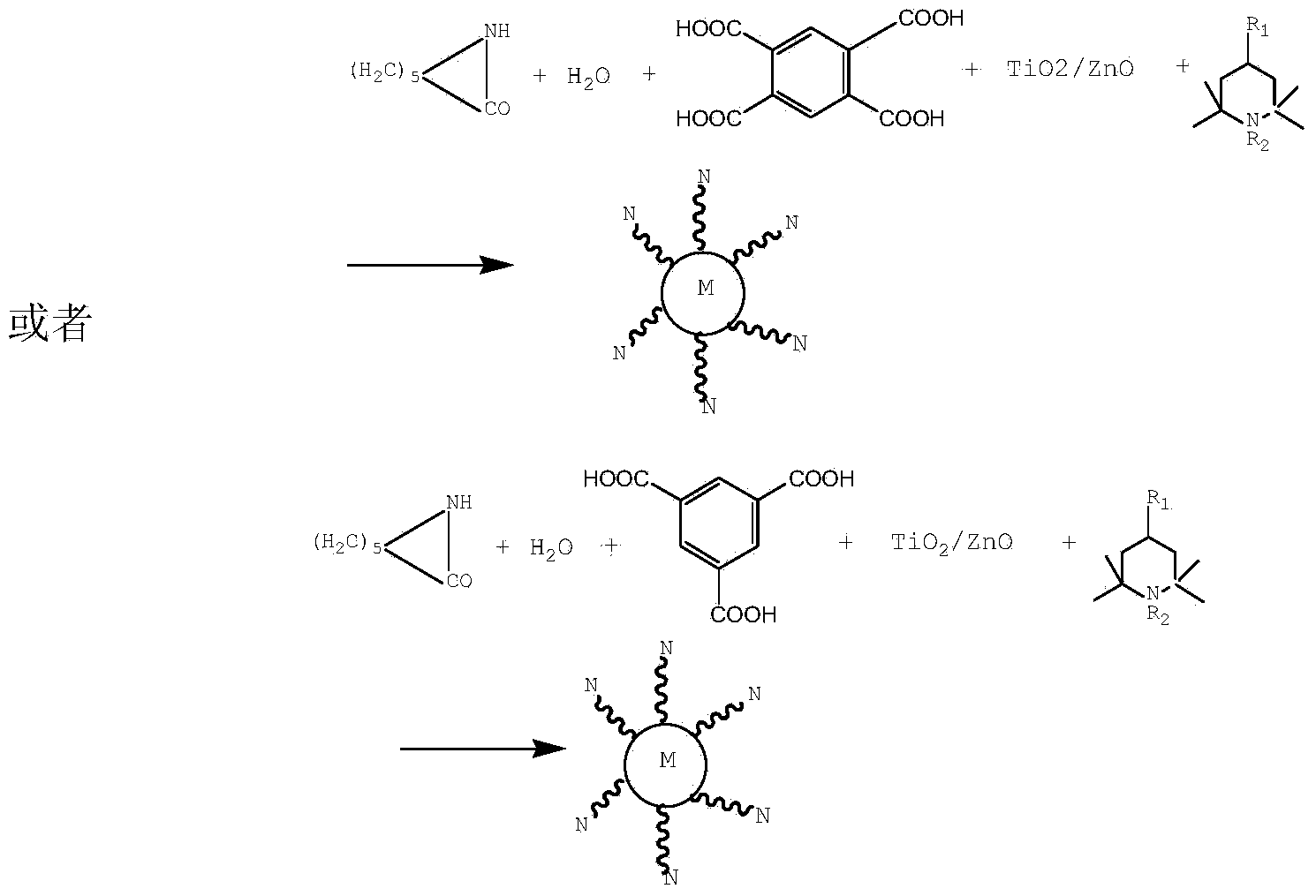

Uvioresistant nylon-6 fiber for ultrathin and light fabric and preparation method thereof

ActiveCN103774272AImprove liquidityBarrier transmissionMelt spinning methodsArtifical filament manufactureIn situ polymerizationNylon 6

The invention relates to an uvioresistant nylon-6 fiber for an ultrathin and light fabric and a preparation method of the uvioresistant nylon-6 fiber. The uvioresistant nylon-6 fiber is formed by branched-chain nylon-6 functional master batches and conventional nylon-6 chips through blending and spinning, wherein the branched-chain nylon-6 functional master batches account for 6-10% in weight percentage; the preparation method comprises the steps of firstly, preparing the branched-chain nylon-6 functional master batches through in-situ polymerization or blending; secondly, crystallizing and drying the branched-chain nylon-6 functional master batches and the conventional nylon-6 chips respectively and mixing, and then performing vacuum drying to obtain blended chips; and finally, performing melt spinning to the blended chips with melt spinning equipment. The using amount of ultraviolet absorbents is reduced, the fiber spinnability is improved, the uvioresistant and the ultraviolet aging resistant effects are ensured; the fabric can strongly absorbing ultraviolet radiation while light weight is ensured, and is suitable for developing thin and light clothes in summer.

Owner:中国化学纤维工业协会

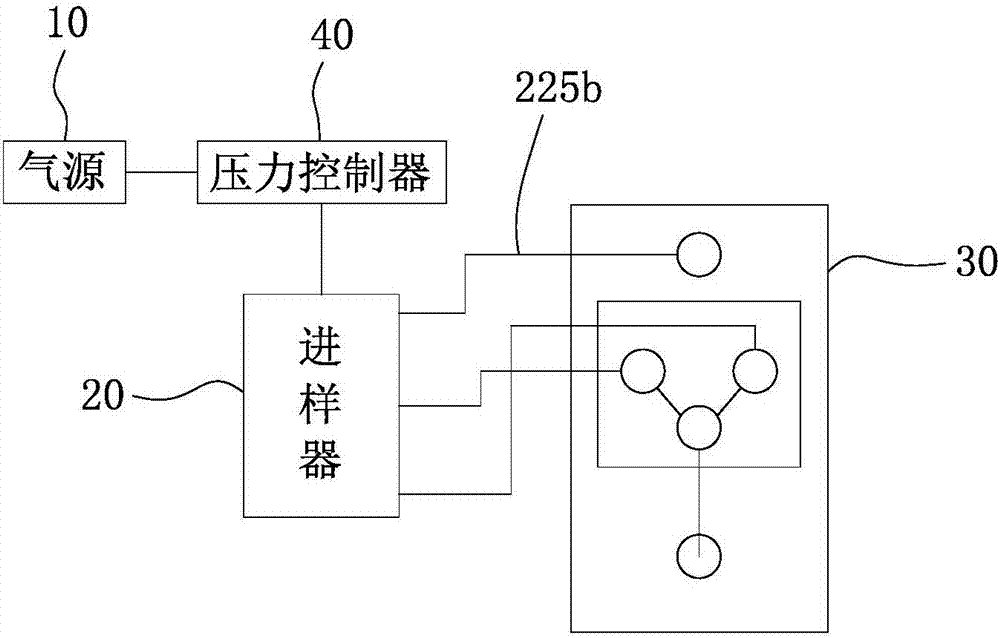

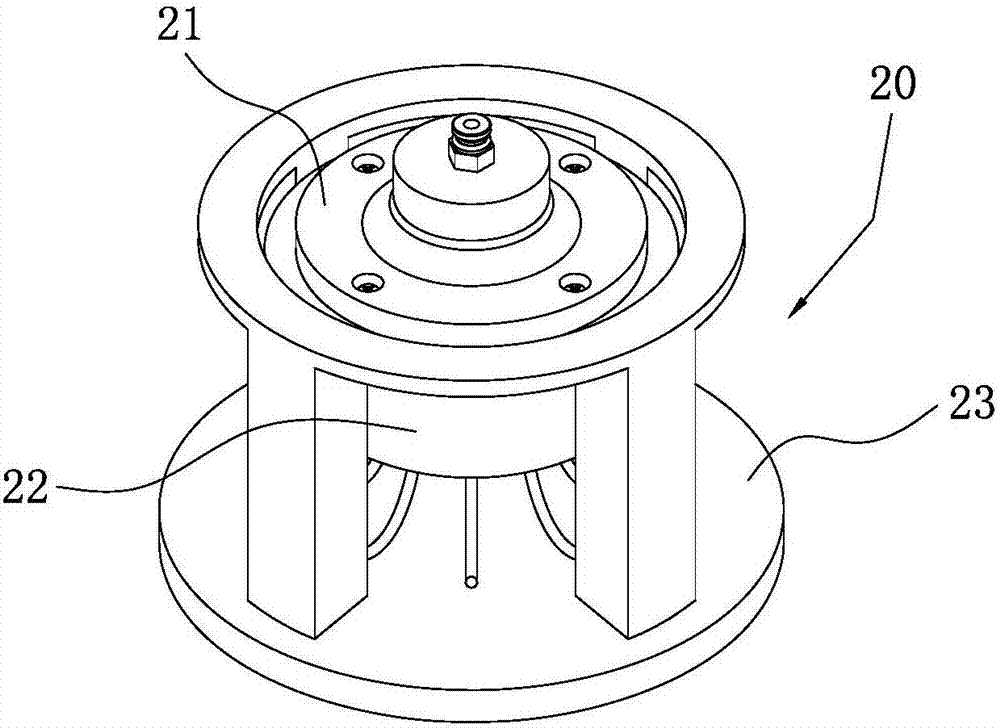

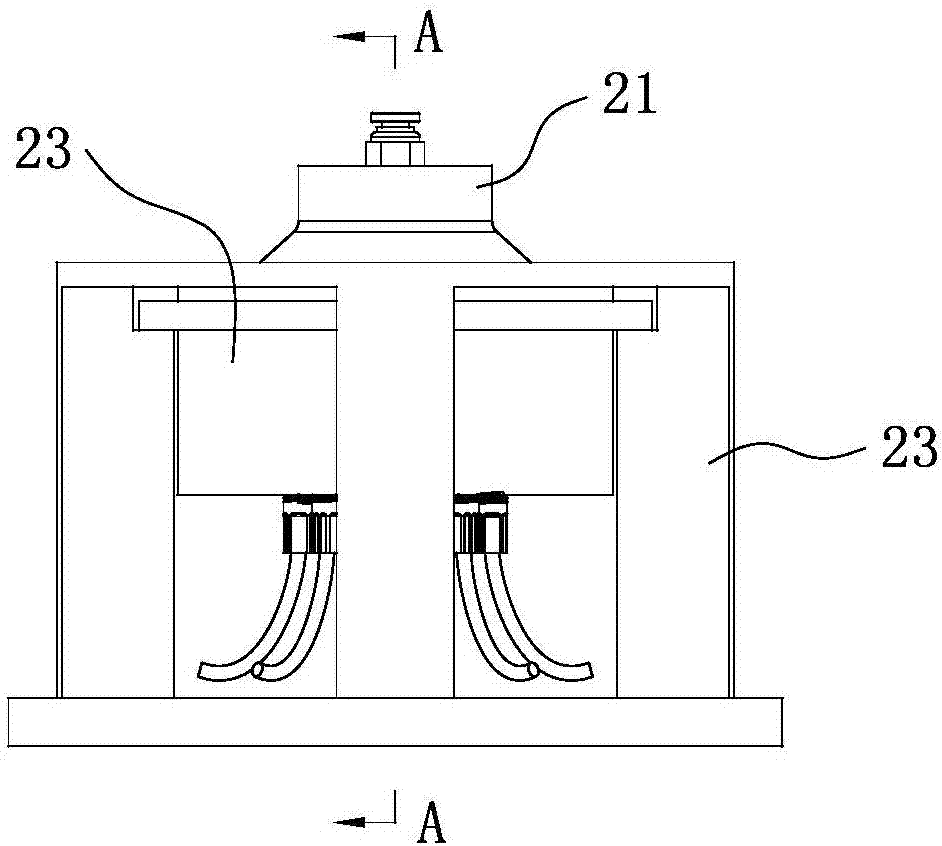

Sample injector and microfluidic system

ActiveCN107999154AStable extrusionSteady injectionLaboratory glasswaresFluid controllersEngineeringAtmospheric pressure

The invention relates to the technical field of analysis equipment of biology, chemistry and the like, in particular to a sample injector. The sample injector includes an upper cover, a lower shell and a support base; the lower shell is mounted on the support base; an open sample injection cavity is formed in the end, away from the support base, of the lower shell; the upper cover covers and sealsan opening of the sample injection cavity; an air inlet is formed in the upper cover and is communicated with the sample injection cavity, and a plurality of sample cells are arranged in the sample injection cavity and are uniformly distributed in the sample injection cavity. The sample injector has the advantage that the sample cells are arranged in the sample injection cavity. Needed sample fluid is injected into each sample cell, the air inlet is connected with an air source, and airpressure generated by the air source extrudes the sample fluid out of the sample sells; the sample cells areuniformly distributed in the sample injection cavity, and the air pressure enters the sampleinjection cavity from the air inlet is uniformly distributed in the sample cells so that the sample fluid in each sample cell can be stably extruded out, and not only is fluid sample injection stable, but also the accuracy is high.

Owner:广东永诺医疗科技有限公司

Nano composite material of graphene/nylon/elastomer and preparation method thereof

InactiveCN106478939AImprove performanceSolve the problem of fragmentationElastomerHigh volume manufacturing

The invention discloses a preparation method of a graphene / nylon / elastomer nano composite material. The preparation method comprises the following steps: at first, pre-dispersing graphene in molten polyamide monomers; then adding a catalyst and an activator into the mixed melt of pre-dispersed graphene / polyamide monomers, mixing to obtain a blended solution; adding the blended solution into an extruder, carrying out reactions, extruding the reaction products, carrying out granulation to obtain the master batch of a graphene / nylon nano composite material; adding the abovementioned master batch and elastomer master batch into the extruder, melting, blending, and extruding the mixture to obtain the graphene / nylon / elastomer nano composite material. Graphene is evenly dispersed in the graphene / nylon / elastomer nano composite material. The industrial massive production of the nano composite material is realized. The phenomenon that the toughness of a composite material degrades due to added graphene is greatly relieved. Compared with pure nylon, the mechanical properties such as strength, toughness, modulus, and the like, and thermal properties such as thermal degradation temperature and the like, of the provided nano composite material are prominently improved, and thus the application range is enlarged.

Owner:HEFEI GENIUS NEW MATERIALS

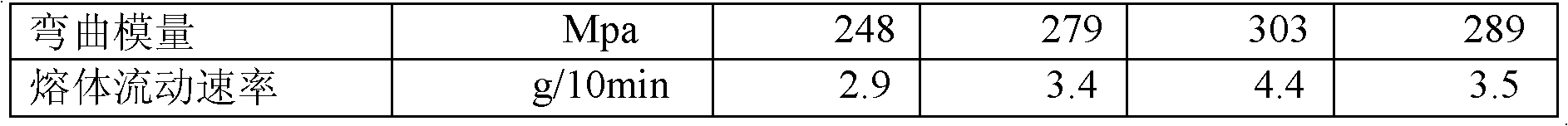

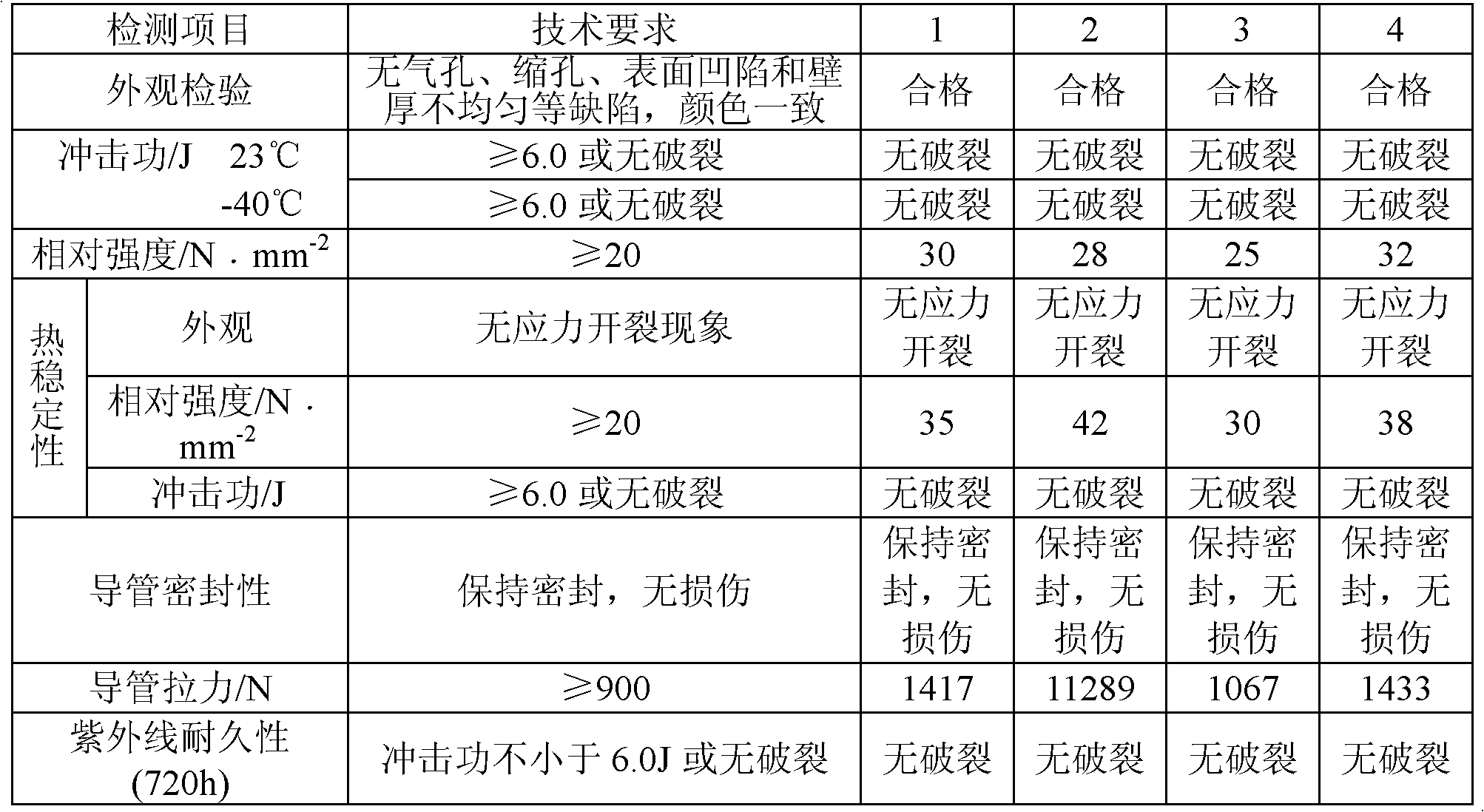

Special glass fiber reinforcement PA66 composition for heat-insulation strips and method for preparing special glass fiber reinforcement PA66 composition

The invention provides a special glass fiber reinforcement PA66 composition for heat-insulation strips and a method for preparing the special glass fiber reinforcement PA66 composition. The composition comprises, by weight, 55-75 parts of nylon 66, 0-10 parts of toughening agents, 0-15 parts of polyethylene, 20-30 parts of chopped glass fibers, 0.01-1 part of silane coupling agents, 0.01-1 part of antioxidants and 0.1-3 parts of lubricants. The special glass fiber reinforcement PA66 composition for the heat-insulation strips and the method have the advantages that the special glass fiber reinforcement PA66 composition is high in performance and extrusion rate and excellent in appearance, requirements of the heat-insulation strip industry on the performance and the appearance of materials can be met, and the special glass fiber reinforcement PA66 composition and the method have important application and popularization value.

Owner:TIANJIN KINGFA NEW MATERIAL

Recycled waste polystyrene plastic produced special modified material for household appliances, and preparation method thereof

The invention discloses a recycled waste polystyrene plastic produced special modified material for household appliances, and a preparation method thereof, and the material can be used for solving the problem that, in the existing technology, the recovery rate of polystyrene plastic of television shells is lower, and resource is wasted. The material is composed of the following components in parts by weight: 100 parts of waste polystyrene television shell broken material, 5-8 parts of SEBS, 0.1-0.3 parts of EBS, 0.1-0.5 parts of calcium stearate and 0.1-0.3 parts of zinc stearate, wherein the waste polystyrene television shell broken material is obtained by detaching the waste television, smashing the polystyrene broken material, rubbing, cleaning, rinsing, drying, and soaking in brine, screening, then, cleaning again, and drying. The invention also provides the preparation method of the recycled waste polystyrene plastic produced special modified material for the household appliances. The method can be used for effectively recycling the polystyrene plastic of the waste televisions, and has the advantages of saving resource, protecting environment, lowering the cost, simplifying the preparation process, and the like.

Owner:四川塑金科技有限公司

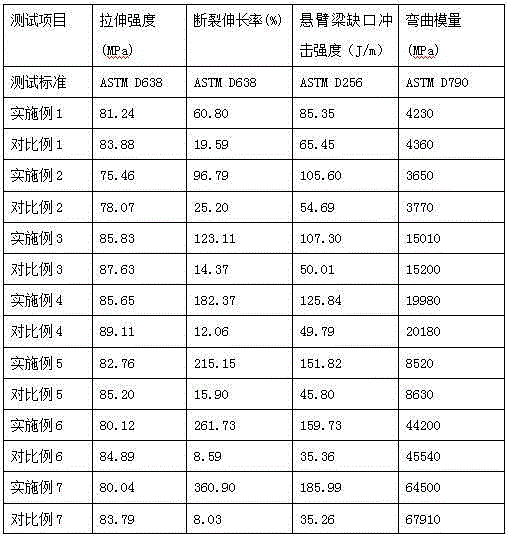

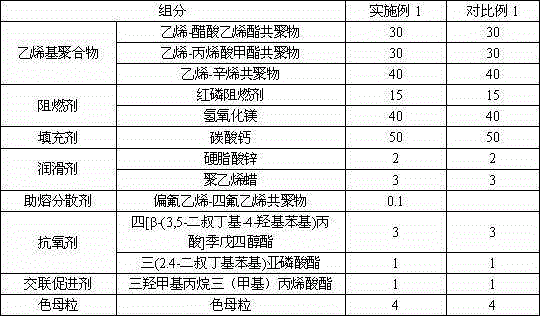

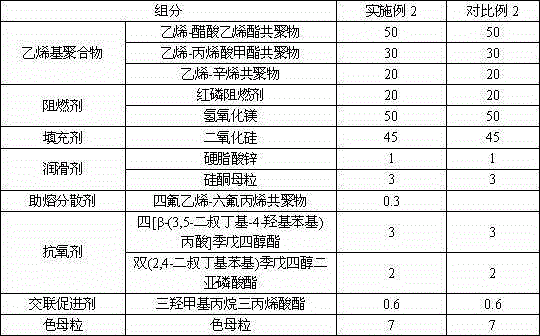

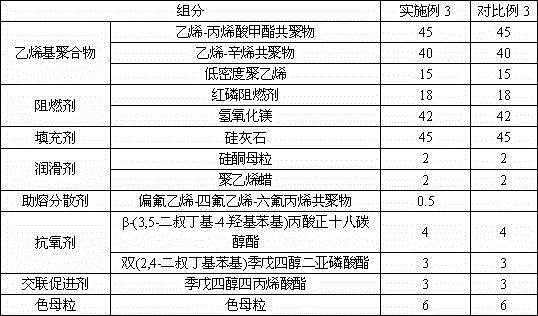

High-extrusion-rate heat-shrinkable tube and production method thereof

The invention discloses a high-extrusion-rate heat-shrinkable tube. The preparation materials of the high-extrusion-rate heat-shrinkable tube comprise, by weight, 100 parts of vinyl polymers, 0-70 parts of a fire retardant, 0-60 parts of filler, 0.1-5 parts of a lubricant, 0.1-3 parts of a flux dispersing agent, 0.1-10 parts of an antioxidant, 0-3 parts of a crosslinking accelerator and 0-10 parts of color master batch. The high-extrusion-rate heat-shrinkable tube has the advantages that not only is the extrusion rate high, but also the extrusion is stable in high speed, and good machining and use performances are also achieved.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +4

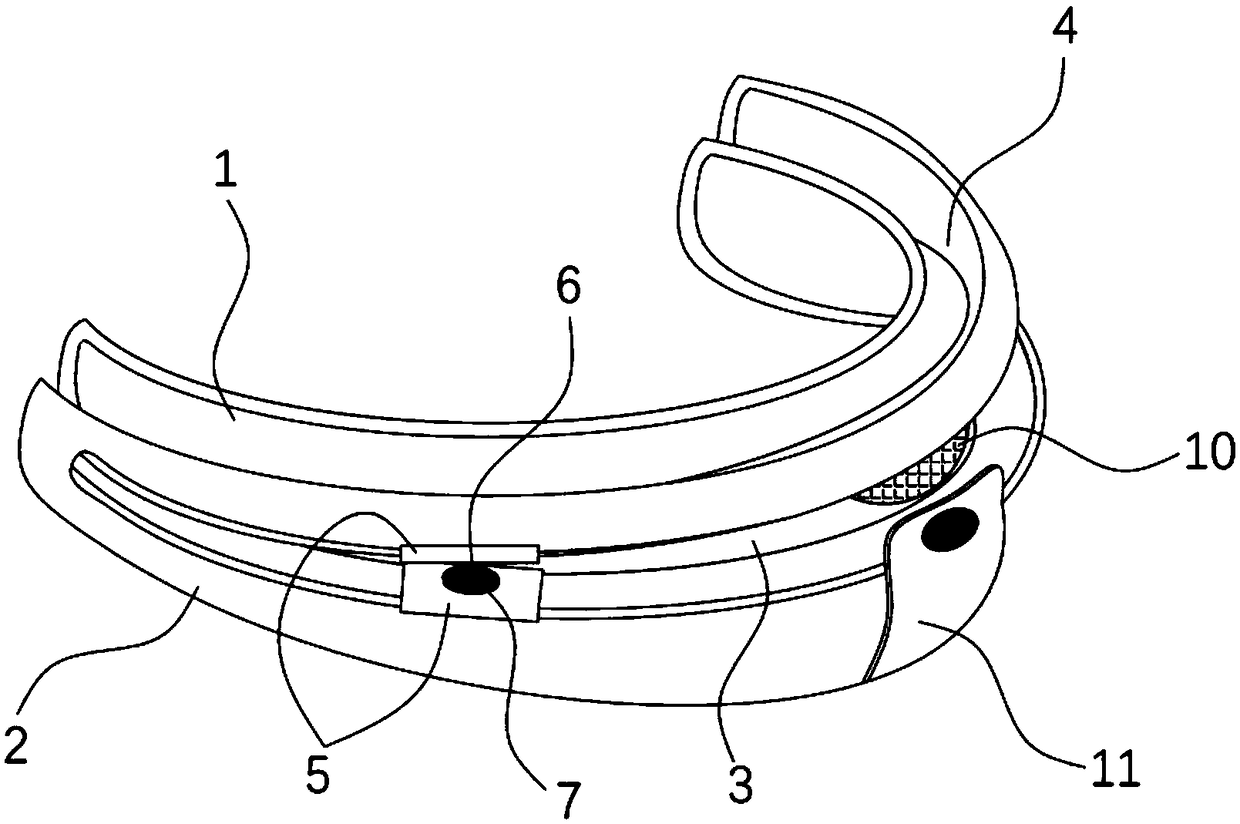

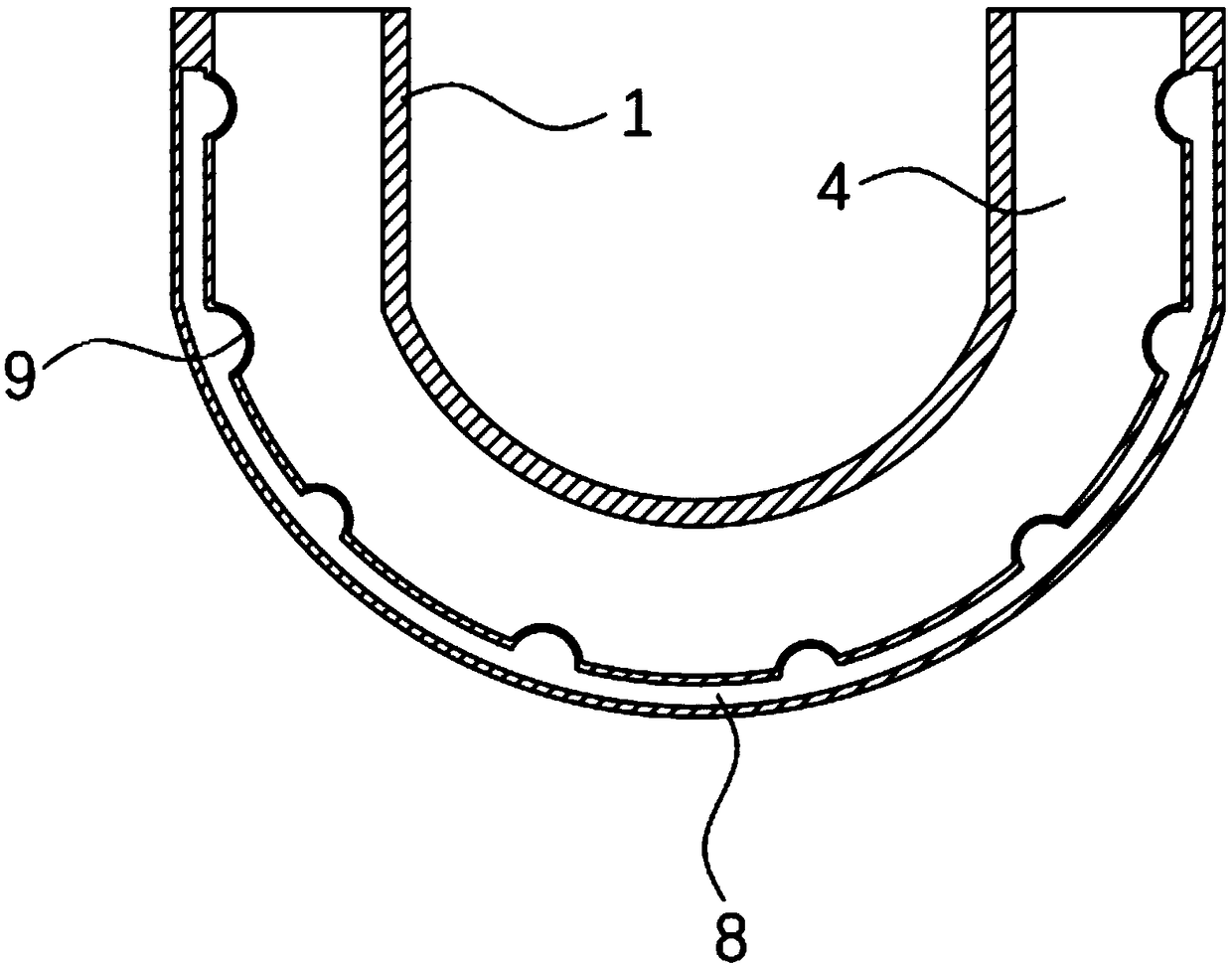

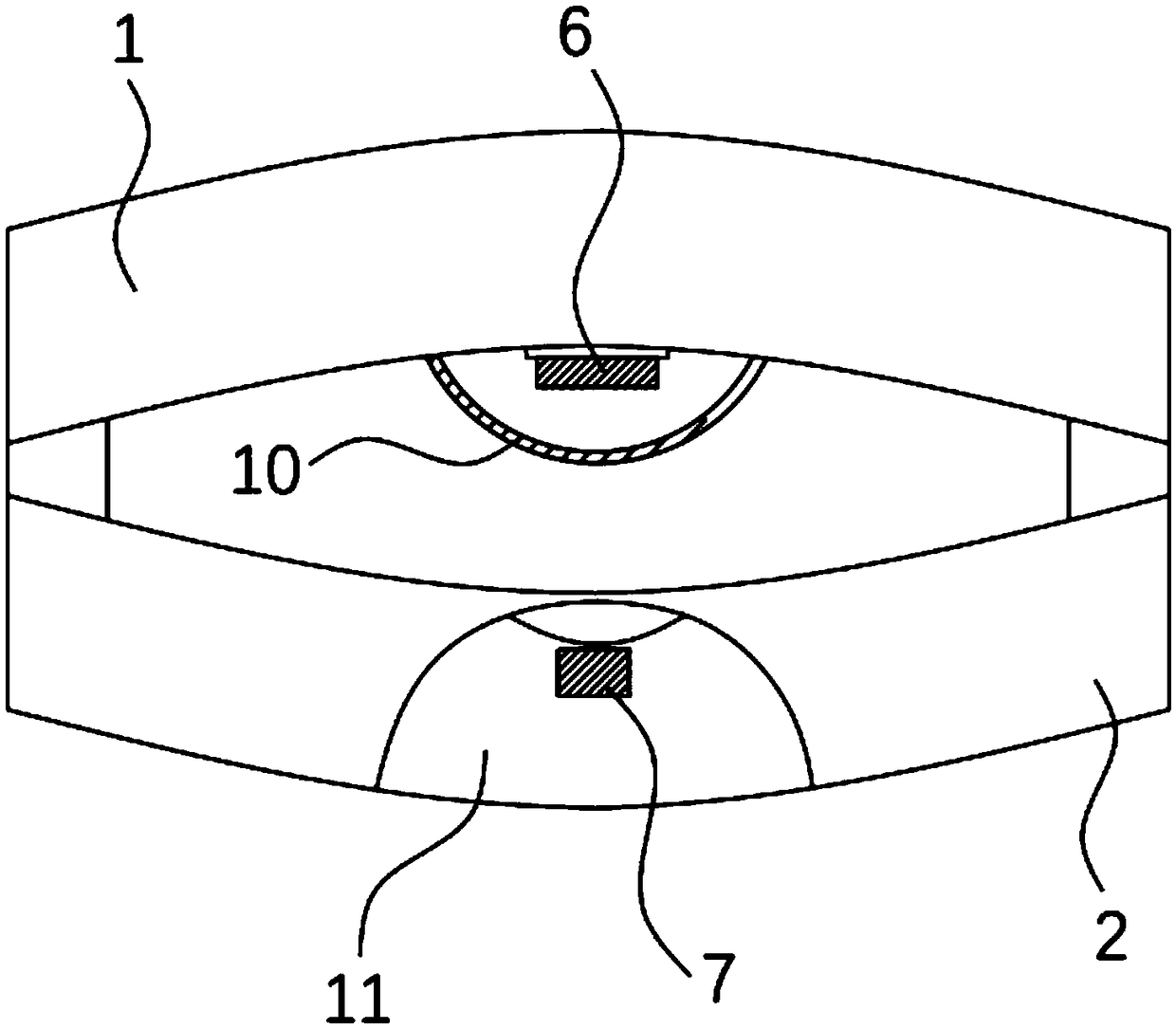

Medical magnetic tooth socket

ActiveCN109223270AEasy to solveImprove protectionNon-surgical orthopedic devicesLower tooth socketMagnet

The invention discloses a medical magnetic tooth socket, including upper and lower tooth sockets. The upper and lower tooth sockets are provided with alveoli. The tooth socket is characterized in thatthe two ends of the upper and lower tooth sockets are fixedly connected, At least one pair of fix stickers are circumferentially glue on that opposite side surfaces of the upper dental cover and thelower tooth socket at equal distances. The fixed stickers located on the upper dental cover are fixedly connected with a first magnet, and the fixed stickers located on the lower dental cover are fixedly connected with a second magnet, and the first magnet and the second magnet are mutually repellent. The two magnets repel each other, so that the mouth of the patient will remain open under this force, so that the foam, saliva, etc. in the mouth of the patient can flow out along the gap between the upper and lower tooth sockets.

Owner:中俄国际医学研究股份有限公司

Differential three-screw extruder with triangularly-arranged screws

The invention relates to a differential three-screw extruder with triangularly-arranged screws. The differential three-screw extruder mainly comprises a feeding device, a machine barrel, screws, a machine head, a heating and cooling device, an exhaust port, a motor and a transmission device. The three screws comprise two male motors and a female rotor and are arranged in a triangular mode; when the three screws are combined, at least one thread meshing area is provided; the number of screw flight heads in the thread meshing area is integer multiples of the number of the male rotors; the rotational speeds of the male rotors and the female rotor are in an inverse proportion with the number of the spiral flight heads so as to realize the differential rotation; and the male rotors and the female rotor are not interfered during movement. The three screws can be arranged in the shape like an inverted Chinese character 'Pin', the shape like the Chinese character 'Pin' or other triangular arrangement modes. According to the machining requirement of materials, thread sections with different helical pitches and cross section molded lines or other types of thread sections can be arranged at different sections, such as a feeding section, a fusion section, a venting section and a metering section of each screw; when the three screws are installed, at least one differential rotating meshing area is ensured to be provided, and the three screws can be meshed or not meshed at different sections so as to realize the mixing enhancement, venting effect or other functions. The extruder disclosed by the invention has good capacities of mixing, plasticizing and delivery and is suitable for the machine-shaping of multiple materials such as plastics, rubbers, foods, explosive materials and the like.

Owner:BEIJING UNIV OF CHEM TECH

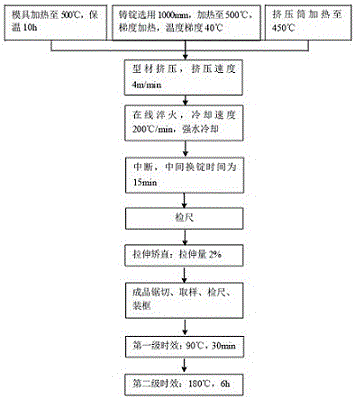

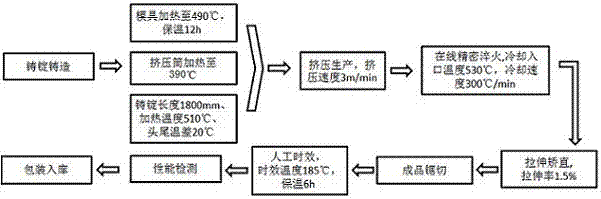

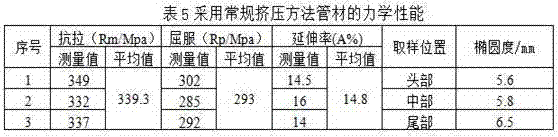

Preparation method of large-sized Al-Mg-Si-Mn alloy tube for textile equipment

InactiveCN107099704AGuaranteed performanceEnsure stabilityExtrusion control devicesIngot castingWater spray

The invention relates to the technical field of alloy profile preparation, in particular to a preparation method of a large-sized Al-Mg-Si-Mn alloy tube for textile equipment. The specific steps include casting and ingot casting, die heating, extrusion container heating, ingot casting heating, extrusion production, in-line precision quenching, stretching and straightening, finished product cutting, artificial seasoning, performance detecting and packaging and warehousing. The large-sized Al-Mg-Si-Mn alloy tube comprises the following components, by weight: 0.7-1.1% of Mg, 0.8-1.2% of Si, 0.4-0.5% of Mn and no more than 0.5% of Fe, further comprises at least one of the following elements: no more than 0.10% of Cr, no more than 0.05% of Zn, no more than 0.05% of Cu, no more than 0.05% of Ti, and no more than 0.03% of V, and the balance Al. Compared with traditional extrusion methods, according to the preparation method of the large-sized Al-Mg-Si-Mn alloy tube for the textile equipment, the components of Al-Mg-Si-Mn alloy and technology ranges of all extrusion processes are adjusted, the technology control process is more refined, the production stability is guaranteed, at the same time, precise in-line water spray quenching is adopted, so that mechanical properties are much better, good uniformity of the tube after being extruded can be guaranteed, and the production efficiency is improved greatly.

Owner:广西南南铝加工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com