Preparation method of large-sized Al-Mg-Si-Mn alloy tube for textile equipment

A textile equipment, al-mg-si-mn technology, applied in the field of preparation of large-scale Al-Mg-Si-Mn alloy pipes for textile equipment, can solve the problems of unstable online quenching performance, offline quenching deformation, etc., to achieve The effect of fine process control, fast cooling rate and better mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

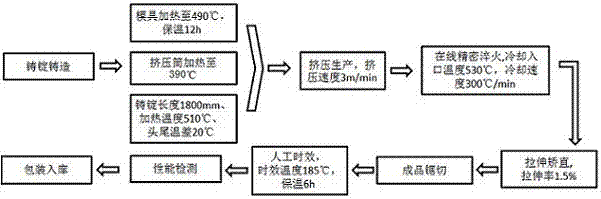

[0031] A kind of preparation method of large-scale Al-Mg-Si-Mn alloy pipe material for textile equipment, such as figure 1 shown, including the following steps:

[0032] (1) Casting ingots, the cast alloy is large-scale Al-Mg-Si-Mn alloy ingots, the outer diameter of the round tube of large-scale Al-Mg-Si-Mn alloy ingots is Ø400mm, and the wall thickness is 15mm; The composition and weight percentage of Al-Mg-Si-Mn alloy ingot are: Mg is 0.98%, Si is 0.95%, Mn is 0.46%, Fe is 0.15%, Cr is 0.05%, Zn is 0.03%, Cu is 0.03%, Ti is 0.03%, V is 0.02, and the rest is Al;

[0033] (2) Mold heating: heat the mold to 490°C in a heating furnace and keep it warm for 12 hours;

[0034] (3) Extrusion cylinder heating: heat the extrusion cylinder, and control the temperature of the extrusion cylinder at 390°C;

[0035] (4) Ingot heating: Heating the ingot with a length of 1800mm, adopting the gradient heating method, the temperature difference between the head and the tail is 20°C, and th...

Embodiment 2

[0046] A method for preparing large-scale Al-Mg-Si-Mn alloy pipes for textile equipment, comprising the following steps:

[0047] (1) Casting ingots, the cast alloy is large-scale Al-Mg-Si-Mn alloy ingots, the outer diameter of the round tube of large-scale Al-Mg-Si-Mn alloy ingots is Ø300mm, and the wall thickness is 8mm; The composition and weight percentage of Al-Mg-Si-Mn alloy ingot are: Mg is 0.7%, Si is 0.8%, Mn is 0.4%, Fe is 0.15%, Cr is 0.05%, Zn is 0.03%, Cu is 0.03%, Ti is 0.03%, V is 0.02, and the rest is Al;

[0048] (2) Mold heating: heat the mold to 465°C in a heating furnace and keep it warm for 12 hours;

[0049] (3) Extrusion cylinder heating: heat the extrusion cylinder, and control the temperature of the extrusion cylinder at 300°C;

[0050](4) Ingot heating: Heating the ingot with a length of 600mm, adopting the gradient heating method, the temperature difference between the head and the tail is 6°C, and the heating temperature of the ingot in the heatin...

Embodiment 3

[0061] A method for preparing large-scale Al-Mg-Si-Mn alloy pipes for textile equipment, comprising the following steps:

[0062] (1) Casting ingots, the alloys cast are large-scale Al-Mg-Si-Mn alloy ingots, the outer diameter of the round tube of large-scale Al-Mg-Si-Mn alloy ingots is Ø500mm, and the wall thickness is 30mm; The composition and weight percentage of Al-Mg-Si-Mn alloy ingot are: Mg is 1.1%, Si is 1.2%, Mn is 0.5%, Fe is 0.15%, Cr is 0.05%, Zn is 0.03%, Cu is 0.03%, Ti is 0.03%, V is 0.02, and the rest is Al;

[0063] (2) Mold heating: heat the mold to 520°C in a heating furnace and keep it warm for 12 hours;

[0064] (3) Extrusion cylinder heating: heat the extrusion cylinder, and control the temperature of the extrusion cylinder at 395°C;

[0065] (4) Ingot heating: Heating the ingot with a length of 1800mm, adopting the gradient heating method, the temperature difference between the head and the tail is 50°C, and the heating temperature of the ingot in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com