Method for producing resin strand

a technology of resin strands and strands, which is applied in the field of resin strand production, can solve the problems of affecting the quality of resin strands, so as to reduce the formation of strands, improve product quality, and increase yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

The Present Invention

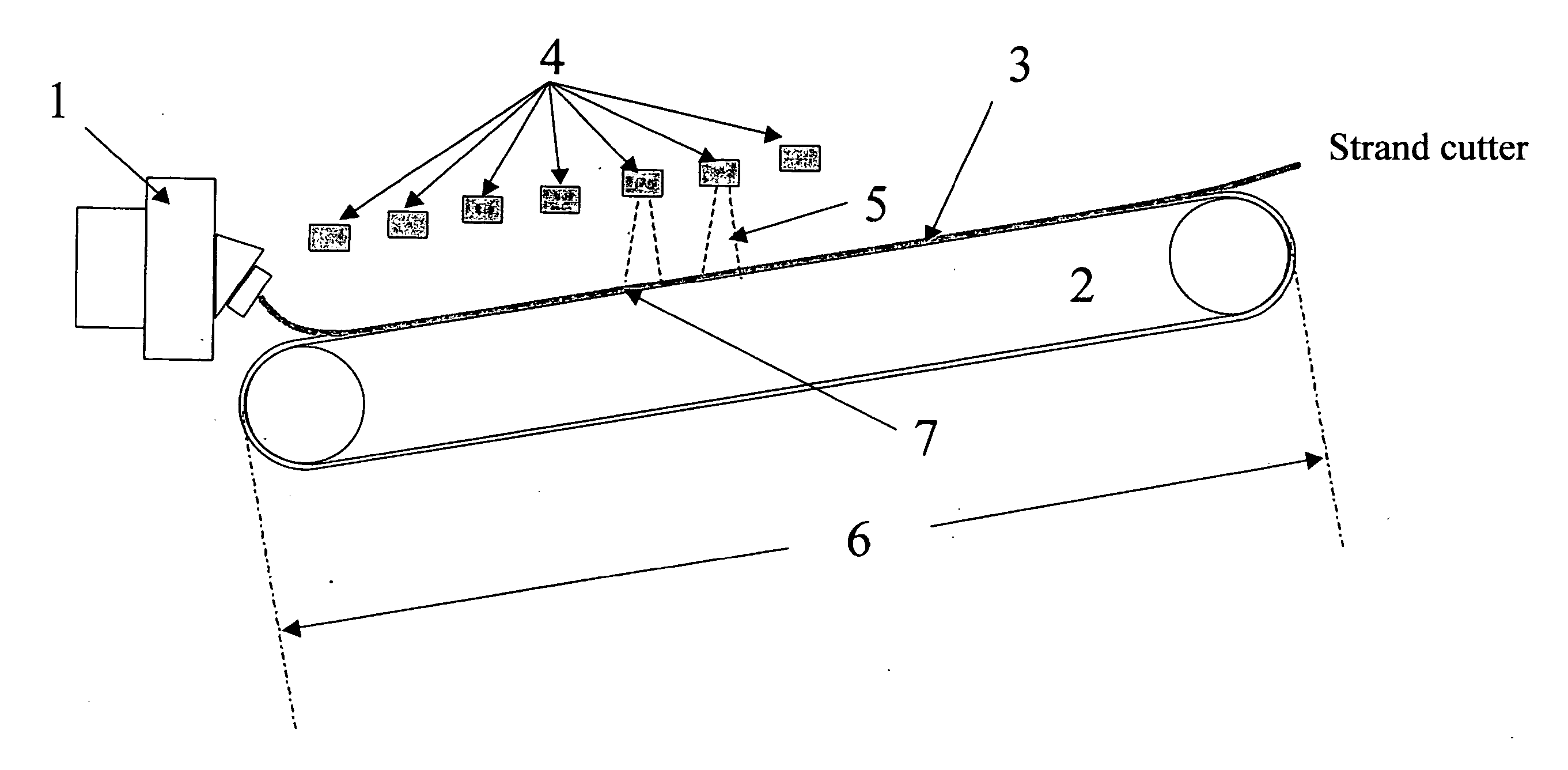

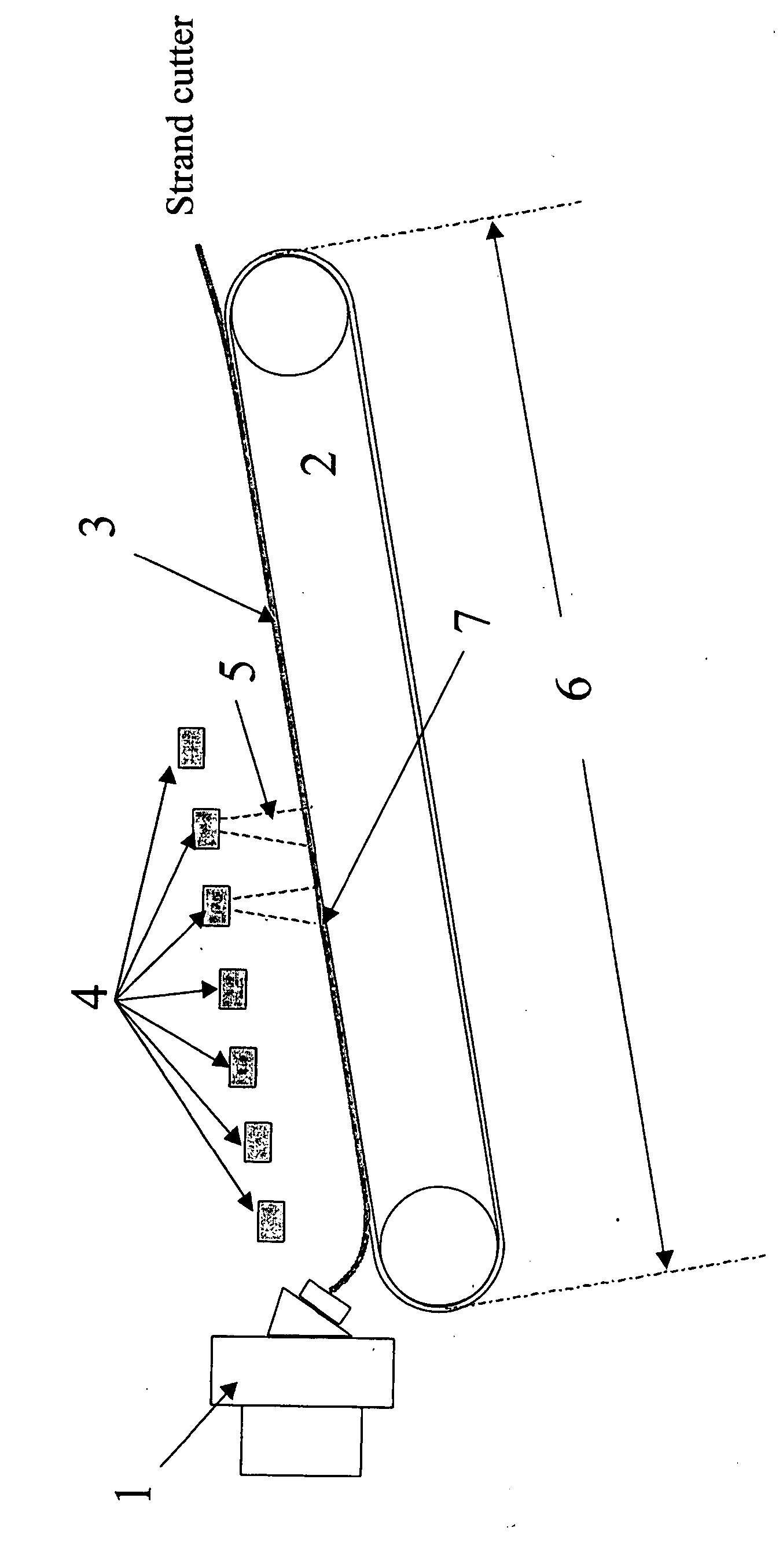

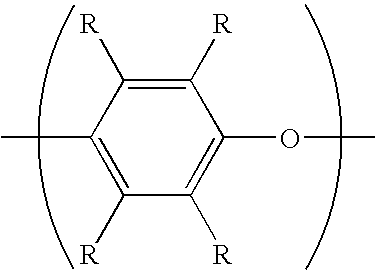

[0180] The maximum cylinder temperature of a co-rotating twin screw extruder was set at 320° C., the extruder having an L / D of 48 provided with one feed port in the upstream side and one feed port in the downstream side [ZSK70MC: manufactured by Coperion Corporation, having 12 temperature control blocks (L / D per block being 4) and an auto screen changer block; upstream feed port: the first block, downstream feed port: the sixth block, vent ports to remove volatiles by vacuum suction: the fifth block and the tenth block]. From the upstream feed port were fed separately (using separate feeders without being blended) to the extruder and melt-kneaded 35 parts by mass of polyphenylene ether [S201A: manufactured by Asahi Kasei Chemicals Corporation], 0.1 part by mass of granular maleic anhydride manufactured by ACROS ORGANICS (Germany), 10 parts by mass of a styrene-ethylenebutylene-styrene block copolymer [Kraton G1651: manufactured by Kraton Polymers] as elastomer ...

example 2

The Present Invention

[0186] All experiments were performed in the same manner as in Example 1 except that the strands were cooled by installing three water spraying apparatuses for cooling strands in total were installed at positions ranging from 1.8 m apart from the die holes (a position downstream by 28% of the total length of the conveying part of the conveyor) to 2.3 m apart from the die holes (a position downstream by 35% of the total length of the conveying part of the conveyor), and various performances were evaluated. The results are shown in Table 1.

examples 3 and 4

The Present Invention

[0187] All experiments were performed in the same manner as in Example 1 except that the extruder capacity was changed, and various performances were evaluated. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com